Unterflursägemaschine

The invention refers to a lower floor panel AEG machine with an elongated machine table and with at least underneath the machine table a planned and along the same in relation to displaceable sawing aggregate with at least over the level of the machine table raisable and under the level of the machine table lowerable circular saw blade and in the cutting plane of the lower floor panel AEG machine and above the edition of the workpieces of serving machine table this raisable and lowerable Druckbalken is arranged.

On such lower floor panel AEG machines plates from aluminum or timber materials are divided.

Plates from aluminum or from timber materials exhibit partially strong internal tensions, those in Herstellungs-bzw. Cooling process are caused. With dividing the plates it occurs from there usually that the separate parts move against each other and behind the saw blade narrows and/or closes the Schnittspalt at all completely directly. This has the consequence that the saw blade does not only have to zerspanen with its front the material, but that also on the opposite, ruckwärtigen side again so-called re-cutting arises. This re-cutting worsens on the one hand the quality of the planes of section, on the other hand one thereby a large energy expenditure is necessary, and decreased as consequence of it will the sawing achievement and/or it must the necessary achievement of the sawing engine be increased from the beginning.

Conventional sawings machine have directly behind the saw blade a froe (the USA 5,447,085; DE-C2 4,004,705; DE-A1 2,442,592; DE-A1 2,364,910; EP-A1 519,347; GB-A 2,138,742). This froe penetrates into the sawing gap and keeps the separate parts apart. With these conventional sawings machine either the workpiece at the most stationary sawing aggregate is by-pushed or a mobile sawing aggregate isolates the being certain workpiece. In both cases froe and workpiece move relatively to each other. By the friction between froe and workpiece substantial forces arise. For this reason it is not possible to use these well-known measures with lower floor panel AEG machines on which thick plates, e.g. to 150 mm, or whole disk packages with package heights up to 200 mm are divided. For such lower floor panel AEG machines there is so far only the possibility of working with so-called stage cut procedures: E.G. with a plate with 60 mm thickness first a cut with a cutting depth by 20 mm is made, then afterwards a second cut in the same level with a cutting depth of 40 mm and afterwards a third cut in the same level, with which then the plate splits becomes. This procedure required however very much time and is not economical from there.

On the basis of this state of the art the invention placed itself the task to suggest here a suitable solution in order to repair the shown disadvantages. This succeeds according to invention thus that in the cutting plane at least at the Druckbalken intended and a froe lowerable opposite this hebund is arranged. Lower floor panel AEG machines have, always a Druckbalken, which presses the workpieces which can be divided from above protecting the allocation procedure on the machine table. In this Druckbalken one or more froes are planned, which are lowered in each case immediately after the separation of the plates or disk packages behind the saw blade and into the Schnittspalt to penetrate. The positioning of the froes is so intended that these lie in the initial range of the plates. With different disk seaweeds either several froes can be necessarily or a froe can mobile and positionable be. The control is programmed thereby so laid out o and that the froe lowers itself directly behind the driven past circle legend sheet.

On the basis the design the invention is more near described, without limiting it to the remark example shown. Show:

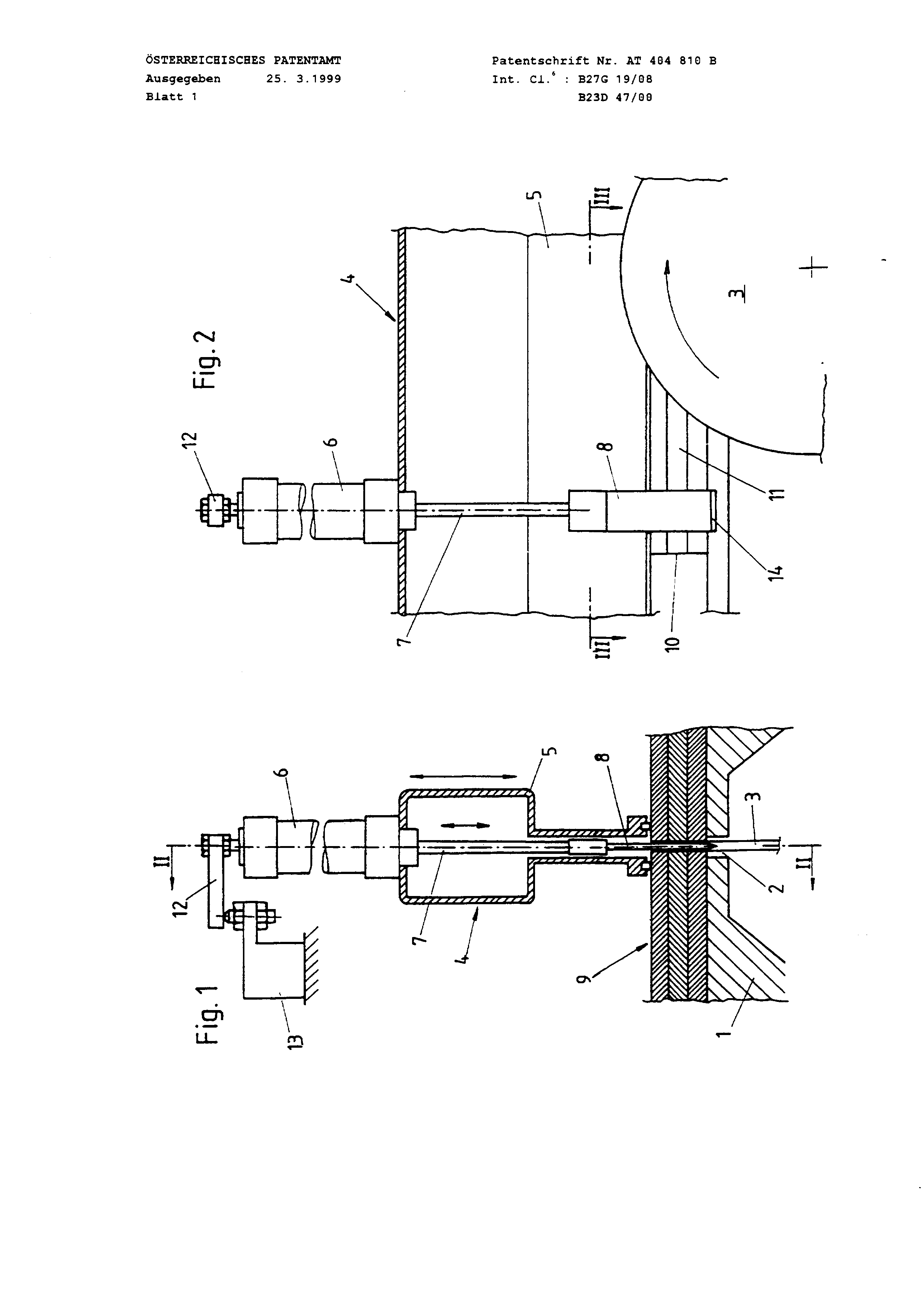

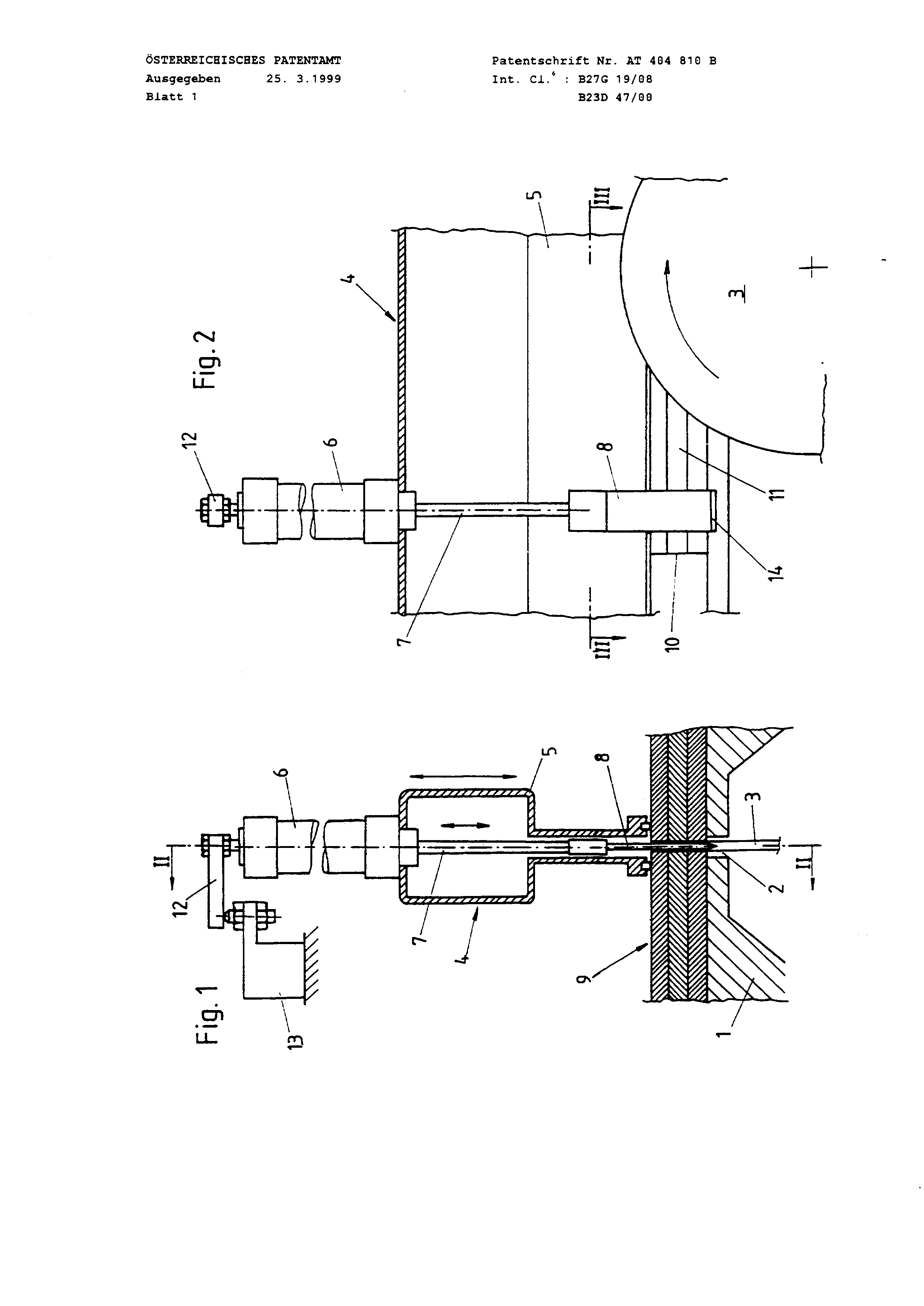

Fig. 1 a detail cut by a lower floor panel AEG machine with lowered Druckbalken and lowered froe; Fig. 2 a profile after the line I1-11 in Fig. 1; Fig. 3 a horizontal cut along the line II1-111 in Fig. 2.

Here the lower floor panel AEG machine not illustrated more near possesses an elongated machine table 1, its longitudinal axis right-angled to the indication level after Fig. 1 stands. Underneath this machine table 1 with the longitudinal gap 2 for depresses the circular saw blade 3 lies, the not represented sawing aggregate displaceable along the machine table 1, which carries hebund the lowerable circular saw blade 3.

Above the machine table 1 the Druckbalken 4 is arranged, which extends over the length of the lengthwise slot 2 and which consists of a downward open profile 5. At the top side of this hollow section 5 a piston cylinder unit 6 is arranged with vertical axle, whose piston rod 7 rises up into the inside of the hollow section 5 and which at its lower end carries a froe 8. The piston rod 7 intersperses appropriately the housing of the piston cylinder unit 6, and at its upper, opposite which housings mentioned managing section are at this piston rod 7 lateral a out collar that lever 12 specified, which cooperates with a machine-laterally arranged attack 13, which is adjustable if necessary regarding its altitude opposite the machine table 1.

RK 404,810 B the function of the last-mentioned two components, i.e. the lever 12 and the attack 13, is below still discussed. The Druckbalken 4 is led at its two ends at vertical rails and with a stroke mechanism hebund lowerable.

Fig. 1 illustrated in the detail cut the froe 8th on the machine table, already activated, 1 s lies a package 9 from three plates, the Druckbalken 4 is lowered on the package 9 and squeezes this together in the range of the sawing gap, the highranking circular saw blade 3 already into the package 9 brought in (Fig. 2), and directly behind in such a way brought in circular saw blade the froe 8 lowered itself and thereby into the Schnittspalt brought 3 in. The packages from the plates which can be divided can exhibit different heights H. It is conceivable that on the lower floor panel AEG machine only a relatively thin plate is divided, equally is conceivable it that a package from plates is presented with the rated altitude permissible for the respective machine type. Independently of the height H of the package 9 which can be divided it should be appropriately guaranteed however that the froe 8 opposite the machine table t always essentially resembles itself on that measure lowers, so that the lower edge 14 of the froe 8 lies approximately in the level of the machine table 1. Now the lever 12 and the machine-firm attack 13 guarantee this. Independently of it, how far the Druckbalken 4 lowers itself opposite the machine table 1, the bringing in froe lowers itself only so far that its lower edge 14 lies in the range of the level of the machine table 1. In place of such a mechanical movement delimitation it would be also possible to plan a process control which steers the downward movement of the froe 8 in dependence of the height of H of the presented package 9. Such a process control would be above all appropriate if the froe 8 concerning the Druckbalkens 4 is not stationarily arranged, but is adjustably stored opposite this in its longitudinal direction.

The froe 8 is arranged appropriately in that range of the Druckbalkens 4, which is appropriate for the section of the machine table 1 neighbouring, in which with the beginning of a Schnittvorganges the circular saw blade 3 over the level of the machine table 1 is raised. Along the Druckbalkens 4 also several can be planned such hebund lowerable froes. The piston cylinder unit 6 can be subjected pneumatically or hydraulically. In principle also mechanical stroke mechanisms are usable.

If a package 9 consisting of plates is presented on the machine table 1 and if the Druckbalken 4 is lowered, then for the time being the froe 8 raised within the hollow section 5, which forms the Druckbalken 4, is. Now the circular saw blade 3 raises an end of the elongated machine table 1 from its lower end position to and begins then the separation cut, on the basis of a face 10 of the package. In this range of the face 10 of the package 9 also the froe 8 is stored. As soon as the circular saw blade 3 began its separative work, into the disk package brought in and passed the raised froe 8 (Fig. 2), the froe lowers itself 8, whereby its downward movement is limited by the lever 12 and the attack 13, and prevents thereby that the separation gap 11 tapers itself and/or locks at all. The under floor sawing machine has a elongated machine table (1), and a sawing unit with a travelling saw unit and a liftable circular saw blade (3) situated lower than surface of the table. An adjustable pressure girder (4) lies above the cutting plane. A clearance key (8)is oriented in the pressure girder area next to the cut-out section of the machine table lifts over the edge of the table at the start of sawing 1.

Lower floor panel AEG machine with an elongated machine table (1) and with at least one underneath the machine table (1) intended and along the same displaceable sawing aggregate with at least one over the level of the machine table (1) raisable and under the level of the machine table (1) lowerable circular saw blade and in the cutting plane of the lower floor panel AEG machine and above present the workpieces of serving machine table (1) opposite this raisable and lowerable Druckbalken (4) arranged it is characterized, by the fact that in the cutting plane at least at the Druckbalken (4) intended and opposite this lift - and lowerable froe (8) is arranged.

2= lower floor panel AEG machine according to requirement 1, by the fact characterized that the froe (8) within that range of the Druckbalkens (4) is arranged, which the section of the machine table (1) neighbouring lies, in which with the beginning of the Schnittvorganges the circular saw blade (3) over the level of the machine table (1) is raisable. 3. Lower floor panel gemaschine according to requirement t, by the fact characterized that along the Druckbalkens (4) several hebund lowerable froes (8) is intended. 4. Lower floor panel AEG machine after one of the requirements 1 to 3, by the fact characterized that the froe (8) with a piston cylinder unit (6) is connected and the piston cylinder unit (6) to RK 404,810 B RST 5° 6° 7, 9o Druckbalken (4) is stored.

Lower floor panel AEG machine after one of the requirements 1 to 4, by the fact characterized that the froe (8) and/or the piston cylinder unit connected with it (6) is program controlled.

Lower floor panel AEG machine after one of the requirements 1 to 4, by the fact characterized that to the manipulation of the froe (8) planned piston cylinder unit (6) at the top side of the Druckbalkens (4) and the froe (8) within the downward open, the Druckbalken of forming hollow section (5) is fixed lies.

Lower floor panel AEG machine according to requirement 4, by it characterized that the piston rod (7) of the piston cylinder unit (6) with a laterally auskragenden lever (12) is connected, together with one maschinenfest intended attack (13) the sinking way of the froe (8) independently of the height of a disk package which can be divided (9) limited.

Lower floor panel AEG machine according to requirement 7, by characterized that the altitude of the machine-laterally planned attack (13) opposite the machine table (1) is adjustable.

Untertlursägemaschine according to requirement 7, by characterized that the auskragenden lever (12) basic section of the piston rod (7) of the piston cylinder unit (6) their housings upward towered above.