CENTRALIZER FOR A FIBER OPTIC CONNECTOR.

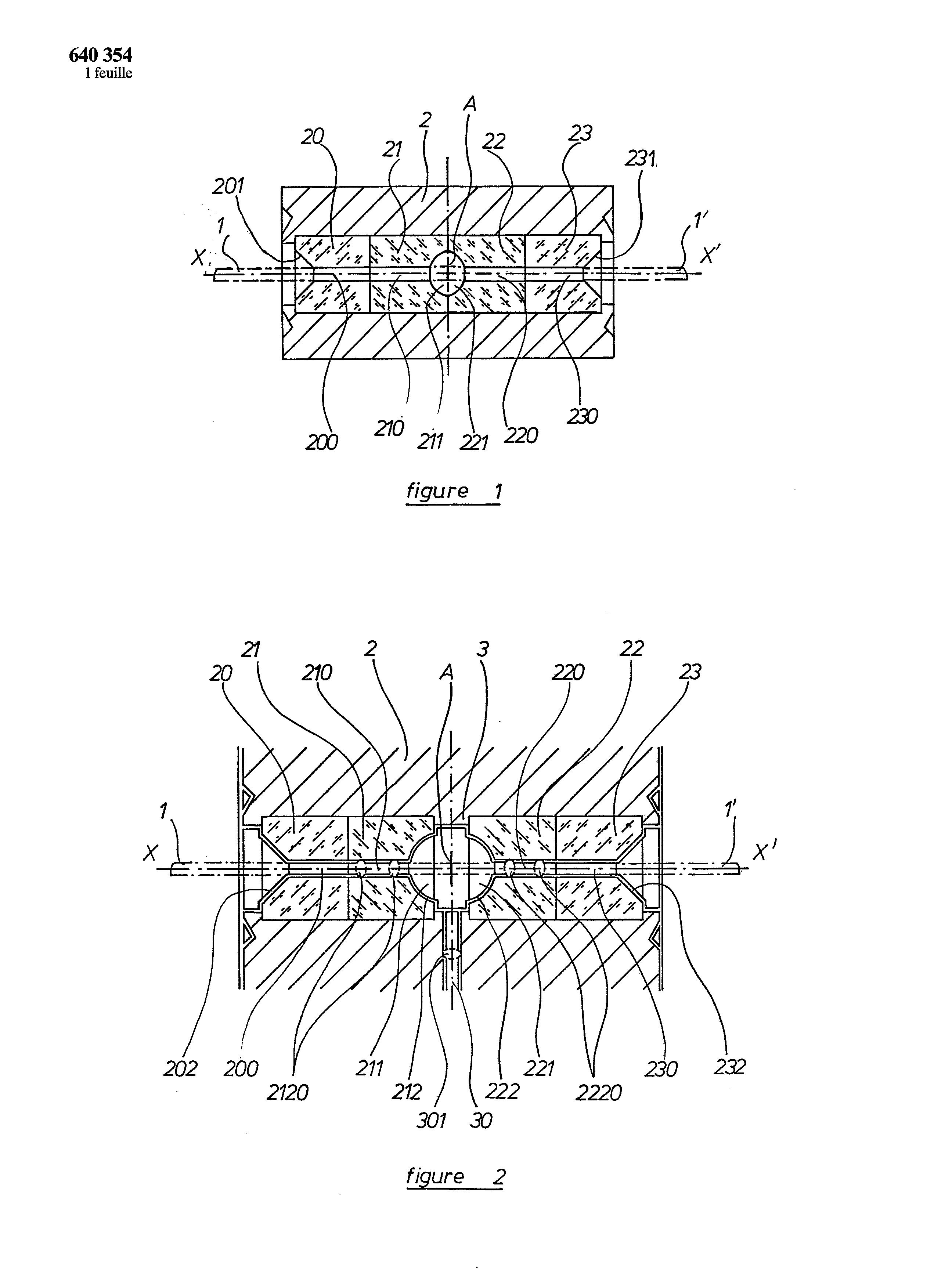

Claims 1. centralizer for a fiber optic connector including a ferrule in assembly (2) guiding elements (20 to 23) constituted by a hard material, each pierced with a central hole (200, 210, 220, 230) in facing, characterized in that said elements, abutting, comprise in respect to, at the junction of the fibers show a " adement (211.221) forming a reservoir for receiving a plastic container with a liquid fiber coupling the fiber ends.2. the centralizer of claim 1, characterized in that lo the recess DCs each guide element forming a reservoir is substantially rotationally symmetrical to the longitudinal symmetry axis of the centralizer.3. the centralizer of claim 2, characterized in that said elements having a recess forming a réserx5 see are mounted abutted to an inner ring (3) of the shell (2), said ring positioned at the juncture of the fibers providing for spacing apart adjacent components to form a liquid reservoir coupling capacity increased.4. the centralizer of claim 3, characterized in that the reservoir is in communication with the outside through a lumen (30) through the ferrule.Centralizer according to one of claims 1 to 4, characterized in that each element is coated with a layer of solid oil repellent material (202, 212, 222, 232).6. the centralizer of claim 5, characterized in that the material is silicone oil.7. the centralizer of claim 5, characterized in that the oil repellent material is molybdenum disulfide the MOS " 8. centralizer according to one of claims 1 to 7, characterized in that at least two guide elements (21.22) respectively disposed on both sides of the joining zone of fibers comprise on the periphery of the central hole an erosion zone annular (2120, 2220) oil repellent material between two areas of oil repellent material and intended to cause the stoppage of flow by capillary action of the liquid optical coupling in the central holes during disassembly of the connection.9. the centralizer of claim 8, characterized in that each annular erosion zone is propagated through all of the guide channel, the entrance cones (201.231) of the guide channel and the reservoir being covered with a layer oil repellent.The centralizer of claim 4, characterized in that the light (30) providing communication with the exterior of the tank also has an erosion zone (301) of the constituent material of the ferrule to ensure the flow stop of the optical coupling liquid after filling the reservoir.11. Centralizer according to one of the preceding claims, characterized in that the guide elements consist of hard material stones timepiece.The present invention relates to a centralizer for a fiber optic connector.In the field of fiber optics connection between two fibers is ensured by means of connectors for butt joining of two fiber elements. This type of connection requires a perfect centering opposite faces of fibers as well as a permanently holding these faces in the contact position. Different solutions have been proposed, particularly in the case of connectors for single mode optical fibers. The connectors have most often a centralizer for ensuring the connection via two interlocking flanges. In particular in the German Patent 27, 58 964 is described a centralizer for optical fiber wherein terminal guiding elements constituted by stones timepiece breakthroughs are held in position in a ferrule assembly by spacers. The connector species although having qualities of wear resistance and precision drilling guide elements does not allow easy use of a index liquid compatible with the refractive index of the optical fiber to ensure optimal transmission of optical signals.One type of connector having a center for optical fibers usable with a material having a refractive index which is compatible with that of fibers to be joined was described in U.S. Patent 39, 44 328. The body of this type of centraliser comprises epoxy resin, by molding, it is not possible to centering accuracies comparable to those obtained in the case of the use of stones timepiece pierced as guide element. In addition, this type of centralizer is preferably used with a self-curable liquid material having a refractive index in order to ensure permanent fiber in the connection position. In the case of using a liquid index compatible non-curable, for temporary connections, the disconnection of the fibers with the disadvantage of causing removal and loss of the liquid index of the guide hole, the fibers acting in the guide hole, as a pumping piston.The present invention aims to remedy the aforementioned disadvantages and in particular the implementation of a fiber optic connector for centrenr maintaining precision centralizers having guide element for timepiece stones pierced.Another object of the invention is the implementation of a center for a fiber optic connector and may further be used as temporary connector without the loss of the index liquid compatibly used for coupling of the two fibers.Another object of the invention is the implementation of a centralizer for a fiber optic connector wherein the guide elements have, facing the contact surface of the fibers, a minimum coefficient of friction.Such a center for a fiber optic connector will advantageously be used in the field of telecommunications.The centralizer for a fiber optic connector according to the invention is defined according to the technical characteristics of the present claim 1.Other aspects of the invention will appear caractéñstiques and using the description and drawings below where the same references denote the same elements and in which - Figure 1 represents a sectional view according to a longitudinal plane of symmetry of the centralizer for a fiber optic connector; - Figure 2 represents a detail of embodiment of the invention in accordance with Figure 1.In Figures I and 2 the proportions and odds ratios of the different elements are not complied DCs to impart greater clarity to the set.As shown in Figure 1, the centralizer for a fiber optic connector 1 and 1' comprises in a ferrule assembly 2 fiber guiding members 20, 21, 22, 23. In Figure 1 the guide elements shown are four in number. Any number, greater than one, of guide members may be used without departing from the scope of the present invention. The guide members 20, 21, 22, 23 are formed of a ceramic such as hard matéñau , tungsten carbide or by stones timepiece, each having a through center hole in opposite. The guide members are joined and the aligned central holes 200, 210, 220, 230 form a guide channel in which the fiber strands, such as I and 1', are introduced through inlet cone 231.201 junction. In Figure 1, the strands of fibers 1 and 1', independent of the centralizer, are represented in chain-dotted and the junction portion of the fiber, location of the centralizer where the fiber ends are in contact, is located substantially in the middle of the ferrule assembly 2 and is denoted by A.The guide elements j- ointifs 21, 22 comprise in vis-a-vis at the junction region has a recess 21 I-fibers, 221 forming a reservoir for receiving fibers for assembling the index liquid compatible with that of the fibers and coupling the fiber ends. The guide elements, stones timepiece, consist of synthetic sapphire or ruby corundum. Each stone Lëvidement 211.221 21.22 is substantially rotationally symmetrical to the longitudinal symmetry axis of the X ' X of the centralizer. The recess may be obtained by means of conventional machining stones timepiece.In accordance with a particular embodiment of Figure 2, the stones 21, 22 having a recess 211.221 forming tank are mounted abutting an inner ring 3 of the shell 2. the ring 3 is disposed substantially at the junction area of the fiber and provides a clearance stones to form a liquid tank capacitance coupling increased. The reservoir formed by the gaps 211.221 and the central space of the ring 3 is in communication with the outside via a lumen 30 through the ferrule 2. the ferrule 2 is made of a machinable material by turning, for example brass. The guide elements or stones timepiece are mounted in the ferrule, abutting the grommet in accordance with Figure 2, crimped in the ferrule. The predrilling of the set stones ensures after grandissage holes a perfect alignment of the guide channel and a centering faces of the fibers very accurate. The central hole of each stone or member has a diameter corresponding to that of the fibers. The diameter of the hole forming the light 30 communication between the reservoir with the exterior is about 0.3 mm. In a preferred embodiment of the invention as shown in Figure 2, each guide element is coated with an oil repellent solid material layer 202, 212, 222, 232. Oil repellent material by consider any material whose surface after interrupted 640,354 cation that has a higher surface tension than an adjacent area in-zone-eroded not coated with oil repellent material. This layer of material such as silicone oil repellency is molybdenum disulfide or the MOS " this layer may be applied by a bath. The thickness of this layer is of the order of a few tens of angstroms. The oil repellent material layer provides a guide surface to very low coefficient of friction for providing fiber joint without damage to them. According Lo embodiment of Figure 2, two stones or elements respectively disposed on both sides of the joining region extracting fibers comprise on the periphery of the central hole an erosion zone annular 2120, 2220 of the oil repellent material. This erosion zone wherein the oil repellent material layer has been removed, located between two zones of oil repellent material, serves to cause a flow stop, by capillarity and by hunting phenomenon by each fiber strand, of the optical coupling liquid in the central holes during disassembly of the connection. Each area of éroz0 SiON film 2120, 2220 may for example be obtained by spark erosion using an electrode suitable introduced at the erosion zone to create. The areas of erosion 2120, 2220 extend in a direction parallel to the axis X ' X on a short distance from the I'm i00 to 150. During the dismantling of the connection, the index liquid is drawn by the consistent fiber displacement in the central holes 210 and 220. The encounter by the index liquid erosion areas 2120, 2220, an effect that an anchor of the vein liquid at these areas and allow stopping the flow and loss of the liquid incide . The material areas oléoîuge that can be placed on synthetic stone-like materials, brass, nickel plated steel, light 30 providing communication with the exterior of the tank also has an erosion zone 301 of the constituent material of the ferrule to ensure the flow stop of the optical coupling liquid after filling the reservoir. Any embodiment in which the oil repellent material layer has been removed on all of the guide channel and wherein a layer of oil repellent material has been deposited and held on the outer walls of the centralizer does not come out of the frame of the invention. In this embodiment each annular erosion zone is propagated through all of the guide channel except the entrance cones 201.131 members guiding the ends of the guide channel.C. 1 sheet drawings 640,354 1 sheet has 2 20 ., 21, 22 23,230 210,220 2oo 211,221 231, fig. 1, 21 2, 3 22,210 has 220, 23 1,202 260,211 221,230 2120, 212 222, 2220 301,232 fig. 2 1. A centering device for use in a connector for optic fibres (1, 1'), comprising a coupling ring (2) and a pair of guide members (3, 4) housed and positioned in the coupling ring (2) and defining therebetween a chamber (5) arranged to receive a liquid for optically coupling said fibres, each of said guide members (3, 4) having a hole (300, 310, 400, 410) for receiving one of said fibres (1, 1'), both holes (300, 310, 400, 410) being coaxial, characterized in that the walls of each of said pair of guide members include a first portion (302, 312, 402, 412) that is clad with a layer of oil repellent material and a second portion (313, 413) that is not clad with said material, said portions being arranged to define annular barriers that will prevent said liquid from flowing out of said connector. 1. centralizer for a fiber optic connector (1, 1 ') comprising a ferrule assembly (2) and two guides (3, 4) housed and positioned in the shell (2) and defining between them a housing (5) for receiving a coupling liquid optical fibers, each of said guides (3, 4) having a hole (300, 310, 400, 410) for receiving one of said fibers (1, 1'), the two holes (300, 310, 400, 410) being coaxial, characterized in that the walls of each of the two guide comprise a first portion (302, 312, 402, 412) coated with an oil repellent material layer and a second portion (313, 413) is not coated with the material, arranged so as to define annular barriers preventing flow of said liquid out of the connector. 2. the centralizer of claim 1, characterized in that the walls of said holes include at least two of said material coated areas, between which there is an area (313, 413) free of oil repellent material. 3. centralizer according to one of claims 1 and 2, characterized in that it further comprises a lumen (22) connecting said housing (5) outwardly of the centralizer. the EO 4. the centralizer of claim 3 characterized in that the walls of said lumen (22) comprise at least two of said material coated areas, between which there is an area (223) free of oil repellent material. in ES 5. the centralizer of any one of claims 1 to 4, characterized in that said material is molybdenum disulfide. 6, centralizer according to any one of claims 1 to 4, characterized in that said material is silicone.