Locking unit for e.g. connecting case and strap of watch, has tubular body comprising spring arranged in manner to exert force on bolt to project bolt relative to tubular body, where spring is made of compressible elatomer

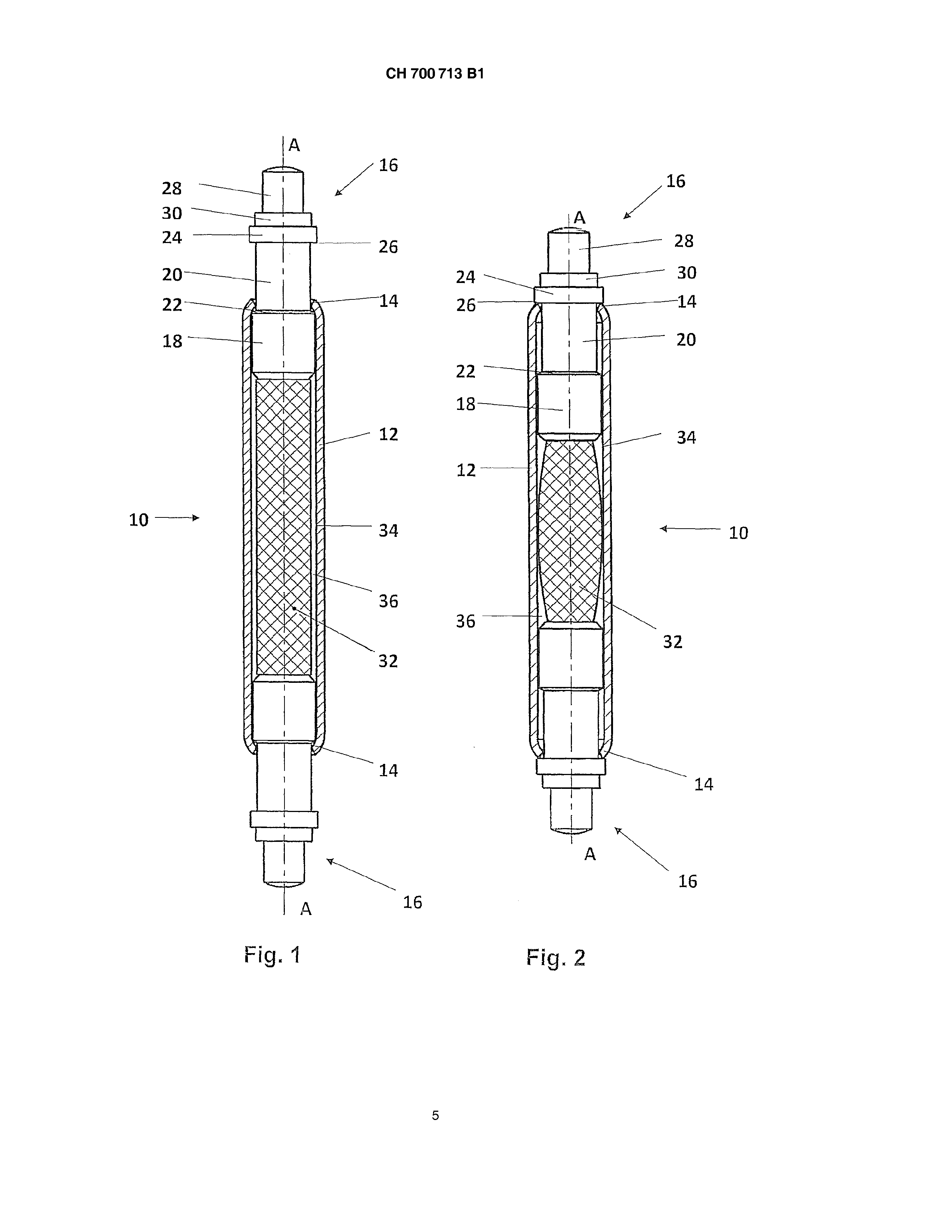

Describing technical field la invention concerns the clothing area clockwork. Eile relates, more particularly, a locking member for joining together two parts relatively to each other.State of the technique in the present application, the term of locking member of a cover element covers different elements. In particular, this term encompasses a link of a watchband for, currently, the mechanical connection of a bracelet to a watch case, particularly to the horns whose area provided. The linking means is well known to the skilled person and is commonly known as bar. The term of locking member of a cover element also includes another member to bond together two bracelet links between them. Of lock devices used in clasps bracelet, or pawls ball used to index a rotating bezel with reference to the box are also included in the generic definition of locking member of a cover element.[0003] a rod has a hollow tubular body defining an axis and having, at its ends, two pivots retractable axially in the tubular body. The tubular body also contains a compression spring between the two pivots to hold them apart. Alternatively known of this bar resumes the above structure wherein a first pivot is retractable axially in the tubular body while the second pivot is fixed. Such a bar is intended to cooperate with cylindrical holes arranged in facing, being carried by the horns of a watchcase. The horns are distant from one another so as to allow, when the delivered the pivots within the tubular body, disposing the bar between the horns. When the axis of the bar is in alignment with the holes of the cusps, the pivots are received automatically in the cylindrical holes and provide, therefore, the binding of the bracelet to the watch case. The same principle of connection also applies to links and at bracelet clasp.[0004] l ' spring member is typically achieved by a coil spring consisting of a steel wire wound into a helix. This type of spring imposes a section and a web length sufficient to obtain a spring with adequate mechanical properties. In effect, the spring must be able to dampen axial forces exerted on it through the pivots and returning to its initial shape by spreading the pivot pins when these axial forces disappear.In addition, the spring should repeat this operation a sufficient number of times without collapsing or distend to ensure the mechanical connection and the maintenance of the bracelet. Further, a simple practical point of view, the manufacture of such a spring imposes minimum dimensions, below which it is not possible to realize a spring at a reasonable price.[0005] la present invention is therefore to provide a bar that could be accomplished to sizes smaller than those of the state of the technique, while maintaining or even improving the advantages provided by a conventional strip, in wear and functionality. The advantages obtained for a bar is further achieved with other locking members of the trim members.Disclosure of the invention more particularly, the invention relates to a locking member watch trim member comprises a hollow tubular body defining an axis AA and fitted at its ends with at least one latch mounted axially mobile AA reference to tubular body, said tubular body also containing a spring member arranged to exert a force on the latch tending to bring the latch protruding in reference to the tubular body. According to the invention, the spring member is made of compressible elastomeric material.[0007] d'other characteristics are defined in the claims. The invention also relates to a watch strap and on a timepiece equipped with a connecting member according to the invention.Brief description of the drawings d'other features of the present invention will appear more clearly upon reading the description which will follow, made with reference to the attached drawing, in which:figure 1 Figure 2 represents an array according to the present invention in a position "rest", represents an array according to the present invention in a position "compressed".HC (O) 700713 b1 one embodiment of the invention la Figure 1 shows a strip 10 according to the invention, in a first position, said rest. The bar 10 comprises a tubular body 12, generally cylindrical, defining the central portion of the strip 10 and a longitudinal axis AA of the bar 10. The ends 14 of the tubular body have a restricted diameter, the role of which will appear further away.[0010] la strip 10 further includes first and second pivots 16, defining latches to fulfill the function of locking the bar, c'est i.e. allow it to secure a bracelet with a watch case. The pivots 16 are arranged so as to slide without play to the first and the second end of the tubular body 14, according to the longitudinal axis of the strap the AA. More specifically, each pivot 16 includes a first portion 18 housed within the tubular body 12. the outer diameter of the first portion 18 is adjusted relative to the inner diameter of the tubular body 12, so as to guide the sliding of the pivots 16. Each pivot 16 also has a second portion 20 having a diameter matching that of the tapered ends 14 of the tubular body 12, which contributes also guiding the sliding pins 16. A shoulder 22 is thus defined between the first 18 and the second portion of each pin 16, the shoulder 22 being arranged to abut against the interior of the tubular body 12 . 14 constrictions each second portion 20 terminates in a third portion 24 of a diameter greater than that of the second part 20, thereby defining a second shoulder 26 20 between the second and the third portion 24. The latter shoulder 26 is arranged to abut against the exterior of the tubular body 14 constrictions 12.Finally, the free ends of each pivot 16, a last portion 28 is arranged for cooperation with a hole of corresponding size, in member with which the strip 10 is intended to cooperate. Optionally, as shown in Figures, an additional portion 30 may be provided for practical questions between third portion 24 and the last part 28.[0011] un spring member 32 is disposed within the tubular body 12. it is arranged so as to exert a force on the pivots 16 tending to bring the first shoulder 22 abutting the constriction 14 corresponding. This configuration is shown in Figure 1 and corresponds to the rest position of the bar according to an important aspect of the invention, the spring member 32 is made of compressible elastomeric material. It is dimensioned such that, in the rest position, it is only slightly deformed and compressed. The skilled person will be able to provision the spring 32 so that, in this position, the pivots 16 are retained without clearance and ensure their mechanical function of link. Further, the operation of the pivots 16 should be easy while ensuring a good fit. The spring member 32 may be made by conventional techniques of molding, extrusion or cutting, in materials such as the NBR (nitrile-butadiene Genfoot) or a Buna-n (1.3 butadiene-acrylonitrile Genfoot NDA), disclosed HNBR ( hydrogenated nitrile-butadiene Genfoot), an EPDM (ethylene copolymers with propylene dien monomer), the SBR (styrene-butadiene-copolymers Genfoot).[0013] l ' spring member 32 is, preferably, tubular, advantageously cylindrical, but it may also have sections of various shape, or be of any three-dimensional shape, such as a sphere, since it may be encompassed within the tubular body 12 and cooperate with the two pivot pins 16.[0014] l ' spring member 32 is capable of being compressed in response to a mechanical stress on the one or on the pivots 16, to draw them toward each other in the longitudinal axis AA of the bar 10. The pivots 16 may be moved towards one another to an extreme position, called compressed position, shown in Figure 2. in this position, the second shoulder 26 pivots is brought into abutment against the constriction 14. This function is intrinsic to a strip, and allows, Iorsqu ' it is in the compressed position, be inserted between the horns of a watchcase, custom sized. Thus, when the bar 10 is aligned with holes comprised in the horns, the ends 28 of the pivots 16 are received automatically in the holes, the effect of the spring 32.[0015] depending on the nature of the elastomer and the stroke of the pivots 16 between the rest position and the compressed position, the spring member 32 may undergo deformation involving an increase in its dimensions, especially at its section, as well as shown in Figure 2. in such an event, the spring member 32 is further dimensioned to define, Iorsqu ' it is in its rest position, between it and the inner wall of the tubular body 12 34, a free space 36 within which it can deform upon compression. This avoids any adverse friction between the spring member 32 and the inner wall of the tubular body 34. It shall be possible to provide different shapes for the headspace 36, with, as shown, a gap 32 between the regular spring 34 and the wall of the tubular body 12, or interstice irregular, defining, for example, a concave profile. The concavity may be distributed along the length of the spring member or only in its central portion, where the deformations may be the most important. When compressed, the spring 32 occupies, at least partially, the free space 36 defined in the rest position.[0016] integration tests show that it is possible to realize webs according to the invention up to very small sizes, not possible with a traditional bar.[0017] thus, what has just been described about a strap for attaching a strap to a watch case, can be applied, more generally, to any connecting member of a bracelet, including a means for bonding two bracelet links between them. Can be, for example, providing members link to overall diameter smaller than 1 mm, with spring bodies whose section is less than 0.5 mm. The use of removable connecting organs for bonding two links to each other, is particularly beneficial and advantageous, compared to the use of pins driven away.HM 700713 b1 en addition, the tests also show that the spring members according to the invention have, despite their small size which could leave are difficulties at mechanical, advantageous properties to the springs usually used. Thus, a large number of compression cycles, the force of the spring conforms to the initial force. Further, in operation, the pivots can be operated such a highly smooth.[0019] thus is provided a connecting member for a watchband, offering a large number of advantages with respect to the webs of the state of the technique. The description above has been given by way of example without limitation of the invention and the skilled person will be able to envisage other variants and modifications without exiting the scope of the invention.They can therefore be expected to have a single pivot slidably mounted with reference to the tubular body. The other stationary or be arranged so that its axial position can be adjusted with reference to the tubular body, so as to define a pretension on the spring member and act on the force it exerts in the rest position. Without the necessity of the describe in detail, the skilled person will be able to adapt the invention as described above, other locking members of a clockwork casing element, such as those used in clasps bracelet, or systems indexing ratchet like ball used to index a rotating bezel with reference to the box. In these elements are also implemented latches, typically taking the form of a stud or of a ball, capable of moving between two extreme positions. A spring member according to the invention, made of compressible elastomeric material is arranged so as to cause the latch in one of these extreme positions, which is a locking position. In these different applications, the use of an elastomeric spring member provides the same advantages as described above under a small bar. The unit i.e. barret (10), has a hollow tubular body (12) defining a longitudinal axis (AA) and equipped with a bolt (16) at its ends. The tubular body has a tubular spring (32) arranged in a manner to exert force on the bolt to project the bolt relative to the tubular body, where the spring is made of compressible elastomer. An internal wall (34) is defined by the tubular body. The spring is arranged in a manner to define a free space (36) between the spring and the internal wall, when the spring is at rest. (10) locking member trim member watch comprising a hollow tubular body (12) defining an axis (A.A) fitted at its ends and at least one latch (16) mounted axially movable (A.A) with reference to the tubular body (12), said tubular body (12) also containing a spring element (32) arranged to exert a force on the latch tending to bring the latch protruding in reference to the tubular body, characterized in that said spring member (32) is made of compressible elastomeric material. Locking member as defined in claim 1, characterized in that the spring element (32) is tubular in shape. Locking member as defined in claims 1 and 2, wherein the tubular body (12) defines an inner wall (34), characterized in that the spring (32) is arranged so as to define, between it and the said inner wall (34), [...] ' it is at rest, a free space (36) within which it can deform upon compression. Locking member according to claim 3, characterized in that the free space (36) is defined by a regular gap. Locking member according to claim 3, characterized in that the free space (36) is defined by a gap variable locking member as defined in claim 1, characterized in that the spring element (32) is generally spherical. Locking member as defined in any one of the preceding claims, characterized in that said spring member is made of a Buna n-NBR or, hydrogenated, the EPDM, the SBR. Locking member according to one of the preceding claims, characterized in that it comprises two latches pivot, at least one being movable, for use as a connecting element of a watch bracelet. Locking member according to one of claims 1 to 7, characterized in that the lock is formed by a ball, for use in a pawl rotating bezel. 10. Locking member according to one of claims 1 to 7, characterized in that the bolt is a spike for a strap clasp. 11. Watch strap having a plurality of links, at least some of said links being joined together by a locking member (10) according to claim 8. 12. a timepiece comprising a watch bracelet, the bracelet being connected to the case by means of a locking member (10) according to claim 8.