STRUCTURE OF FABRIC FOR PROTECTIVE CLOTHING.

[0001] The invention concerns a structure of fabric for a protective clothing for task forces, with a Colonel off, a Futterstoff and a wetness barrier, whereby the wetness barrier had a climatic diaphragm, arranged between Colonel off and Futterstoff, which is laminated on a carrier material, as well as their use for the production of protective clothing for task forces, in particular fire-brigade jackets and - hosen.

Multi-layer articles of clothing with a Colonel off, a wetness barrier and a Futterstoff are carried frequently in the industry as well as by task forces, like for example military, police or the fire-brigade. Often these articles of clothing must be hitzefest, flame resistantly and reissfest, may no water, how fire fighting waters or rains let through, are however humidity, which results from sweating, of the body of the carrier outward abgeben.

Usually that is manufactured Colonel off from a heat-firm and flame resistant material, while the wetness barrier between Colonel off and Futterstoff is arranged and exhibits a two-layered structure. Here a climatic diaphragm on a carrier material is applied, which keeps penetrating humidity away on the one hand from the outside such as rains or fire fighting waters of the skin of the carrier and on the other hand on the skin to the outside surface of the article of clothing transports developing humidity. For this purpose the climatic diaphragm of the wetness barrier is arranged to the Colonel off, while the substrate of the wetness barrier is arranged to the Futterstoff. The Futterstoff is if necessary with an additional fleece versteppt.

A such structure of fabric exhibits usually a specific weight of 600 g/m2 or more, as well as a steam transmittance resistance Ret of 25 - 30 m2pa/w. This Ret value is a measure for the breathing activity of the material, whereby with smaller values a higher breathing activity is obtained. A higher breathing activity of the material reduces the heat stress, whereby in particular a cycle collapse for example on by Uberhitzung, are called days and when fire in corroding in the internal area one avoids. At the same time it is however necessary to receive or improve the Wasserdichtigkeit of the protective clothing, just like the heat transition. As important this Ret value is, for example in the EN 343:2007 (protective clothing against rains) documented. Here three classes were created; Class 1 (worst class):

Class 2:

Class 3:

Ret > here a protective clothing has 40 m2pa/W, # Ret # 40 m2pa/w Ret # 20 m2pa/W in accordance with class 1 an only limited Tragedauer.

For the classification of protective clothing numerous further standards stand for order, with their assistance the material and/or the structure of fabric different performance classes to be assigned kann.

There protective clothing for the fire fighting after EN 469:2005 + A1: 2006 high demands of the isolation of the structure of material and suffers thus natural the breathing activity makes under it, when defining of the Ret in the EN 469 on it to consideration was taken and the best class with Ret # 30 m2pa/w specified. If the RetGrenzwerte of the performance classes would be demanded after EN 343:2007 also in the EN 469:2005, the supply of protective clothing for the fire-brigade would not be after EN 469:2005 or only in a very much limited range möglich.

New fabric constructions improve the breathing activity on approx. 20 m2pa/w, without however an improvement of the values for the heat transitions Xf and Xr, substantial thereby, too erzielen.

The EN 367 the heat transition Xf describes during flaming effect, whereby in a first performance level of the Hitztransferindex HTI24 # 9.0 seconds and HTI24 - HTI12 # 3 s amounted to must, during in the higher performance level 2 a HTI24 # 13.0 s and HTI24 - HTI12 # 4 s to reach ist.

The HTI 2 and/or HTI24 calls itself that time, into the temperature on the back of a material of the ambient temperature (mostly 25°C) increased by 12°C and/or 24°C, if at the front a flame is held by the material. Since during a rise in temperature around 12°C usually the carrier of the protective clothing a first pain felt and during a rise in temperature around 24°C the first fire injuries arise, in particular the difference of the two values is a measure for that time, which is to the carrier of the protective clothing at the disposal to depart from a danger area as soon as it a first pain due to for example flame effect verspürt.

The heat transition Xr concerns the EN ISO 6940 during radiation effect, whereby in the stage 1 a radiation heat transfer index RHTI40 # 10.0 s and RHTI24 - RHTI 2 # 3 s and in the stage 2 a RHTI40 # 18.0 s and RHTI24 - > RHTI 2; 4 s to reach sind.

In the EN 20811 the performance levels for the Wasserdichtigkeit Y are descriptive, whereby an increase of pressure of < kPa of the performance level 1 and an increase of pressure of # 20 kPa of the performance level 2 to assign ist.

The steam transmittance resistance is just as in the EN 31092 regular, whereby in the performance level 1 a Ret value of > 30 m2pa/W and in the performance level 2 m2pa/W demanded by # 30 m2pa/W sind.

The structure of fabric in accordance with the conditions of the technology, described above, fulfills generally the conditions for the performance level 2.

In order to improve the stretcher comfort, for task forces, at whose protective clothing no high demands are made regarding the heat firmness, fabric superstructures were developed, with which the climatic diaphragm is laminated directly on the Futterstoff, around the specific weight of the protective clothing on 380 g/m2 to 450 g/m2 too senken.

A such protective clothing exhibits besides usually a better Ret value opposite at least three-fold fabric superstructures described above. This essentially two-layered structure of fabric in accordance with the state of the art fulfills generally the conditions for the performance level 3 after the EN 343:2007. However a such structure of fabric is reduced due to its to small heatproof quality for the protective clothing for example for the fire-brigade only geeignet.

It is task of the invention to make a material available that a increased breathing activity with higher protection from fire injuries for the order places and the requirements of the performance level 2 of the standards specified above fulfilled, but did not only improve values opposite admits nascent materials and at the same time a smaller specific weight aufweist.

This task is solved according to invention by a structure of fabric of the initially mentioned kind by the fact that between Colonel off and wetness barrier an additional layer with essentially gridlike structure is arranged. By a layer with essentially gridlike structure in the context of this revealing a fabric or a Gestrick with lattice-like structure is understood. This additional layer, for example a fabric with high volume at the same time small weight, causes a increased heat firmness of the structure of fabric, in particular an increase the heat transfer index and the radiation heat transfer index is obtained. Thus it is possible for the task forces also at high temperatures to stay longer at the place of work. Since according to invention between the Colonel off and the climatic diaphragm located on the Futterstoff an additional fabric or Gestrick is arranged, remains with injury of the upper material, for example when breaking the upper material at sharp edged articles, which receives created air cushion by the additional fabric or Gestrick, so that a further improvement of the heat protection is obtained here when simultaneous improvement the breathing activity. Also the mechanically sensitive climatic diaphragm is at the same time protected and the Wasserdichtigkeit of the structure of fabric remains bewahrt.

In a particularly preferred execution of the invention the additional layer is a Gestrick, which favourable-proves a specific weight of maximally 150 g/m2 exhibits. By use of a knitted material the weight of the structure of fabric according to invention increases only slightly regarding the weight of a structure of material in accordance with the state of the art. The moreover one the Gestrick exhibits naturally an irregular surface, whereby an additional air cushion is formed, that again a positive influence on the heat protection ausübt.

In a further preferential execution is the climatic diaphragm of the wetness barrier the Futterstoff zugewandt.

Investigations of the applicant showed that during arrangement of the climatic diaphragm for the carrier of the article of clothing an increased evacuation of the humidity takes place from the skin surface the carriers, whereby an improved stretcher comfort obtains wird.

In a further execution of the invention the wetness barrier on their exhibits the Colonel off turned side of the carrier material of distance elements. The use of distance elements between Futterstoff and wetness barrier is well-known. They serve in particular the education of an isolating air cushion, in order to reduce the heat effect to the carrier. In the available invention however these distance elements between Colonel off and wetness barrier are arranged and are prefer-prove on that the Colonel off turned side of the carrier material, around an improvement of the breathing activity too erzielen.

Preferably the distance elements made of plastic are manufactured, evenly distributed on that the Colonel off turned side of the carrier material and essentially burl-like trained. Such ones “dots” are particularly suitable to train an air cushion between the additional fabric as well as the carrier material of the wetness barrier and carry thereby again for an improved heat firmness as well as breathing activity bei.

Alternatively for this that exhibits Colonel off on its wetness barrier turned page of distance elements in a further execution of the invention. Preferably here the distance elements are evenly on that the wetness barrier turned side of the upper material distributed and for example essentially rib-like ausgebildet.

The structure of fabric described above is suitable in particular for the use for the production of protective clothing for task forces, in particular for the production of fire-brigade jackets and fire-brigade trousers with increased breathing activity and improved Hitzeschutz.

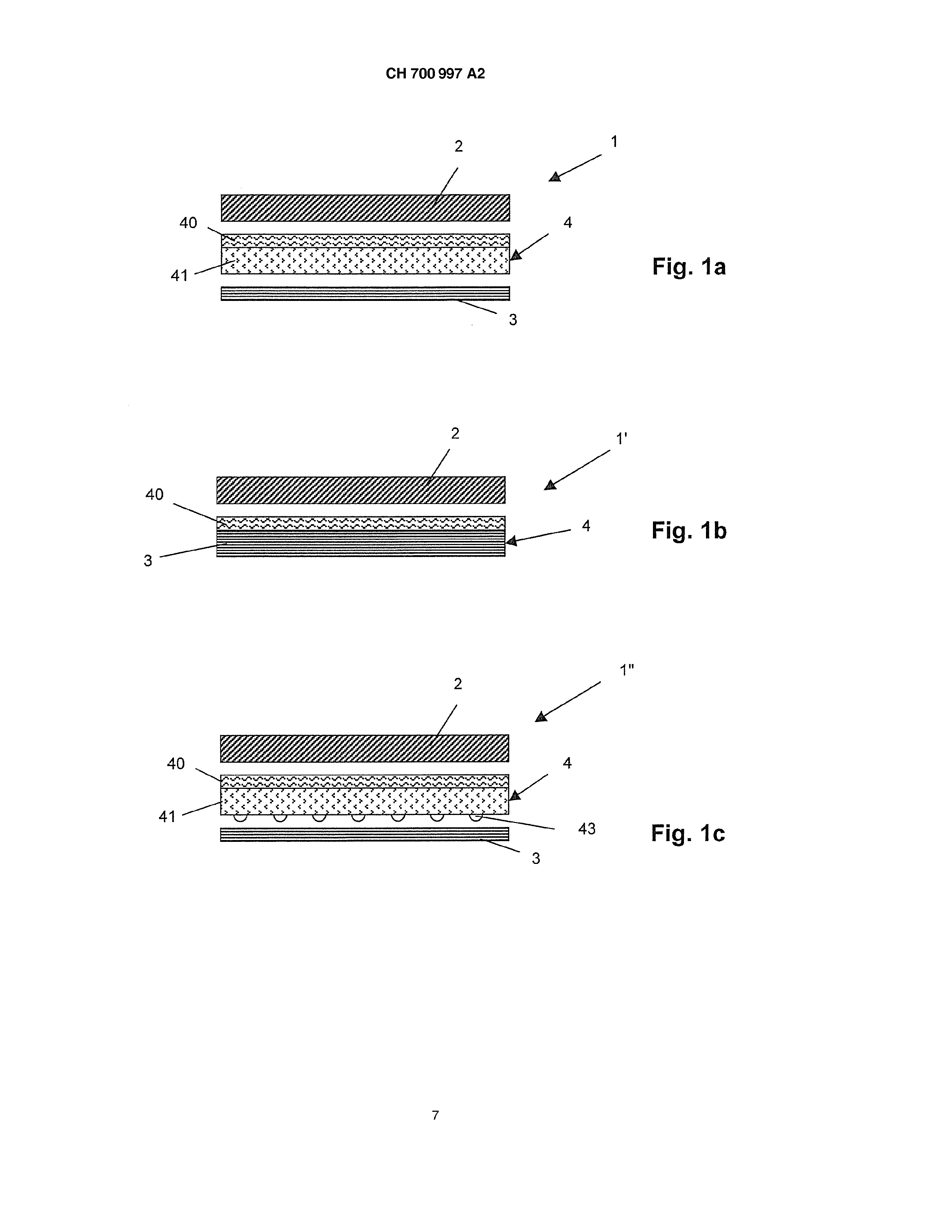

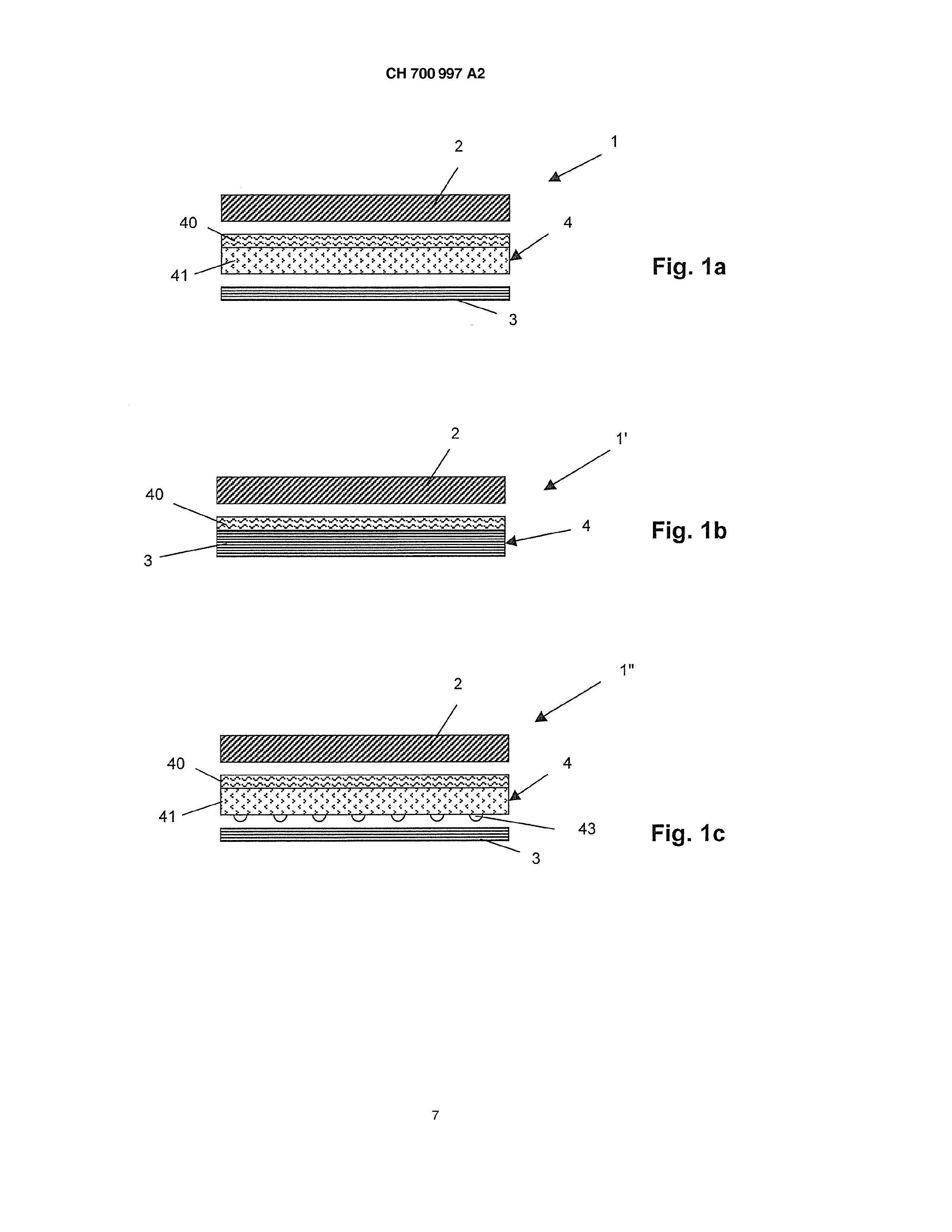

In the following on the basis of not restrictive remark examples with associated figures the invention is more near described. In it show:

Fig. la a three-fold structure of fabric in accordance with the state of the art; Fig. 1 b Fig. lc Fig. 2 Fig. 3 Fig. 4 a two-layered structure of fabric in accordance with the state of the art; a further three-fold structure of fabric in accordance with the state of the art; a first structure of fabric according to invention; a second structure of fabric according to invention; and a third Gewebeaufbau. according to invention

The three-fold structure of fabric 1 in accordance with Fig. la usually with the production of protective clothing for task forces in particular for the fire fighting one uses. It exhibits a Colonel off 2 and a Futterstoff in accordance with the state of the art a 3, whereby a wetness barrier 4 between Colonel off 2 is arranged and Futterstoff 3. The fodder fabric 3 is here mostly additionally for example quilted with a thermal fleece (not shown).

The wetness barrier 4 has a climatic diaphragm 40, which is turned to the Colonel off 2. This climatic diaphragm is up-laminated on a carrier material 41, which gives the necessary mechanical firmness to the climatic diaphragm 40. A such layer structure 1 of different materials exhibits usually a steam transmittance resistance (Ret) from approximately 25 m2pa/w to 30 m2pa/w. The warming transitions Xf, Xr of such layer structures amount to usually:

HTI24 = 1819S HTI24 - HTI12 = 6 S RHTI24 = 21 - 22 S RHTI24 - RHTI12 = 6 - 7 S the specific weight of this structure of fabric 1 amounts to here to the 600 g/m2 or mehr.

In the Fig. lb a further structure of fabric 1 is represented " after the state of the art, with which the climatic diaphragm 40 directly on the Futterstoff 3 is located. One with this structure of fabric 1 " manufactured protective clothing exhibits a small specific weight 380 g/m2 to 450 g/m2 and fulfills also the achievement requirements for the breathing activity, however the attainable values for the heatproof quality make the employment of this structure of fabric 1 " only reduced possible for protective clothing for the fire fighting (see also following table A).

So far this disadvantage was eliminated by the use of an additional thermal fodder, which is arranged between the wetness barrier 4 and the carrier of the protective clothing, (not represented). This leads however to a drastic reduction of the breathing activity as well as to a significant increase of the specific weight, so that within the range of the protective clothing for the fire fighting the original advantages of this structure of fabric 1 are practically again destroyed made " and no more advantage in relation to the structure of fabric 1 after Fig. la to attain ist.

An improvement of the breathing activity as well as the heat protection Iässt also with fabric superstructures 1 " after the conditions of the technology obtain themselves, - as for example in Fig. lc described - on that the climatic diaphragm exhibit 40 turned away sides of the carrier material 41 of the wetness barrier of 4 distance elements 43. The distance elements 43 are for example from a flexible plastic manufactured and essentially evenly distributed over the surface of the carrier material. They form to the Futterstoff 3 an air cushion, for that against heat effect from the outside, for example a fire, as isolation wirken.

In some cases fabric superstructures exhibit a Futterstoff, which instead of a thermal fleece in regular distances rib-like structures in the form of approximately 1 mm after the conditions of the technology - 2 mm of thick, on which fodder fabric exhibits fastened cords (mostly in longitudinal direction of thread) in the distance of approx. 8 mm -10 mm. A such layer structure possesses usually a steam transmittance resistance (Ret) from approximately 20 m2pa/w to 23 m2pa/w.

The warming transitions Xf, Xr of such layer structures amount to usually:

HTI24 = 16.5 - 18 S HTI24 - HTI12 = 5.0 S RHTI24 = 20 - 21 S RHTI24 - RHTI12 = 5 - 6 S the heat transition is thus worse with improved breathing activity than with the example described above in accordance with Fig. la.

If this machined corrugated members are attached however at that the wetness barrier neighbouring side of the upper material and if the climatic diaphragm the Futterstoff is turned, then the breathing activity of the structure of fabric according to invention is significantly increased and at the same time the heat protection verbessert.

After Fig. 2 a first execution of the structure of fabric according to invention 100 points likewise to a Colonel off 2 and a Futterstoff a 3 (however without thermal fleece equipment) as well as a wetness barrier 4 up, whereby the climatic diaphragm 40 of the wetness barrier 4 is turned to the Futterstoff 3. Additionally a Gestrick 5 is arranged between Colonel off 2 and carrier material 41 of the wetness barrier 4. This Gestrick 5 works the breathing activity and/or the steam transmittance resistance Ret as isolation fabric and/or spacer and increases on the one hand the thermal resistance and/or the Hitztransferindizes HTI and RHTI by on the average 15% during itself by on the average 35% opposite a structure of fabric in accordance with Fig. la verbessert.

With the structure of fabric according to invention 100 " in accordance with a second execution form after Fig. again the wetness barrier 4 is in such a manner arranged 3 the fact that the distance elements 43, which so-called “dots”, between Colonel off 2 and wetness barrier 4 arranged Gestrick 5 is turned which. Also with this structure of fabric 100” that the steam transmittance resistance Ret and thus the breathing activity of the material can be improved 100” despite the additional Gestricks 5 something, during the heat protection showed up around 30% to 40% improved wurde.

In a third variant the structure of fabric according to invention 100 points” after Fig. 4 despite a smaller specific weight the necessary heatproof quality as well as an excellent breathing activity up. Here is between the Colonel off 2, e.g. Nomex® (a Aramidgewebe) and the wetness barrier 4, with which the climatic diaphragm prefer-proves for example by means of point gluing with the Futterstoff 3, to a mixture fabric made of viscose rayon and Aramid or however a fabric from pure Aramid, is inseparably connected, a Gestrick 5 arranged. This Gestrick works the breathing activity and/or the steam transmittance resistance Ret as isolation fabric and/or spacer and increases on the one hand the thermal resistance and/or the heat transfer indices HTI and RHTI, during itself by 10% to 30% opposite a structure of fabric in accordance with Fig. la verbessert.

By the Gestrick according to invention 5 in particular in combination with the arrangement to the conditions of the technology arranged wetness barrier 4, Iässt mirror-operates the breathing activity of the structure of fabric 100, 100 ", 100sowie its heat firmness substantially improves. The Gestrick 5 exhibits prefer-proves machined corrugated members, equally a Waffelstruktur or a 3D-Optik can be obtained by suitable cord technology, so that the fabric exhibits a large volume with small weight. In this way in the Gestrick 5 even as well as in the gaps between Gestrick 5 and wetness barrier 4 and/or Colonel off 2 an air cushion is formed, for that in particular the heat effect on the carrier of the protective clothing sinks Iässt. The moreover one the Gestrick 5 protects the wetness barrier 4 which is under if that is for example torn up to Colonel off 2 or by flaming contact breaks open. It is manufactured preferentially from a heat-resistant material and holds in particular also mechanical loads stand.

It understands itself that the available invention is not limited to the execution forms represented above. For the invention that an additional fabric between Colonel off and wetness barrier is arranged, during prefer-proves at the same time the climatic diaphragm of the wetness barrier the Futterstoff is substantial turned is, in order to obtain an increase of the breathing activity. This additional fabric can be manufactured from most different materials, has however prefer-proves a large volume with small weight by its gridlike Struktur.

Table A:

Structure of fabric Fig. HTI24 HTI24 _12 RHTI24 RHTI24 _12 Ret spez.

[m2pa/W] weight [g/m2] EN 469:2005 - 13.0 4.0 18 4 30.00 no requirements Nomex/wetness barrier/Steppfutla 18.8 6.1 21.5 6.8 25.42 595 ter Nomex/fodder liner 1 b 7.8,2.5,9.7,3.2 13.64 400 Nomex/wetness barrier with Ab1 C of 18.2 6.0 19.7 6.4 19.29 565 owners/fodder fabrics Nomex/Gestrick/fodder liner 4 18.5 5.9 20.7 6.1 17.45 490 The invention concerns a structure of fabric (100) for a protective clothing for task forces, with a Colonel off (2), a Futterstoff (3) and one between Colonel off (2) and Futterstoff (3) arranged wetness barrier (4), whereby the wetness barrier (4) had a climatic diaphragm (40), which on a carrier material (3) is laminated, and between Colonel off (2) and wetness barrier (4) an additional layer (5) with essentially gridlike structure is arranged. Structure of fabric (100, 100 ", 100 ") for a protective clothing for task forces, with a Colonel off (2), a Futterstoff (3) and one between Colonel off (2) and Futterstoff (3) arranged wetness barrier (4), whereby the wetness barrier (4) had a climatic diaphragm (40), those. on a carrier material (3, 41) laminated it is characterized, by the fact that between Colonel off (2) and wetness barrier (4) an additional layer (5) with essentially gridlike structure is arranged. 2. Structure of fabric (100, 100 ", 100 ") according to requirement 1, by the fact characterized that for example the additional layer (5) a fabric or a Gestrick is. 3. Structure of fabric (100, 100 ", 100 ") according to requirement 1 or 2, by the fact characterized that the additional layer (5) a specific weight of maximally 150 g/m2 exhibits. 4. Structure of fabric (100, 100 ", 100 ") after one of the requirements 1 to 3, by the fact characterized that the climatic diaphragm (40) of the wetness barrier (4) the Futterstoff (3) is turned. 5. Structure of fabric (100, 100 ", 100 ") after one of the requirements 1 to 4, by the fact characterized that the wetness barrier (4) on their the Colonel off (2) turned side of the carrier material (of 41) distance elements (43) exhibits. 6. Structure of fabric (100, 100 ", 100 “) according to requirement 5, by the fact characterized that the distance elements (43) made of plastic are manufactured, evenly on that the Colonel off (2) turned side of the carrier material (41) is distributed and is essentially burl-like trained. 7. Structure of fabric (100, 100 ", 100”) according to requirement 5, by the fact characterized that the distance elements evenly on that the wetness barrier (4) turned side of the upper material (2) distributed and essentially rib-like trained is. 8. Structure of fabric (100, 100 ", 100”) after one of the requirements 1 to 3, by the fact characterized that the climatic diaphragm (40) of the wetness barrier (4) on the Futterstoff (3) is inseparably arranged. 9. Structure of fabric (100, 100 ", 100”) according to requirement 8, by the fact characterized that Colonel off (2) on its wetness barrier (4) turned page of distance elements exhibits. 10. Structure of fabric (100, 100 ", 100”) after one of the requirements 1 to 9 characterized by a specific weight of < 500 g/m2. 11. Use of a structure of fabric (100.100 ", 100”) after one of the requirements 1 to 10 for the production of protective clothing for task forces, in particular of fire-brigade jackets and - trousers.