ELEMENT Of LUMINOUS INTERIOR TRIM, IN PARTICULAR FOR MOTOR VEHICLE, AND PANEL OF DOOR EQUIPS With SUCH an ELEMENT.

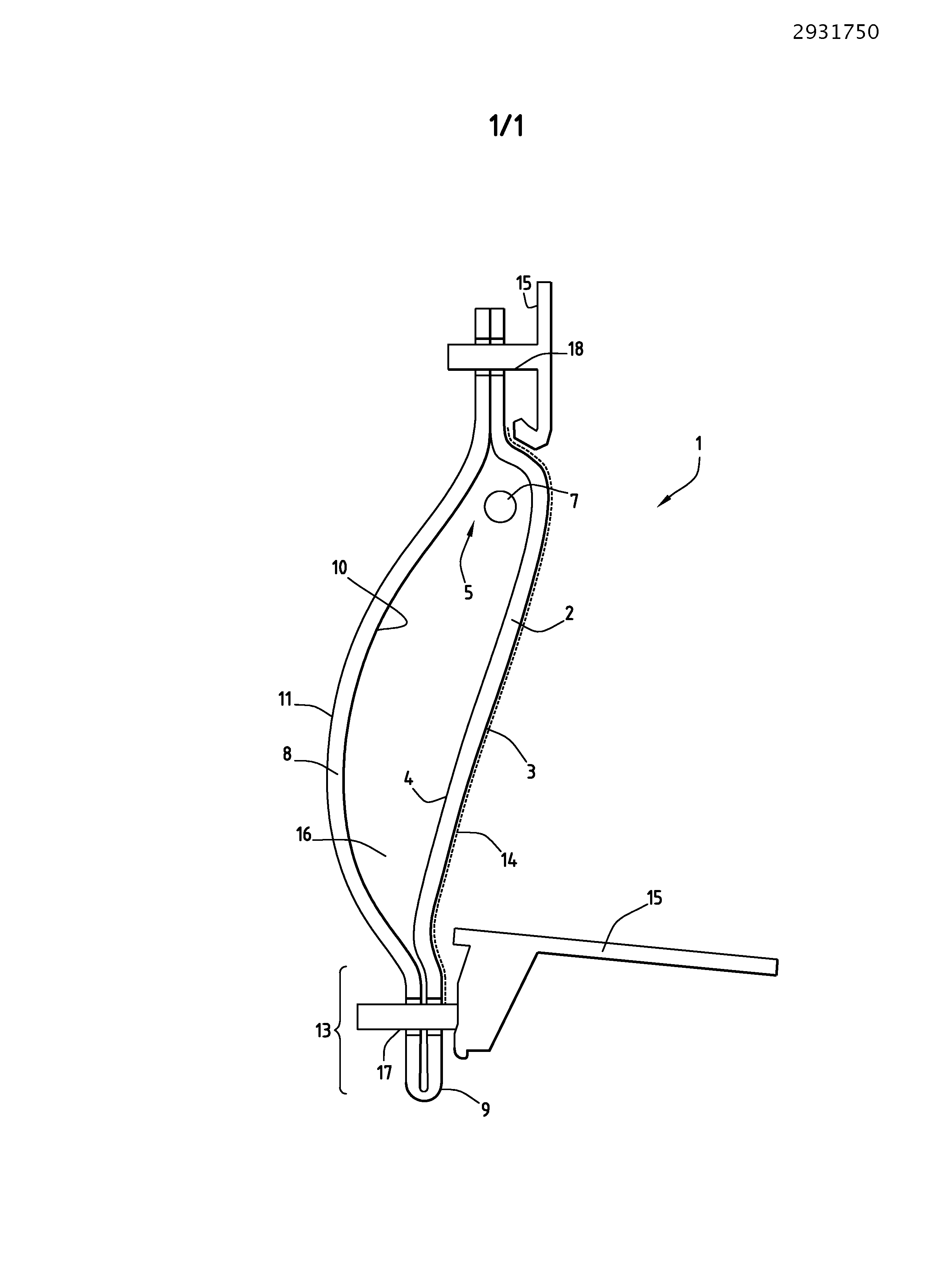

A luminous interior trim and a door panel provided with spacer. The cover member is particularly suited to be integrated in a motor vehicle. However, this trim element can also have other applications, for example in non-motor vehicles, such as aircraft or trains. The element according to the invention can even serve as furnishing element. The invention particularly to ensure uniform ambient illumination of the trim element while avoiding leaking of light out of the desired illumination area. The invention is particularly advantageous for medallions of door panels but could also be used in particular with the instrument panels or false ceilings of the motor vehicle. In a moving motor vehicle the night, the instrument panel is illuminated, but the rest of the vehicle is in the dark, except optional point lamps which may be turned on and off. However, it is desirable that there is a certain lighting atmosphere inside the automobile, for reasons of convenience of passengers, without that it has a risk to the driver. The point sources of light are Dazzling and cannot be achieved satisfactorily ambient illumination. A performing such a fill light, with interior trim parts of low thickness. Elements are known vehicle interior trim mounted to a door panel, called medallions door, capable of ensuring ambient illumination within the vehicle. To this end, the medallions comprises a wall translucent backlit by a light source positioned behind the wall. The wall may be covered, if necessary, a coating of appearance as a textile comprising weft threads sufficiently spaced to pass light, or leather having perforations. Forms in the coating appearance may be provided to obtain light patterns. Furthermore, the light emitting region of the non-visible side is covered by a cover insert which forms with the wall of the medallion a closed space inside of the door, the light source being positioned within the space. The light being emitted in a direction substantially parallel to the translucent wall, the cover and the wall form an angle to each other such that the light is reflected by the cover and directed towards the translucent wall of the medallion to create uniform illumination of the trim element. However, it is difficult to carry out sealed junctions between the cover extension and the wall, so that the light can exit the space formed by the wall and the cover and to pass through openings in the door, such as those provided for receiving the ashtrays, the door handles, or speakers. The undesired passage of the light through the openings may lead to light pollution for the driver and/or unsightly light effects. Furthermore, performing a cover insert is expensive since it is necessary to perform two successive molding operations to obtain the cover and the translucent wall of the medallion. The using a cache may also produce noise since the wall and the cover are susceptible to friction at the location of their junction when the vehicle vibrates. The invention is intended to solve in particular the problems described above. To this end, in the invention, the cover is an extension of the wall of the medallion, the connection between the panel and the cover being carried out by means of a flexible hinge. The cover, the wall and the flexible hinge are formed integrally i.e. that they form a single piece. Therefore, it is possible to bend the shield to the wall of the medallion by folding the hinge to create the enclosed space within which is positioned the light source. Such construction is less expensive as a cache insert since it is possible to realize the cover and the wall of the medallion in a single moulding operation. It also eliminates the noise since it reduces the number of parts which may come into friction with each other, the hinge between the wall and the cover forming an integral part of these two elements. Furthermore, the invention avoids light leakage at the location of the hinge. It is possible to realize the cover in the wall of the same material as the medallion (translucent material). It is then desirable to cover the inner surface of the cover a layer of reflective paint. Preferably, it is a paint mat with a color such as, according to the model for representing colors CIE 1976 (L *, a *, b *) (CIELAB), its luminance L * is strictly greater than 60, and preferably greater than 70. Alternatively, a reflective film can be overmolded on said inner surface. The layer of paint or overmolded film ensure that light is reflected from the surface of the shield to the translucent wall of the medallion. It is also possible to cover the outer surface of the cover facing the door by a layer of opaque paint or overmolding a opaque film on said outer face to prevent leakage of light to the outside of the illumination area. It is also possible to perform the cover into a material different from that of the wall of the medallion. In this case, preferably, a light reflective material is selected for the cache. The materials of the cover of the wall and connect to the location of the flexible hinge, a transition between the two materials being observable at the hinge. A luminous interior trim element, in particular for a motor vehicle, characterized in that it comprises: -a translucent wall with a surface which is intended to be visible to the driver; and -a lighting device comprising a light source positioned on the opposite side to the visible surface of the translucent wall to backlight the translucent wall, and a reflective cover for reflecting the light emitted by the light source towards the translucent wall, reflective-the cover being connected to the translucent wall by a flexible hinge, reflecting the cover, the translucent wall and the flexible hinge forming a single piece, the cover-reflective and the translucent wall being folded toward each other by folding the hinge, so that the wall and the cover translucent reflective delimit a closed space within which is positioned the light source. In particular embodiments, the cover member has one or more of the following features, taken (s) alone or in all technically possible combinations: reflective-the cover is made of the same material as the translucent wall; -the interior face of the cover facing the closed space is covered with a layer of reflective paint or a reflective film fixedly mounted on the inner face; -the paint or the film is matt appearance and one or more colours such as, according to the model for representing colors CIE 1976 (L *, a *, b *) (CIELAB), its luminance L * is strictly greater than 60, and preferably greater than 70; -the exterior surface of the cover oriented in the direction opposite to the closed space is covered with a layer of paint or overmolded film opaque; the cover-reflective and the translucent wall are made of two different materials, the material of the reflective cover having reflective properties, the materials of the cover and of the translucent wall joining at the location of the flexible hinge; -the light source is formed by a tubular optical waveguide made of a translucent material, such as an optical fiber, and at least one point light source, such as a diode, positioned at one end of the light guide, -light emitted by the point light source is routed through the light guide via the asperities made in the inner surface of the light guide in a direction substantially parallel to the translucent wall, -the wall and the mask forming between them an angle such that the light is directed towards the translucent wall; and -the wall is covered with a coating of aspect, such as textile or leather having perforations. The invention also relates to a door panel for a motor vehicle comprising a body extending vertically and an element covering the aforementioned type, attached to the body using securing means. The invention be included at the reading of the description that follows and for the examination of the single Figure (Figure 1) the accompanying. The figure is exemplary but not limiting of the invention. The Figure 1 shows a cross-sectional view of a medallion of the invention attached to a door panel of a motor vehicle. More specifically, Figure 1 shows a medallion door 1 having a translucent wall 2 vertically oriented. The wall 2 3 has a face oriented towards the interior of the vehicle visible by passengers of the vehicle and a face 4 oriented towards the exterior of the vehicle on the side of the door that is not visible to passengers. A device 5 of illumination comprising a light source 7 is positioned behind the translucent wall 2 on the side of the face 4 so as to backlight the wall 2. The light source 7 is formed by means of a diode (or other point light source) positioned at one end of a tubular optical waveguide made of a translucent material, such as an optical fiber. The light emitted by the light source 7 is conveyed by the light guide to be directed in a direction substantially parallel to the translucent wall 2 via asperities made in the inner surface of the light guide. 5 The lighting device further includes a reflective cover 8 which forms with the wall 2 such an angle that the light emitted by the light source 7 is reflected by the reflective cover 8 to the translucent wall 2 to the backlight. Cache The reflective 8 is connected to the wall 2 by a flexible hinge 9. The wall 2, the cover 8 and the hinge 9 form a one-piece, i.e. that there is continuity of material between the elements 2, 8, and 9. The cover 8 and the wall 2 are folded toward each other by folding the hinge 9, wherein the mask 8 and the wall 2 delimit a closed space 16 inside which is positioned the light source 7. The hinge 9 can be used to block the light emissions down the medallion 1. It is also possible to use a reflector element (not shown) upwardly covering the light source 7 so as to block spurious emissions of light to the top at the location of the area where the cover 8 and the wall 2 are pressed against each other. The cover 8 can be made from the same material as the wall 2 1 of the medallion. The cover 8 in a translucent material, it is preferably covered at its inside 10 pointing in the direction of the space 16 of a layer of reflective paint. Preferably, it is a paint mat with one or more colours such as, according to the model for representing colors CIE 1976 (L *, a *, b *) (CIELAB), its luminance L * is strictly greater than 60, and preferably greater than 70. Alternatively, a reflective film is over-molded or bonded to the inner face 10. It is also possible to cover the outer face 11 of the cover 8 oriented on the side of the vehicle door with a layer of opaque paint or overmolding a opaque film over this outer face 11 to prevent the emission of light out of the illumination area of the enhancer 1. Alternatively, the cover 8 is of a material different than that of the wall 2, the material of the cover 8 is selected to reflect light. Therefore, applying a layer of paint or a reflective film on the interior face of the cover 8 is saved. In this embodiment, the materials of the cover 8 and the wall 2 of the medallion 1 connect to the location of the hinge 9 at a joining area of material 13. The cover 8 and the wall 2 are made of different thermoplastic materials, of the same family, such as the family of polypropylenes or the family of ABS. In some embodiments, it is also possible to alternate areas mat gloss appearance and in the cache 8 to obtain a homogeneous illumination of the translucent wall 2 of the medallion. Therefore, the portions of the cache 8 reached by a small amount of light have a glossy appearance; while the part of the cache 8 reached by an amount large light have a matt appearance so as to obtain a uniform illumination of the medallion 1. The wall 2 is covered further, if necessary, a coating of aspect 14 such as a textile comprising weft threads sufficiently spaced to pass light locally, or leather having perforations. Patterns in coating 14 aspect can be performed to obtain light patterns. The medallion 1 is suspended from a body 15 of a door panel of a motor vehicle by joining means 17 and 18, the means for securing the panel 1 binder 17 to the body 15 at the location of the hinge 9, the means of securing the end of the medallion 18 binder 1 opposite to that of the hinge 9 to the body 15 where the cover 8 and the wall 2 are pressed on the other. The element i.e. medallion (1), has a lighting device (5) with a reflecting cover plate (8) ensuring reflection of light emitted by a light source (7) e.g. LED, towards a translucent wall (2). The plate is connected to the wall by a flexible hinge (9), where the wall, plate and hinge form a monoblock part. The plate and the wall are folded towards each other by folding the hinge, so that the wall and the plate define closed space (16), where the light source is positioned in interior of the space. An independent claim is also included for a door panel for a motor vehicle comprising a body. 1. Trim component (1) interior light, in particular for a motor vehicle, characterized in that it comprises: -a translucent wall (2) having a face (3) intended to be visible by the driver, and -a lighting device (5) comprising a light source (7) positioned on the side opposite the visible side (3) of the translucent wall (2) to backlight the translucent wall (2), and a reflective cover (8) for reflecting the light emitted by the light source (7) to the translucent wall (2), the cover-reflective (8) being connected to the translucent wall (2) by a flexible hinge (9), reflecting the cover (8), the translucent wall (2) and the flexible hinge (9) forming a single piece, the cover-reflective (8) and the translucent wall (2) being folded toward each other by folding the hinge (9), so that the translucent wall (2) and the cover (8) reflective delimit a closed space (16) within which is positioned the light source (7). 2. Cladding element according to claim 1, characterized in that the cover reflective (8) is made of the same material as the translucent wall (2). 3. Cladding element according to claim 2, characterized in that the inner face (10) of the cover (8) facing the closed space (16) is covered with a layer of reflective paint or a reflective film fixedly mounted on the inner face (10). 4. Cladding element according to claim 3, characterized in that the paint or film is a matt appearance and one or more colours such as, according to the model for representing colors CIE 1976 (L *, a *, b *) (CIELAB), its luminance L * is strictly greater than 60, and preferably greater than 70. 5. Element according to one of claims 2 to 4, characterized in that the outer face (11) of the cover (8) oriented in the direction opposite to the closed space (16) is covered with a layer of paint or overmolded film opaque. 6. Cladding element according to claim 1, characterized in that the cover (8) and the reflective translucent wall (2) are made of two different materials, the material of the reflective cover (8) having reflective properties, the materials of the cover (8) and of the translucent wall (2) joining at the location of the flexible hinge (9). 7. Element according to one of claims 1 to 6, characterized in that the light source (7) is formed by a tubular optical waveguide made of a translucent material, such as an optical fiber, and at least one point light source, such as a diode, positioned at one end of the light guide, -light emitted by the point light source is routed through the light guide via the asperities made in the inner surface of the light guide in a direction substantially parallel to the translucent wall (2), -the wall (2) and the cover (8) forming between them an angle such that the light is directed to the translucent wall (2). 8. Element according to one of claims 1 to 7, characterized in that the wall (2) is coated with a coating of aspect (14), such as textile or leather having perforations. 9. Door panel for a motor vehicle, characterized in that it includes a body (15) which extends vertically and defined in any one of claims 1 to 8 attached to the body (15) by securing means (17, 18). Interior lining light, in particular for a motor vehicle, and a door panel provided with spacer