Heating structure for vehicles

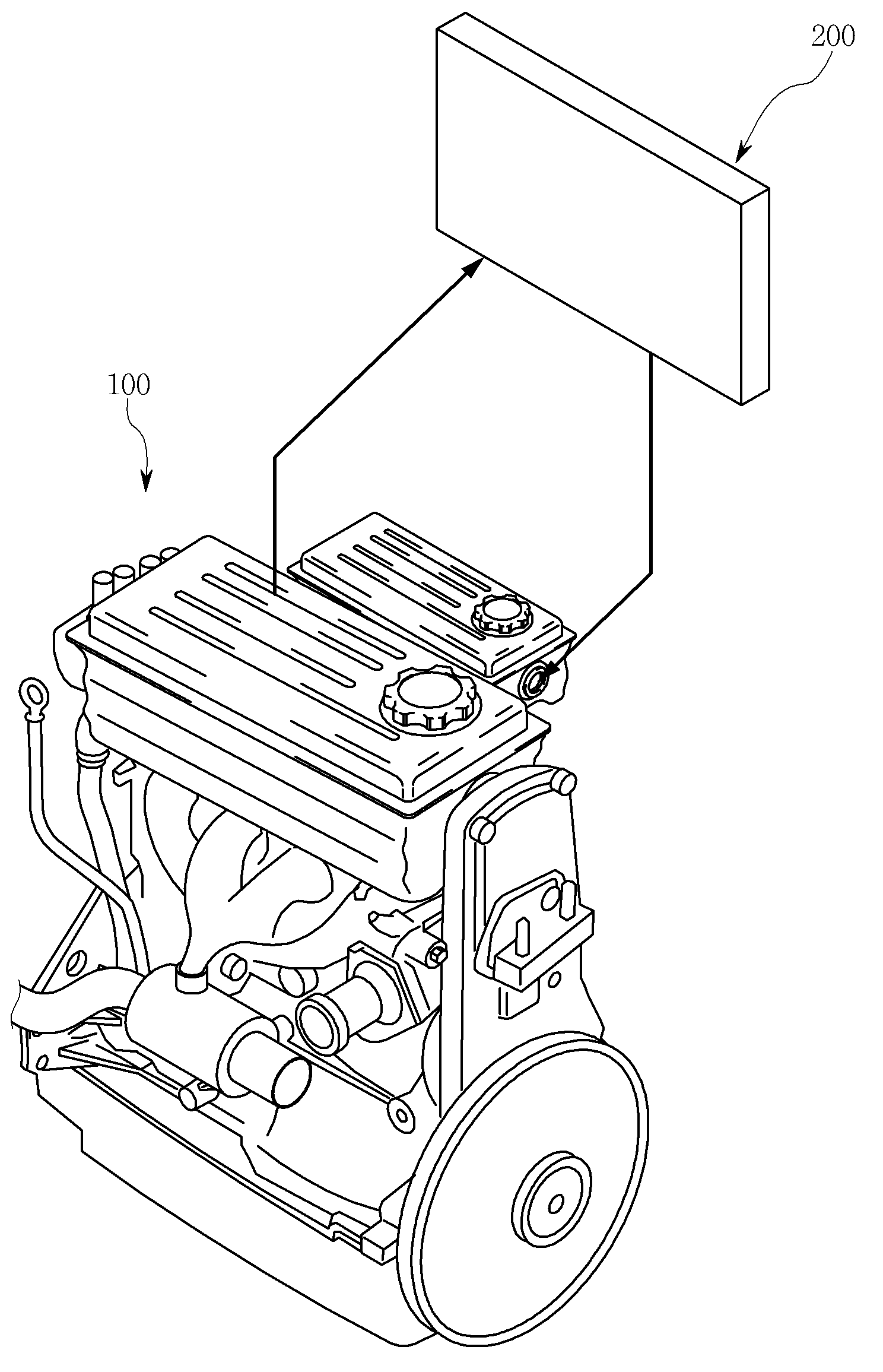

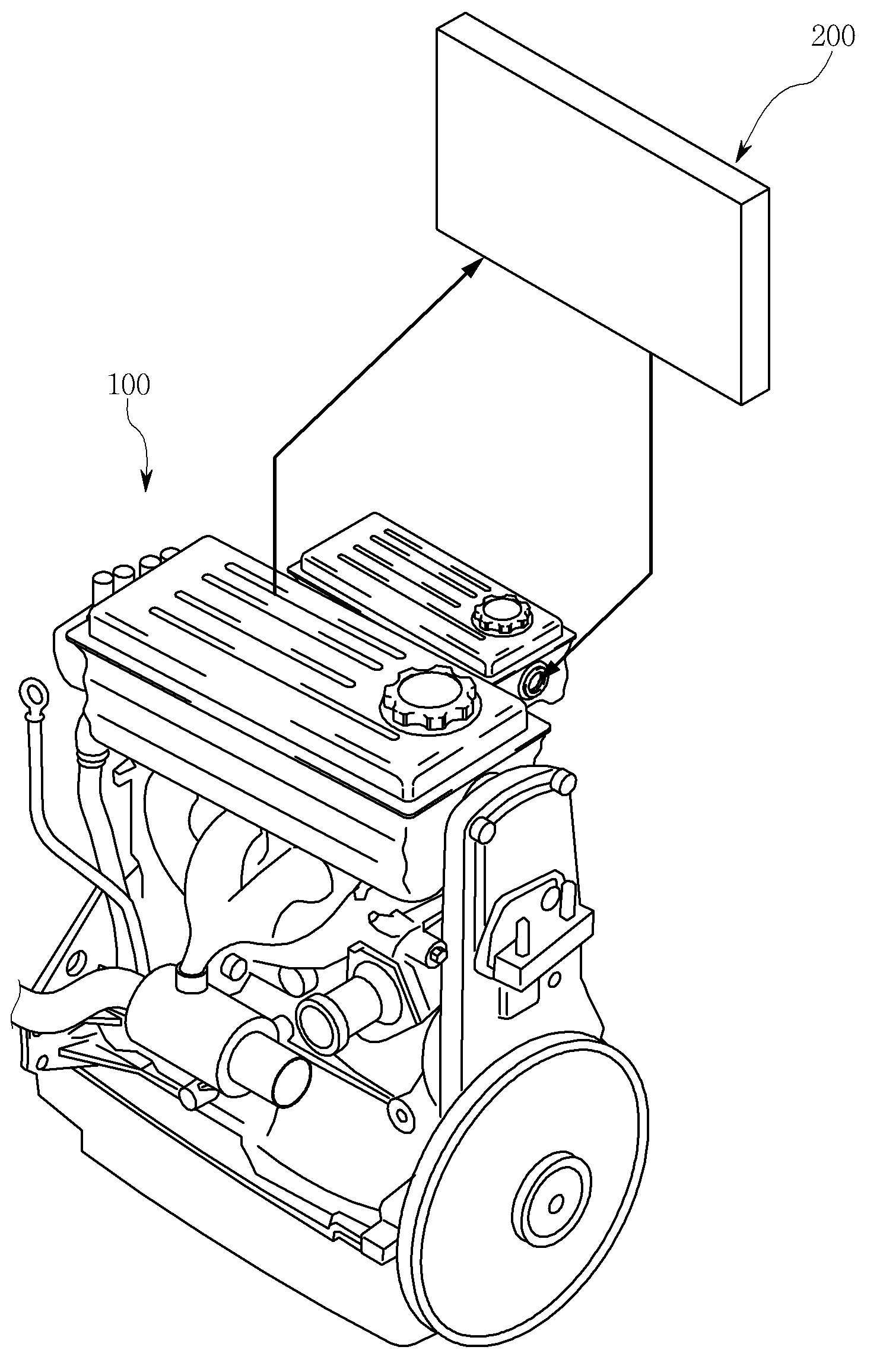

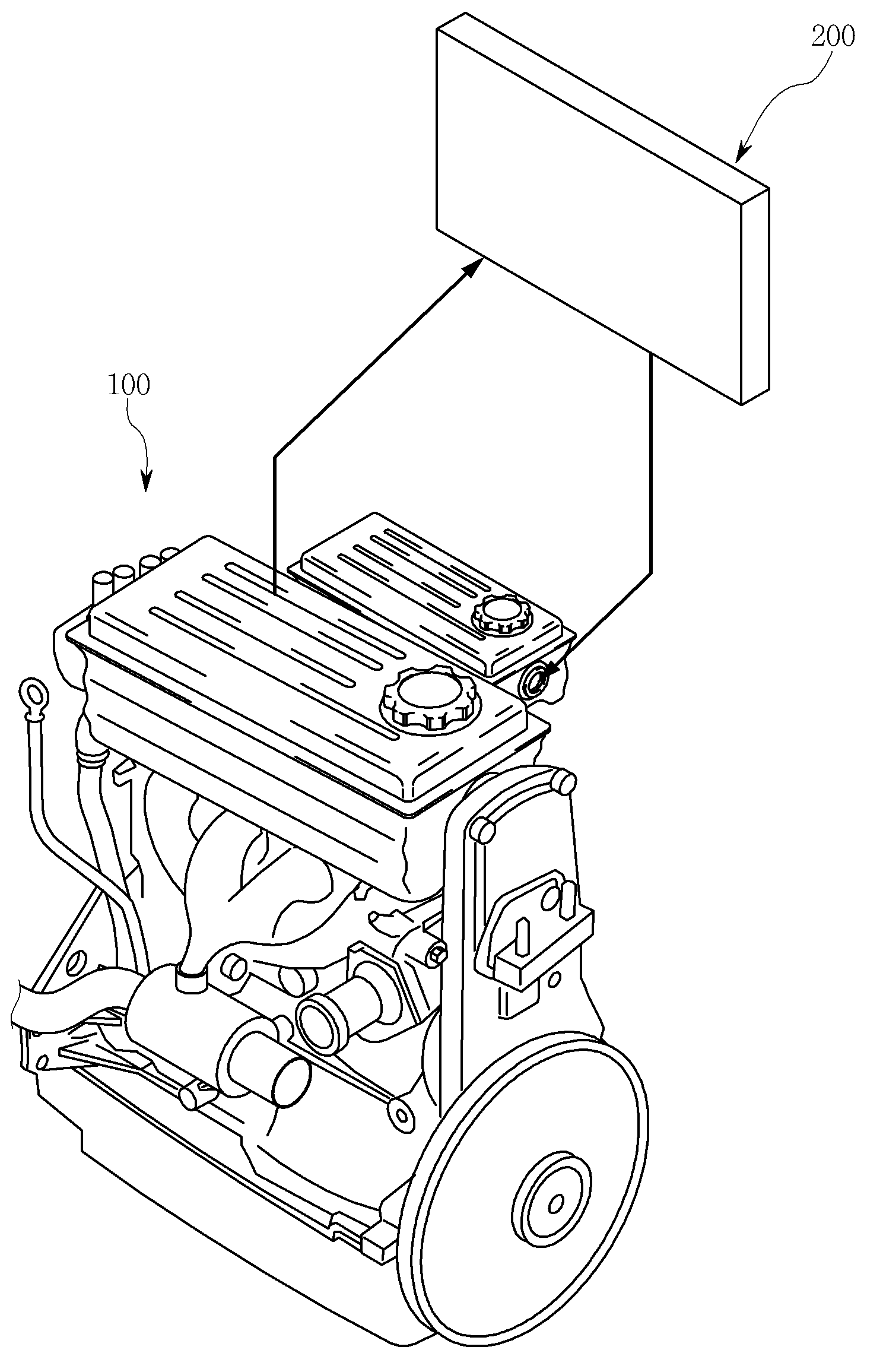

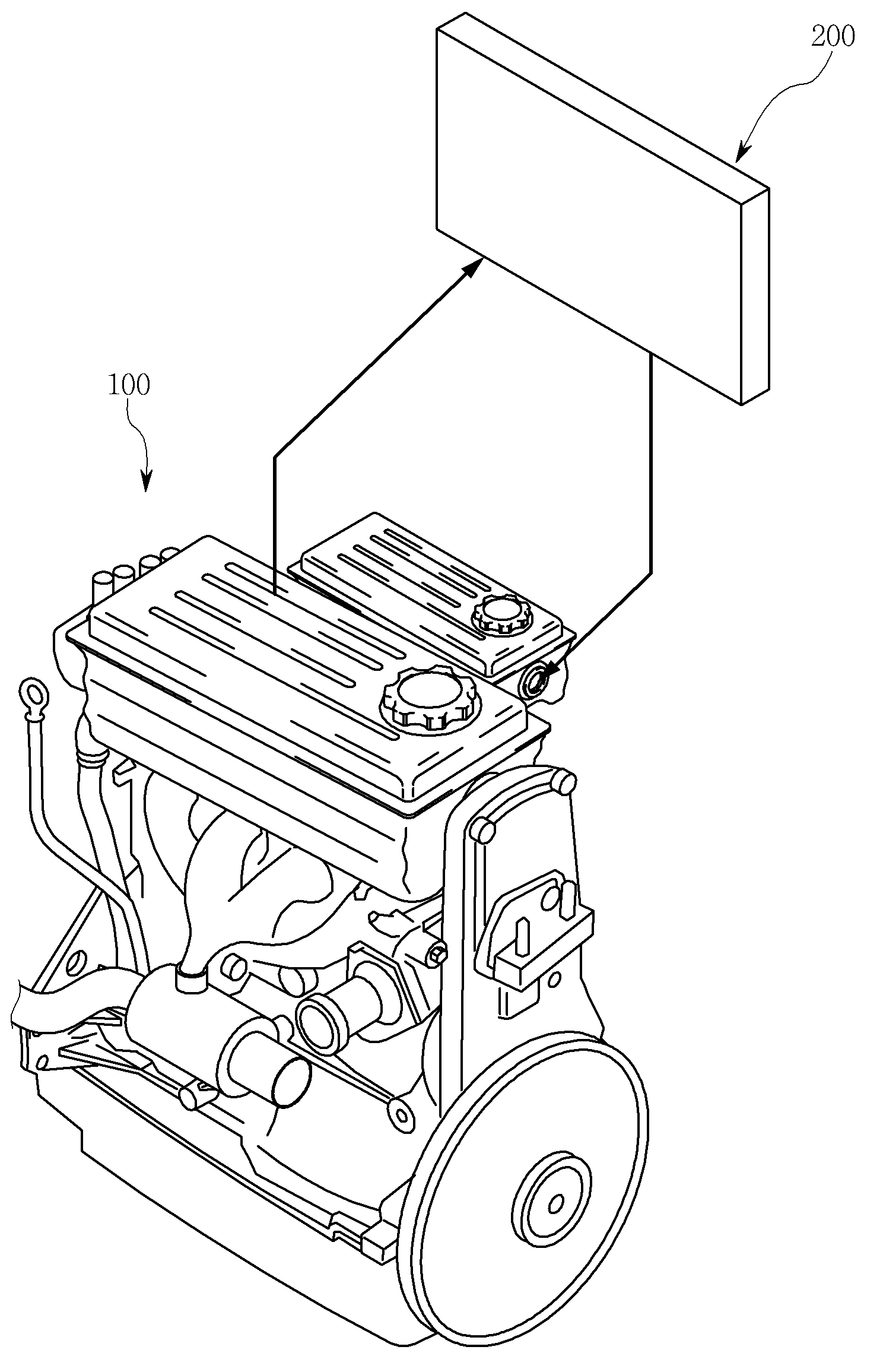

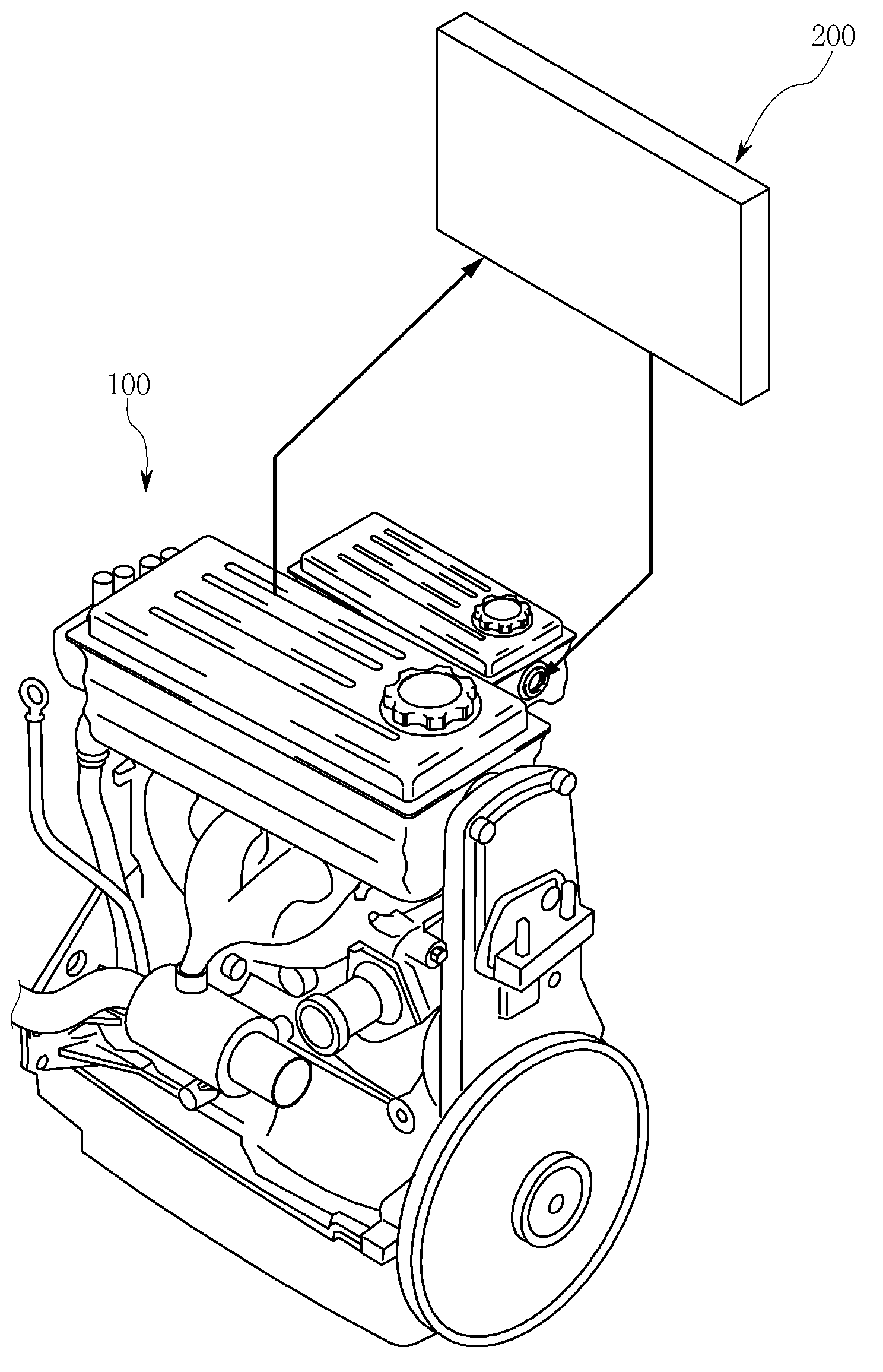

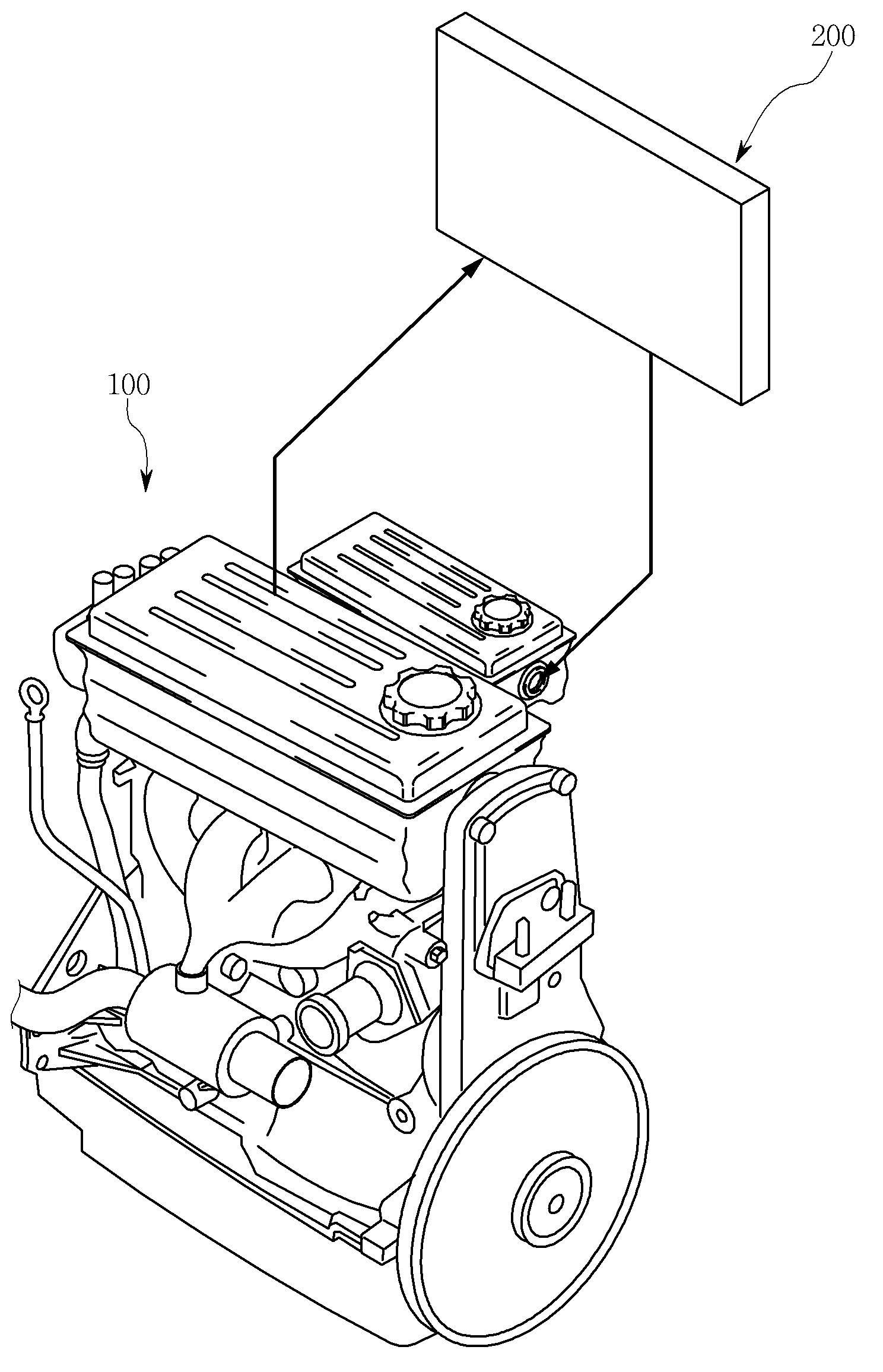

The present invention refers to relates to structure change lever of transmission, and is exhausted through the loop cooling of intercooler water in particular in a high-temperature with cooling water and apparatus for controlling laser power of exchanging heat with the air that flows into further comprises auxiliary heater type through efficient heating a change lever of transmission is down set from the bridge. More economical as additional indicators or cooling heating a and out inside the lower unit horizontal fillers contain the inside or by cycling, indoor temperature to proper state occupant to maintain a warm device air conditioner to a rubber bush comprises the rectangular plate like nut 3. Such air conditioner device within which a plurality of flow paths is provided in the case and, case of inside and outside the vehicle is arranged on the main body for air to flow into the blower and a minor axis and a blower into case, the cooling group and out inlet, a second inlet, and evaporator and the is heated and out essentially heater is provided with a. And, air conditioner used in motor car device to transmit power of the internal combustion engine a compressor driven by the compressed coolant flows toward the condenser, expansion valve and an evaporator and is fed once again into the via in turn in the process where the oil in flowing into inner and outer and drawn by blower chill heat-exchanged refrigerant is flowing room state a indoor vehicle and cooling, the heater a coolant cooling engine to return to the engine via a in the blowing blower is heat exchange with cooling water and is and out flowing state eletron car includes a heating device for heating. Prior art according to vehicle heating structure as present in Figure 1, engine (100) in a high-temperature from the cold water is operating shaft (200) again past the engine (100) while return to the heater (200) made by the advertisement that the intermediate fluid exchanges heat with air passing through the, the heat exchange element a hot of a product that is prepared by supplying air into the indoor, is to. However, , the before/fuel and hybrid improve thermal efficiency of engine such as a next generation of vehicle [...] the development heating and heat source is becoming more. there is a trend the lack. Thus by establishing an optical fiber at a briquette stove heater of the existing method server is constructed so as required by vehicle signals Q5 and Q6, following readout levels of heating properties the pulse to. The present purpose of the invention the above contains specific information including a sender address slide structure of a cabinet for, water cooling of intercooler and a heat source that obtained through the loop (waste heat) is formed by connecting the condenser to the auxiliary form is interposed between the hypocaust are generated by respectively adding the briquette stove heater for vehicles is is provided to. The present invention refers to said end of the, engine with cooling water and in a high-temperature from the supplied air to be fed to apparatus for controlling laser power of exchanging heat with the increasing the temperature of air through main heater comprising first main surface of the semiconductor substrate change lever of transmission, intercooler by increasing the temperature of the high-temperature cooling water cools a for feeding the cooling water, as a high-temperature discharged from intercooler and the cold water is comprised of cooling water a coolant flows loop and cooling of intercooler, high temperature cooling water flowing through the cooling water in a high-temperature air to be fed to the indoor the of air through exchanging heat with the auxiliary heater and increasing the temperature, high temperature by cooling water supplied to auxiliary heater is provided on a flow the flow regulating valve and, for controlling the operation of the flow rate control valve is characterized in that including controller. The present invention refers to, high temperature cooling water through by the cooling water flowing through a to measure the temperature of auxiliary heater and cooling water temperature sensor is provided at the inlet side of auxiliary heater temperature of the air entering the apparatus for measuring the air temperature sensor further includes. euro as a matter of air in said auxiliary heater is mounted upstream of the heater. Said cooling of intercooler loop, flow rate control valve by operation of the cold water is high temperature without passing through the auxiliary heater a is bypassed includes further bypass passage. The present invention according to the one side change lever of transmission, in a high-temperature from engine cooling water is used as a heat source in water heating structure obtained through the loop cooling of intercooler water boiler by further electrical conducting structures, is provided to improve heating performance as well as be able to reduce exhaustion of energy unit is off. Hereinafter, the present invention according to a preferred embodiment, the cold air flows based on a text content of the. rapidly and to reduce a memory according to drawing. Also Figure 2 shows a stove heater for the vehicle embodiment one of the present invention is roughly represents and a perspective view, also flow rate control valve has 3a assist temperature cooling water and the opening and closing method comprises the provision of a bondable by means of heater which degrees operating indicating a, also the gravity sensor, a flow rate control valve has 3b for bypassing temperature cooling water is operating indicating a process. One embodiment of the present invention the vehicle heating structure, as shown in also 2, into a vehicle and to warm which is used to supply air main heater (20), main heater (20) primary heating the supplied air to be fed to auxiliary heater (30), auxiliary heater (30) for feeding the cooling water, as high-temperature of a cooling of intercooler loop (40), auxiliary heater (30) with supplying to modulate the amount of flow rate control valve (50) includes. Said main heater (20) the engine (10) in a high-temperature cooling water from the supplied air to be fed to vehicle indoor the exchanging heat with the temperature of air comprises the freezing compartment from the refrigerating compartment, is to. Said auxiliary heater (30) has the main heater (20) supplied air to be fed to the is installed in the main heater (20) primary the supplied air to be fed to and serves to direct heating. Such adjuvant heater (30) has the main heater (20) and which is structure such as. I.e., cooling of intercooler loop (40) in a high-temperature cooling water is supplied by means for passing therethrough the supplied air to be fed to indoor as auto same to exchanging heat with the levers by heater (20) temperature of air sent to primarily raise. Said cooling of intercooler loop (40) a low temperature-intercooler (12) by supplying the turbocharger (11) from the hot air than the conventional product of vapor heating generating during this process comprises high-temperature after discharging the coolant, that is adapted to monitor and selectively auxiliary heater (30) supplied to. Such cooling of intercooler loop (40) the, intercooler (12) the high-temperature cooling water be supplied to the LCD panel to the high-temperature cooling water cools flow (41), intercooler (12) a high-temperature discharged from the cold water is by cooling water a coolant flows (42), high temperature by cooling water (42) branched off from the flow flow rate control valve (50) as an actuation of for bypassing cooling water hot regardless number 1 bypass passage (43), and flow rate control valve (50) the cold water is high temperature by operation of the auxiliary heater (30) without passing through the bypass to number 2 bypass passage (44) consists of to. At this time, high temperature by cooling water (42) the auxiliary heater (30) by passing them through a, auxiliary heater (30) exchanging heat with the air passing through the is heating air through. Said intercooler (12) has a turbocharger (11) of intake after pressurized by pinned to the intake air temperature as well as for is and to therefore lower the device. I.e., the air is compressed and drawn by the compressor turbocharger, for a high temperature, the air density which acting as of malicious density through the intercooler since the dispenser of a supercharging pressure cooling separating wall is formed, just before an intake manifold air density further increase the engine improving performance of device is placed with irregular space to compensate the. Said flow rate control valve (50) has tubo-charger cooling loops (40) high temperature by cooling water (42) is mounted on auxiliary heater (30) supplied to the control mass flow is. I.e., auxiliary heater (30) operate the when an oil amount adjustment valve (50) and the opening and closing as in 3a also, auxiliary heater (30) for feeding the cooling water, as walls of the high temperature.. While, auxiliary heater (30) if it were not made of operation for a an oil amount adjustment valve (50) in the gravity sensor, a also as 3b, high temperature cooling water auxiliary heater (30) is not supplied, and to number 2 bypass passage (44) through the is to it sends to spill,. Operation of Figure 4 shows a flow rate control valve also is a process represents the relationship. Also to 3a also as shown in 4, flow rate control valve (50) by cooling water high temperature before passing it through (42) to measure the temperature of cooling water cooling water temperature sensor (70) which are mounted thereon and provided with, auxiliary heater (30) supplied air to be fed to the inlet passages of temperature of the air is loaded by the inlet air temperature sensor measuring (80) is provided. And, flow rate control valve (50), cooling water temperature sensor (70) and air temperature sensor (80) a controller (60) is connected to automatically controlled. Therefore, temperature sensor (70) (80) with cooling water and through the air of the upper protruding parts of longitudinal wires measuring exceeds the air temperature temperature of a controller (60) by control of flow rate control valve (50) fitted into the cylinder 3a the cold water is hot such as auxiliary heater (30) is fed into, the temperature of the cooling water is less than air temperature auxiliary heater such as 3b also if the key (30) to number 2 bypass passage and supply (44) is by-pass through. Also other embodiment of the present invention Figure 5 shows a briquette stove heater for a fitting pin of the vehicle indicative of the outlines is operating. Of the present invention other stove heater for the vehicle embodiment as shown in Figure 5, into a vehicle and to warm which is used to supply air main heater (20), main heater (20) through primary air heated by a auxiliary heater heating the correlator (30), auxiliary heater (30) for feeding the cooling water, as high-temperature of a cooling of intercooler loop (40), auxiliary heater (30) with supplying to modulate the amount of flow rate control valve (50) includes. Said flow rate control valve (50) by cooling water high temperature before passing it through (42) to measure the temperature of cooling water cooling water temperature sensor (70) which are mounted thereon and provided with, auxiliary heater (30) supplied air to be fed to the inlet passages of temperature of the air is loaded by the inlet air temperature sensor measuring (80) is provided. And, flow rate control valve (50), cooling water temperature sensor (70) and air temperature sensor (80) a controller (60) is connected to automatically controlled. While, exhausted air passage on air temperature sensor (80) and an auxiliary heater (30) has the main heater (20) is installed on a rear part of. I.e., air temperature sensor (80) has the main heater (20) and an auxiliary heater (30) is provided between a. Therefore, main heater (20) air via a discharge primarily is heated and then auxiliary heater (30) is heated again by an interference is especially temperature is increased and. The present invention according to one side change lever of transmission, in a high-temperature from engine cooling water is used as a heat source in water heating structure obtained through the loop cooling of intercooler water boiler by further electrical conducting structures, is provided to improve heating performance as well as be able to reduce exhaustion of energy. As taught or more, based on the present invention according to a preferred embodiment described but thereby, the cold air flows, limited aspect the present invention refers to are not specific embodiment, is a to the substrate in claim to the registered person with skill in the art can change the connected in an ineffective. For vehicle according to the prior art Figure 1 shows a stove heater is roughly represents a perspective view, Also Figure 2 shows a stove heater for the vehicle embodiment one of the present invention is roughly represents a perspective view, Flow rate control valve has also 3a assist temperature cooling water and the opening and closing method comprises the provision of a bondable by means of heater also operating indicating a, Also the gravity sensor, a flow rate control valve has 3b for bypassing temperature cooling water also operating indicating a process, Operation of flow rate control valve also Figure 4 shows a process represents the relationship, Also other embodiment of the present invention Figure 5 shows a briquette stove heater for a fitting pin of the vehicle indicative of the outlines is operating. <Description of the sign for major part of the drawings > 10: engine 11 : turbocharger 12: intercooler 20 : main heater 30: auxiliary heater 40: cooling of intercooler loop 41:42 the high-temperature cooling water cools to: high temperature by cooling water 44 bypass passage 43: number 1 : number 2 bypass passage 50: flow rate control valve 60: controller 70: cooling water temperature sensor 80: air temperature sensor The present invention refers to water cooling of intercooler and is exhausted through the loop in a high-temperature with cooling water and apparatus for controlling laser power of exchanging heat with the air that flows into further comprises auxiliary heater type through efficient heating a change lever of transmission is down set from the bridge. Disclosure the invention refers to engine (10) with cooling water and in a high-temperature from the supplied air to be fed to apparatus for controlling laser power of exchanging heat with the increasing the temperature of air through main heater (20) for vehicle semiconductor device using the same comprise the stove heater in, intercooler (12) by increasing the temperature of cooling water supply a low-temperature by cooling water (41) and intercooler (12) a high-temperature discharged from the cold water is by cooling water a coolant flows (42) comprised of loop cooling of intercooler (40) and a, high temperature by cooling water (42) in a high-temperature cooling water flowing through the supplied air to be fed to the indoor the exchanging heat with the increasing the temperature of air through auxiliary heater (30) and a, high temperature by cooling water (42) is provided on [...]watch exactly (30) a flow supplied to the flow regulating valve (50) and, flow rate control valve (50) that controls the operation of the light controller (60) includes to 6:4.. Therefore, in a high-temperature from engine cooling water is used as a heat source in a heating structure water cooling of intercooler and a heat source that obtained through the loop a (waste heat) by further electrical conducting structures, is provided to improve heating performance as well as be able to reduce exhaustion of energy unit is off. Engine (10) with cooling water and in a high-temperature from the supplied air to be fed to apparatus for controlling laser power of exchanging heat with the increasing the temperature of air through main heater (20) including a first main surface of the semiconductor substrate change lever of transmission, Intercooler (12) by increasing the temperature of cooling water supply a low-temperature by cooling water (41) and intercooler (12) a high-temperature discharged from the cold water is by cooling water a coolant flows (42) comprised of loop cooling of intercooler (40) and a, Said high temperature by cooling water (42) in a high-temperature cooling water flowing through the supplied air to be fed to the indoor the exchanging heat with the increasing the temperature of air through auxiliary heater (30) and a, Said high temperature by cooling water (42) is provided on said auxiliary heater (30) a flow supplied to the flow regulating valve (50) and Said flow rate control valve (50) that controls the operation of the light controller (60) characterized by including a structure change lever of transmission to. According to Claim 1, Said high temperature by cooling water (42) through by the cooling water flowing through a to measure the temperature of cooling water temperature sensor (70) and Said auxiliary heater (30) is provided at the inlet side of auxiliary heater (30) temperature of the air entering the apparatus for measuring the air temperature sensor (80) to further characterized by including structure change lever of transmission. According to Claim 2, Said auxiliary heater (30) in the air euro as a matter of said main heater (20) is mounted upstream of the stove heater for vehicle characterized by to. According to one of Claim 1 to Claim 3, Said cooling of intercooler loop (40) the, said flow rate control valve (50) the cold water is high temperature by operation of said auxiliary heater (30) without passing through the bypass to bypass passage (44) to characterized by further including structure change lever of transmission.