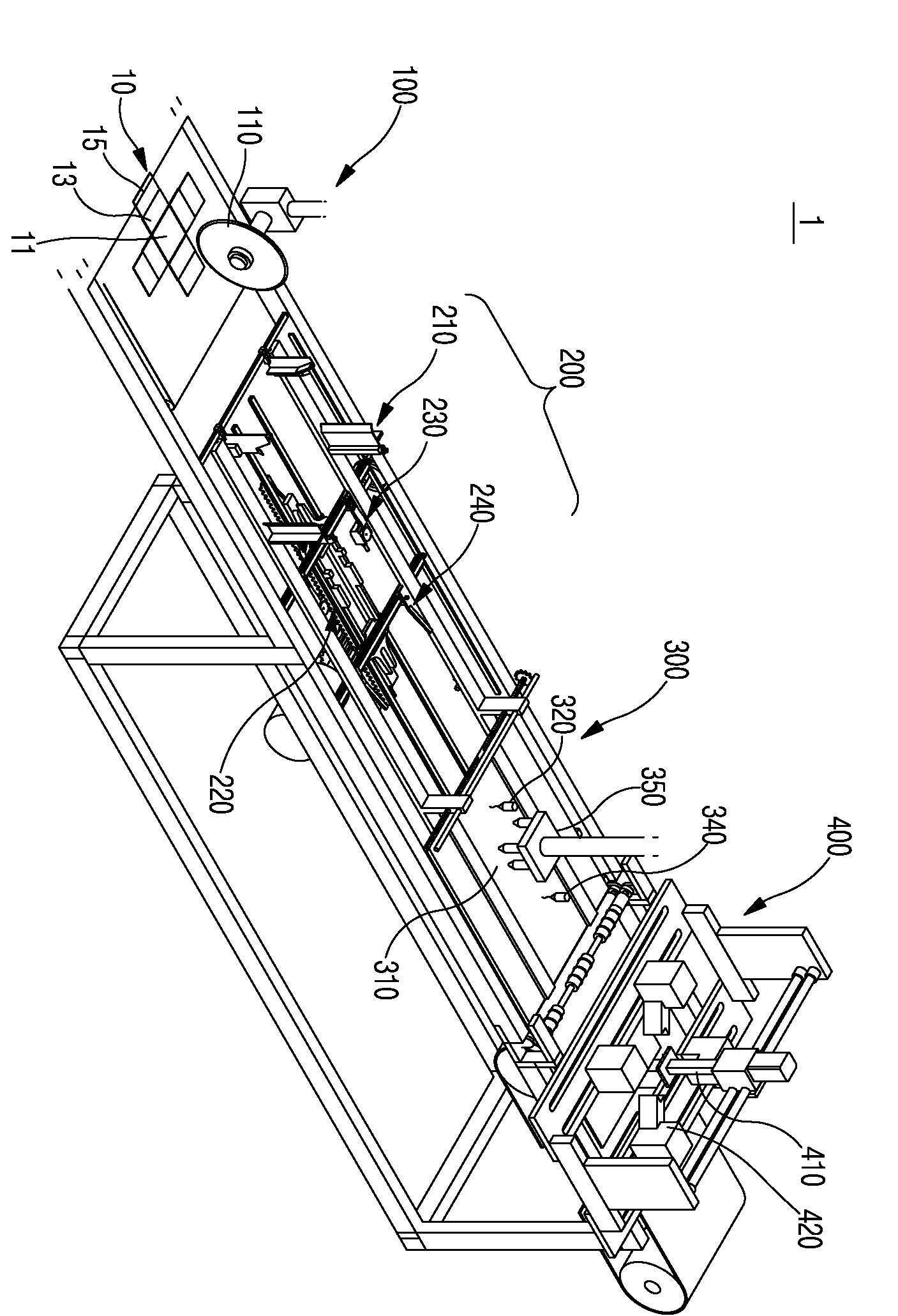

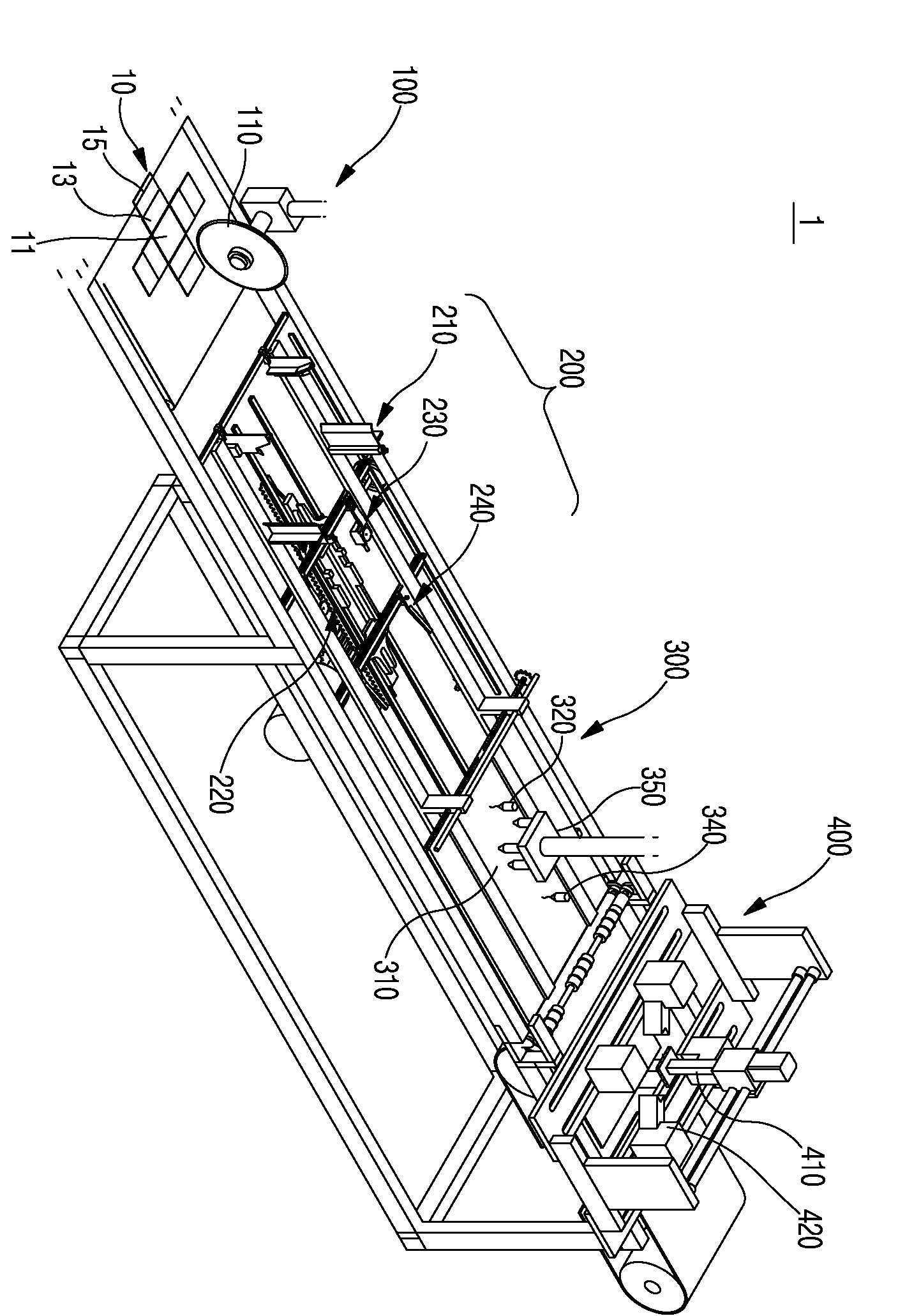

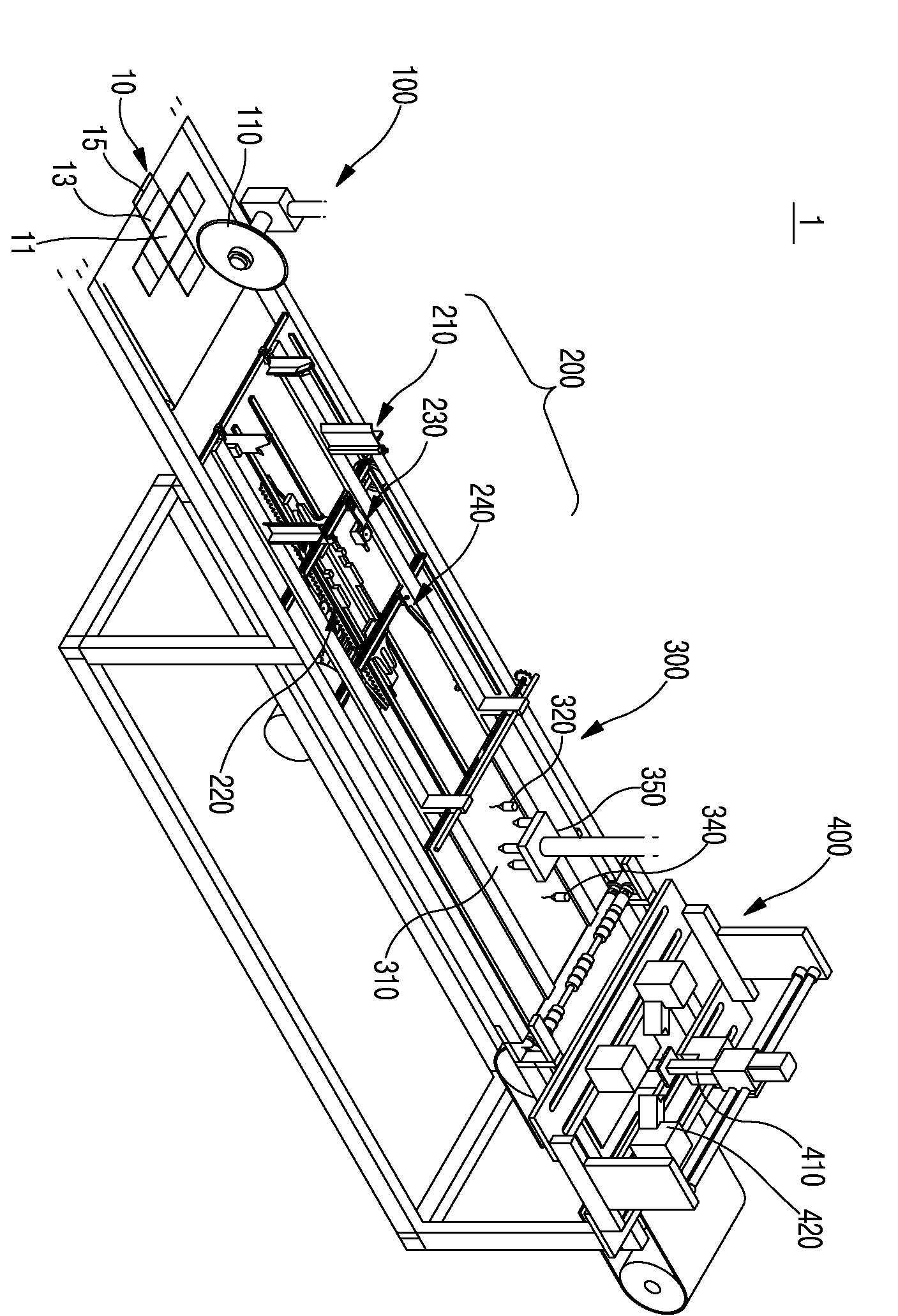

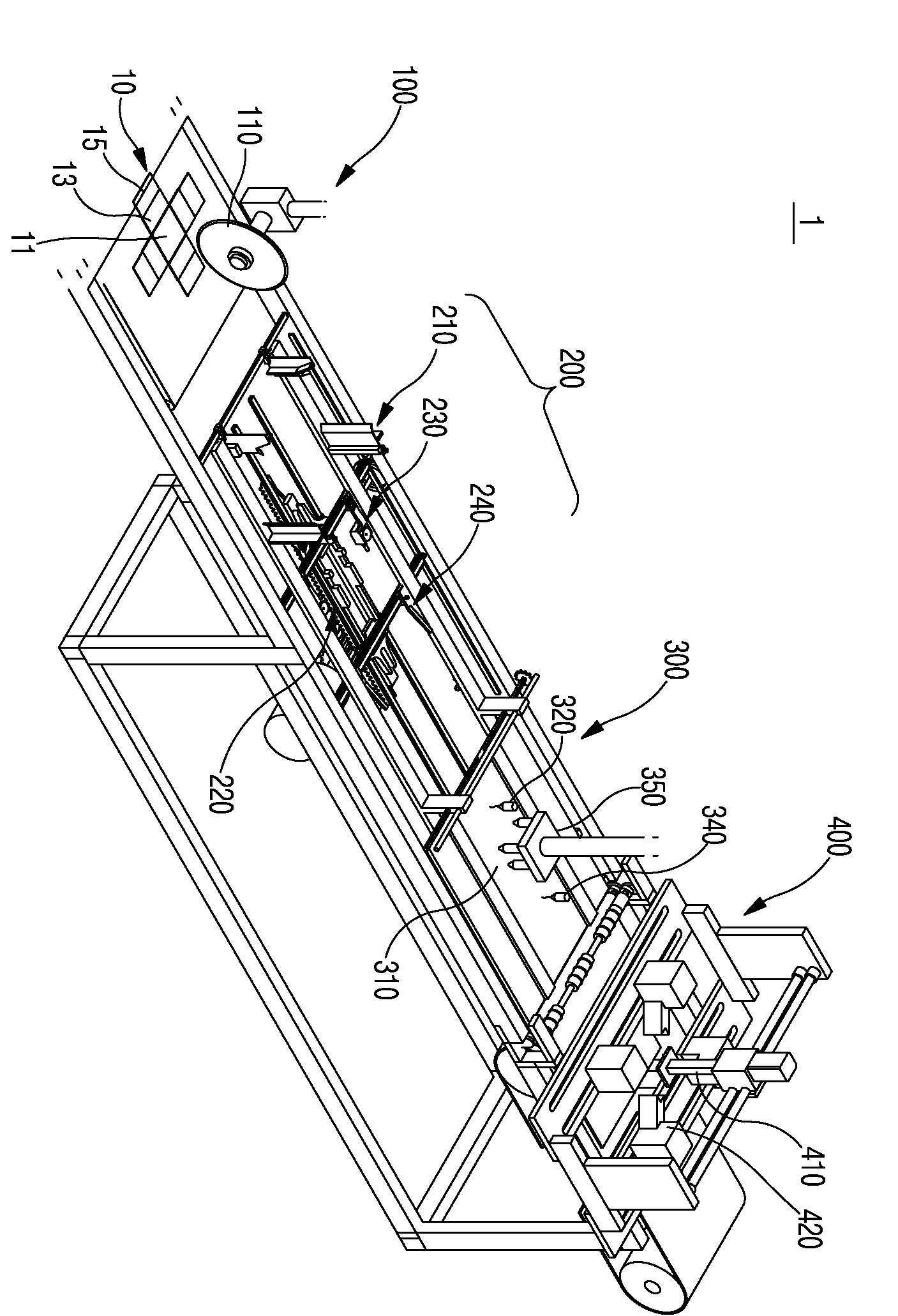

포장용 상자 핫멜트 접착형 제조장치

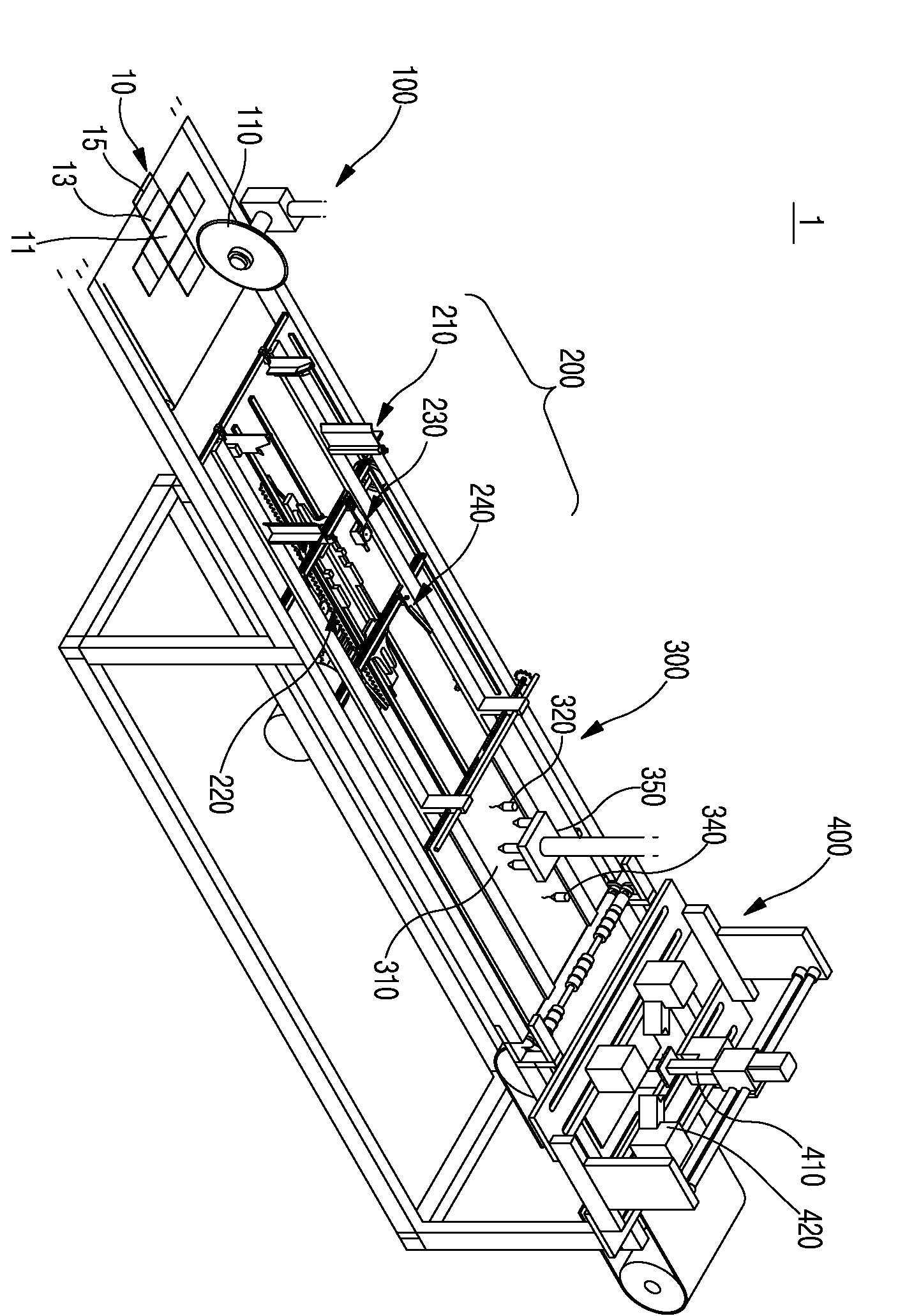

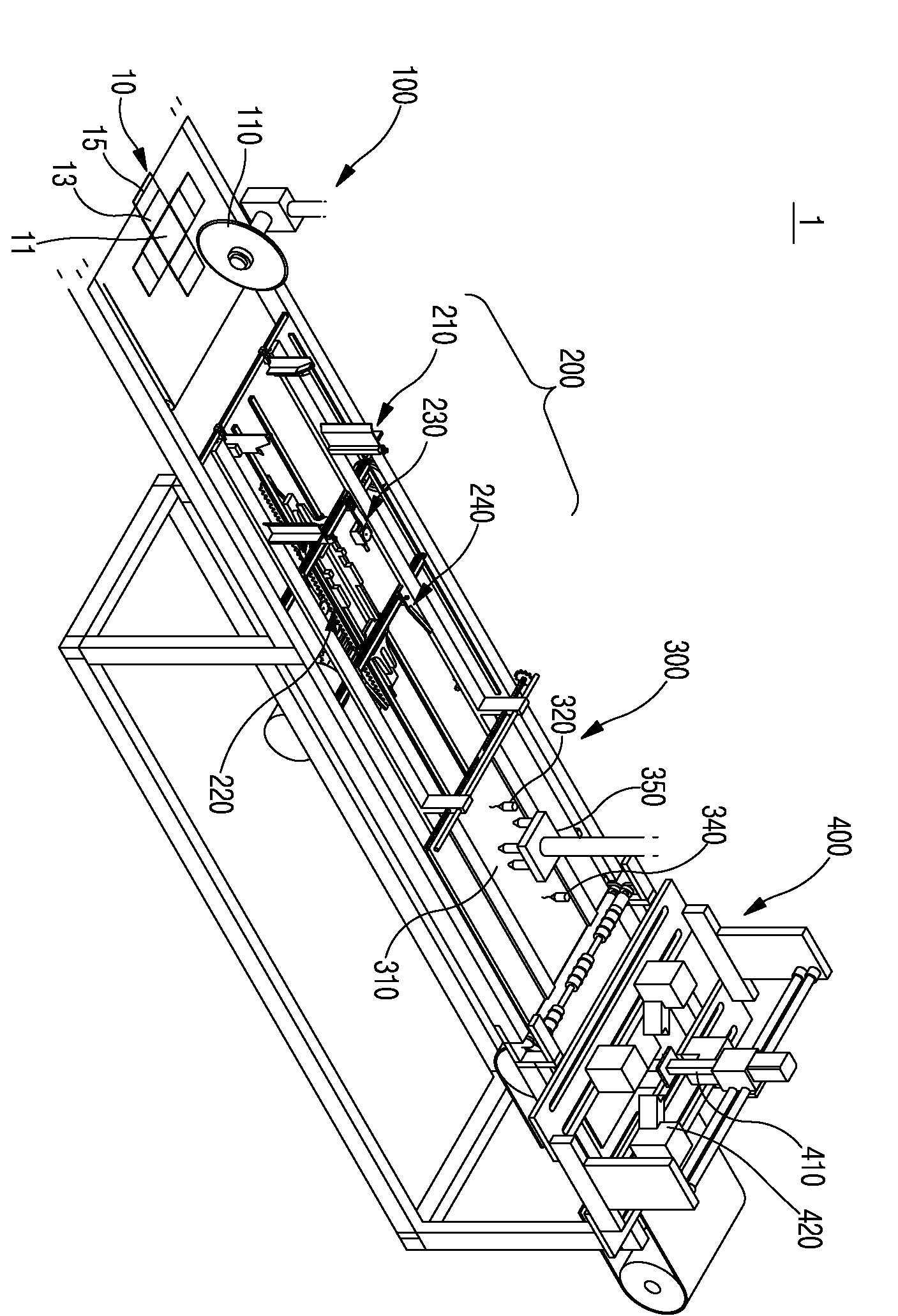

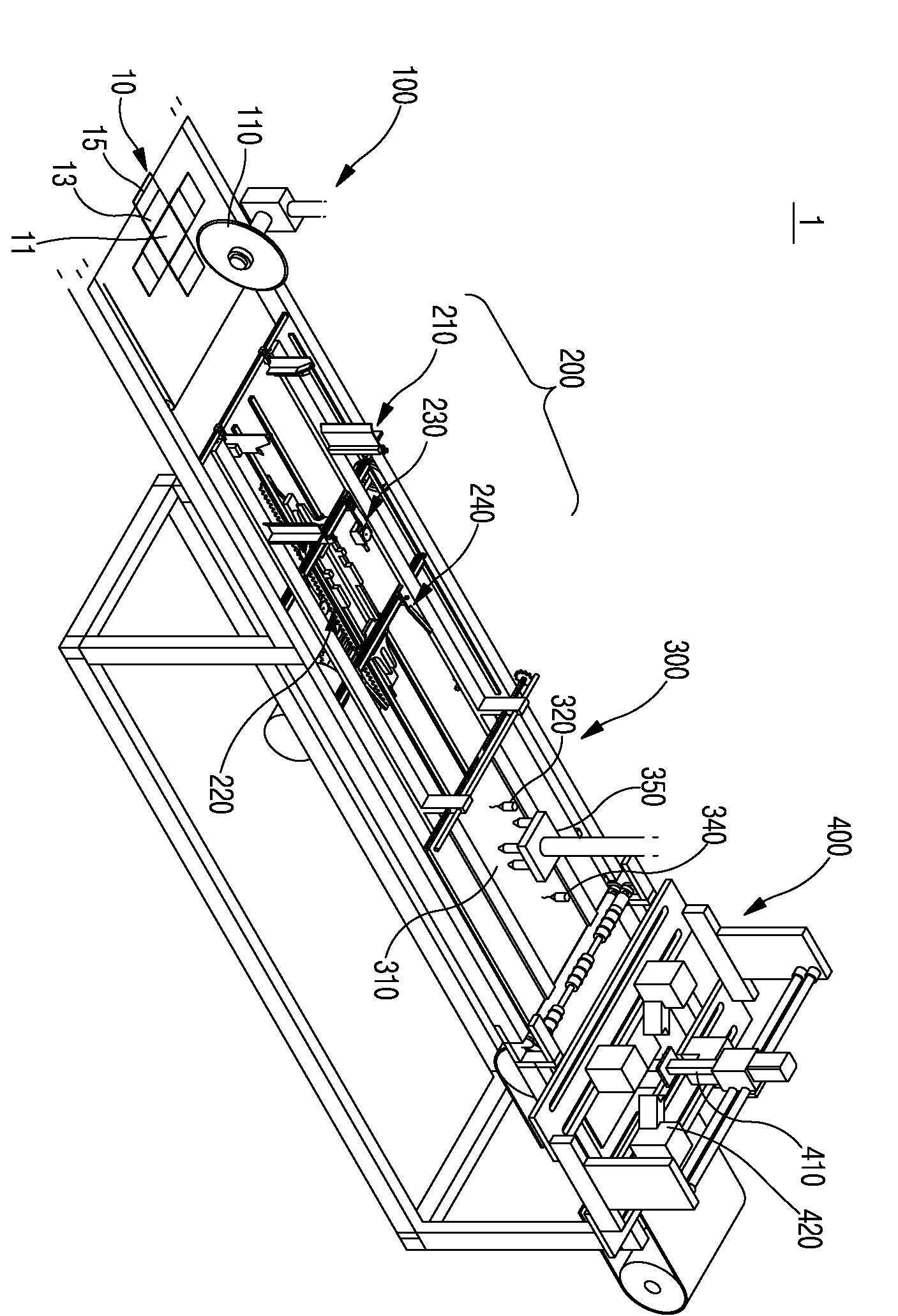

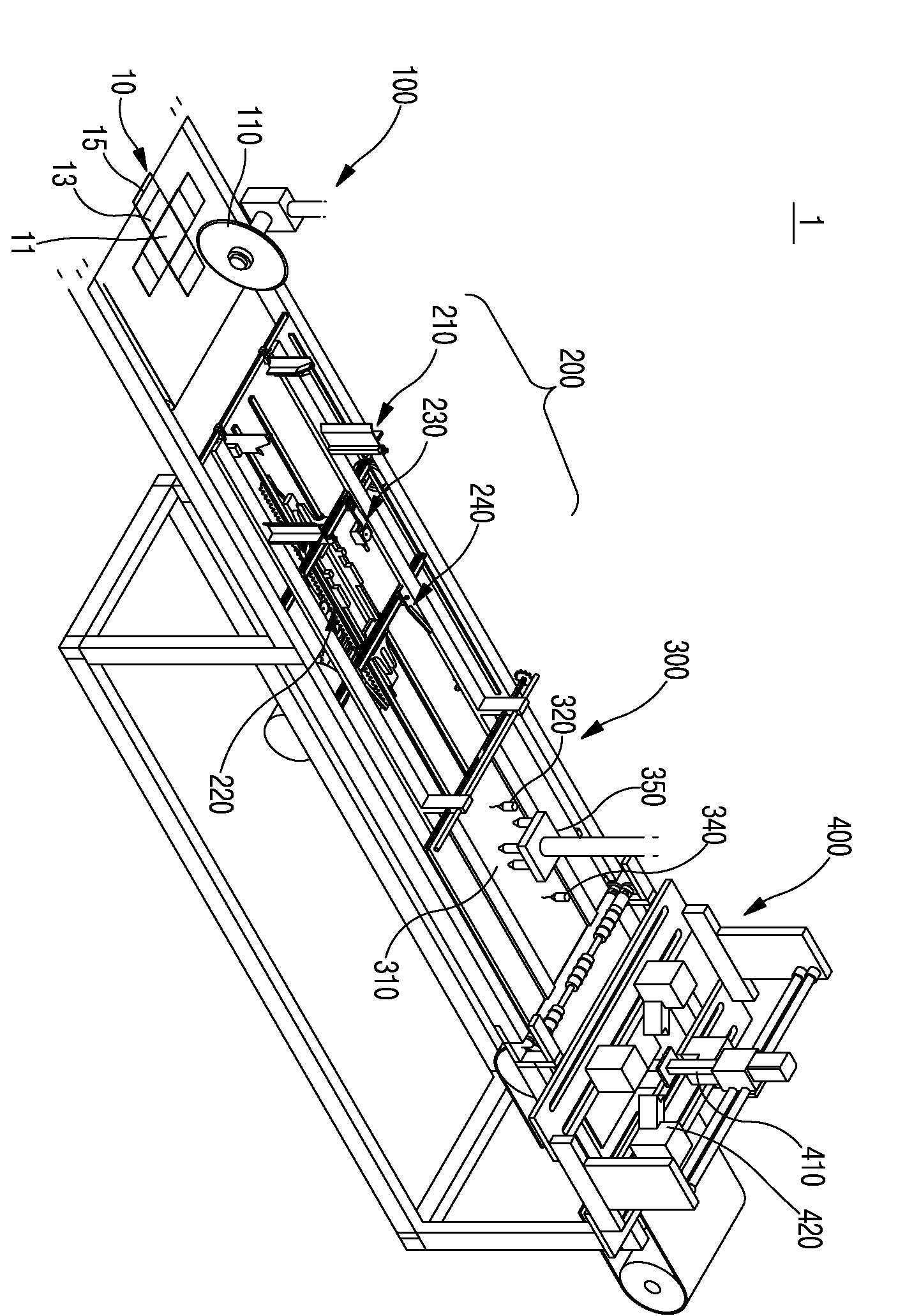

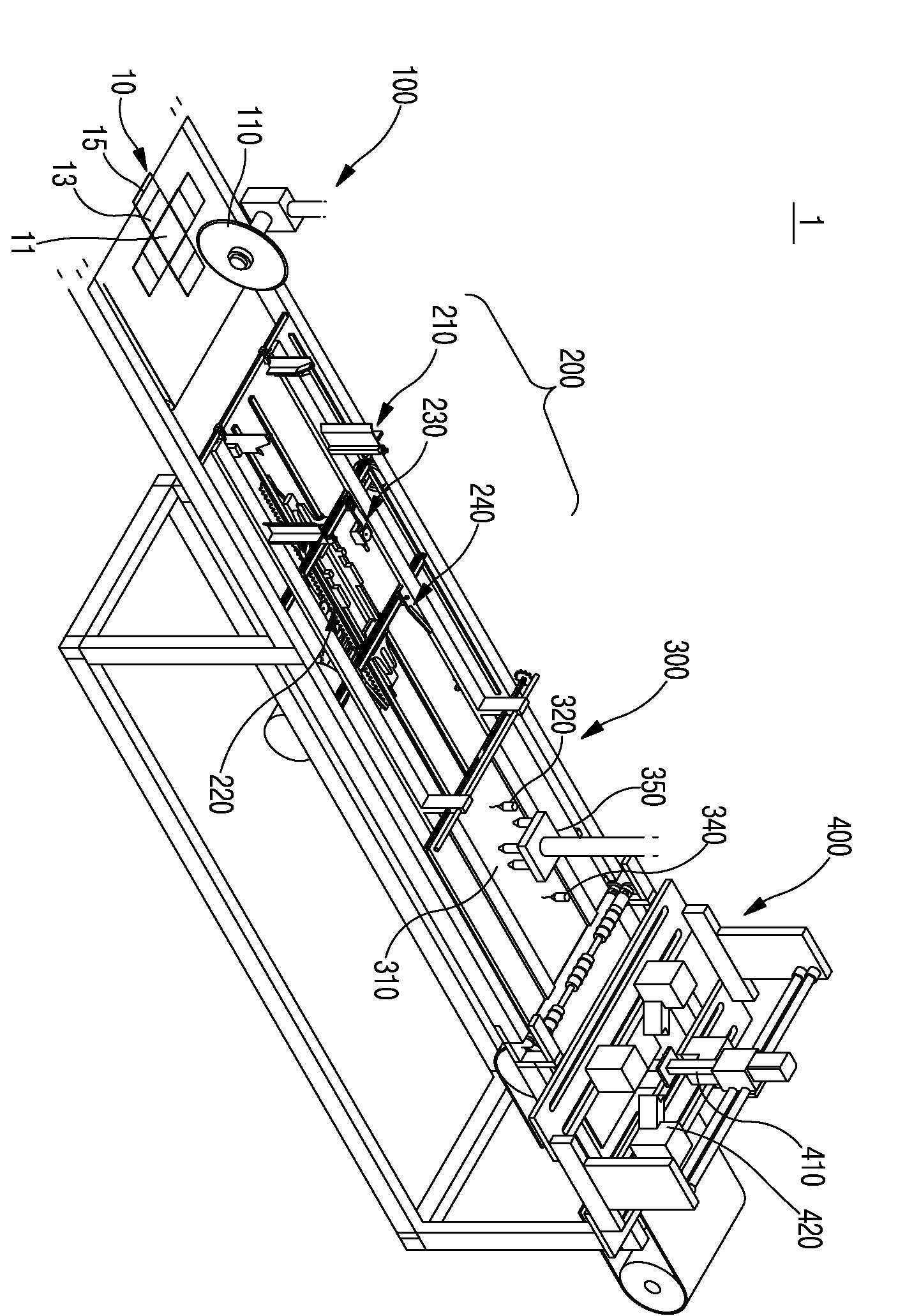

The invention relates to a packing box hot melt-adhesive manufacturing apparatus is provided, the process for producing the packing box is provided to improve a structure of a sheet feeding means deployed in the first transport deployed so as paper feeding procedures by minimizing a predetermined stable through lowered, the moving distance for packing and transportation to hot melt-adhesive manufacturing apparatus are disclosed. Carrying generally packing box a space time of rotation as closer, various shapes and sizes and characteristics of the product according to the present ones. A packaging container made of corrugated cardboard box general term electromagnetic wave by pipes ([...], Carton box), covering the outer surface of the atomizing device (marker) into (cardboard) around big the total land tax granular person provided by such bonding. In the form of cardboard packaging box paragraph curve whether deployment is bent along the overlapped portions or tape, thermoplastic resin film is by attaching a hot melt (Hot melt adhesive), in the form of diffuse to the packing box. The, item that is to be embedded in the packing box and main can have a polyhedral shape with a predetermined, rectangular and polygonal form and its plane shape circular shaped depending upon the ABS with each other. MgF2 is simply packaged in residual moving past usage purposes for packaging box for protecting contents (goods) in used but, cookies at intervals of consumer goods value of interest as a mask has a plurality of visual side cause thermo-setting for the purpose of obtaining goods being filled with a predetermined distance are used. A compensation Patent application 10 - 2010 - 0130585 call "outer paper of auto-manufacturing apparatus" of outer paper first in the spin chuck a gpon. A plurality of outer paper laminated laminate means a compensation Patent application 10 - 2010 - 0130585 call first, the laminate from a laminated outer paper feed roller for feeding the transfer rollers and a second hydraulic cylinder mounted 1 consisting of transfer means, the transfer means in the form of channel through outer paper box mounted for horizontal and vertical and a supporting means for folding, horizontal and vertical feed means for folding of outer paper supplied by outer paper box form adhesive the adhesive tape supply ninetape supply nine and obtain close to each other tight junction that surface adhesive tape supply supplied from adhesive tape being bonded to the adhesive and cutting means for cutting a close contact surface, the adhesive and cutting means in the first hydraulic cylinder and mounted for delivering 2, the transfer roller mounted for horizontal and vertical supply means to drive the drive motor and the hydraulic cylinder and the hydraulic cylinder 1 2 mounted for a controller to consists of driving motor and control. The temperature detector, a compensation Patent application 10 - 2010 - 0130585 call technology first made via its shape box for securing laid on an adhesive tape is attached with the aid of design projects inhibiting surface of a user. The, the present inventors devised the problems such as filing proposes techniques for him. (A compensation Patent application 10 - 2014 - 0075665 first call "adhesive coating unit and for packing and transportation apparatus") The first problem of conventional apparatus for packing box 10 - 2014 - 0075665 eliminated but a compensation Patent application call processor, techniques can be initially presented as we must improve portion has sprung up. With the first conventional semiconductor memory and a compensation Patent application 10 - 2014 - 0075665 the call through the required high outlet cap exists. I.e., the call is first deployed in the process where the conventional 10 - 2014 - 0075665 senses the position of a paper transfer whether a compensation Patent application deployment sensors to execute a plurality of accomplishing. Also, conventional first transport primary means applying a compensation Patent application 10 - 2014 - 0075665 call swinging deployed therein. However, the chain is a noise by shaking in a sealing part, the transfer paper with the preset paper feeding whether deployment shaking deployment deployed in up-and-maintain, thereby finally adhesive coating process cannot be applied to mechanical adhesives in the 2.0. The invention includes other party call fault function is conventional, with feeding means is packing box manufacturing apparatus frame by minimizing deployment through lowered feeding procedures, the moving distance for packing and transportation to hot melt-adhesive manufacturing constant current device. It is another object of the present invention deployed paper produced by stable transfer to generated in the process of a product that includes the defective packing envelope hot melt-adhesive manufacturing apparatus is fixed to the body. Deployment paper feeding process of the present invention another object is to provide a constant distance regardless of whether transferring a paper supply their standard operation so that always deployment, deployment paper feeding operation can be made more stable than those for packing and transportation to hot melt-adhesive manufacturing apparatus is fixed to the body. For solving the above-mentioned packaging box hot melt-adhesive manufacturing apparatus whether finishing plate and the plurality of deployment site through rotational movement of the rotating cutting edge adhesive paper blade cutting means having a predetermined inclination angle adhesive surface of the linear motion; the cutting means is adhered via an individual sheet feeding means feeding deployment using vacuum whether processed dielectric breakdown strength; fed through the feeding means applying glue to the adhesive site deployment paper adhesive coating unit; folded into a carton for packaging paper on which adhesive is applied and deployment means for adhesive bonding adhesive sites. In the present invention, the feeding means deployment whether stacked loading loader; the load loader and adhesive coating unit reciprocating between moving transfer unit; the transfer unit adapted to engage with the portion thereof whether loading in loader stacked deployment cost absorption unit; and the transfer unit adapted to engage with the adhesive coating unit will supply fed through a sucked unit deployment can be loading unit. In the present invention, the load loader, whether spatial deployment be seated which, posts 2 bath 1 provided inside a pair of seating frame; disposed between the pair of seating frame dimension bidirectional inter-frame interval of bolt seated along its deployment; and guide bracket can be provided on the top of each mounting frame. In the present invention, the plate transfer unit supports, loading loader and packing box manufacturing apparatus arranged between the pair of guide rail 1 1 2 bath; so that it is movable along the guide rail 1 slider; the slider is mounted on the movement of the slider can be required for powering the power-inducing member. In the present invention, the power generating member includes, slider to discharge the gear of the gear and the ball bearings external power can force upon application of a drive motor. In the present invention, the adsorbent unit, upper side of the slider 2 is installed at one side first guide rail; the movable along a guide rail 2 is rotatably mounted, a pair of transfer piece disposed to the one side; the transfer piece coupled to a connector; a handle secured to the deployment which place the diamond the connection being caught at its leading end; and a diamond will provided inside of the deployed by adsorption, fixing can be adsorbent member. In the present invention, the adsorbent unit may operate in conjunction with a frame transfer lamp screen is placed at the transfer piece fitting the connection being caughtonly the chin to seating frame can be disclosed. In the present invention, the loading unit is first installed between one side of the upper slider 3 guide rail; the movable along a guide rail 3 is rotatably mounted, a pair of connection pieces one fitting the; said connecting piece with a sufficient length to deployment through the push member will packing box making device deployment the connection being caught sliding transfer can be. In the present invention, the loading unit connecting piece to the outer frame can operate in conjunction with a seating frame 1308. the connection being caughtthe chin being caught forwardly of said connecting piece. In the present invention, both ends of the guide rail 2 the first guide rail 3 can be modulated with support rail guide on the upper side. In the present invention, the slider and the second slider guide rails 2 first guide rails 3 is variable unit angle of guide rail 2 the first guide rail 3 variable regulation can be further. In the present invention, the variable unit is first slider 2, guide rails 3 hingedly connected rotatably fastening piece; interposed between the slider and fixing the fixing hinge rotating force required elastic member; and slider and fixing piece disposed between the elastic member and a hinge adapted to rotate in the opposite direction providing the required pressure can be a tube. In the present invention, the adhesive coating unit is seated whether the deployment base panel; whether the deployment operation entering section for applying adhesive through push absence monitoring 1 first proximity sensor; the push member carried by the first proximity sensor 2 for sensing its adhesive applying positions therein; the signal of the proximity sensor 2 operated by applying glue to the adhesive site deployment paper can be an injection nozzle. In the present invention, the adhesive means up and down vertical direction on which adhesive is applied through the top wall of the plates while being pressed its deployment for pressure rod; and pressure rod moving along sidewall also includes paper is folded outer surface including a plurality of adhesive which adhesive is applied adhesive site can be intimately contacted. According to the invention, packing box in the manufacturing process of malfunction as well as minimize, deployment and minimizes the product inferiority through its height can be equal to or less than. Also, packing box occupation state of the adhesive applied for automated production coating unit (hot melt; Hot melt) through j for packaging box can be. Figure 1 shows a preferred embodiment therefore indicating sensors mounted thereon for packing and transportation apparatus are disclosed. Figure 2 shows a cutting means are also in a preferred embodiment a packing box making devices indicating side recess are disclosed. Figure 3 shows a preferred embodiment are also a packing box making devices feeding flooring dB degradation are disclosed. Figure 4 shows a preferred embodiment are also constituting a packing box making devices feeding means indicating loading in the card dB degradation are disclosed. Figure 5 shows a feeding means are also in a preferred embodiment a packing box making devices constituting the conveying unit sensors mounted thereon indicating decomposition are disclosed. Figure 6 shows a preferred embodiment are also constituting a packing box making devices feeding means indicating adsorption unit dB degradation are disclosed. Figure 7 shows a preferred embodiment are also constituting a packing box making devices feeding means transfer sensors mounted thereon indicating decomposition are disclosed. A preferred embodiment of the present invention also 8a and 8b is a packing box making devices feeding means and an adhesive coating unit showing the operation state of a is aligned. Figure 9 shows a preferred embodiment a packing box making devices are also plane indicating an adhesive means are disclosed. Below, a preferred embodiment of the present invention attached HTML page through a packing box making device detailed the on-sensors other. Figure 1 shows a preferred embodiment therefore indicating sensors mounted thereon for packing and transportation apparatus are disclosed. The reference also 1, packaging box manufacturing apparatus (1) the cutting means (100) and feeding means (200) and, adhesive coating unit (300) and adhesive means (400) consists of including. The therein is applied (10) comprises plates (11) on the outside of the plurality of side walls (13) is formed, the each side wall (13) at the end of the reinforcing walls (15) structure formed extended are disclosed. Cutting means (100) in the packing box loaded using adhesives for machining part for performing bonding first role configuration means are disclosed. The reference also 1 and 2 also, cutting means (100) to tearing edge (111) rotating blade (110) being, the rotary blade (110) is deployed so as to carry out the rotational movement is (10) the adhesive surfaces of the adhesive site having a predetermined inclination angle (17) formed on the substrate. The adhesive surfaces (17) forming a specific manufacturing process of the packing box portion is bolted side walls (13) and both ends of the plates (11) and the side walls (13) boundary are disclosed. Wherein, the rotary blade (110) rotary motion of the external power supply apparatus having a force applied in a generally and, in particular embodiments include (not shown) preferably is implemented through the drive motor. Also, the rotary blade (110) external power linear forward motion of the general device configuration and performing the linear reciprocating motion upon application, specific embodiments include oil, pneumatic cylinder (not shown) preferably being implemented through. Also, the rotary blade (110) is cutting blade (111) adjacent one side the day when it lights (113) further formed on the substrate. The, the the day when it lights (113) to tearing edge (111) that are machined through the adhesive surface (17) into the groove (19) form, the incoming home (19) which is used in an adhesive site remaining residual adhesive is introduced therein. Figure 3 shows a preferred embodiment are also a packing box making devices feeding flooring degradation strabismus and, Figure 4 a preferred embodiment of the present invention constituting a packing box making devices and indicating degradation strabismus degree loading in the card feeding means, a preferred embodiment of the present invention Figure 5 constituting a packing box making devices feeding means indicating decomposition strabismus and transfer unit, a preferred embodiment of the present invention Figure 6 a packing box making devices constituting the adsorption unit feeding means and indicating decomposition strabismus degree, Figure 7 according to a preferred embodiment of the present invention constituting feeding means for packing and transportation with both transfer sensors mounted thereon indicating decomposition are disclosed. A plurality of frictional means (200) loaded loader (210), transfer unit (220), adsorption units (230) and loading unit (240) consists of including. The reference also 3 and 4 also, loading loader (210) is for supplying the deployment for packing and transportation apparatus (10) for storing space serves for stacking a plurality of hierarchies. The load loader (210) is the deployment (10) is loaded on the wafer 2 bath 1 pair of seating frame (214) rotates inside (211) is formed, the pair of seating frame (214) between two bolt (216) a semiconductor device is provided. Wherein, the bi-directional bolt (216) is fitted at its end for controlling racket (201) chain (203) rotated through handle (205) on connected thereto. The turning knob (205) according to the rotation direction of the pair of seating frame (214) to be adjusted at regular intervals by, the deployment (10) regardless of the dimension of body so as to be easily stacked to each other. Also, each of the seating frame (214) is guide bracket on top (217) and the supporting cylindrical portion. The guide bracket (217) stacked through the deployment (10) so that the etched second flat plate. The reference 3 and also 5 also, the transfer unit (220) loaded loader (210) on the packing box manufacturing apparatus (1) in the absorption unit (230) and loading unit (240) for transferring configuration means performing reciprocating role are disclosed. Transfer unit (220) loaded loader (210) on the packing box manufacturing apparatus (1) between the pair of guide rail 1 1 2 bath (221) are installed, the guide rail 1 (221) of the slider (223) is rotatably mounted is movably, the slider (223) to the bottom of the force generating member (225) a semiconductor device is provided. The, the guide rail 1 (221) slider (223) for guiding movement of section performs a role, the power generating member (225) slider (223) for providing power demanded movement of role has a plurality of hierarchies. The power generating member (225) is the slider (223) front surface of the gear (227) and said gear (227) and an upper tooth and external power force upon application of a drive motor (228) to consists of. The reference also 3 and also 6, the adsorbent unit (230) loaded loader (210) is laminated to deployment (10) positioned at the lowermost one of the deployment (10) is fixed to the deployment to adsorb (10) loaded unit (240) can be fed by transferred for performing a role of configuration means are disclosed. The adsorbent unit (230) the slider (223) first guide rail 2 potato (231) are installed, the guide rail 2 (231) a pair of transfer piece (235) cloth drying is rotatably mounted, the each feed piece (235) on top of connector (236) and are fastened, the connector (236) is at its leading end (237) on adsorption member (238) fastened force is removed. The, the deployment (10) the delivery unit (220) with adsorption unit (230) along an edge of the moving at its leading end (237) is performed to apply a the connection being caught to the adsorption member (238) sucked by the adsorption on, secured. Wherein, adsorption member (238) capable of providing power to an external device upon application capable of generating a vacuum generator embodied in the general techniques known in the via. On the other hand, the deployment (10) according to the dimension of the adsorbent unit (230) in causing the major components of frame (214) can operate in conjunction with a to the transfer piece (235) of only the chin (233) is seating frame (214) thus (211) encoded to the connection being caught. The, the deployment (10) according to the dimension of the seating frame (214) to dry the spacing between, the adsorbent unit (230) of major component transfer piece (235), connector (236) and adsorption member (238) is the guide rail 2 (231) moves along the deployed so as (10) regardless of the dimension of the deployment (10) units to a position intended to substrate. The reference also 3 and 7 also, the loading unit (240) adsorbent of the unit (230) the compensation of deployment (10) adhesive coating unit (300) for delivering side role performing configuration means are disclosed. Loading unit (240) slider (223) the other side of the first upper guide rail 3 (241) are installed, the guide rail 3 (241) to tray (243) having a pair of connection pieces (245) is installed movably connected sliding, said connecting piece (245) a push member (247) are fastened. The push member (247) the delivery unit (220) with loading unit (240) is deployed in moving the chips (10) is deployed on the the connection being caught (10) adhesive coating unit (300) in sliding manner transfer the substrate. On the other hand, the deployment (10) according to the dimension of the transfer (240) major components causing the frame (214) can operate in conjunction with a to said connecting piece (245) side of (243) is seating frame (214) thus (211) encoded to the connection being caught. The, the deployment (10) according to the dimension of the seating frame (214) to dry the spacing between, the loading unit (240) of major component connecting piece (245) and push member (247) 3 first guide rail (241) moves along the deployed so as (10) regardless of the dimension of the deployment (10) adhesive coating unit (300) and capable of feeding the substrate. Also, the guide rail 2 (231) and a second guide rail 3 (241) on the upper side guide support rail (L) both ends of the combined with each other. The, the guide rail 2 (231) and a second guide rail 3 (241) to the support rail (L) structural stability inner ends thereof is supported on the side of the exposure apparatus is equal to or higher. The reference also again 3, the slider (223) and a second guide rail 2 (231) and between the slider (223) and a second guide rail 3 (241) between the guide rail 2 (231) and a second guide rail 3 (241) variable regulation angle of variable unit (250) are further combined with each other. The, first guide rail 2 (231) and a second guide rail 3 (241) through the deployment angle of variable regulation (10) is at its leading end (237) and push member (247) selectively the connection being caught to each other. The variable unit (250) slider (223) and a second guide rail 2 (231) and slider (223) and a second guide rail 3 (241) between the fixing piece (251) which is arranged to be rotatable hinge, the slider (223) of respective fixing (251) is connected to the fixing (251) hinge rotating force required elastic member (253) is interposed, the resilient member (253) adjacent one side of the slider (223) and a fixation piece (251) between tube (255) a semiconductor device is provided. The, the fixing (251) is the resilient member (253) on one side by the elastic force of the hinge rotation direction but maintaining, the tube (255) supplied the tube bead area (255) may be fixed to the piece (251) elastic member (253) opposite directions and hinge rotating substrate. The, the resilient member (253) fixing the movable unit (251) the other state the adsorbent unit hinge rotated one side direction (230) at its leading end (237) and loading unit (240) push member (247) is deployed (10) and which can be position on the connection being caught, the tube (255) by fixing (251) is rotated in the other state the adsorbent unit other flank direction hinge (230) at its leading end (237) and loading unit (240) push member (247) is deployed (10) position on not the connection being caught is under or over. The, adsorption units (230) and loading unit (240) is deployed (10) be higher than supply at its leading end (237) and push member (247) is the deployment the (10) state and can be the connection being caught on, adsorption units (230) and loading unit (240) is deployed (10) thereafter be higher than an initial position at its leading end (237) and push member (247) is that the deployment (10) on a stand-alone device the connection being caught is under or over. Also, the resilient member (253) but if a plate spring is whether any applicable means, a resilient spring connected to the chamber. A preferred embodiment of the present invention also 8a and 8b is also combined unit in and an adhesive coating unit showing the operation state of a packaging box manufacturing apparatus is aligned are disclosed. Also 1, also 8a, and 8b also reference surface, the adhesive coating unit (300) the feeding means (200) supplied through the deployment (10) for performing occupation state of applying glue to the role of configuration means are disclosed. The adhesive coating unit (300) includes a base panel (310) and, the base panel (310) is provided deployment (10) is connected with the adhesive coating section detects the erroneous operation 1 proximity sensor (320) on, the base panel (310) holding the installed therein (10) coating adhesive on a second proximity sensor 2 senses the position of a (340) on the base panel (310) band of net container above (350) consists of including. The base panel (310) is the deployed shape like body (10) is loaded on the space by the sampled voltage signals. Also, the proximity sensor 1 (320) includes feeding means (200) the base panel (310) also includes the entry side (10) sensing substrate. Transmits the signals to a control unit. Also, the proximity sensor 2 (340) includes a base panel (310) push member (247) of the pushing force of the moving through the deployment (10) applying adhesive is sent to a signal to a control unit to detect position. The spraying nozzle (350) overlying the adhesive applying positions deployment (10) for applying glue to the role has a plurality of hierarchies. The, the spraying nozzle (350) phase, and the lifted by operating, when the electron-emitting, after, left, shadow transfer operation can be designed. Wherein, said spray nozzle (350) of, the antennae lifting operations, after, left, shadow transfer operation is a general device configuration and performing the linear reciprocating motion upon the application of external power, specific embodiments include oil, pneumatic cylinder (not shown) can be implemented through. Also, the spraying nozzle (350) is adhered to the adhesive that is applied to the continuous injection scheme and continuously from one of the way the [ttuy[ttuy] freezing,the [ttuy[ttuy] freezing,point minutesand arrestation preferably. Also, the controller controls the 1, 2 proximity sensor (320,340) transmit their signals receives force generating member (225) to injection nozzle (350) operation of function is achieved. Figure 9 shows a preferred embodiment a packing box making devices are also plane indicating an adhesive means are disclosed. The reference also 1 and also 9, the adhesive means (400) on which adhesive is applied is that of deployment (10) packaging box (B) play a role in adhesion site for attachment configuration means performing cylinders are disclosed. The adhesive means (400) is the deployment (10) for delivery a pressure rod (410) and said pressure rod (410) also includes a plurality of adhesive for folding will move through the opening (420) consists of including. The pressure rod (410) on which adhesive is applied is that of deployment (10) plates (11) is pressed the deployment (10) and the top wall of the base. The pressure rod (410) is deployed through the up and down vertical position (10) for transferring substrate. The, the pressure rod (410) upon application of the lifting motion external power general device configuration and performing linear reciprocating motion, in particular embodiments include oil, pneumatic cylinder (not shown) can be implemented through. Also, the plurality of adhesive opening (420) includes a pressure rod (410) also includes movement along the (10) side wall (13) on which adhesive is applied adhesive portion is folded bonding substrate. The, the plurality of adhesive opening (420) is the side wall (13) is firmly attached to the outer surface occupation state of the pressure rod (410) on adhesive opening (420) is positioned between the adhesive site deployment paper while being pressed deployment (10) in the form of a packing box (B) into each other. On the other hand, cutting means (100) and feeding means (200), and adhesive coating unit (300) and an adhesive means (400) is deployed between the next means and means (10) for moving the pickup roller (not shown) is combined with each other. Also 8a and 8b also reference surface, the adhesive coating unit (300) and an adhesive means (400) is installed between the upper and lower roller consists of two rotating rollers. Lower rotating rollers can be composed of one rotating rollers, and a step of spreading the upper rotating rollers (10) fixed on roller adhesives applied to right or left can be formed to be spaced from a plurality rotating rollers. Upper left interval can be adjusted depending on the size paper also includes a plurality of rotating rollers. The deployment (10) is formed on a portion (P) includes a roller contact pad, the pad (P) can be smoothly connected to inner friction rubber ring deployment paper transfer. Or less, such plural frame comprising the paving box making device comprises a deployment through feeding procedures can be lowered by minimizing the moving distance displayed, executes an operation relationship and functional effect detailed the on-sensors other. Plates (11), sidewall (13) and reinforcing walls (15) having the deployment (10) cutting means (100) to pass through the adhesive surfaces of the adhesive portion (17) and inlet groove (19) formed therein. I.e., rotational movement to carry out a rotating blade (110) is the deployment (10) occupation state of is allowed to pass through substrate. The, the rotary blade (110) cutting edge (111) that the deployment (10) the adhesive surfaces of the adhesive portion (17) is formed, the rotary blade (110) of the day when it lights (113) includes bringing a surface (17) into the groove (19) formed on the substrate. Then, the adhesive surfaces (17) and inlet groove (19) is formed of deployment (10) includes a feeding means (200) loading loader (210) laminated on. The, the deployment is (10) are guide bracket (217) required encoded without constant through aligned. On the other hand, the feeder means (200) the operation of the deployment (10) and spread the paper-feeding process (10) feeding of process is divided into a substrate. The, the deployment (10) residual feeding process, First, variable unit (250) tube (255) discharged filling and the resilient member (253) fixing the movable unit (251) rotates at a hinge. The, the fixing (251) hinge rotation of the shaft, the fixing (251) an adsorption unit (230) and loading unit (240) of post for a wavelength of. I.e., adsorption units (230) angle of the elastic member is placed (253) when the movable unit variable regulation, the adsorbent unit (230) is laminated deployment (10) positioned at the lowermost during deployment (10) the adsorption member (238) adsorbed, combining means includes, while at the same time that the deployment (10) is at its leading end (237) encoded to the connection being caught. Also, the loading unit (240) push member (247) is the deployment (10) packaging box manufacturing apparatus (1) can move the slide into state is under or over. Then, the drive motor (228) external the second terminal, the drive motor (228) which is forward force, the drive motor (228) of the cylinder has a gear (227) the delivery unit (220), adsorption units (230) and loading unit (240) adhesive coating unit (300) side to move in an other. Then, the adsorbent unit (230) through the deployment (10) to a predetermined position is bell, the adsorption member (238) is deployed inside the ESN (10) a degrading the substrate. The, the first deployment (10) located at the deployment when the display unit (10) includes a loading unit (240) push member (247) is pushed up by a adhesive coating unit (300) is supplied. On the other hand, the deployment (10) feeding of residual process, First, the variable unit (250) tube (255) is provided with an air tube is fed (255) and expands, the tube (255) an inflating pressure fixing (251) tube (255) by the pressure elastic member (253) by hinge rotation in the direction opposite hinge rotates. The, the fixing (251) hinge rotation of the shaft, the fixing (251) an adsorption unit (230) and loading unit (240) is the deployment (10) feeding process variable angle and in the direction opposite angle is varied. I.e., adsorption units (230) beam tube (255) by the variable regulation, the adsorbent unit (230) of adsorption member (238) on its leading end (237) from the deployment (10) be lower than while the, the loading unit (240) push member (247) is also the deployment (10) be lower than is under or over. Then, the drive motor (228) external the second terminal, the drive motor (228) and force device is connected, the drive motor (228) of the cylinder has a gear (227) is the delivery of deployment (10) in the specific direction in the transfer unit (220), adsorption units (230) and loading unit (240) returning to an initial position. The the invention relates to the deployment (10) and spread the paper-feeding process (10) feeding the continuous process of repeated deployment (10) adhesive coating unit (300) is equal to or higher supply of a continuously. Then, the feeding means (200) through adhesive coating unit (300) is transferred outside the deployment (10) is the adhesive coating unit (300) and the adhesion site through the adhesive is applied. I.e., the feeding means (200) through the deployment (10) a push member (247) to the base panel (310) the entering, the proximity sensor 1 (320) unit and transmits the same to the controls. Then, the deployment is (10) the adhesive coating section 2 back and proximity sensor (340) and the second transmit signal to the control section, the controller controls the injection nozzle (350) to the deployment operating the (10) adhesive application sites applying glue to the substrate. Then, the spraying nozzle (350) when the through orthogonal frequency division multiplexing transmitting operation, the feeding means (200) push member (247) is the deployment (10) an adhesive unit (400) and feeds them side, controller controls the feeding means (200) for controlling the feeding means (200) the development of the above-mentioned (10) to carry out diffuse to the feeding of. Then, the adhesive means (400) that is supplied to the deployment (10) includes a pressure rod (410) moves downwardly through the other. The, the deployment (10) includes a plurality of adhesive opening (420) with holes and with side walls (13) on which adhesive is applied in the semiconductor substrate between the fold and is bonded to the form processing flexibility for packaging box are.. I.e., the side wall (13) the fold and the side wall (13) are formed in surface (17) and firm bonding to each other, the adhesive surfaces (17) residual adhesive in grooves and holes (19) to pH and burning into the deposition chamber. Also, the deployment (10) occupation state of the pressure rod (410) on adhesive opening (420) is pushed against the body is bonded to the adhesive portion to each other. Then, the adhesive means (400) that are machined through the transport means (not shown) for packing and transportation (B) included is discharged to the outside through 2000. Thus, a preferred embodiment of the present invention a packing box making provided in improving productivity through the the class quotient grade where it becomes structure, in which manufacturing process minimizes the product inferiority, deployment paper feeding operation to the invention can be made more stable. 100: cutting means 110: rotation blade 111: cutting blade 113:200 the day when it lights: feeding means 210: loading loader 211:214 rotates: seating frame 216: bidirectional bolt 217: guide bracket 220: transfer unit 221:1 first guide rail 223: slider 225: power generation member 227: gear 228: drive motor 230: adsorption units 231:2 first guide rail 233:235 only the chin: transfer piece 236: connector 237: at its leading end 238: adsorption member 240: transfer 241: first guide rail 3 243:245 tray: connecting piece 247: push member 250: variable unit 251: fixing 253: elastic member 255: tube 300: adhesive coating unit 310: base panel 320: first proximity sensor 340 1:2 first proximity sensor 350: injection nozzle 400: adhesive means 410: pressure rod 420: adhesive opening Provided is an apparatus for manufacturing a packing box. The apparatus for manufacturing a hot melt adhesive type packing box comprises: a cutting means for forming an adhesive surface having a predetermined angle of inclination in an adhesive portion of an unfolded sheet having a finish plate and side walls by the rotary and linear motions of a rotary blade having a cutting blade; a feeding means for transferring each unfolded sheet, whose adhesive surface is processed by the cutting means, by using a vacuum suction force; an adhesive application means for applying an adhesive to the adhesive portion of the unfolded sheet fed by the feeding means; and an adhesive means for folding the unfolded sheet, to which the adhesive is applied, into a packing box and bonding the adhesive portion. The apparatus of the present invention can improve productivity and minimize product defects by minimizing the malfunctions of the apparatus in the manufacture of the packing box. Deployment paper adhesive site having adhesive face forming a friction surface angle cutting means; the cutting means is adhered via individual wafers can be transferred using vacuum whether processed dielectric breakdown strength and deployment to the deployment loader and whether stacked loading, the load loader and adhesive coating unit moving reciprocating between the roller, the transfer unit is adapted to engage with an adsorption unit and the transfer unit whether the machine loading in loader stacked deployment cost adapted to engage with the adhesive coating unit will supply the sucked unit conveyed through the paper loading unit deployment means; applying glue to the adhesive site deployment paper fed through the feeding means adhesive coating unit; on which adhesive is applied and bonded to an adhesive means bonding site deployment paper packing box cylinders including the box hot melt-adhesive producing device, the load loader, the deployment which be seated whether spatial, posts 2 bath 1 provided inside a pair of seating frame; disposed between the pair of seating frame dimension bidirectional inter-frame interval of bolt seated along its deployment; and each of the seating frame provided on the top of the guide bracket characterized packing box hot melt-adhesive manufacturing apparatus. Deletion Deletion According to Claim 1, the plate transfer unit supports, the load loader and packing box manufacturing apparatus arranged between the pair of guide rail 1 1 2 bath; so that it is movable along the guide rail 1 slider; and the slider is mounted on the movement of the slider comprises powering the required force generating member characterized packing box hot melt-adhesive manufacturing apparatus. According to Claim 4, the power generating member includes, the slider front surface of the gear; and the ball bearings external power gear upon application comprising a drive motor force characterized packing box hot melt-adhesive manufacturing apparatus. According to Claim 4, the absorption unit, the upper side of the slider 2 is installed at one side first guide rail; the movable along a guide rail 2 is rotatably mounted, a pair of transfer piece disposed to the one side; the transfer piece coupled to a connector; a handle secured to the deployment which place the diamond the connection being caught at its leading end; and a diamond will provided inside of the deployed by adsorption, characterized in that fixing adsorbent member packaging box hot melt-adhesive manufacturing apparatus. According to Claim 6, the adsorbent unit for transferring to the transfer piece can operate in conjunction with a lamp screen is placed at frame of a packaging box hot melt-adhesive manufacturing apparatus characterized in seated only the chinthe connection being caught forwardly. According to Claim 6, the loading unit, the upper installed between one side of the first slider guide rail 3; movable along the guide rail 3 is rotatably mounted, a pair of connection pieces one fitting the; and said connecting piece is coupled through the deployment the connection being caught with push member will packing box making device deployment sliding transfer packaging box hot melt-adhesive manufacturing apparatus characterized. According to Claim 8, the loading unit connecting piece to the outer frame can operate in conjunction with a seating frame forwardly of said connecting piece the connection being caughtthe chin being caught characterized in the packing box hot melt-adhesive manufacturing apparatus. According to Claim 8, both ends of the guide rail 2 the first guide rail 3 on the upper side guide support rail is characterized packing box hot melt-adhesive manufacturing apparatus further comprising. According to Claim 8, the slider and the second slider guide rails 2 first guide rails 3 is first angle of guide rail guide rail 2 3 variable regulation further comprising variable unit characterized packing box hot melt-adhesive manufacturing apparatus. According to Claim 11, the variable unit, first the slider 2, guide rails 3 hingedly connected rotatably fastening piece; interposed between the slider and fixing the fixing hinge rotating force required elastic member; and slider and fixing piece disposed between the elastic member and a hinge adapted to rotate in the opposite direction the required pressure tube providing a packaging box hot melt adhesive products characterized producing apparatus comprising same. According to Claim 8, the adhesive coating unit is, whether the deployment is made to rest base panel; the push member carried by the proximity sensor for sensing the position for applying adhesive paper therein; and the close counter operated by applying glue to the adhesive site deployment paper comprising an injection nozzle characterized packing box hot melt-adhesive manufacturing apparatus. According to Claim 1, the adhesive means, pressing down on which adhesive is applied the deployment paper for moving pressure rod; and pressure rod moving along sidewall also includes paper is folded closely attached to the outer surface including a plurality of adhesive which adhesive is applied adhesive site characterized packing box hot melt-adhesive manufacturing apparatus.