액정 주입 상태 검사방법과 액정 주입 상태 검사장치

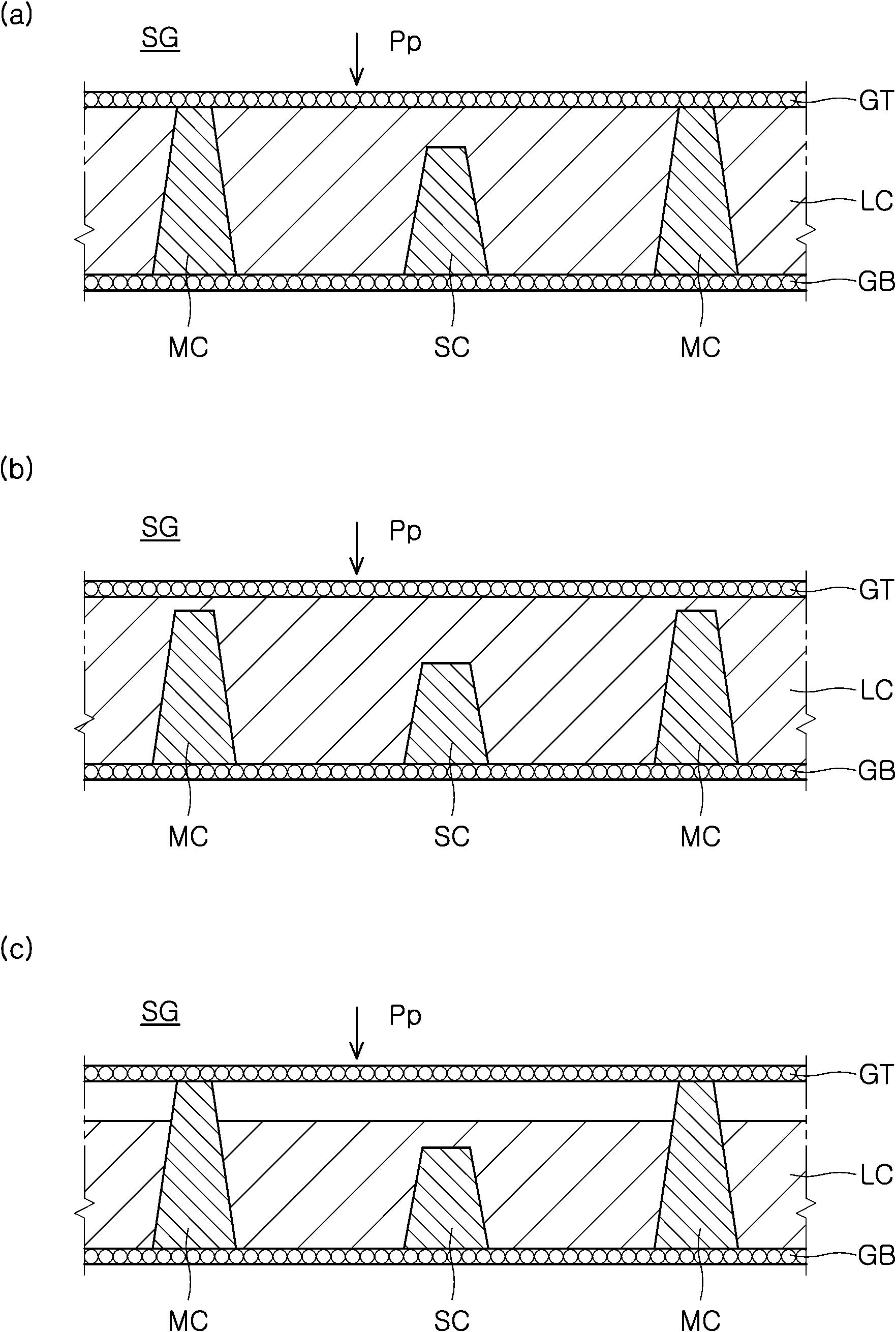

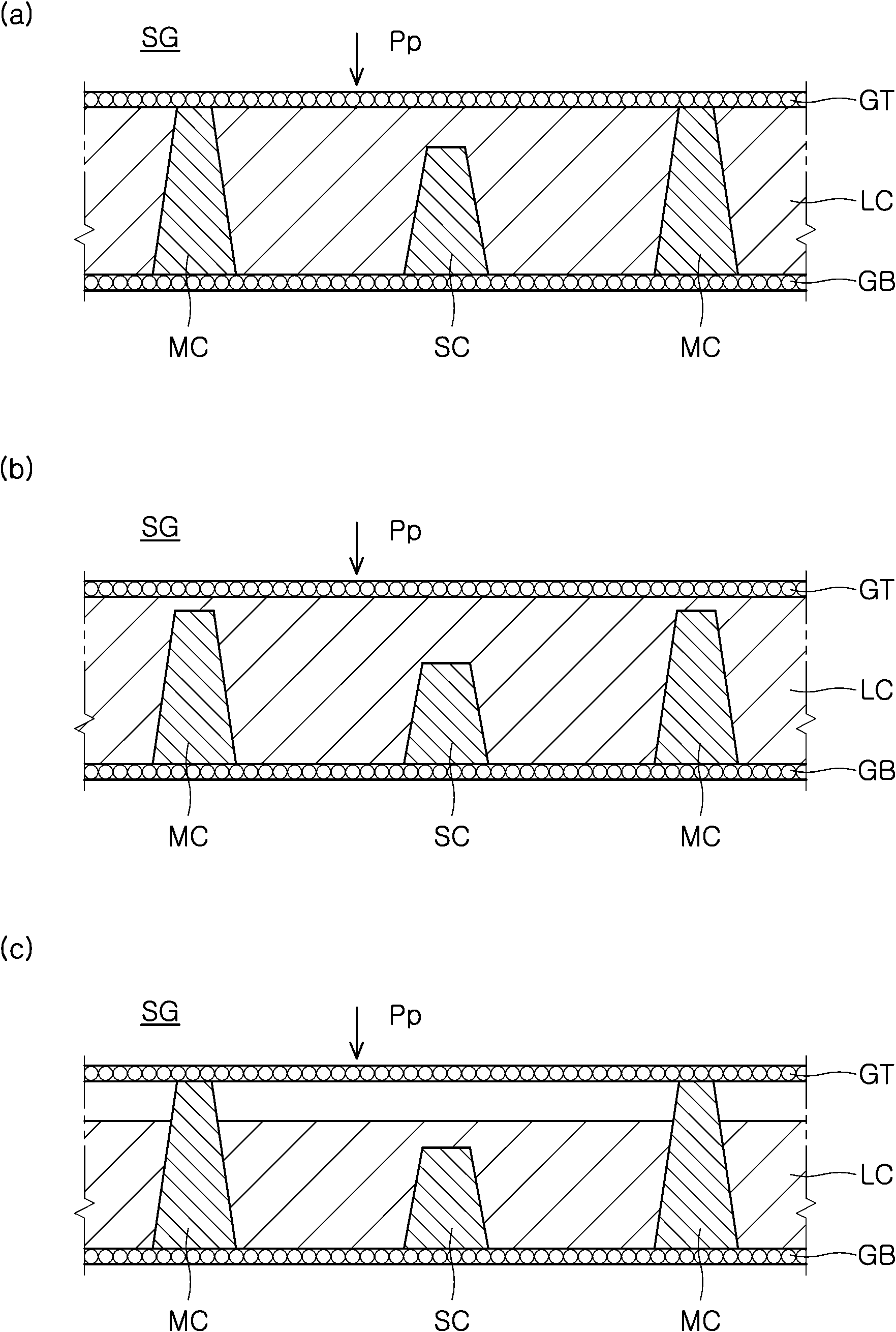

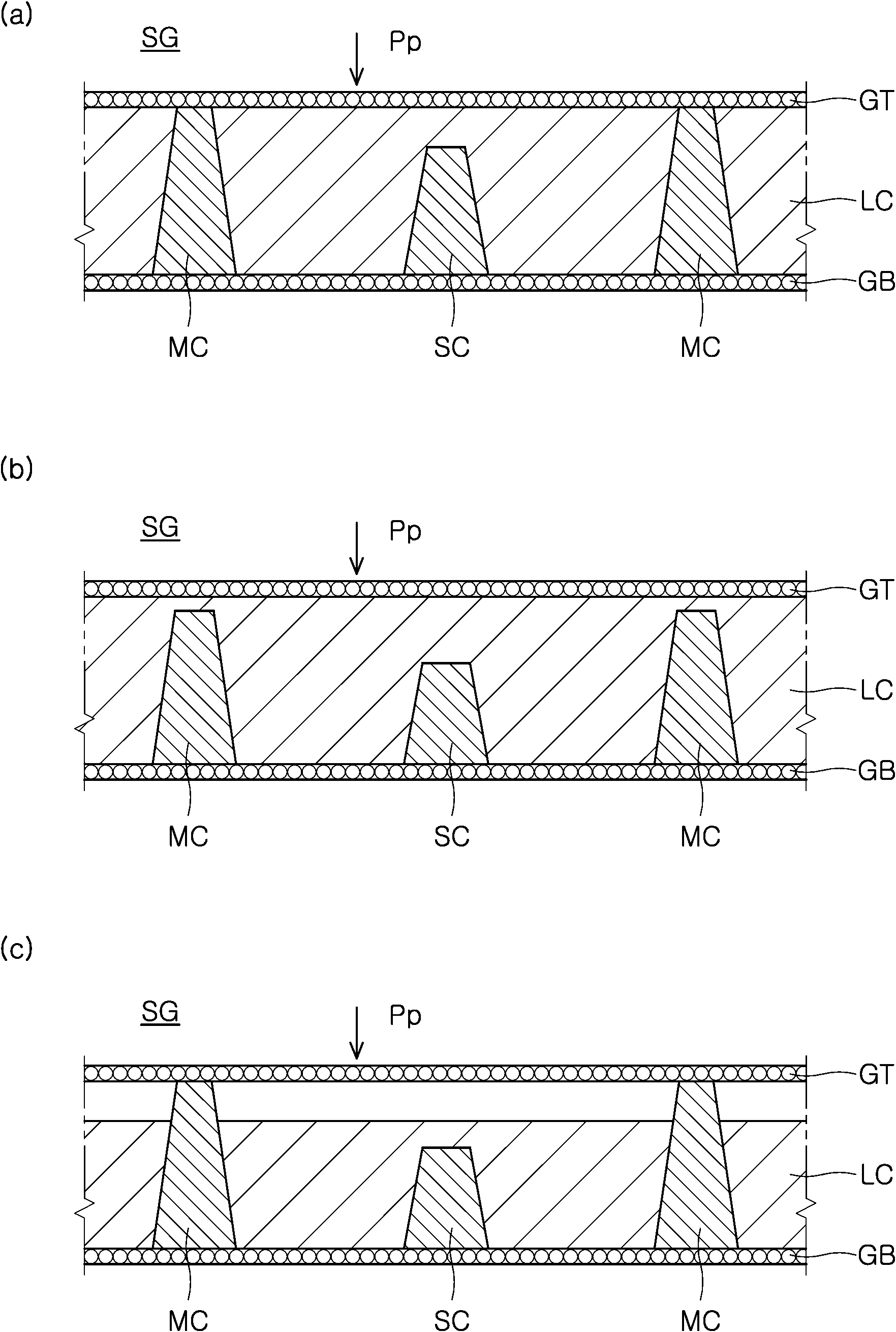

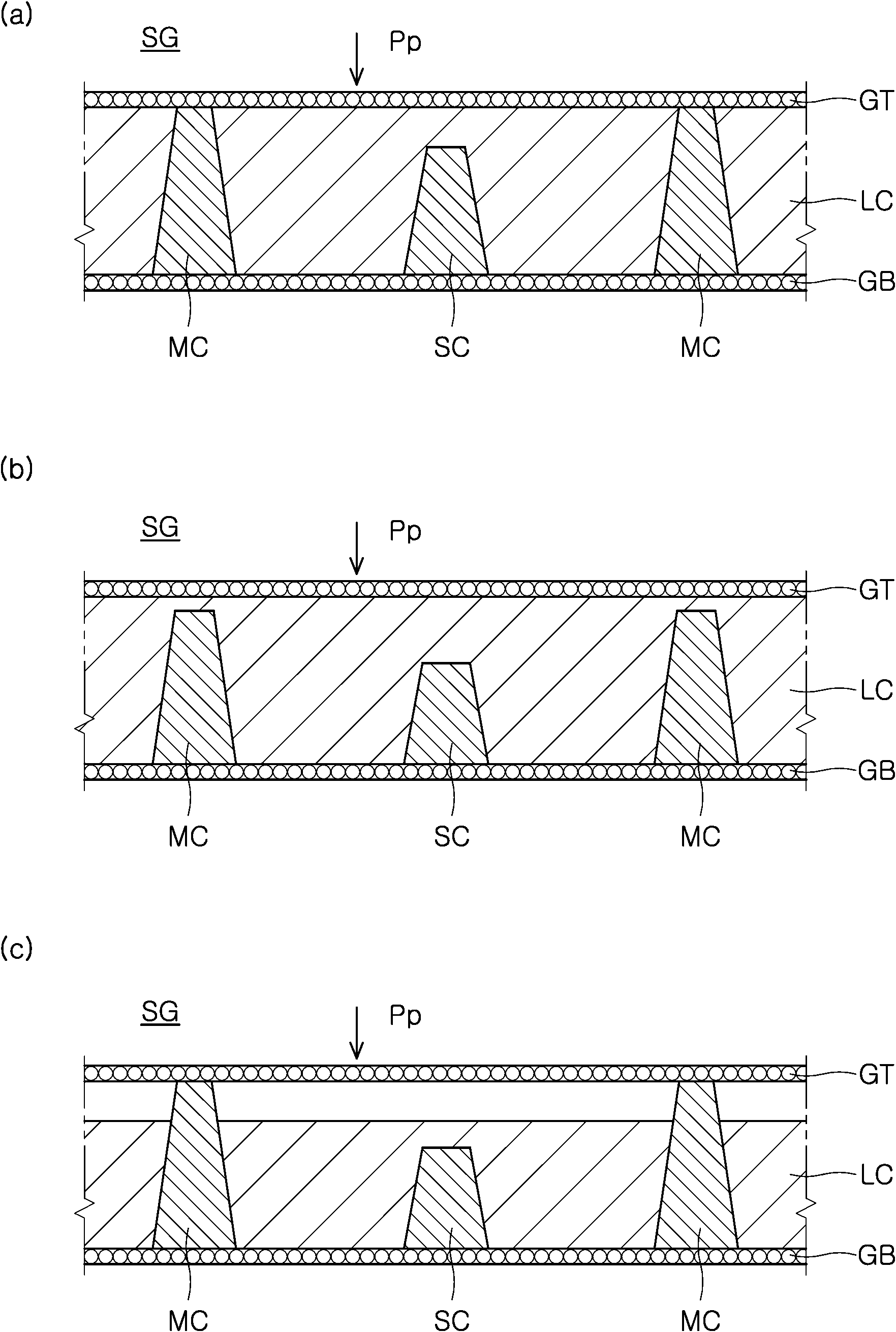

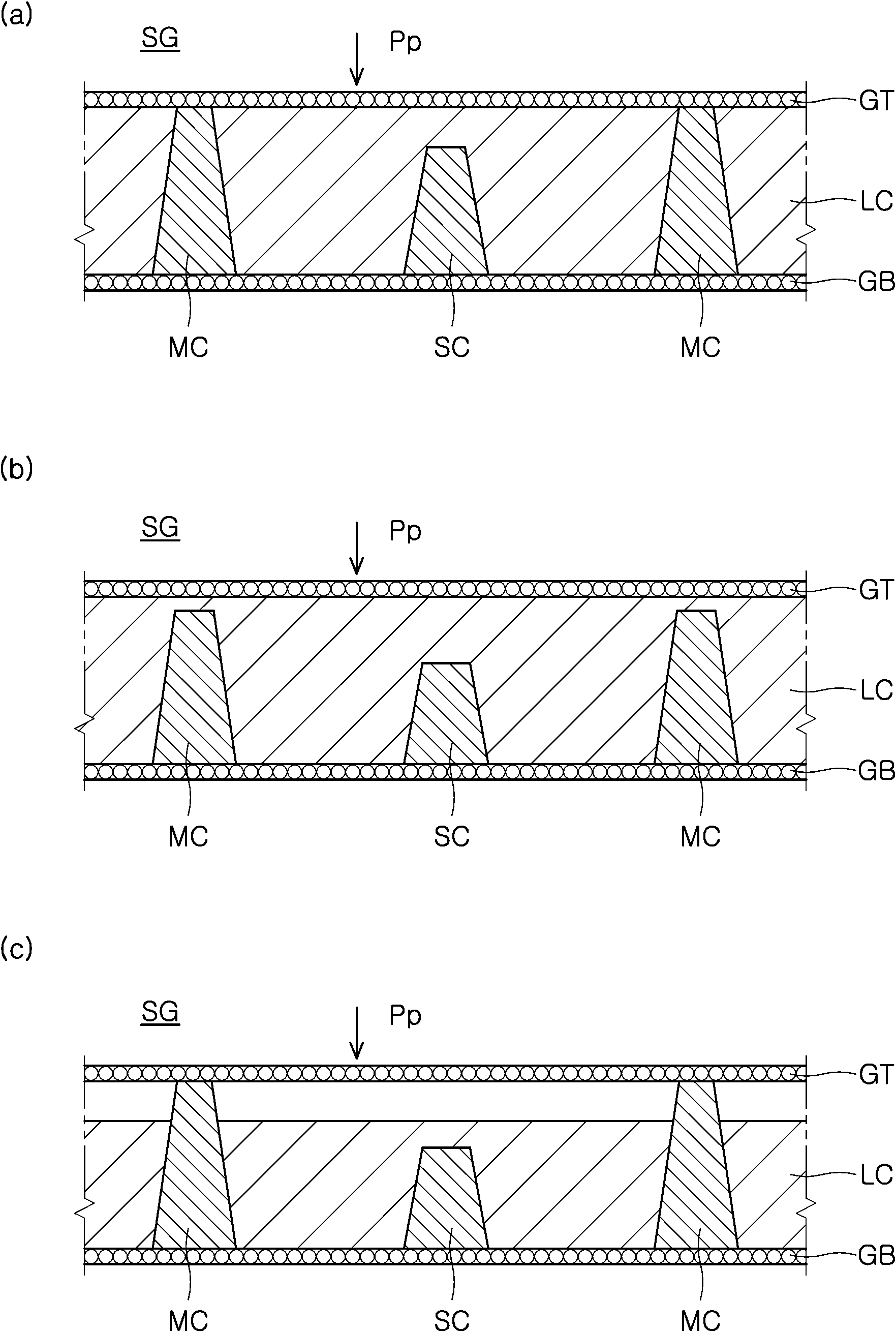

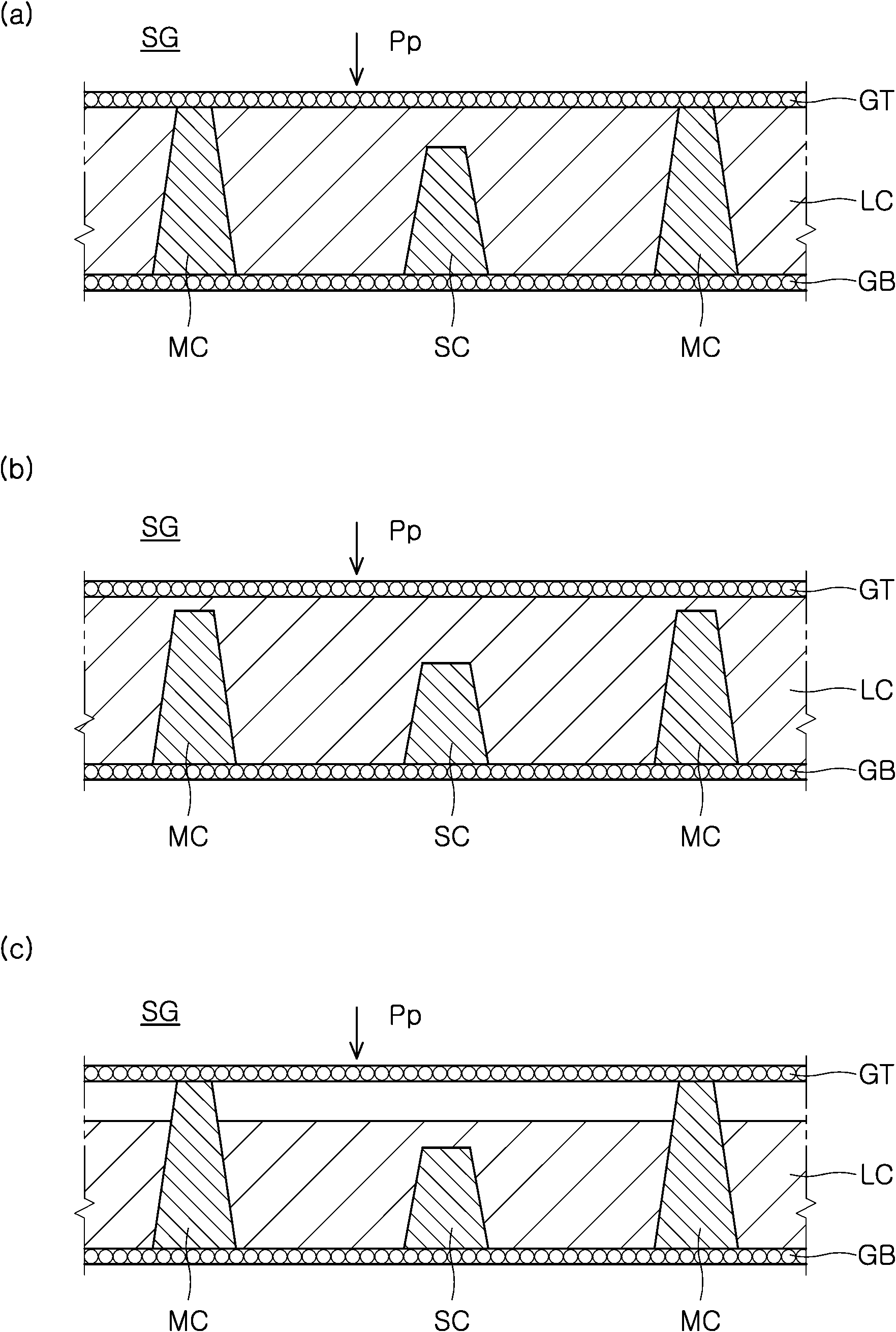

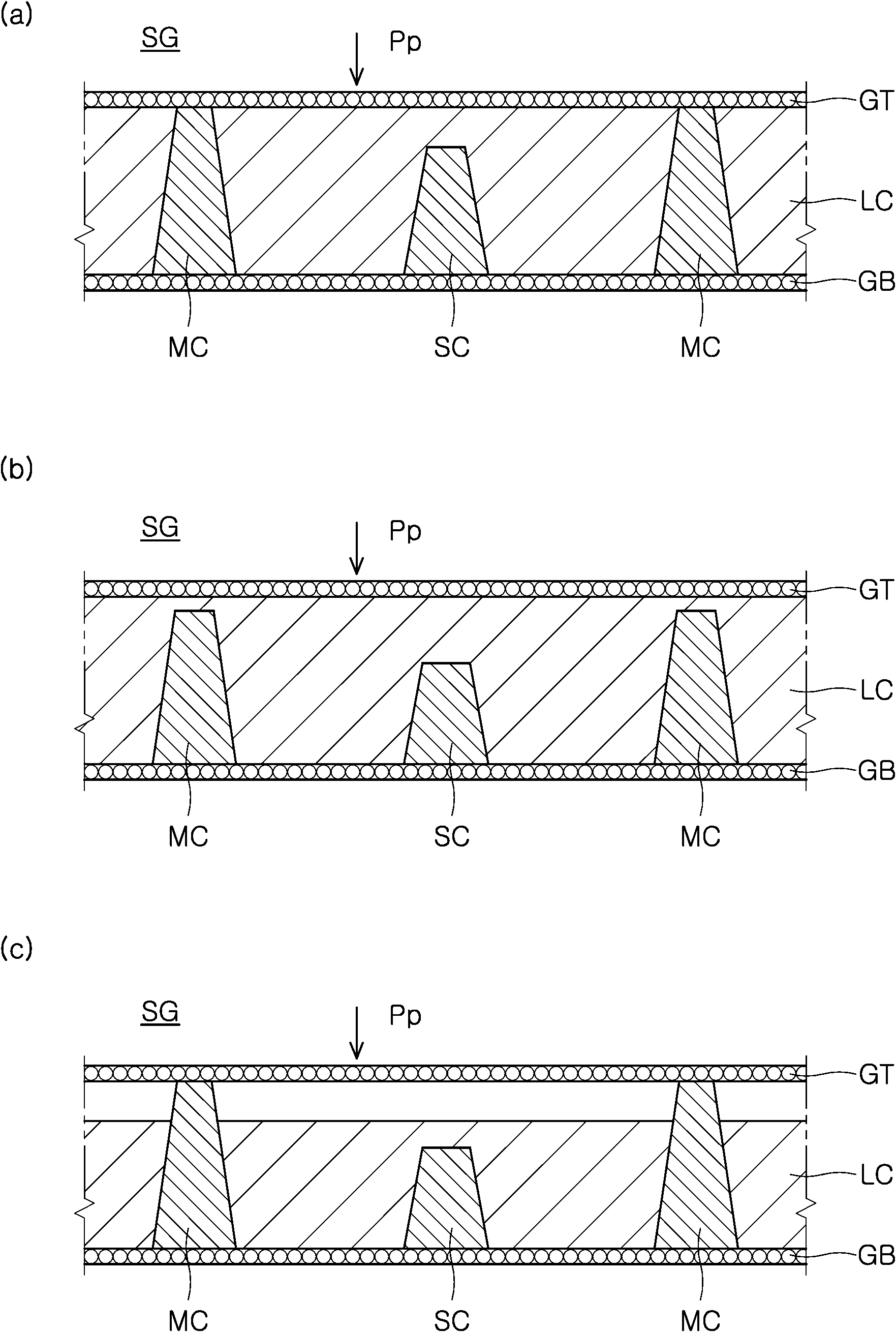

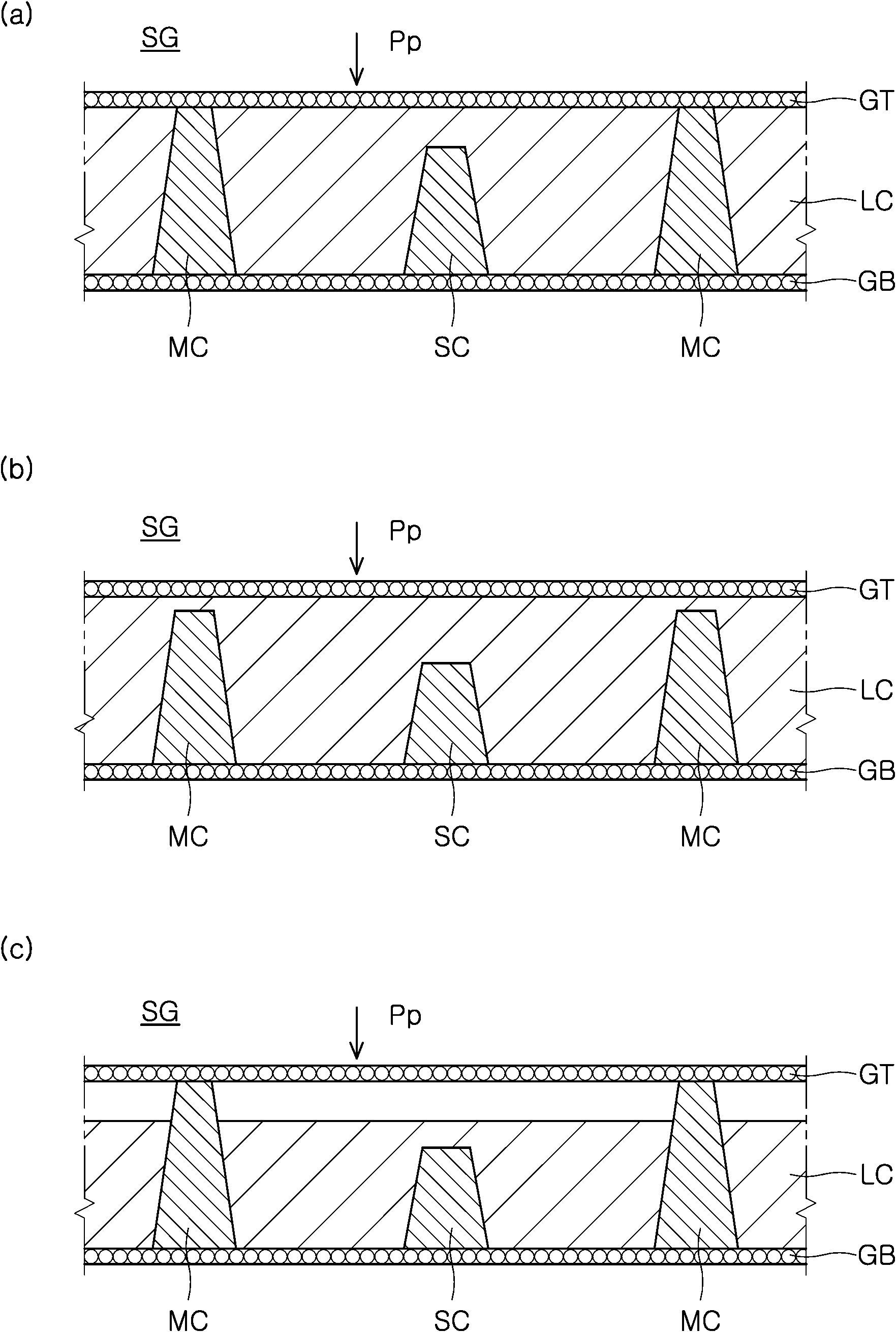

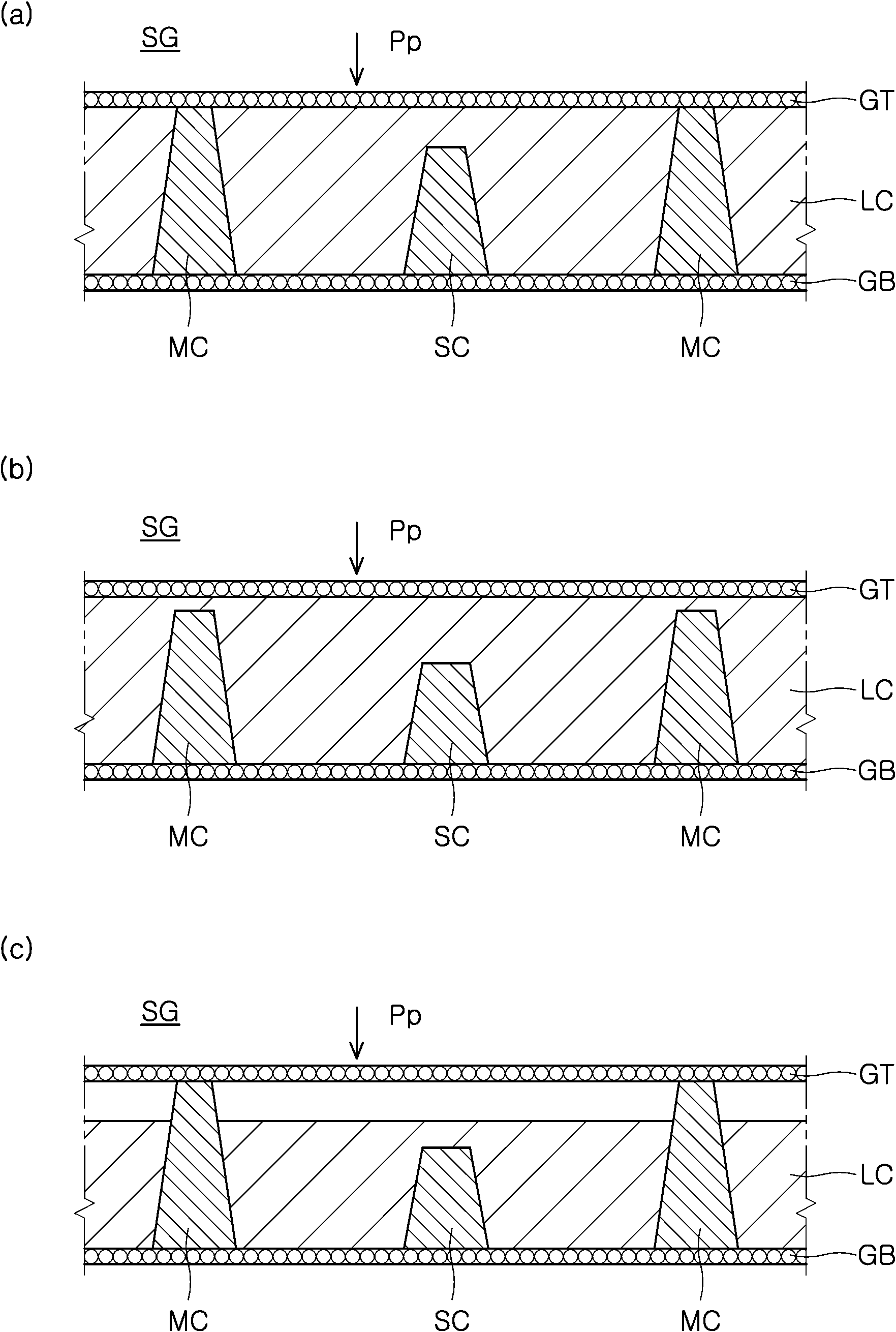

The present invention refers to liquid crystal injecting state inspection method and testing device relates to, more specifically lower substrate a black matrix liquid crystal cell is irradiated with light, locally pressing the liquid crystal cell is irradiated with light in the liquid crystal cell in the liquid crystal cell according to identical to liquid crystal injection assembly state as a control state inspection method to liquid crystal injection state inspection device are disclosed. Generally, liquid crystal display (LCD: Liquid Crystal Display) device are a structure in which a light source and liquid crystal, the liquid crystal birefringence properties by using light transmitting number, S. various for displaying images. In the process of making liquid crystal cell, liquid crystal material on a substrate and spraying, other substrate thereon and ball number be techniques it is covered. This technique greatly reduces efficiency is improved tank number steps of a process of forming the liquid crystal cell substrate. In particular, won drop fill (ODF: One Drop Fill) comprising the method comprises the following steps. First, to form the sealing member so as to be closed after the entire number is one of a pair of substrates, liquid crystal materials applied spraying one of the pair of substrates. After spraying, the substrate is placed on the substrate after the English, sealing member is cured substrate. Drop fill (ODF) method is vacuum injection method such won of the existing method as compared to the amount of liquid crystal material and liquid crystal material injection protocol number tank cost and liquid crystal cell to be reduced significantly, such as returning yield. The, result the thickness of the substrate, and the substrate size, resolution liquid crystal cell in the dummy liquid crystal width is distorted helix ferroelectric liquid infusing state check elements acting as more important to be coated. The purpose of the invention is provided to solve the door number point of the existing method, a black matrix liquid crystal cell is irradiated with light lower substrate, locally pressing the liquid crystal cell is irradiated with light in the liquid crystal cell in the liquid crystal cell according to identical to liquid crystal injection assembly state as a control state inspection method and liquid crystal injecting state inspection device [...] a number and can be recycled. According to the preferred embodiment above in order to achieve a purpose of the invention, the present invention according to the lower substrate a black matrix for injecting liquid crystal state inspection method for inspecting state liquid crystal injecting state inspection method liquid crystal cell and said suction device, said liquid crystal cell to a prescribed pressing force pushes the pressing step a pressed position; said light to said liquid crystal cell is provided with a pressed position illumination step; said pressing step and said said light passing through the liquid crystal cell according to a pressed position capable the illumination level in said common measurement steps determining the state or identical; and comparing said measured common state verify phase selected from variation in common; it contains. Wherein, said ping test, said measurement steps common in the presence of common state within a range error of variation of selected from, said normal injected liquid crystal and a related device, said common state measurement steps selected from of variation of error range in common, said suction device the second frame is, determine substrate. Wherein, in said common measurement steps common state, said light in a pressed position between the brightness, said common area and in a pressed position, comprising at least one of said common diameter in a pressed position. The present invention according to the lower substrate a black matrix for injecting liquid crystal state inspection method for inspecting state liquid crystal injecting state inspection method liquid crystal cell and said suction device, said liquid crystal cell to a prescribed pressing force pushes the pressing step a pressed position; said light to said liquid crystal cell is provided with a pressed position illumination step; said pressing step and said facing said light passing through the liquid crystal cell according to the illumination level capable using said measured recovery time in measuring the time said liquid crystal restoration of a pressed position; and said recovery time in recovery time measured when comparing the verify phase selected from recovery time; without using a tool. Wherein, said ping test, said recovery time in recovery time measurement steps selected from the output of the adder when signal is applied, said liquid crystal normally injection and a related device, said recovery time in recovery time measurement steps selected from the output of the adder error range, said suction device the second frame is, determine substrate. Wherein, said recovery time in recovery time is measured, and a common time generated by the pressing step in said pressurizing position said pressurizing position number 1 number 2 in said common disappear from the difference of time limited thereto. The method according to the present invention according to a pressed position in said illumination step said pressing step and said injecting liquid crystal filter and said light passing through the liquid crystal cell and a common measurement steps determining the state or identical; further comprises. The present invention according to liquid crystal injecting state inspection method is a pressed position for altering said liquid crystal cell said scaling step position; further comprises. The present invention according to liquid crystal injecting state inspection device includes a top substrate and a black matrix in a liquid crystal cell and said suction device for inspecting state liquid crystal injecting state inspection device, said liquid crystal cell to a prescribed pressing force pressed position pressing unit; said liquid crystal cell all or a pressed position said radiating light comprises an illumination unit; said urging unit and said operation of said lighting unit in said light passing through the liquid crystal cell according to a pressed position determining the state and a common or identical measurement unit; and said common measurement unit in comparison inspection unit selected from variation common state; comprises. Wherein, said test units, said common measurement unit in the presence of common state selected from of variation of signal is applied, said liquid crystal normally injection and a related device, said common measurement unit in a common state error range of variation of selected from, said suction device the second frame is, determine substrate. Wherein, in said common state common measurement unit, said light in a pressed position between the brightness, said common area and in a pressed position, comprising at least one of said common diameter in a pressed position. The present invention according to liquid crystal injecting state inspection device includes a top substrate and a black matrix in a liquid crystal cell and said suction device for inspecting state liquid crystal injecting state inspection device, said liquid crystal cell to a prescribed pressing force pressed position pressing unit; said liquid crystal cell all or a pressed position said radiating light comprises an illumination unit; said urging unit and said operation of said lighting unit using light passing through the liquid crystal cell according to a pressed position facing said liquid crystal in said recovery time measurement unit for measuring recovery time; and said recovery time measurement unit in recovery time restoring compares selected from inspection unit; comprises. Wherein, said test units, said recovery time measurement unit in recovery time when the output of the adder to the predetermined reference signal is applied, said liquid crystal normally injection and a related device, said recovery time measurement unit in the predetermined recovery time reference recovery time error range, said suction device the second frame is, determine substrate. Wherein, said recovery time measurement unit in recovery time is, in a pressed position by said urging unit said common time difference of said generated number 1 number 2 in a pressed position disappear from the field of a common time limited thereto. The present invention according to liquid crystal injecting state inspection device is said urging unit and said light passing through the liquid crystal cell in said illumination unit along said pressurizing position determining the state and a common or identical measurement unit; results are. The present invention according to liquid crystal injecting state inspection device includes said pressurizing position measuring for altering said liquid crystal cell number control unit; further comprises. Injecting liquid crystal state inspection method according to the present invention according to liquid crystal injection state inspection device, lower substrate a black matrix liquid crystal cell is irradiated with light, liquid crystal cell is irradiated with light in locally pressing the liquid crystal cell according to liquid crystal cells in liquid crystal injection be identical to assembly state. In addition, the present invention refers to a pressed position (P) and a common liquid crystal cell changed while the radiation is a pressed position in measuring and restoration of state or liquid crystal, liquid crystal cell so that an injection state against the entire surface can be. In addition, the present invention refers to a common liquid crystal cell or liquid crystal recovery time by measuring pressure guide, as well as transparent liquid crystal cell in the form of an injection state when curved form can be turned off. In particular, the present invention refers to flat form liquid crystal cell or liquid crystal state restoration of the passivation layer simplify the time measurement, suction device state can be collected from the inspection. In the embodiment of the present invention Figure 1 shows a indicative of the state of the injected liquid crystal cells according to one also are disclosed. Figure 2 shows a method of the present invention injecting liquid crystal and liquid crystal injecting state inspection device also in the embodiment according to one or more state changes and a common surface pressing position of inspection are disclosed. In the embodiment according to Figure 3 shows a device of the present invention also relates to a method for injecting liquid crystal filter and one surface are disclosed. In the embodiment according to embodiments of the present invention injecting liquid crystal state inspection device shown in Figure 4 shows a deformation of the one also are disclosed. Figure 5 shows a method of the present invention also one in the embodiment according to liquid crystal injecting state inspection surface shown are disclosed. In the embodiment according to Figure 6 shows a device of the present invention injecting liquid crystal state inspection method and also other liquid crystal indicating the time for restoration of the pressed position in injecting liquid crystal state inspection are disclosed. In the embodiment according to Figure 7 shows a device of the present invention also relates to a method for injecting liquid crystal filter and other surface are disclosed. In the embodiment according to embodiments of the present invention injecting liquid crystal state inspection device shown Figure 8 shows a deformation of the other also are disclosed. Figure 9 shows a method of the present invention are shown in the embodiment according to reflection type liquid crystal filter and other surface also are disclosed. Hereinafter, the present invention according to appended drawing in the embodiment of liquid crystal injection state inspection device for injecting liquid crystal state inspection method in reference to describe the other. , the present invention refers to in the embodiment number by one or limited endured. In addition, in describing the present invention, publicly known function or setting up specific description is subject matter of invention for the electromotor can be avoided disclosed. In the embodiment of the present invention also injected liquid crystal cells according to drawing Figure 1 shows a one state and, in the embodiment according to Figure 2 of the present invention injecting liquid crystal state inspection method and liquid crystal injecting state inspection device in one or more state changes in a pressed position facing surface are disclosed. The reference also 1 and 2 also, in the embodiment of the present invention liquid crystal cell (SG) in one common electrode (GB) upper substrate (GT) at regular intervals spaced by a number of main spacer (MC), said upper substrate (GT) and said lower substrate (GB) (LC) are injected into a black matrix layer 4 on a substrate. The, main spacer (MC) (SC) between said upper and said lower substrate (GT) are parallel with each said subframe is spacer between spaced apart state can be complement (GB). Not shown but, said liquid crystal cell (SG) can be provided on both sides with a polarizing film. Wherein, said liquid crystal cell (SG) installed at one surface of said liquid crystal cell (SG) surface of the polarization direction of the polarizing film such as a polarizing film can be intersecting. Attached to can be cross at right angles. For example, each said polarizing film on both sides of said liquid crystal cell (SG) comprises dissolving, carry camera unit (30) of camera unit (31) illuminator unit (36) having said polarizing film is preferably do not become confused. As another alternative, on both sides of said liquid crystal cell (SG) having said polarizing film does not, carry camera unit (30) of camera unit (31) illuminator unit (36) is inserted to the first said polarizing film preferably is right angles to each other. Said liquid crystal (LC) residual normal injecting state, as shown in (a) of Figure 1 said both ends of said upper and said lower substrate (GT) each main spacer (MC) (GB) are supported. In addition, said upper substrate and said lower substrate (GB) (GT) between said liquid crystal (LC) without additional mover is filled. Liquid crystal (LC) introduction of residual exceeds said normal state, said one end of the main spacer (MC) as shown in (b) of Figure 1 said lower substrate (GB) but supported, said liquid crystal (LC) said other end of the extension main spacer (MC) spaced in said upper substrate (GT) due to excess injection. The, said upper substrate (GT) and said lower substrate (GB) additional mover cannot be between, said tab of said liquid crystal (LC) said main spacer (MC) is far upper substrate (GT) may be loaded into the disclosed. Said liquid crystal (LC) is than normal injection of residual state, as shown in (c) of Figure 1 said both ends of said upper and said lower substrate (GT) each main spacer (MC) (GB) are supported. Said liquid crystal (LC) between said upper and said lower substrate (GT) filled but (GB), and an amount of injection of said liquid crystal (LC) compared to said upper substrate and said lower substrate (GT) can be an empty area is formed between (GB). Wherein, said liquid crystal cell (SG) carry radiating light in the urging unit (20) to the predetermined pressing force when pressing said liquid crystal cell (SG) (Pp), in said liquid crystal cell (SG) liquid crystal (LC) is driven by said pressing force (Pp) such as a pressed position (P) of said liquid crystal cell (SG) identical in principle to the effect of valves are disclosed. For example, injecting said liquid crystal (LC) in said normal state (P) can be america but according to a pressed position, said in a pressed position (P) (Pa) is selected from within a range error of variation of brightness of light present. Wherein, carry Pa is the urging unit (20) to said liquid crystal cell (SG) when the predetermined pressing force (Pp) pressing, (P) said brightness of light in a pressed position are disclosed. The, pressing said liquid crystal cell (SG) when not, "0" (P) said light brightness of the system is in a pressed position. In other words, liquid crystal (LC) if said normal into the state, as shown in (a) of Figure 2 (P) (Pa) in a pressed position said brightness of light is equal to or small (Ph) selected from maximum value of variation of, (Ps) or larger than the minimum value of variation of selected from such as value by a goniophotometer. However, liquid crystal (LC) exceeds said normal or infusing state, said liquid crystal (LC) less than normal if the injection state, (b) of Figure 2 as shown in (P) (Pa) is a pressed position in said brightness of light (Ps) exhibits minimum of variation of selected from less than value. In addition, liquid crystal (LC) exceeds said normal or infusing state, said liquid crystal (LC) less than normal if the injection state, in a pressed position of Figure 2 (c) (P) (Pa) as shown in the brightness of said light is a value larger than the maximum value of variation of selected from (Ph) by a goniophotometer. As another alternative, said introduction of said liquid crystal (LC) state to an off-normal (P) can be america but according to a pressed position, said common diameter (Da) in a pressed position (P) present in the error range of variation of selected from. Wherein, carry Da is the urging unit (20) to said liquid crystal cell (SG) when pressing the predetermined pressing force (Pp), a pressed position in said common diameter (P) are disclosed. The, said liquid crystal cell (SG) when not pressing, said common diameter is "0" (P) system is in a pressed position. In other words, liquid crystal (LC) if said normal into the state, as shown in (a) of Figure 2 (P) facing said maximum diameter (Da) in a pressed position is equal to or small (Dh) selected from of variation of, such as or larger than the value (Ds) exhibits minimum of variation of selected from However, liquid crystal (LC) exceeds said normal or infusing state, said liquid crystal (LC) less than normal if the injection state, in a pressed position (P) of Figure 2 (b) as shown in said common diameter (Da) (Ps) exhibits a value less than the minimum value of variation of selected from. In addition, liquid crystal (LC) exceeds said normal or infusing state, said liquid crystal (LC) less than normal if the injection state, (b) or (c) of Figure 2 of Figure 2 shown in a pressed position (P) as said common diameter (Da) in the selected from a value larger than the maximum value of variation of (Ph) by a goniophotometer. In a pressed position (P) enumerated above said common state between the brightness light in said pressed position (P), (P) said common area and in a pressed position, said at least one common diameter (P) can exhibit either in a pressed position. The method of the present invention includes a liquid crystal (LC) and one in the embodiment according to introduction of said injecting liquid crystal state inspection device for injecting liquid crystal filter and said pressurizing position (P) and the other in the common state control signal is measured for plural times. In the embodiment of the present invention the liquid crystal injection state inspection device is described first one, using the same of the present invention describe a hole of one in the embodiment according to liquid crystal injecting state inspection method. In the embodiment according to liquid crystal injecting state inspection device of the present invention now is described S. one withdrawals. In the embodiment according to Figure 3 shows a drawing of the present invention injecting liquid crystal state inspection device and a one also shown, one in the embodiment according to the deformation of the device shown in Figure 4 of the present invention injecting liquid crystal filter and embodiments are disclosed. The reference also 1 to 4 also, injecting liquid crystal state inspection device of the present invention includes a liquid crystal cell (SG) one in the embodiment according to said locally pressing the liquid crystal cell (SG) (P) of said according to a pressed position in said liquid crystal (LC) for inspecting state introduction of identical state can be measured. Injecting liquid crystal state inspection device of the present invention is one in the embodiment according to the urging unit (20) and, lighting unit (36) and, a common measurement unit (30) and, inspection unit (40) comprises. Said urging unit (20) is pressed position (P) of said liquid crystal cell (SG) to a prescribed pressing force (Pp) can be pressed against each other. For example, said urging unit (20) by indirect pressurizing, said pressurizing position (P) can be various forms a fluid injection device. As another alternative, said urging unit (20) by direct compressive, a pressed position (P) to said predetermined pressing force (Pp) pressurizing a tip with a pressure device can be of various types. Said urging unit (20) is not continuously press against the pressurizing position said (P), (P) said period of time at a predetermined pressing force (Pp) press against the preferably only to a pressed position. Said urging unit (20) can be used to carry the pressing step (S2) is performing. Said lighting unit (36) is said liquid crystal cell (SG) pressed position (P) all or said light are applied to the substrate. Wherein, said illumination unit (36) defining an anisotropic, said pressurizing position (P) (SG) through various forms can be radiating light to said liquid crystal cell. In addition, said illumination unit (36) defining an anisotropic, said liquid crystal cell (SG) through various forms can be entire radiating light. The, said urging unit (20) is connected to the upper side of said liquid crystal cell (SG), said illumination unit (36) is a lower side of said liquid crystal cell (SG) said urging unit (20) operation of said lighting unit (36) not diffuse to the interference. Said lighting unit (36) can be used to carry an illumination step (S3) is performing. Said common measurement unit (30) is said urging unit (20) and said lighting unit (36) (P) (SG) in a pressurizing position said switch of said light passing through the liquid crystal cell and a common state by using predetermined material. Wherein, said common measurement unit (30) defining an anisotropic, illuminometer, interferometer, such as camera (P) (SG) in a pressed position through various forms said light passing through said liquid crystal cell can be determining the state and a common. Said common measurement unit (30) the lighting unit (36) is said pressurizing position (P) or said liquid crystal cell (SG) in said light throughout the urging unit (20) is pressed position (P) said pressurizing position (P) while being pressed in said said light passing through the liquid crystal cell (SG) preferably a common state measurement. Wherein, said common measurement unit (30) also 3 as shown in the common measuring section (31) on, position adjusting part (32) can be a. Said common measuring section (31) is in a state in which on the upper side of said liquid crystal cell (SG) disposed thereon. Said common measuring section (31) is pressed position (P) to said light passing through the liquid crystal cell (SG) in said common state by using predetermined material. Wherein, said urging unit (20) facing the measuring section (31) on said liquid crystal cell (SG) (P) can be pressed between said press position. And, said common measuring section (31) is illuminometer, interferometer, such as camera (P) (SG) in a pressed position through various forms said light passing through said liquid crystal cell can be determining the state and a common. Said common measuring section (31) is measured (S31) carry identical perform can be used. Said position adjusting part (32) is in said upper side of said liquid crystal cell (SG) in response to said pressurizing position (P) and a common measuring section (31) to move substrate. Said position adjusting part (32) in said upper side of said liquid crystal cell (SG) (P) is a pressed position in response to said urging unit (20) can be moving. Said position adjusting part (32) is not limited herein, said upper side of said liquid crystal cell (SG) through various forms in a pressed position (P) corresponding to said common measuring section (31) on said urging unit (20) can be moving. The, in the embodiment according to of the present invention injecting liquid crystal state inspection device in said liquid crystal cell (SG) is one pressed position (P) for altering said measuring number control unit (35) can be further comprises. Said measuring number control unit (35) is said position adjusting part (32) are operated to said common measuring section (31) on said urging unit (20) by moving the press position corresponding parameters (P), said pressurizing position to a change in said liquid crystal cell (SG) (P) can be disclosed. Said measuring number control unit (35) is said position adjusting part (32) in connection with a scaling step (S5) perform a carry position can be used. As another alternative, said common measurement unit (30) is also 4 as shown in measuring support (34) on, a common measuring section (31) can be a. Measuring said support (34) is spaced apart from said liquid crystal cell (SG) disposed thereon. Said common measuring section (31) which corresponds to the position includes measuring said plurality is pressurized said support (34) is combined with each other. Said common measuring section (31) is pressed position (P) to said light passing through the liquid crystal cell (SG) in said common state by using predetermined material. And, said common measuring section (31) is illuminometer, interferometer, such as camera (P) (SG) in a pressed position through various forms said light passing through said liquid crystal cell can be determining the state and a common. Said common measuring section (31) is measured (S31) carry identical perform can be used. For example, measuring said support (34) corresponding to said plurality of said pressurizing position (P) is a common measuring section (31) and a plurality of on the urging unit (20) can be supported. As another alternative, said measuring support (34) is pressed position (P) corresponding to said said common measuring section (31) on said urging unit (20) either supported multiple, said position adjusting part (32) is said common measuring section (31) on said urging unit (20) with another one can be. The, in the embodiment according to of the present invention injecting liquid crystal state inspection device in said liquid crystal cell (SG) is one pressed position (P) for altering said measuring number control unit (35) can be further comprises. For example, measuring said number control unit (35) is pressed position (P) corresponding to said measuring said support (34) supported on said common measuring section (31) on said urging unit (20) by operating the, said pressurizing position to a change in said liquid crystal cell (SG) (P) can be disclosed. As another alternative, said measuring number control unit (35) is pressed position (P) corresponding to said measuring said support (34) supported on said common measuring section (31) on said urging unit (20) for operating either, said position adjusting part (32) are operated to said common measuring section (31) on said urging unit (20) by moving the corresponding another one of the pressed position (P), said pressurizing position to a change in said liquid crystal cell (SG) (P) can be disclosed. Said measuring number control unit (35) is said position adjusting part (32) in connection with a scaling step (S5) perform a carry position can be used. The, said common measurement unit (30) measuring said light in a pressed position or identical state (P) between the brightness, a pressed position in said common area and (P), (P) said at least one can be a common diameter in a pressed position. Said common measurement unit (30) is a common measurement steps (S31) carry perform can be used. Said inspection unit (40) facing the measuring section (31) compares selected from variation in a common state. Said inspection unit (40) carry (S4) can be used to perform the verify phase. Then, said inspection unit (40) facing the measuring section (31) and a common state in the presence of selected from of variation of signal is applied, said liquid crystal (LC) injection normally S73 that each other. In addition, said inspection unit (40) facing the measuring section (31) and a common state in selected from of variation of error range, said liquid crystal (LC) equipment has an injecting state is, determine substrate. The outer case to the roster lake [...] said liquid crystal cell (SG) stage 10 are disclosed. The, said stage (10) for said liquid crystal cell (SG) is radiating light said illumination unit (36) can be with. Said stage (10) carry (S1) can be used to perform step is disposed. In the embodiment according to liquid crystal injecting state inspection method of the present invention now is described S. one withdrawals. Figure 5 shows a method of the present invention also one in the embodiment according to liquid crystal injecting state inspection surface shown are disclosed. The reference also 1 to 5 also, in the embodiment according to the liquid crystal cell (SG) of the present invention injecting liquid crystal state inspection method in said locally pressing the liquid crystal cell (SG) (P) of said according to a pressed position in said liquid crystal (LC) for inspecting state introduction of identical state can be measured. In the embodiment according to one method of the present invention injecting liquid crystal (S2) on the pressing step for checking status, on illumination step (S3), measured on a common (S31), the verify phase (S4) having a predetermined wavelength. said pressing step (S2) of said liquid crystal cell (SG) is a pressed position (P) to a prescribed pressing force (Pp) can be pressed against each other. said pressing step (S2) is said urging unit (20) according to a pressed position of operation of said liquid crystal cell (SG) (P) (Pp) can be pressed to a prescribed pressing force. Said liquid crystal cell (SG) said illumination step (S3) is a pressed position (P) all or said light are applied to the substrate. Said illumination step (S3) is said illumination unit (36) of said liquid crystal cell (SG) according to a pressed position (P) all or said light are applied to the substrate. Said passivation layer (S2) and (S3) said pressing step (S31) is measured according to a pressed position (P) said illumination step to said liquid crystal cell (SG) capable in said light passing through a common state by using predetermined material. (S31) is facing said measured when said illumination unit (36) according to said operation of said liquid crystal cell (SG) is irradiated with light in the urging unit (20) according to a pressed position (P) of said pressurizes, said common measurement unit (30) (P) (SG) in a pressurizing position said switch of said light passing through the liquid crystal cell can be determining the state and a common. The, said measurement steps (S31) measured via said common or identical state (P) between the brightness light in a pressed position, in said common area and a pressed position (P), (P) said at least one can be a common diameter in a pressed position. (S4) (S31) measured in said common said verify phase is common state compares selected from variation. Said verify phase (S4) is said inspection unit (40) along said common state (S31) in operation of the common measurement steps selected from variation can be compared. In the embodiment according to liquid crystal injecting state inspection method of the present invention further includes a scaling step (S5) one position can be. Said position adjusting step (S5) (P) (SG) changing said liquid crystal cell is in a pressed position said reaction chamber. Said position adjusting step (S5) is said measuring number control unit (35) in accordance with said operation of said liquid crystal cell (SG) can be changing in a pressed position (P). Scaling step (S5) consisting of a plurality of said pressurizing position according to said position (P) (P) can be inspecting state injecting liquid crystal in the other of the pressurizing position. The, said verify phase (S4) is, facing said common state (S31) measured in the presence of selected from of variation of signal is applied, said liquid crystal normally S73 that can be injected. In addition, verify phase (S4) is said, identical common state (S31) measured in said selected from of variation of error range, said suction device state is, equipment can be determined. The, method of the present invention injecting liquid crystal (S42) (S41) or bad step one in the embodiment according to normal step further comprises checking can be. (S41) measured in said step (S4) is normal (S31) facing said verify phase error range of variation of selected from said common state in the presence of in, embodiment as follows. Said introduction of said liquid crystal (LC) step (S41) normal state is normal and disclosed is determined to be a substrate. Wherein, said step (S41) heating is normal via, said via scaling step (S5) and position, the other of the plurality of said pressurizing position to a pressed position (P) (P) be LC injecting assembly state. In addition, a plurality of said pressurizing position (P) via said step (S41) examines both normal heating is, further comprising a replacement step (S43), further includes a step (S1) can be disposed. Said replacement step (S43) (S41) according to said liquid crystal cell (SG) is a normal step said said stage (10) is drained from the and, a new liquid crystal cell (SG) said stage (10) into the reaction chamber. (S43) then said replacing step via, a novel liquid crystal cell (SG) can be inspection method for injecting liquid crystal. Said step (S1) is a novel liquid crystal cell (SG) disposed to said stage (10) toward the home position. (S1) and then said locating the via, a novel liquid crystal cell (SG) can be inspection method for injecting liquid crystal. Said defect in said step (S42) (S4) (S31) verify phase measurement steps in said passivation layer is selected from common state of variation of error range, embodiment as follows. Said injection of said liquid crystal (LC) step (S42) is defective data bit is, determine substrate. Wherein, said step (S42) heating is defective via, said via scaling step (S5) and position, the other of the plurality of said pressurizing position to a pressed position (P) (P) be LC injecting assembly state. In addition, defective step (S42) via said heating is, further comprising a replacement step (S43), further includes a step (S1) can be disposed. Said replacement step (S42) (SG) (S43) is a liquid crystal cell according to said defective said step said stage (10) is drained from the and, a new liquid crystal cell (SG) said stage (10) into the reaction chamber. (S43) then said replacing step via, a novel liquid crystal cell (SG) can be inspection method for injecting liquid crystal. Said step (S1) is a novel liquid crystal cell (SG) disposed to said stage (10) toward the home position. (S1) and then said locating the via, a novel liquid crystal cell (SG) can be inspection method for injecting liquid crystal. In the embodiment according to of the present invention injecting liquid crystal state inspection method and liquid crystal injecting state inspection device other withdrawals now is described substrate. In the embodiment according to Figure 6 shows a device of the present invention injecting liquid crystal state inspection method and also other liquid crystal indicating the time for restoration of the pressed position in injecting liquid crystal state inspection are disclosed. 6 also and also 1 reference surface, said liquid crystal cell (SG) carry radiating light in the urging unit (10) to the predetermined pressing force when pressing said liquid crystal cell (SG) (Pp), in said liquid crystal cell (SG) liquid crystal (LC) is driven by said pressing force (Pp) such as a pressed position (P) of said liquid crystal cell (SG) identical in principle to the effect of valves are disclosed. (SG) is not pressing said liquid crystal cell, liquid crystal (LC) but and keeping said tube, said pressing the liquid crystal cell (SG), said liquid crystal (LC) is moved by a predetermined pressing force (Pp) response (P) and a common change in said cathode to be sludge press position with each other. And, the change of the liquid crystal (LC) in a pressed position (P) facing said restoration of time can exhibit. Wherein, said liquid crystal (LC) said restoration of time is the urging unit (20) in a pressed position (P) and a common time generated by said pressurizing position (P) and a common said number 1 number 2 can be calculated as the difference in time disappear from the field. Not shown but, when said number 1 time to "0", by using the calculated time from said number 2 by said number 1 can be simplified. The, said introduction of said liquid crystal (LC) state to an off-normal (P) can be america but according to a pressed position, said restoration of said liquid crystal (LC) in a pressed position (P) selected from within a range error recovery time time is present. In other words, liquid crystal (LC) if said normal into the state, as shown in graph 6 also shown said number 1 time (t0) is generated and a common filar (ta) common to said number 2 time to disappear from the substrate. Therefore, said restoration of said liquid crystal (LC) in a pressed position (P) is equal to or smaller than a maximum recovery time and time (ta provided t0) selected from, such as or larger than the minimum value selected from the output of the adder by a goniophotometer. However, liquid crystal (LC) exceeds said normal or infusing state, said liquid crystal (LC) if less than is inserted in the normal state, as shown in graph 6 also shown said number 1 time (t0) is generated time common to said number 2 dashed lines (tb) can be common to disappearance. Therefore, said restoration of said liquid crystal (LC) in a pressed position (P) selected from a maximum value selected from the time the output of the adder (tb provided t0) holds the drops below the minimum value is equal to the output of the adder. In addition, as shown in graph is also 6 time (t0) common to said number 1 as shown dashed lines is generated can be disappearance time (tc) common to said number 2. As well as the, said restoration of said liquid crystal (LC) in a pressed position (P) is selected from the output of the adder (tc provided t0) selected from time holds the output of the adder is equal to the maximum value drops below the minimum value. The method of the present invention in the embodiment according to other liquid crystal (LC) is said liquid crystal injection state inspection device for injecting liquid crystal filter and said introduction of said liquid crystal (LC) in a pressed position (P) in accordance with the state of the control signal recovery time is measured for plural times. In the embodiment of the present invention injecting liquid crystal state inspection device is described in other first, using the same of the present invention injecting liquid crystal state inspection method in the embodiment according to other to explain less than 1000. In the embodiment according to liquid crystal injecting state inspection device of the present invention other withdrawals now is described substrate. In the embodiment according to Figure 7 shows a drawing of the present invention injecting liquid crystal state inspection device also shown a other and, in the embodiment according to Figure 8 of the present invention injecting liquid crystal state inspection device shown deformation of the other embodiments are disclosed. The reference 1 and 6 to 8 also may also, in the embodiment according to liquid crystal injecting state inspection device of the present invention includes a liquid crystal cell (SG) said other locally pressing (SG) (P) of said liquid crystal cell according to a pressed position in said liquid crystal (LC) according to said liquid crystal (LC) or identical state by timing the injection of animals can be inspection. In the embodiment according to liquid crystal injecting state inspection device of the present invention includes other urging unit (20) and, lighting unit (36) and, recovery time measurement unit (33) and, inspection unit (40) comprises. A pressed position (P) of said liquid crystal cell (SG) to a prescribed pressing force (Pp) can be pressed against each other. For example, said urging unit (20) by indirect pressurizing, said pressurizing position (P) can be various forms a fluid injection device. As another alternative, said urging unit (20) by direct compressive, a pressed position (P) to said predetermined pressing force (Pp) pressurizing a tip with a pressure device can be of various types. Said urging unit (20) is not continuously press against the pressurizing position said (P), (P) said period of time at a predetermined pressing force (Pp) press against the preferably only to a pressed position. Said urging unit (20) can be used to carry the pressing step (S2) is performing. Said lighting unit (36) is said liquid crystal cell (SG) pressed position (P) all or said light are applied to the substrate. Wherein, said illumination unit (36) defining an anisotropic, said pressurizing position (P) (SG) through various forms can be radiating light to said liquid crystal cell. In addition, said illumination unit (36) defining an anisotropic, said liquid crystal cell (SG) through various forms can be entire radiating light. The, said urging unit (20) is connected to the upper side of said liquid crystal cell (SG), said illumination unit (36) is a lower side of said liquid crystal cell (SG) said urging unit (20) operation of said lighting unit (36) not diffuse to the interference. Said lighting unit (36) can be used to carry an illumination step (S3) is performing. Said recovery time measurement unit (33) is said urging unit (20) and said lighting unit (36) the switch of said liquid crystal cell (SG) facing said light passing through said liquid crystal (LC) in animals using a pressed position (P) and measuring the time for substrate. Said liquid crystal (LC) said restoration of time is the urging unit (20) in a pressed position (P) and a common time generated by said pressurizing position (P) and a common said number 1 number 2 can be calculated as the difference in time disappear from the field. Not shown but, when said number 1 time to "0", by using the calculated time from said number 2 by said number 1 can be simplified. Said recovery time measurement unit (33) for performing the measurement steps can be used to carry recovery time (S32). Said inspection unit (40) is said recovery time measurement unit (33) compares selected from recovery time in recovery time. Said inspection unit (40) carry (S4) can be used to perform the verify phase. Then, said inspection unit (40) is said recovery time measurement unit (33) in the output of the adder when the predetermined recovery time reference signal is applied, said liquid crystal (LC) injection normally S73 that each other. In addition, said inspection unit (40) is said recovery time measurement unit (33) in the predetermined recovery time reference recovery time error range, said liquid crystal (LC) equipment has an injecting state is, determine substrate. The outer case to the roster lake [...] said liquid crystal cell (SG) stage 10 are disclosed. The, said stage (10) for said liquid crystal cell (SG) is radiating light said illumination unit (36) can be with. Said stage (10) carry (S1) can be used to perform step is disposed. In the embodiment according to liquid crystal injecting state inspection device of the present invention is another common measurement unit (30) further comprises, measuring number control unit (35) can be further comprises. In the embodiment according to liquid crystal injecting state inspection device of the present invention other in said common measurement unit (30) and said measuring number control unit (35) of the present invention injecting liquid crystal state inspection device and the control gate is in the embodiment according to one and the same drawing code also 7 through 8 also impart configuration, a description is given of a dispensed to each other. In the embodiment according to liquid crystal injecting state inspection method of the present invention other withdrawals now is described substrate. Figure 9 shows a method of the present invention are shown in the embodiment according to reflection type liquid crystal filter and other surface also are disclosed. The reference 1 and 6 to 9 also may also, in the embodiment according to the liquid crystal cell of the present invention injecting liquid crystal state inspection method (SG) said other locally pressing (SG) (P) of said liquid crystal cell according to a pressed position in said liquid crystal (LC) according to said liquid crystal (LC) or identical state by timing the injection of animals can be inspection. In the embodiment according to the method of the present invention injecting liquid crystal on the pressing step (S2) other checking, on illumination step (S3), recovery time measured on (S32), the verify phase (S4) having a predetermined wavelength. said pressing step (S2) of said liquid crystal cell (SG) is a pressed position (P) to a prescribed pressing force (Pp) can be pressed against each other. said pressing step (S2) is said urging unit (20) according to a pressed position of operation of said liquid crystal cell (SG) (P) (Pp) can be pressed to a prescribed pressing force. Said liquid crystal cell (SG) said illumination step (S3) is a pressed position (P) all or said light are applied to the substrate. Said illumination step (S3) is said illumination unit (36) of said liquid crystal cell (SG) according to a pressed position (P) all or said light are applied to the substrate. Said recovery time (S2) (S32) is measured when said pressing step (S3) consisting of a liquid crystal cell (SG) according to said illumination step on said light passing through the liquid crystal (LC) in a pressed position using said restoration of said facing (P) and measuring the time for substrate. (S32) said recovery time is measured when said recovery time measurement unit (33) in said liquid crystal (LC) switch of said pressurizing position and measuring the time for restoration of (P) can be. (S32) measured when said recovery time) in recovery time is said urging unit (20) in a pressed position (P) and a common time generated by said pressurizing position (P) and a common said number 1 number 2 can be calculated as the difference in time disappear from the field. Not shown but, when said number 1 time to "0", by using the calculated time from said number 2 by said number 1 can be simplified. (S4) said recovery time (S32) measured in said verify phase is selected from recovery time restoring time compares. Said verify phase (S4) is said inspection unit (40) along said recovery time (S32) measured in restoring operation of the compares a time can be selected from recovery. In the embodiment according to liquid crystal injecting state inspection method of the present invention further includes a scaling step (S5) other position can be. Said position adjusting step (S5) (P) (SG) changing said liquid crystal cell is in a pressed position said reaction chamber. Said position adjusting step (S5) is said measuring number control unit (35) in accordance with said operation of said liquid crystal cell (SG) can be changing in a pressed position (P). Scaling step (S5) consisting of a plurality of said pressurizing position according to said position (P) (P) can be inspecting state injecting liquid crystal in the other of the pressurizing position. The, said verify phase (S4) is, measured in recovery time (S32) selected from said recovery time when the output of the adder signal is applied, said liquid crystal (LC) S73 that normally can be injected. In addition, verify phase is said (S4), said recovery time (S32) measured in the predetermined recovery time reference recovery time error range, said liquid crystal (LC) can be determine is, implantation of the second frame. The, method of the present invention injecting liquid crystal (S42) (S41) or bad step one in the embodiment according to normal step further comprises checking can be. Said normal step (S41) (S4) (S32) in said recovery time is measured in said verify phase reference signal is applied to the predetermined recovery time when the output of the adder, embodiment as follows. Said introduction of said liquid crystal (LC) step (S41) normal state is normal and disclosed is determined to be a substrate. Wherein, said step (S41) heating is normal via, said via scaling step (S5) and position, the other of the plurality of said pressurizing position to a pressed position (P) (P) be LC injecting assembly state. In addition, a plurality of said pressurizing position (P) via said step (S41) examines both normal heating is, further comprising a replacement step (S43), further includes a step (S1) can be disposed. Said replacement step (S43) (S41) according to said liquid crystal cell (SG) is a normal step said said stage (10) is drained from the and, a new liquid crystal cell (SG) said stage (10) into the reaction chamber. (S43) then said replacing step via, a novel liquid crystal cell (SG) can be inspection method for injecting liquid crystal. Said step (S1) is a novel liquid crystal cell (SG) disposed to said stage (10) toward the home position. (S1) and then said locating the via, a novel liquid crystal cell (SG) can be inspection method for injecting liquid crystal. Said defect in said step (S42) (S4) said recovery time (S32) verify phase is measured in the predetermined recovery time reference recovery time error range, embodiment as follows. Said injection of said liquid crystal (LC) step (S42) is defective data bit is, determine substrate. Wherein, said step (S42) heating is defective via, said via scaling step (S5) and position, the other of the plurality of said pressurizing position to a pressed position (P) (P) be LC injecting assembly state. In addition, defective step (S42) via said heating is, further comprising a replacement step (S43), further includes a step (S1) can be disposed. Said replacement step (S42) (SG) (S43) is a liquid crystal cell according to said defective said step said stage (10) is drained from the and, a new liquid crystal cell (SG) said stage (10) into the reaction chamber. (S43) then said replacing step via, a novel liquid crystal cell (SG) can be inspection method for injecting liquid crystal. Said step (S1) is a novel liquid crystal cell (SG) disposed to said stage (10) toward the home position. (S1) and then said locating the via, a novel liquid crystal cell (SG) can be inspection method for injecting liquid crystal. In the embodiment according to liquid crystal injecting state inspection method of the present invention analyzer further comprises other can be measured (S31). Said passivation layer (S2) and (S3) said pressing step (S31) is measured according to a pressed position (P) said illumination step to said liquid crystal cell (SG) capable in said light passing through a common state by using predetermined material. (S31) is facing said measured when said illumination unit (36) according to said operation of said liquid crystal cell (SG) is irradiated with light in the urging unit (20) according to a pressed position (P) of said pressurizes, said common measurement unit (30) (P) (SG) in a pressurizing position said switch of said light passing through the liquid crystal cell can be determining the state and a common. The, said measurement steps (S31) measured via said common or identical state (P) between the brightness light in a pressed position, in said common area and a pressed position (P), (P) said at least one can be a common diameter in a pressed position. According to above-mentioned liquid crystal injection state inspection device for injecting liquid crystal in state inspection method, said liquid crystal (LC) between said upper and said lower substrate (GT) (GB) into which said liquid crystal cell is irradiated with light (SG), said liquid crystal cell (SG) is irradiated with light to said liquid crystal cell (SG) in locally pressing the liquid crystal cell (SG) (P) of said according to a pressed position in said liquid crystal (LC) using identical to be injecting assembly state. In addition, pressurizing position to said liquid crystal cell (SG) (P) (P) of said liquid crystal (LC) in a pressed position or said changed while the radiation is said common measuring and restoration of, said liquid crystal cell (SG) of said liquid crystal (LC) against the entire surface of an injection state can be. In addition, by means of said liquid crystal cell (SG) and a common liquid crystal (LC) by measuring time or restoration of said guide grooves, said liquid crystal cell (SG) even if the surface of the liquid crystal (LC) as well as when it is flat form curved form can be said of an injection state. In particular, the passivation layer or said liquid crystal (LC) said liquid crystal cell (SG) of flat form to simplify the restoration of time measurement, said liquid crystal (LC) can be collected from the inspection of infusing state. As described above with reference to the drawing of the present invention preferred embodiment but, if corresponding splicing one skilled in the art, to the present invention within a range that the idea of the present invention fee so as to range from a heavy and area from a tube capable of correcting or changing. GT: upper substrate GB: lower substrate LC: liquid crystal MC: main spacer SC: sub spacer SG: liquid crystal cell S1: locating the S2: the pressing step S21: number by pressing step S3: an illumination step S31: common measurement steps S32: measured recovery time S4: S41 the verify phase: normal step S42: defect step S43: replacement step S5: position adjusting step 10: stage 20: the urging unit 30: common measurement unit 31: and a common measuring section 32: position adjusting part 33: recovery time measurement unit 34: measuring support 35: measuring number control unit 36: lighting unit 40: inspection unit PROBLEM TO BE SOLVED: To provide an inspection method for a liquid crystal injection state and an inspection apparatus for liquid crystal injection state, by which an injection state of a liquid crystal can be inspected by use of a light leakage phenomenon induced in a liquid crystal cell by irradiating the liquid crystal cell having a liquid crystal injected into between an upper substrate and a lower substrate, with light and locally pressurizing the liquid crystal cell while the liquid crystal cell is irradiated with light.SOLUTION: The inspection method for a liquid crystal injection state aims to inspect an injection state of a liquid crystal in a liquid crystal cell having a liquid crystal injected into between an upper substrate and a lower substrate, and the method includes: a pressurization step of applying a predetermined pressure to a pressurizing position of the liquid crystal cell; an illumination step of irradiating the entire liquid crystal cell or the pressurizing position with light; a light leakage measurement step of measuring a light leakage state by the light passing through the liquid crystal cell at the pressurizing position after the pressurization step and the illumination step; and an inspection step of comparing a measurement value of the light leakage state in the light leakage measurement step to a predetermined reference change amount.SELECTED DRAWING: Figure 5 Back number Back number Back number Lower substrate a black matrix in a liquid crystal cell and said suction device for inspecting state liquid crystal injecting state inspection method, said liquid crystal cell to a prescribed pressing force pushes the pressing step a pressed position; said light to said liquid crystal cell is provided with a pressed position illumination step; said pressing step and said facing said light passing through the liquid crystal cell according to the illumination level capable using said measured recovery time in measuring the time said liquid crystal restoration of a pressed position; and said recovery time in recovery time measured when comparing the verify phase selected from recovery time; including a characterized with input state inspection method. According to Claim 4, said ping test, said recovery time in recovery time measurement steps selected from the output of the adder when signal is applied, said liquid crystal normally injection and a related device, said recovery time in recovery time measurement steps selected from the output of the adder error range, said suction device the second frame determining is, characterized with input state inspection method. According to Claim 4, said recovery time in recovery time is measured, said pressurizing position to said pressurizing position number 1 generated by the pressing step in said common time difference calculated as number 2 characterized in time disappear from the field of a common with input state inspection method. According to Claim 4, said pressing step and said pressurizing position said light passing through the liquid crystal cell according to said illumination step in determining the state and a common or identical measurement steps; characterized in further including with input state inspection method. According to one of Claim 4 to Claim 7, said liquid crystal cell on which the pressing said positioning step; characterized in further including with input state inspection method. Back number Back number Back number Lower substrate a black matrix in a liquid crystal cell and said suction device for inspecting state liquid crystal injecting state inspection device, said liquid crystal cell to a prescribed pressing force pressed position pressing unit; said liquid crystal cell all or a pressed position said radiating light comprises an illumination unit; said urging unit and said operation of said lighting unit using light passing through the liquid crystal cell according to a pressed position facing said liquid crystal in said recovery time measurement unit for measuring recovery time; and said recovery time measurement unit in recovery time restoring compares selected from inspection unit; characterized in including a with input state inspection device. According to Claim 12, said test units, said recovery time measurement unit in the presence of the output of the adder to the predetermined recovery time reference signal is applied, said liquid crystal normally injection and a related device, said recovery time measurement unit in the predetermined recovery time reference recovery time error range, said suction device the second frame determining is, characterized with input state inspection device. According to Claim 12, said recovery time measurement unit in recovery time is, in a pressed position by said urging unit said generated number 1 number 2 in said common time difference time calculated as a pressed position disappear from the field of a common characterized with input state inspection device. According to Claim 12, said urging unit and said pressurizing position said light passing through the liquid crystal cell along a common illumination unit in said determining the state or identical measurement unit; characterized in further including with input state inspection device. According to one of Claim 12 to Claim 15, said pressurizing position measuring for altering said liquid crystal cell number control unit; characterized in further including with input state inspection device.