램 교체장치 및 교체방법

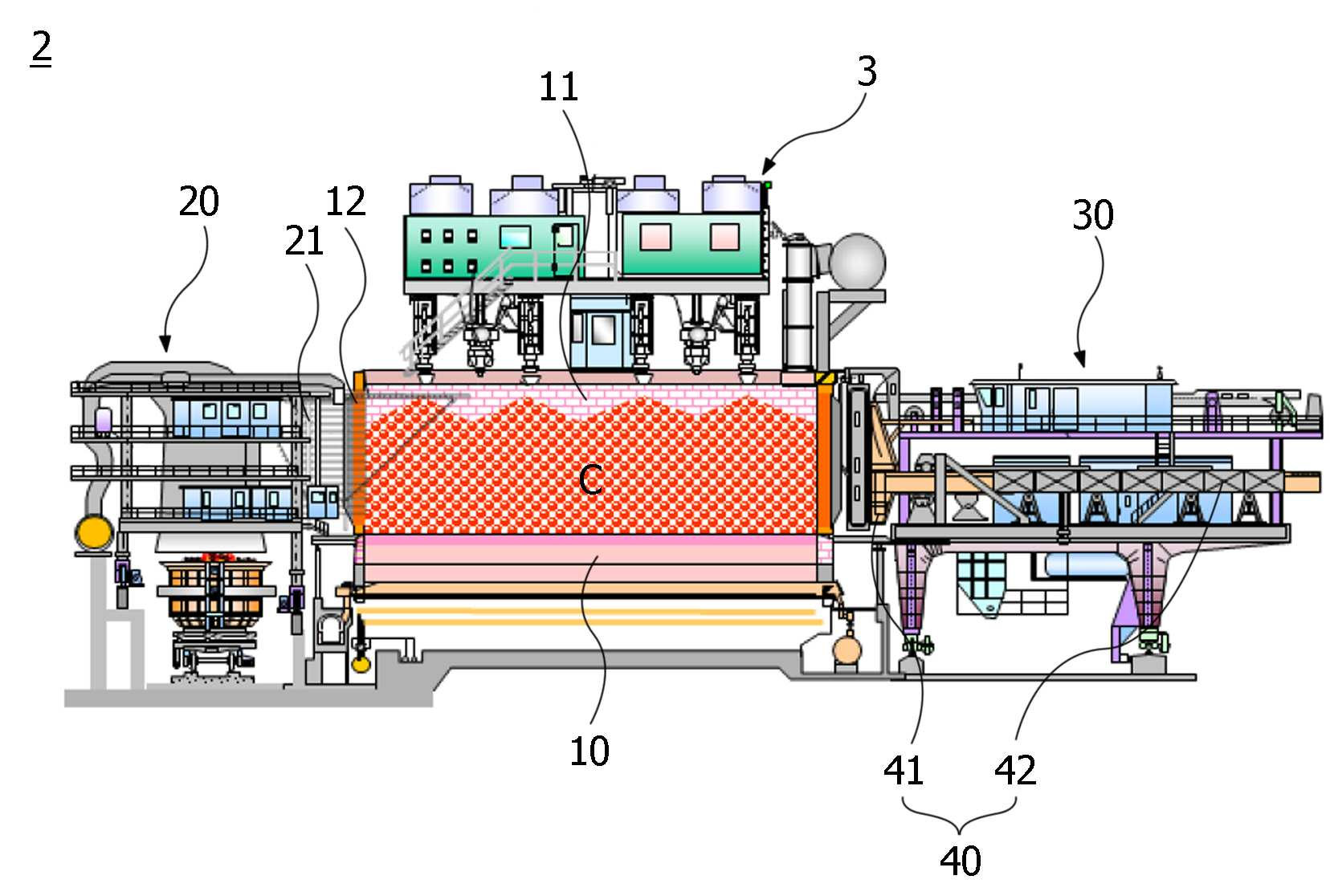

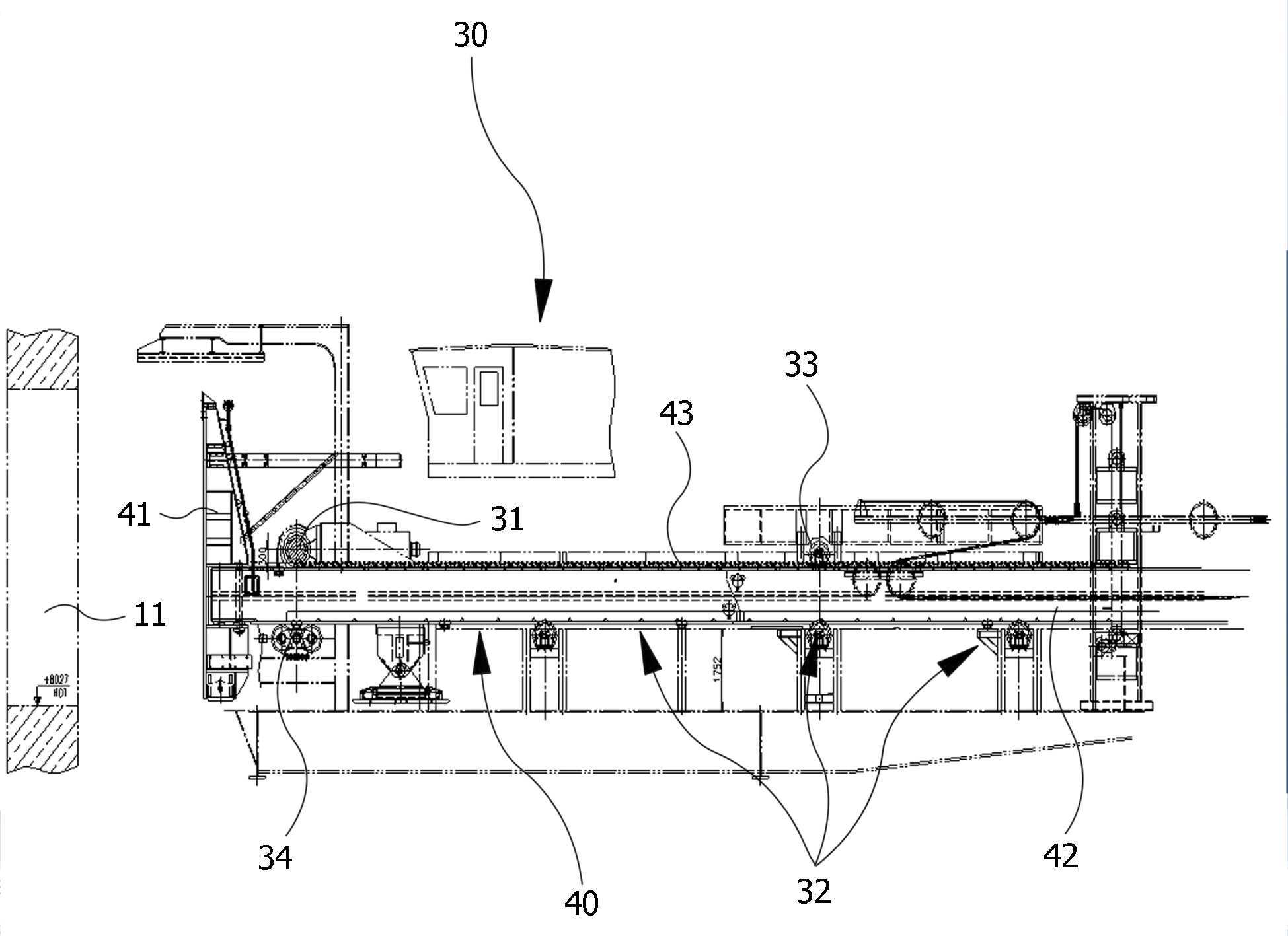

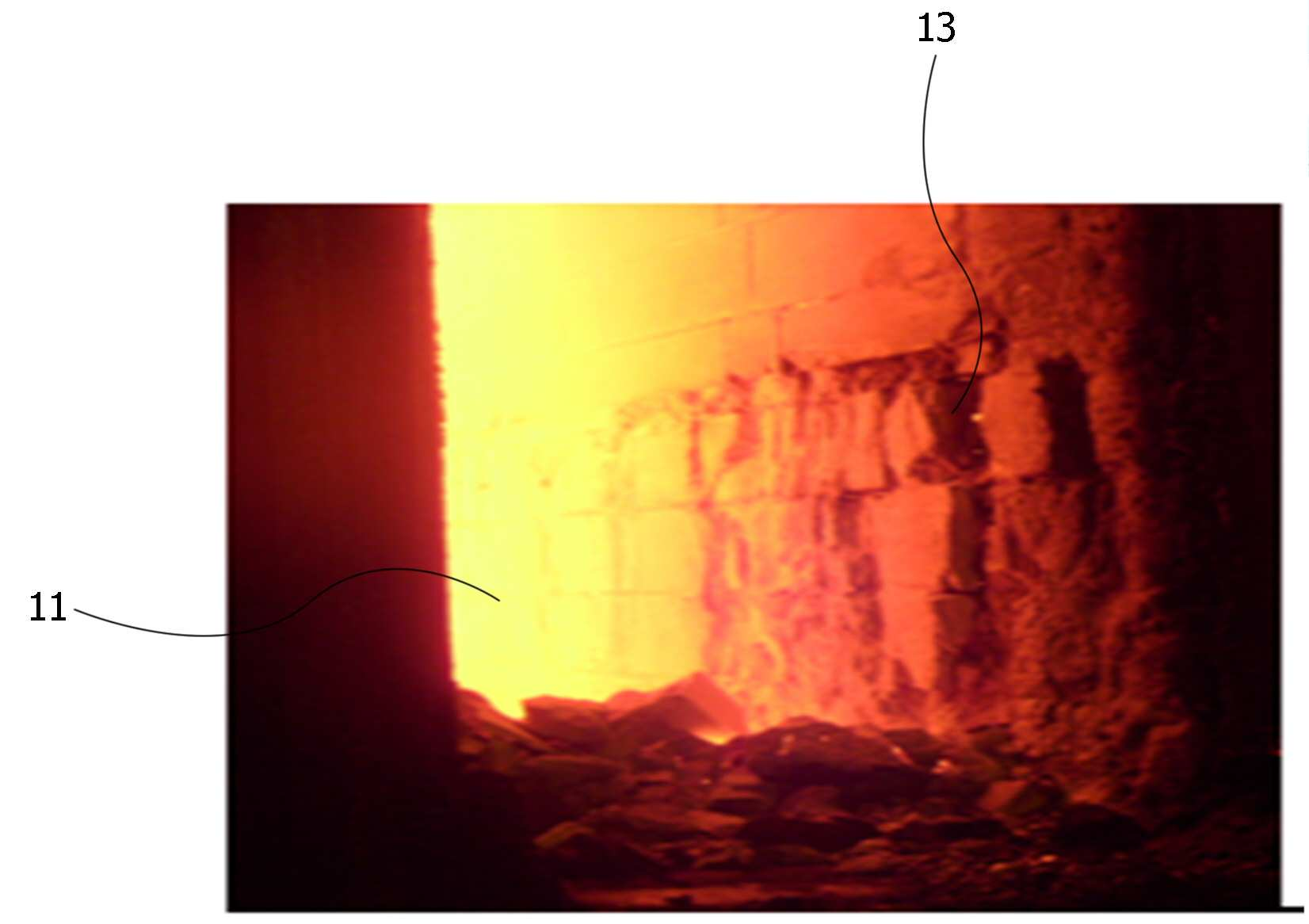

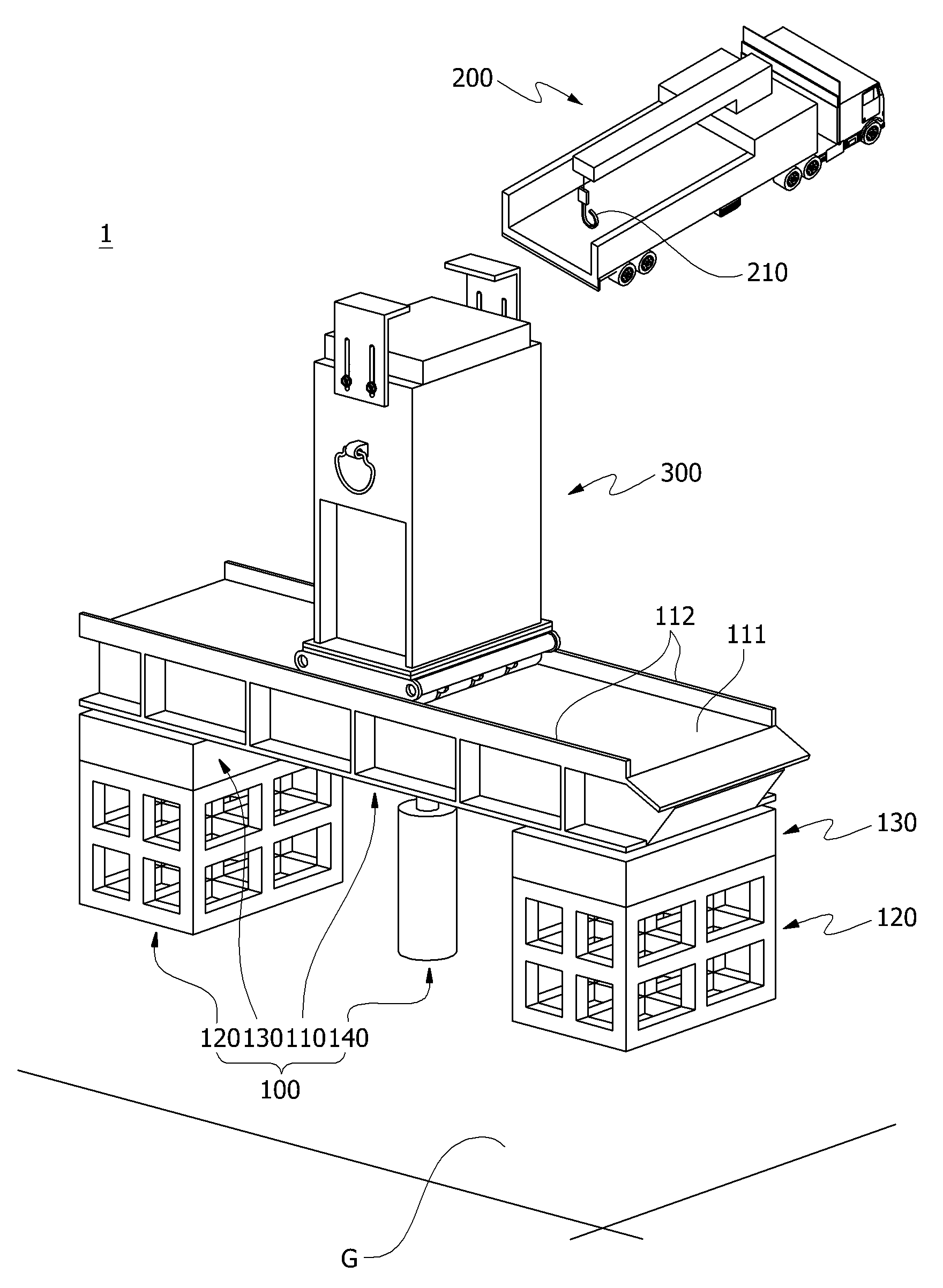

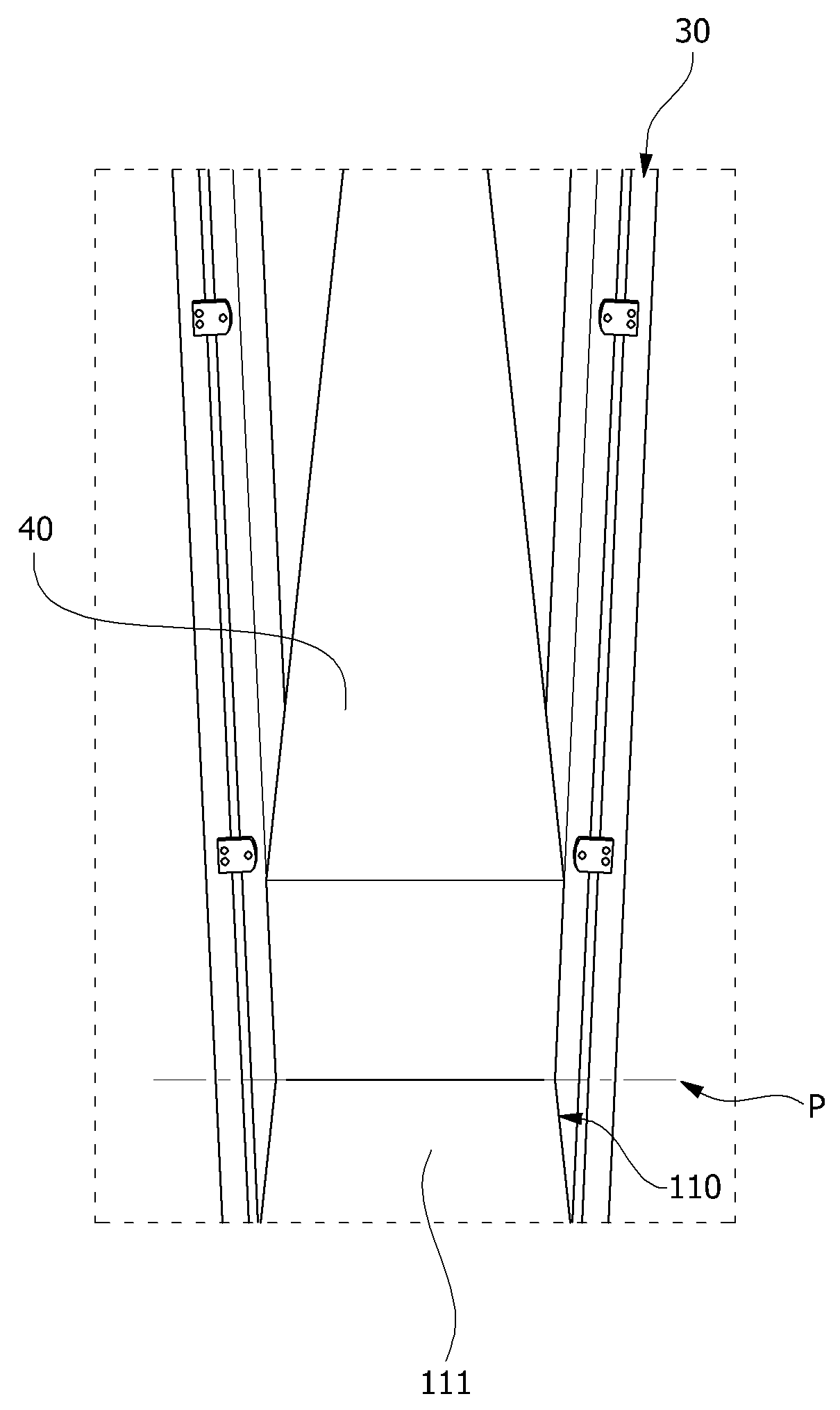

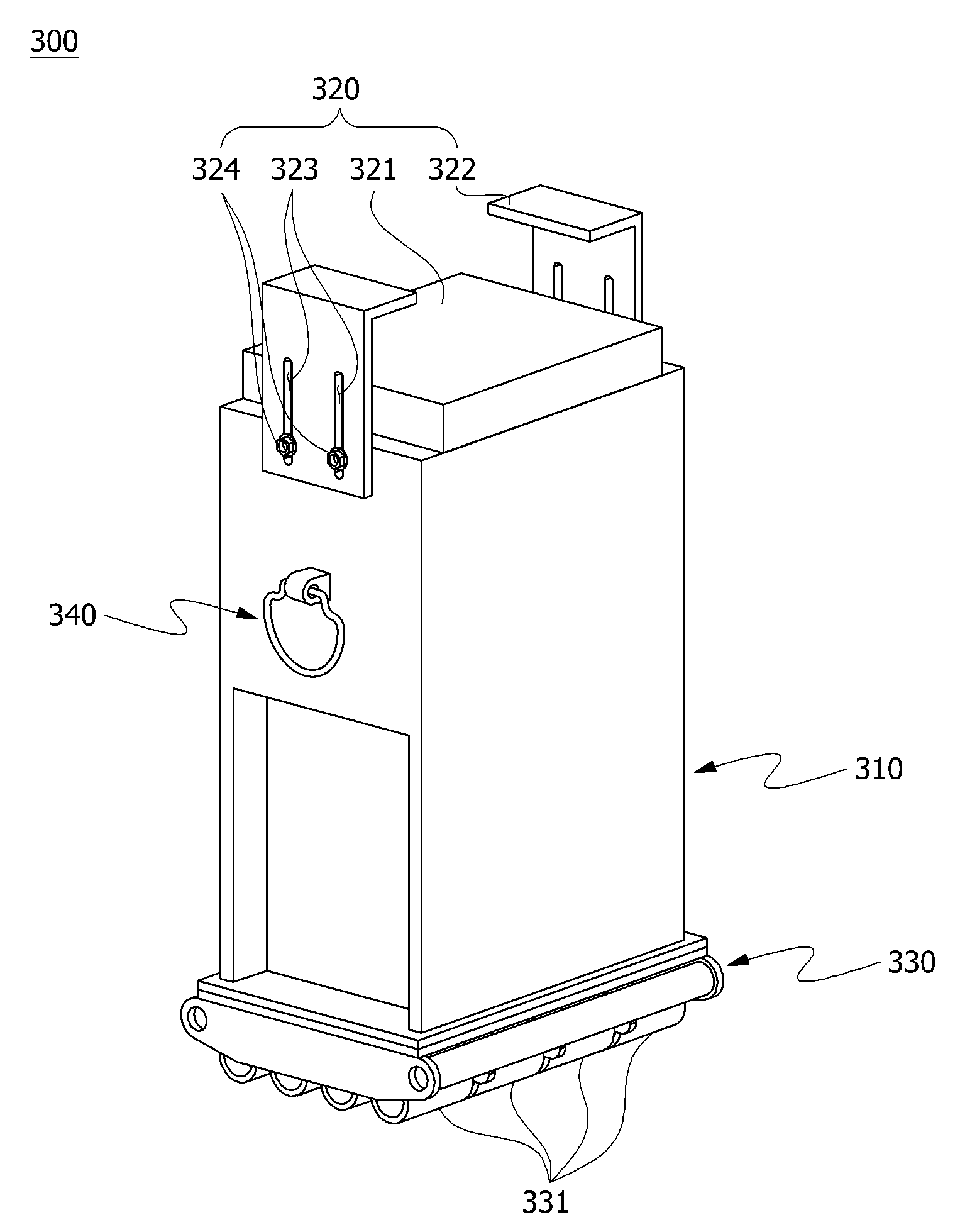

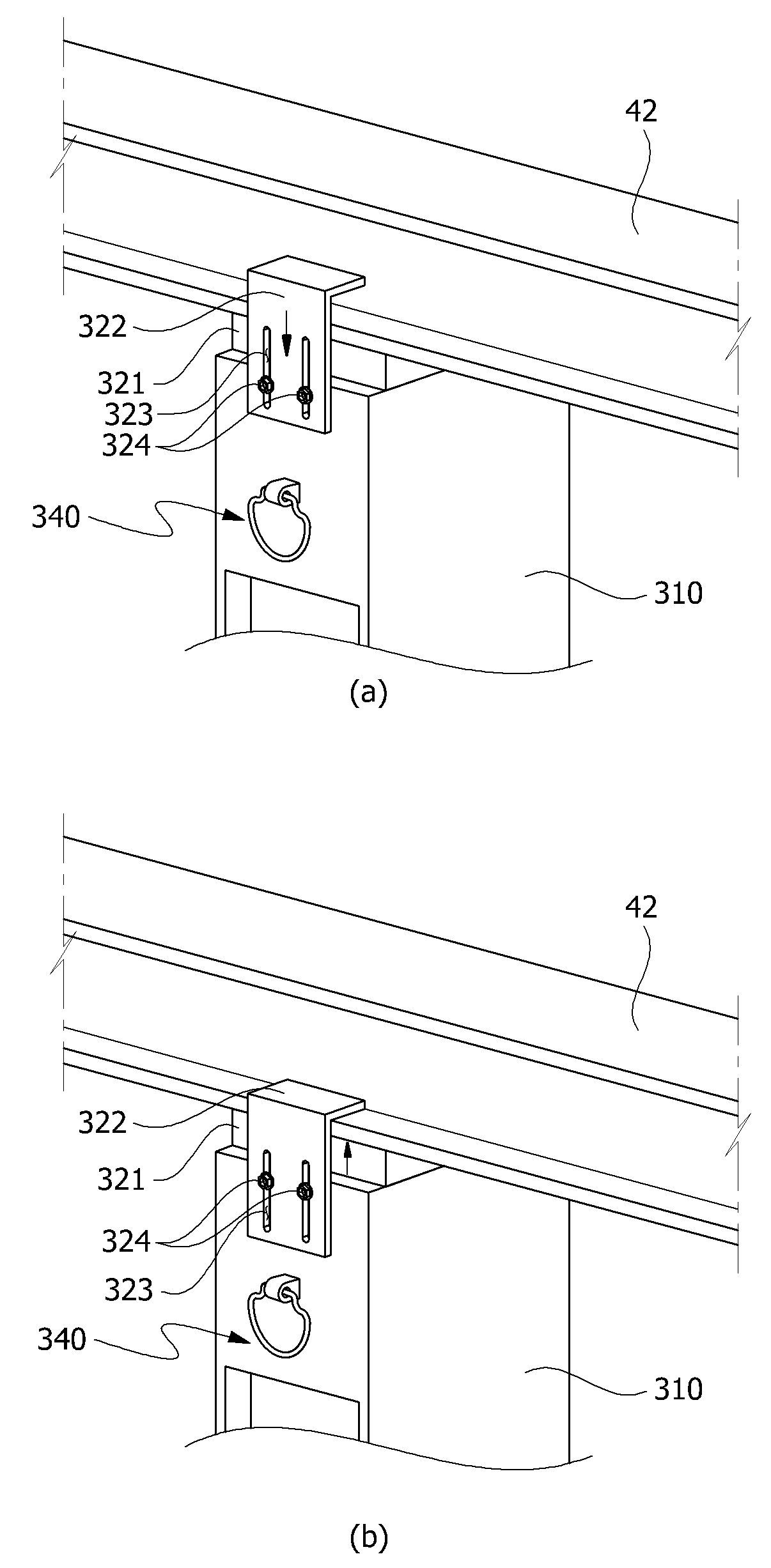

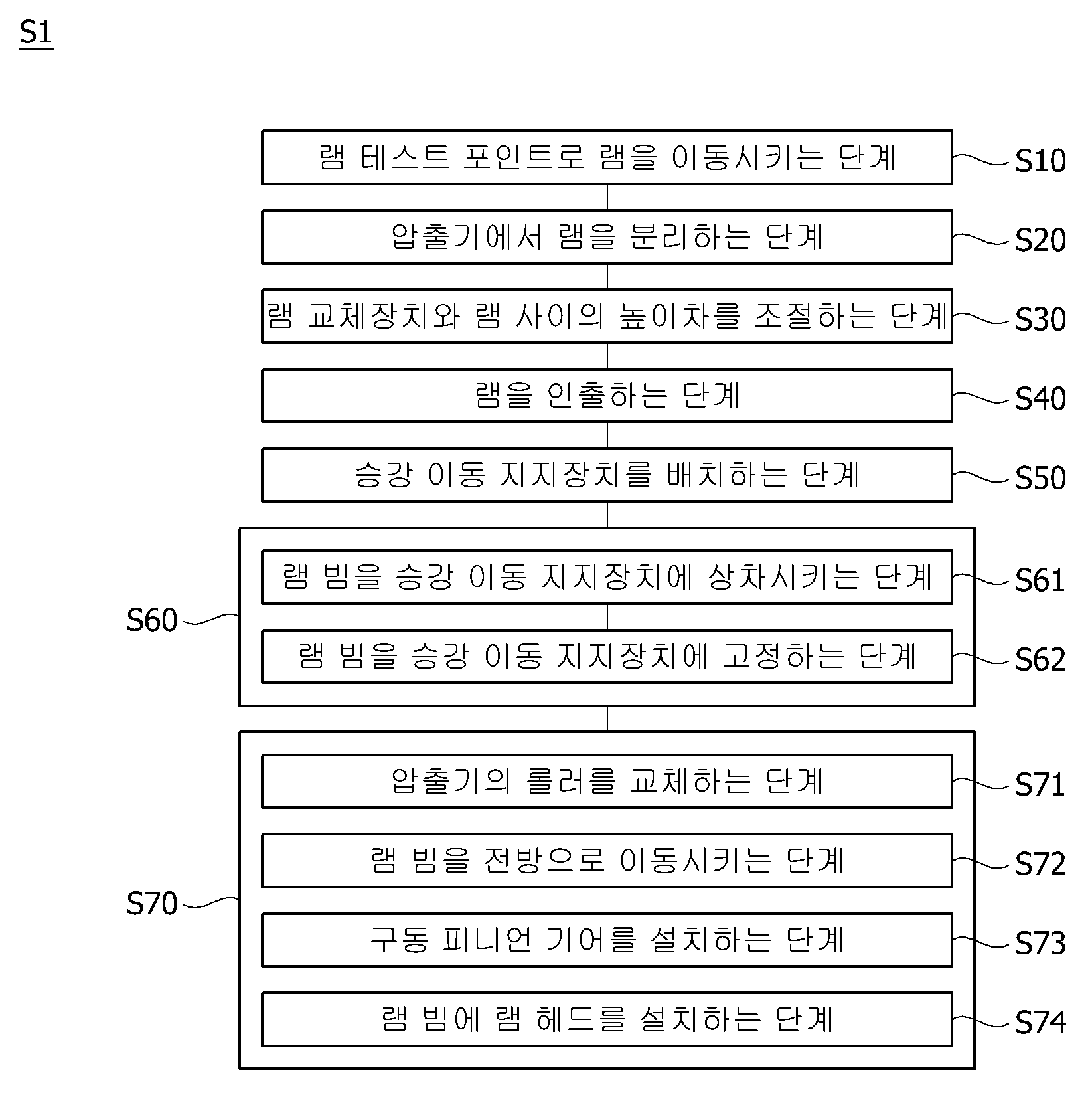

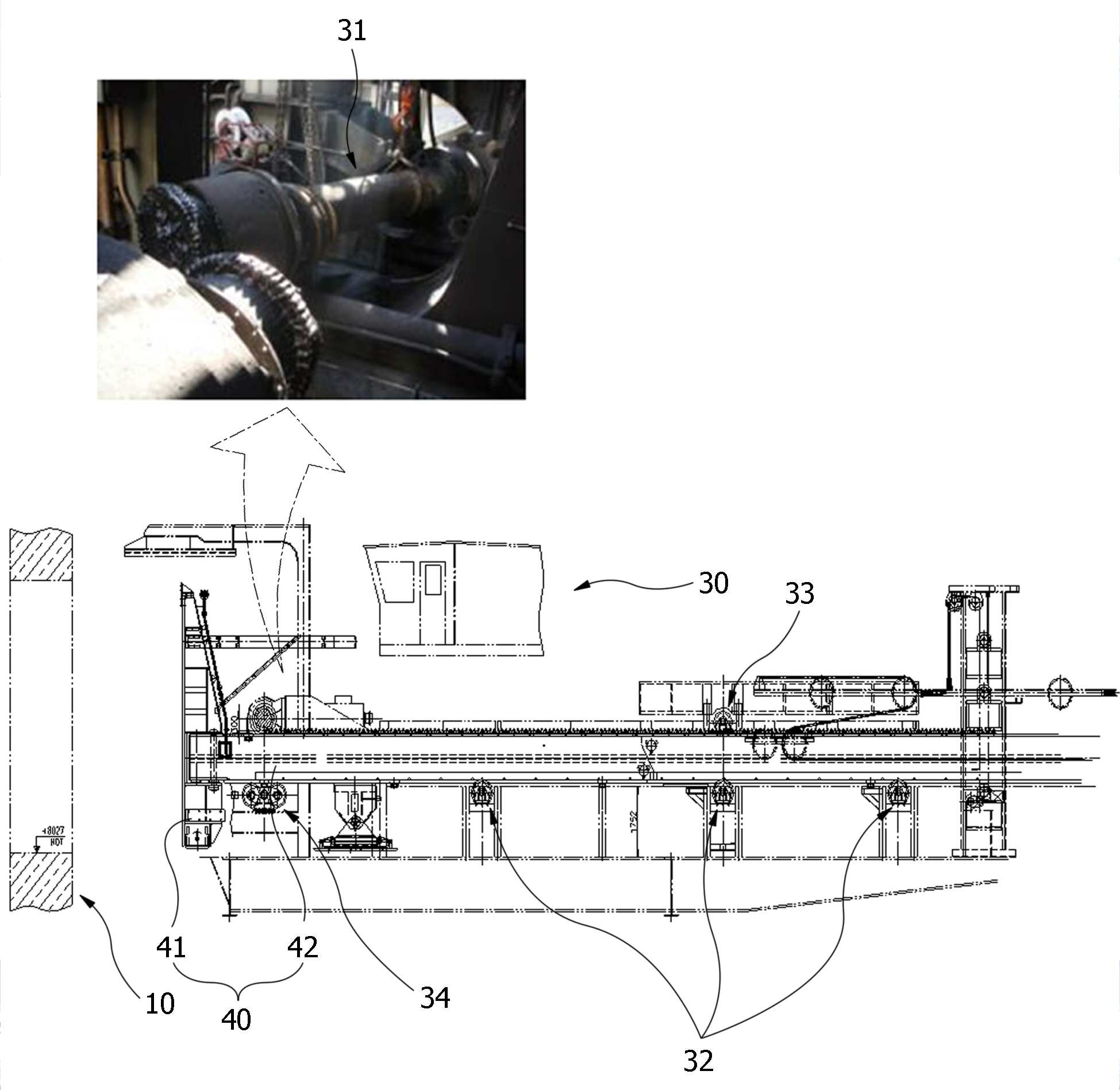

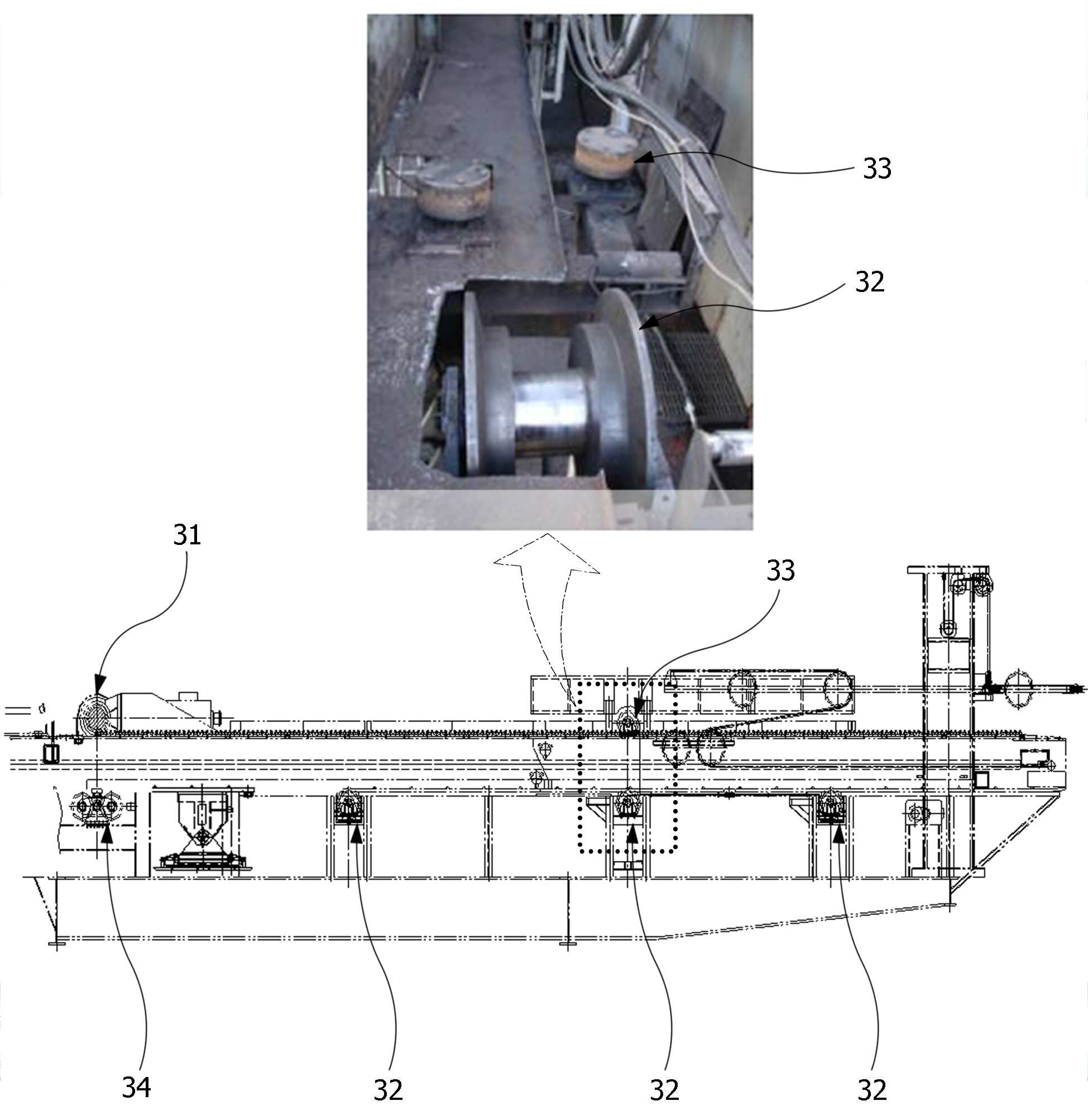

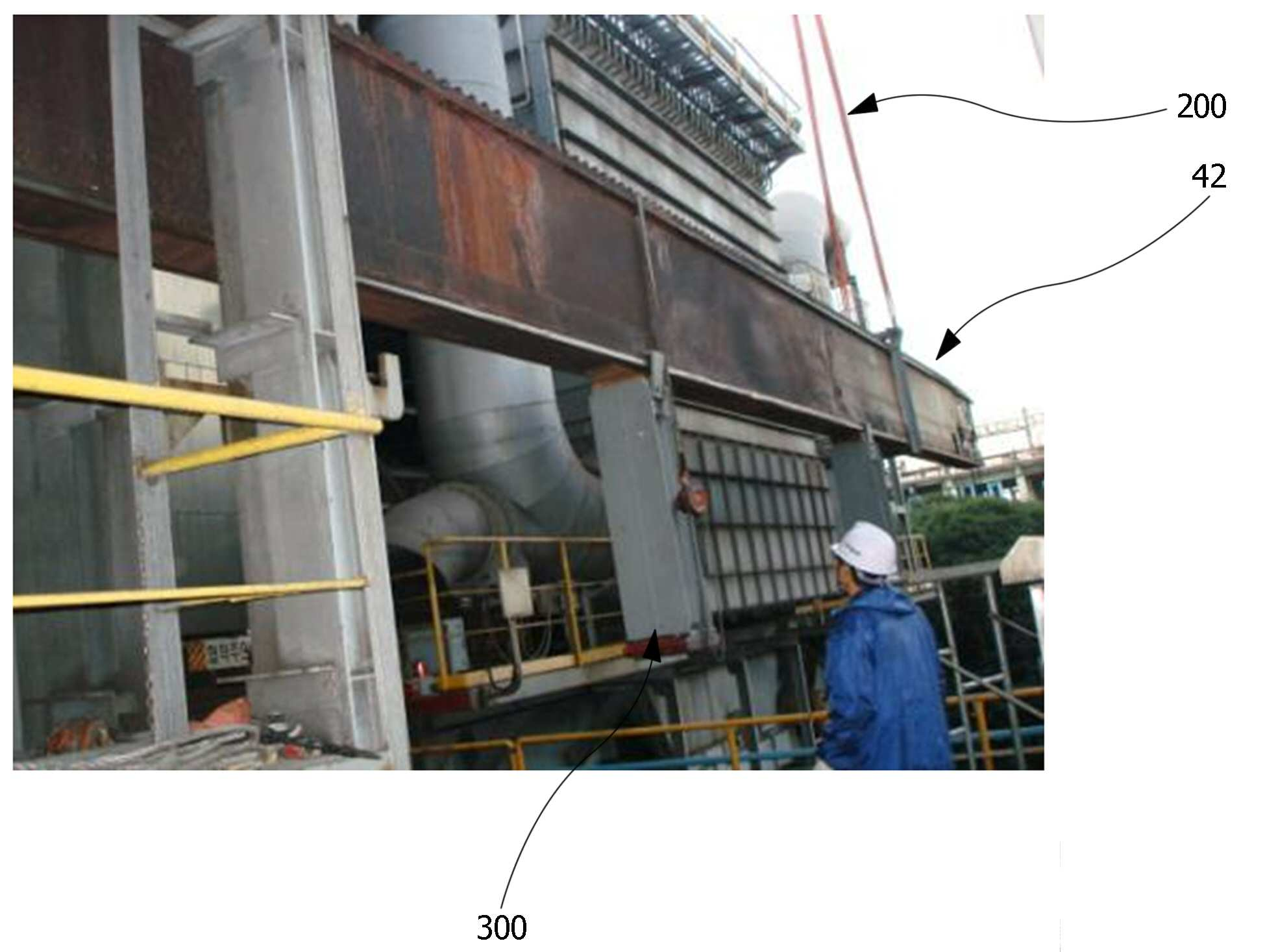

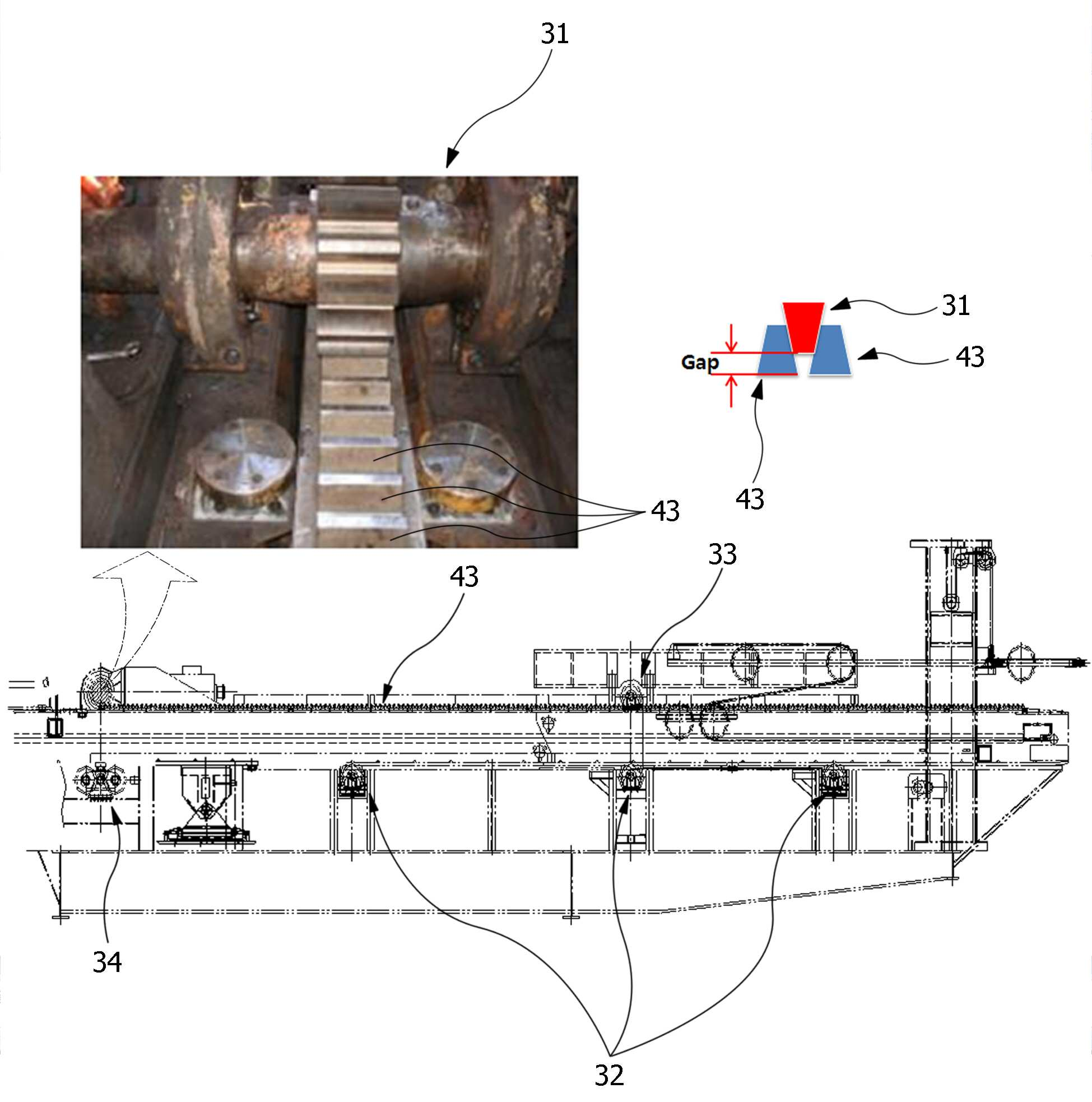

The present invention refers to ram replacement device and replace the method are disclosed. More specifically, ram life coke oven facility judges on the ram to generate a pull-out of the device and replace the method hereinafter for and insertion of ram ram replacement are disclosed. A plurality of coal charged into a coke oven equipment generally and has a carbonization chamber, within about 18 hours of 1,250 °C heat to the carbonization chamber for producing coke centering apparatus 2000. In such coke number bath process, each upper charge hole it burnt, this carbonization chamber fuel fed to hydrocarbon chamber, beverage container have been completed by coke oven coke of the hook open through a region after the processing position (coke the casting section) are transferred extinguishing difference. With reference to 1 also residual, coke and apparatus for coke oven equipment (2) includes a charge (3) by using coal coke oven (10) of a carbonization chamber (11) and introduced into a, to a vacuum state from coking process is overlaid and spraying are disclosed. Coking process is complete, trans [...] coke guide (Coke guide, 21) (Transfer Car, 20) is a carbonization chamber (11) side is adhered, is smoothly transitions into a coke quenching car side (C) extrusion to a substrate. For example, trans [...] (20) is a carbonization chamber (11) at an entrance of a coke oven door (12) [...] is in cock guide (21) by advance, a carbonization chamber (11) in (C) extinguishing difference is made can be derived coke american compression passage therein. And, extruder (30) ram (40) for extrusion and coke (C) using american compression embodiment, trans [...] (20) of cock guide (21) through (C) is fire-extinguishing difference between coke can be derived. Also 1 and 2 also refers to the extruder (30) and an extruder (30) installed ram (40) a user opens a, motor (Motor) is accordance with the rotation of the pinion gear is installed at one side driving (Pinion Gear, 31), said driving pinion gear (31) ram physically (40) of rack gear is moved (Rack Gear, 43), thereof in an extruder (30) installed ram (40) is injected, backward operation to be coated. The, ram (40) is a carbonization chamber (11) is used for beverage container to a coke carbonization chamber (11) can expel other. However, ram (40) for cooling a piston anchor bolt collapsed at distortion state in the coke during the extrusion, as shown in also 3, modified ram (40) formed by refractory carbonization chamber (11) method of wall damage (e.g.: electromagnets (13), hydraulic) the door number is generated. Thus, a carbonization chamber (11) for tire production filled up or decreased power line operation results with each other. The technical objectives of this invention is to solve said door number point provided, ram life judges on the ram to generate a pull-out of the device and method hereinafter for and insertion of a replacement ram ram ram replacement number [...] substrate. The present invention mentioned above is the number if the number is not limited and not referred to and wherein another and number are below may be unambiguously understand one skilled from the substrate are disclosed. In the embodiment of the present invention is according to one preferred said number and, in replacement device for replacing ram extruder ram, said ram to move a mobile device; and said mobile device to said ram moves up and down by a support part wherein, with said support to adjust said height difference to be lifted ram replacement device is achieved by ram. Said support portions, said support when moving said ram ram and a plate-like support; support; and a plate-shaped support portion disposed between said up and down while the support, said support plate to said lifting cylinder can be lifting and lowering. Said ram is movable along a longitudinal direction of a plate-shaped support said replacement device up and down further comprises mobile support device can be installed. Lifting said mobile support device is fixed to said upper ram, body; said ram body fixed to the fixing portion disposed on a top of said ram; mobile part wherein, said mobile portion said body can be detachably fitted. And, the fixing portion is said ram, said body movably arranged vertically up and down plate; and said ram which fixed on one side of the lug, said lug the fixing of the one side of said ram raising said lifting plate fixedly ram can. Wherein, said lugs having a plate have can be. And, the air guided through said lug is formed as a vertically one side of said engaging further comprises fixing member can be. On the other hand, lifting said mobile support device further comprises said body it will grow cheap is outward to the can. In the embodiment of the present invention is according to one preferred number and said, ram extrusion using replacement device equipped in the ram in replacement method that replaces the ram, ram test point moving said ram; the step of separating said ram from said extruder; adjusting said height difference on said ram ram replacement device; subsequently withdrawing said ram; placing the mobile support lifting device; replace ram people on top of said mobile support lifting device; said ram portion and including a ram extruder is achieved by providing a replacement method. Wherein, mounted on top of said mobile support device includes lifting the replacement of a ram, said ram to said mobile support device and said beam in said pilot poppet lifting ram beam securing the lifting ram can be mobile support device. In addition, the ram is then said extruder, said extruder roller the replacement processor; front tape through said ram beam; providing a driving pinion gear; and said ram beam the plunger head can be provided. Wherein, said ply roller, thrust roller and pivot roller can be at least any one of. And, said driving pinion engaging said driving pinion elastically installed in the step provided ram beam hinge, said hinge of said driving pinion gear adjusting it conceives the [swi - can be adjusted. Said replacement device according to one embodiment of the invention has an open configuration such as the ram, ram supporting bar, and the ram so that the ram hereinafter for powder on a clamping plate so as to cause neither ram extruder affects the friction even when installed securely supporting ram facilitates the installation thereof can. In addition, equal to or greater than life and a program to prevent the damage of a carbonization chamber hereinafter for the replacement by preventing, coke production capacity efficiency can be secured. Figure 1 shows a coke oven equipment and also representing a surface, Figure 2 shows a coke oven and a program and also indicating pipelines installed in a surface, Figure 3 shows a modified ram also damaged by indicating a carbonization chamber and a surface, Figure 4 shows a device according to one embodiment of the invention representing a surface replacement ram and therefore, Figure 5 shows a device according to one embodiment of the invention representing a surface of ram test position and therefore replacement ram, Figure 6 shows a device according to one embodiment of the invention representing the mobile support device and therefore replacement ram elevation, Figure 7 shows a mobile support device for lifting plate using ram also lifting clamp fixing and indicating how a surface, Figure 8 shows a ram replacement method according to one embodiment of the invention indicating block and therefore, Figure 9 shows a replacement method according to one embodiment of the invention representing the driving pinion gear and therefore [...] in ram, Figure 10 shows a representative extruder also has been replaced by a roller and a surface, Figure 11 shows a device according to one embodiment of the invention replacement device therefore moved forward movement of ram using ram beam of a surface and, Also it conceives the [swi Figure 12 shows a worm drive pinion elastically installed adjusting ram (Bash-a lash) - operation device for a surface are disclosed. The present invention refers to various modification may have various can apply in the embodiment which is, in the embodiment illustrated and described specific broadcast receiver to the drawing. However, the present invention is defined with respect to a particular embodiment form which are not included, all changing range of idea and techniques of the present invention, including the water to replacement should understood to evenly. Number 2, number 1 including various components such as the term describes a ordinal number signifies can be used but, defined by said terms of said components are not. Components are mounted to one of said terms distinguished from other components object 1308.-RB. Any component and other components "connected" or folder "connected" when referred to that, or the other components connected directly or may be connected, other components might lead to intermediate is present it will will be. While, any component and other components referred to as "directly connected" or folder that when "directly connected to", should be understood to does not exist in the middle of other components will. In the example embodiment described, other components which components of "(on) or on (on or under) (below)" when described to be formed in, (on) or on (on or under) (below) is formed by two components can be provided for one or more other components directly together (directly) arranged between said two elements forming comprising both (indirectly). In addition '(on) or on (below) (on or under)' when one component is represented as a reference can be also includes a rear surface as well as the meaning of the installment. A term used in a particular application only is used to account for in the embodiment, the present invention intending to be define is endured. It is apparent that a single representation of the differently in order not providing language translators, comprising plurality of representation. In the application, the term "comprising" or "having disclosed" specification of articles feature, number, step, operation, components, parts or specify a combination not present included, another aspect of one or more moveable number, step, operation, component, component or a combination of these is understood to presence of or additionally pre-times those possibility should not number. Not defined differently, such as generally defined dictionary used for providing language translators of respective technical terms have the meanings must be consistent semantics and having interprets, the application will not become manifest in defining, or overly formal sense interpreted not ideal. Hereinafter, with reference to the attached drawing in the embodiment described dilate, drawing the same reference number or code is independent components to impart the corresponding local description dispensed the on-sensors other. Also with reference to 4 to 7 also residual, the replacement device according to one embodiment of the invention ram (1) comprises a support (100) and a ram (40) to move a mobile device (200) can be a. And, mobile device (200) includes a ram (40) capable of front or move rearward. Wherein, referred to as' front 'it extruder (30) based on a carbonization chamber (11) and means side, referred to as' rear' it extruder (30) based on a carbonization chamber (11) side facing away by big. In addition, replacing said ram device (1) comprises a support (100) movably arranged in the up and down on top of the mobile support device (300) can be further comprises. Ram (40) when the door, support (100) mobile device (200) moved by a ram (40) can be supporting. In addition, support (100) is, ram (40) a extruder (30) is provided by inserting when ram (40) a lifting support mobile support device (300) can be elastically lower. Wherein, ram (40) the plunger head (41) on the ram beam (42) can be comprising. And, plunger head (41) includes a ram beam (42) can be detachably fitted on one side of the. In addition, ram (40) when the door, support (100) includes a ram (40) with height difference adjusting substrate. 4 Also refers to the residual, support (100) is a plate-shaped support portion (110), support (120) and plate support (110) and a support (120) disposed between the liftable cylinder (130) can be a. As shown in fig. 5, built in self test position (P) shifted ram (40) moving device (200) when the main body using, support (100) oxygen support (110) includes a ram (40) supporting the bottom of an other. Also 4 and 1 also refers to the residual, built in self test position (P) ram (40) is a carbonization chamber (11) and the shaft (rear) has been moved over the opposite side of the graphics, ram (40) of rack gear (43) engages so that it is extruder (30) for driving the pinion gear (31) by the rotation of the ram (40) can be moved the ram test position (P). And, ram test position (P) in a plane ram (40) can be varying of recognizing. Ram (40) when the deformation of the determined, ram (40) a mobile device (200) by a plate-shaped support portion (110) on the upper surface of (111) can be moved. The, ram (40) with the lower surface of a plate-shaped support portion (110) on the upper surface of (111) between the height difference occurs between the traces, support (100) of liftable cylinder (130) using plate-like support (110) by lifting, height difference occurs between can be prevent. Wherein, liftable cylinder (130) an air cylinder or hydraulic cylinder can be used. In addition, a plate-shaped support portion (110) is, as shown in fig. 4, upper surface (111) disposed on both sides of the perpendicularly protruding from the guide (112) can be further comprises. Guide (112) has a top surface (111) up and down along a mobile support device (300) is moved when, lifting mobile support device (300) guiding, up and down by the circumference of the mobile support device (300) is inserted in a width direction by preventing, safety can be prevented. In addition, guide (112) is, ram (40) when the door, ram (40) guiding disapproval. On the other hand, support (120) is liftable cylinder (130) that is on (G) can be disposed between. And, support (120) provided at the lower wheel (not shown) is fitted to the support (100) can move. And, mobile support (100) has a space for securing a ground (G) (120) (not shown) can be stopper is to be performed. On the other hand, support (100) is, as shown in fig. 4, support (120) which is arranged between the plate-shaped support portion (110) of a lifting support member (140) further include disapproval. Lifting support member (140) includes a support (120) after increasing plate disposed between the upper end support (110) can be supporting. The, lifting support member (140) includes a support (120) by servicing the load on the central part of which sink in monitor case. Mobile device (200) includes a ram (40) generate a ram (40) can be moving. Wherein, mobile device (200) include, as shown in fig. 4, crane can be used. Mobile support lifting device (300) includes a plate-like support (110) movably along the longitudinal direction of the plate-like support (110) can be disposed on top of the. Thus, mobile support lifting device (300) includes a ram (40) can be used in replacement of. In particular, deformation ram (40) when the door rather than changing method of emerging ram (40) for the shank to prevent damage to the to the lifting and lowering device (300) includes a ram (40) during change of ram (40) further insertion of installation can be large. I.e., ram (40) encompass a mobile support lifting device (300) mobile device (200) moved by ram (40) can be moved while supporting. Thereby, said ram replacement device (1) is raised and mobile support device (300) using replacement emerging ram (40) servicing the corrupted by friction or the like. Mobile support lifting device (300) includes a ram (40) which can support a ram (40) at one side of movable wall allows for, ram (40) load in view of the support (100) oxygen support (110) can be provided at a predetermined interval apart. 6 Also with reference to the residual, mobile support lifting device (300) includes a body (310), ram fixing portion (320) and mobile portions (330) can be a. As shown in fig. 6, ram fixing part (320) includes a body (310) disposed on a top of ram (40) body (310) fixed to the substrate. The mobile portion (330) includes a body (310) can be detachably fitted to the bottom of the, body (310) is support (100) oxygen support (110) movable along causes. Ram fixing part (320) includes a body (310) are located inside the hydraulic cylinder (not shown) be moved up or down by a lifting plate (321) and lugs (322) can be a. An elevator plate (321) ram (40) ram beam (42) for stable to prevent the sliding ram in beam (42) are vertically mobile support device (300) can be swivelled to a to. The, an elevator plate (321) can be made of such as rubber or urethane group, thereby, an elevator plate (321) when moving the mass of the wall provides a ram beam (42) according to can be minimize. Lug (322) is having a changeable height disclosed. Lug (322) vertically one side of longer market public affairs (323, [...] hole) can be formed, market public affairs (323) comprises a sensor measures through (324) by lugs (322) includes a body (310) can be fixed. I.e., lugs (322) formed on one side of the market public affairs (323) a fixing member (324) through the combination of lugs (322) for a wiper hereinafter can be controlled. Hereinafter, an elevator plate (321) and lugs (322) using new ram (40) vertically moving the mobile support device (300) for method of fixing a heat-sensors other. (A) of Figure 7 refers to the residual, changing raises said second ram (40) vertically moving the plate (321) after self, lugs (322) in a desired part (40) fixed on one side of the substrate. Wherein, lugs (322) is, as shown in fig. 7, can be shape in the V cross-section. The, lug (322) of market public affairs (323) a fastening member (324) is the surface plate fitted therewith, lugs (322) includes a body (310) can be vertically moved and from separating from the. And, lug (322) one side of ram (400) and the fixing of the fixing member (324) using lugs (322) body (310) fixedly secured to each other. Then, as shown in (b) of Figure 7, an elevator plate (321) upward raising ram (40) are vertically mobile support device (300) fixed to the substrate. Thus, ram (40) are integrated mobile support device (300) to a mobile can be supported. The mobile portion (330) includes a body (310) detachably to the bottom of the force is removed. The mobile portion (330) is mobile support device lifting (300) is a plate-shaped support portion (110) movable along a longitudinal direction of causes. Mobile device (200) by ram (40) structure of a movement of, minimizes vibration in a mobile part (330) is urethane roller (331) can be provided. However, ram (40) by a load of a urethane roller (331) is controlled of integers, moveable portion (330) generate a moveable portion (330) is preferably detachably installed. On the other hand, lifting mobile support device (300) includes a body (310) is installed at one side to the it will grow cheap (340) can be further. It will grow cheap (340) is, as shown in fig. 6, body (310) can be provided on a side. The, mobile device (200) in the embodiment of in crane hook portion (210) it will grow cheap a (340) after fixed, said mobile support device are integrated crane (300) a plate-like support (110) capable of moved to the overhead of. Then, it will grow cheap (340) in hanger (210) and the number of fastening, said crane includes a replace new ram (40) vertically moving the mobile support device (300) on top of polished. And, said mobile support device are integrated crane (300) supported new ram (40) a extruder (30) side can be moving. Mobile device (200) includes a ram (40) a backup ram (40) can be moving, in addition, as described above, lifting mobile support device (300) a plate-like support (110) capable of moved to the overhead of. Hereinafter, said ram replacement device (1) for replacement method herein refer to ram (S1) to less than 1000. Only, the replacement method (S1) according to one embodiment of the invention are described in ram, said ram replacement device (1) components written in said ram device replacing the same number (1) description is given to individual components of dispensed the on-sensors other. Also 8 to 12 also refers to the residual, said ram replacement method (S1) is said ram replacement device (1) for automatically withdraw a method and a program installed in a new ram are disclosed. The replacement method (S1) said ram, ram test point moving ram (S10), the step of separating the ram extruder from (S20), adjusting the height of the difference (S30) on ram ram replacement device, subsequently withdrawing the ram (S40), placing the mobile support lifting device (S50), replace (S60) people on top of the lifting ram mobile support device, ram extruder can be comprising providing a (S70). Built in self test point moving ram (S10) in ram (40) of rack gear (43) engages so that it is extruder (30) for driving the pinion gear (31) member and the ram (40) a ram test position (P) to move the other. And, ram test position (P) in a plane ram (40) can be varying of recognizing. The step of separating the ram extruder from (S20) in ram (40) when the deformation of the determined, ram (40) of plunger head (41) in a desired beam (42) and separated from the, also 9 as shown in, driving pinion gear (31) such as returning to dismount. (S30) adjusting the height of the difference in ram on ram ram replacement device (40) with the lower surface of a plate-shaped support portion (110) on the upper surface of (111) between the height difference occurs between the traces, support (100) of liftable cylinder (130) using plate-like support (110) by lifting, height difference occurs between can be prevent. Subsequently withdrawing the ram (S40) in mobile device (200) which raises said ball number to the ram (40) a plate-like support (110) on the upper surface of (111) moves along can be cast. The, said ram replacement device (1) device of mobile support device (300) may also be used but using, deformation ram beam (42) equipment and not the although not necessarily drawn. Placing said mobile support device (S50) lifting ram in replacement device (1) of device (200) using mobile support to the lifting and lowering device (300) a plate-like support (110) capable of moved to the overhead of. For the replacement of a mobile support device on top of said ram in people (S60) lifting ram replacement device (1) of device (200) using mobile support to the lifting and lowering device (300) into the top of the ram beam (42) moving a poppet sleeve. And, mobile support lifting device (300) ram fixing part (320) through, as shown in fig. 7, ram beam (42) are integrated mobile support device (300) secured on top of. The, mobile support device for the replacement of a lifting ram (S60) includes a ram beam people on top of the mobile support device into the portion of the poppet (S61) and vertically moving the mobile support device on lifting ram beam (300) comprising the steps of securing to (S62) can be. Providing a replacement device in said ram extruder ram (S70) (1) of device (200) using a ram (40) is mounted to the extruder. Providing a ram extruder (S70) roller extruder is down (S71), ram beam moved forwardly (S72), providing a driving pinion gear (S73) and ram beam comprising a plunger head is then can be (S74). With reference to the residual 10 also, replacing a roller in the extruder (S71) ram beam (42) to move forward before ram beam (42) can be assisting movement of the bar. Wherein, ply roller (32), thrust roller (33) and pivot roller (34) can be a. With reference to the residual also 11, ram beam in front tape through said ram device replacement (S72) (1) of device (200) using a ram beam (42) moved forward a reaction chamber. 12 Also refers to the residual, driving pinion gear (S73) providing a driving gear pinion gear (31) in a desired beam (42) of rack gear (43) are installed in a groove. The, driving pinion gear (31) on the rack gear (43) can be adjusting it conceives the [swi - operation device for a (Bash-a lash) of. It conceives the [swi - 8 mm - 12 mm is the gap (Gap) can be permit adjustments to said [...]. Preferably, the gap (Gap) is 10 mm - [...] said it conceives the [swi can be permit adjustments. A plunger head providing a ram beam (S74) in ram beam (42) at the end of the plunger head (41) of a machine. The, plunger head (41) a method for recovering a new plunger head (41) can be replaced. In said through a browser but of the present invention in the embodiment, a corresponding art 155.520 poriae idea of the present invention within a range that the present invention not patent the following is claimed and area away from varying the modification and changes may be understand it will rain. And, the crystal of the present invention defined in the claims appended related differences change range will be interpreted. 1: Ram replacement device 2: coke oven equipment 3: Charge 10: coke oven 11:30 A carbonization chamber: extruder 31: Drive pinion gear 32: ply 33: Thrust roller 34: pivot roller 40: Ram 41: plunger head 42: Ram beam 43: rack gear 100: Support 110: plate support 111: Upper surface 120: support 130: Liftable cylinder 200: mobile device 300: Lifting mobile support device 310: body 320: Ram fixed part 321: an elevator plate 322: Lugs 333: market public affairs 340: Fixing member 350: it will grow cheap S1: ram replacement method The present invention relates to an apparatus for replacing RAM comprising a transfer device transferring the RAM and a support unit supporting the RAM transferred by the transfer device, wherein the support unit moves up and down to adjust a height difference with the RAM, and to a method for replacing RAM using the same. Accordingly, when replacing RAM, the apparatus supports the RAM to easily take out the RAM, and helps installation of the RAM by safely supporting the RAM, so deformation by friction or the like does not occur when the RAM is installed on an extruder. In replacement device for replacing ram extruder ram, said ram to move a mobile device; said mobile device to said ram moves up and down by a support; said support and moved up and down along the longitudinal direction of the mobile support device wherein, said mobile support device is fixed to said upper ram lifting, body; said ram body fixed to the fixing portion disposed on a top of said ram; mobile part wherein, said body said mobile portion detachably fitted a ram replacement device. According to Claim 1, said support, said support when moving said ram ram and a plate-like support; support; and a plate-shaped support portion disposed between said up and down while the support, said support plate to said lifting cylinder elevator ram replacement device. Back number Back number According to Claim 1, said ram fixing unit, said body movably arranged vertically up and down plate; and said ram which fixed on one side of the lug, said lug the fixing of the one side of said ram raising said lifting plate fixedly ram ram replacement device. According to Claim 5, said lugs having a plate have a ram replacement device. According to Claim 6, said lug is formed as a vertically on one side of the second fixing member further including ram air guided through said engaging a replacement device. According to Claim 1, said body further including a ram outward to it will grow cheap replacement device. Ram replacement device for replacing a ram extruder using ram installed in replacement method, built in self test point moving said ram; the step of separating said ram from said extruder; adjusting said height difference on said ram ram replacement device; subsequently withdrawing said ram; placing the mobile support lifting device; replace ram lifting people on top of said mobile support device; said portion and providing a ram extruder and, for the replacement of a mobile support device mounted on top of said ram lifting step, said pilot poppet to said mobile support device said ram ram beam fixed to said mobile support device are held at the lifting ram beam including a lifting ram replacement method. Back number According to Claim 9, said ram is then the extruder, said extruder roller the replacement processor; front tape through said ram beam; providing a driving pinion gear; and said plunger head including a ram beam provided ram replacement method. According to Claim 11, said ply roller, thrust roller and pivot roller at least any one of a ram replacement method. According to Claim 11, said driving pinion engaging said driving pinion elastically installed ram beam hinge provided in the step, said driving pinion gear of said hinge adjusted adjusting it conceives the [swi - ram replacement method.