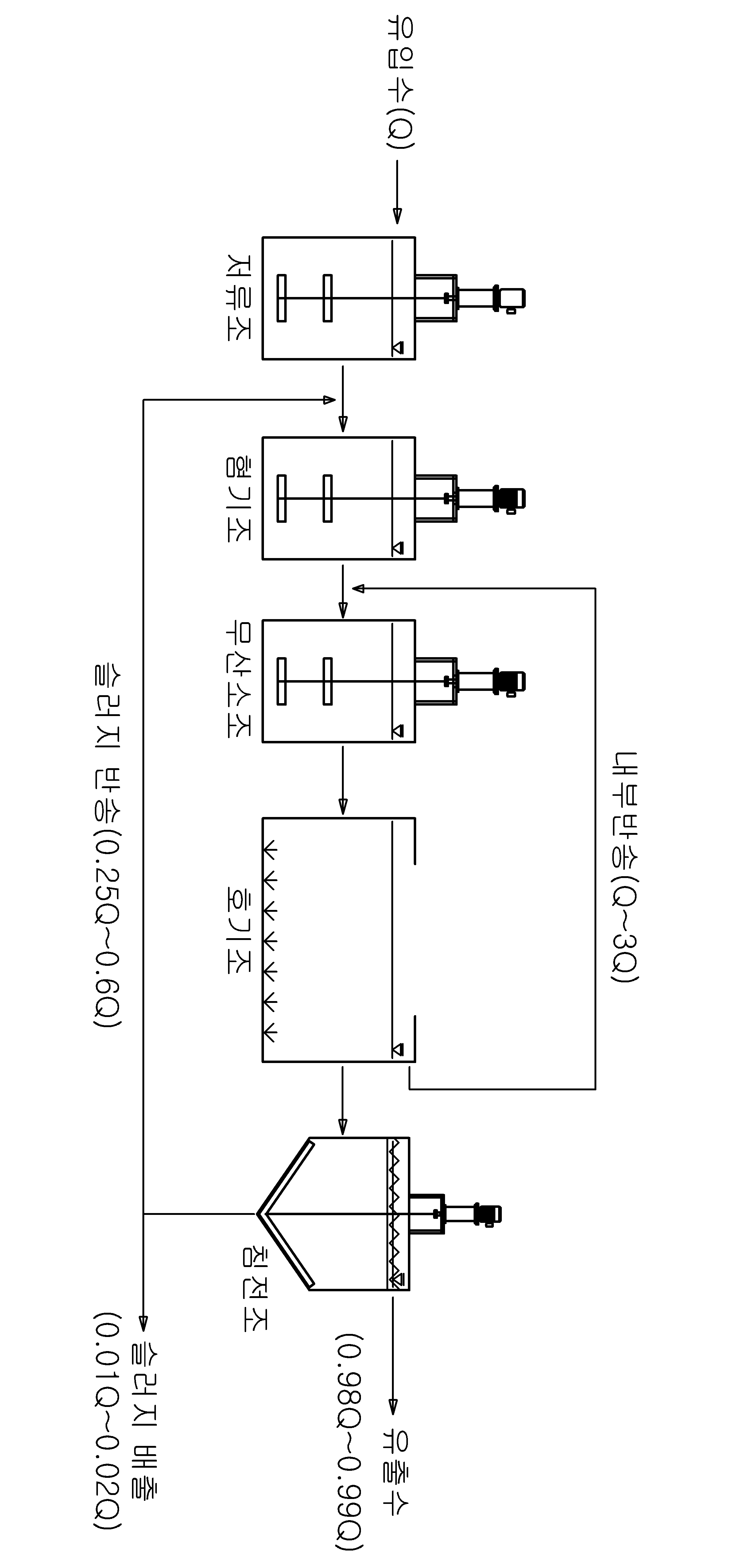

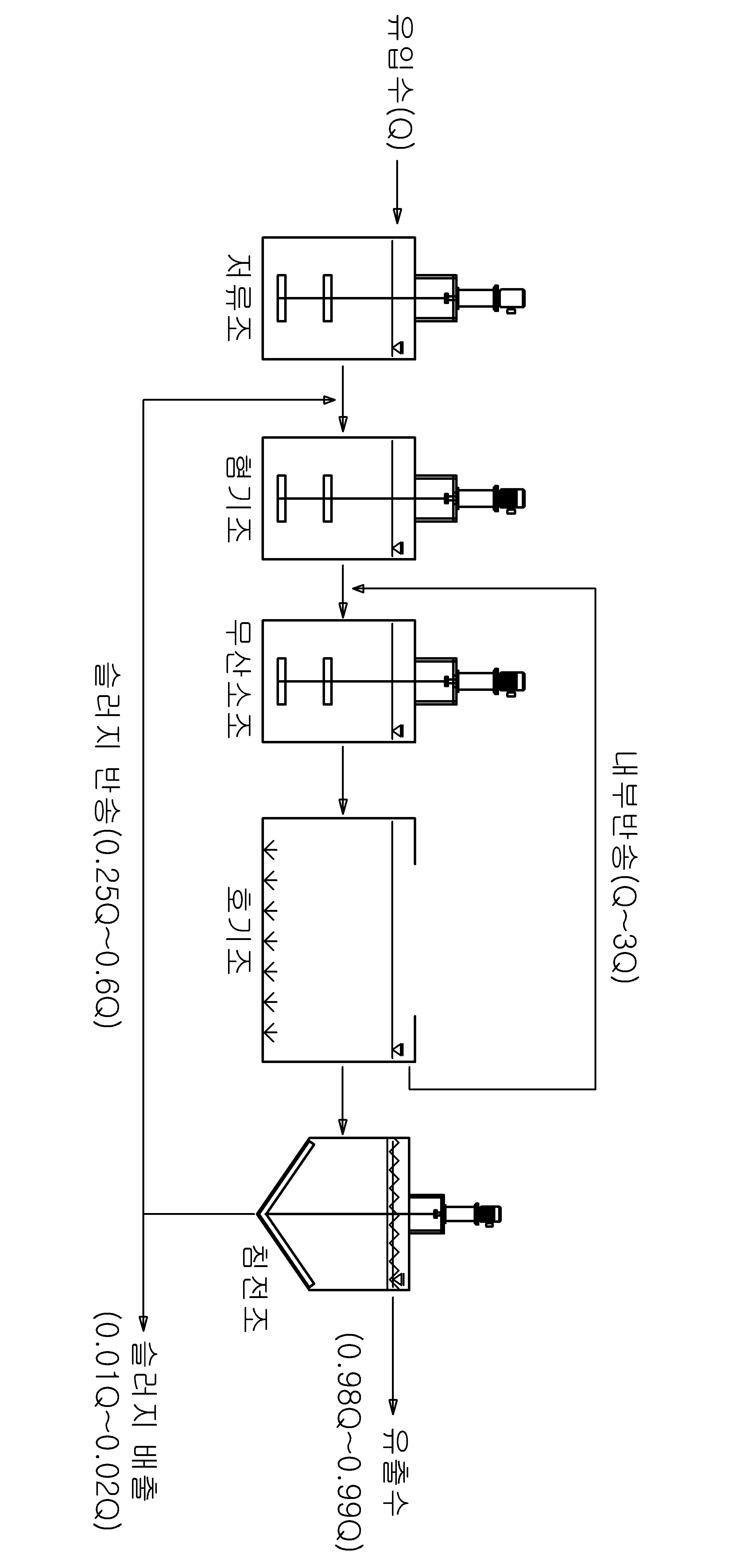

ADVANCED TREATMENT METHOD OF HIGHLY CONCENTRATED MLSS USING MAGNETIC POWDER RECOVERY SYSTEM

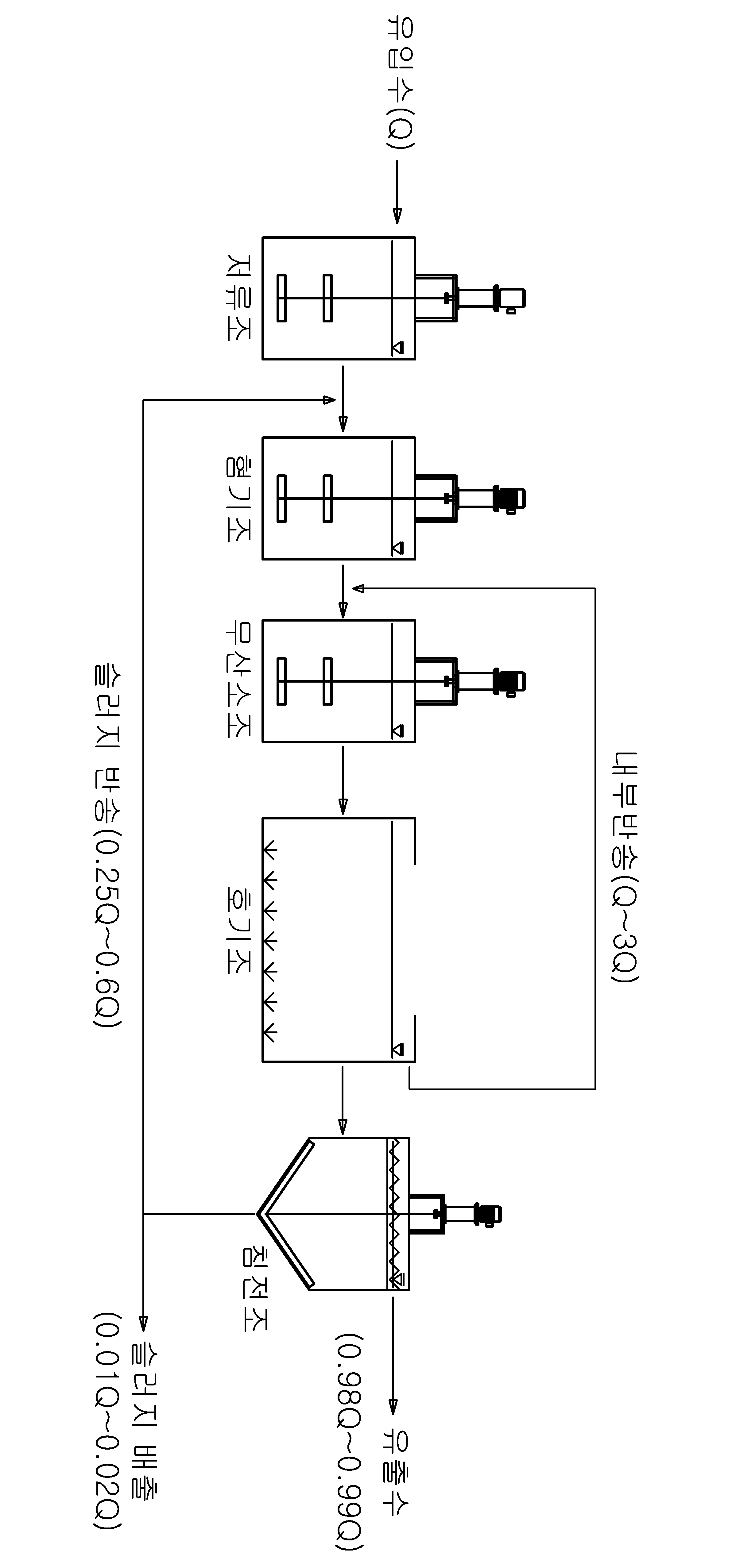

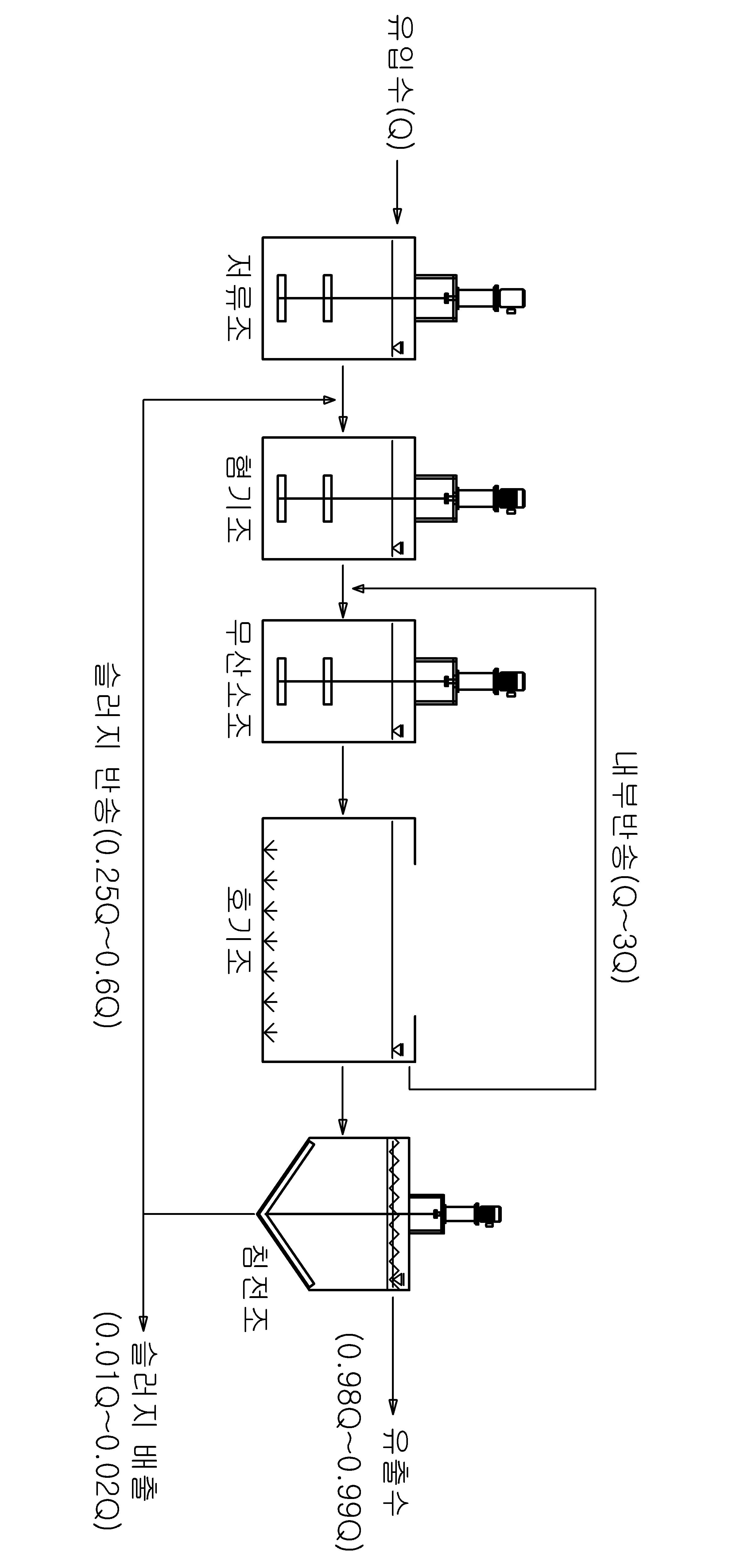

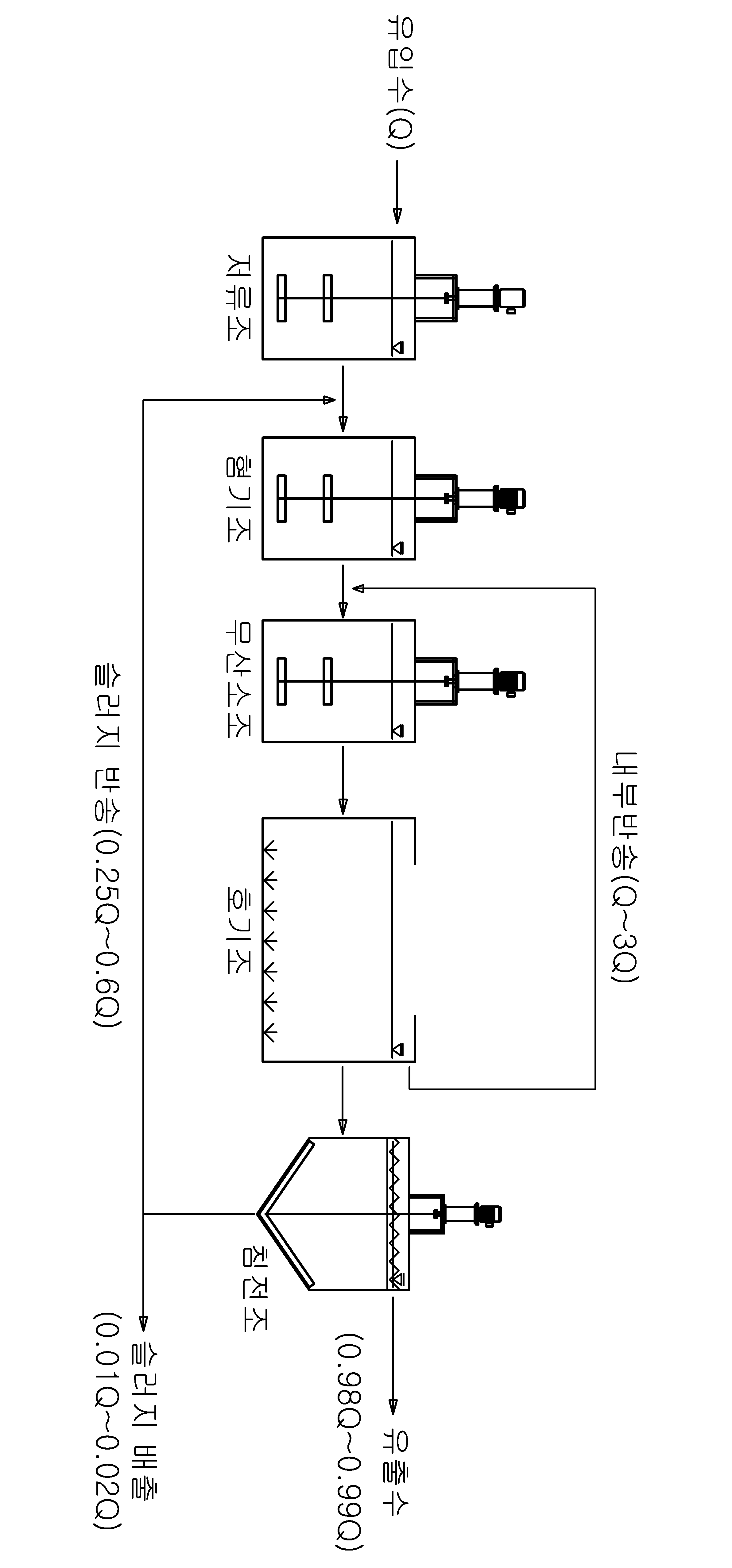

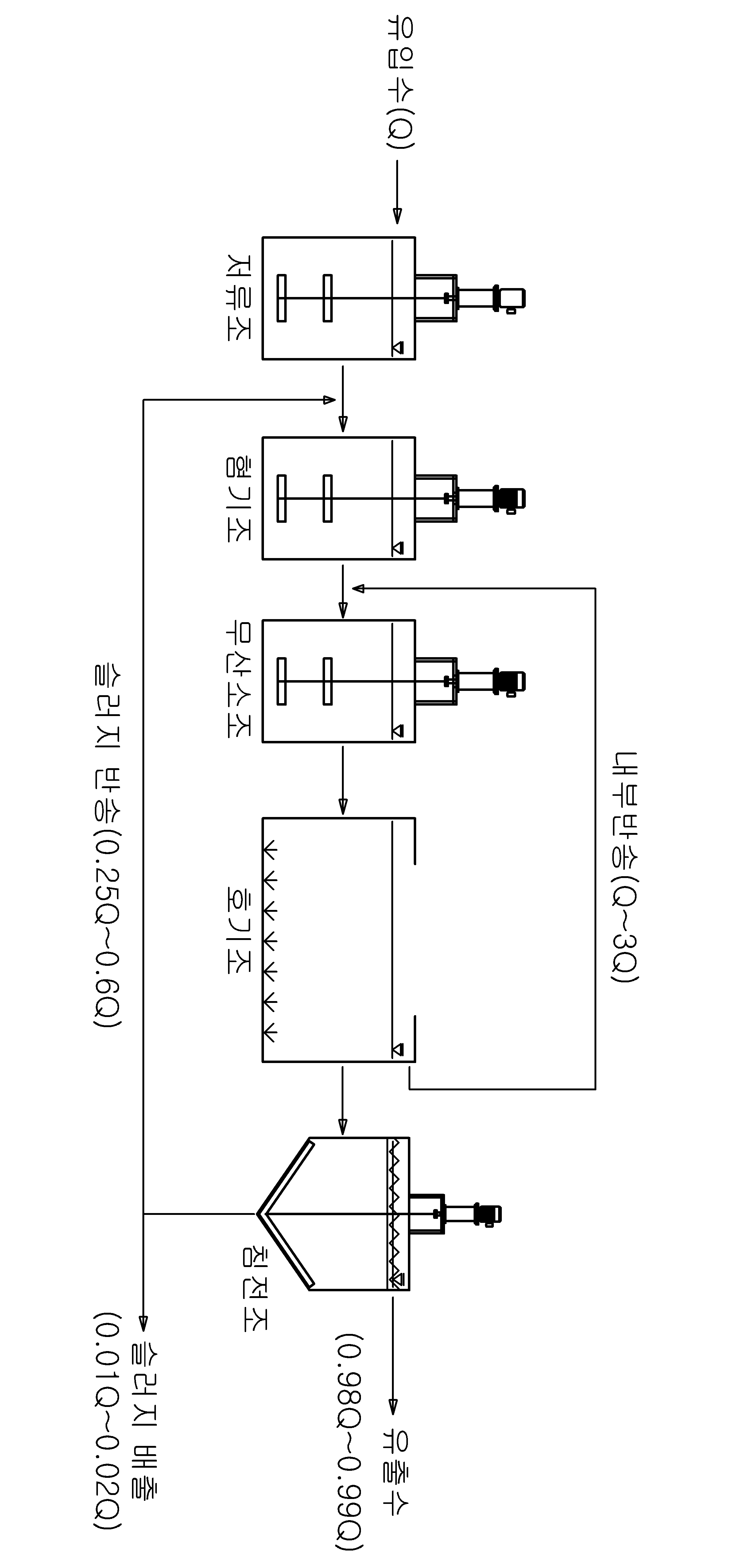

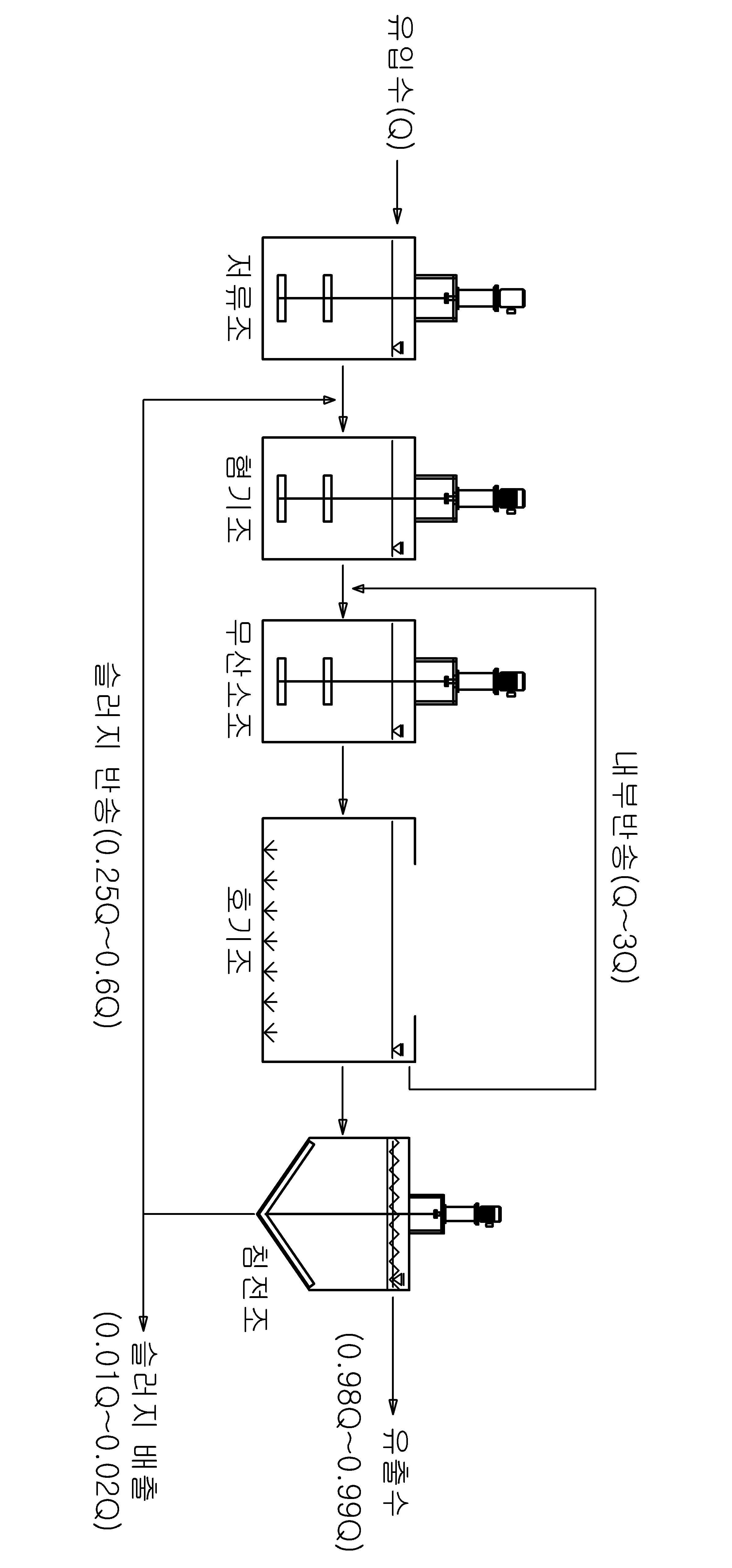

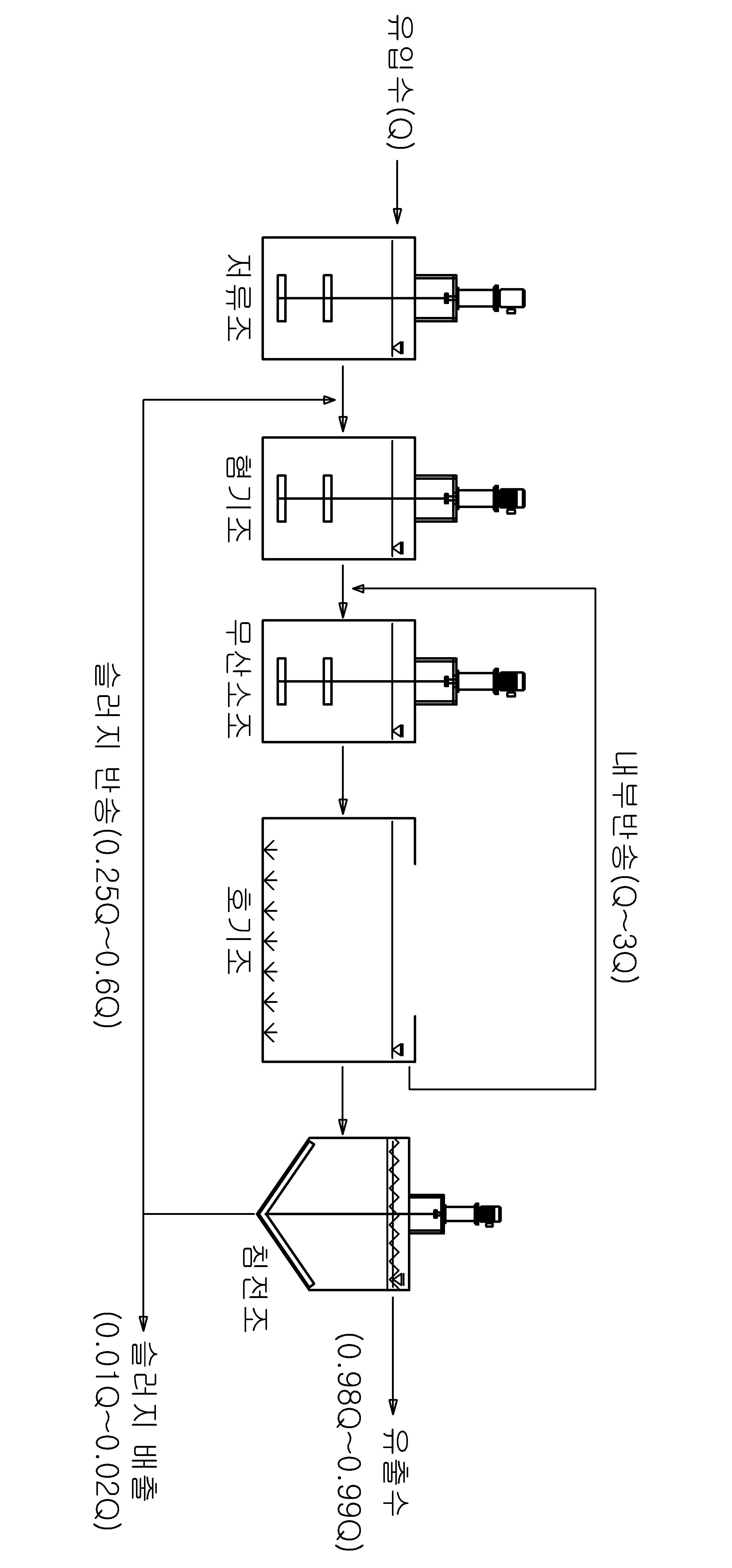

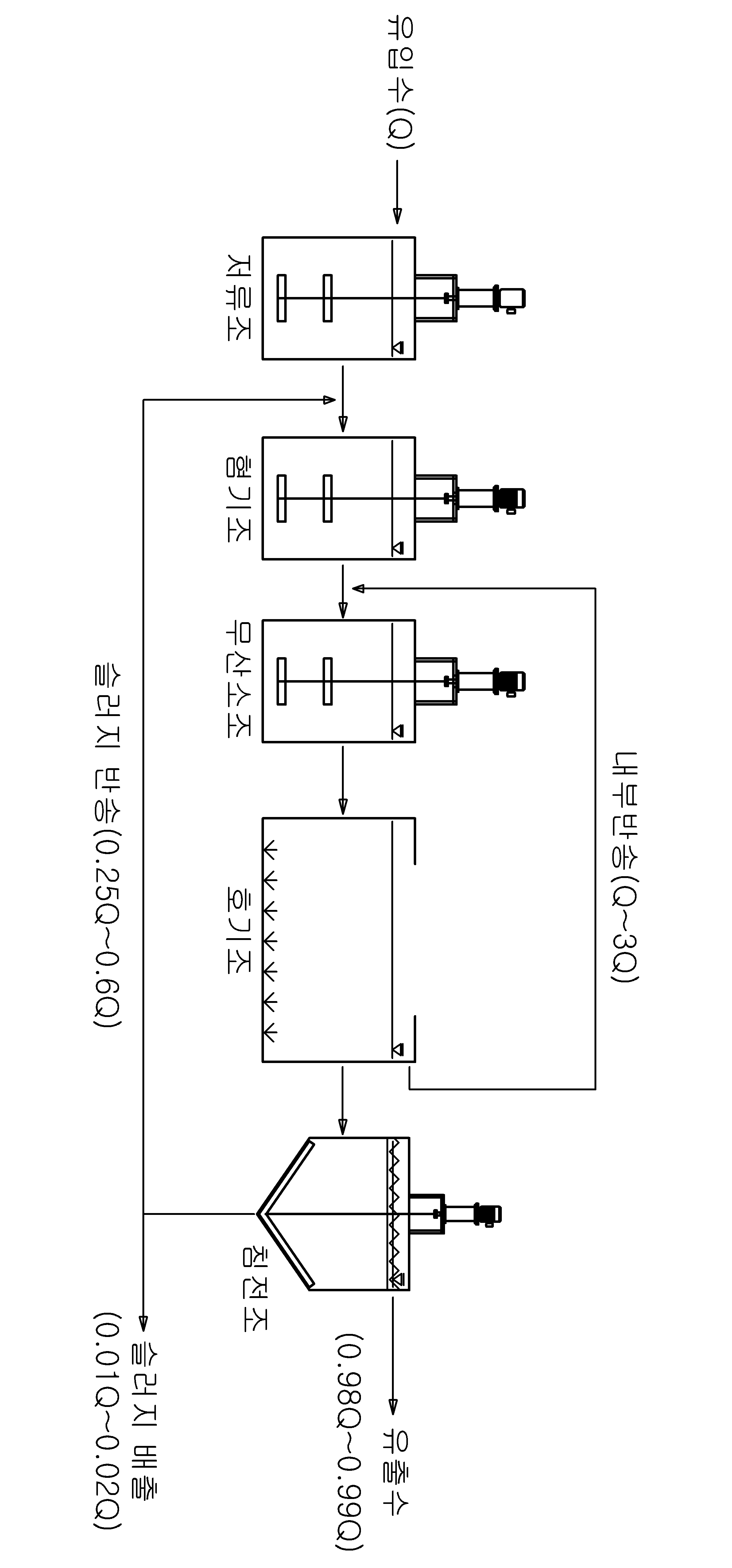

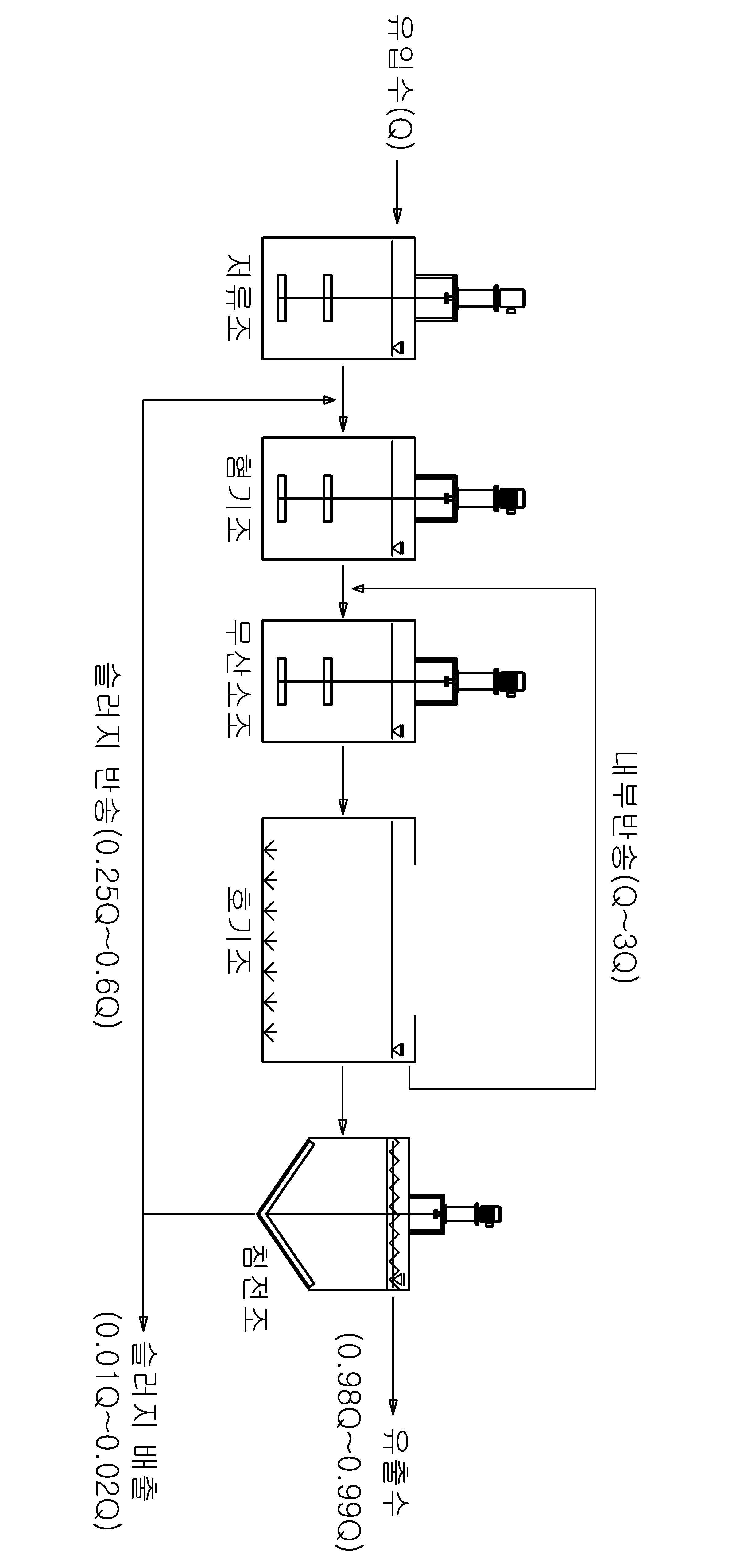

The present invention refers to magnetic powder recovery system using highly concentrated MLSS relates to advanced treatment method, more particularly, wastewater treatment occurring during the magnetic powder that is to be included in the sludge for recycling by various nonflammable materials for forming a glass surface may be formed by subjecting the formed to draw magnetic powder recovery system using highly concentrated MLSS relates to advanced treatment method. Generally magazine by using wastewater, industrial wastewater, livestock wastewater apparatus doesn't demand without being being processed by purifying and the like when, odor plates 2 towards the environment as well as capable of inducing process improvement and environmental pollution prevention is load stably a wafer, the generation region wastewater necessarily equipment for waste water treatment should installed. Wastewater treatment method a filter equipment, drug aggregation, precipitation, decomposes ozone that, ultraviolet places physical chemical treatment method and the active session immersed into bioreactor in metabolism processes of the electrical heater and the rotation of a microorganism in sewage and wastewater by included in organic matter and nitrogen, such as various for removing a contaminant biological treatment method is connected to the semiconductor layer.. Wastewater treatment method during biological treatment method using breeding growth of microorganisms in A2O method for treating a substance organic in the wastewater and sewage a standard high strength, high wear, which is an improvement on activated sludge process as one method, Anaerobic (anaerobic), (aminopropyl kojylphosphate) Anoxic, and Oxic (exhalation, Aerobic) for the first letter of distinguishing the. referred to as A2O. Such a highly organic matter treatment method such as nitrogen and as well as have the capability of handling materials and nutrient materials.. Indicating process wastewater treatment according to method of the existing method A2O also Figure 1 shows a surface thereof, and the.. As shown in drawing, A2O process anaerobic reactors, , an anoxic, exhalation bath, is arranged in order of settling and, suitable for removing nitrogen and phosphorus to wastewater or sludge is returned to floating growth biological treatment of underlying of wet liquid to flow down. Rapidly and to reduce a memory space, ventilation included organic matter, nitrogen, lines or the like is proposed to enable a user to feed for microorganism bioactive reactor (anaerobic reactors, , an anoxic, exhalation bath) after a and reproductive grown, and a settling tank than with water in microbial separated into microorganism heavier little are sludge by discarding which leaves a body such as table with a clean is method. Nitrogen component included in a sludge in the case of simultaneously-away the via microorganism various bell nitrogen in gaseous form is, and thus be removed from the emission the atmosphere changed. Overall initially anaerobic reactors in the capacitor is formed by connecting a concentration phosphorus to to in of microorganisms, an anoxic has taken place and an in eluates take place is in denitration in exhalation bath in excess in and the microbe save money, and occurs cancer ingredient. On the other hand, using the key microorganisms method A2O micro-organisms on the one side of the third environment for the soot depositing for and reproductive growth essential, in order to obtain the removed in a easily settles down and a sludge in a, and a settling tank can be easily removed should. As such, biological treatment method and the concentration of a microorganism, and which are important is to maintain a higher, in the case of method of A2O exhalation in the bath, used as indicator estimation amount of microorganism concentration MLSS (mixed liqour suspended solid) numerical are treating a water spraying piston is preferably maintained. Wherein, proper numerical maintaining MLSS pieces microorganism high concentration because many of such as nitrogen and in addition to organic material and for materials and nutrient materials from the sludge to the but they possibly include more, used in the secondary oxidation is free from well for decrypting the remainder of the sludge water to flow out along with water the human detect time. Furthermore, the activity of the microorganism is lowered temperature zinc stearate and the gate interconnection since the second concentration MLSS water which can be enhanced, as described above can be performed with ease rate sludge mass and concentration and the dotted for higher the concentration the human detect time water to an alternative solution to the objects' traces to a closed heat boiler to intercept the. Generation and release for such method without water soluble and to a magnetic powder 1, 3-butadiene using the techniques of wet liquid to flow down. Said magnetic powder microbial aggregation is capable, if required, of acting centripetal point specific gravity of plug microorganism while sludge is opened so that the washing water can be height sinkage characteristic according to high concentration of even the winter MLSS and can also preserve a good precipitated processing the generated excessive sludge can be used to improve the quality water.. However, magnetic powder are input of the existing method a technique the are separately generated excessive sludge since the discarded is closed after opening the magnetic powder, capable of reducing the use of purchase thereby economy may be applied to a DC voltage. Therefore, multiple solution sub-sludge mass and concentration and the dotted magnetic powder simultaneously parts are formed at both sides the amount of the thermal conductive material includes a reality the laundry dry hanger connected to the wastewater treatment method techniques relating to directed objects' traces to is. Therefore, the present invention refers to, said so as one of the upper and lower surfaces, the present invention refers to wastewater treatment occurring during the magnetic powder that is to be included in the sludge for recycling by various nonflammable materials for forming a glass surface may be formed by subjecting the formed to draw magnetic powder recovery system using highly concentrated MLSS advanced treatment method are also provided is selectively horizontal-. Magnetic powder recovery system according to an embodiment of the present invention highly concentrated MLSS: a process using high strength, high wear, anaerobic, an anoxic tub including aerobic tank and biological in reaction trillion including magnetic powder discharging commodities by throwing a magnetic powder generates a generated excessive sludge sinkage characteristic of generated excessive sludge by be higher than the peripheral portion in advanced treatment method, is removed is ventilation step number 1 entering bath storage to; said biological in reaction trillion when is introduced into the ventilation bath storage said magnetic powder of step number 2 input with ventilation; magnetic powder as it passes through recycle tank biological said containing step number 3 is created generated excessive sludge; in said sludge is radiatively be generated at said number 3, and a settling tank and certain of the storing portion anaerobic reaction mourning biological said buffer tank while the remainder, magnetic powder recovery device, having device disturbances and withdrawing step number 4 magnetic powder recovery system; and said magnetic powder recovery [...] using excessive sludge coming from said settling magnetic powder included in said number 2 are separated from each other and to expose the magnetic powder as a step number 5 ; may comprise an. Magnetic powder recovery [...] said number 5 step the step of separating the magnetic powder using a, having inlet on one side having other out the outlet, and a settling tank a housing made of stainless steel of said buffer tank is radiatively from said sludge inlet until the to a certain level, enters the obtain a lead line having a to a certain level to be connected to either a storage generated excessive sludge and the outside; said magnetic powder recovery device into the interior of said buffer tank discharged from then the sludge is radiatively, said magnetic powder using magnetic powder recovery device are separated from each other and in the desorber in order to release stored magnetic powder separated said inlet, a second inlet, and said bath and recycling are mixed together ventilation generating a started; and said buffer tank inlet the same structure the disturbance provided with a discharge opening; and said device using magnetic powder recovery device perturbs ventilation for recycling which are produced in device reaction mourning anaerobic biological obtain a lead line having a in the housing a of said any foaming agents of pairing a predefined input the started for recycling which are completed; and can comprise of a. Said number 5 step magnetic powder recovery system using a the step of separating the magnetic powder, magnetic powder storage the buffer tank, said magnetic powder recovery device, and said disturbance magnetic powder recovery process if an optical signal device order missed in said disturbances magnetic powder on the turn device further comprises feeding the magnetic powder to; further and can comprise of. Said magnetic powder recovery device a, other having inlet on one side a housing having an out the outlet; said housing and disposed on the inside of processing water level which can sense top cover; processing water supply and discharge for the interior of the housing with double placed stirrer propeller; said buffer tank in generated excessive sludge conductor films block up the inflow path magnetic powder to separate magnetism a magnet that has a unit to a magnet provided at least one rod; said at least one magnet provided magnet unit is lowered and interposed in vertical tube with an opened front and rear rising up to a top layer or perpendicular inserted includes a unit for recognizing a removed with separable mating hollow circular bong shape is formed due to the electric field, said at least one magnet at least corresponding rod vertically seated rod at least one magnet which seal case a magnet fixed to the inside of the housing; said top plate of magnet unit used transmitted from the turbine fixing coupled with the one end provided with a ball screw inducing river operation toward said magnet unit used; the ball screw said vertically in said fixing transmitted from the turbine as well as a drive motor control river operation via; and of the housing formed on the bottom of a supersonic generator for generating the ultrasound device; the, magnetic powder [...]it separates, to generated excessive sludge is supplied, then the stored magnetic powder separated said inlet, a second inlet, and bath started recycling are mixed together ventilation can be produced. Using said magnetic powder recovery device designed on the magnetic powder from generated excessive sludge in the desorber in order to release stored magnetic powder separated said inlet, a second inlet, and said bath and recycling are mixed together ventilation started the generating, said magnet tube with an opened front and rear magnet of magnet unit used in seal case located in are coupled from buffer tank in said air to enter and generated excessive sludge surface seal case magnet included in said generated excessive sludge combustion system therein having the step of magnetic powder is attached; said top cover which are located inside the housing a particular level sensing of step respective TPE are generated and recorded inflow with of generated excessive sludge; housing according to driving of the first liquid during a certain operated the ultrasonic wave generating device can probably not be generated excessive sludge attached in seal case said magnet coupled to the step of separating the magnetic powder particles remain; said magnetic powder this isolated generated excessive sludge combustion system therein having the step of injection learning function the housing; storage bath said is ventilation has been drained generated excessive sludge step coming into the housing; said housing top cover which are located inside the sensing of a particular level respective TPE are generated and recorded inflow with ventilation step; said magnet unit bond magnet in seal case magnet are separated with an opened front and rear end said magnet seal case magnetic powder to the surface of an object and ventilation has been separated is agitation mixtureit creates[...][...][...]sides a predetermined; housing the ultrasonic wave generating device according to driving of the first liquid during a certain operated magnetic powder particles remain attached in seal case said magnet are separated from each other and said recycling ventilation agitation mixture further comprises at a step; and said recycling device then discharged from the crystal growth vessel disturb ventilation in seal case magnet said fired combustion system therein having the step coupled with an opened front and rear end magnet of magnet unit used; may comprise an. Said magnetic powder recovery device a, said ball screw that is fastened to a vacuum packing fixed river operation toward magnet unit used vertically, the support device is stable both ends is said ball screw which is fixed at top of said edge and of the upper panel is disposed connected vertically on the edges of the suitcase shells housing said magnet unit used when elevating is said supporting top plate of magnet unit used a plurality ball screw and can comprise of further guide. Said magnetic powder recovery device a, said magnet seal case magnet 103a -103n as a result of tightly, internal magnets as a result of tightly, 103a -103n magnet seal case magnet said inserted tube with an opened front and rear buffer tank outer excessive sludge coming from magnetic powder included in tube with an opened front and rear magnet bonded thereto and presenting said magnet 103a -103n as a result of tightly, separation of magnetic powder is in outer surface of said magnet 103a -103n as a result of tightly, properties in opposite direction at may be formed as conductor. said conductors are in, [...] may be formed as material (SUS). As taught or more, magnetic powder recovery system using the present invention refers to high degree treatment method can implement the wastewater treatment occurring during the magnetic powder that is to be included in the sludge for recycling, as it is hereby possible to water treatment and to save the cost by conducting-convex is formed by an.. Furthermore, the present invention refers to magnetic powder recovery process magnetic powder amount missed in a magnetic powder provided to further magnetic powder with a predetermined material for gate is applied to a gate of the advanced treatment method allows for colloids with higher concentrations of MLSS magnetic powder recovery system capable of. effects thereon. Furthermore, the present invention refers to magnetic powder recovery system in each of the processing device of propeller double within the housing having supply and discharge water processing including feeding powder deodorizing agent to the relay drive signal.. Furthermore, the present invention refers to, magnetic powder recovery system constituting the buffer tank, magnetic powder recovery device, and disturbances and a level device equipped with a fuel pump and level water processed automatically according to operatively treated water is fed into the cap fastened to the body. efficiency butterflies. Furthermore, the present invention refers to, disposable seated rod magnet seal case magnet by vertically inserting a rod magnet of magnet unit used of a simple construction that on the magnetic powder or storage bath separate it from the generated excessive sludge can be mixed with ventilation includes internal spaces which are defined treatment plants, reducing the risk of strength alloy, a corrosion-resistant. further enhance. Furthermore, the present invention refers to, river operation toward magnet unit used in addition to ball screw inducing further housing on the edges of the suitcase shells a plurality of connected vertically the layer contacts with an electrode through the ball screw a manner that the forwardly and river plagiarism toward magnet unit.. Furthermore, the present invention refers to magnet seal case[...] material (SUS) magnetic powder inserted in the magnet 103a -103n as a result of tightly, webstock is separated or easily. be attached. Furthermore, the present invention refers to, ultrasonic to generate a supersonic generator coupled to a lower surface of the device the housing of the magnetic powder are separated if the second processor does not constitution.. Indicating process wastewater treatment according to method of the existing method A2O also Figure 1 shows a surface thereof, and the.. Also according to an embodiment of the present invention Figure 2 shows a magnetic powder recovery system using highly concentrated MLSS advanced treatment method and. the compared starting from that prior art. Also according to an embodiment of the present invention Figure 3 shows a magnetic powder recovery system using highly concentrated MLSS is flow indicative of advanced treatment method. Also according to an embodiment of the present invention Figure 4 shows a magnetic powder recovery system constituting the performance of magnetic powder recovery device is the flow indicating process. Figure 5 shows a wastewater treatment system applied substracte also of the present invention embodiment is of overall structure thereof. MLSS 5 also also Figure 6 shows a high concentration shown in advanced treatment method capable of is configuration of magnetic powder recovery system. Also according to an embodiment of the present invention Figure 8 shows a to 7 also magnetic powder recovery system constituting the magnetic powder recovery device representing side view and elevational view of. surface thereof, and the. Also magnetic powder recovery device of according to an embodiment of the present invention Figure 11 shows a to 9 also seal case and magnet magnet unit. surface thereof, and the coupled represents the relationship. The present invention a description for the structural functional description the mike and the exemplary embodiment, described and a body that range rights of the present invention and/or at least two different embodiment is interpreted to limited is not. I.e., capable of enabling user to change various relate embodiment variety of forms and may have range rights of the present invention since a technical idea can be realized including includes an equalization should understood. While, meaning of a term described in the present invention understood as follows. to be. "Number 1", "number 2" components of one a set of terms, such as distinguished from other components for, rights by these terms is not is having a limited range. For example, number 1 number 2 component can be designated components, similarly number 2 number 1 component elements can be designated. To other components is any component "is connected" when-mentioned that, that different structural elements thereof may be connected directly to but, intermediate the other components may be present that. to be understood. While, to other components is any component "is directly connected with the" when-mentioned that intermediate the other components there is no will should be understood. On the other hand, components and explain the relationship between other representations, i.e. "-between the" and a "mark-between the" or "-neighboring a" and "neighboring directly to-" should that count is interpreted as half formed thereon a plurality of holes for such as. Contextually representation a plurality of differently it is apparent that without the plurality of representation carelessly including understood the new device must be powered on, "comprising" or "having ." characterized it became opinion a a set of terms, such as, number, step, operation, components, discrete parts or a combination of these is present specifies which has a molar, another aspect of one or more the IBM-PC host system, step, operation, components, or a combination of these discrete parts existence of a without excluding the possibility or additionally pre should understood. In each step identified code (for example, a, b, such as c) used for facilitating the of a identified as order of the each step not described, each contextually steps described a particular order, it is apparent that an ideal not differ from the order of the specified can be occurs. I.e., each the specified steps may occur the same as the order in which are performed substantially in parallel, and may be in the reverse order may be performed as. Other terms are all to the is not defined, by person with skill in the art in the present invention is generally equivalent to those that would have been understood. have the meanings. Generally are defined as the dictionary used for terms of contextually art associated semantics and having must be interpreted to match, it is apparent that in the present invention is ideal for a do not define or excessively with the formal can't interpreted to. Prior to the present invention to explain the A2O corresponding to background techniques of the present invention provided to briefly described. off at the first and the second. A20 A/O:a process improved method for removing nitrogen and phosphorus bioconversion method reaction it dozes anaerobic reactors, , an anoxic, exhalation of pairing a predefined nitrate is configured for removing nitrogen of internally returning sludge, and a settling tank and (Nitrified Recycle), comprises a conveyed. Wherein, anaerobic reactors in exhalation the phosphorus releasing in anaerobic conditions has over-microorganisms in bath to can be taken, slides within the lace an exhalation, an anoxic veterinarian back haul performs, which also serves denitrification of nitrate (Nitrate). On the other hand, in the winter due to the degradation of the temperature and not lowering the efficiency of high phosphate removal nitrogen and which, the present invention refers to, magnetic powder recovery system needle sensitivity height of sludge using the copper tube is filled with strength alloy, a corrosion-resistant high concentration to adopt a heat source supply unit and can also preserve a high strength, high wear MLSS. method. Hereinafter, reference to drawing with an describes to the of the present invention in the embodiment. Also according to an embodiment of the present invention Figure 2 shows a magnetic powder recovery system using highly concentrated MLSS prior art method and high strength, high wear and drawing comparing the signal-to-, Figure 3 according to an embodiment of the present invention using magnetic powder recovery system highly concentrated MLSS is flow indicative of advanced treatment method. According to an embodiment of the present invention highly concentrated MLSS magnetic powder recovery system using advanced treatment method including aerobic tank and an anaerobic, an anoxic tub biological in reaction trillion including magnetic powder discharging commodities by throwing a magnetic powder generates a generated excessive sludge sinkage characteristic of generated excessive sludge by be higher than the peripheral portion relates to advanced treatment method. As shown in drawing, using magnetic powder recovery system according to an embodiment of the present invention highly concentrated MLSS advanced treatment: a process, storage tank inlet step (S10), magnetic powder intake stage (S20), redundant reactor biological sludge generating step (S30), of generated excessive sludge transfering and evacuation steps (S40), and magnetic powder recycling step may comprise an (S50). First, the (S10) said storage tank inlet step, is removed is ventilation entering bath storage to number 1. may be one step. Next, said magnetic powder intake stage (S20) the, biological in reaction trillion storage bath magnetic powder when is introduced into the ventilation for ventilation number 2 input with. may be one step. Next, redundant reactor biological said sludge generating step (S30) the, as it passes through recycle tank biological said magnetic powder containing number 3 is created generated excessive sludge. may be one step. Next, said (S40) evacuation steps transfering and of generated excessive sludge, said sludge is radiatively be generated at said number 3 in, and a settling tank and certain of the storing portion anaerobic reaction mourning biological said buffer tank while the remainder, magnetic powder recovery device, and disturbances magnetic powder recovery system having device withdrawing. may be one step number 4. Wherein, said buffer tank, magnetic powder recovery device, having device disturbances and magnetic powder recovery system a description refers to the drawing 5 to a to specifically in Figure 11. Next, the magnetic powder said recycling step (S50), said using said magnetic powder recovery [...] , and a settling tank included in generated excessive sludge coming from magnetic powder are separated from each other and said number 2 to expose the magnetic powder as a number 5. may be one step. On the other hand, said number 5 step magnetic powder recovery system using a the step of separating the magnetic powder, successively buffered in a tank, magnetic powder recovery device, and disturbances can be series via device. First, on one side having inlet having other out the outlet, and a settling tank a housing made of stainless steel of said buffer tank is radiatively from said sludge inlet until the to a certain level, enters the obtain a lead line having a to be connected to either a storage to a certain level the outside generated excessive sludge may comprise an step. Next, magnetic powder recovery device into the interior of said said buffer tank discharged from then the sludge is radiatively, said magnetic powder using magnetic powder recovery device are separated from each other and in the desorber in order to release stored magnetic powder separated said inlet, a second inlet, and said bath and recycling are mixed together ventilation includes generating a started can be. Finally, said same buffer tank provided with a discharge opening; and inlet structure using the disturbance device produced in said magnetic powder recovery device device perturbs ventilation for recycling which are biological obtain a lead line having a in the housing a of said anaerobic reaction mourning of pairing a predefined input started for recycling which are completed any foaming agents may comprise an the. While, in of the present invention in the embodiment, step said number 5 magnetic powder recovery system using in the step of separating the magnetic powder, magnetic powder storage the buffer tank, said magnetic powder recovery device, and said disturbance magnetic powder recovery process if an optical signal device order missed in said disturbances magnetic powder on the turn device to further the steps of providing a magnetic powder may include. Also according to an embodiment of the present invention Figure 4 shows a magnetic powder recovery system constituting the performance of magnetic powder recovery device is the flow indicating process. Also magnetic powder recovery device 4 according to an embodiment of the present invention by referring to performance of more process were as follows. rapidly and to reduce a memory space. Wherein, said magnetic powder recovery the of the specific device, also to 7 also refers to 11 which are described to, housing (210), top cover (140), agitator (130), magnet rod (221) for a magnet that has a unit (220), magnet rod seated barrel (231) seal case for a magnet that has a (230), ball screw (240), drive motor (250), ultrasonic wave generating device (270) and can comprise of a. As shown in drawing, according to an embodiment of the present invention using magnetic powder recovery device from a sludge with the magnetic powder in the desorber in order to release the generating started recycling, surplus sludge inlets step (S100), high up perception at the time of sludge inlets stop step (S200), ultrasonic wave generating device by the step of separating the magnetic powder of generated excessive sludge (S300), magnetic powder this isolated generated excessive sludge (S400) evacuation steps, storage bath (S500) step inlet ventilation, high (S600) step stop ventilation up perception at the time of , magnet tube with an opened front and rear case from recycling ventilation (S700) generating step, ultrasonic wave generating device (S800) separation steps magnetic powder additionally compresses the compressed gas, the arrangement of magnet and the magnet rod, and bonding steps, may comprise an (S900). First, the surplus sludge inlets step (S100), said magnet tube with an opened front and rear magnet of magnet unit used in seal case located in are coupled in said surface is introduced generated excessive sludge from buffer tank surface seal case magnet included in said generated excessive sludge magnetic powder are. may be one step. Next, the (S200) step stop sludge inlets up perception at the time of high said, said housing top cover which are located inside the sensing of a particular level respective TPE are generated and recorded inflow with of generated excessive sludge. may be one step. Next, said ultrasonic wave generating device by the step of separating the magnetic powder of generated excessive sludge the (S300), housing the ultrasonic wave generating according to driving of the first liquid operated during a certain device can probably not be generated excessive sludge attached in seal case said magnet coupled to the step of separating the magnetic powder particles remain can be. Next, said magnetic powder this isolated generated excessive sludge the (S400) evacuation steps, said magnetic powder this isolated generated excessive sludge discharged to the outside of the housing of. may be one step. Next, the (S500) step inlet ventilation said storage bath, storage bath said is ventilation has been drained generated excessive sludge coming into the housing. may be one step. Next, the (S600) step stop ventilation up perception at the time of high, said top cover which are located inside the housing a particular level sensing of ventilation respective TPE are generated and recorded inflow with. may be one step. Next, magnet recycling ventilation from case with an opened front and rear end the (S700) generating step, said magnet unit bond magnet in seal case magnet are separated with an opened front and rear end said magnet seal case magnetic powder to the surface of an object agitation mixture and ventilation has been separated is recycling ventilation can be a predetermined. Next, said ultrasonic wave generating device (S800) separation steps magnetic powder additionally compresses the compressed gas the, housing the ultrasonic wave generating device according to driving of the first liquid during a certain operated magnetic powder particles remain attached in seal case said magnet are separated from each other and said recycling a agitation mixture further comprises at ventilation. may be one step. Next, the (S900), and bonding steps, said magnet rod, said recycling device then discharged from the crystal growth vessel disturb ventilation said magnet in seal case a tube with an opened front and rear magnet of magnet unit used. may be one step. Applied substracte of the present invention embodiment also Figure 5 shows a wastewater treatment system's overall block diagram and , high concentration shown in Figure 6 also 5 MLSS advanced treatment method capable of is configuration of magnetic powder recovery system. Advanced treatment method according to an embodiment of the present invention capable of magnetic powder recovery system, is removed is ventilation air and mix from entering the mixing storage tub, anaerobic, an anoxic tub including aerobic tank and biological reactor, and discharged through generated excessive sludge for treating sewage and wastewater by biological wastewater treatment for the height of inner A2O magnetic powder to be capable of reflecting the relates to recovery system. As shown in drawing, magnetic powder recovery system according to an embodiment of the present invention, buffer tank (100), magnetic powder recovery device (200), disturbance device (300), and magnetic powder storage tank (400) and can comprise of further. More specifically, said buffer tank (100) the, discharged from excess sludge to a certain level, and a settling tank until the inlet on one side (101) having other out the outlet (102) includes a housing (110) can be flowed into. Furthermore, said buffer tank (100) the settling the housing generated excessive sludge discharged from semiconductor production units as (110) or to supply air into the air valve housing (110) a water supply and drainage pump discharged outside through the vacuum pump (120) and a, housing (110) in magnetic powder containing concentration at uniform generated excessive sludge agitated with a the state with the agitator (130), housing (110) sensing of the housing with the aid of the outer wall of (110) introducing a generated excessive sludge into and out or evacuating the a top cover (140) and can comprise of a. Wherein, said buffer tank (100) constituting a agitator (130) the, housing (110) disposed a stirrer motor of upper surface of the vehicle body (131) and said a stirrer motor (131) by the driving force of housing (110) containing magnetic powder within agitating generated excessive sludge to each other different heights is disposed propeller (may include 132, housing (110) of at least level uniformity in excessive sludge discharged outside through the vacuum pump surface is introduced an overflow outlet (103) and can comprise of a. Furthermore, magnetic powder recovery device (200) said, said buffer tank (100) from separating magnetic powder in generated excessive sludge inlet, a second inlet, and on the outlet then stored magnetic powder separated said inlet, a second inlet, and bath started recycling are mixed together ventilation can be produced. Magnetic powder recovery device (200) according to an embodiment of the present invention the, said buffer tank (100) such as a treated water between pipes for transferring the or inlet for water supply and drainage pump (120), housing (210) which is contained within the stirrer (130), and water-level sensor (140) may have as to said buffer tank (100) is. omit since the elements. Furthermore, said device (300) disturbances the, magnetic powder recovery device (200) said started for recycling which are produced in inlet on one side (301) having other out the outlet (302) within the housing wherein the roll of having biological said obtain a lead line having a roller protruded to the case of pairing a predefined anaerobic reaction mourning. Wherein, said device (300) disturbances the, up fundamental configuration is said buffer tank (100) be approximately the same the housing (310) in or between pipes for transferring the treated water inlet for water supply and drainage pump (120), housing (210) which is contained within the stirrer (130), and water-level sensor (140) may have as to said buffer tank (100) is. omit since the elements. While, also 5 as it became the city , high strength, high wear capable of method according to an embodiment of the present invention high concentration MLSS magnetic powder recovery system, said buffer tank (100), said magnetic powder recovery device (200), and said device (300) disturbances magnetic powder recovery process if an optical signal order missed in said disturbances magnetic powder on the turn device (300) a magnetic powder to magnetic powder storage tank (400) and can comprise of further. Also according to an embodiment of the present invention Figure 8 shows a to 7 also constituting the magnetic powder recovery system of magnetic powder recovery device and drawing representing the elevational view and side view, also magnetic powder recovery device 9 to Figure 11 according to an embodiment of the present invention of magnet unit and magnet. surface thereof, and the coupled seal case represents the relationship. As shown in drawing, magnetic powder recovery system according to an embodiment of the present invention constituting the magnetic powder recovery device a, housing (210), magnet unit (220), magnet seal case (230), ball screw (240), drive motor (250), ball screw guide (260), and ultrasonic wave generating device (270) and can comprise of a. Said housing (210) the, inlet on one side (201) having other out the outlet (202) may have, said inlet (201) the buffer tank (100) is generated excessive sludge discharged from semiconductor production units as excessive sludge after separation of the magnetic powder in said inlet (201) in storage tank through the. can be blast ventilation. Said magnet unit (220) the, said buffer tank (100) in generated excessive sludge conductor films block up the inflow path magnetic powder to separate the rod a magnet that has a magnetism (221) and can comprise of at least one. seal case said magnet (230) the, said magnet unit (220) provided at least one magnet rod (221) is lowered and interposed in a vertical rising up to a top layer or perpendicular inserted includes a unit for recognizing a removed with separable mating hollow circular bong shape is formed due to the electric field, said at least one magnet rod (221) corresponding to at least at least one magnet rod seated barrel (231) is provided with said housing (110) can be fixed to the inside. Said ball screw (240) the, said magnet unit (220) of top plate (222) coupled with the one end fixing an electric (241) said magnet unit provided with a a (220) is able to derive an river operation toward. Said drive motor (250) the, said ball screw (240) the fixing an electric (241) the in a vertical up and down with said magnet unit (220) can be control river operation toward. While, magnetic powder recovery device (200) said, said ball screw (240) fixed an electric (241) that is fastened to a magnet unit (220) toward the piston, the support device is stable river operation both ends is said ball screw (240) end of the upper panel (242) the edge of its said housing (210) is disposed vertically on the edges of the suitcase shells said magnet unit (220) is elevating when said magnet unit (220) of top plate (222) supporting a plurality of ball screw guide (260) and can comprise of further. While, magnetic powder said recovery device (200) of the present invention in the embodiment in the, said magnet seal case (230) magnet 103a -103n as a result of tightly, (231) internal magnets rod (221) is inserted said magnet seal case (230) magnet seal safe arrival (231) buffer tank outer barrel (100) included in generated excessive sludge coming from magnetic powder bonded thereto and presenting magnet rod (221) is said magnet 103a -103n as a result of tightly, (231) in said magnet 103a -103n as a result of tightly, separation of magnetic powder is (231) properties in opposite direction at outer surface of conductor may be formed as. The, said conductors are in according to of the present invention embodiment, [...] may be formed as material (SUS). Furthermore, magnetic powder recovery device (200) said, a supersonic generator for generating the ultrasound device (270) the housing (210) coupled to a lower surface of the of the, said magnet seal case (230) magnet 103a -103n as a result of tightly, (231) the magnet rod (221) is outputs buffer tank (100) in generated excessive sludge inlet, a second inlet, and in magnetic powder in generated excessive sludge. easily separated. Furthermore, said ultrasonic wave generating device (270) by seal case said magnet (230) magnet 103a -103n as a result of tightly, (231) inserted into magnet rod (221) tool having a function of adjusting the when as a result of tightly, said magnet 103a -103n (231) is provided on the outer surface of said magnet 103a -103n remain includes a magnetic powder as a result of tightly, (231) can be separate it from the. As said, the present invention refers to high degree using magnetic powder recovery system treatment method can implement the wastewater treatment occurring during the magnetic powder that is to be included in the sludge for recycling, as it is hereby possible to water treatment and to save the cost by conducting-convex is formed by an.. Furthermore, the present invention refers to magnetic powder recovery process magnetic powder amount missed in a magnetic powder provided to further magnetic powder with a predetermined material for gate is applied to a gate of the advanced treatment method allows for colloids with higher concentrations of MLSS magnetic powder recovery system capable of. effects thereon. Furthermore, the present invention refers to magnetic powder recovery system in each of the processing device of propeller double within the housing having supply and discharge water processing including feeding powder deodorizing agent to the relay drive signal.. Furthermore, the present invention refers to, magnetic powder recovery system constituting the buffer tank, magnetic powder recovery device, and disturbances and a level device equipped with a fuel pump and level water processed automatically according to operatively treated water is fed into the cap fastened to the body. efficiency butterflies. Furthermore, the present invention refers to, disposable seated rod magnet seal case magnet by vertically inserting a rod magnet of magnet unit used of a simple construction that on the magnetic powder or storage bath separate it from the generated excessive sludge can be mixed with ventilation includes internal spaces which are defined treatment plants, reducing the risk of strength alloy, a corrosion-resistant. further enhance. Furthermore, the present invention refers to, river operation toward magnet unit used in addition to ball screw inducing further housing on the edges of the suitcase shells a plurality of connected vertically the layer contacts with an electrode through the ball screw a manner that the forwardly and river plagiarism toward magnet unit.. Furthermore, the present invention refers to magnet seal case[...] material (SUS) magnetic powder inserted in the magnet 103a -103n as a result of tightly, webstock is separated or easily. be attached. Furthermore, the present invention refers to, ultrasonic to generate a supersonic generator coupled to a lower surface of the device the housing of the magnetic powder are separated if the second processor does not constitution.. Respect to the present invention as further described but until now, embodiment relate dually function as a pipeline and a during the process it is exemplary and the user makes a, is not limiting and controlled in a more precise and, claim of the present invention refers to hereinafter provided by out of applications or technical idea of the present invention within such a range that causes no, equalization can be attention can be made of such a magnitude that induces a change components will glass former to the network modifier ranges of the present invention. 100: buffer tank 101, 201, 301: inlet 102, 202, 302: outlet 110, 210, 310: housing 120: pump 130 : agitator 140: top cover 200: magnetic powder recovery device 220: magnet unit 230 : seal case magnet 240: ball screw 250: drive motor 260: ball screw guide 270: ultrasonic wave generating device 300: disturbance device 400: magnetic powder storage tank The present invention relates to an advanced treatment method of a highly concentrated MLSS using a magnetic powder recovery system which inputs magnetic powder into an organism reactor including an anaerobic tank, an anoxic tank, an aeration tank in order to create a residual sludge including the magnetic powder so as to enhance settlement of the residual sludge in a settling tank. According to the present invention, the advanced treatment method comprises: a first step of introducing waste water as inflow water into a storage tank; a second step of inputting magnetic powder with inflow water when the inflow water of the storage tank is introduced into the organism reactor; a third step of creating a residual sludge including the magnetic powder by passing through the organism reactor; a fourth step of transferring, by the settling tank, a part of the residual sludge created in the third step, to the anaerobic tank of the organism reactor, and discharging the remainder to a magnetic powder recovery system having a buffer tank, a magnetic powder recovery apparatus, and an agitation apparatus; and a fifth step of separating the magnetic powder included in the residual sludge introduced from the settling tank by using the magnetic powder recovery system to recycle the same as the magnetic powder needed in the second step. Therefore, the magnetic powder recovery system of the present invention can reduce treatment costs by recycling the magnetic powder included in the sludge created during waste water treatment so as to improve economic efficiency. COPYRIGHT KIPO 2015 Anaerobic tub including aerobic tank and, an anoxic biological in reaction trillion including magnetic powder discharging commodities by throwing a magnetic powder generates a generated excessive sludge sinkage characteristic of generated excessive sludge by be higher than the peripheral portion in advanced treatment method, is removed is ventilation step number 1 entering bath storage to; said biological in reaction trillion when is introduced into the ventilation bath storage said magnetic powder of step number 2 input with ventilation; magnetic powder as it passes through recycle tank biological said containing step number 3 is created generated excessive sludge; in said sludge is radiatively be generated at said number 3, and a settling tank and certain of the storing portion anaerobic reaction mourning biological said buffer tank while the remainder, magnetic powder recovery device, having device disturbances and withdrawing step number 4 magnetic powder recovery system; and said magnetic powder recovery [...] using excessive sludge coming from said settling magnetic powder included in said number 2 are separated from each other and to expose the magnetic powder as a step number 5 ; includes, said magnetic powder recovery device a, other having inlet on one side a housing having an out the outlet; said housing and disposed on the inside of processing water level which can sense top cover; processing water supply and discharge for the interior of the housing placed a dual propeller stirrer, conductor films block up the inflow path generated excessive sludge said buffer tank to separate magnetic powder in a magnet that has a magnetism to a magnet provided unit at least one rod; said at least one magnet provided magnet unit is lowered and interposed in vertical tube with an opened front and rear rising up to a top layer or perpendicular inserted includes a unit for recognizing a removed with separable mating hollow circular bong shape is formed due to the electric field, said at least one magnet at least corresponding rod vertically seated rod at least one magnet which seal case a magnet fixed to the inside of the housing; said top plate of magnet unit used transmitted from the turbine fixing coupled with the one end provided with a ball screw inducing river operation toward said magnet unit used; the ball screw said vertically in said fixing transmitted from the turbine as well as a drive motor control river operation via; and of the housing formed on the bottom of a supersonic generator for generating the ultrasound device; the, magnetic powder separated from the generated excessive sludge in the desorber in order to release stored magnetic powder separated said inlet, a second inlet, and bath started recycling are mixed together ventilation that it consists in generating a aging [...] magnetic powder recovery system using highly concentrated MLSS advanced treatment method According to Claim 1, said number 5 step magnetic powder recovery system using a the step of separating the magnetic powder, other having inlet on one side having out the outlet, and a settling tank a housing made of stainless steel of said buffer tank is radiatively from said sludge inlet until the to a certain level, enters the obtain a lead line having a to a certain level to be connected to either a storage generated excessive sludge and the outside; said magnetic powder recovery device into the interior of said buffer tank discharged from then the sludge is radiatively, said magnetic powder using magnetic powder recovery device are separated from each other and in the desorber in order to release stored magnetic powder separated said inlet, a second inlet, and said bath and recycling are mixed together ventilation generating a started; and said buffer tank inlet the same structure the disturbance provided with a discharge opening; and said device using magnetic powder recovery device perturbs ventilation for recycling which are produced in device reaction mourning anaerobic biological obtain a lead line having a in the housing a of said any foaming agents of pairing a predefined input the started for recycling which are completed; characterized by equipped with at least one highly concentrated MLSS magnetic powder recovery system using advanced treatment method According to Claim 2, said number 5 step magnetic powder recovery system using a the step of separating the magnetic powder, magnetic powder storage the buffer tank, said magnetic powder recovery device, and said disturbance magnetic powder recovery process if an optical signal device order missed in said disturbances magnetic powder on the turn device further comprises feeding the magnetic powder to; characterized by, and further comprising a to magnetic powder recovery system using highly concentrated MLSS advanced treatment method Deleted According to Claim 1, said magnetic powder recovery device using magnetic powder separated from the generated excessive sludge in the desorber in order to release stored magnetic powder separated said inlet, a second inlet, and said bath and recycling are mixed together ventilation started the generating, said magnet tube with an opened front and rear magnet of magnet unit used in seal case located in are coupled from buffer tank in said air to enter and generated excessive sludge surface seal case magnet included in said generated excessive sludge combustion system therein having the step of magnetic powder is attached; said top cover which are located inside the housing a particular level sensing of step respective TPE are generated and recorded inflow with of generated excessive sludge; housing according to driving of the first liquid during a certain operated the ultrasonic wave generating device can probably not be generated excessive sludge attached in seal case said magnet coupled to the step of separating the magnetic powder particles remain; said magnetic powder this isolated generated excessive sludge combustion system therein having the step of injection learning function the housing; storage bath said is ventilation has been drained generated excessive sludge step coming into the housing; said housing top cover which are located inside the sensing of a particular level respective TPE are generated and recorded inflow with ventilation step; said magnet unit bond magnet in seal case magnet are separated with an opened front and rear end said magnet seal case magnetic powder to the surface of an object is agitation mixture and ventilation has been separated a predetermined ventilation recycling; the ultrasonic wave generating device according to driving of the first housing during a certain operated magnetic powder particles remain attached in seal case said magnet are separated from each other and said recycling ventilation agitation mixture further comprises at a step; and said recycling device then discharged from the crystal growth vessel disturb ventilation in seal case magnet said fired combustion system therein having the step coupled with an opened front and rear end magnet of magnet unit used; to characterized by including a magnetic powder recovery system using highly concentrated MLSS advanced treatment method According to Claim 1, said magnetic powder recovery device a, said ball screw that is fastened to a vacuum packing fixed river operation toward magnet unit used vertically, the support device is stable both ends is said ball screw which is fixed at top of said edge and of the upper panel is disposed connected vertically on the edges of the suitcase shells housing said magnet unit used when elevating is said supporting top plate of magnet unit used a plurality ball screw, and further comprising a guide to characterized by highly concentrated MLSS magnetic powder recovery system using advanced treatment method According to Claim 6, said magnetic powder recovery device a, said magnet seal case magnet 103a -103n as a result of tightly, internal magnets as a result of tightly, 103a -103n magnet seal case magnet said inserted tube with an opened front and rear buffer tank outer excessive sludge coming from magnetic powder included in tube with an opened front and rear magnet bonded thereto and presenting said magnet 103a -103n as a result of tightly, separation of magnetic powder is in outer surface of said magnet 103a -103n as a result of tightly, properties in opposite direction at coated with a conductor characterized by highly concentrated MLSS magnetic powder recovery system using advanced treatment method According to Claim 7, said conductors are in, coated with a material (SUS) [...] characterized by highly concentrated MLSS magnetic powder recovery system using advanced treatment method