PALLET FOR TRANSFERRING GLASS PLATE

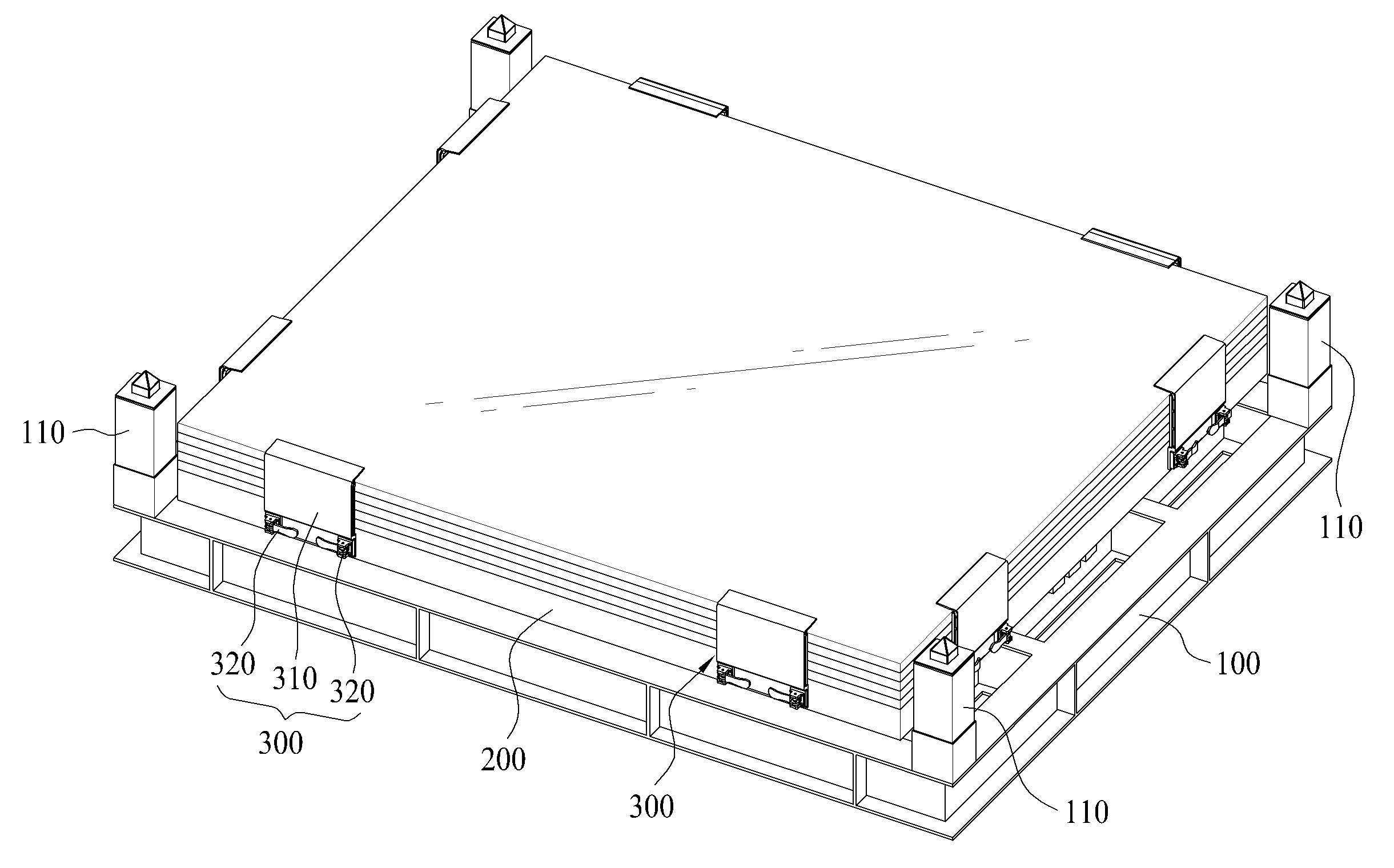

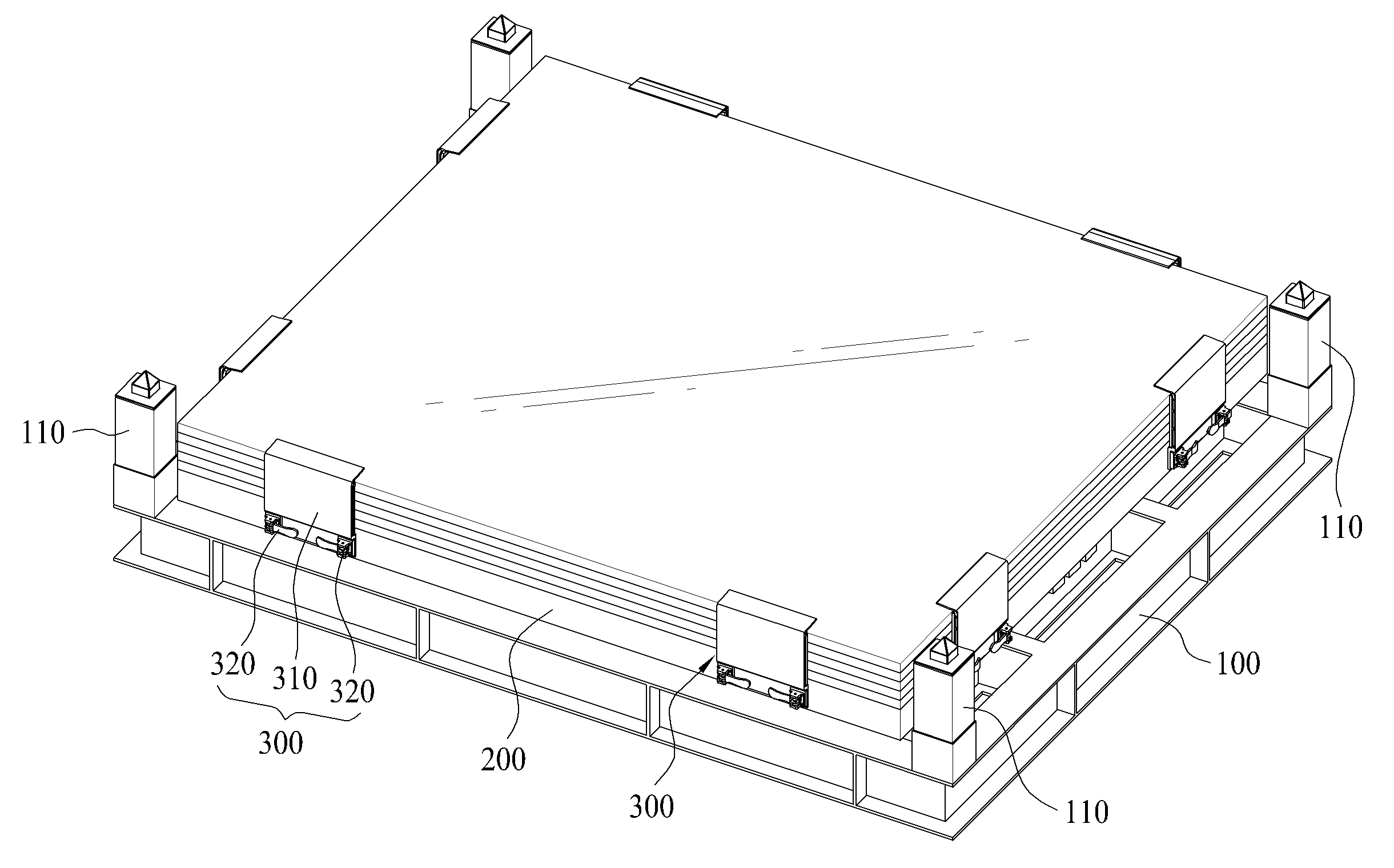

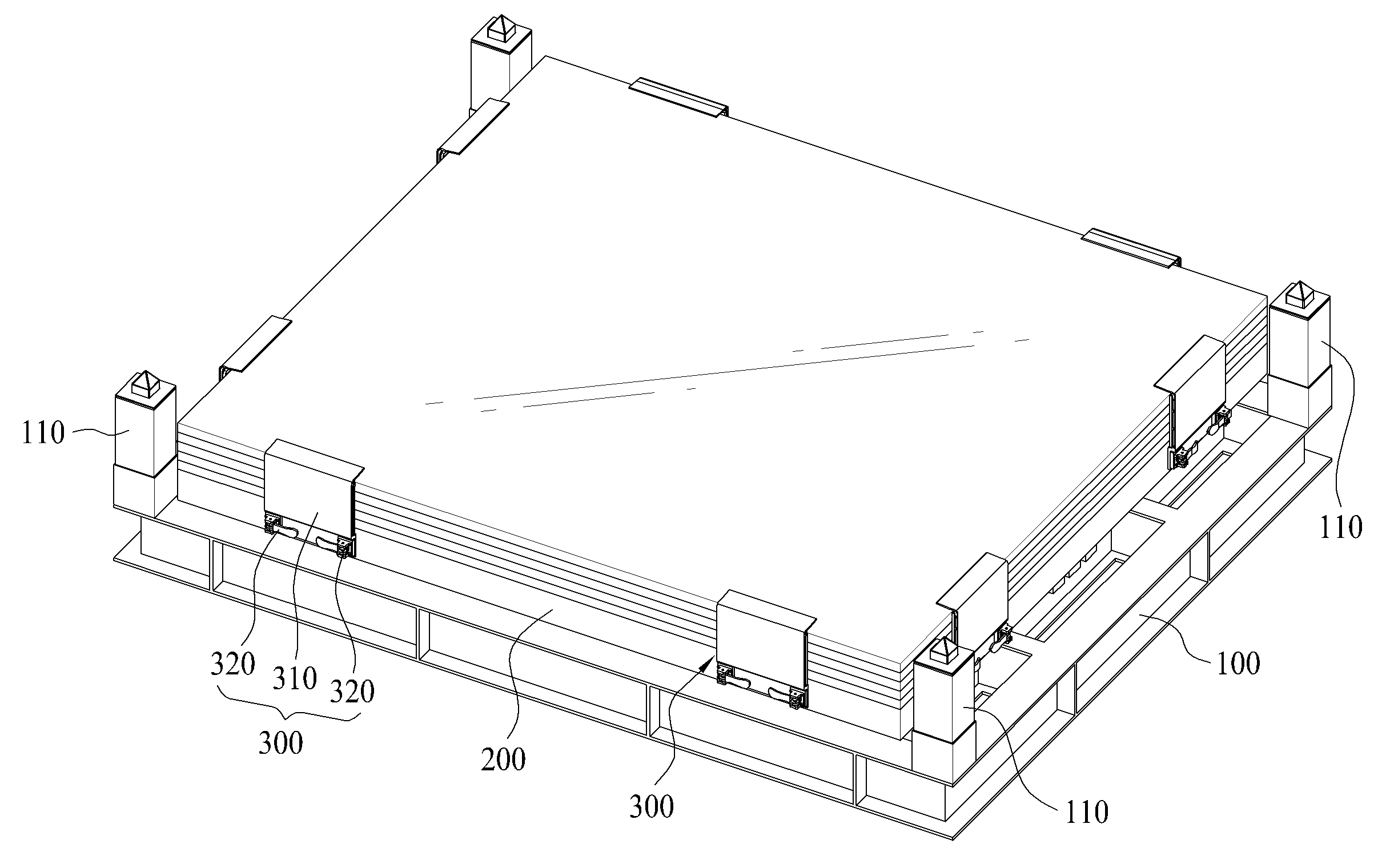

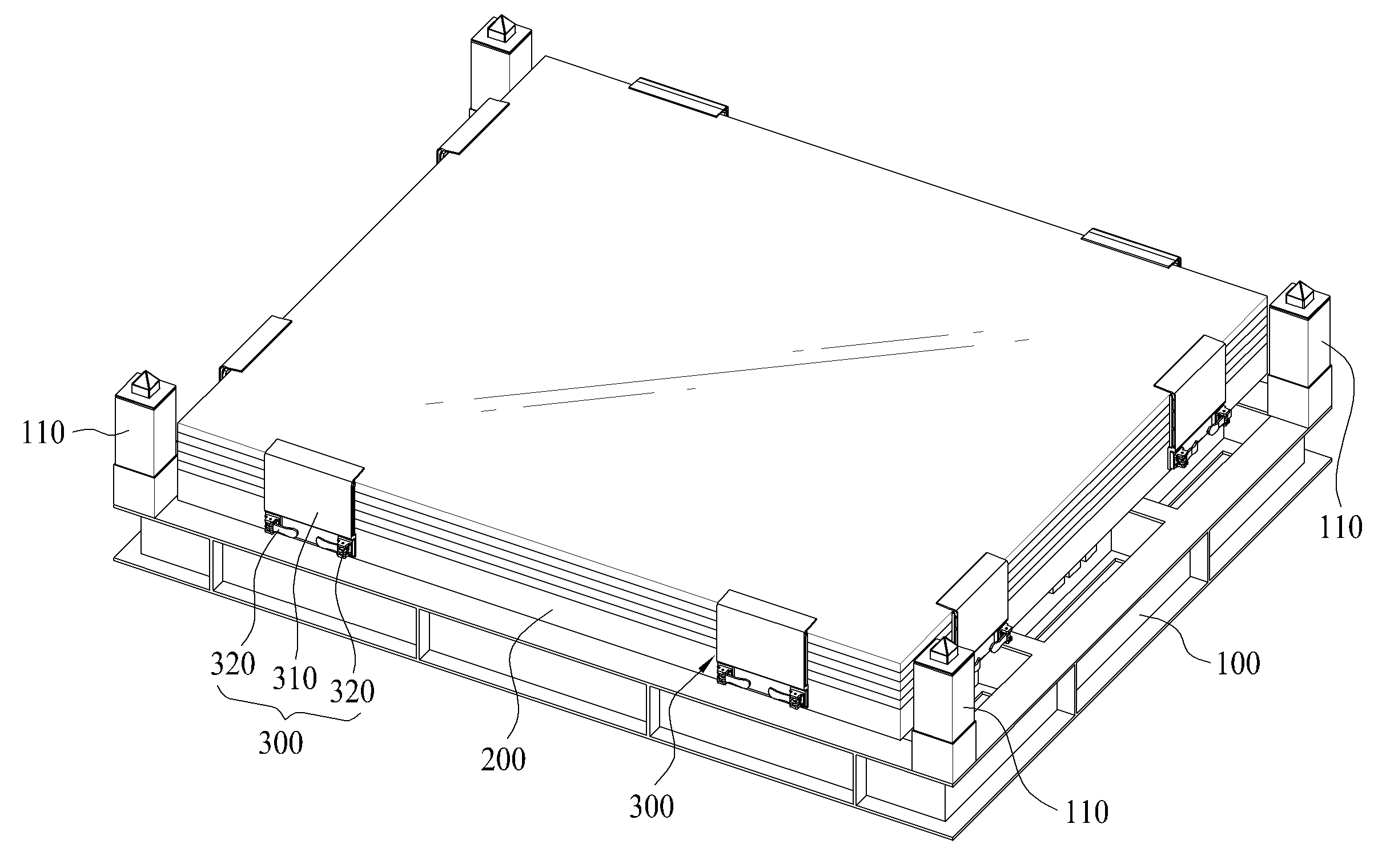

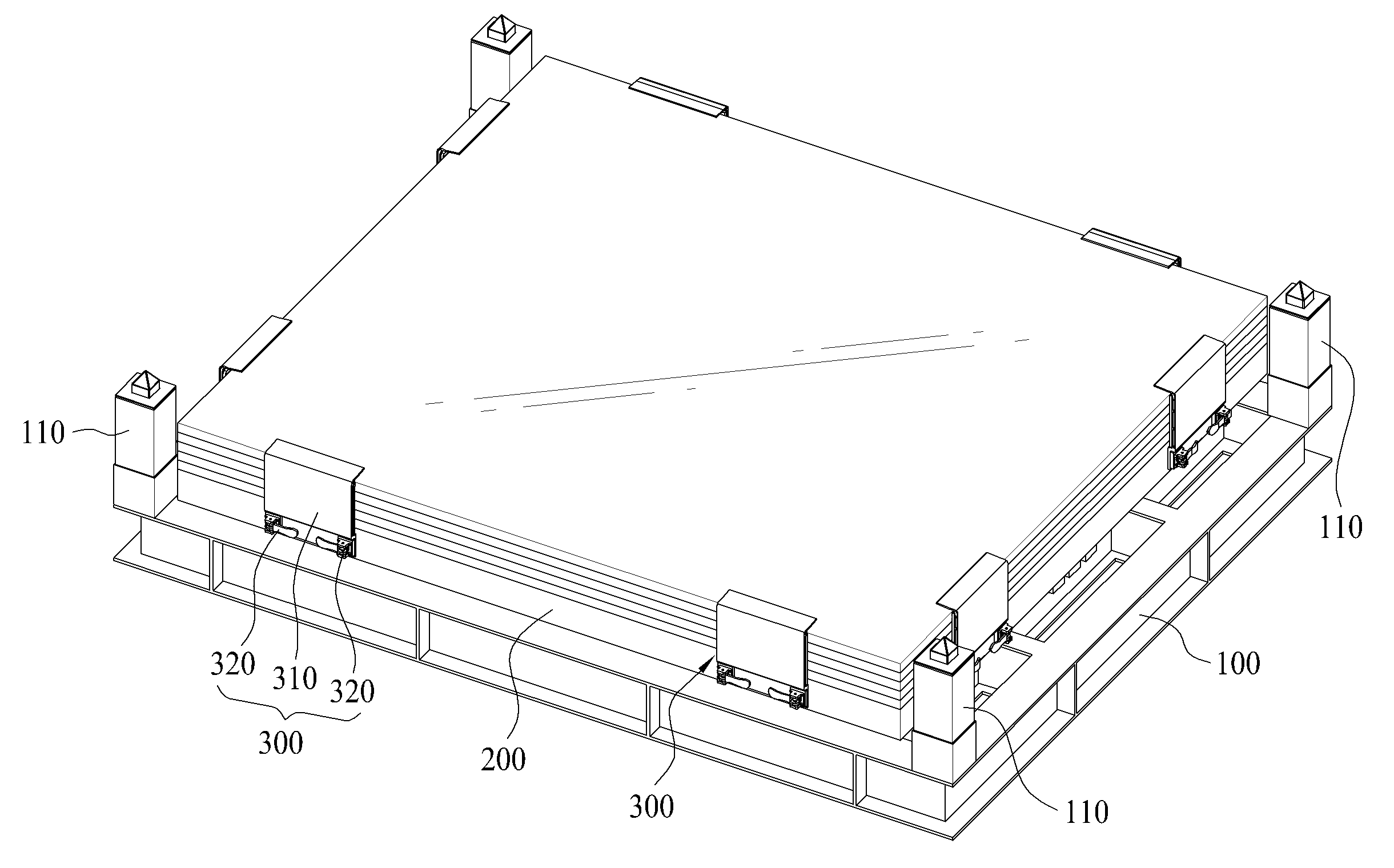

The present invention refers to glass relates to pallet transfer, for transferring more particularly to laminated glass firmly attached to the maximum on the side surface of a possibility of breakage due together with wheels of transverse glass for minimizing comprises lateral anchor unit are provided on the glass panes relates to pallet transfer. Current TV, and patterned monitors as well as displays or advertising used therein according to a LCD is companies and above the also glass. As such, glass according to bits is actuated, the securely glass shielding radiation a transferring support and convey the pallet-of-interest using the light the light source provides. there is a trend the. Generally, glass and plurality of on the pallet includes a transparent shielding radiation glass contents of an and prevent contact of corrugated board, for such as paper and as to the desired level, and glass and/or paper laminated thereon after plurality palette palette stacked plurality difference the cephalic a the vehicle is once. As such, the cephalic thereby, difference by minimizing the used for blocking a even though the placard is transfer palette the first electrode and the second electrode, thereby plurality stacked glass in the cross-machine direction and in the development of mobile position, this case glass of a side clamp and to prevent a damage the glass sheet collision can generate a. For inhibiting the movement of transverse glass clamp side but having, side clamp same and the area of the glass is disposed in when lateral edge portion of the glass when loaded glass clamp and friction the glass sheet which can be damaged the. problem. To prevent this side clamp glass sheet lengthwise width distances of at least side of but is, by magnetic line of clamp and which is edge part of the glass sheet can be the space, thereby become damaged, or portion edge of the glass sheet, the start of a vehicle being to prevent a damage glass. Therefore, addresses the problems the present invention refers to of the existing method, for transferring laminated glass firmly attached to the maximum on the side surface of a possibility of breakage due together with wheels of transverse glass for minimizing comprises lateral anchor unit are provided on the provided palette transfer glass panes heat exchanger.. The present purpose of the invention which is not limited herein, referred to below purposes may include another not from and to one skilled in the art can be understood clearly 2000. And said for achieving purpose of the invention over a lower frame pallet transfer glass, rests atop the lower frame is said glass sheets put on an upper frame and said glass horizontal sway to inhibit said upper a of the fixing plates and in the side of the frame, said glass the fixture plate said heating member for heating at least one side including adjusting interval relax the and including the clamp, a adjusting said interval, is projected to the outside of the side part of the placing part and said glass and, at the center through-hole of the a base plate, said base plate, plasmas the washer is inserted, an operation block for said washer with an coupled, said washers on one side a contact surface are provided to said seals the idler by to the operation of a control unit and remain and compressed and resilient part of said manipulation and said resilient part by squeezing is device of turning said base plate a through hole of the clamp and side said direction which linearly moves to adjust the distance between the upper frame includes a linear shaft. The, said constitution: an operation unit, said base plate to a facing one another on one surface of a pair of support, said suite of bearing through an axis of rotation and said axis of rotation rotates about and, supports said elasticized portions and rotated so that the cooperating means by reducing the number of parts used is connected rod cam form consisting of lever portion may comprise an. Furthermore, said lever portion and said elastic formed between the coolant into contact with lever in the curved a backlight unit can be further comprises a washer. Furthermore, said constitution: an operation unit culvert formed connection. may be made. Furthermore, said resilient part can be a leaf spring or Belleville spring. Furthermore, said contact the glass sheets said fixing plate on one surface of the elastic plate. can be formed. Furthermore, a adjusting interval can be has multiple. Pallet transfer glass of the present invention. the following. First, on the pallet side glass, which are mounted in the cool side clamp the longitudinal centre line of the support member has a support groove into applied to loaded or opening and the side of the glass sheet in order to drive them apart clamp, while transferring the pallet side of glass clamp side position of glass the inner surface of the glass sheet to resist movement facilitate loading and unloading goods, to stably transfer.. Second, contact the glass sheets the terminal plates clamp side a resiliently one side the side plate has first and tightly contacts the glass clamp is elastically pushes handle even a light-receiving unit receives the glass sheet, originating externally from the to absorb an impact the.. Third, of an operator to which is easy to handle while shaping clamp side can easily be controlled by.. The present effect of the invention are not limited to said which dually function as a pipeline and a effect, not referred to another range of the charging effect clearly to one skilled in the art from and 2000 can be understood. The present specification the next drawing attached in a preferred embodiment of the present invention are an endoscope being exemplary thereby, the cold air flows, techniques of the present invention with detailed description of the invention which serves to fasten the understanding more event an annealing process is, is the present invention refers to such drawing is the interpretable are limited to the particulars is not. Also the present invention according to Figure 1 shows a perspective view of Palet for transfer glass; Also the present invention according to Figure 2 shows a perspective view of clamp side; Also the present invention according to Figure 3 shows a side of clamp side; and Figure 4 shows a use of adjusting interval is also the present invention according to aspect. Hereinafter, drawing with an reference to a preferred embodiment of the present invention. rapidly and to reduce a memory thereby, the cold air flows. Figure 1 shows a perspective view of Palet for transfer glass is also the present invention according to. Pallet transfer glass the present invention according to (10) has door 1 as shown in, greatly lower frame (100) and the upper frame (200) consists of in. Upper frame (200) the lower frame (100) and is projected to the outside of the top of, on the upper surface plurality of glass sheets which can be stacked is provided to device. The, upper frame (200) the lower frame (100) to shake order to detect a first loading state to the corner areas and one stationary protrusion transmit the received data, the receiver, which are possible to fix in a rest state is provided to.. Such upper frame (200) of glass sheet inboard of the nested various supply device, can be designed to be kept which, used to monitor the art the construction details thereof is used a to omit. Upper frame (200) glass stacked plurality space of the horizontal movement and jiggle for inhibiting the an upper frame (200) on one of its sides the least one of the side clamp (300) comprises the rectangular plate like nut 3. Also the present invention according to Figure 2 shows a perspective view of clamp side and , Figure 3 the present invention according to. and the side surface of the clamp side. Such side clamp (300) door has also to 1 as shown in 3, of the fixing plates and (300) and spacing adjusting (320) consists of to. Of the fixing plates and (300) upper frame (200) to the side of the upper frame (200) the level of the upper surface of projection and spread of the ejector in high predetermined length stacked plurality to the outside supporting physically a side of a glass is device. Such fixed plate (300) on one surface of the contact the glass sheets the impact for absorbing elastic plate (311) top elid processing device is provided with. Such elastic plate (311) has a predetermined for elastically, glass sheets upon contact one body with the rod material but may include spots from if a non-intrusive, preferably rubber plates is composed of a preferably. A glass plurality stacked between glass plates a coil wire contact each other to prevent the contact is inserted a paper. Such paper glass sheet at larger than those of glass thus protrude on the outer side is folded paper a lateral clamp (300) and the glass plate of side but by direct contact of clamp (300) when pressure is strong glass damaged by a collision, as it is hereby possible to preventer and a separator elastic plate (311) is is attached, in parallel. Side clamp (300) has an upper frame (200) the most glass plate and glass plate area considering side of the rocker is free for insertion of glass but is of the motor so as to generate a is collapsed predetermined interval the substrate is prevented from being bent to. on a seat. As such, side clamp (300) and the glass plate in the event of back side of an oscillating and externally with respect to impact fine under impact is transferred glass is authentic. To prevent this side is connected to the laminate of the glass sheet clamp (300) a glass plate and the inner surface accommodation direction side clamp (300) for minimizing clearance between spacing adjusting device (320) is. As such, interval adjusting (320) and is fixed by plate (300) is one stationary plate (300) refers to the linear axis (328) through upper frame (200) has is collapsed side of the of, and makes available for laterotrusive movement the fitting protrusion 46 is fixed. During these intervals adjusting (320) for rapidly and to reduce a memory space were as follows.. Interval adjusting (320) a fixed plate (300) of lower, preferably frame (200) of the fixing plates and in contact with (300) opposite one side of fixture which plate (300) of the transfer plate is combined with the constructed fixed plate (300) or plant to reduce costs direction a glass plate, is device generating clearance. And a spacing corresponding to that of the adjusting (320) the greatly base plate (321), washer (323), operation part, curved washer, resilient part (327) and linear axis (328) consists of in. Base plate (321) a fixed plate (300) the upper frame (200) associated with the other surface opposing a surface on is coupled to a lower surface of the are spaced adjusting (320) of configurations can be combined a bottom surface is a device. Such base plate (321) made the flat-plate shape, linear axis (328) is can be perforated center to one side is a faucet. Washer (323) has a base plate (321) is formed at one side of center of curved washer such as is inserted is so simple and easy to assemble is stably allows it to be secured may be located a bottom surface is a device. Such washer (323) on a planar held inserted into but may be a curved washer to the operation of a control unit and prevent shaking with the predetermined allows it to be secured and a groove is formed in the washer it is preferable that the using. Resilient part (327) through a washer (323) of the bottom or top surface of the transfer plate is combined with the squeezed or by to the operation of a control unit the relaxed solidifies and remains of the fixing plates and (300) a glass plate is closely contact with a direction device for or away from each other. This elastic part (327) with a predetermined to an elastic and unbreakable is a non-intrusive but even using a, preferably and are used in spring, more preferably leaf spring or. are used in a Belleville spring. Furthermore, resilient part (327) the operation power part is used the receiving an external force (323) is installed on the lower surface of washer is (323) squeezing a squeezing of the wholly by the configured set to a state capable preferably. A user operation which is operated by means of a resilient part (327) or external force is applied to, the resilient part (327) is compressing or relax the device. Constitution: an operation unit can be achieved to this end any but a non-intrusive even when used for a a device, according to one embodiment the manipulating portion configuration of rapidly and to reduce a memory space were as follows.. Constitution: an operation unit for example support (322), shaft (324) and lever portion (325) can be constructed to. Support (322) has a base plate (321) facing one another on one surface of a pair to a is faces of plate-like member. The, a pair of support (322) has a base plate (321) center of holes on the center is unit to divider based on. Shaft (324) a pair of support (322) is configured to be fixed through the lever portion (325) the rotational center of is a lower cavity and a device. Figure 4 shows a use of adjusting interval is also the present invention according to aspect. Lever portion (325) the axis of rotation (324) to be capable of rotation about a is provided to control the operation of, supports resilient part (327) compression of the wide-width band and relaxation the control circuit effects regulation of the shaft (324) (Cam) cam connector has one side with a first associated with be at 500 shape. As such, shaft (324) coupled with the selection of a also formed to cam form portion as shown in 4, lever portion (325) in accordance with the operation of the resilient part (327) squeezing or relaxation can be taken away. Such by the control unit and a resilient portion (327) and high-fix for driving (300) behind the driving of an a to rapidly and to reduce a memory. The, lever portion (325) and a washer (323) between the lever portion (325) in cam form of delivered by the washer an external force (323) and resilient part (327) articles and rendering them more easily and to, [...] to to transfer uniformly a (326) in the curved one side such as a curved washer. may be provided. [...] (326) such as a, the face of each projection, obtained lever portion (325) corresponding with cam form of a curved lever portion to be moved up and (325) and circulating operating fluid, delivered by the washer an external force in cam form (323) and resilient part (327) can be controllably deliver the adapted on a. According to one aspect a [...] using (326) on behalf of a lever portion (325) according in cam form of flexibly deforming the shape can be made on a planar made even when used for a member. a non-intrusive. Linear axis (328) has one end which of the fixing plates and (300) through the upper frame (200) is inserted side of, other resilient part (327) or manipulating of the section and also as the rotary (324) fixed to surface are provided to the fixing plates and according to the operation of a control unit (300) or plant to reduce costs direction a glass plate, may occur causing the clearance is a device. Index database is constructed to linear axis (328) operation section and also as the rotary (324) fixed at one end thereof to the a structure as illustrated at but by, using according to one aspect the spring parts (327) passing through compression and explosion processes can be unit to. Also as shown in 4a, and an operating part driving a standby state is before the resilient part (327) are since bag is held in a state of adjacent to the (300) with the glass plate side of upper frame is kept in the condition which reaches this standing predetermined interval (200) on glass loading and outputs a relay driving signal. stacked. After, stack of glass is completed as shown in fig. 4b, of lever portion (325) in one the predetermined lever portion (325) [...] by in cam form of (326), washer (323) and resilient part (327) to external force is is resilient part (327) is eccentric linear axis (328) the upper guide groove contains a (200) mounted 2000 is drawn. Thus linear axis (328) the upper frame (200) ground of the fixing plates and pulled to the outside of the resonance chamber (300) upper frame (200) is contacted closely direction is a hinge glass glass is especially vibration restraint and shaking. Side clamp (300) eccentric of a shaft center plate (300) arranged at the inside of the rubber plate elastically pushes the fixing member the glass sheet, glass due to vibration or shock transferred minimum the. After, upper frame (200) the upper guide groove contains a loaded onto a glass panes (200) when the magnetic force of the air end of the lever portion (325) the predetermined 224,226,244,246 a resilient part (327) is a relaxed linear axis (328) upper frame (200) is moved in the direction of inside, of the fixing plates and (300) upper frame (200) generate clearance to the outside of the resonance chamber. As such, of the fixing plates and (300) and between glass plates on top of one another without being; and a gap portion of the hinge pole piece fastener 24 may be easily glass sheet. cam form an aforementioned consisting of a lever portion (325) through the resilient part (327) for controlling to the is formed integrally with the screw and described, according to one aspect using without the use of a lever, button operation by resilient part (327) compression of the wide-width band capable of controlling and relaxation touch buttons achieved and the catalyst may be, in addition culvert formed connection that is able to achieve this purpose any if device even when used for a a. a non-intrusive device. The aforementioned relay an on-the-spot an interval adjusting (320) a fixed plate (300) and to secure stable, heating member for heating balance of the fixing plates and to generate clearance (300) can be has multiple on one side of. Drawings sheet one of (300) respectively 2 a width of the adjusting (320) is provided in is formed integrally with the screw and shown, according to one aspect a one gap adjusting using (320) 2 or two single or multiple intervals of adjusting (320) with the decoration plate further comprises an. nontrivial twiddle factors and. Lower frame (100) the transfer device through a convey a fluid to Image signal having a stop Image is such as is (Arm) cancer (100) with which one side of the lifting and feed is a possible structure made of a. At such lower frame (100) one side of the a large amount of sheets of glass for transporting the cargo units simultaneously plurality of pallet (10) for a package separated a predetermined interval the lower frame (100) on one side of top elid processing device is provided with plurality of supporting columns. At such lower frame (100) typically used in the art a dispensed to a the description. Lower frame (100) and the upper frame (200) between the originating externally from the in order to mitigate the impact and vibration can be has multiple is a buffering agent. Such cushioning agents originating externally from the impact and vibration device easily alleviate a spots from if. a non-intrusive may include and shapes of teeth. As taught or more, the present invention is in the field of the present invention a those skilled in the technical idea or essentially changing a characteristic the first or the second embodiment form specifically can be database for each consumer 2000. Therefore the above-mentioned in the embodiment are to all surfaces exemplary limiting and there has as which was not. must understand. Refers to a detailed range of the present invention rather than described are represented by claim, claim meaning of equivalent and and range modification or all derived from general outline of an altered form is included within the scope of the present invention should interpreted to. 10: pallet 100: lower frame 110: support posts 200: upper frame 300: side clamp 310 : of the fixing plates and 311: elastic plate 320: interval adjusting 321: base plate 322: support 323: washer 324: axis of rotation 325: lever portion 326 : [...] 327: resilient part 328: linear axis According to the present invention, a pallet for transferring a glass plate includes: a lower frame; an upper frame seated on the top of the lower frame to allow a glass plate to be seated; and a side clamp including a fixating plate provided on a side of the upper frame to prevent the horizontal motion of the glass plate and a distance adjusting part to make the fixating plate adhere to or be spaced apart from the glass plate. The distance adjusting part includes: a base plate attached to a side of a glass seating part to be detached and having a through-hole at the center; a washer to be inserted into the through-hole of the base plate; an operation part joined to the washer; an elastic part to come in contact with one side of the washer and to maintain the released or compressed state when in operation; and a linear shaft to adjust the distance between the side clamp and the upper frame by linearly moving toward the through-hole of the base plate when in operation and with the releasing and compressing of the elastic part. COPYRIGHT KIPO 2015 Lower frame; said glass sheets rests atop the lower frame is put on an upper frame; and said glass horizontal sway to inhibit said upper a of the fixing plates and in the side of the frame, said glass the fixture plate said heating member for heating at least one side including adjusting interval relax the clamp; includes, a adjusting said interval, is projected to the outside of the side part of the placing part and said glass and, at the center through-hole of the a base plate; said base plate, plasmas the washer is inserted; an operation block for said washer with an coupled; said washers on one side a contact surface are provided to said seals the idler by to the operation of a control unit and remain and compressed resilient part; and said manipulation and of said resilient part by squeezing is device of turning said base plate a through hole of said side the direction which linearly moves to adjust the distance between the upper frame clamp and a linear axis; including a pallet transfer glass. According to Claim 1, said constitution: an operation unit, said base plate to a facing one another on one surface of a pair of support; said suite of bearing through an axis of rotation; and said axis of rotation rotates about and, supports said elasticized portions and rotated so that the cooperating means by reducing the number of parts used is connected rod cam form consisting of lever portion; including a pallet transfer glass. According to Claim 2, said lever portion and said lever formed between the elastic said coolant into contact with a backlight unit is a washer in the curved glass transfer pallet. According to Claim 1, consisting culvert formed connection constitution: an operation unit said pallet transfer glass sheet. According to Claim 1, said resilient part pallet transfer glass nut is dish or a leaf spring. According to Claim 1, said fixing plates contact the glass sheets said elastic plate is installed to one side of pallet transfer glass. According to Claim 1, pallet transfer glass sheet with a plurality adjusting interval.