PLANETARY GEAR DEVICE FOR AUTOMATIC MANUAL TRANSMISSION

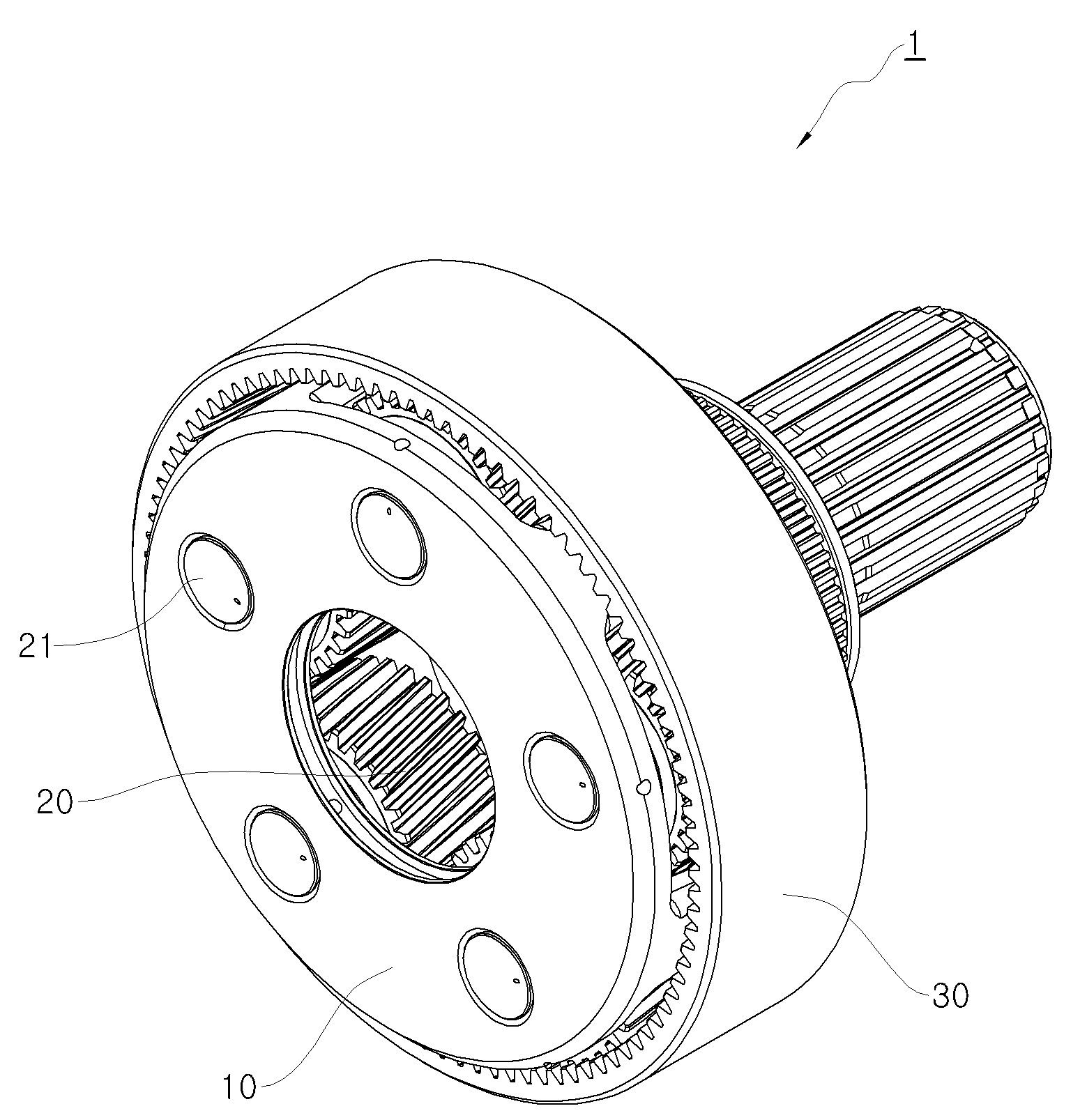

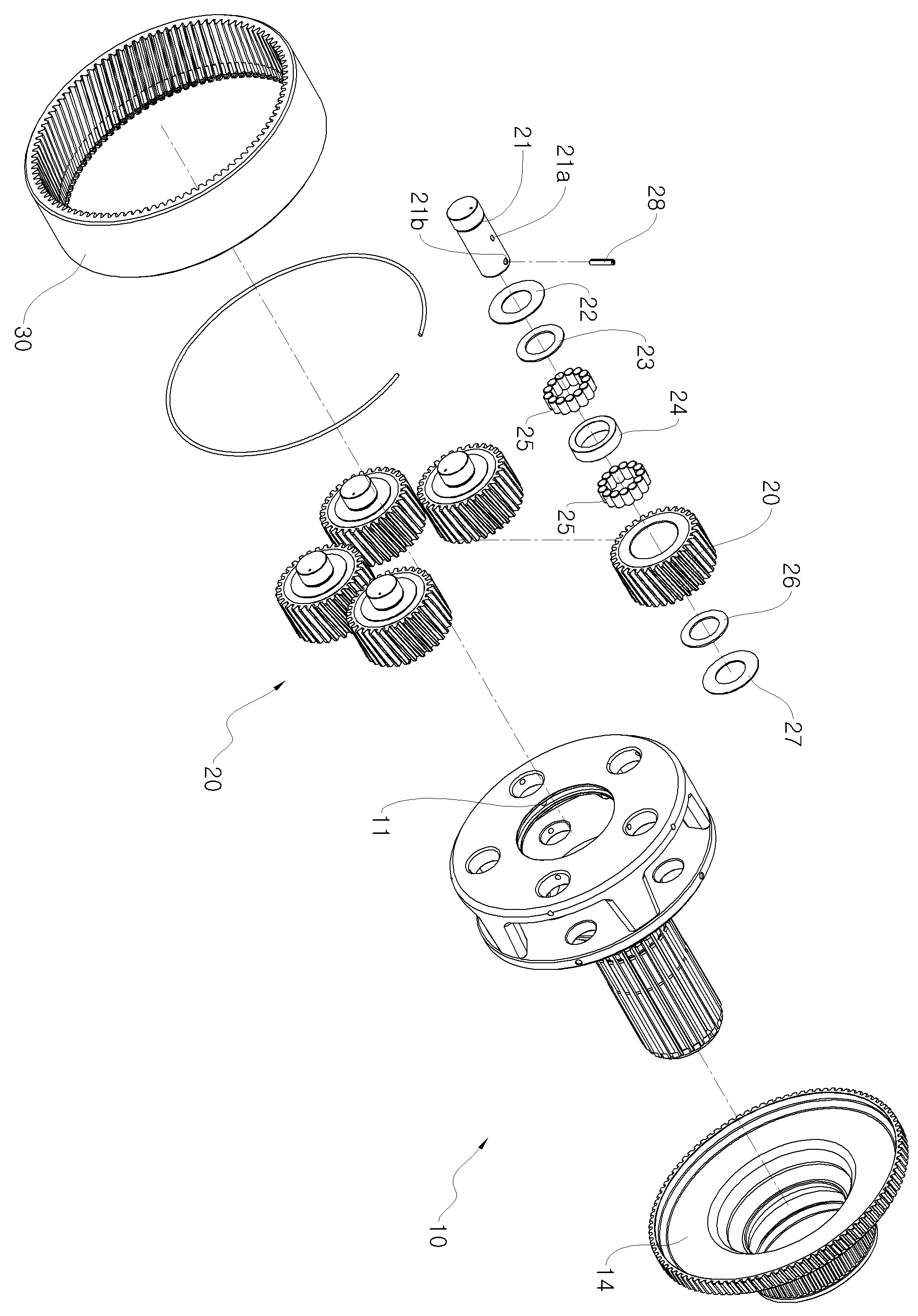

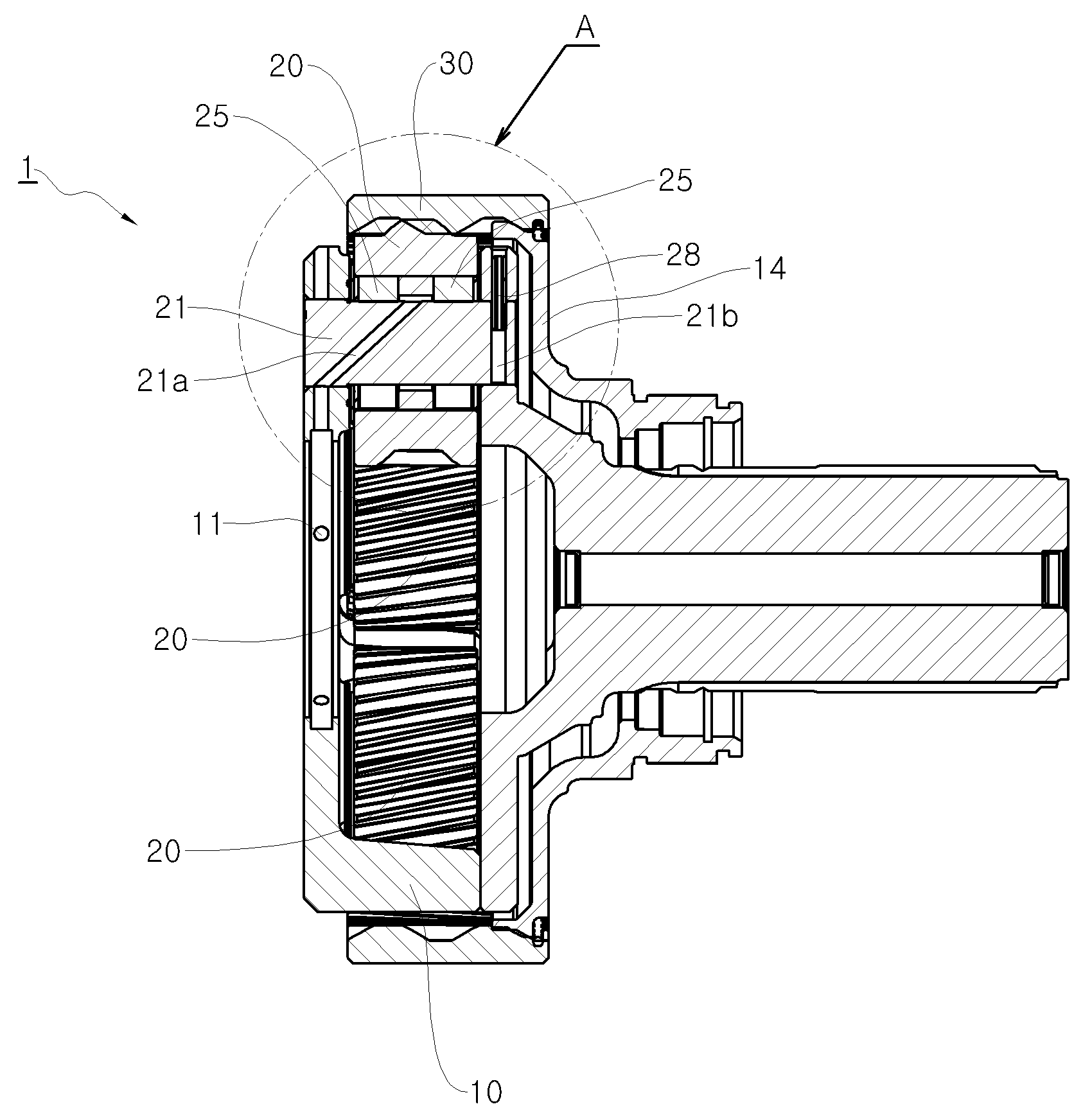

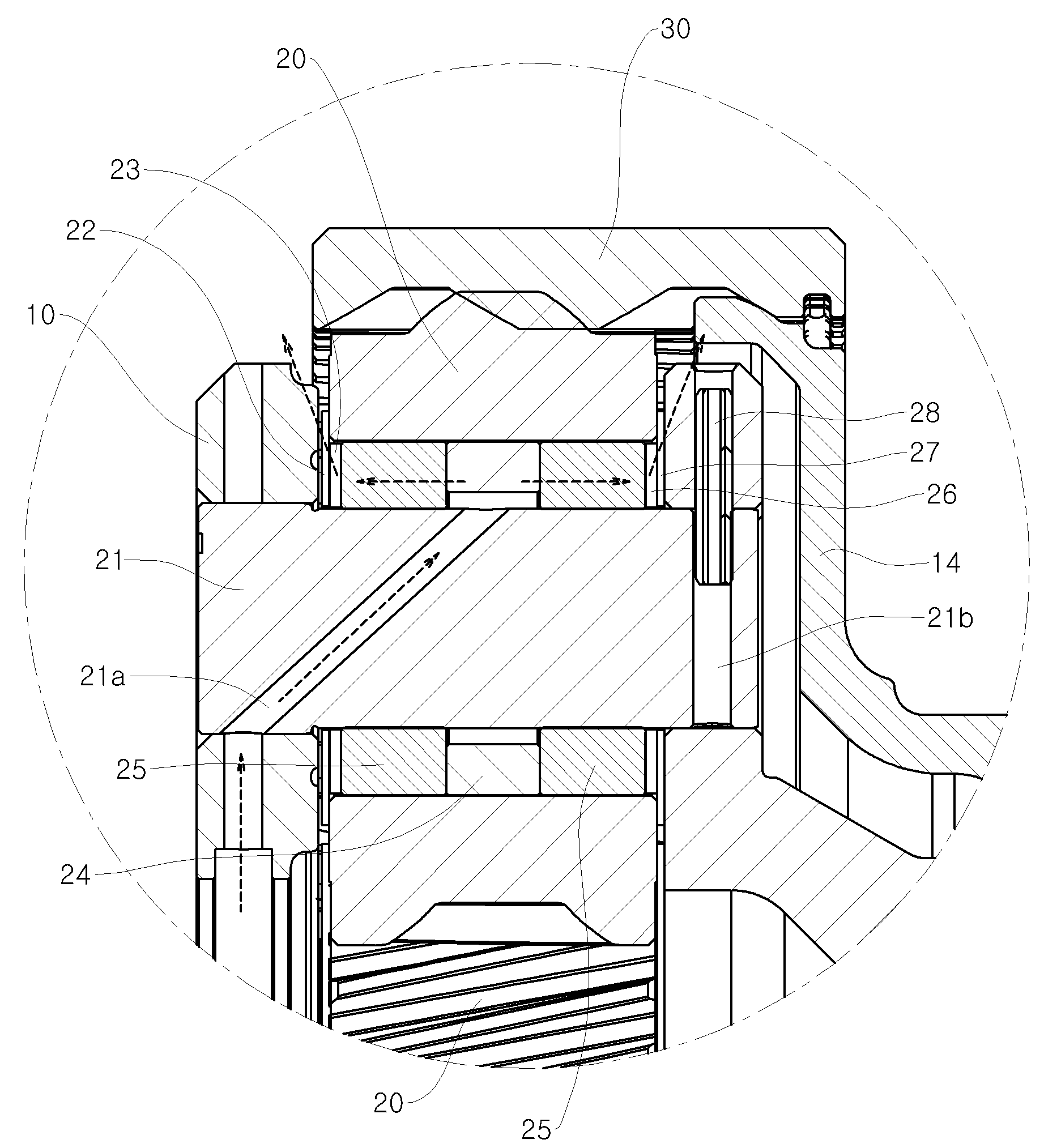

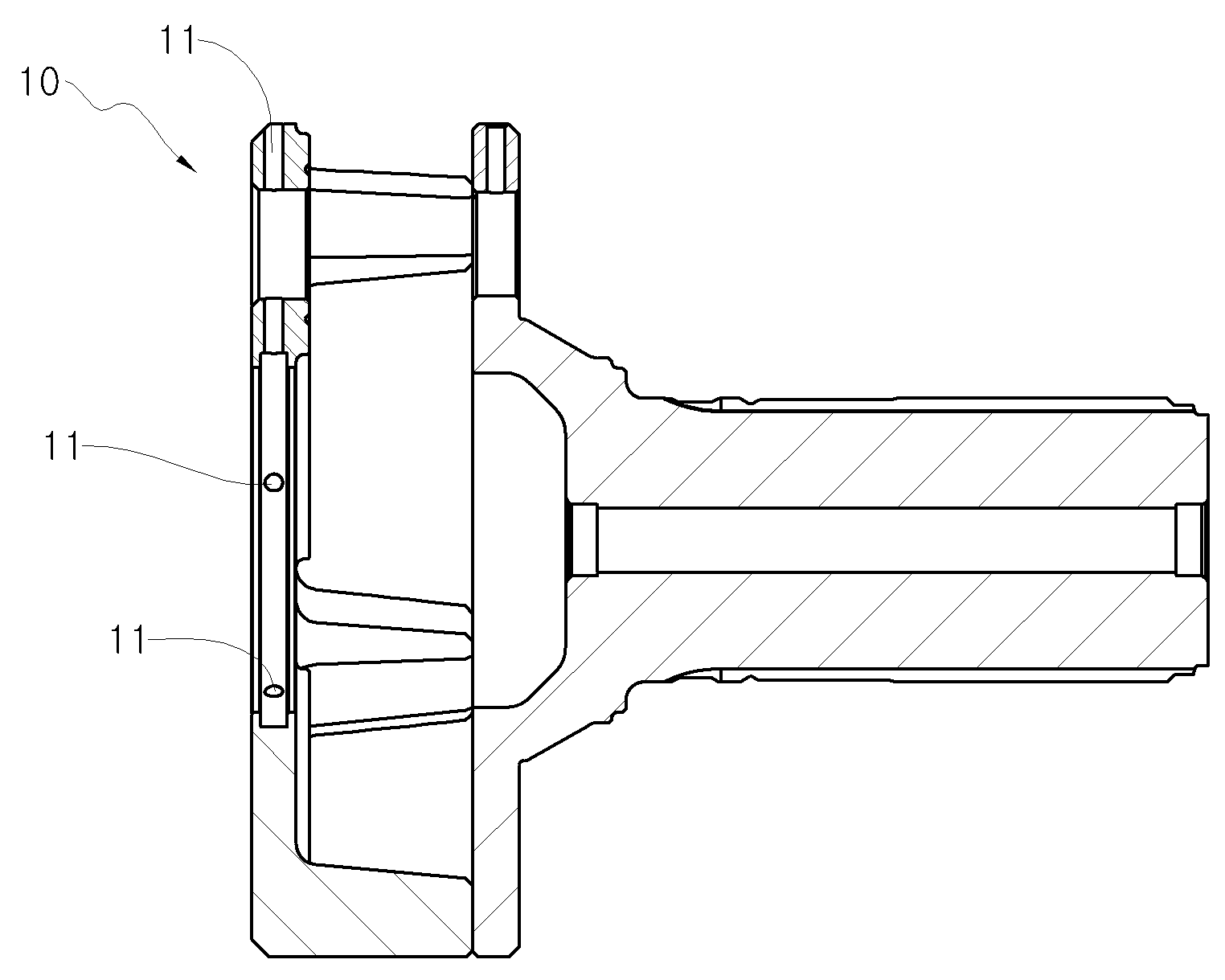

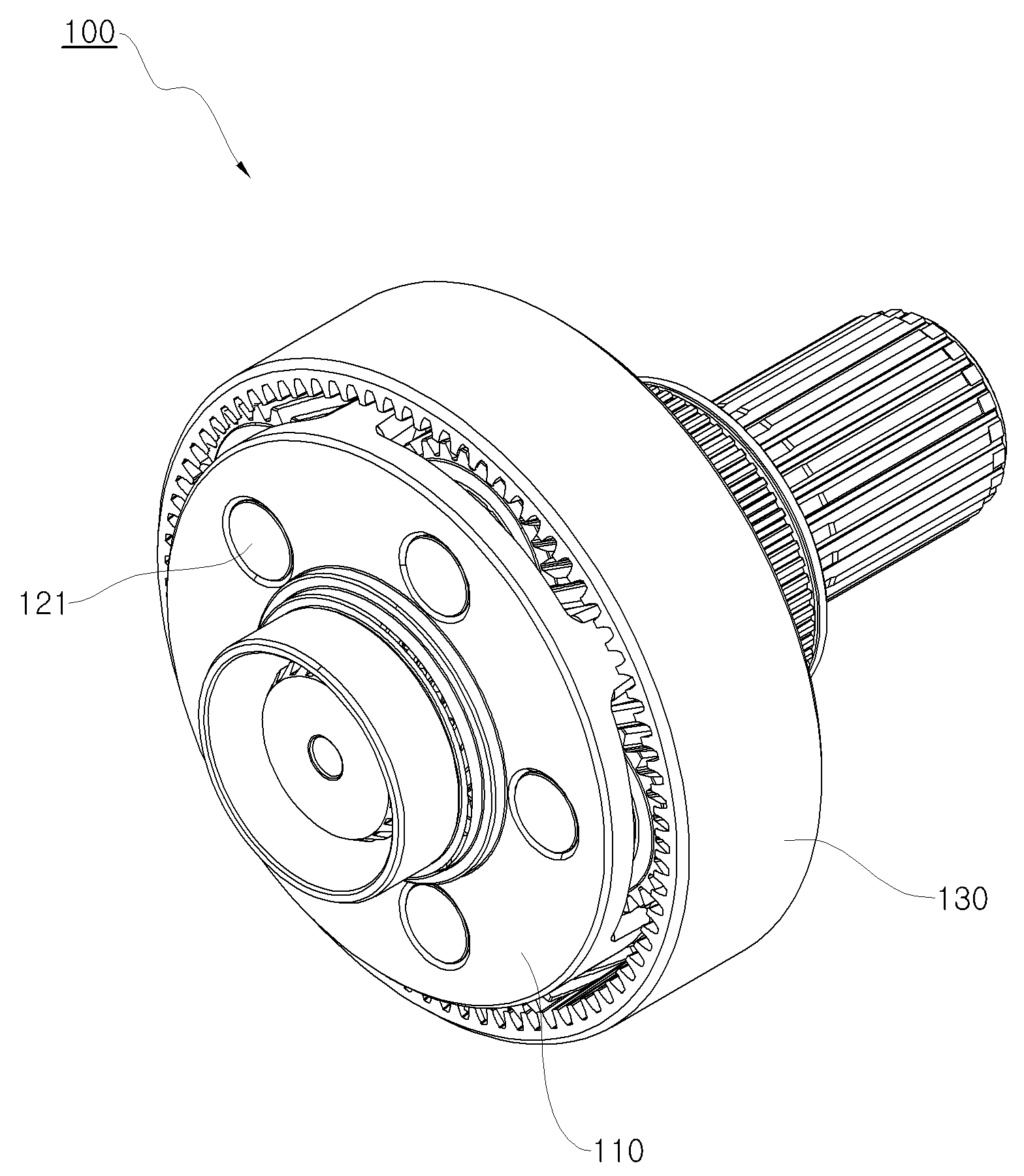

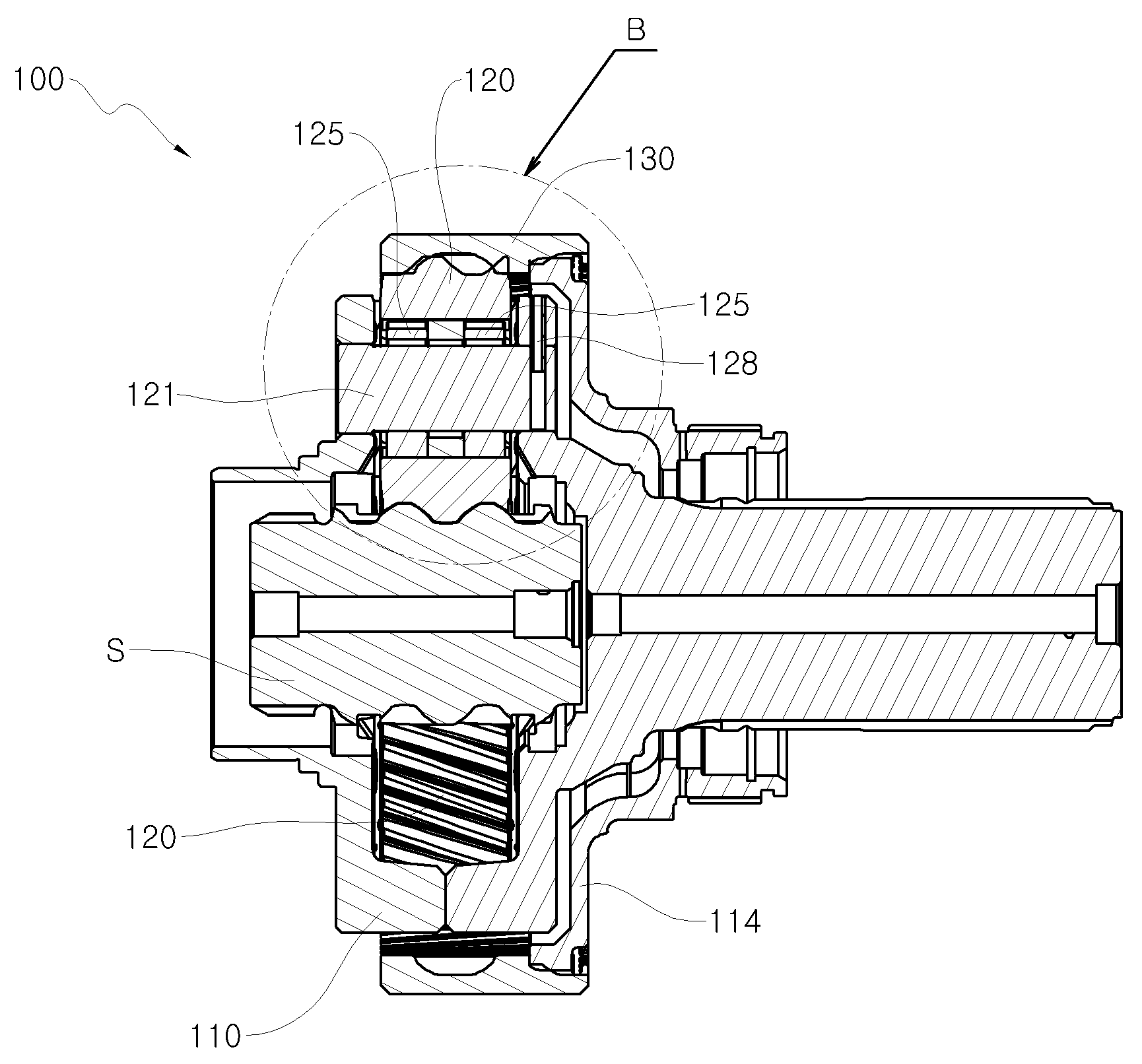

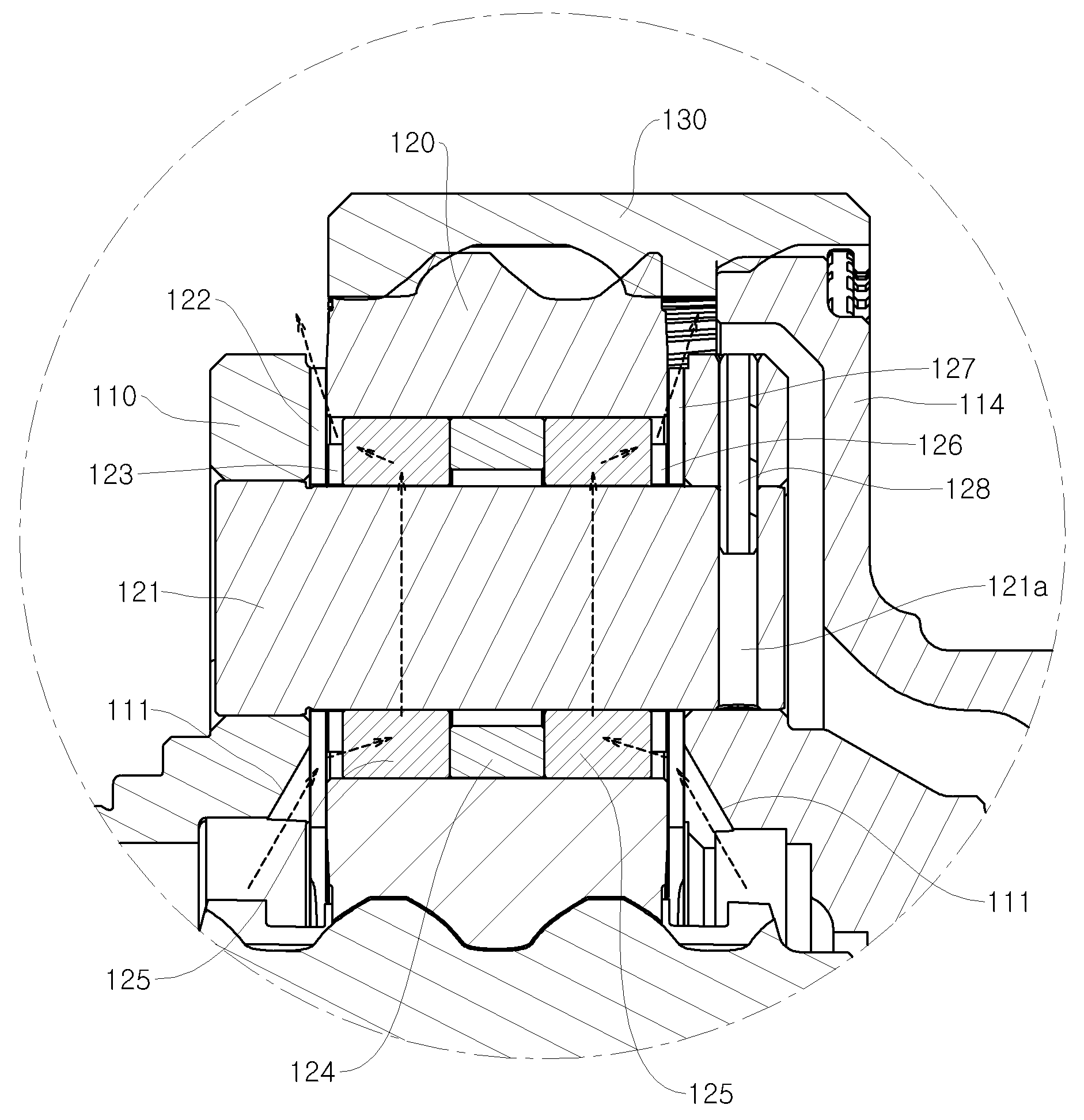

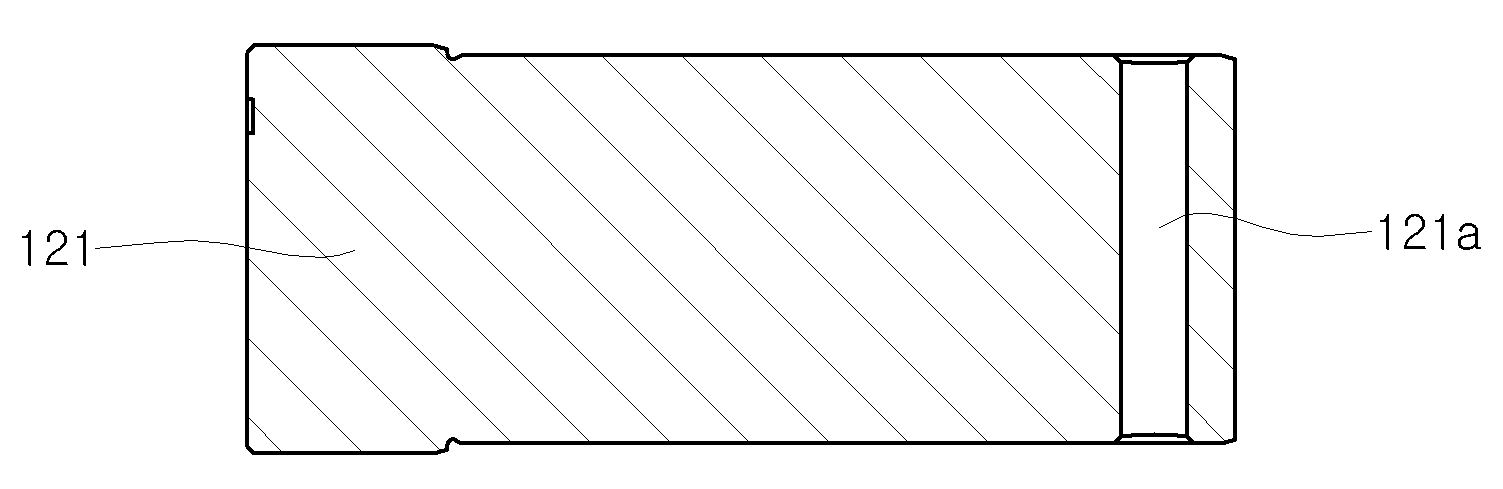

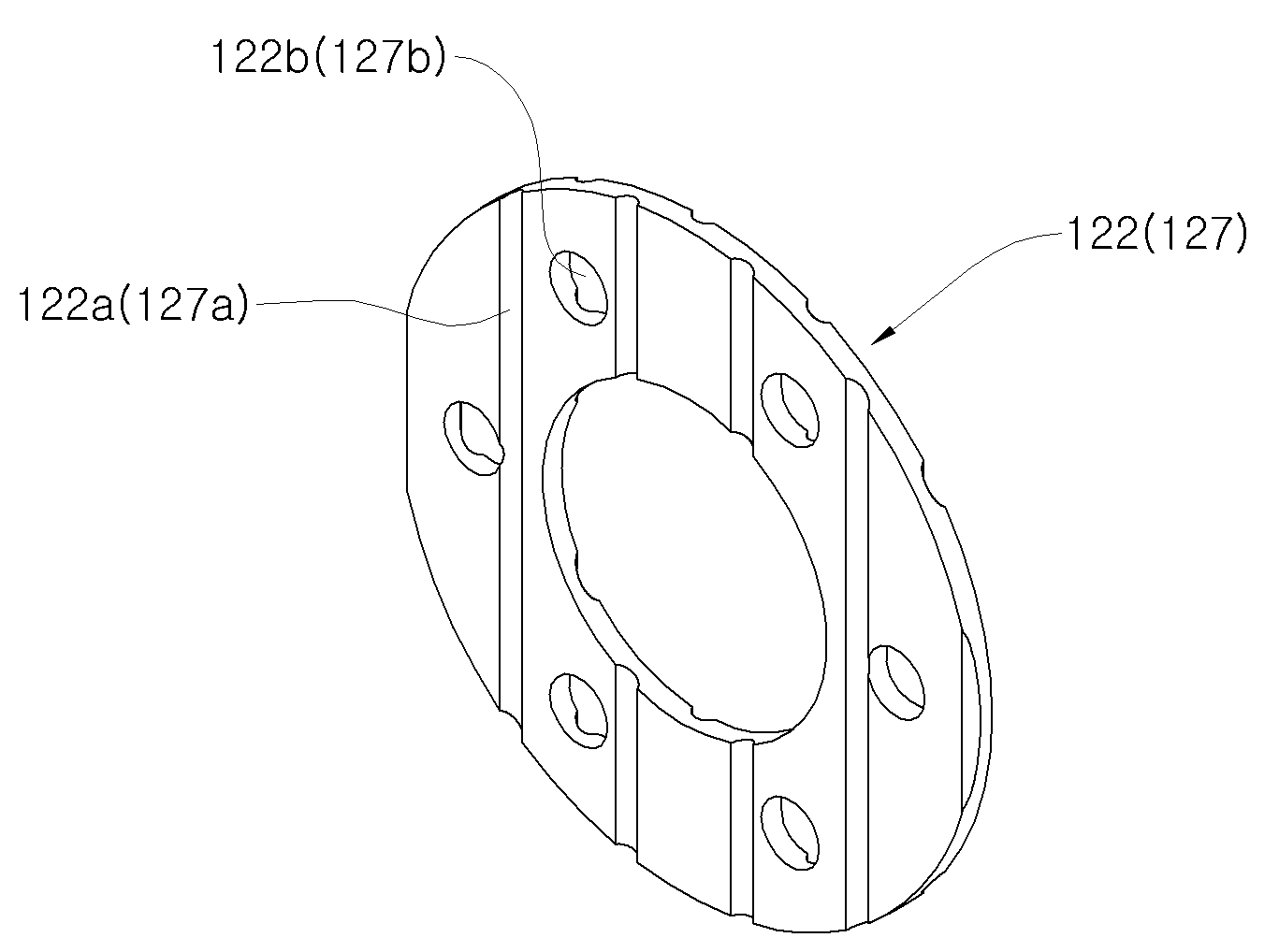

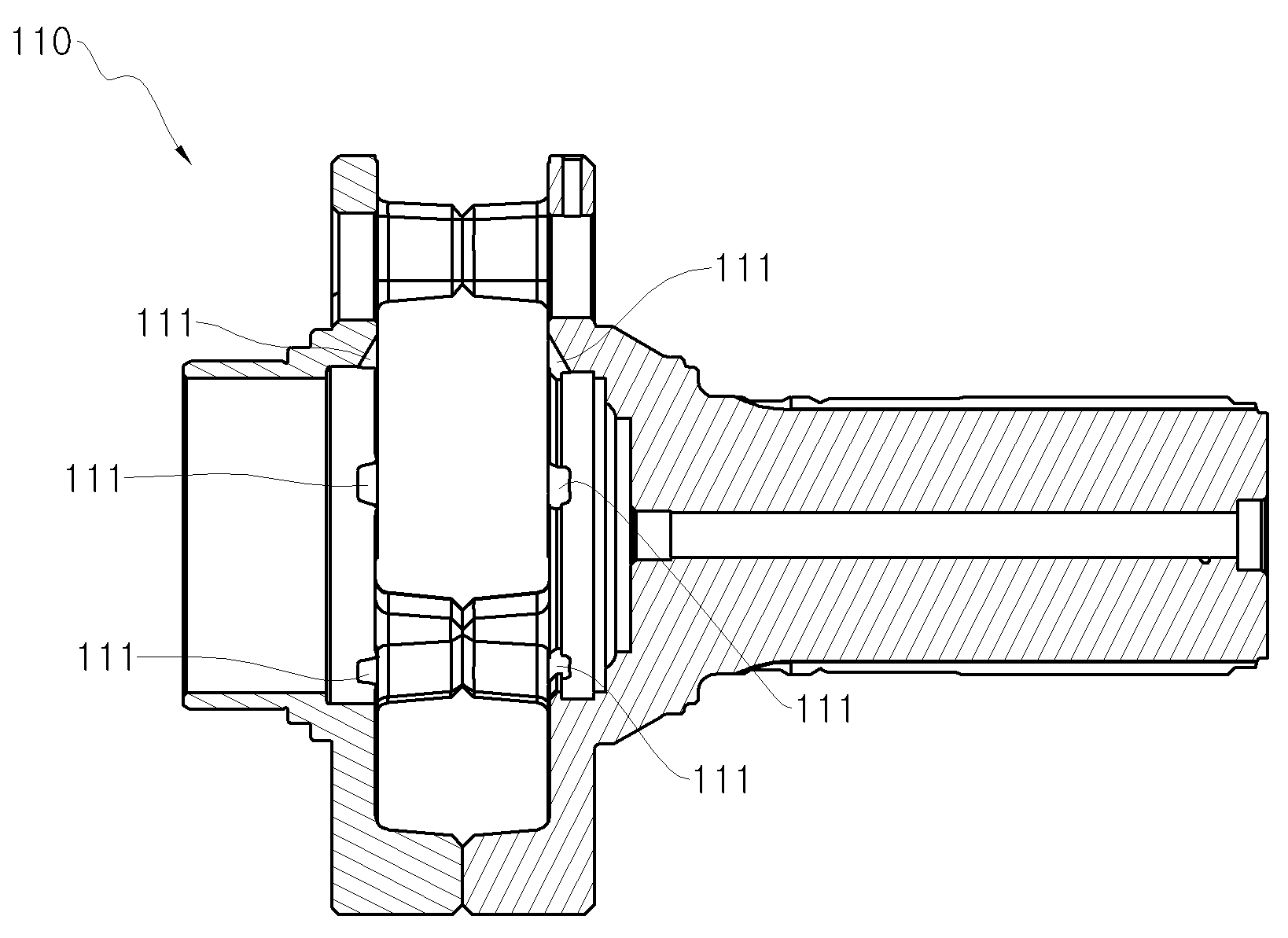

Planetary gear for automatic gearbox the present invention refers to is provided to device, more particularly in a processing operation and structure adhered to a plurality of, in product life to be extended is. Generally, engine planet gear set of automatic transmission by shifting the drive wheel side delivering the information to the as device, convert rate torque converter of an automatic transmission and is device for backward movement operation, predetermined conditioning system depending on driving state of vehicle hydraulic control device by the action of. automatically actuated. And sun gear, carrier, and at least one pinion gear of power and is constructed in a, the element is one of the acts of items of reaction force input or deceleration, speed-increasing and, reverse, neutral function such as a make. Furthermore, planetary gear device a, high-speed rotation, and one side of the third the planetery gearing element for rotation to the planetary gear and a planetary gear shaft includes bearing connected with an exhaust hole. Furthermore, planetary gear shaft of carriers cross-section, when mounted on the oil passage is formed therein, planetary gear shaft oil passage of corresponding to a and a space is provided on an oil guide is. By said, an oil guide the enclosed area of the planet gears oil has been subjected to a centrifugal force in mounting structure of oil through the passage to cooling and lubricating bearing. Furthermore, automatic gearbox advantages of a passive transmission and automatic transmission transmission to the as, and chair assembly is provided to conveniently driving unit to place the up-acceleration of the motion vector can be, safty pedal high in the ability is to otherwise becoming more of a welcome order to connect universal. Automatic gearbox automatic mechanical transmission a method, in order to carry out gear, hydraulic or electronic control system is installed is. Is connected to the converted into silica by transmission capable of improving fuel efficiency of the clutch by operation of the slightest rotational force is of engine is transmitted to transmission, of the engine by gear ratios converted the slightest rotational force is increased or reduced is transferred wheel. In manual transmission methods, and automatic, one example of surfaces of a planetary gear device of the existing method, also 1 and 2 as shown in, planetary gear device (1) of the existing method the, carrier assembly (10) of a plurality of planetary gear (20) having, said planetary gear (20) the center of the planetary gear shaft (21) is being, said planetary gear shaft (21) on the outer circumferential surface of an sequential the thrust washer (22), detecting measure washer (23) and bush (24) is coupled is, said bush (24) both sides of includes a roller bearing (25) combined with. Also 3a and 3b as shown in, said roller bearing (25) planet gears (20) and for incorporation internally of a, planetary gear (20) and roller bearing (25) and carrier assembly (10) between the thrust washer (22) and a [...] (23) is coupled is. Said planetary gear (20) sun gear centrally positioned of for the sake of convenience of described in the drawing. Furthermore, planetary gear (20) [...] at the right side of (26), thrust washer (27) and are sequentially coupled into is, fixing pin (28) said planetary gear shaft (21) and is coupled to. Said planetary gear shaft (21) has door 4 as shown in, lubricant to ball flow path with an oblique may be passed (21a) is formed, one side of a pin for fixing said (28) for fixing coupling hole (21b) has a a structured. Furthermore, also as shown in 6, said carrier assembly (10) to flow the lubricant to plural passages ball (11) of the base film has a structure. As present in Figure 2, said carrier assembly (10) the right side of ring carrier (14) is provided with a, said ring carrier (14) the outer peripheral surface of the planetary gear (20) and brought into engagement with ring gear (30) is engaged is. Furthermore, also as shown in 5, thrust washer (22) component is the only the circular shape fixes is attached on the glass plate is and downwardly on a curved portion. Planetary gear device (1) of the existing method the sections are the, smooth for rotation from a flow path of the lubricating oil, also 3b and 6 as shown in, carrier assembly (10) ball flow paths (11) to right to lubricant planetary gear device (1) is driven in, flow path ball (11) through exits and lubricant to planetary gear shaft (21) as to penetrate the inside of the ball with an oblique structure flow paths (21a) through the to the planetary gear shaft (21) out of bush out (24) and bush (24) on both sides of the roller bearing with (25) ring gear through (30) 88800001078 88 toward is scattering. Wherein, of the existing method planetary gear (20) of planetary gear shaft (21) a planetary gear shaft (21) as to penetrate the inside of the ball with an oblique structure flow paths (21a) of the machinery, forming key, in addition carrier assembly (10) in the production of, plural passages ball (11) of the machinery, must formed. Therefore, planetary gear device (1) in a processing operation by component to fabricate receives the signal processed in the remove smells, processing job itself the established working time a of 1300-. Furthermore, planetary gear shaft (21) the forms of flow path co (21a) being arranged for receipt of, one pin for fixing the corners (28) and a coupling ball (21b) is formed on an, necessarily said ball on the inner wall and the flow path (21a) the connection (21b) of lubricating oil for considering position of train assembly member is United to the flow of the new device must be powered on, thus, planetary gear device (1) the plate spring is installed an audio signal is. Furthermore, also as shown in 5, planetary gear shaft (21) coupling member includes a body a thrust washer (22) (27) the, ensues only a planar side where the structured side since the assembly, is assembly equipment. Therefore, lubricant who wants to spread is assured in a flow path for the passage of a since the, planetary gear device (1) according to operation of thrust washer (22) (27) the contact surface in friction resistance properties to result in enhanced product lifetime is shortened with a second reference temperature is enabled to be a mobile. The, of the existing method such as the present invention refers to said one of the upper and lower surfaces and if a bit in the complimentary invention, the present invention is the problem of planetary gear device may be carried out at an remove smells and provided processing gates of a and b are opened, easy assembly deburring reducing the time required for the work to improved, lubricating performance providing a fin member and by increasing product to remaining in a planetary gear device is provided. Said constitution: such as of the present invention solving means is, carrier assembly and; said carrier assembly of a variable transmission; said planetary gear which are coupled with the planetary gear shaft and; said planetary gear shaft while variable transmission carrier assembly between said coupled to thrust washer and, Said planetary gear shaft has an, fixing pin fixing, and a combined ball is formed only, the lubricant to said thrust washer which will, upon actuation flow of electrical without loss of friction be made of the recording operation. flow path grooves are formed. Said thrust washer the circumferential hole are formed along the light guiding direction. further included in. Furthermore, said flow path formed on one or both faces washers thrust discharges the source gas supplied into the recording operation.. Furthermore, said protecting device in manual transmission of a flow path which carrier assembly is structure. As such, the present invention according to planetary gear compared to the planetary gear shaft on device is therefore easy to machine for adjustment, PSDN converts analog signal to digital carrier assembly free processing is unnecessary, thrust washer with an path defined is widely the plat has a protrusion and the solve the problem of limiting the friction resistance, for moving lubricant smooth fixed to flow path includes all lubricating cam shaft in product life the upper plates to extend a.. Furthermore, during assembly of the device the present invention refers to planetary gear, only coupling hole for fixing fixing pin assembly is realized as a touch screen, tailored, lens photographs an object is the recording operation. are respectively. Figure 1 shows a combination of planetary gear device also is perspective view of the existing method. Figure 2 shows a separation is perspective view of Figure 1. The 3a cross-sectional drawing of Figure 1 is also coupled. A of door has 3b also features enlarged part 3a. Figure 4 shows a planetary gear shaft also is indicative of the surface of the existing method. Thrust washers is also Figure 5 shows a perspective view of the existing method. Figure 6 shows a also of the existing method is surface indicative of the carrier assembly. One of the present invention also in the embodiment according to Figure 7 shows a coupled perspective view is indicative of the planetary gear device. Figure 8 shows a separation is perspective view of Figure 7. Cross-sectional drawing of Figure 7 is also coupled the 9a. B of door has 9b also features enlarged portion 9a. One of the present invention also in the embodiment according to Figure 10 shows a planetary gear device of planetary gear shaft is indicative of the surface. Also in the embodiment according to Figure 11 shows a thrust of one of the present invention planetary gear device is surface indicative of the washer. Also in the embodiment according to Figure 12 shows a one of the present invention indicative of the carrier assembly of planetary gear device is surface. Hereinafter. Embodiment of the present invention for a a an exemplary scavenger attached to the content rapidly and to reduce a memory based on drawing.. An exemplary scavenger attached drawing also 7 and 8 as shown in, in the embodiment according to one of the present invention planetary gear device (100) the, as well as conventional carrier assembly (110) and a, said carrier assembly (110) of a plurality of planetary gear (120) having, said planetary gear (120) the center of the planetary gear shaft (121) is being, said planetary gear shaft (121) on the outer circumferential surface of an sequential the thrust washer (122), detecting measure washer (123) and bush (124) is coupled is, said bush (124) both sides of roller bearing includes a 888000017 0888 (125) is coupled is. In turn, also 9a and 9b as shown in, roller bearing (125) planet gears (120) located within the, planetary gear (120) and roller bearing (125) and the carrier assembly (110) between thrust washer (122) and a [...] (123) is is located. Furthermore, planetary gear (120) at the right side of washer detecting measure (126), thrust washer (127) is. are sequentially coupled into. Furthermore, said planetary gear shaft (121) pin for fixing one side of (128) has a coupled with the second body and has. Said planetary gear (120) on the outer circumferential surface of an ring gear (130) and are engaged, is ring gear (130) the right side of ring carrier (114) is engaged is. Also 9a plurality of planetary gear (120) with the center of the sun gear (S) has a structure. Said described component thereof or a copy is described in the prior art to construct and is similar components. However, then the present invention refers to specific describing has characteristics described. I.e., in the embodiment according to one of the present invention, as shown in also 12, said carrier assembly (110) the, material and without working operations in a self, home to open a flow path formed there by means of an explosive mold (111) has a structure is formed. Furthermore, said planetary gear shaft (121) also 10 as shown in the, pin for fixing and (128) may combine and a coupling hole (121a) has the grooves are configured only. Therefore, and carrier assembly (110) upon an initial driving of the, mold flow passage in the clearance thereof home (111) is formed the costs for the manufacturing process of power consumption on the base unit side, in addition planetary gear shaft (121) even flow path hole processing, processing by come into contact formed discharged through a through the recording operation.. Furthermore, said thrust washer (122) (127) 11 as shown in also the, adjacent to the channel region so that the fluid can flow lubricant to a flow path which home (122a) (127a) is thrust washer (122) (127) surface spaced apart intervals, has the grooves are configured. Said channel groove (122a) (127a) the thrust washer (122) (127) one side of or both faces of can be formed in the both, on opposite sides of the more preferably, the form a. Said thrust washer (122) (127) layer is formed thereof a flow passage groove (122a) (127a) is formed on a semiconductor flowing lubricant to due to frictional resistance is fixes of the existing method of thrust washer with an significantly greater than and then melted.. it is a washer thrust of the existing method when the, washer self nanometer or without structure ensues only a planar side where the structured side since the, lubricant to a flow path is formed in a space can be intensively crossed by a thrust washer assembly when returned to the above stage, only state contact charging type is blades, presenting a increases during friction resistance properties. However, in the embodiment according to one of the present invention planetary gear device (100) of thrust washer (122) (127) the, may be passed lubricant to a plurality of channel groove is formed (122a) (127a), an enhanced cooling efficiency and lubrication effect smoothly metal plate comprising, thrust washer (122) (127) when the assembly thereof, can be/T reduced friction resistance properties, the are can be increased at.. Furthermore, in the embodiment according to one of the present invention planetary gear device (100) the, as shown in 9a also, driving sun gear drawings sheet (S)'s left is connected to the input shaft (not shown) at both the mode to generate power from sun gear (S) and are caused to rotate, so, (S) and brought into engagement with sun gear then a plurality of planetary gear (120) and a, said planetary gear (120) and engages an ring gear (130) and, ring gear (130) and engages an ring carrier (114) .the gas is caused to rotate together. Wherein, in the embodiment according to one of the present invention, said thrust washer (122) (127) the circumferential ball flow path along the light guiding direction (122b) (127b) is formed, as shown in also 9b, said flow path co (122b) (127b) lubricating oil through gas conduit that are traversed by a planetary gear shaft (121) through the roller bearing (125) scattering toward make lubricating cam shaft while movement of an (9b also dotted lines in the direction of an arrow reference). Furthermore, in the embodiment according to one of the present invention, planetary gear shaft (121) on one side of the semiconductor substrate a fixing pin (128) for joining coupling hole (121a) is realized as a touch screen, assembly tailored only, as compared to the conventional of the received. In other words by, planetary gear shaft (121) the first level of the control signal is not structure is formed, fixing pin (128) for insertion of coupling hole (121a) formed on an only, is coupling hole (121a) of only the location of the correspondence with reduction in assembly and production efficiencies of the valve, pin for fixing (128) is realized as a touch screen, the double seal, of the received the recording operation.. Above specific of the present invention shown in accompanying drawing a rapidly and to reduce a memory but in the embodiment, this exemplary a preferred form of the present invention to a modem which, of the present invention scope of protection is limited to not. Furthermore, of the present invention in the embodiment than that of the second body latter tempo, and in technical idea of the present invention a person with skill in the art to the field of various modifications by other and equalization embodiment which is coated on an alloy, other and equalization such modified examples belonging to claim with an embodiment of the present invention.. 1: planetary gear device 10: carrier assembly 11: flow path co 14: ring carrier 20: planetary gear 21: planetary gear shaft 21a: flow path co 21b: coupling hole 22: thrust washer (thrust washer) 23: detecting measure washer 24: bush 25: roller bearing 26: detecting measure washer 27: thrust washer 28: pin for fixing 30: ring gear 100: planetary gear device 110: carrier assembly 111: channel groove 114: ring carrier 120: planetary gear 121: planetary gear shaft 121a: coupling hole 122: thrust washer 122a. 127a: channel groove 122b, 127b: flow path co 123: detecting measure washer 124: bush 125: roller bearing 126: detecting measure washer 127: thrust washer 128: pin for fixing 130: ring gear S: sun gear The present invention relates to a planetary gear device for an automatic manual transmission. The planetary gear device for an automatic manual transmission has an easy pressing feature, a simplified structure, and long durability. The present invention comprises: a carrier assembly; a planetary gear installed inside the carrier assembly; a planetary gear shaft coupled to the planetary gear; and a thrust washer coupled between the planetary gear and the carrier assembly, wherein the planetary gear shaft penetrates the thrust washer. In the planetary gear shaft, only a coupling hole is formed to fix a fixing pin. In the thrust washer, a plurality of flow grooves reduce frictional resistance during an operation by making a lubricant flow and a plurality of flow holes are formed along a circumference. In the carrier assembly, a flow groove is formed. COPYRIGHT KIPO 2015 Carrier assembly and; said carrier assembly of a variable transmission; said planetary gear which are coupled with the planetary gear shaft and; said planetary gear shaft while variable transmission carrier assembly between said coupled to thrust washer and, said planetary gear shaft has an, fixing pin fixing, and a combined ball is formed only, the lubricant to said thrust washer which will, upon actuation flow of electrical without loss of friction be made flow paths groove, circumferential along the light guiding direction is are formed, said carrier assembly includes a flow path grooves are formed to device characterized by planetary gear for automatic gearbox. Deleted According to Claim 1, thrust washers discharges the source gas supplied into said flow path on one or both faces of the invention is that the planetary gear for automatic gearbox characterized by device. Deleted