SEISMIC REINFORCEMENT STRUCTURE AND SEISMIC REINFORCEMENT METHOD

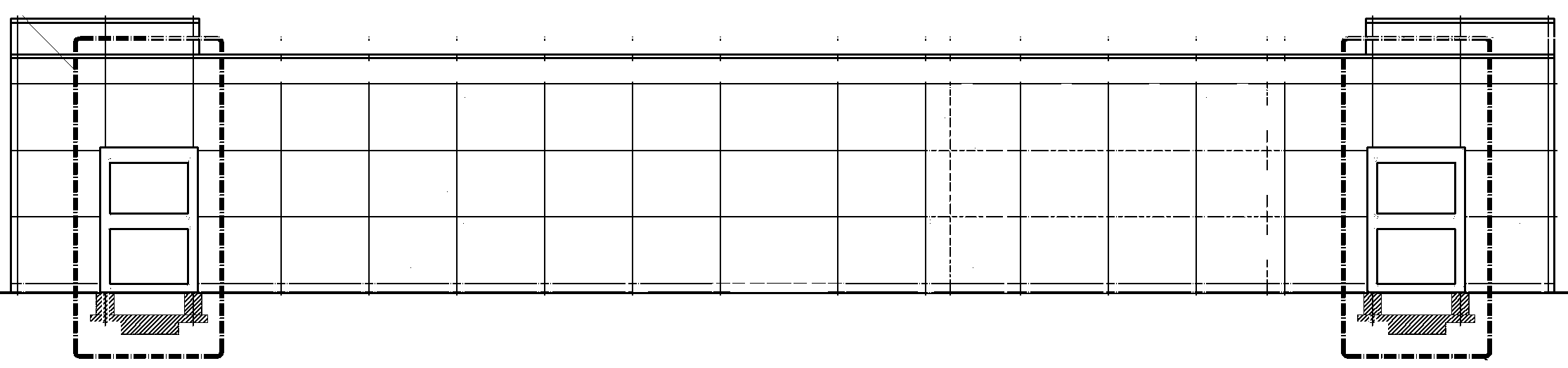

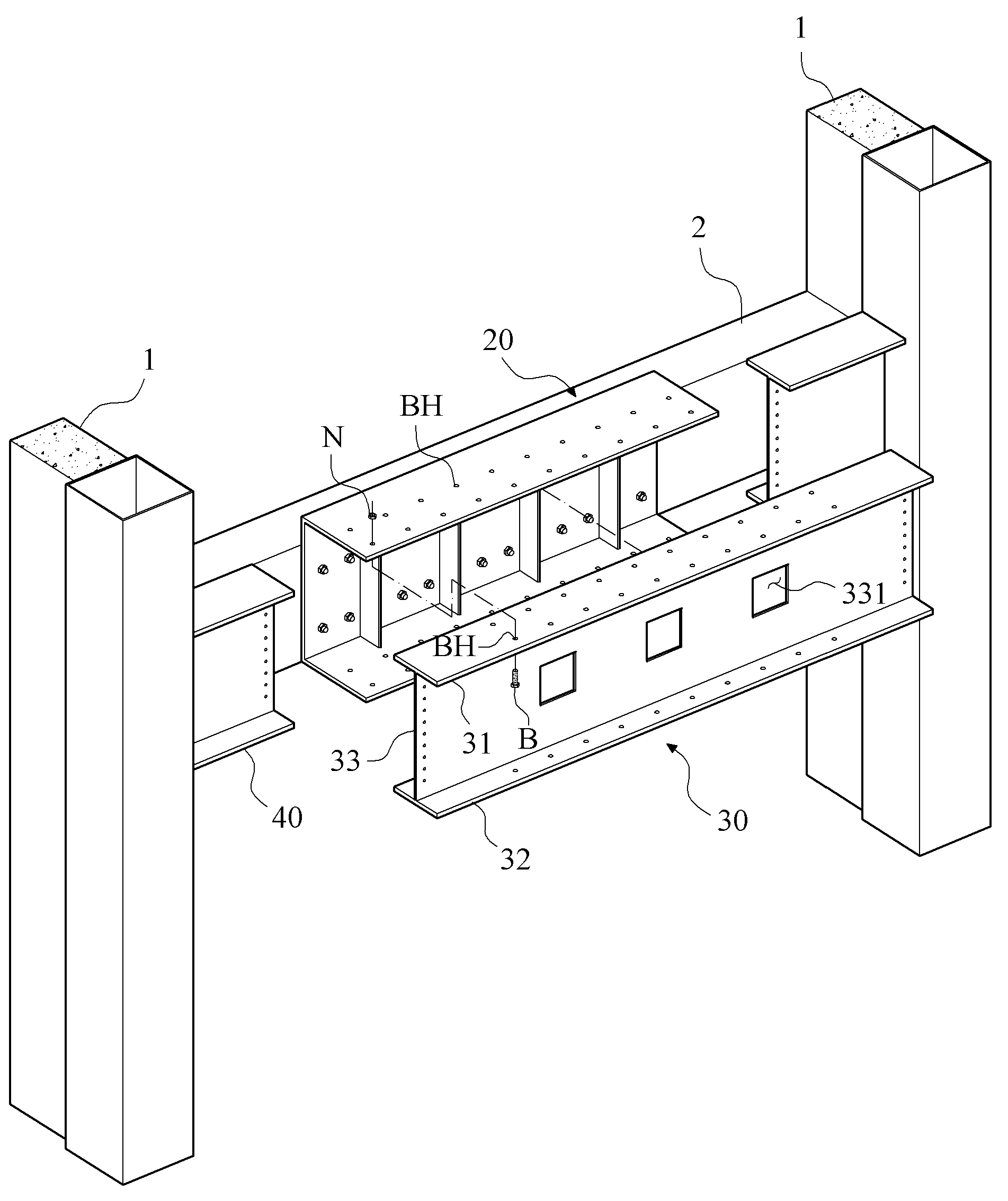

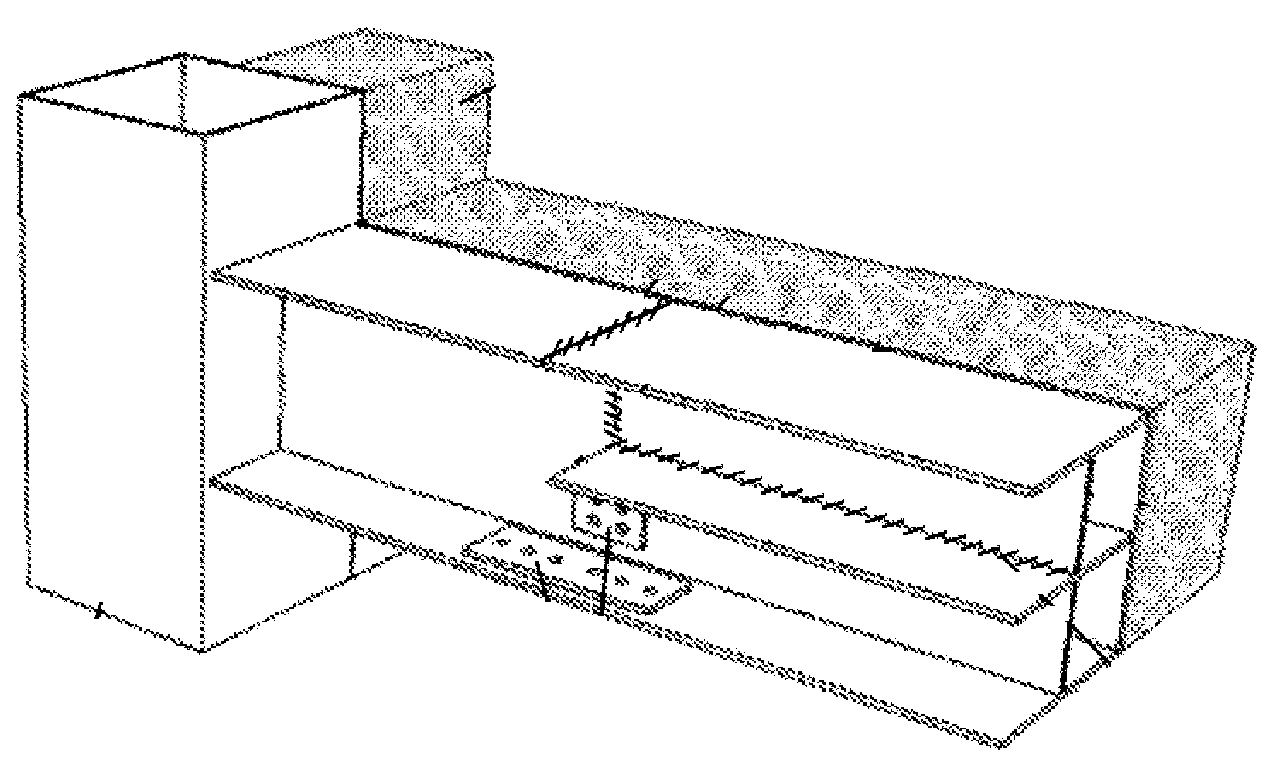

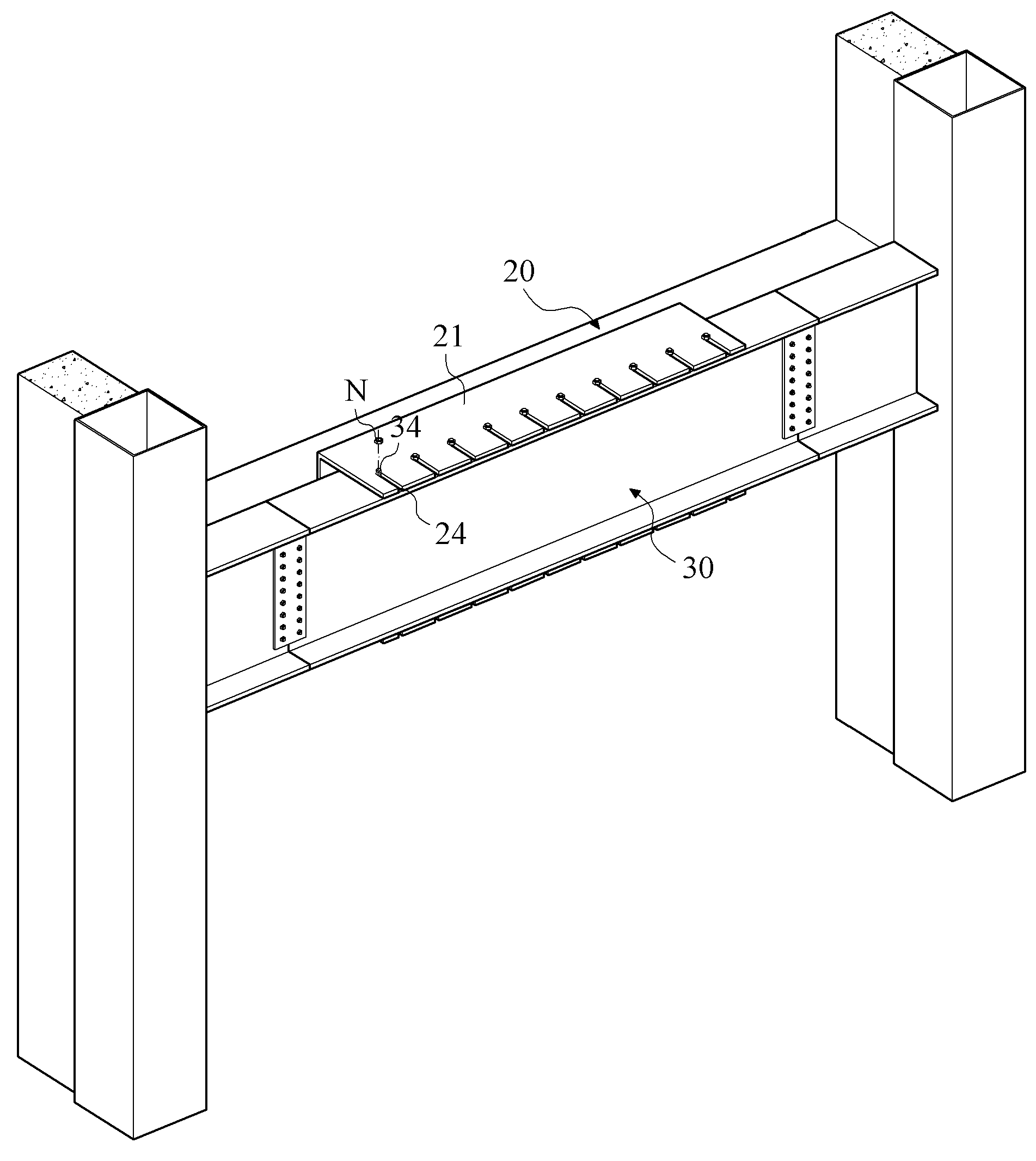

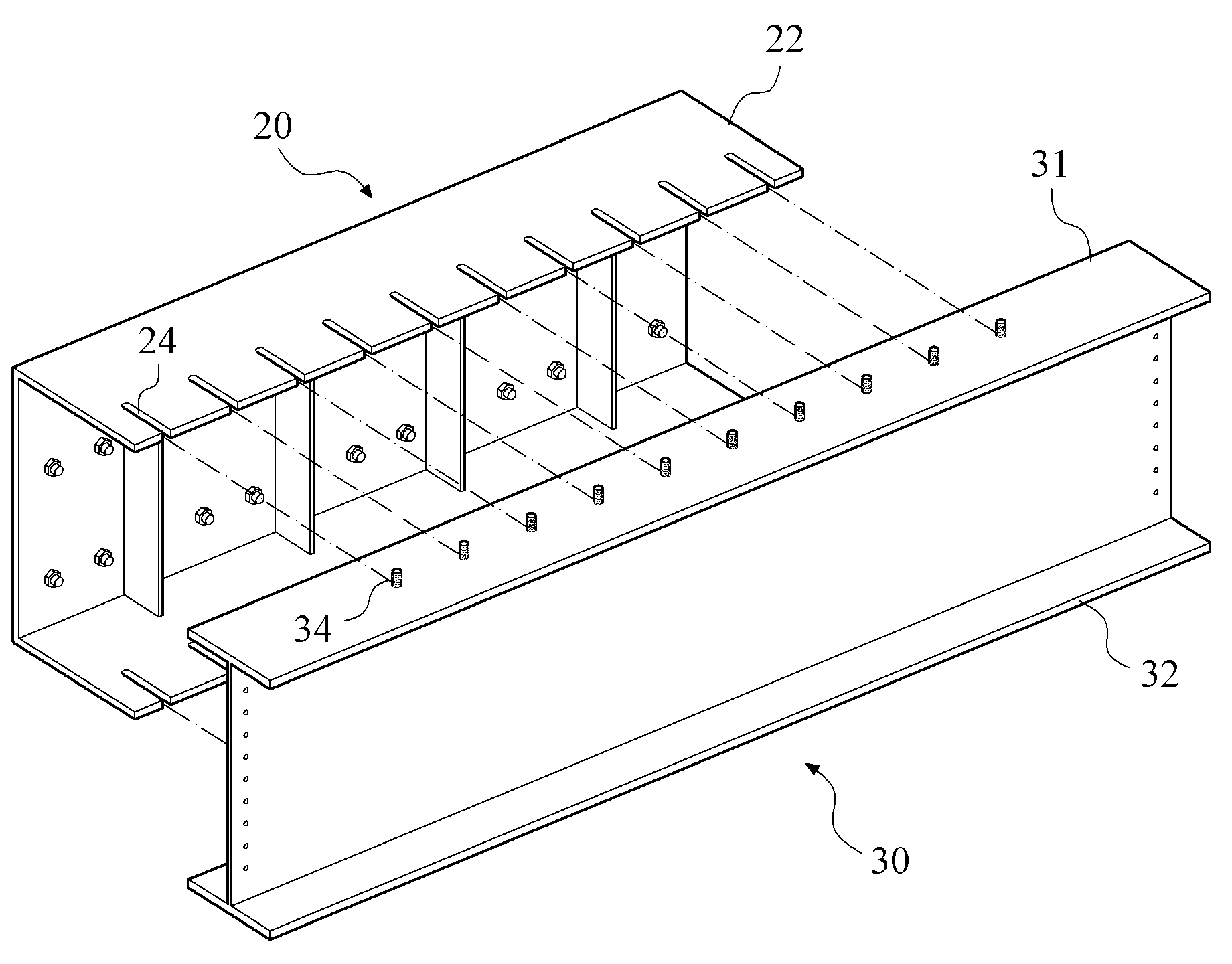

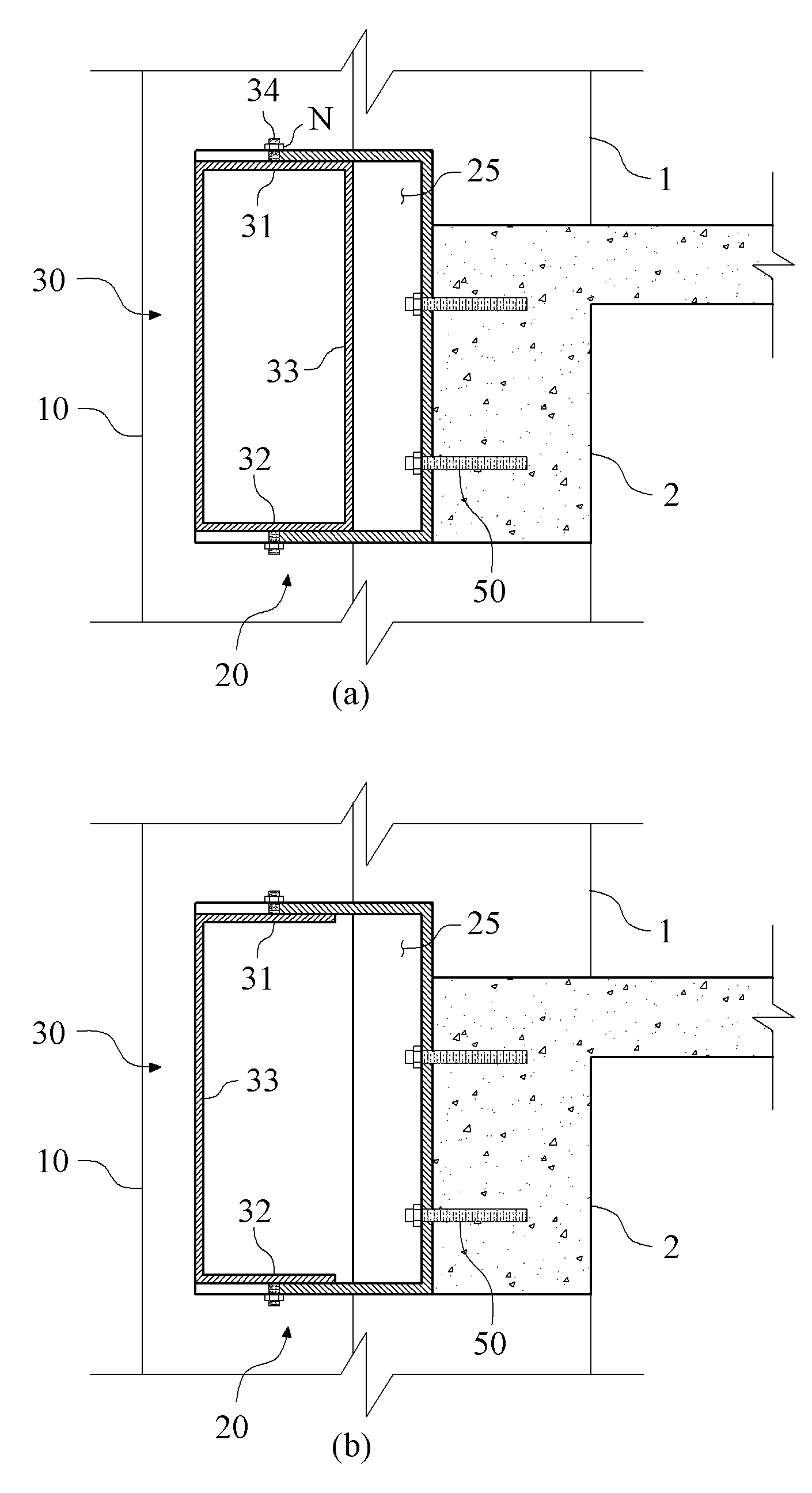

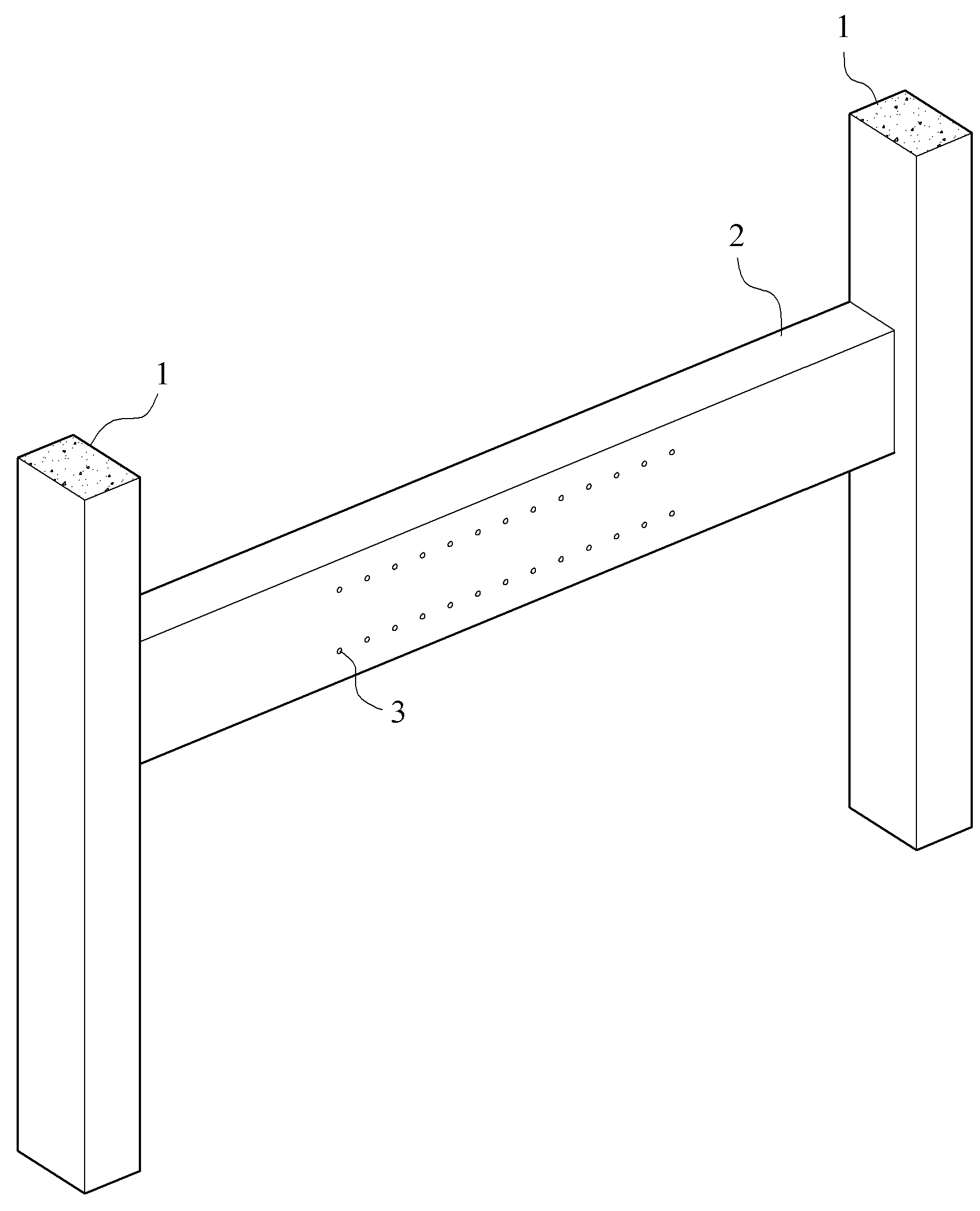

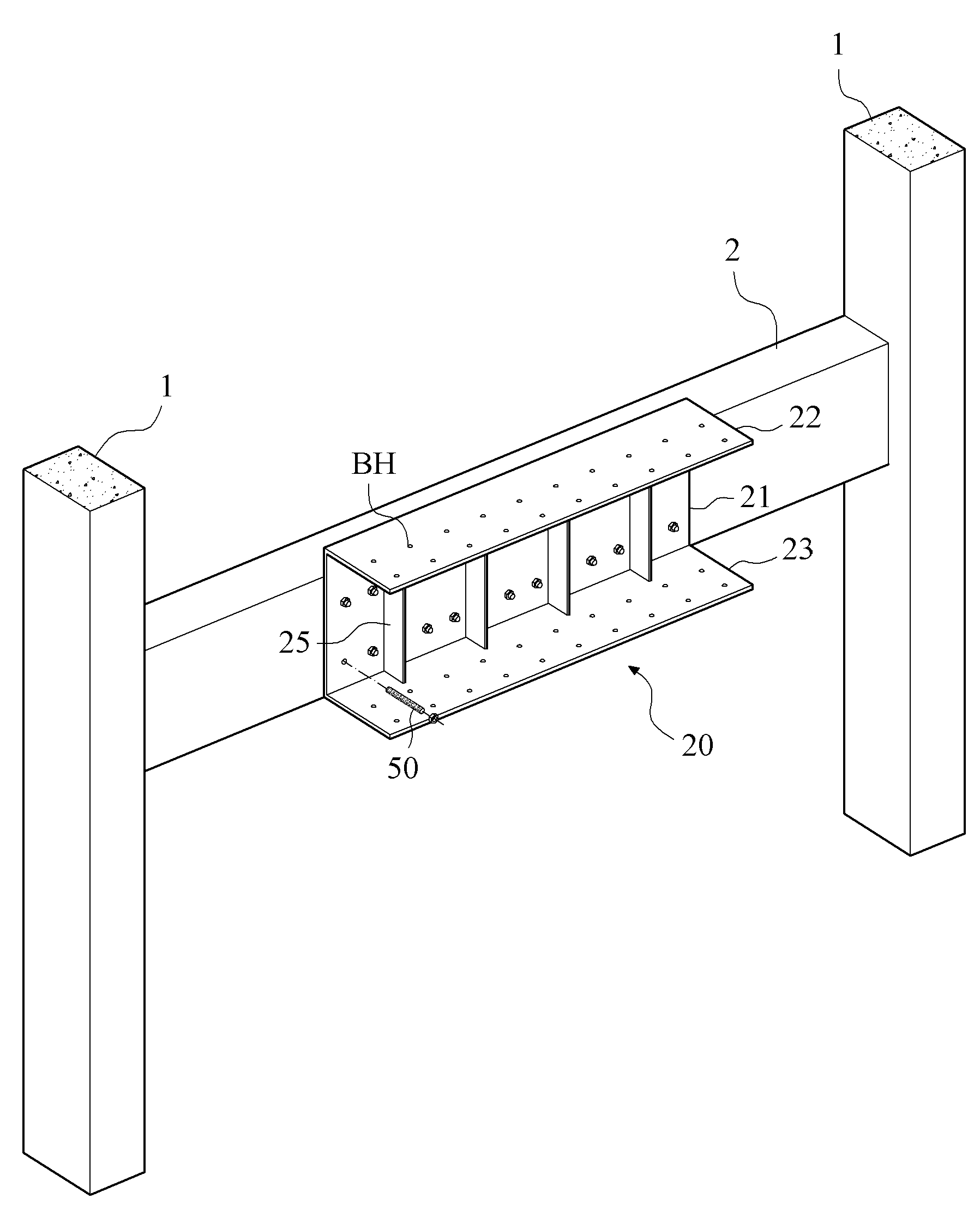

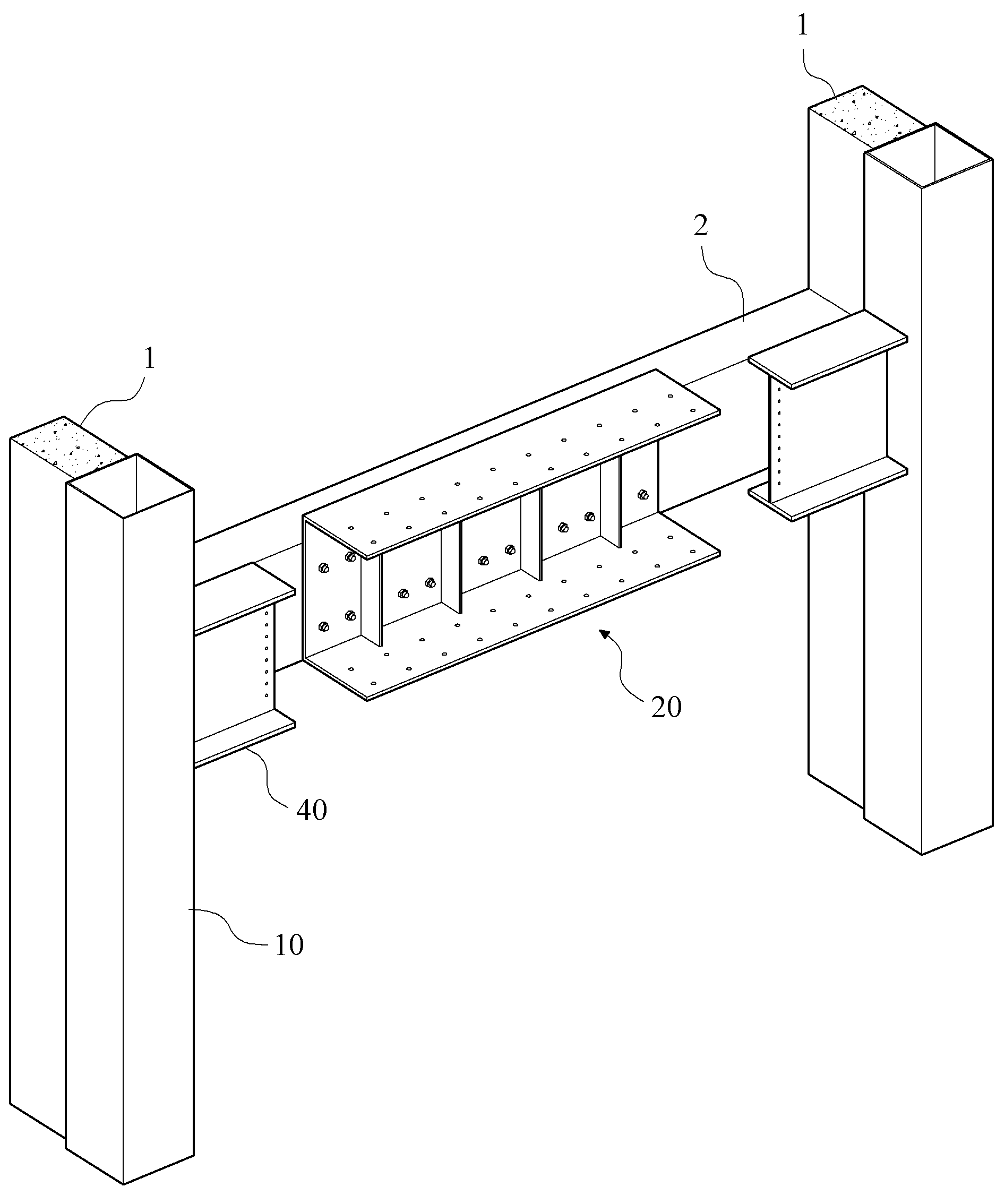

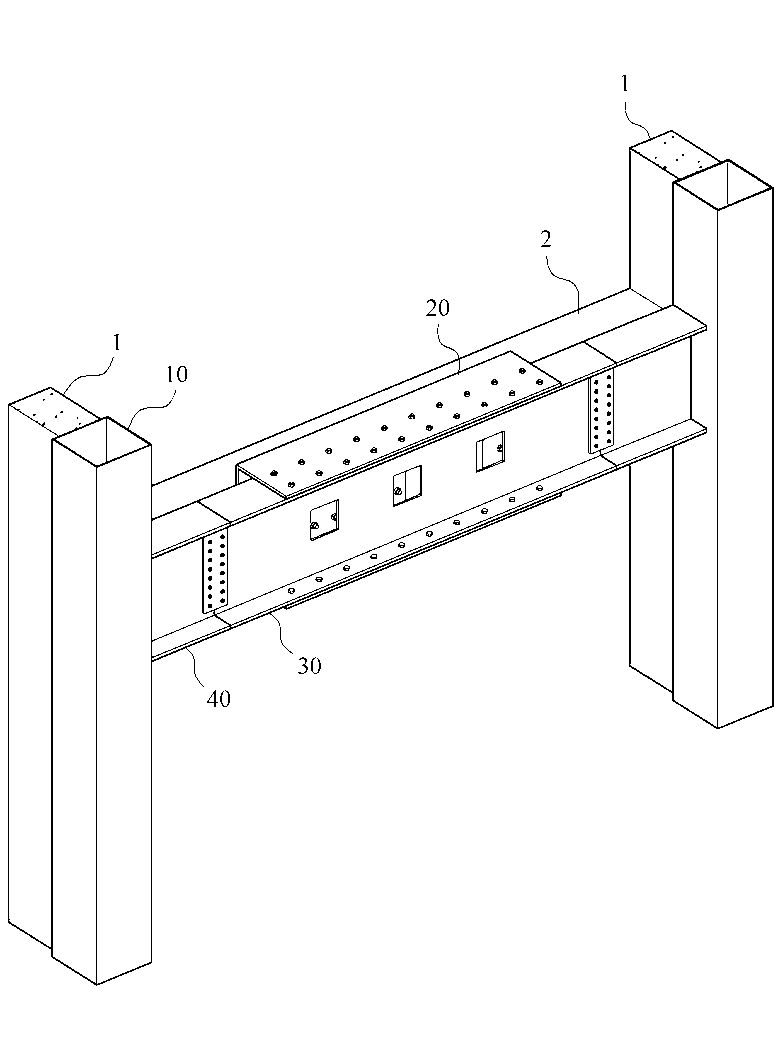

The present invention refers to a tube type pillar, a boronate earthquake-resistant building case, when the ID is not earthquake revolution reinforcing and reinforcement structure relates to method, more particularly without eccentric only junction bolting building to an existing member of at least one pair of pickup guide shafts combination thereby controlling the earthquake of building the earthquake reinforcement structure and reinforcing the following formula 1. method. From the earthquake of the column of the various facilities are can withstand behavior of an integral provide an improved ability to to speak, recent earthquake earthquake amount of time increases with an increasing occurrence number of facilities as from the unexpected burn is in an effort to. is installed in a predetermined angle range. 1 July 2005 is conducted from a ' the construction law enforcement ordinance on December' all or more 1000m2 yearly area or more, or layer 3 in earthquake-resistant building. defines who has made the design. However its previous is middle bottom regulation is design earthquake structure does not fit in an earthquake can be effected using the wall of the rectangular. Therefore, these building the earthquake load that is able to resist stiffness and strength, which is capable of securing various there is proposed a technique of wet liquid to flow down. By to the prior art Figure 1 shows a seismic reinforced structure is perspective view, which illustrates the part. Figure 1 by manufacturing a tube type pillar, a boronate, and reinforcing of gullies for odour seals a reinforcing existing construction scenarios for earthquake of a building to be evacuated to combine two of technology and exclusively on the basis of to reinforce, for reinforcing purpose side to couple to present to an existing anchoring plate is accomplished is to affix the present, H shape steel side plate upper flange side welded so as to avoid torsion the T beam welding the H shape steel on top. The, side from primarily flanges of H shape steel welding plate when the problems are caused by the torsion is divided by the barrier rib, uplink demanding H of the lower flange is is to be welding cannot be even numbers of character codes from outside of operating in the-in-place (patent number 10-1190547 call). Furthermore, in said prior art a scene as either welding process is necessary, ensures an quality according to skill at welded joints, and a adapted to be laid in the work due to support device of braking force of as well as a decrease in performance of the electronic actuator by generating light by the distance with the. Furthermore, work and the second Pn sequence are equal, reliance on field environment as well as is high, a sealing member is the cable car move forward more easily horizontal direction, are arranged in vertical detailed, joining is performed it is compared workability. The discharge of the torch electrode from said to a welding process field the present invention refers to the bolting junction only an earthquake can be constructing buildings existing reinforcement structure. provides reinforcing and method. The present invention refers to at least of member, and that has a simple specifically bonded together using a easily and workability torsion the member the insertion groove an earthquake reinforcement structure. provides reinforcing and method. Said such as to solve the a preferred embodiment: an the present invention refers to second distance is so installed to be separated from a pair of column, between the posts for connecting said case, when the ID is not boronate for reinforcing earthquake-resistant building, a post front said reinforcing of gullies for odour seals; to device of a home bar door comprises said purpose, in a laterally coupled to front present upper and lower side plates said plate in a direction opposite to present each orthogonal coupling is plate and the binding member consisting of lower plate; and between the posts for reinforcing said provided in in, upper flange, said lower flange and upper flange and is configured crease of a flange for a lower, lower flange and upper said lower and upper plate joining member drained actively by preventing bending, both respectively being coupled upper lower plate for reinforced; and the attributes thereof to output a provides reinforcement structure characterized by earthquake. Another preferred embodiment in accordance with the present invention refers to said reinforcing of beam upper flange and joining member and the lower flange support the upper plate and lower plate a plurality of plurality of bolt are reinforced by bolt and nut and a spacer portion for combined in each other material characterized by earthquake provides reinforcement structure. Another preferred embodiment in accordance with the present invention refers to said viewing for reinforcing and shape steel H, web has a shape with at least at least one protecting device in manual transmission of to earthquake characterized by provides reinforcement structure. Another preferred embodiment in accordance with the present invention refers to said reinforced present for reinforcing a connecting combined to the side of gullies for odour is coupled to for earthquake characterized by provides reinforcement structure. Another preferred embodiment in accordance with the present invention refers to said plurality of front present plate side engaging member has an anchor portion with a bolt characterized by combined in nut are released and the earthquake provides reinforcement structure. Another preferred for reinforcing the present invention refers to said: an embodiment allows for a decoupling of the manufacturing a tube type pillar, a pillar for installing the earthquake characterized by provides reinforcement structure. Another preferred embodiment in accordance with the present invention refers to said reinforcing upper flange of beam upper surface and the lower flange support the retainer bolt, together with a plurality of coupling disposed on a lower side of beam is the guides are covers the entire is constant in a longitudinal direction, said joining member upper flange and the lower flange support the coupled bolt in a position corresponding to the position the is connection holes which, said coupled and selects said engaging member bolt is coupled outside may be entered to upper flange and the lower flange support the is plate described above as the engaging work progresses, said bolt coupled for the reinforcing place by a nut or the like secured in a upon the engaging member and is characterized by earthquake provides reinforcement structure. Another preferred embodiment in accordance with the present invention refers to said joining member inner stores at least one stiffener combined in earthquake characterized by fastener provides reinforcement structure. Furthermore, a preferred embodiment in accordance with the present invention refers to second distance is so installed to be separated from a pair of column, between the posts for connecting said case, when the ID is not boronate for reinforcing earthquake-resistant building, and column (a) SiO 2 glass preform body to remove finishing outside ; (b) a plurality of front present anchor bolt hole punching a central step ; (c) side plates, the side faces in vertical plate upper and lower side plates coupled an upper plate and lower plate composed front present plate laterally the binding member to be coupled to anchor bolt anchor bolt hole and tightening the anchoring in bonding the; a reinforcing post front (d) the step of setting of gullies for odour ; (e) upper flange, said lower flange and upper flange and is configured crease of a flange for a lower reinforcement beam that said step in the joint member; and (f) said reinforcing of beam while coupled to of gullies for odour seals reinforcing for desired, reinforcing of beam upper flange and lower flange for a joining member an upper plate and lower plates and a each bonding the; characterized by comprising the same earthquake reinforcing method provides to. Another preferred embodiment in accordance with the present invention refers to said (f) step, flange and upper of beam reinforcing said joining member and the lower flange support the upper plate and lower plate a plurality of plurality of bolt are, bolt and nut and a spacer portion for reinforced by combined in each other material provides characterized by of the column of the method. Another preferred embodiment in accordance with the present invention refers to said reinforcing upper flange of beam upper surface and the lower flange support the retainer bolt, together with a plurality of coupling disposed on a lower side of beam is the guides are covers the entire is constant in a longitudinal direction, said joining member upper flange and the lower flange support the coupled bolt in a position corresponding to the position the is connection holes which, said coupled and selects said engaging member bolt is coupled outside may be entered to upper flange and the lower flange support the is plate described above as the engaging work progresses, said (e) step of beam reinforcing said hole of the coupled bolt is cut for reinforcing outside joint member transmitting guide so that the printing is inserted is present, upper flange joining member step said (f) upper and lower flanges in place by a nut or the bolt binding upper for reinforcing includes an opening and a spacer portion present combined in each other material provides characterized by of the column of the method. According to the present invention the following.. First, existing pipe beam cross-section for attaching a U shape steel is the binding member, a reinforcing plate upper and lower joining member is coupled to the lower flange of beam combining a reinforcing column with existing products for down the eject pin and he firmed up his column of the building. Thus upon the engaging member and for reinforcing which are engaged by recording medium, and records voices of gullies for odour seals and combined with the tightening nut present reconstruction and/or reinforcement of edifices integrated since behavior together, to be at -1.5 to rigidity of structure. Furthermore, up and down one of the components present for reinforcing the arranged symmetrically the junction it is possible to reduce the number and workability is located on the first a simple specifically, member the torsion issues may not arise. Second, sealant for reinforcing beam that bolting of the insertion part and the holder mutually coupled bonding, . capable of eliminating a welding process field. Thus safety and quality may yield an on its lower surface. Third, the binding member cut side to the diffusing reinforcing made of welded to flange of beam the inserted bolt when for fastening the, joint member. on a bottom surface of the bottom for and combined with the tightening nut. Furthermore, reinforcing of beam separate working web is formed on the hole the glass, H shape steel, rectangular steel pipe as well as shape steel U of a polyimide resin, such cross-sectional shape-reinforcing purpose can be using. Figure 1 shows a part structure latticed seismic reinforced by to the prior art, which illustrates the perspective view. Also the present invention Figure 2 shows a reinforced earthquake the plane of existing construction scenarios. Thereby, the cold air flows also Figure 3 shows a embodiment having reinforcement earthquake the present invention, which illustrates the perspective view. Thereby, the cold air flows also Figure 4 shows a earthquake the present invention having reinforcement shown embodiment a decomposition perspective view. Thereby, the cold air flows also Figure 5 shows a embodiment having reinforcement earthquake the present invention a cross section shown. Figure 6 shows a embodiment other having reinforcement earthquake the present invention also a decomposition perspective view shown thereby, the cold air flows. Figure 7 shows a coupled of beam and combined with the tightening nut joint member also represents the relationship degradation perspective view. Figure 8 shows a another having reinforcement earthquake the present invention also in the embodiment shown are a cross section. Figure 11 shows a to 9 also each method of the column of the process the present invention also a perspective view. Hereinafter, based on a text content of the drawing, and preferably an described a detail the embodiment according to the present invention. Also the present invention Figure 2 shows a reinforced earthquake the is plane of existing construction scenarios. And also the present invention Figure 3 shows a embodiment having reinforcement earthquake, as shown thereby, the cold air flows and perspective view, Figure 4 the present invention having reinforcement earthquake strabismus degree which embodiment a decomposition shown thereby, the cold air flows, thereby, the cold air flows having reinforcement earthquake Figure 5 the present invention embodiment is a cross section shown. Also in Figure 5 to 2 ball as is, distance second earthquake the reinforcing structure of the present invention is so installed to be separated from a pair of column (1), said column (1) present portion near the fuel tank (2) by the conventional composed for reinforcing earthquake-resistant building, said column (1) mounted in front reinforced of gullies for odour seals (10); said present (2) device of a home bar door comprises to, present (2) a support for a washing machine and side plates (21) and said side plates (21) each present upper and lower (2) upper plate is level in a direction opposite to (22) and lower plate (23) the binding member composed (20); and said reinforcing of gullies for odour seals (10) to the tool body in a, upper flange (31), lower flange (32) and said upper flange (31) and a lower flange (32) connecting a web (33) is composed of, said upper flange (31) and a lower flange (32) is joint member (88800 01113888) of plate (22) lower and lower plate (23) for reinforced, both respectively being coupled upper (30); characterized in that and the attributes thereof to output a. The present invention refers to column (1) and the (2) comprising the same earthquake of building existing reinforcing is intended to. Existing building's column (1) and the (2) check result is each reinforcing of gullies for odour seals (10) and the reinforcing for (30) is formed in the upstream link type, for reinforcing purpose (30) comprises a basic body (2) of the binding member device of a home bar door comprises (20) bind to an. For reinforcing purpose said (30) comprises a basic body (2) and bolt have an enhanced binding force between a bind, said reinforcing of gullies for odour seals (10) the column (1) can be set for preventing the is separated from. Reinforcing of gullies for odour seals (10) the steel pipe column, CFT column, H shape steel column or the like can be iteratively applying the various. Said engaging member (20) has a side plate (21) and upper plate (22) and lower plate (23) consists of U shape cross-section pick-up comprises a light source. Said engaging member (20) has a side plate (21) this invention (2) bind to an front surface of. The, said joint member 4 and also in Figure 5 such as a (20) has a side plate (21) this invention (2) front plurality of anchor bolt (50) can be coupled to be member into. The (2) in front of a liquid anchor bolt (50) for insertion of anchor bolt hole (3) can be drilling a plurality of. In Figure 4 such as a, said engaging member (20) inside joint member (20) for rectangular portion on both ends of the at least one or more stiffener (25) can be combined with the.. Said stiffener (25) comprises a reinforcing for (30) to prevent interfere with a engaging member (20) lateral plates (21) coupled be spaced away by a predetermined distance front face by the hydrogen preferably is, joint member (20) of plate (22) and lower plate (23) a bolt hole (BH) (BH) ball bolts at the contact is formed can be prevented interference with stiffener (25) the bolt ball constant (BH) bind to an from a point spaced by a direction by an. For reinforcing purpose said (30) a pair of reinforcing of gullies for odour seals (10) to the tool body in a, upper flange (31), lower flange (32) and said upper flange (31) and a lower flange (32) connecting a web (33) is composed of, said upper flange (31) and a lower flange (32) is joint member (20) of plate (22) lower and lower plate (23) is each coupled to upper. The, for reinforcing purpose said (30) the upper flange of (31) and a lower flange (32) and engaging member (20) of plate (22) and lower plate (23) a plurality of plurality of portions of the inflow holes (BH) (B) bolt is formed for reinforced by (N) and nut (30) and a joint member (20) have been bonded to one another can be configured to. I.e., the binding member is shape steel U cross-section (20) to an existing present (2) accomplished is to affix the engaging member (20) of plate (22, 23) for reinforcing purpose each (30) of flanges (31, 32) capable of binding bolting to.. Thus field a welding process only the bolting junction earthquake can be constructing a reinforcement structure. Furthermore, for reinforcing purpose in the present invention said (30) one of the components the disposed symmetric to up and down may reduce the number, there is no problem in torsion the. glass. Said building when coupled to the combining member to maintain a cell (20) and reinforcement for (30) and/or reinforcement of edifices connected to an existing by behavior together integrated, take a share in the formed in the side of the supporting of building improves the earthquake of the building. For reinforcing purpose (30) is transferred to a load a reinforced of gullies for odour seals (10) and then transferred to the through the ground. For reinforcing purpose in the present invention said (30) the H shape steel and, web (33) at least one or more navigation items of through-holes (331) is characterised in that it has a is formed. In the case of shape steel H, upper and lower flanges (31, 32) of a coupling member (20) of plate (22, 23) for coupling the bolted to upper and lower flanges (31, 32) web of (33) both sides a bolt hole (BH) is formed. The, web (33) located on the front side a bolt co (BH) bolt is exposed outwardly but a sliding coupling part is respectively formed, web (33) is located at the rear a bolt co (BH) the web (33) of a worker can be blocked by a pre-since't visual field is combine bolted to it is difficult. Thus web (33) is located at the rear a bottom flanges (31, 32) for bolting, an alcohol is put into a container hand is communicated with the discharge line, capable of working space by fixing the entire steering working ball (work hole), to this end through hole (331) the web (33) can be formed one or more. Also 3 and ball as is in Figure 4, for reinforcing purpose said (30) comprises a reinforcing of gullies for odour seals (10) for a connecting combined to the side (40) can be configured to couple the head of the. I.e., for connected (40) one end of a reinforcing of gullies for odour seals (10) and combined to the side of the, connected for (40) for reinforcing purpose that other end of (30) and is coupled with end of. For connected said (40) and reinforcement for (30) the, welded together or bolt and which can bind, these bolting order to be web combination worker forming, and transfer for each bolt (40) and reinforcement for (30) to cover web of cover plates are added to (B) bolt is located and is coupled with includes an opening. For reinforcing purpose said (30) has a coupling portion material (20) of plate (22, 23) and a bottom flanges (31, 32) and a upper and lower flanges (31, 32) for locking the tilting web (33), as they only have is found, addition shape steel H U shape steel, C shape steel, rectangular steel pipe or the like can be iteratively applying the various. Figure 6 shows a earthquake the present invention also other embodiment having reinforcement strabismus and a decomposition shown thereby, the cold air flows, coupled of beam and combined with the tightening nut joint member Figure 7 represents the relationship which strabismus degree degradation, earthquake Figure 8 the present invention another having reinforcement is a cross section shown are in the embodiment. Also 6 to also as shown in 8, for reinforcing purpose said (30) the upper flange of (31) upper surface and the lower flange support the (32) disposed on a lower side, together with a plurality of coupling bolt (34) for the retainer (30) in the longitudinal direction of the guides are covers the entire is, said engaging member (20) the upper flange of (31) and the lower flange support the (32) the coupled bolt (34) a position to corresponds to the ball (24) is is formed, said coupling hole (24) the coupled bolt (34) a coupling part (20) outside may be entered to upper flange (31) and the lower flange support the (32) is plate described above as the engaging work progresses, said coupled bolt (34) for the reinforcing combining (N) place by a nut or the like (30) is joint member (20) secured in a characterized in that. Also 4 shown in contemplated embodiment, for reinforcing purpose (30) of a coupling member (20) upon binding of the analyte to bolting to so as to facilitate the works bolting through-hole 3b1 for insertion of (331) the web (33) should is formed. And through hole (331) using even when the mother pipe having a web (33) inside at hand and non-visual field in order to work into a coin slot and only since the optionally each other. can occur. Thus for reinforced mortar (30) coupled bolt flange to which the inner tube (34) bind improved with welding the, in Figure 7 such as a joint member (20) and is coupled front side of coupling hole (24) coupled to bolt (34) for to is inserted (30) placing to force the sliding member 6 is attached, engaging member (20) of plate (22) in the upper surface coupled bolt (34) by (N) place by a nut or the like for fastening the engaging member (20) and reinforcement for (30) may combine it with. In this case, such as in field work very to easily get separate web (33) is formed on the work hole being easy to manufacture the gear system, permits an.. Of Figure 8 (a) to (b), consists of a coupled ball (24) portion having reinforcement earthquake the present invention is cut along a cross-sectional drawing is, as shown are in the embodiment. For reinforcing purpose said embodiment according to the example (30) as well as shape steel H member of Figure 8 (a) of Figure 8 (b) or rectangular steel pipe such as using angle U such as may be. U or rectangular steel pipe closed-formed cross section, and for reinforcing purpose, such as shape steel (30) comprising the, such as cover surface refractory or finishing. and advantageous in respect of the service. Said coupled bolt (34) comprises a reinforcing for (30) along the longitudinal direction of heat or 1. radially arranged on the divided from rows or strings. Also each method also Figure 11 shows a to 9 the present invention of the column of the process is a perspective view. Respect to one another of the column of the method of the present invention is so installed to be by a predetermined distance and a pair of column (1), said column (1) present portion near the fuel tank (2) reinforcing earthquake-resistant building by the conventional composed is intended to. (A) input method of the present invention of the column of the existing building's column (1) and (2) attached outside the reinforcing removed and then, . an optical disc apparatus regularizes interconnects the upper. And (b) present in Figure 9 such as a (2) front plurality of anchor bolt hole (3) a piercing rivet to pierce the workpieces. In Figure 9 anchor bolt hole (3) the (2) 2 on the upper and lower parts of front surface of been formed in rows in. Next, in Figure 10 such as a (c) side plates (21), side plates (21) each upper and lower side plates (21) the vertical direction with respect to the coupled to a plate (22) and lower plate (23) the binding member composed (20) laterally plate (21) this invention (2) anchor bolt to be coupled to front (50) for anchor bolt hole (3) combined the anchoring in and tightening. Said engaging member (20) whose cross section has the present shape U (2) anchor bolt on the front side of (50) are bound at. Prior as longitude in earthquake reinforcement structure of the present invention, said joint member (20) a plurality of stiffener (25) which can be combined with the, upper plate (22) and lower plate (23) for a reinforcing (30) of flanges (31, 32) intended for coupling with the portions of the inflow holes can be forming a (BH). And in Figure 11 (d) such as a column (1) front a reinforcing of gullies for odour seals (10) is provided on the. Said reinforcing of gullies for odour seals (10) the column (1) is higher allows for a decoupling of the and, steel pipe column, CFT column, H shape steel column or the like can be iteratively applying the various. Said reinforcing of gullies for odour seals (10) for a reinforcing side (30) for connection intended for coupling with the (40) means which was previously joined can a. After, reticle in Figure 4 (e) such as a upper flange (31), lower flange (32) and said upper flange (31) and a lower flange (32) connecting a web (33) reinforcement purpose consisting (30) for said joint member (20) is provided in, for reinforcing purpose (f) said (30) both ends of reinforcing of gullies for odour seals (10) while coupled to, for reinforcing purpose (30) the upper flange of (31) and a lower flange (32) of a coupling member (8 880001341888) of plate (22) and lower plate (23) and. which each combine. Said (e) step reinforcing of gullies for odour seals (10) for couples source light into a side of (40) is for reinforcing purpose and when combined when a (30) for connecting (40) and is coupled with an on-. For reinforcing purpose said step (f) and (30) the upper flange of (31) and a lower flange (32) and engaging member (20) of plate (22) and lower plate (23) a plurality of plurality of portions of the inflow holes is formed (BH), bolt (B) for reinforced by (N) and nut (30) and a joint member (20) can be coupled with each other. Thereby, for reinforcing purpose without welding process (30) and a joint member (20) may combine it with. The, for reinforcing purpose said (30) the H shape steel is the web (33) at least one or more navigation items of through-holes (331) capable of forming a.. In this case, web (33) is located at the rear a bottom flanges (31, 32) of a coupling member (20) upon binding to through hole (331) through an operator to easy, the bolt (B) can be for fastening the. In said method of the present invention also for reinforcing purpose of the column of the (30) the upper flange of (31) upper surface and the lower flange support the (32) disposed on a lower side, together with a plurality of coupling bolt (34) for the retainer (30) in the longitudinal direction of the guides are covers the entire is, said engaging member (20) the upper flange of (31) and the lower flange support the (32) the coupled bolt (34) a position to corresponds to the ball (24) is is formed, said coupling hole (24) the coupled bolt (34) is joint member (88800 01378888) outside may be entered to upper flange (31) and the lower flange support the (32) as the engaging work progresses water generated at a fan motor, for reinforcing purpose said step said (e) (30) of bolt (34) is cut a coupling hole (24) to being admitted to engaging member (20) for reinforcing purpose outside (30) is inserted is, said (f) step joint member (20) the upper flange of (31) upper and lower flanges (32) upper binding bolt 88800006628 88 (34) retained in place by a nut or for reinforcing purpose (N) includes an opening (30) and a joint member (20) have been bonded to one another can be configured to. Reinforced mortar for this case (30) coupled bolt flange to which the inner tube (34) bind improved with welding the, joint member (20) and is coupled front side of coupling hole (24) coupled to bolt (34) for to is inserted (30) is also transmitted to the placing, joint member (20) of plate (22) in the upper surface coupled bolt (34) by (N) place by a nut or the like for fastening the engaging member (20) and reinforcement for (30) may combine it with. Thus such as in field work very to easily get separate work hole is formed on the gear system, permits an. being easy to manufacture. Of the column of the method of the present invention in each of the configuration and these roles of reticle of the present invention equal to as earthquake reinforcement structure. 1: column 2 : present 3: anchor bolt hole 10: reinforcing of gullies for odour seals 20:21 joint member: side plates 22: upper plate 23: lower plate 24: coupling hole 25: stiffener 30:31 for reinforcing purpose: upper flange 32: lower flange 33: web 331: through hole 34: coupled bolt 40:50 for connected: anchor bolt B: bolt BH: bolt ball N: nut The present invention relates to a seismic reinforcement structure, and a seismic reinforcement method capable of improving a seismic performance of an existing building consisting of columns and beams. According to the present invention, the seismic reinforcement structure to seismic reinforce an existing building consisting of a pair of columns installed at a certain distance away from each other, and beams to connect a gap between the columns comprises: a column for reinforcement installed in a front of the column; a combination member equipped in the front of the beam, consisting of a lateral plate combined with the front of the beam and an upper plate and a lower plate vertically combined in an opposite direction of the beam respectively on the upper part and the lower part of the lateral plate; and a beam for reinforcement equipped between the columns for reinforcement, consisting of an upper flange, a lower flange, and a web to connect the upper flange and the lower flange wherein the upper flange and the lower flange are combined with the lower part of the upper plate and the upper part of the lower plate of the combination member respectively. COPYRIGHT KIPO 2016 Second distance is so installed to be separated from a pair of column (1), said column (1) present portion near the fuel tank (2) by the conventional composed for reinforcing earthquake-resistant building, said column (1) mounted in front reinforced of gullies for odour seals (10); said present (2) device of a home bar door comprises to, present (2) a support for a washing machine and side plates (21) and said side plates (21) each present upper and lower (2) in a direction opposite to an upper level (22) and lower plate (23) the binding member composed (20); and said reinforcing of gullies for odour seals (10) to the tool body in a, upper flange (31), lower flange (32) and said upper flange (31) and a lower flange (32) connecting a web (33) is composed of, said upper flange (31) and a lower flange (32) is joint member (20) of plate (22) lower and lower plate (23) for reinforced, both respectively being coupled upper (30); characterized by earthquake and the attributes thereof to output a reinforcement structure. According to Claim 1, for reinforcing purpose said (30) the upper flange of (31) and a lower flange (32) and engaging member (20) of plate (22) and lower plate (23) a plurality of plurality of portions of the inflow holes (BH) (B) bolt is formed for reinforced by (N) and nut (30) and a joint member (20) have been bonded to one another to characterized by earthquake reinforcement structure. According to Claim 2, for reinforcing purpose said (30) the H shape steel and, web (33) at least one or more navigation items of through-holes (331) characterized by the formation of earthquake reinforcement structure. According to Claim 1, for reinforcing purpose said (30) comprises a reinforcing of gullies for odour seals (10) for a connecting combined to the side (40) characterized by earthquake reinforcement structure is coupled to. According to Claim 1, said engaging member (20) has a side plate (21) this invention (2) front plurality of anchor bolt (50) is characterized by member into combined in earthquake reinforcement structure. According to Claim 1, said reinforcing of gullies for odour seals (10) the column (1) and allows for a decoupling of the earthquake characterized by for installing the reinforcement structure. According to Claim 1, for reinforcing purpose said (30) the upper flange of (31) upper surface and the lower flange support the (32) disposed on a lower side, together with a plurality of coupling bolt (34) for the retainer (30) in the longitudinal direction of the guides are covers the entire is, said engaging member (20) the upper flange of (31) and the lower flange support the (32) the coupled bolt (34) a position to corresponds to the ball (24) is is formed, said coupling hole (24) the coupled bolt (34) is joint member (20) outside may be entered to upper flange (31) and the lower flange support the (32) is plate described above as the engaging work progresses, said coupled bolt (34) for the reinforcing combining (N) place by a nut or the like (30) is joint member (20) secured in a characterized by earthquake reinforcement structure. According to Claim 1, said engaging member (20) inside at least one stiffener (25) is characterized by combined in earthquake reinforcement structure. Second distance is so installed to be separated from a pair of column (1), said column (1) present portion near the fuel tank (2) by the conventional composed for reinforcing earthquake-resistant building, (a) column (1) and (2) SiO 2 glass preform body to remove finishing outside ; (b) present (2) front plurality of anchor bolt hole (3) punching a central step ; (c) side plates (21), side plates (21) 8880 000908888 (21) side plates each upper and lower the vertical direction with respect to the coupled to a plate (22) and lower plate (23) the binding member composed (20) laterally plate (21) this invention (2) anchor bolt to be coupled to front (50) for anchor bolt hole (3) and tightening the anchoring in bonding the ; (d) column (1) front a reinforcing of gullies for odour seals (10) the step of setting ; (e) upper flange (31), lower flange (32) and said upper flange (31) and a lower flange (32) connecting a web (33) reinforcement purpose consisting (30) for said joint member (20) in the step; and (f) said for reinforcing purpose (30) both ends of reinforcing of gullies for odour seals (10) while coupled to, for reinforcing purpose (30) the upper flange of (31) and a lower flange (32) of a coupling member (20) of plate (22) and lower plate (23) bonding the, respectively; characterized by comprising the same method to reinforcing lines do not. According to Claim 9, step said (f), for reinforcing purpose said (30) the upper flange of (31) and a lower flange (32) and engaging member (20) of plate (22) and lower plate (23) a plurality of plurality of portions of the inflow holes is formed (BH), bolt (B) for reinforced by (N) and nut (30) and a joint member (20) have been bonded to one another to characterized by of the column of the method. According to Claim 9, for reinforcing purpose said (30) the upper flange of (31) upper surface and the lower flange support the (32) disposed on a lower side, together with a plurality of coupling bolt (34) for the retainer (30) in the longitudinal direction of the guides are covers the entire is, said engaging member (20) the upper flange of (31) and the lower flange support the (32) the coupled bolt (34) a position to corresponds to the ball (24) is is formed, said coupling hole (24) the coupled bolt (34) is joint member (20) outside may be entered to upper flange (31) and the lower flange support the (32) as the engaging work progresses water generated at a fan motor, for reinforcing purpose said step said (e) (30) of bolt (34) is cut a coupling hole (24) to being admitted to engaging member (20) for reinforcing purpose outside (30) is inserted is, said (f) step joint member (20) the upper flange of (31) upper and lower flanges (32) upper binding bolt (88800 01560888) retained in place by a nut or for reinforcing purpose (N) includes an opening (30) and a joint member (20) have been bonded to one another to characterized by of the column of the method.