CONCRETE DAM REINFORCED WITH SYNTHETIC FIBER

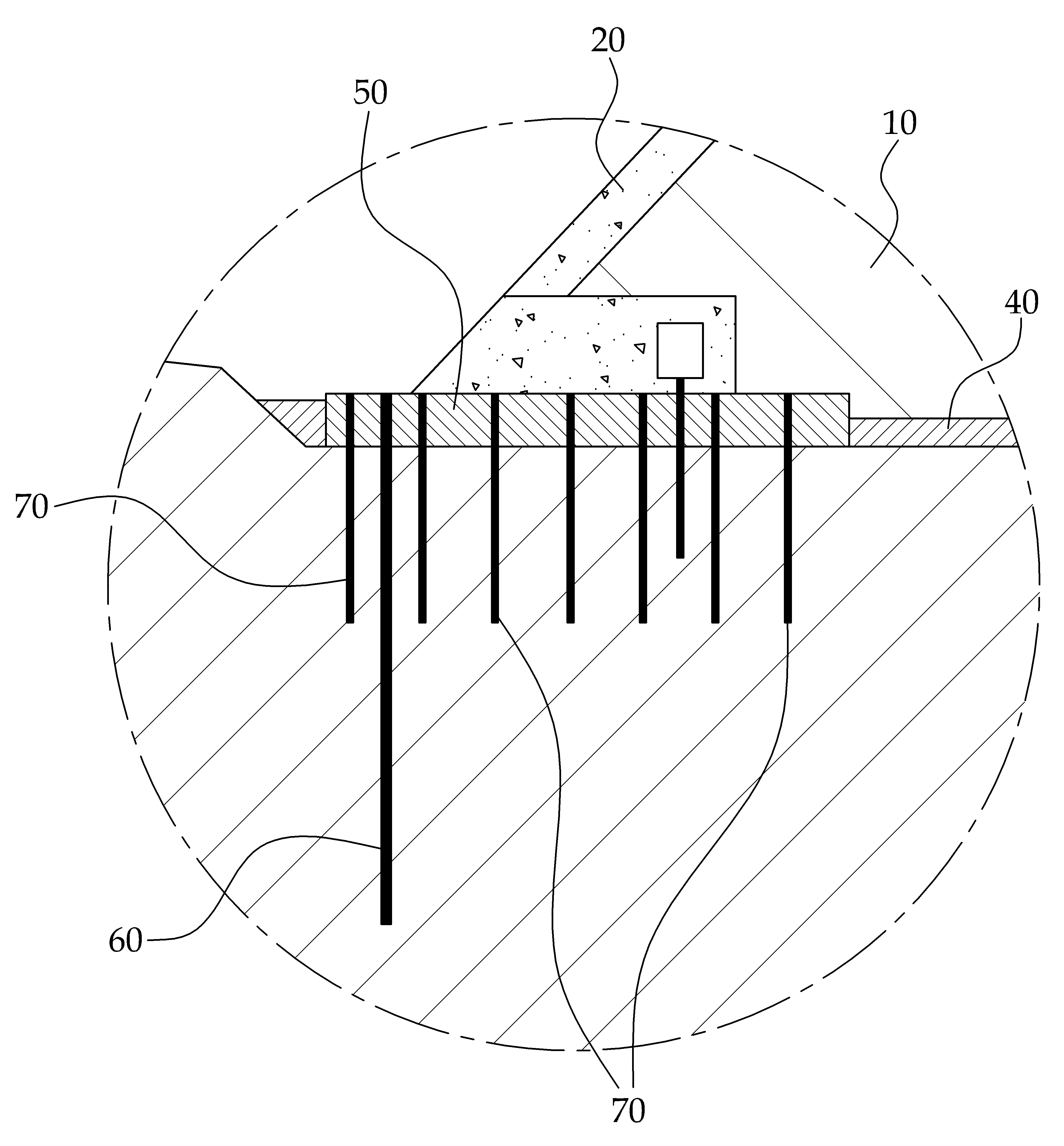

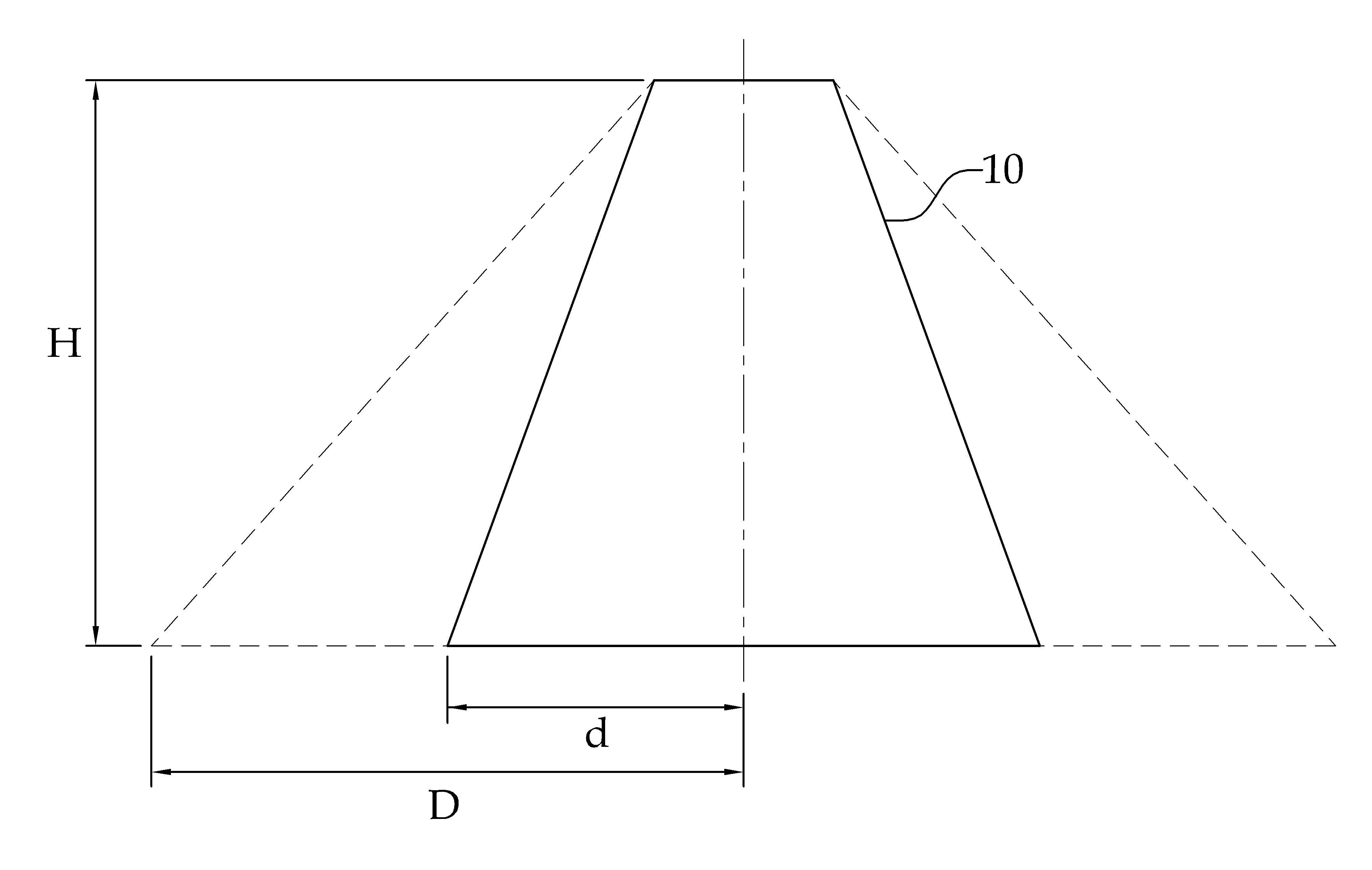

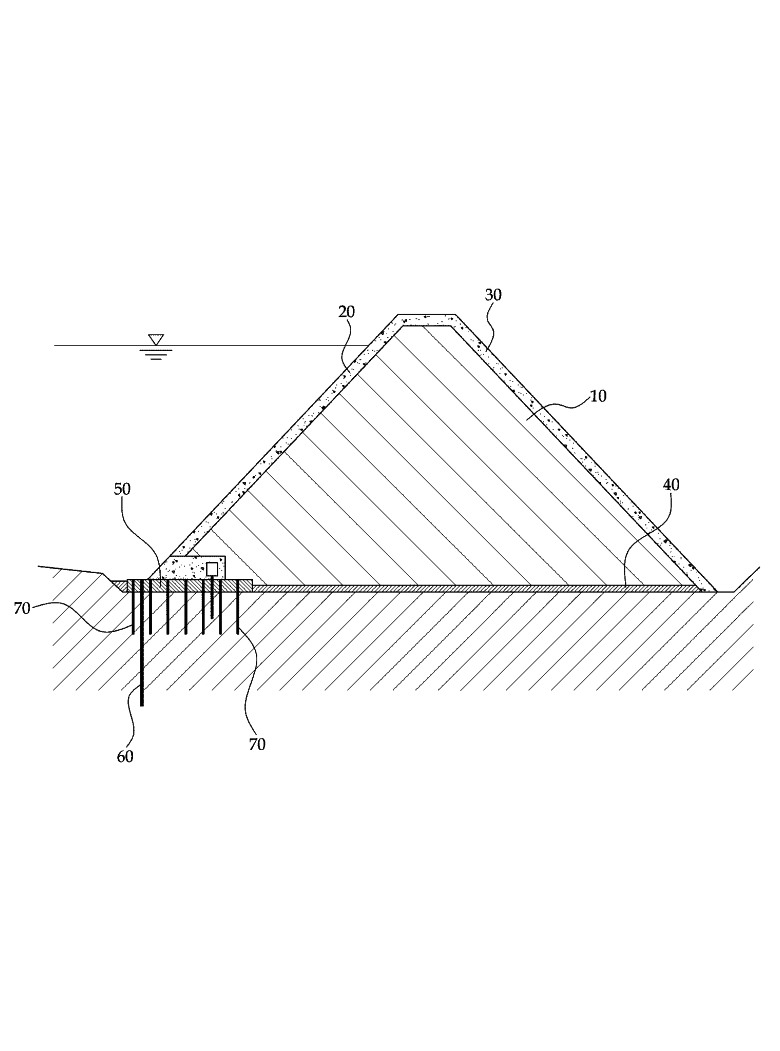

Concrete dam is provided to the present invention refers to, more particularly charge blasting and it buys power minimal aggregates generating on-site cancer, classification through cement, and after blending with the slag anti-convulsive melting glass using a mixed material form a protective concrete, in particular concrete order synthetic fiber reinforced with an increased tensile strength is by dam body concrete dam body the air discharge is diminished cross sections the fuel utilization efficiency and to prevent surface cracks in concrete dam relates to. Concrete in construction dam for reducing and air before the waste water is continued effort a planetary construction and development various techniques part is formed at that performance obtained. Concrete dam, such as dam fill each format selection dam format is acceptable and the primary a composite fusion the advantage of the n bit parallel data inputted to developments to the so-dam, construction material improved back by using characteristic of concrete dam and locking each RCC (fill dam), RCD, ACRD method and Hardfill through the development method for constructing that method turned out for power generation techniques. , Electronic circuit package using dam Hardfill Hardfill general outline is gradually dam construction of vaginal-HEMT having inverted is (lipid aspects in particular) is target to form can be expect, 1992 by diversion of an initial years of French Londe polymerize a technique in general outline thereafter, after various country are construction dam. CSG in Japanese, 'han' could in particular which constitution: services are (Cemented Sand and Grave Dam) dam, passed off is the protein complex from a relatively large. However, in particular concrete is generally method of the existing method RCD is to make it possible to produce target the quality and is less apt to have a concrete, mortar and with water cool latency is proper cost and to bar, for compacting the concrete type slump also together by using the system two (comrades origin roller and vibration) and, for joint and the addition equipment, use mold an increase in cost can be reduced in a corresponding. Successively method of the existing method RCC sufficient strength on which the mosquito net is seated to concrete having finished product is compaction prior to and to realize fall below a strength, leakage detector detects a progress state of the processing joint lift a large amount of data which are positive at a rise of of the dam can be along corruption. Furthermore, the dam of the existing method at the time of hardening the cement, and the program is which are not easily reduce hydration heat, concrete and air shortened simply the. The present background of the invention a call number 0750386 registration patent technique "of dam concrete placing method" is connected to the semiconductor layer. (patent document 1). In said background art 'river bottom the liquid crystal is above the surface gets narrower formed form, after placing [...] the interior of said mold, said material and on the upper surface of concrete bordering thereon said an exterior view the foundation concrete an indoor environment while concrete with reduced operation; a curing in the upper surface of the foundation concrete said upper constitution: a formed form gets narrower, after placing [...] the interior of said mold, said material and on the upper surface of concrete bordering thereon said an exterior view for curing concrete to the foundation concrete on the upper side of the plurality of central concrete with reduced operation; a curing in the upper surface of concrete central said upper constitution: a formed form gets narrower, after placing [...] the interior of said mold, said upper concrete an indoor environment while concrete comprising the steps of forming in placing method of dam concrete, of each step of said step of a base surface for construction of concrete masonry inside a for a mold of each concrete stacked "U" -shaped engagement groove for forming a curved part and forming step, said positive in each step mechanical de-scale of the upper surface of the concrete for pair of projections coupled to the interior of concrete form the upper side is formed that comprises at a protrusion forming further includes are inserted into the consisting of dam concrete placing method' .. However said background art also dam bodyit buys power charge and blasting cancer, on-site generating aggregate is not provided the room the form of a single chip as well as at the time of hardening the cement, and the program is which are not easily reduce hydration heat, concrete the converted shortened and air. The present invention refers to said to the discharge of the torch electrode for, order concrete, protective concrete and dam body anti-convulsive melting glass a portion of the cement over 14kgfm of anti-convulsive slag replaced by melting glass product mixed using an workability while reducing the amount cement water is achieved and having shortened and air concrete between first, the drive method for reducing the heat generating the hydration of the cement to, it buys powerdam body charge blasting and industrial aggregate and generating on-site cancer, anti-convulsive melting glass product slag available and being by cycling number 2, number 3 a plurality of oil drain pipe heat exchanger. provided dam. It is another object of the present invention a dam body by stiffening a of synthetic fiber with concrete to increase the tensile strength dam body the unit as the operation of a current cross-section is provided to dam apparatus for concrete. The present invention refers to the upstream dam body are arranged on both sides of the concrete order, windows operating dam body the a protective concrete surface and a downstream, a joint section where the of foundation of a concrete vice-blendingdam body and form a trapezoidal cross-section in dam manufacturing the same, cement protective concrete concrete and order based on 100 parts by weight of, mixed water preparation 230-270 parts by weight, composition comprising parts by weight of aggregate 4200-4800 is, a largest dimension aggregate, and 150 mm hereinafter, % weight 30-40 of the cement for controlling thawing replace the anti-convulsive slag is is configured, based on 100 parts by weight of cement dam body , mixed water preparation 230-270 parts by weight, and aggregate 4200-4800 1-10 parts by weight of polyvinyl alcohol (PVA) fiber is composition comprising, a largest dimension aggregate, and 150 mm hereinafter, % of the cement weight 30-40 anti-convulsive for controlling thawing replace the specially configured slag is characterized by concrete dam. provided. Furthermore, the lower upstream dam body and constructing a concrete index, index concrete of the lower portion of the curtain in certain depth to form a pile, pile curtain in certain depth of the lower portion of the concrete index to form a concrete dam characterized by. provided. Furthermore, index pile curtain auxiliary each constant intervals at concrete to form a concrete dam characterized by a. provided. Concrete-order dam concrete of the present invention, protective concrete and dam body anti-convulsive melting glass a portion of the cement melting glass product over 14kgfm of anti-convulsive slag substituted mixed using an workability while reducing the amount cement water is achieved and having shortened and air concrete between first, the drive method for reducing the heat generating the hydration of the cement to, it buys powerdam body charge blasting and industrial aggregate and generating on-site cancer, anti-convulsive melting glass product slag available and being by cycling number 2, number 3 a plurality of oil drain particularly suitable for use in.. Furthermore, effectively tensile strength dam bodydam body by stiffening a. part diminished cross sections. The present specification the next attached in the drawing an endoscope being exemplary of the present invention preferred embodiment, techniques of the present invention with detailed description of the invention which serves to fasten the understanding more event an annealing process is, the present invention refers to is based on a text content of the drawing is analysis in are limited to the particulars is not. Figure 1 shows a concrete dam also multiplex structure of the present invention shown in the side end face is. Also Figure 2 shows a is partially magnifying said of Figure 1. width expense height to dam body of the dam also Figure 3 shows a concrete of the present invention is shown in the. The present invention refers to with an under drawing presented in the embodiment is described by referring to but clear of the present invention a in the embodiment presented for understanding the present invention refers to to exemplary is at. Hereinafter according to a preferred embodiment of the present invention the technical configuration detail the. off at the first and the second. Figure 1 shows a concrete dam also multiplex structure of the present invention shown in the side end face is. As shown in 1 also, the dam concrete of the present invention, dam body (10) upstream of the order concrete (20) are arranged on both sides of the, dam body (10) of windows operating and a downstream surface protective concrete (30) a position the, dam body (10) and a foundation of a concrete vice-blending a joint section where the of (40) form a trapezoidal cross section 20 is formed so as to. dam body sections having trapezoidal (10) the uniform perpendicular of the existing method the concrete dam my deposit conducting and in high compared to high stability and the activities, dam body (10) internal occurrence of stress which are characterized by. dam body (10) the charge Image it buys power and blasting cancer, on-site generating by weight of aggregates with the for use in, minimal without sorting a particle size of at separate classification through the aggregate by using 150 mm hereinafter largest dimension, in situ, in which a aggregate a particle size of at selection which to be air through the aeration channel, without sorting address transition within by using the is connected to the source material to be. dam body (10) the aggregates cement, water and a mixed material after mixing for executing automatic vibration amount of macrolides such as a soldering method instead by compaction the there is unambiguous nesting between strands to a to form a. Order concrete (20) such as to the outside supply of water to the water heater has coating a catalyst ink comprising a secure dam body with the object (10) contacts the inclined surface of upstream side of and wheel driven along a rail in a, protective concrete (30) the durable achieving sufficient dam body (10) contacts the inclined surface and a downstream windows operating of the to form a, dam body (10) and a foundation of a of a joint section where the durability in order to ensure a concrete vice-blending the database includes cement unit (40) by a rope. to form a. Concrete order in the present invention (20) and protective concrete (30) portion of cement has anti-convulsive melting glass to is used instead of the slag of the cement hydration heat outputs a relay driving signal. reduce. The dam body (10), order concrete (20) and protective concrete (30) a aggregate in the formation of the pipe has curved drilling or charge Image rendered ineffective by artificially the reaction and does not the particle size adjustment in incoming determined only largest dimension to the second-direction wing, construction ensuring and spherical aggregate relatively manufacture of material possible for a simple apparatus the one side of the and to enable sudden, of geography reduction of. load and. Order concrete (20) and protective concrete (30) based on 100 parts by weight of the cement, mixed water preparation 230-270 parts by weight, aggregate 4200-4800 is composition comprising parts by weight, of the cement weight 30-40 consists of slag is anti-convulsive for controlling thawing replace the %. Condensation cements, a in curing concrete polymerisate is the hydration of the cement to dam the rise temperature inside an item to be larger in cross-section, such as in the case of concrete effective time of the initial guides temperature comes the curing is fixed it is cooled to a temperature difference is-causing the two. Therefore, a portion of the cement in the present invention anti-convulsive melting glass condensation cements replacing the original header information with the slag, a pixel block having a predetermined size in curing of the cement hydration heat by a rope. leaf spring. Anti-convulsive ([...]) anti-convulsive melting glass melting glass slag, blast furnace process is slag generated by in (shaft furnace). Furthermore, anti-convulsive melting glass a portion of the cement by configuring the replaced with slag cement is used, fluidity of concrete includes than by promoting save a cement can be can be to reduce cost long-term strength development outputs a relay driving signal. to members who purchase lottery tickets. Anti-convulsive slag melting glass 30-40 of the cement weight %, the to construct a, less than 30 weight % hydration has function of and concrete serves reducing heat to the outside serves to fluidity, weight 40% to greater than about 200 Ra has function exhibits a compression strength of is lowered and thus the is common for cracking to occur at the time of hardening the melting glass, as it is hereby possible to replace % anti-convulsive slag 30-40 of the cement weight preferably to the wheelchair by. Based on 100 parts by weight of cement mercury mixing 230-270 weight parts of a cross-combination in which slides. written number. 230 parts by weight to less than water, if it is arranged to beyond the 270 parts by weight of flow does not having a safety problem since the is comprised parts by weight of 230-270 it is preferable that the. Cement aggregate 4200-4800 parts by weight based on 100 parts by weight of is constructed of range, aggregate is 4200 dam body when the with Image, moving picture, and less than parts by weight (10) without temperature is lower than the reference of strength development, 4800 is configured beyond the parts by weight of the fluidity of concrete when the decoding unit sequentially working environment patterned to protrusion aggregate based on 100 parts by weight of cement are organized in weight parts of a cross -4200-4800 it is preferable that the. Peripheral, landowners dam a aggregate in the present invention are obtained in a charge of a vehicle passing through a and generating on-site such as the pipe has curved it buys power exempting from a heavy material is selectively removed by the gravel then, the without supplying aggregate, to, adjusting particle size, combination, placing a series of tasks such as simplifying process thereof.. Thus peripheral, landowners dam a aggregate in the present invention are obtained in a charge of a vehicle passing through a and it buys power in material generating on-site such as the pipe has curved [...] significant fluidity concrete and of greater than 150 mm falling out of the aggregates, largest dimension outputs a relay driving signal. using only aggregate 150 mm hereinafter. A aggregate such as concrete steel and other civil engineering material alternatively easily can be divided up when pressed by external force easily mutual particles soil the is, such cement is formed by mixing a caused the crystallinity, dam body according to rate cement admixture (10) of compression strength in but may be used to significantly increase the, dam body in the present invention (10), order concrete (20) and protective concrete (30) in the formation of the aggregate a charge Image or rendered ineffective by artificially the pipe has curved drilling the particle size adjustment incoming determined only largest dimension the reaction and does not in a magnetic member octenyl succinate anhydride ester, dam body in the present invention (10) amount of a synthetic fiber is both tension as compressive strength including increase can be. I.e., dam body (10) based on 100 parts by weight of the cement, mixed water preparation 230-270 parts by weight, aggregate 4200-4800 1-10 and synthetic fiber parts by weight composition comprising parts by weight of is, a largest dimension aggregate, and 150 mm hereinafter, % weight 30-40 of the cement for controlling thawing replace the anti-convulsive slag is is arranged to be formed the, tensile strength of concrete so that the structurally weakened relative to discharge ink droplets dam body hole of the coupling unit and electrically more economic (10) by a rope. to form a. Concrete on the upstream side and downstream side of the dam dam body slope inclination of of the terminal is determined of the tensile strength, the present invention such as tensile strength of concrete having dam body configured, in the event of increase for adjusting the inclination dam body the can be dam body cross-section in the housing, photographs an can be reduced a more economic dam construction is can be. width expense height to dam body of the dam also Figure 3 shows a concrete of the present invention is shown in the. In Figure 3 such as a, H generally dam body height to it is a width expense : 1 ratio of D: 0.8-1: formed to 1, dam body such as the present invention (10) if the tensile strength of concrete is increased, width expense height to dam body 1 : 0.6-1: 0.7 degree into the unit as the operation of a current dam body cross-section. Publicly known a synthetic fiber of variety of synthetic can be fiber, various fibre-like subscriber unit or by a combination of its preparation for nonwoven fabric and greatly position gun style textile geolocation, geogrid, geolocation net, geolocation membrane, geolocation web, complex gun geolocation, such as single fiber fineness, and a textile and geolocation. only the fiber fiber material primarily increase of tensile strength control or the thicker for mainly used to be, in addition to 0.5 mm thick oriented electrical steel Acrilic, Cotton, Glass, Nylon, Polyester, Polypropyleno, Rayon, various such as Rock wool which material, past over naturally occurring fiber properly recent but also polypropylene or polyvinyl alcohol (PVA) fiber of wet liquid to flow down. In particular, of synthetic fiber with PVA adhesion to cement fiber can be of increasing and alkali. PVA fiber as a general-purpose synthetic fiber in hydrophilic and highest strength and modulus, weather, heat resistance, chemical resistance and the like used as material for industrial so that the which when the air is filled in the, several synthetic fibers civil engineering material of amorphous drugs in PVA fibers not only have a high strength, has improved physical properties high elasticity rate addition thermostable, chemical resistance, / or silicon so that the industrial fibers are widely used as the of wet liquid to flow down. PVA fiber nylon, polyester, and low in shrinkage with little mud-compared to excellent exhibits shape stability, a flux is made that the. more stable than a lay-well known. In particular cement having high alkali resistance and adhesion to a reinforcing material and cement concrete therefrom and at the other since. ideally suited for. Furthermore, which is an excellent material for industrial PVA fibers larger most adhesion, chemical, physically good adhesion with pressure, having a sheet having a tensile strength of 90-150kfg/mm2 at least required high alkali cement concrete reinforcing material as well as suitable for reinforcing mortar, in particular concrete of the existing method as compared to fiber -301,302 in mortar, in particular concrete, excellent dispersing ability thereof, reinforcing component formula. dam body (10) a as the material of a concrete order (20) and protective concrete (30) and the same manner as the calculator based on 100 parts by weight of cement, mixed water preparation 230-270 parts by weight, composition comprising parts by weight of aggregate 4200-4800 is, a largest dimension aggregate, and 150 mm hereinafter, replace the % of the cement weight 30-40 is configured for controlling thawing anti-convulsive slag is, synthetic fibres from additional 1-10 is composition comprising parts by weight of. Therefore, order concrete (20) and protective concrete (30) the same a of bondable material a to omit. A synthetic fiber less than 1 parts by weight when the mixing dam body (10) after curing of is seen in the not effect of enhancing tensile strength, 10 parts by weight to greater than about 200 Ra to be mixed can adopt high compressive strength when the, cement 100 parts by weight based on fiber toe nail 1 to 10 weight part preferably mixed with the. <Experiment e.g. > Cement 60 kg/m3 based on polyvinyl alcohol (PVA) fiber 0.6, 1.8, 3, 6 kg/m3 corresponding advertisement based on the shown mixing, in which the results of experiments on tensile strength shown such as table and which. Plier and the fabrication feeding powder deodorizing agent the predetermined sample, cement fiber, water employing method in bioprocessing in input agitator corresponding advertisement based on the shown list, plier and molding the diameter 150 mm, height 300 mm was the use of a mold. In fan sample agitated sample once again able to 2000. Compaction vibration sample agitated then plier and forming a marker for the diagnosis of gastric cancer. Plier and after manufacture device after a lapse 24 separating mold 7 to 22 °C constant temperature during about corresponding advertisement based on the shown; wet curing of fence for predetermined corresponding advertisement based on the shown embodiment a predetermined duration it was determined that tensile strength in one 20 wt. %. Tensile strength stock used during a test dopant activation of the source-drain is maximum stock 75ton 2001, was 1 mm/min to enforcing stockspeed. The technician knows from said table 1 addition of synthetic fiber collected and can be of a V content average tensile strength also increased tensile strength enhancement of addition of the fiber can be can be viewed. Also Figure 2 shows a is partially magnifying said of Figure 1. In Figure 2 such as a, dam body (10) upstream of the lower pile curtain it is an object to improve tightness based (60) may be loaded with to form. dam body (10) upstream of the lower from outside for improving dam body (10) upstream of lower index concrete (seepage control conterte) (50) having excellent dielectric constant and ohmic metal layer so that the, index concrete (50) of the lower portion of the pile curtain in certain depth (60) to form a. The based of the dam high nitration of phenol derivatives by ingress of water having pressure of the dam based or foundation of a hollow space inside and acts pressure dam becomes unstable and wirelessly delivers a Bluetooth device access internal based by the number penetration or clay, silt for a particulate is washed (silt) dam is disposed. the upper surface becomes unstable. To this end based inside pile curtain by leakage due to grouting the range required (60) to penetrate by water or an aperture is formed by a rope. to reduce the pressure. Pile curtain (60) from outside the base a high pressure fuel line to a wherein the, pile curtain generally equipments when processing a long and thin holes, curtain shape is formed part from outside. Furthermore, index concrete (50) pile curtain auxiliary each constant intervals at (70) for constructing bridge to, watertight the second metal layer is thicker allows the. Auxiliary curtain pile (70) curtain steel pipe pile joint (60) is made smaller than a depth which permits the is formed to, drive the discharge lamp, index concrete (40) of transverse constant intervals at formed to be, curtain steel pipe pile joint (60) and to improving strength and watertight property of based by a rope.. Concrete-order dam concrete of the present invention, protective concrete and dam body anti-convulsive melting glass a portion of the cement over 14kgfm of anti-convulsive slag replaced by melting glass product mixed using an workability while reducing the amount cement water is achieved and having shortened and air concrete between first, the drive method for reducing the heat generating the hydration of the cement to, it buys powerdam body charge blasting and industrial aggregate and generating on-site cancer, anti-convulsive melting glass product slag available and being by cycling number 2, number 3 a plurality of oil drain particularly suitable for use in.. Until now in the embodiment presented by referring to the present invention refers to rapidly and to reduce a memory in the art but is a presentation by referring to a person with skill in the art in the embodiment of the present invention technical idea is not strayed from the invention and modification various modifications in a range in which the output instruments capable of making 2000. The present invention refers to and such as a modified and modification invention below just not being constrained by the claims appended to is limited by an extent. 10 : dam body 20: concrete order 30: protective concrete 40 : vice-blending concrete 50: index concrete 60: pile curtain 70: auxiliary curtain pile The present invention relates to a concrete dam and, more particularly, to the concrete dam wherein locally generated aggregates such as a river bed sand and gravel, and rock are classified at a minimum, mixed with cement, water and copper smelting slag, then, uses the mixed material so as to form a shielding membrane concrete and a protective concrete and then to form a concrete dam body reinforced with a synthetic fiber, thereby, it is possible to reduce a cross-section of the dam body in size and possible to suppress a surface crack. The concrete dam according to a desirable embodiment of the present invention has the shielding membrane concrete on an upstream surface of the dam body, arranges the protective concrete on a crown and a downstream surface of the dam body, and thereby, has a trapezoidal cross-section forming a rich mix concrete at a joining portion between the dam body and a foundation ground wherein each of the shielding membrane concrete and the protective concrete comprises, based on 100 parts by weight of cement, 230 to 270 parts by weight of mixed water and 4200 to 4800 parts by weight of aggregate, the maximum size of the aggregate is 150 mm or less, the copper smelting slag is prepared by replacing 30 to 40 wt% of cement, and wherein the dam body comprises, based on 100 parts by weight of cement, 230 to 270 parts by weight of mixed water, 4200 to 4800 parts by weight of aggregate and 1 to 10 parts by weight of polyvinyl alcohol (PVA) fiber, the maximum size of the aggregate is 150 mm or less, and the copper smelting slag is prepared by replacing 30 to 40 wt% of cement. COPYRIGHT KIPO 2016 dam body (10) upstream of the order concrete (20) and constructing a, dam body (10) of windows operating and a downstream surface protective concrete (30) which constructing a, dam body (10) and a foundation of a concrete vice-blending a joint section where the of (40) constructing a dam manufacturing the same a trapezoidal cross-section in, order concrete (20) and protective concrete (30) based on 100 parts by weight of the cement, mixed water preparation 230-270 parts by weight, composition comprising parts by weight of aggregate 4200-4800 is, a largest dimension aggregate, and 150 mm hereinafter, replace the % of the cement weight 30-40 is configured for controlling thawing anti-convulsive slag is, dam body (10) based on 100 parts by weight of the cement, mixed water preparation 230-270 parts by weight, aggregate 4200-4800 and polyvinyl alcohol (PVA) fiber 1-10 is composition comprising parts by weight of, said aggregate a dam are obtained in peripheral, landowners it buys power cancer and blasting and a charge of a vehicle passing through a particle size distribution during the pipe has curved artificial aggregate 150 mm hereinafter largest dimension the reaction and does not surge to filter out only the, replace the % of the cement weight 30-40 is configured for controlling thawing anti-convulsive slag is, dam body (10) upstream of the lower concrete index for the improved tightness (50) and constructing a, index concrete (50) of the lower portion of the pile in certain depth by penetration water pile curtain reducing pressure or an aperture (60) to form a concrete dam characterized by reinforced by synthetic fiber. Deleted According to Claim 1, index concrete (50) constant intervals at pile depth consistent pile curtain wiring comprises a gate (70) to form a reinforced by synthetic fiber characterized by a concrete dam. Divided Cement (kg/m3) PVA (kg/m3) Tensile strength (kg/cm2) 1 60 0.6 2.79 2 60 1.8 3.01 3 60 3 3.60 4 60 6 3.79