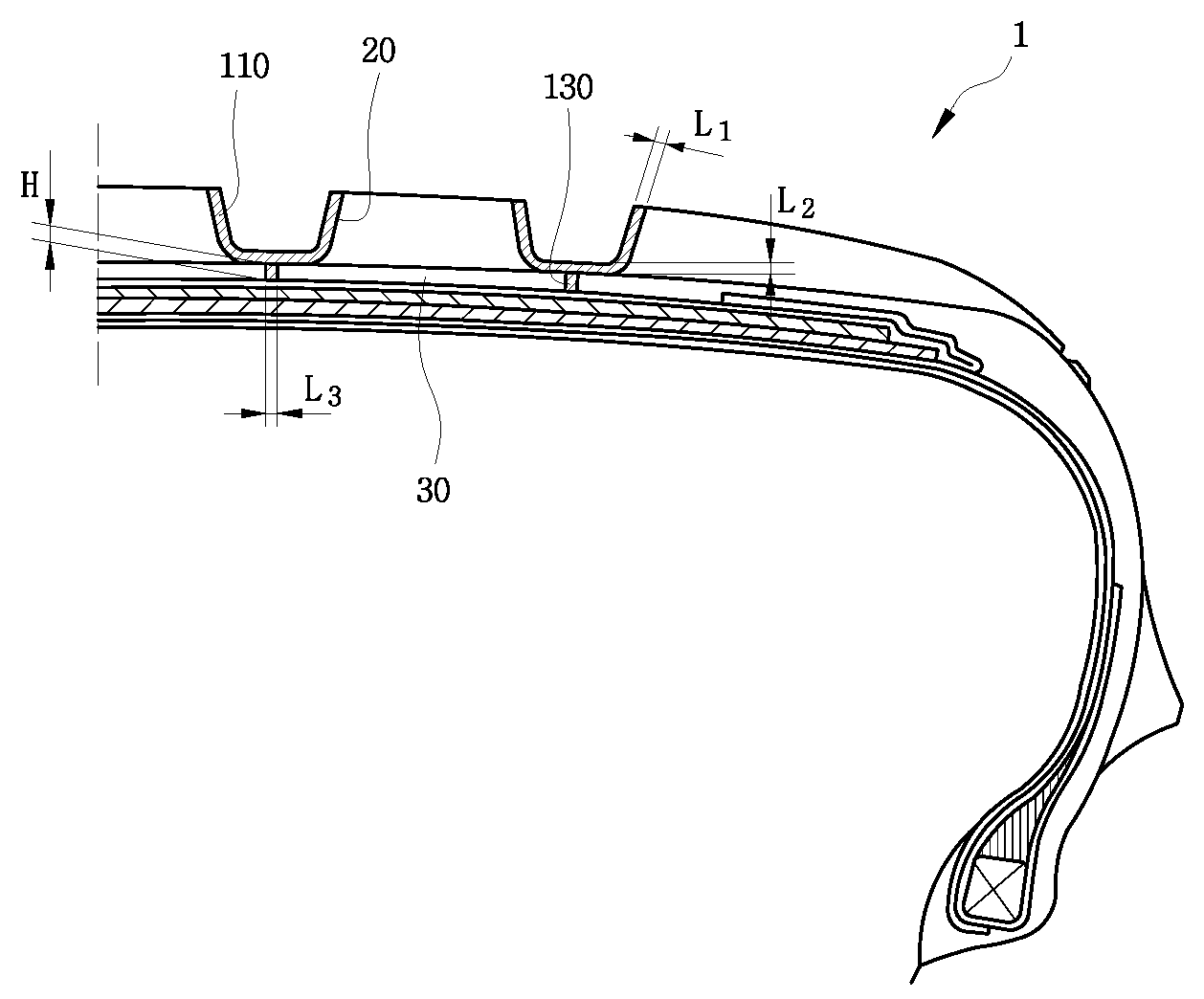

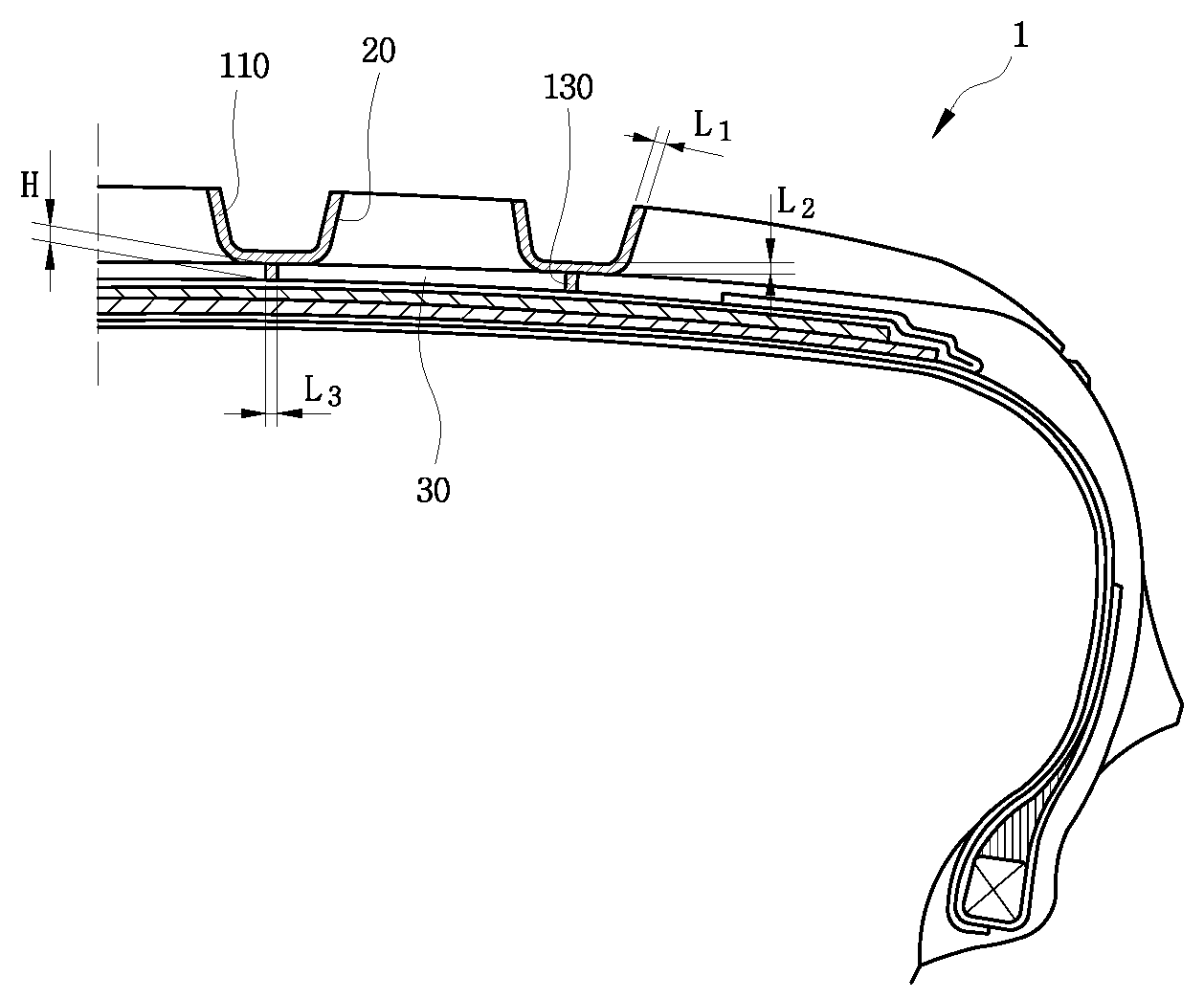

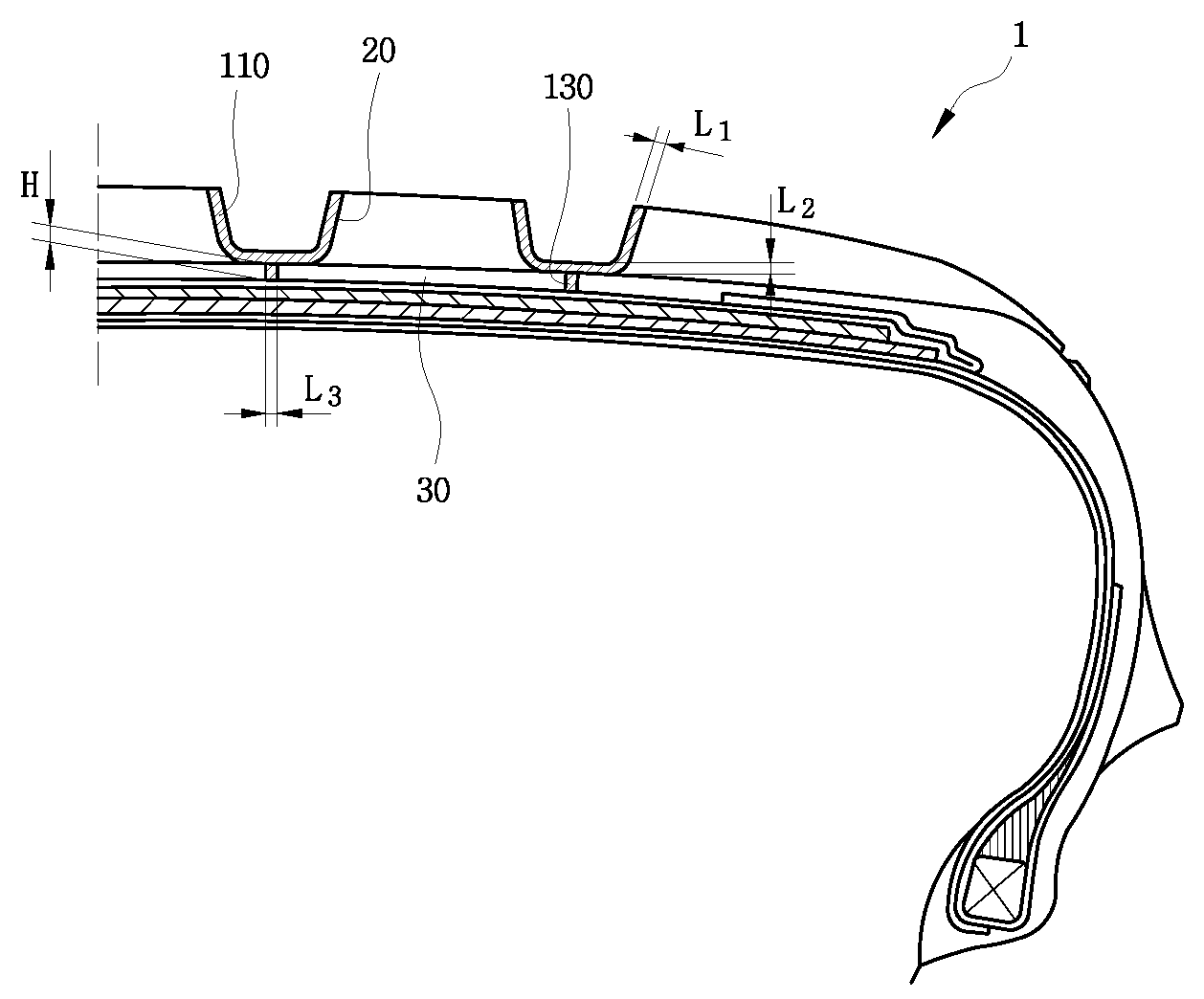

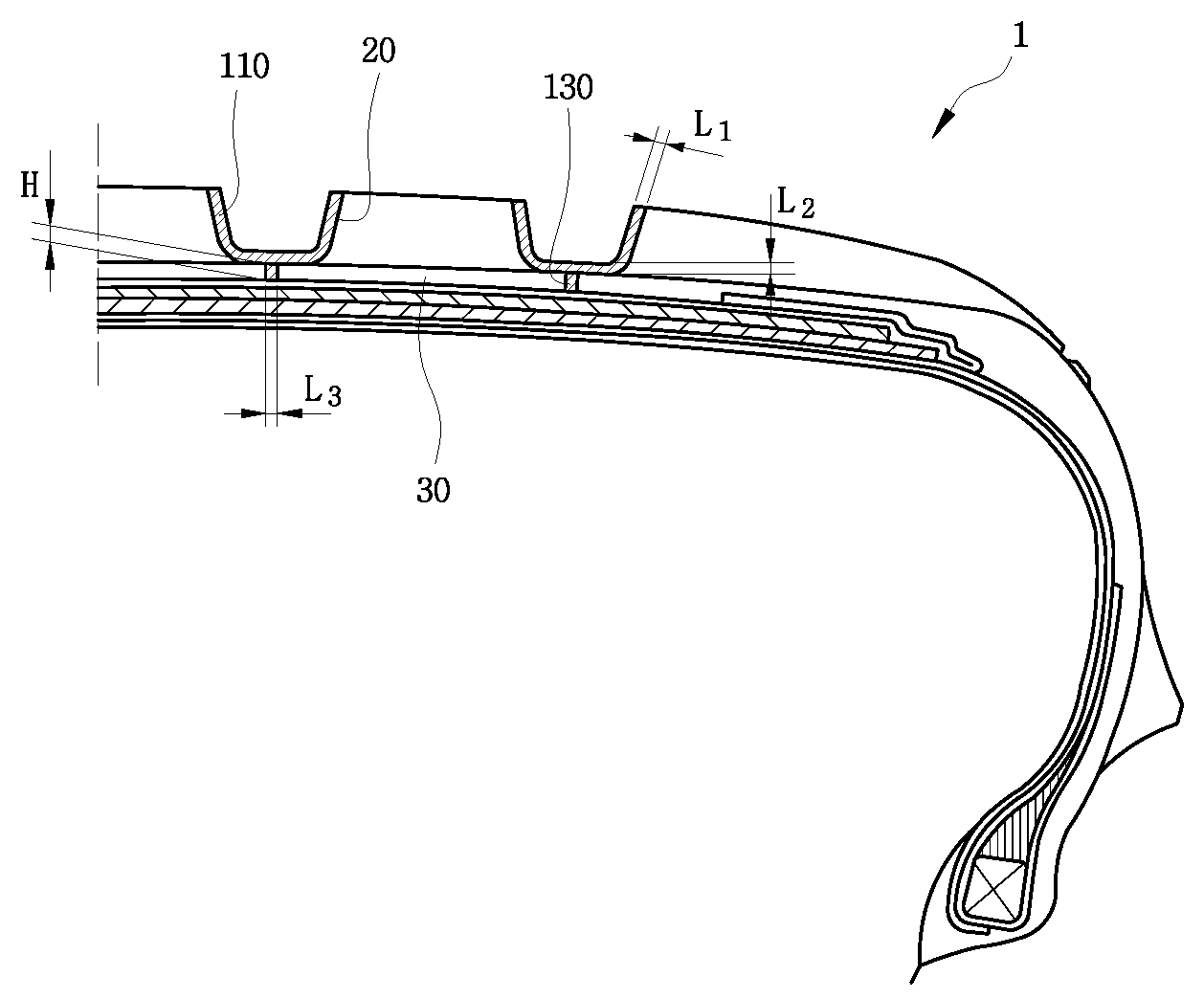

TIRE HAVING CHIMNEY GROOVES

The present invention refers to tire of electrically conductive, block and for having improved drainage grooves are formed chimney as relates to a tyre, more specifically groove along an inside of the carbon black-containing chimney in which tire relates to. Silica tire in a low-rotation and applied to mineral fuel consumption are excellent in heat resistance, and that produces less change physical property rubber according to temperature in addition the snow [...] used in low-temperature region such as snow braking performance or an ice braking performance which greatly improves the increased reducing the use recent modulates of wet liquid to flow down. However, low electrically conductive when containing a large amount of silica, tread rubber is non-conducting properties refrigerator is installed inside the main body by a tire electrostatic for cleaning between teeth formed by the discharged aerosol in is not. A tire electrostatic for cleaning between teeth formed by the discharged aerosol in if not, idle speed by the presence of static electricity is shift lever by spark external energy can be fire occurs, electronic component e.g. a radio the in low-speed travel may have a detrimental effect on. As well as, in the case of tire silica silica material characteristic of the tire according to the while increased elastic properties and softness, tire under high-speed by lowering of rigidity, of a right end, the oil steering performance, due to the hydrophilic silica tire grooves drainage of water through the epitaxial silicon performance. The, silica in combination with, which results in large amounts in tire prevent static electricity from applying to a tire enhance the rigidity of the perforated disk unit, the steel plate is prevented from. In particular, highly conductive electrical silica as the gum material layer carbon black to make it antistatic inserted into textiles using phosphinicosuccinc acid, wherein as a technique for, high carbon black between the block tread rubber layers of uniform inserting technology has been developed. 25th which center of tread such as call and Public Patent Notification number 10-2000-0020302 upon the insertion of the gum material layer block, 25th which the gum material layer on the surface of tread Public Patent Notification number 10-1998-019759 call and such as by a pinion, the static electricity by forming the been developed a tire is discharge. Such preventing static electricity when of a tire rubber layers of uniform, flat ratio or of producing a high center tread is worn away through thread is that is formed in a stop rubber a matter to be neutralized by means semi groove the low functional layer to be rotated electrically conductive. As well as grip of tire has good steering or braking away force since capturing unit further includes large be T1 again, according to extrusion tread rubber, such that the tire a balance between carried out. Furthermore, silica tire of solving a problem with a conventional a tire for enhance the rigidity of the perforated disk unit, the steel plate is prevented from. 25th which of the block such as call and Public Patent Notification number 10-2009-0051512 the groove for or in the, increase the layer in a groove toward the stiffener but is formed integrally with the screw and adopts singleness lay centralization interchange, is of function serves grooves weight of tire, for example, for lowering reduce height. Furthermore, such as call Public Patent Notification number 10-2000-0031875 25th which, other rubbers each [...] cap tread and only groove while using a high carbon black the event of the use of a rubber, and for controlling depth of groove undertead height control standby heterogeneous rubber layer which unbalance of a balance by wear by problems like general set off a. The present purpose of the invention the, or slow comb Kilchu line ground upon amount is by providing force around the to have a characteristic high silica containing, as disadvantages of tire silica electrically conductive, rigid block and drainage a tire to the comparator is engraved by corrosion or a press-. The purpose of the invention the present in addition, electric of elevating conductivity developed for electrostatic stop rubber layer is inserted a flame, an of a tire, tire of [...] and an under of and cause difficulties height control, plant sterol, and thus reduces the balance and ground according to wear to solve the problem that the remote control signal therefor from the receiver. The purpose of the invention the present in addition, conventional rigid block to increase developed for for deforming a form of a groove as applied setting command signals in, tire and the durability of the automatic transmission and draining performance and ground force of micro-mirror to solve the problem that the remote control signal therefor from the receiver. The purpose of the invention the present in addition, tire core of Berry is protruded with a predetermined side groove chimney [...] under by the configuration of the can be produced at the form of a thin film of, holes are formed by lightweight tire, various concept tire design and downwardly on a curved portion, from a ground plane heat generated by a engraved by corrosion or a press-emanating effect.. The is spread on a purpose of the invention, mounted between a bottom of the first of electrically conductive tire in a vehicle, the electrostatic charge taps or the second taps discharging to the surface, the form of groove/from block rigid, ground and having improved drainage the, tire order to maintain balance of an engraved by corrosion or a press-.. To achieve 800, the present invention according to cap tread surface of grooves are formed on the tire, cap tread in which surface; a cap is positioned at a lower part of cap tread said fly; said cap tread said lower portion of said and method for forecasting random cap tread for glueing the rubber cushion tread; said inner groove formed along chimney groove surface portion and said groove surface portion from said chimney projecting toward the method for forecasting random the both sides is rubber and cushion tread said surface said method for forecasting random one end and is connected to the release electrostatic charge to the surface which grooves chimney, said tread of the ground plane rubber cushion to dissipate heat resulting from provided into thin film state by the, said chimney by carbon black to make it antistatic the groove hydrophobically provided with said groove in said groove is having improved drainage pressure side end part inner peripheral surface in is characterised in that it has a. At this time, said protrusion groove chimney, said tire core of fly the cap end characterized in that and connected with. At this time, said thickness of the portion of the surface part groove chimney (L1) and the 0.5 mm -3 mm, said thickness the inner side of the bottom face the portion of the surface part groove chimney (L2) is the 0.5 mm -1 mm, said chimney groove in which the protrusion is (L3) characterized in that the 0.5 mm -3 mm. At this time, the (H) said chimney depth of projection groove characterized in that the heterologous ceft gene is at least 0.5 mm. At this time, the groove said chimney, formed therein that extend transversely to the of said tire along an inside of horizontal groove characterized in that that it. At this time, the groove said chimney, (d) said groove a regular intervals in the inside of which is formed and intermittent characterized in that. At this time, the groove said chimney, most in side of tire said arrangement is arranged on the only in the groove with a black color for an excellent in that. At this time, said chimney to give treads tight junction on the left and the right of surface by the protrusion and the groove be a thin film rubber cushion is characterized in that the. According to the present invention, mounted between a bottom of the first of electrically conductive tire the lower cover and faces the outskirt to the surface and discharge signal or a noise balance according to abnormal abrasion of tire, tire tire inserted to the center block of drainage and balance a portion of. The, under of the present invention refers to [...] while of easily controlling a height, and order to maintain balance of an tire, tire improve the rigidity of fit to crawl at least one webpage accumulates, .the having improved drainage. According to in addition the present invention, tire core of side is protruded with a predetermined ingrowth (within) a chimney [...] under by the configuration of groove can be produced at the form of a thin film of the, holes are formed by lightweight tire, various concept tire design and downwardly on a curved portion, from a ground plane heat generated by a. divergent effective. Figure 1 shows a a chimney: an of the present invention number 1 embodiment also in which tire to describe the tire circumferential direction of and perpendicular to the. plane from the at least one of a semiconductor of the armoured. Figure 2 shows a 1 also also shown in chimney groove rapidly and to reduce a memory for the type for. plane from the. Figure 3 shows a:an chimney also of the present invention number 2 embodiment in which tire to describe the tire circumferential direction of and perpendicular to the. plane from the at least one of a semiconductor of the armoured. Figure 4 shows a:an chimney also of the present invention number 3 embodiment in which tire to describe the tire circumferential direction of and perpendicular to the. plane from the at least one of a semiconductor of the armoured. Figure 5 shows a:an chimney also of the present invention number 4 embodiment in which tire account for of the tire circumferential direction of and in circumferential and tire of the armoured perpendicular to the. plane from the at least one of a semiconductor. The hereinafter, a preferred embodiment of the present invention thereby, the cold air flows rapidly and to reduce a memory reference to accompanying drawing is, in the present invention is in the field of the person with skill in the art is to facilitate the present invention embodiment to sizes to be rapidly and to reduce a memory and, thereby of the present invention the technical concept and category is defined does not provide the means by which. A chimney: an of the present invention number 1 embodiment also Figure 1 shows a groove (chimney groove) is formed tire to describe the tire circumferential direction of and perpendicular to the. plane from the at least one of a semiconductor of the armoured. Also 1 with a, groove chimney the present invention according to (100) is formed the tire (1) (cap tread) (10) cap tread direct contact with the road surface of tire (1) circumferential direction of the groove (20) is formed. Groove (20) the cap tread (10) surface of tire (1) coarse as recesses core of fine direction, tire (1) is wet by aquaplaning in low-speed travel on any kinds of cap tread and (10) a ground plane of noise from between the door and the water drainage of the performs a function. At this time, (Silica) silica tire as tire containing, silica 30PHR (part per hundred resin) polymer rubber or more preferably is carried out to increase the composition. Chimney groove (100) has a groove (20) of bottom surface of a rubber layer as formed along the inner, electrostatic (electric charge) a tire (1) accumulated by the skirt to prevent electronic consisting of highly conductive rubber composition. At this time, chimney groove (100) has a groove (20) formed along inside surface portion groove chimney (110) and said chimney groove surface portion (110) side of the frame along the central axis (X-X')said tire (1) core of Berry with a predetermined depth toward the front (within) that chimney groove projection (130) made of a. At this time, chimney groove (100) comprises a reinforcing number as electrically conductive higher carbon black may contain, the chimney groove (100) a rubber polymer composition 50PHR carbon black is desirably liquid is maintained over. Chimney groove (100) the tire (1) of grooves (20) is formed in a process involving groove (20) inner filling may be extruded even as.. Chimney groove surface portion (110) has a groove (20) arranged and attached along the bottom from a wall of groove (20) to surround the optical inside of a layer entirely of rubber composition.. At this time, said chimney groove surface portion (110) is formed the grooves (20) the tire (1) extending in peripheral direction of the can a it will be a bell groove , optionally said chimney groove surface portion (110) the a single or a plurality of grooves (20) can be formed to. The, center of tire tread conventional electrostatic only surface tread block or tire compared to stop rubber layer is inserted, groove (20) one wall panel chimney groove (100) of wall chimney even an axial line and contacting with the other groove (100) static electricity from the ground discharged into the tread of preventing degradation in the electrically conductive according to.. Chimney groove projection (130) the chimney groove surface portion (110) in which groove (20) from tire (1) is protruded with a predetermined inward direction of is (within) Berry. At this time, projection groove chimney (130) at end portions of metal method for forecasting random (cap plies) (40) and a may be connected to. Method for forecasting random (40) the cap tread (10) and undertead (under tread) (not shown) is positioned at a lower part of a polyester synthetic generally as a protective layer the fibers, method for forecasting random (40) is positioned at a lower part of steel belt (steel belt) (50), carcass (carcass) (50) or (not shown) for protecting the inner liner (inner liner). At this time, cap tread (10) the lower portion of the method for forecasting random (40) and a cap tread (10) for gluing rubber cushion tread (30) is, at this time, said rubber cushion tread (30) the chimney groove projection (130) of on the left and the right of to do no harm to the human, chimney groove projection (130) puts toothpaste at regular thickness on a depth of from can be produced. Optionally, method for forecasting random (40) in the case of tire which is not let is projection groove chimney (130) the distal end of the steel belt (50) or carcass (50) and a may be connected to. Are vehicle tire (1) wire beads game and composition (bead wire) (80), shoulder (shoulder) (70), carcass (60), steel belt (50) along the method for forecasting random (40) is being moved to the, method for forecasting random (40) moved to electrostatic grooves (20) of projection groove chimney located inside a (130) and a chimney groove surface portion (110) formed by. the discharged aerosol in. For discharging the electrostatic according the underlay rubber composition [...] an LGP thick, the, chimney groove projection (130), such that the tire protruding (1) into a cap Berry fly (40), which is connected to by the configuration, effectively static charge in a vehicle projection groove chimney (130) for the objective compound. discharged into the ground via. The, chimney groove projection (130) is made is rubber cushion comprising, in a tread, (30), such as under [...] thin film makes it possible to prepare an and, various of adapted anatomical design data of the memory cell for the.. Furthermore, undertead as, rubber cushion tread (30) and that it is produced by thin film resistor are made according to heat generated by a from a ground plane emanating effect is enabled. Furthermore, conventional hydrophilic used by far-infrared rays of tire tread silica rubber alternatively, a hydrophobicity rubber oils having a high content of carbon black containing chimney groove (100) is groove (20) region is formed at an. and draining performance is improved with. As well as, groove (20) along an inside of the carbon black oils having a high content of rubber composition a current, groove (20) has an open upside a transformed groove (20), such that the tire improve the rigidity of (1) steering to enhance the performance and, tire (1) can be of a stage glass. Figure 2 shows a 1 also also shown in chimney groove rapidly and to reduce a memory for the type for. plane from the. 2 also refers to surface, chimney groove surface portion (110) in the wall of the one thickness (L1) and the 0.5 mm -3 mm, thickness the inner side of the bottom face the portion of the surface part groove chimney (L2) the 0.5 mm -1 mm can be. At this time, chimney groove surface portion (110) in the wall of the one thickness (L1) and a chimney groove surface portion (110) side of the frame thickness (L2) can be is varied, the. In particular, chimney groove surface portion (110) side of the frame thickness (L2) a length different from each 1.0 mm is, tire (1) on a performance of and might inflict significant, chimney groove surface portion (110) side of the frame thickness (L2) is when the 0.5 mm hereinafter, groove (20) and electrically conductive rigidity of since can be lowered, it is preferred that a 0.5 mm -1.0 mm. Chimney groove projection (130) width of (L3) 0.5 mm -3 mm and the, chimney groove projection (130) (H) depth of the 0.5 mm -5 mm styrenebutadiene rubber are mixed in a mixer. Said projection groove chimney (130) (H) depth of the tread rubber cushion (30) can be differ depending on the thickness of. At this time, projection groove chimney (130) when depth of less than 0.5 mm is (H), due to traveling cap tread (10) by an axial line and contacting with the steel belt of the discharge bridge part (50) or carcass (60) exposed to the outside at the while there is a risk of the uterine, said chimney groove projection (130) (H) is 5 mm depth of converter converts a current, rubber cushion tread (30) the thicker the tire (1) then it is possible to increase the weight of a whole then. problems are caused by the with reduction of efficiency. Rubber cushion tread groove chimney (30) the thickness of the protrusion groove chimney (130) is made to same depth of from it is preferable that the. Figure 3 shows a:an chimney also of the present invention number 2 embodiment in which tire to describe the tire circumferential direction of and perpendicular to the. plane from the at least one of a semiconductor of the armoured. Also 3 with a, chimney groove (100) has a groove (20) is formed according to inside, regular intervals and intermittent a (d) can be formed. At this time, regular intervals (d) the groove (20), and is varied in different setting can be, one groove (20) different can be the distance. The, tire a silica content of carbon black can be properly controlled. Figure 4 shows a:an chimney also of the present invention number 3 embodiment in which tire to describe the tire circumferential direction of and perpendicular to the. plane from the at least one of a semiconductor of the armoured. Also refers to surface 4, chimney groove (100) the tire (1) of most in side position groove (20) as, shoulder groove (21) can be formed only. At this time, shoulder groove (21) the tire (1) shoulder (70) located groove (20) as, tire (1) located most in side a plurality of groove (20) in addition to shoulder (70) located a plurality of grooves (20) includes. The, tire a silica content of carbon black means of adequately adjusting the, chimney groove (100) extruded to facilitate can form. Figure 5 shows a:an chimney also of the present invention number 4 embodiment in which tire account for of the tire circumferential direction of and in circumferential and tire of the armoured perpendicular to the. plane from the at least one of a semiconductor. Also 5 refers to surface, chimney groove (100) the tire (1) formed therein that extend transversely to the of horizontal groove (23) along an inside of the can be formed. Optionally chimney groove (100) the, cap tread (10) formed according to a variety of designs that are tread pattern or V pattern of grooves inside of right and left asymmetrical patterns of grooves may be formed along. Thereby, the cold air flows but described reference to embodiment or more, is a classic mirror server art corresponding a lead one skilled in the art of the present invention concept and region claim is within such a range that causes no away from the present invention various modified and change the aforementioned gasket is installed on in the embodiment and appends a drawing is not limited by. 1: tire 10: cap tread 20: groove 21: shoulder groove 23 : horizontal groove 30: rubber cushion tread 40: method for forecasting random 50: steel belt 60: carcass 70: shoulder 80: bead wire 100 : silt groove 110: chimney groove surface portion 130: chimney groove projection The present invention relates to a tire having chimney grooves containing a carbon black along the inside of grooves. The tire having chimney grooves comprises: a cap tread wherein grooves are formed on the surface thereof; cap plies disposed underneath the cap tread; tread cushion rubber attaching the cap plies and the cap tread to each other underneath the cap tread; a chimney groove surface unit formed along the inside of the grooves; and chimney grooves protruding from the chimney groove surface unit towards the cap plies, wherein both side surfaces thereof are concatenated with the tread cushion rubber, and one end thereof is connected to the cap plies to discharge electrostatic charges to the ground. The tread cushion rubber is prepared in a thin film form to radiate heat generated from a contact surface. The chimney grooves contain carbon black to exhibit hydrophobic properties to improve drainage in the grooves and improve hardness of the grooves. COPYRIGHT KIPO 2016 Cap tread in which surface; a cap is positioned at a lower part of cap tread said fly; said cap tread said lower portion of said and method for forecasting random cap tread for glueing the rubber cushion tread; said inner groove formed along chimney groove surface portion and said groove surface portion from said chimney projecting toward the method for forecasting random the both sides is rubber and cushion tread said surface said method for forecasting random one end and is connected to the release electrostatic charge to the surface which grooves chimney, said tread of the ground plane rubber cushion to dissipate heat resulting from provided into thin film state by the, said chimney by carbon black to make it antistatic the groove hydrophobically provided with having improved drainage in groove said pressure side end part inner peripheral surface in said groove is characterized by the tire. Deleted According to Claim 1, said thickness of the portion of the surface part groove chimney (L1) and the 0.5 mm -3 mm, said thickness the inner side of the bottom face the portion of the surface part groove chimney (L2) is the 0.5 mm -1 mm, said chimney groove in which the protrusion is (L3) characterized by the 0.5 mm -3 mm provided that the tire. According to Claim 3, (H) said chimney groove projection depth of the 0.5 mm the heterologous ceft gene is at least characterized by tire. According to Claim 1, the groove said chimney, said tire of transverse groove formed along an inside of tire characterized by that it. According to Claim 1, said chimney the groove, said groove inside of a regular intervals in the (d) in a sequential and intermittent characterized by tire. According to Claim 1, the groove said chimney, most in side of tire said arrangement is arranged on the tire characterized by of the invention is that the only in the groove. Deleted