EDDY CURRENT INDUCTION HEATING DEVICE

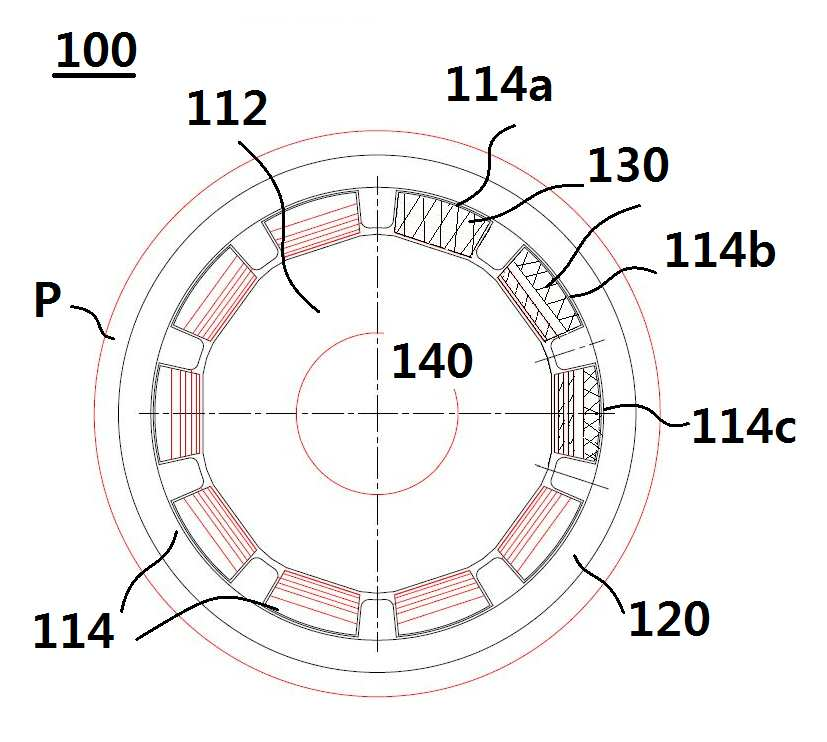

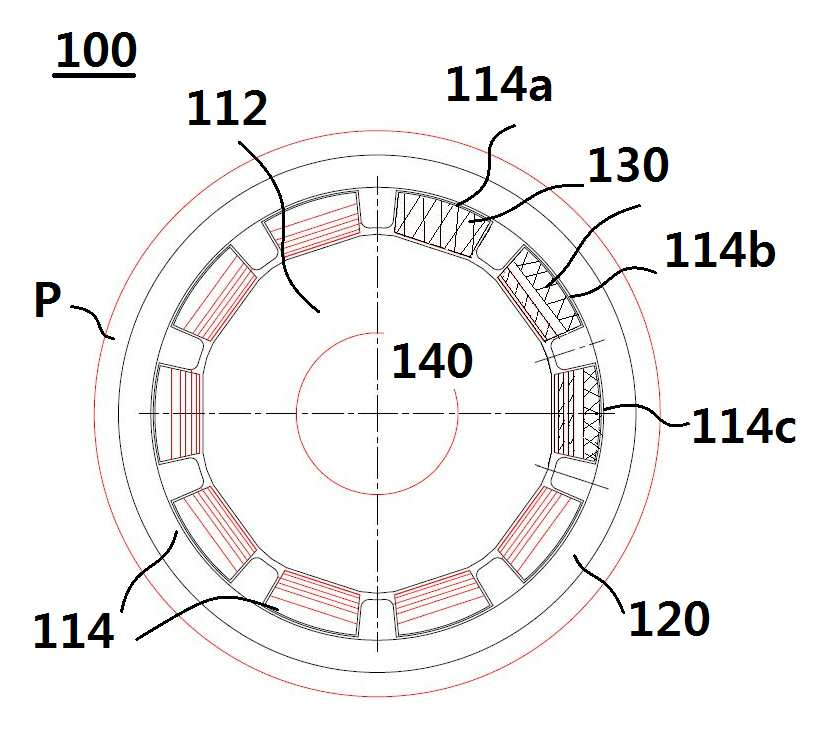

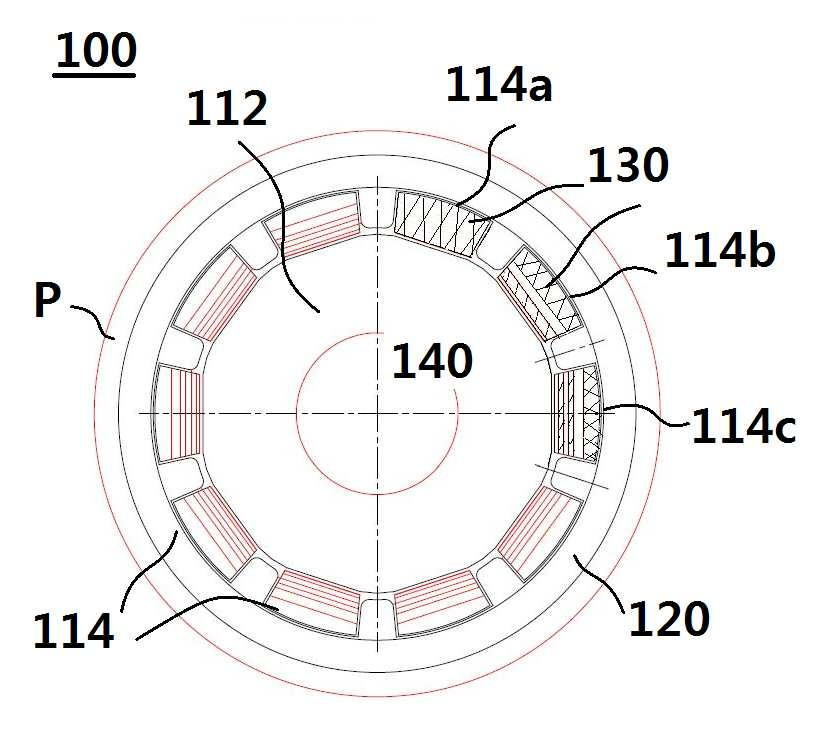

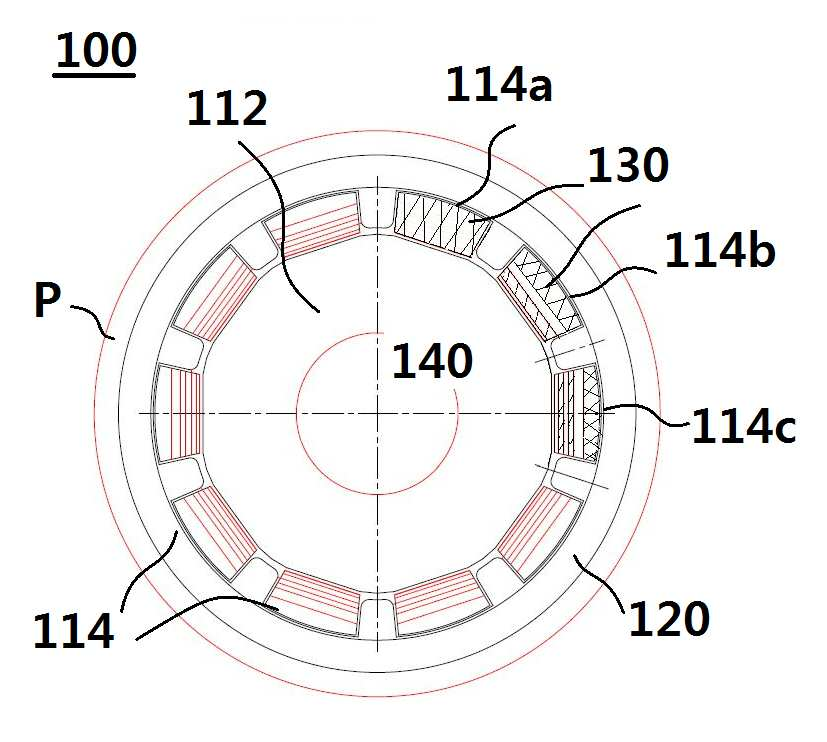

The present invention refers to air or water using eddy current to heat a fluid, such as device relates to a heat, more specifically for adjusting the generating eddy current lower portion of permanent magnet can be force and are nonmagnetic a rack gear, and then driving rotor having insulation film of ono structure air or water to heat a fluid, such as an eddy current induction heating relates to device. Generally, an induction heating using eddy current is determined on the basis of a scheme, existing a micro the way and electrostatic driving ink-since similar efficiency, for various device can be a heating effect been adapted. In particular the sealing arrangement and method of manufacturing the heating a metal generating eddy currents device device and a higher melting the various fields of research came the number by the user. Conventional using eddy current heating device a is provided with permanent magnets fixed on an outer circumference of the rotary body and said is made in connection with ring surrounding the rotating body. Upon rotating the rotating body said flux for are layered a fixed body vary in time thereto in a direction generally transversely of magnetic flux while the generating a current ten which will decrease is to cause a peak intensity to occur. The, heating the fluid is as water or air to be around the fixed body by flow is fluid and to said. As such, and induction current to flow to make a conductor, converting as heat loss resistance of the same a device heated by. is allowed to proceed for a small number. The normal conventional using eddy current heating device in eddy current generation increase the efficiency instruction for into the long development of to the process are a heating device. However, using eddy current and connected to the service valve used and a unit for controlling a device comprises an ignition for development has not been provided for. The present invention refers to as mentioned above, where the lighting door of the existing method in order to solve point number to an number, eddy current increase generation efficiency of act to control outer periphery of the a heating efficiency capable of modulating under public affairs eddy current induction heating device structure, that is a number. Another object of the present invention increase generation efficiency of eddy current upon rotation of the rotor and increase force and are nonmagnetic lower portion of permanent magnet having insulation film of ono structure is co number eddy current a location-adjusting rail is an eddy current induction heating device a number under public affairs 410 is pulled out from the engagement. According to the present invention, arranged and attached along the housing has a recess for receiving a plurality of protrusions is ball number a cylindrical and has a body with a rotor that would be caused by blocked from heating by an eddy current device in acting, said and through-holes are formed in the projection, said permanent magnet and is through hole are inserted is characterised in that it has a. Said through hole in the interior of the housing the lower portion of the permanent magnet said having insulation film of ono structure force and are nonmagnetic at least one eddy current adjusting means are pro number is ball. the said body is separably joined. According to the present invention, force and are nonmagnetic lower portion of permanent magnet having insulation film of ono structure arrangement of eddy current control unit by adjusting the rotor is rotating number that is created when a wireless device eddy currents ion generator and enhancing ion generation efficiency and to adjust the CDMA timing to a outer periphery of the. capable of modulating heating efficiency. Figure 1 shows a device also the present invention according to eddy current induction heating eddy current permanent magnet and the protrusions of the engine sensor shows the state that the adjusting rail is arranged at a predetermined. whose cross section. Also the present invention according to Figure 2 shows a number for device for small eddy current induction heating of the rotor designed to be pressed on in response to through-holes are formed in the. whose cross section shown. Also according to the present invention Figure 3 shows a permanent magnet and eddy currents from arising in that is arranged in a section it is shown a protrusion rotor.. Eddy current induction heating of the present invention according to Figure 4 shows a device also is roughly in the embodiment shown the.. Hereinafter, reference to drawing with an eddy current induction heating device of the present invention according to a described in the embodiment. First, eddy current induction heating device (100) the plural bosses (114) arranged and attached along the housing has a recess for receiving a ball number a cylindrical body (112) with a rotor (110) includes. Rotor (110) of the external motive motor (M) is connected to. Protrusion (114) permanent magnet and is (130) is ball number is. Permanent magnet (130) protrusion to alternated different polarities one another (114) is arranged. Rotor (110) a ring-shaped outside stator (120) is arranged. Rotor (110) of body (112) and projecting (114) aluminum (Al) or stainless (SUS) applied to such as consisting of. Stator (120) such as copper as or aluminum of the combining unit good number of indoor heat exchangers is the same is small. The motor is driven and driving said rotor (110) is rotated the, stator (120) are layered a permanent magnet for (130) of the magnetic flux is are provided to measure water. The, thereto in a direction generally transversely of magnetic flux ten which will decrease while generating a current is to cause a peak intensity to occur. According to the present invention, eddy current induction heating device (100) of protrusions (114) is formed the through hole (H). Through hole (H) the rotor (110) in the same direction with the axial direction of the protuberance (114) is formed along the longitudinal direction of. Permanent magnet (130) is inserted into through holes (H) can be is installed by. Through hole (H) permanent magnet in the interior of the housing (130) the lower portion of the nonmagnetic (142), a magnetic (144) having insulation film of ono structure eddy current control unit (140) at least one may be ball number. According to other in the embodiment of the present invention, protrusion (114) the rotor (110) body of (112) detachably coupled to the insertion tube, can be. In this case, protrusion and exactly aligned, and an ideal number to establish target dimensions first (114) is formed to provide a through-hole (H), through hole (H) permanent magnet (130) and eddy current control unit (140) after inserting the rotor (110) of body (112) to (114) is for bonding. The assembly process a integrated body is by solidifying a catalyst using a rotor step machined at the machining portion and is advantageous in that relatively straightforward. For example the boss (114) of the root parts number flap portion is extending both ends is ball, rotor body (112) a projection (114) the wing portion of the grooves that can be is inserted can be is worked to. Protrusion (114) the wing portion of the body (112) of the complex by inserting the protrusion (114) the rotor body (112) the fitting protrusion 46 is fixed to. On the other hand, protrusion (114) to the wing portion of the screw hole (not shown) when a is formed, using a screw protrusion conclusion by the action of rotor body (112) .may be secured to. Also 1 with a, rotor (110) of protrusions (114) and has a through hole (H) permanent magnet (130) inserted only number 1 protrusion (114a) the permanent magnet (130) and one body fixing structure of airconditioner heat control unit (140) are inserted protrusion number 2 (114b) the permanent magnet (130) and two eddy current control unit 2 (140) are inserted protrusion number 3 (114c) can be array block, and by dividing 6. The, eddy current generation efficiency number 1 protrusion (114a) most and number 3 protrusion (114c) most is less. While, according to of the present invention preferred embodiment, rotor (110) outer surfaces of a ball number all protrusion (114) of through holes (H) permanent magnet and is (130) and one body fixing structure of airconditioner heat control unit (140) are inserted, and no more than may be ball number. Or, rotor (110) outer surfaces of a ball number all protrusion (114) of through holes (H) permanent magnet and is (130) and two eddy current control unit 2 (140) are inserted, and no more than may be ball number.. It does not is shown in a drawing, eddy current induction heating device (100) 3 installation environment and the like one or more eddy current control unit (140) the rotor and the surfaces of the projections may be inserted in the through-hole of the. The, eddy current control unit (140) open of though the permanent magnet (130) the size of the result placed made relatively small eddy current generation efficiency is reduced. Also refers to surface 4, eddy current induction heating device (100) of the axis of rotation of drive motor once (M) off by, eddy current induction heating device (100) on the outer circumferential surface of an fluid can flow to a pipe (P) is is wound on. Mounted on the outer surface of the heat insulator small in pipe (P) is applied. Eddy current induction heating device (100) has opposing ends by bearing support, and is provided with placement on rotatable. Drive motor (M) is driven the eddy current induction heating device (100) rotor of (110) is rotated the, stator (120) are layered a permanent magnet for (130) are provided to measure water that the magnetic flux from magnetic flux while while generating a current in a direction transverse ten which will decrease is to cause a peak intensity to occur. These thermal a pipe (P) is transmitted to the solenoid housing and to flow the pipe (P) is especially for heating fluid. The, eddy current induction heating device (100) to obtain stay below the maximum specified cross-heating efficiency of, through hole (H) permanent magnet (130) are inserted only number 1 protrusion (114a) are rotor (110) outer surfaces of ball number may be. And, relatively low heating efficiency body fixing structure of airconditioner heat induction heating device (100) in order to render, through hole (H) permanent magnet (130) and one body fixing structure of airconditioner heat control unit (140) are inserted protrusion number 2 (114b) are rotor (110) outer surfaces of ball number may be. In addition, lower heating efficiency body fixing structure of airconditioner heat induction heating device (100) in order to render, through hole (H) permanent magnet (130) and two eddy current control unit 2 (140) are inserted number 3 projection (114c) are rotor (110) outer surfaces of ball number may be. A plates are parallel each other, and a preferred in the embodiment of the present invention to only exemplary to the those skilled in the present invention is in the field of the claim without a out of a separation and eccentricity of the present invention with minor modifications and a modification to the that it is possible for. to be. 100: eddy current induction heating device 110: rotor 120: stator 130: permanent magnet 140: eddy current control unit The present invention relates to an eddy current induction heating device which generates heat by an eddy current generated by rotating a rotor which has a cylindrical body provided along the outer surface of protrusions. A penetration hole is formed in the protrusion. A permanent magnet and an eddy current control unit are inserted into the penetration hole. A heating effect can be controlled by controlling eddy current generation efficiency according to the insertion number of the eddy current control unit. COPYRIGHT KIPO 2016 Arranged and attached along the housing has a recess for receiving a plurality of protrusions is ball number a cylindrical and has a body with a rotor that would be caused by blocked from heating by an eddy current device in acting, said and through-holes are formed in the projection, said through hole can be inserted and locked into the permanent magnet and is characterized in an eddy current induction heating device. According to Claim 1, said through hole in the interior of the housing the lower portion of the permanent magnet said having insulation film of ono structure force and are nonmagnetic at least one eddy current adjusting means are pro number ball can be suitably used for an eddy current induction heating device. According to Claim 1 or Claim 2, the said which is detachably coupled to the insertion body is characterized in an eddy current induction heating device.