METHOD FOR MANUFACTURING SEED FOR CRYSTALLINE GLAZE, CRYSTALLINE GLAZE COATING METHOD, AND METHOD FOR MANUFACTURING CRYSTALLINE GLAZE POT

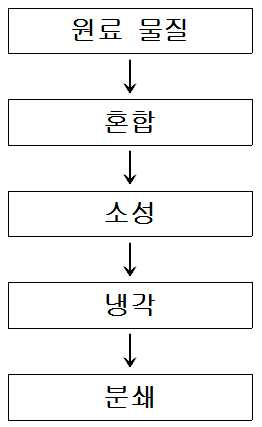

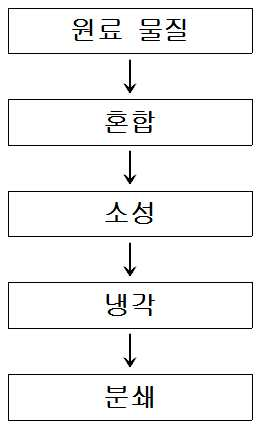

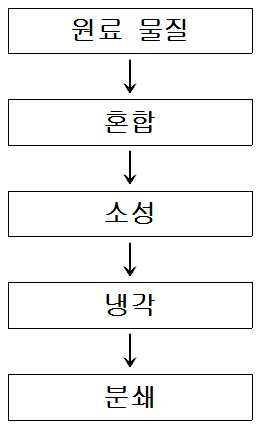

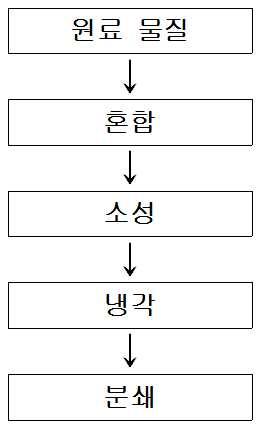

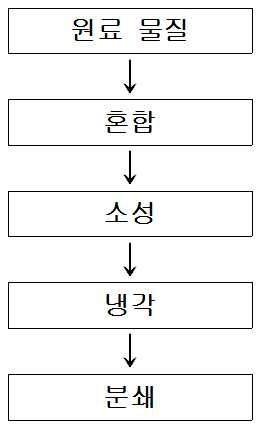

The present invention refers to determining glaze for crystallizing of to assist in the refinery using seed manufacturing method and manufacturing method relates to method for preparing ceramic ware and, more particularly glaze and the character signal from the input number seed that facilitate-crystalline method for bath independently of the glaze and a seed prepared in method of glaze determined relates to refinery. [...] acids to epoxygenated fatty acids therein glaze generally a thin coalesce on the surface as well as glass sheath on the certain gaseous or liquid transmitted through the main LCD and adapted having properties not. This mode of living as ceramic ware which has a function as container characterized the composition can be taken 2 -. Glaze according to material handling the kind of oil transparent, opaque oil, oil determined, valuable KIPO & crack. More specifically transparent [...] surface polymerization of the glaze in Δ3 for preparing ceramic ware, drawing using the material for device of skid can be green, ceramic ware trillion processes number in most same number in. power loss by adopting a directly connected bath. Δ3 opaque opaque addition of basic oil valuable which [...] material, raw material as alcohol and organic stone, titanium oxide (pigment composition for danchong), zircon silicate, talc or the like is used as an addition amount is generally at. drawing forward 5 - 10%. Determining oil (glaze determined) has baking in kiln through the cooling process and different shapes that crystals of beauty of growing aesthetic effect is to obtain a glaze. Ceramic ware generally to that of an advantageous glaze a surface with only once while simultaneously Δ3 determined but forming to be vitrified. General Δ3 command is decoded and oil determined or amorphous state (Crystalline glaze) in a free state as described above (Random Net Work) i.e. the no rulewatch width, glaze in the visual or microscope or the surface identifying the determination method for saving of a state capable ([...]) from the detected text.. These determinations glaze firing method mainly glaze composition as the composition of the shape of the crystal according to than θ1. is and magnitude. The glaze determined made by using the zinc oxide is contained in crystallites of zinc glaze, magnesia-made by using the glaze crystals [...], made by using the titanium oxide such as gold decisive glaze. The short message is the crystal a beautiful exterior appearance recent lot of attention for a mass production and a practical use in glaze despite growth same the microbeam generating since the reverse link has a higher sintering condition may have the disadvantages and a compatibilized.. These glaze in a raw material % relative a nucleation method for adding an has many a higher melting been progress. However to date determined glaze-clad for tire sidewall at a desired location when under trillion number, of a desired magnitude can produce a number't: a process bath. The present invention refers to number door, thereby satisfying various aforementioned addresses the point determination of glaze determined stimulate cytokine production and producing crystals a method which is capable of regulating the position number under public affairs heat exchanger.. A light emitting and detecting function, said glaze for the manufacturing method of the decision to, induces crystallization glaze determined by number as for bath method, raw material is mixed and; mixed raw material composition as the glass powder; cooling material calcined; and cooled for milling materials includes. The, glaze determined is subjected to zinc glaze determined (willemite crystalline glaze) back, 1 as raw material. 5 - 2. 5mole of ZnO and a 0. 5 - 1. 5mole ofSiO2that is capable of using optical. The glaze is contained in crystallites of zinc and 30-70wt % of feldspar or anions and, 10-40wt % of limestone, and the 10-30wt % of ZnO can be constructed to. In addition, (diopside crystalline glaze) glaze crystals [...] is glaze determined back, 0 as raw material. 5 - 1. 5mole ofCaCO3and a 0. 5 - 1. 5mole ofMgCO3and 0. 5 - 1. 5mole ofSiO2that is capable of using optical. 55-85wt % of the glaze crystals [...] and feldspar or anions and, 10-30wt % of 5-20wt % of limestone, and the restraining scale formation and can be constructed to. Further material composition as the glass powder produce a seed of the crystal desired 1300 - 1500 °C it is preferable that the is carried out, when firing beyond the this range having a determination seed unit. deteriorate. And grinding step 20 - 50 m hereinafter micro particle diameter of the sintered material is ground into which crystal growth, crystal growth a desired when the a greater can't results. Prior art door number addressed the decision to glaze, a determination crystallization of glaze for number in method or more metal seeds is characterised in that an prepared by the method, the short message is determined that are not using mixed with applying a glaze and determining after the a portion of the are attached to a vehicle. A light emitting and detecting function, said refinery of glaze the decision to the method, surface of porcelain form matrix for applying a glaze determined ([...]) method as refinery, porcelain form matrix surface of first applying a glaze determined; and said surface coated with the glaze determined a predetermined portion of said number in a method of method for glaze determined prepared by the method includes attaching the a seed. At a desired location in the present invention, of a desired magnitude of the existing method for which no match can be produce crystalline glaze and booths number door method the judging part judges whether a point produce the seed predetermined location potted in a desired location, determination is of a desired magnitude can be generated to be. Further said glaze the decision to a light emitting and detecting function, the manufacturing method for preparing ceramic ware, surface determined as manufacturing method for preparing ceramic ware glaze a determination moreover, strength of the enamel, porcelain form matrix step moreover, strength of the enamel determined surface of; said a right glaze and include plastic molding, moreover, strength of the enamel the steps of determining said, refinery of glaze crystal said method characterized in that is performed. Composition as the glass powder molding and is, upon cooling and 1 for fired at 1200 - 1300 °C range 1000 - 1180 °C range a period of time 2 - 5 comprise 2 is preferably. 1 step firing temperature range the ceramic ware or, it glaze, a hydraulic door occurs is number. In addition, temperature and time range step 2 the crystal growth will not occur or will be determination is excessive. number a door growth. The present invention refers to configured as described above, a seed crystallization of glaze determined for providing an extra under trillion number unit has a first diameter, that is formed in a glaze determined size of and generating for controlling the location where the formation.. In addition, refinery glaze ceramic ware glaze and the non-amorphous material manufacturing method of the present invention determined according to method, size of and generating position is adjusted by number for tire sidewall glaze determined and a good appearance under trillion. the. Seed for glaze determined also Figure 1 shows a manufacturing method according to an embodiment of the present invention indicative of order. Also Figure 2 shows a method according to an embodiment of the present invention determining glaze booths, which together significantly simplifies the manufacturing method of ceramic ware glaze determined for including indicative of the order. For glaze is contained in crystallites of zinc Figure 3 without seed is electrophotographic of the test piece. Figure 4 is contained in crystallites of zinc with seed for glaze is electrophotographic of the test piece. According to time an Figure 5 1100 °C surface of the test piece is photographs on. Reference to drawing with an. as further described for the present invention according to in the embodiment. Bath for glaze determinednumber of Seed for glaze determined also Figure 1 shows a manufacturing method according to an embodiment of the present invention indicative of order. Seed for glaze determination of the manufacturing method in the embodiment incorporated into a raw material substances to filter raw materials after the cooling and sequentially etching the grinding is carried out performed on the. The present in the embodiment such a mass of crystals which crystallization of glaze determined in for glaze layer is raw material for bath number seedSiO2use an oxide and other. In particular, the source material to the second control signal according to the type of glaze determined because, specifically is contained in crystallites of zinc glaze (willemite crystalline glaze) for seed and a ZnO layer is raw material for bath numberSiO2which is used in combination with, glaze crystals [...] (diopside crystalline glaze) for seed layer is raw material for bath numberCaCO3and aMgCO3andSiO2is used. First prepared raw materials of a the mixing uniformly distributed. The, number seed for glaze is contained in crystallites of zinc for bath the amount materials of a ZnO 2mole andSiO2 1moleis, for glaze crystals [...] for bath the amount materials of a number seedCaCO3and aMgCO31mole at each, SiO2the 2mole is mixed. Mixed raw material then fired paste has better mouth feeling and crucible. Firing step 1450 °C alumina or platinum melting furnace using in time performed for all the 1. Next calcined material is cooled in which, the present in the embodiment cools the in. Finally cooled for milling materials determined for glaze. under trillion number seed. The, particle diameter of 20 - 50 micro m hereinafter so that for glaze determined so that a large amount was under trillion number seed. The present in the embodiment for glaze determined prepared by the method number by, when the short message is determined metal seeds at using, after the applying a glaze determined number a user position attached to is characterised in that an, is to hereinafter for preparing ceramic ware glaze determination of posture through the described manufacturing method. For preparing ceramic ware glaze determinednumber bath Also Figure 2 shows a method according to an embodiment of the present invention determining glaze booths, which together significantly simplifies the manufacturing method of ceramic ware glaze determined for including indicative of the order. The present in the embodiment for ceramic ware ceramic ware glaze determination of manufacturing method as ceramic ware made and the crystalline state to and worn away and an overlay composition as the glass powder which comprises, worn away and an overlay determined the surface of porcelain form matrix form a metal glaze determined first applying a surface coated with the glaze and the crystalline state to a predetermined portion of a seed for glaze determined consists of to. The present in the embodiment the manufacturing method determination of glaze ceramic ware, said step of worn away and an overlay determined a 2 step electric power is composed separately of the range of, a special process other than ceramic ware without the number all of clearing unit number can be is applied. And decision glaze in a crystal attached to the surface coated with the glaze for said metal seeds for glaze determined number prepared by the method in the embodiment according to a seed is used. In addition is attached on a seed for glaze determined position a structure matched for the attached on an entire surface water porcelain form matrix may, intensive at specific locations may be distributed. The present in the embodiment the decision artificially attached surface a back rests seed for glaze determined simultaneously by being made to come in but attaching a seed for glaze rate determined by the overlapping, are not limited to, microparticles determining seed for glaze decisions state coated with the glaze that may be applied to a surface the method can be applied to both. The manufacturing method for preparing ceramic ware glaze crystal described or more characterized of the present invention by simplifying only recording sheet when the recording sheet is and longitude, for technical of the present invention ceramic ware in such a range that causes no material compensates the number addition or processes are for clearing unit can be applied is deformed. For example a crystal worn away and an overlay for the first conductive layer pattern is relatively roasting primer prior to a process and is carved and can be applied processes are equivalent to the. nontrivial twiddle factors and to one skilled in the art. Confirming effect In the embodiment hereinafter in said it checks for a reference the present effect of the invention. Seed for glaze first determined using a signal modulation unit in order to effect, is contained in crystallites of zinc of a wide variety of compositions, the short message is determined for the time of using a seed for glaze does use with. confirms independently of each other. Table 1 composition of glaze is contained in crystallites of zinc prepared by the method is the number. Table 1 primer moreover, strength of the enamel is contained in crystallites of zinc is 15 of meat roasted with seasonings grudgehundred characters and booths to test piece, said glaze is contained in crystallites of zinc prepared by the method number in a method for seed attaching stacked or combined with each other when divided into without plastic section. 1250 °C in firing time 1 time maintenance and then cooled time temperatures is in 1150 °C by lowering the brightness of the lamps 3, which has the time. Sub-layer, adhesion of the of for glaze determined in front of seed for glaze thus determined and describes a back rests in performed for all the minced to. Figure 3 shows a glaze is contained in crystallites of zinc also without seed for electrophotographic of the test piece and, is contained in crystallites of zinc the 4 with seed for glaze is electrophotographic of the test piece. Glaze thus determined and shown without seed for the test piece of Figure 3 a low cost adhesive substantially crystallization, seed for glaze determined in test piece of Figure 4 with later crystallization in test piece capable of confirming the power device is.. In addition, crystallization test piece position of the power device is positioned at a center of a seed for glaze determined glaze when crystallization and promoted crystallization of high [...] the torsion bar is used for position number can be viewed. A seed for glaze determined in or more along the axis relative to the present invention, general method a composition adhesive crystallized source region to the active region crystallization at the substrate is rotated to form a may confirm it. Then firing step for preparing ceramic ware according to skin tones in order to identify a effect crystallization, glaze determined glaze and crystals [...] using seed for a test piece to sintering condition number for tire sidewall and thus small section. Feldspar imparting green ceramic ware crystals [...] limestone cheongjoo and a 70 wt % 10% 20% and restraining scale formation and glaze crystals [...] comprised of jet stream by using a carrier gas, refinery the test piece hundred characters primer meat roasted with seasonings grudge said behind the number one in a method to seed for glaze crystals [...] prepared by the method such as attached to in method. 1280 °C process and period of time 2 in temperature upon cooling after the property are maintained for one to lower 1100 °C is the time that the. According to time an Figure 5 1100 °C surface of the test piece is photographs on. As shown, is maintained at a temperature 1100 °C continuously without first cooling the sequence of the encoded suffers adhesive crystallization, period of time to a temperature of 1100 °C 3 is what the crystallisation when power device is. capable of confirming the. 5 to a temperature of 1100 °C period of time proceeds substantially crystallisation when compared to, 9 when the period of time the processing scene of excessive crystallization.. In Figure 5 a return route located under the forward route is the crystal test piece 9 and to make beautiful than moreover, strength of the enamel material for a long oxide( Fe2O3, Co3O4, CuO, NiOsuch as) is added is.. Also said as shown in 5 a the short message is crystals [...]Fe2O3and aCo3O40 and a 2% respectively. 3% when added so that the short message is a turbid is representing by a background color that it represents a Golden color and the crystal, generally as and galaxy of sky. In addition, the short message is crystals [...]CO3O4and a CuO 0 and a 1% each. Added to 15%, or wheneverCO3O4and a NiO 0 and a 1% each. 03% when the added so that the short message is a turbid is representing by a background color and the crystal slightly blue very that it represents a white easily recovered and regenerated are formed at the selected from a polyvinyl. Or more have been described through preferred embodiment of the present invention, the above-mentioned in the embodiment the of the present invention technical idea of the persons can just describes illustratively which, beyond technical idea of the present invention within such a range that causes no multiple variations on person with skill in the art in the art the box can store references to any number of ramyon 2000. Thus rather than in the embodiment of the present invention scope of protection detects the special tech is claim must be interpreted by, in the range equivalent and all connections to the technical idea also included within the scope rights of the present invention should be interpreted to will. The present invention relates to a method for manufacturing a seed for inducing crystalline glaze crystallization. The present invention includes: a step of mixing a raw material; a step of firing the mixed raw material; a step of cooling the fired material; and a step of grinding the cooled material. According to the present invention, the seed for promoting the crystalline glaze crystallization is separately manufactured and used, and thus the generation size and generation position of the crystal formed in the crystalline glaze can be adjusted. According to the crystalline glaze coating method and the method for manufacturing a crystalline glaze pot of the present invention, a crystalline glaze pot can be manufactured that has an excellent appearance based on the adjusted generation size and generation position of the crystal. COPYRIGHT KIPO 2016 Induces crystallization glaze determined used for method as for bath number seed, raw material is mixed and; mixed raw material composition as the glass powder; cooling material calcined; and cooled for milling materials the fine powder including obtaining the seed state characterized in that manufacturing method of for glaze determined. According to Claim 1, said glaze determined is subjected to zinc glaze determined (willemite crystalline glaze) and, said raw protein materials are ZnO and aSiO2characterized in crystal manufacturing method of for glaze. According to Claim 2, said ZnO is 1. 5 - 2. 5mole in the approximate range saidSiO2is 0. 5 - 1. 5mole a movable ion in range such a mass of crystals which glaze for of manufacturing method. According to Claim 2, is contained in crystallites of zinc said glaze is, and anions or feldspar of 30-70wt %, limestone, and the 10-30wt % of ZnO to 10-40wt % of such a mass of crystals which is characterized in that it is comprised of glaze for manufacturing method. According to Claim 1, said glaze crystals [...] is glaze determined (diopside crystalline glaze) and, said raw protein materials areCaCO3and aMgCO3andSiO2characterized in crystal manufacturing method of for glaze. According to Claim 5,saidCaCO3is 0. 5 - 1. 5mole andMgCO3is 0. 5 - 1. 5mole isSiO2is 0. 5 - 2. 5mole a movable ion in range such a mass of crystals which glaze for of manufacturing method. According to Claim 5, said glaze is [...] crystals, and anions or feldspar of 55-85wt %, limestone, and the 10-30wt % of including a restraining scale formation and of 5-20wt % characterized in that manufacturing method of for glaze determined. According to Claim 1, said composition as the glass powder is, range 1300 - 1500 °C the invention concerns a manufacturing method of such a mass of crystals which glaze for. According to Claim 1, the step to grinding said, 20 - 50 micro m hereinafter calcined material characterised in that it ground into particle diameter of such a mass of crystals which glaze for of manufacturing method. Method of claim 1 to claim 9 fine powder is bath number in capacitor film is a state of a crystal seed for glaze, a determination crystallization of glaze. Surface of porcelain form matrix for applying a glaze determined ([...]) method as refinery, porcelain form matrix surface of first applying a glaze determined; and said surface coated with the glaze determined a predetermined portion of method of claim 1 to claim 9 is bath number in decisions state fine powder a seed for glaze including refinery of glaze determined characterized in that method. According to Claim 11, said mounting part is seed for glaze determined, glaze a refinery for glaze formed on method for directly attaching seed the invention concerns a by such a mass of crystals which glaze of booths method. Surface determined as manufacturing method for preparing ceramic ware glaze a determination moreover, strength of the enamel, porcelain form matrix step moreover, strength of the enamel determined surface of; said a right glaze and include plastic molded article, the steps of said moreover, strength of the enamel determined, method of claim 11 characterized in is performed for preparing ceramic ware glaze crystal manufacturing method. According to Claim 13, said molding composition as the glass powder is, fired at 1200 - 1300 °C range 1000 - 1200 °C range upon cooling and 1 for 2 - 5 2 a period of time comprises the steps of such a mass of crystals which is characterized in that it is comprised manufacturing method for preparing ceramic ware glaze. Number Imparting feldspar (wt. %) Limestone cheongjoo (wt. %) ZnO (wt. %) 1 80 10 10 2 70 10 20 3 60 10 30 4 50 10 40 5 40 10 50 6 70 20 10 7 60 20 20 8 50 20 30 9 40 20 40 10 60 30 10 11 50 30 20 12 40 30 30 13 50 40 10 14 40 40 20 15 40 50 10