PLANT GROWING SYSTEM

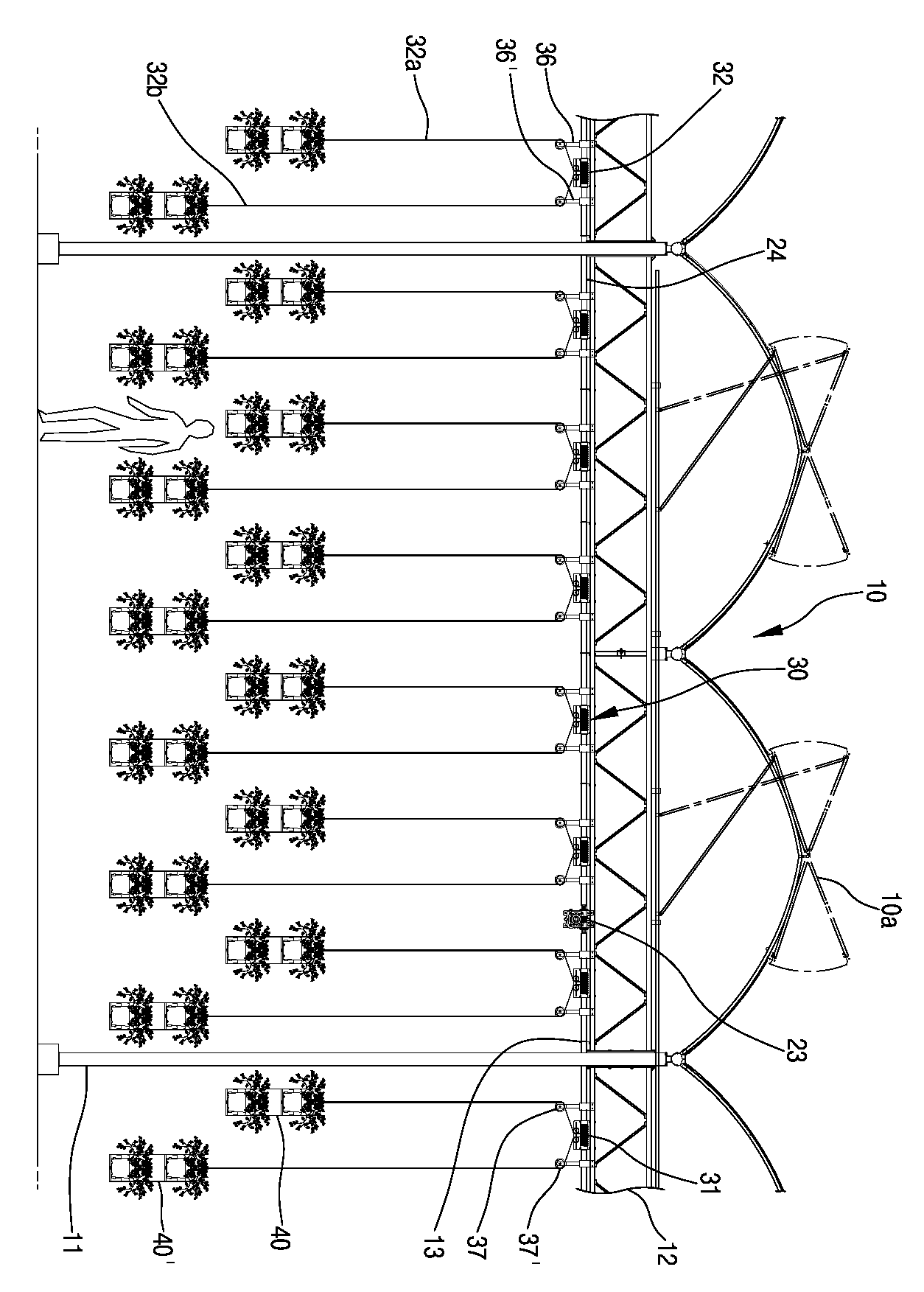

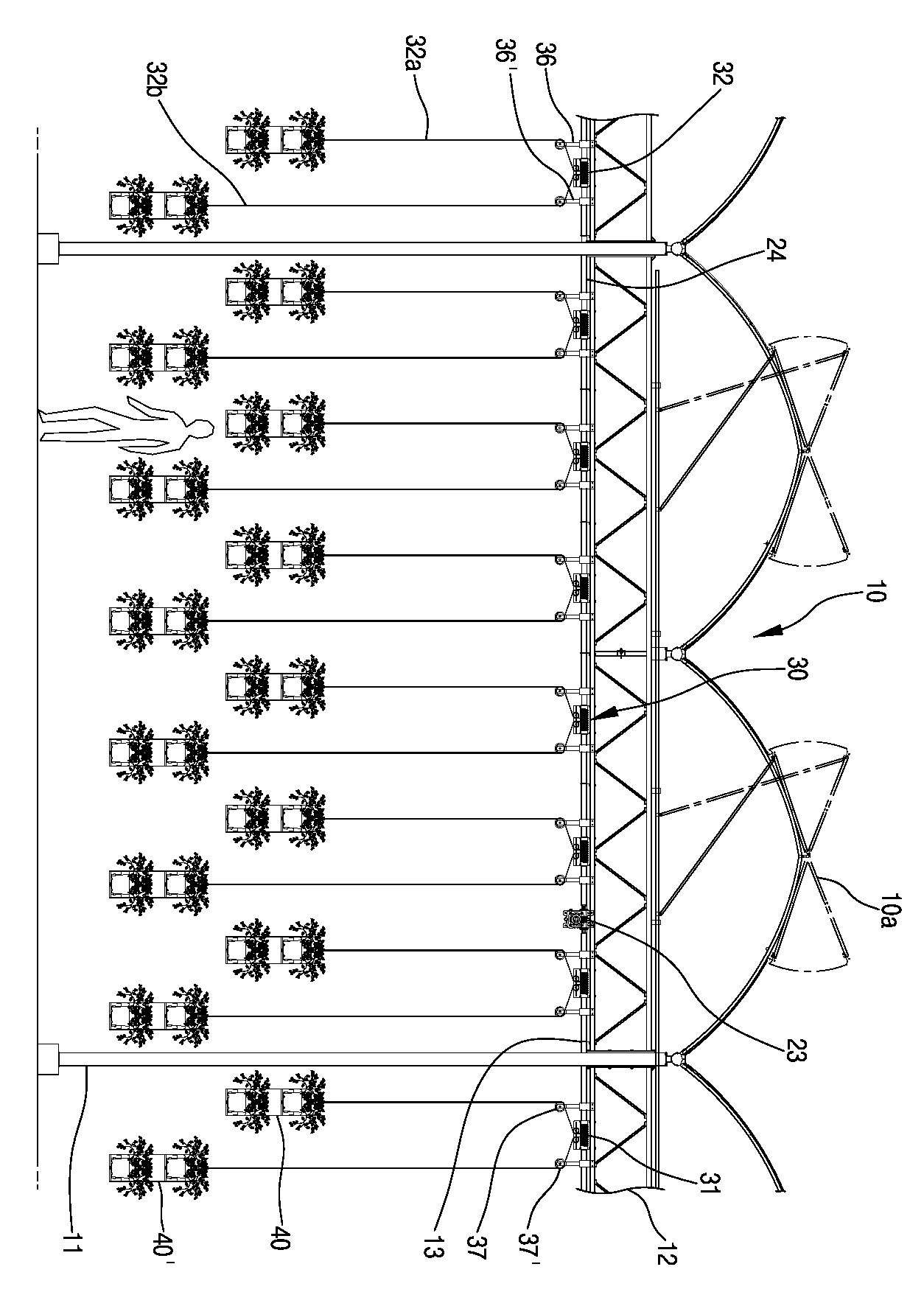

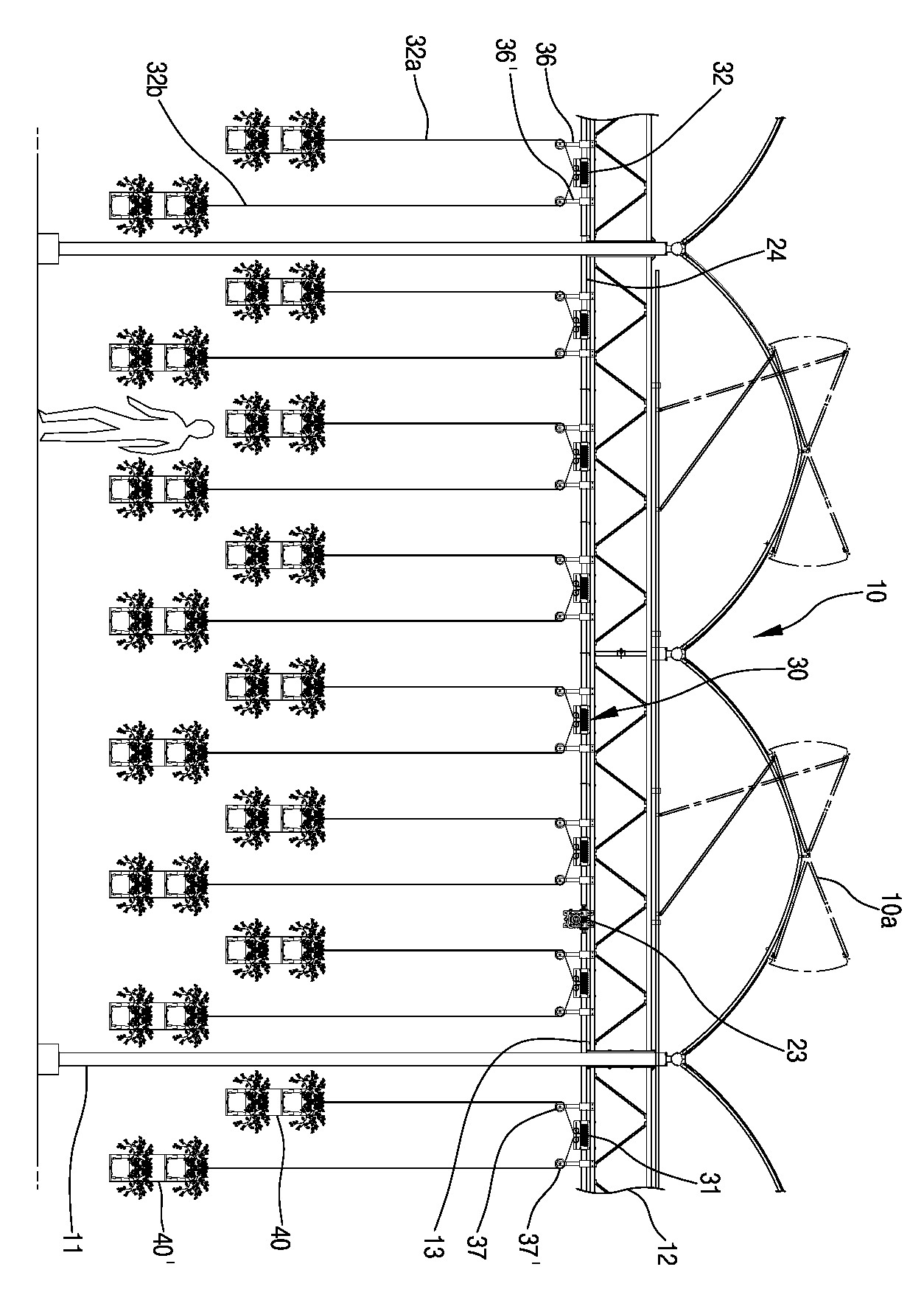

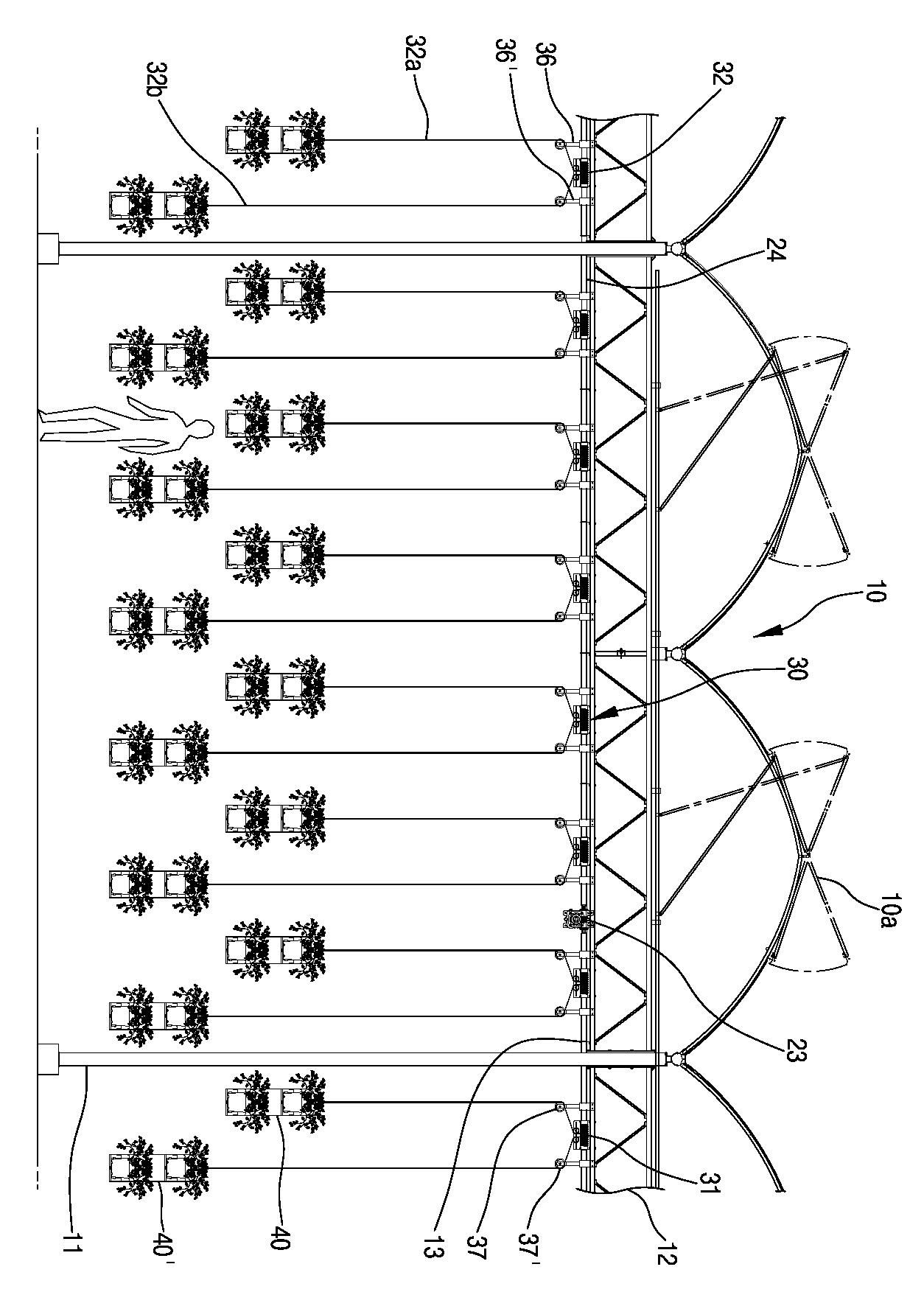

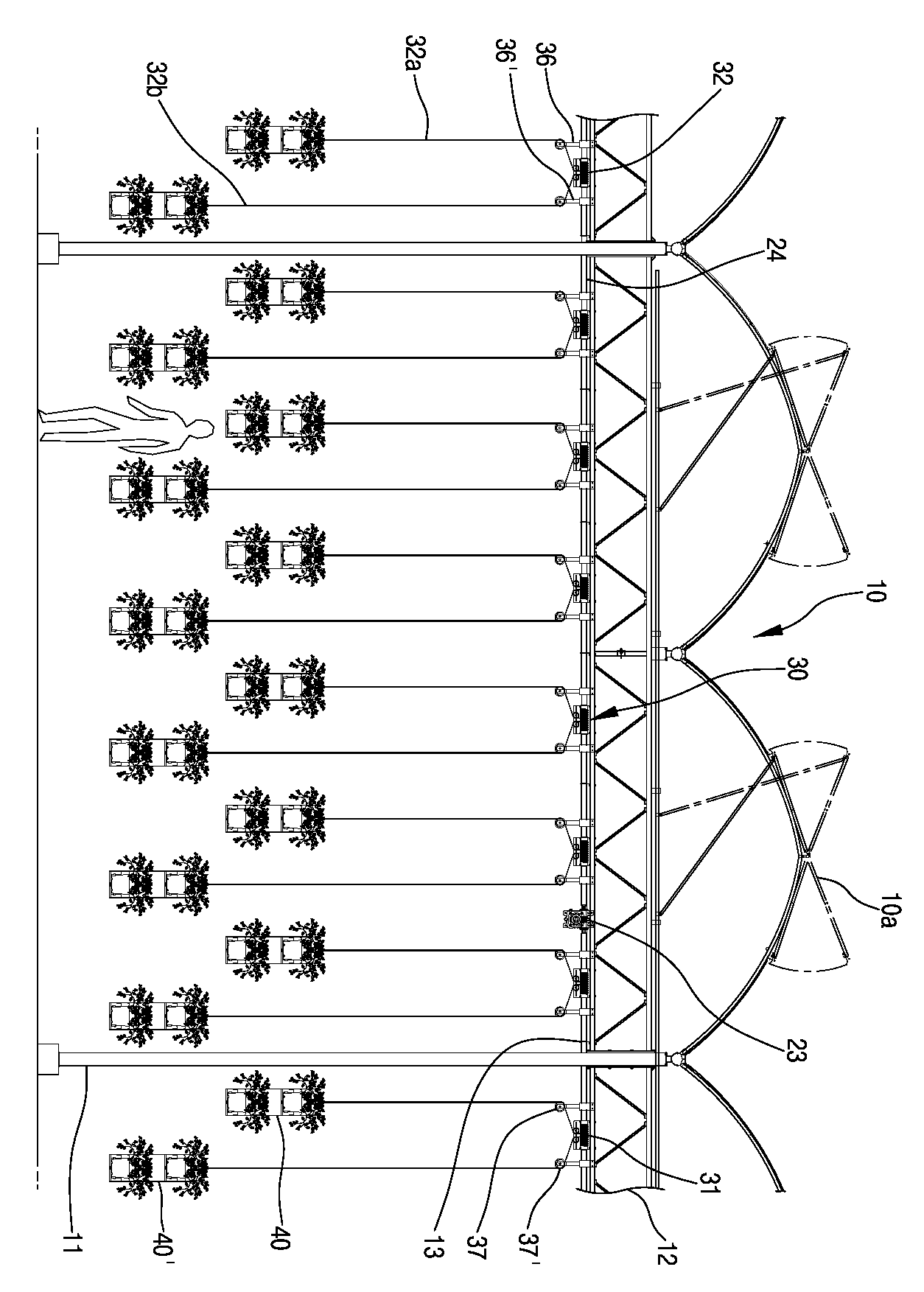

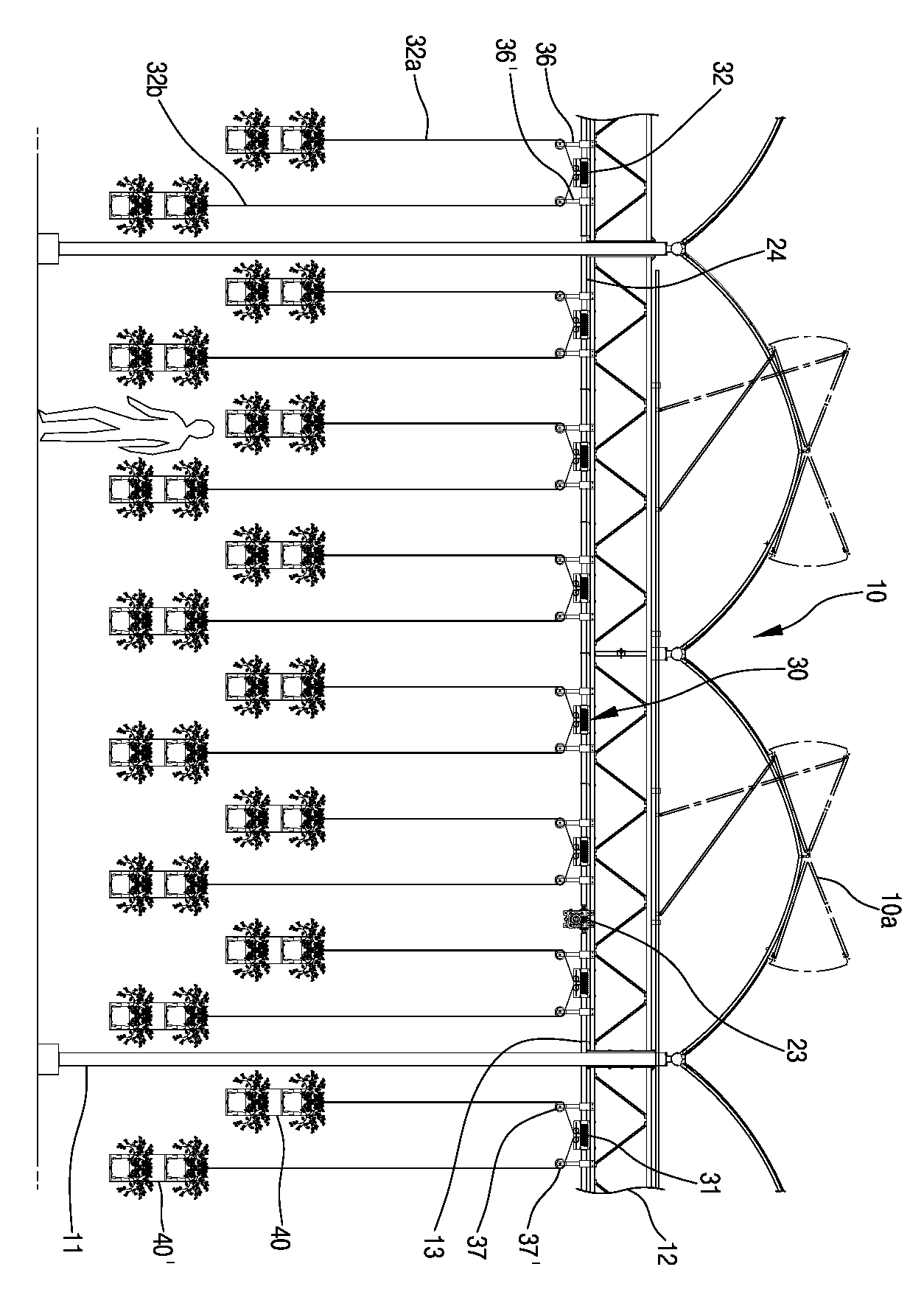

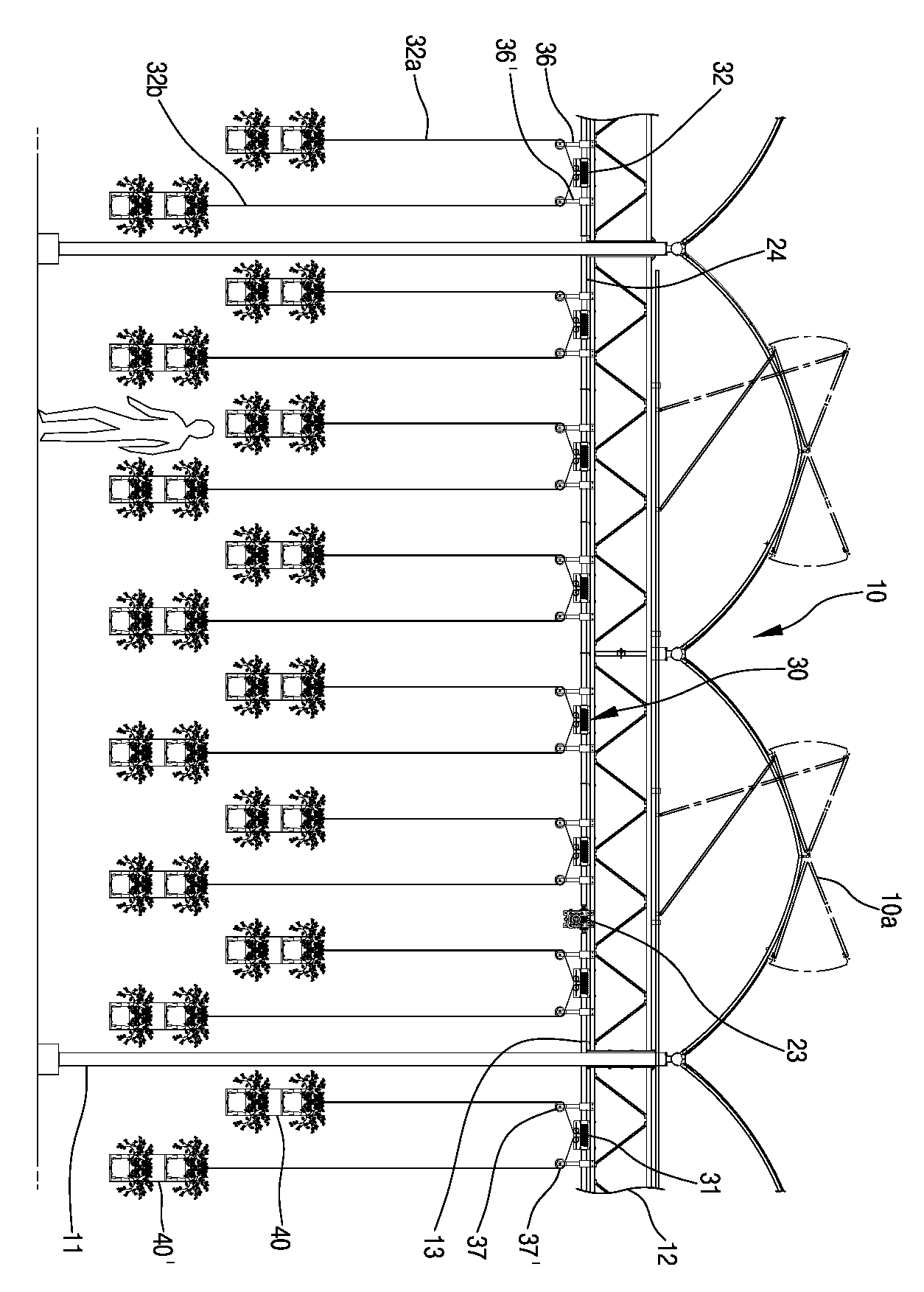

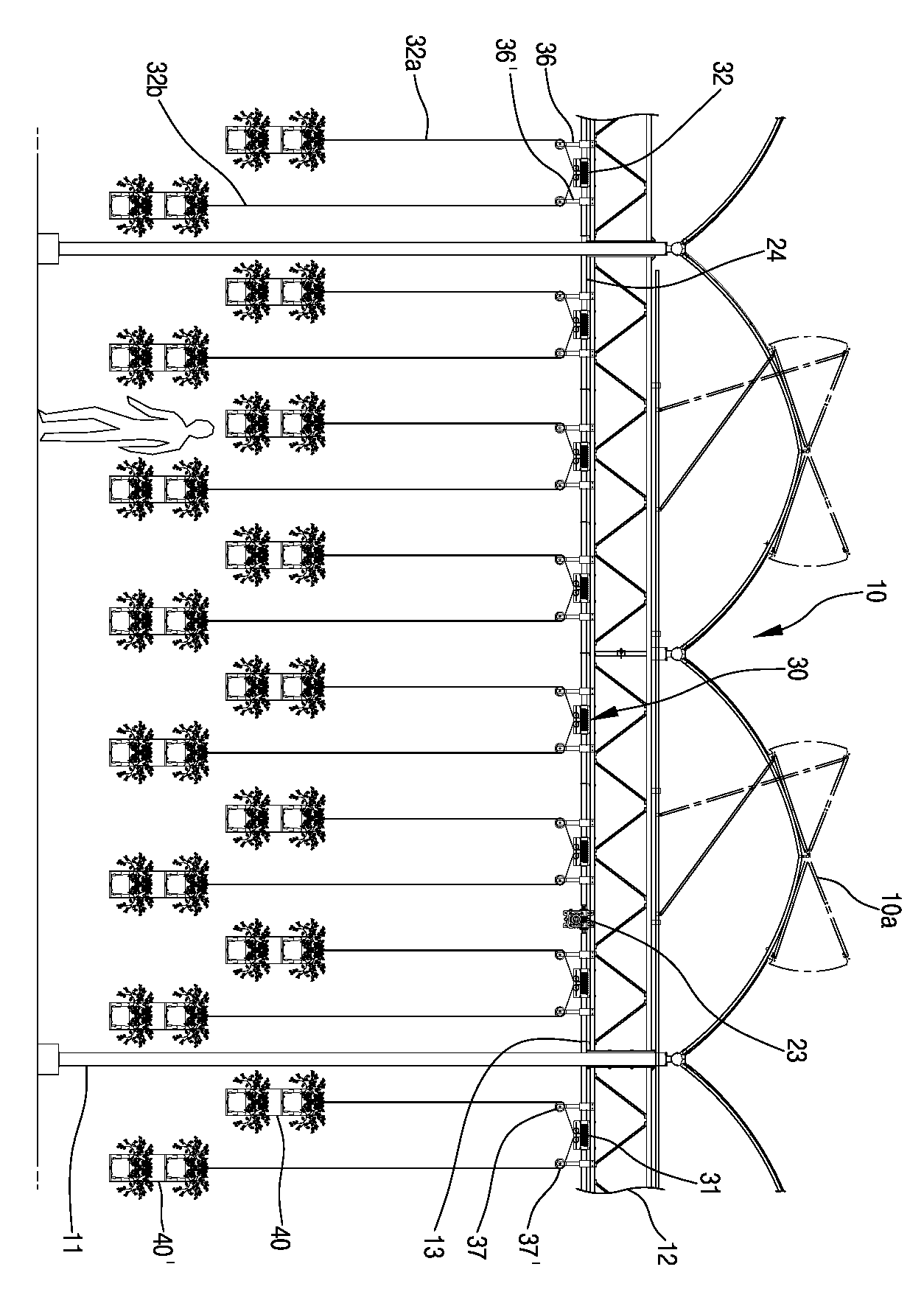

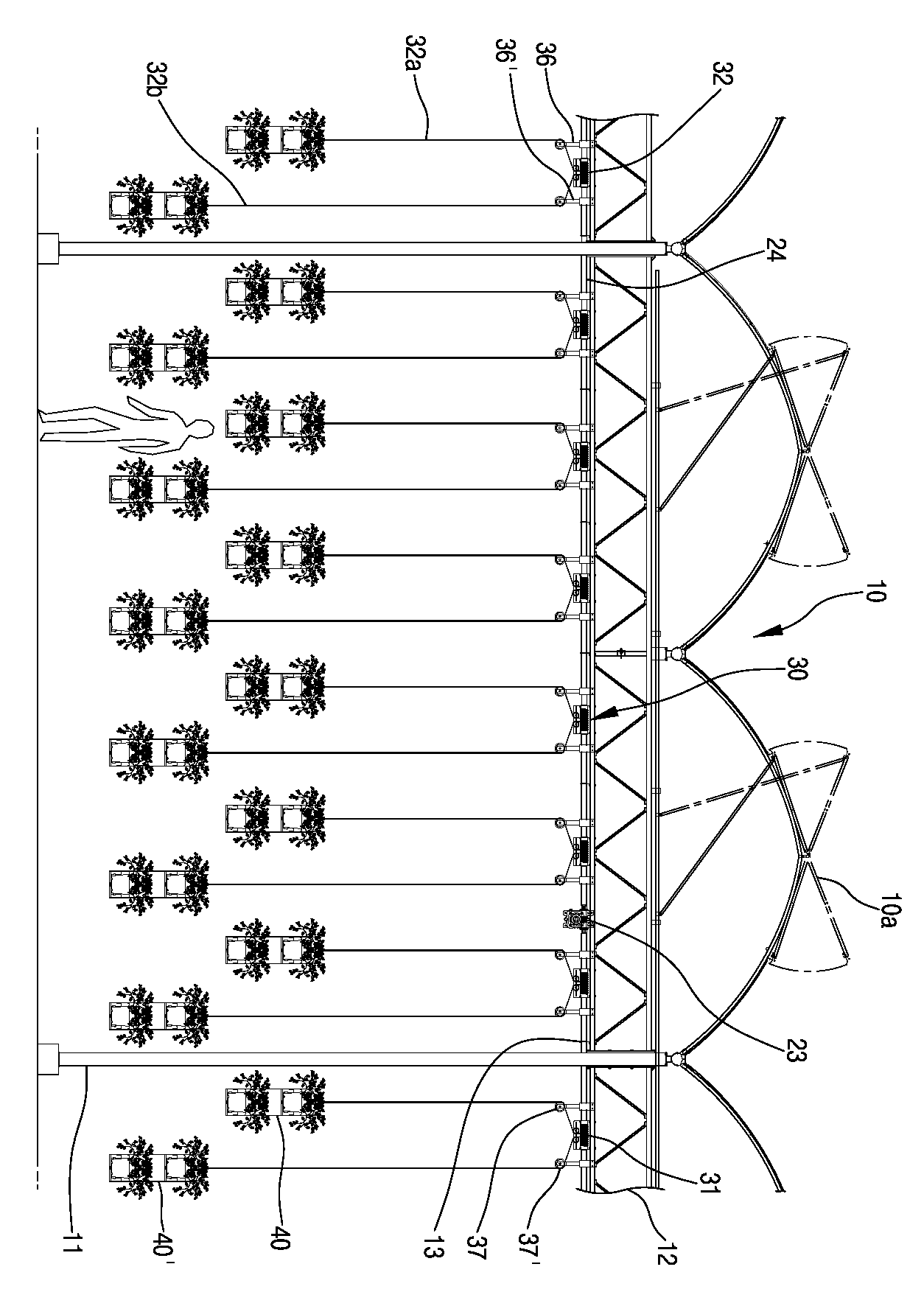

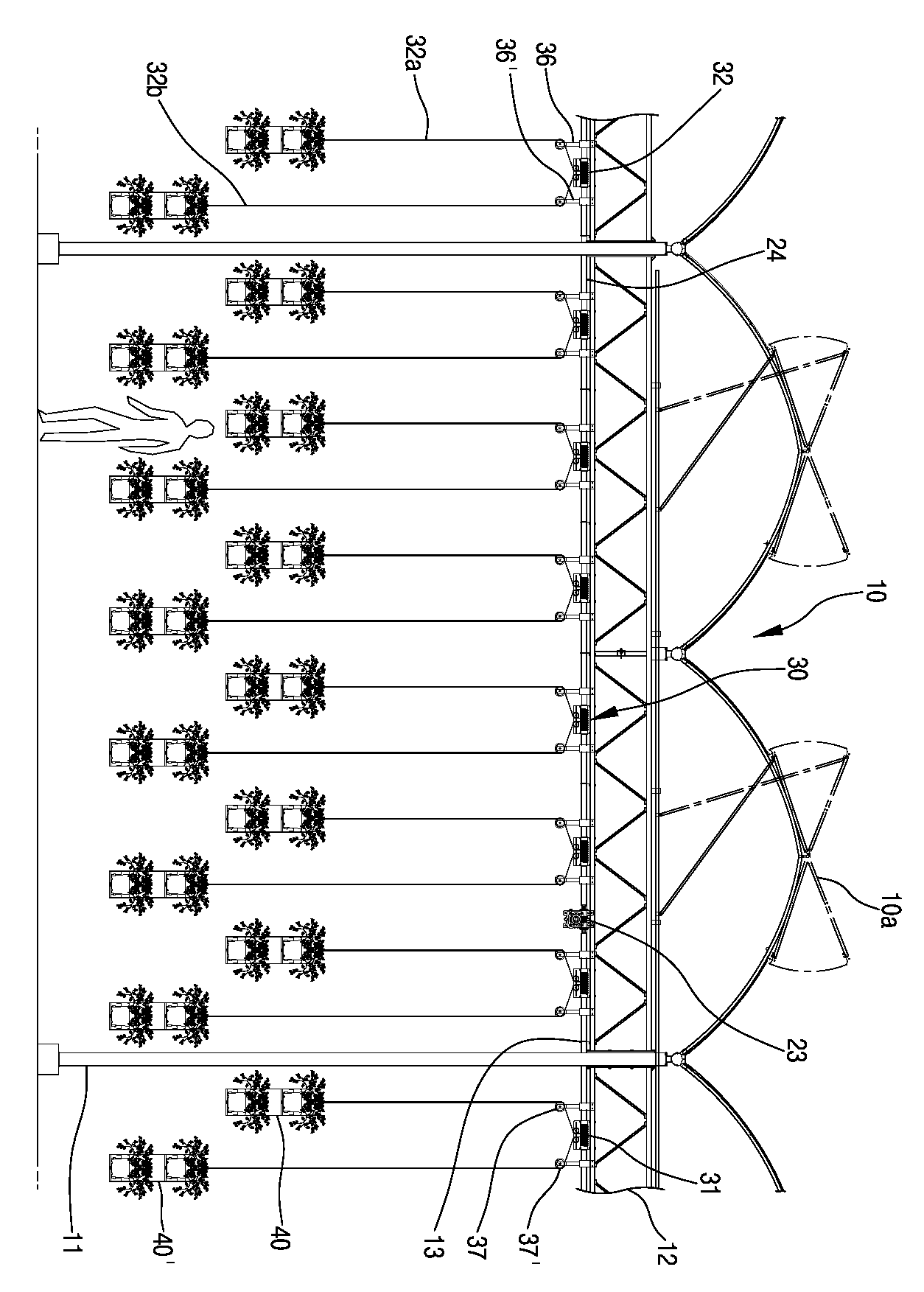

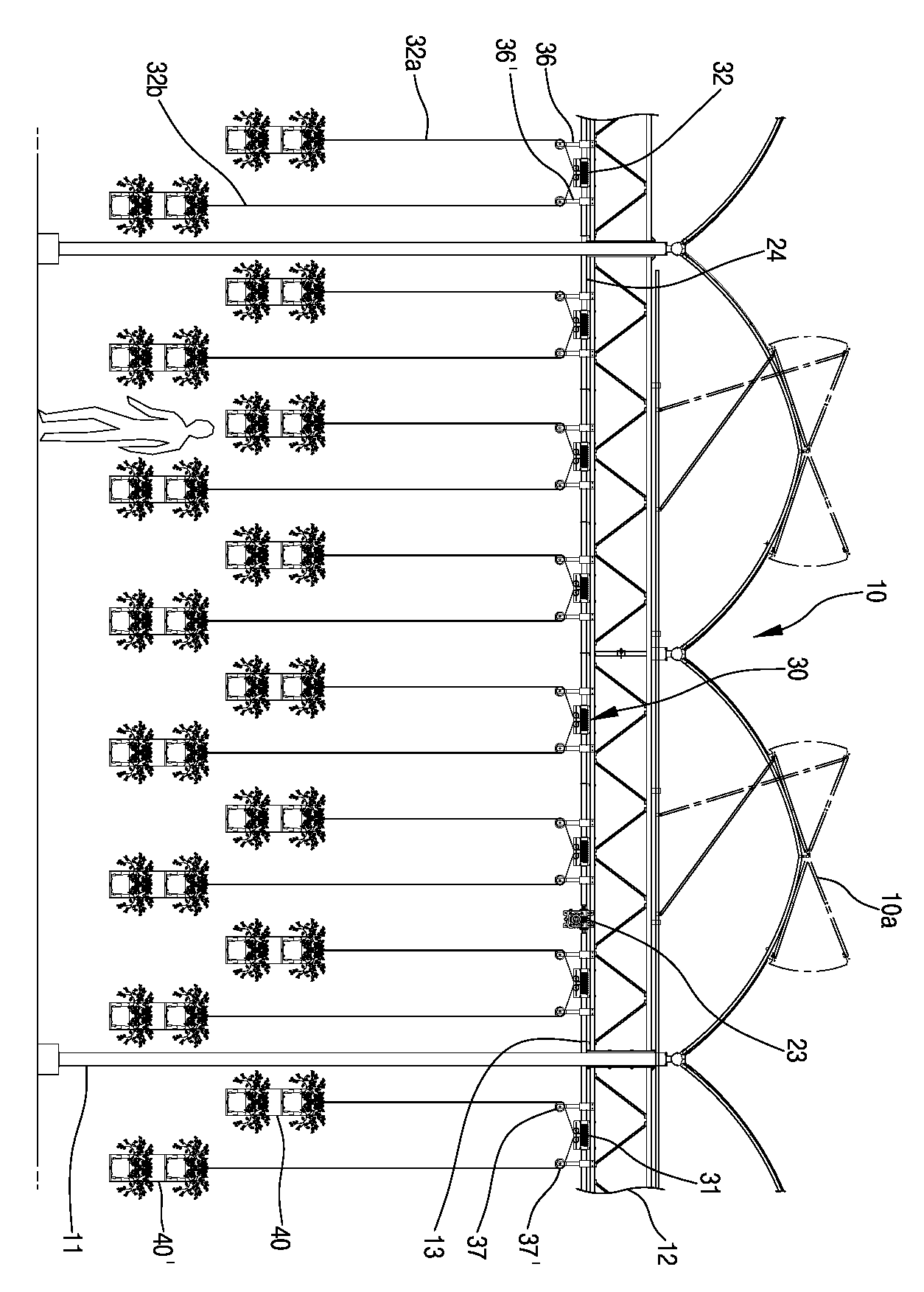

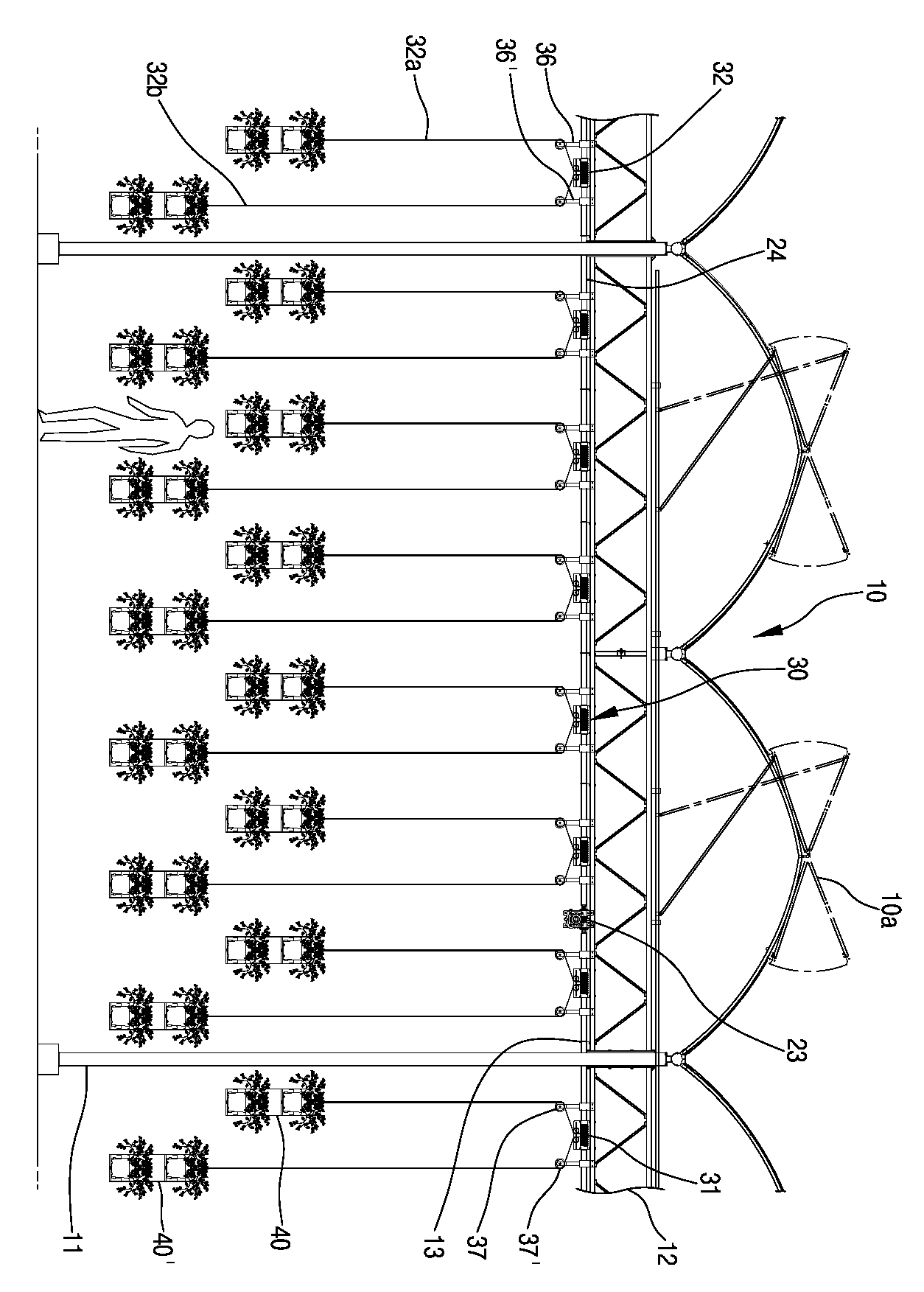

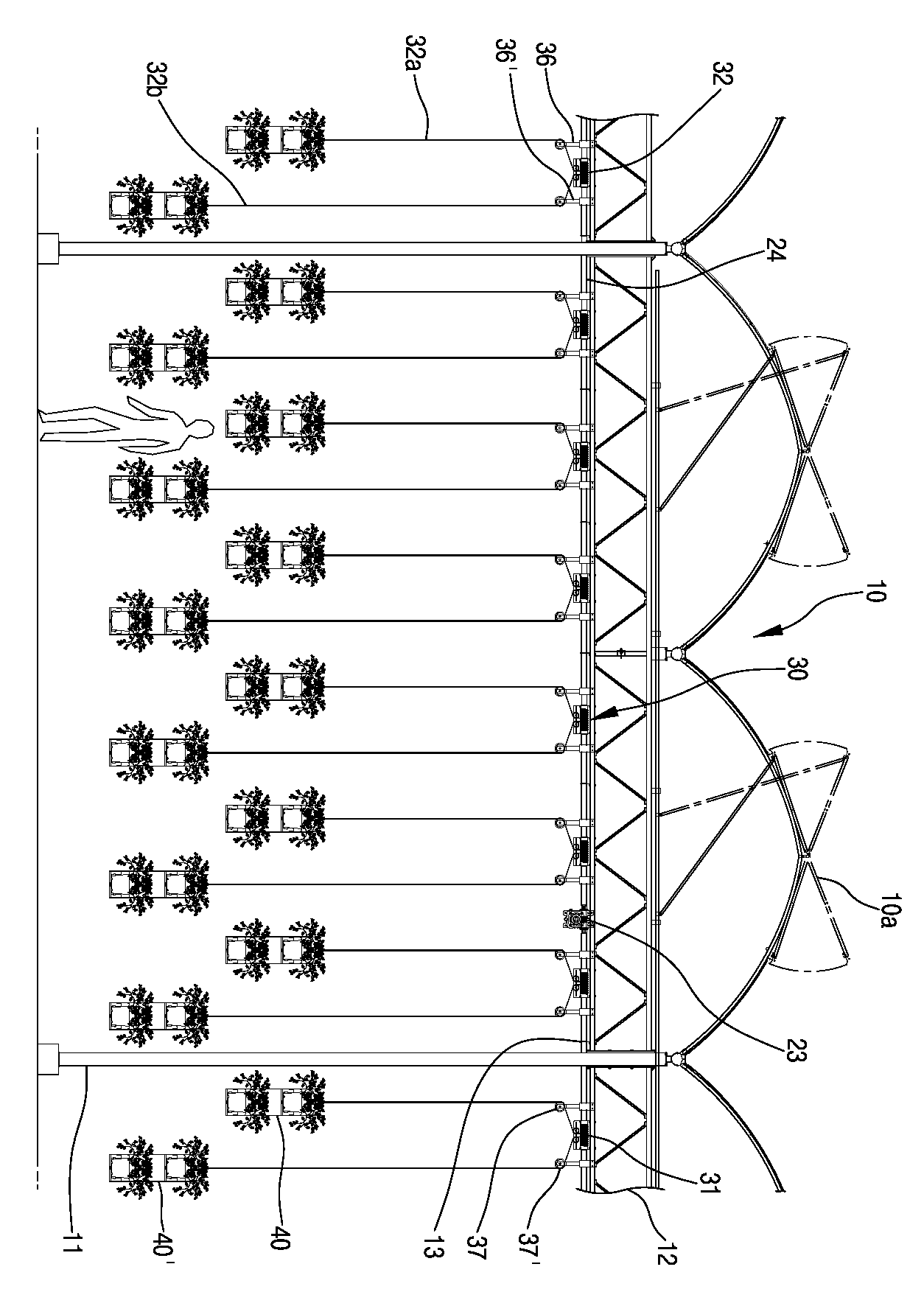

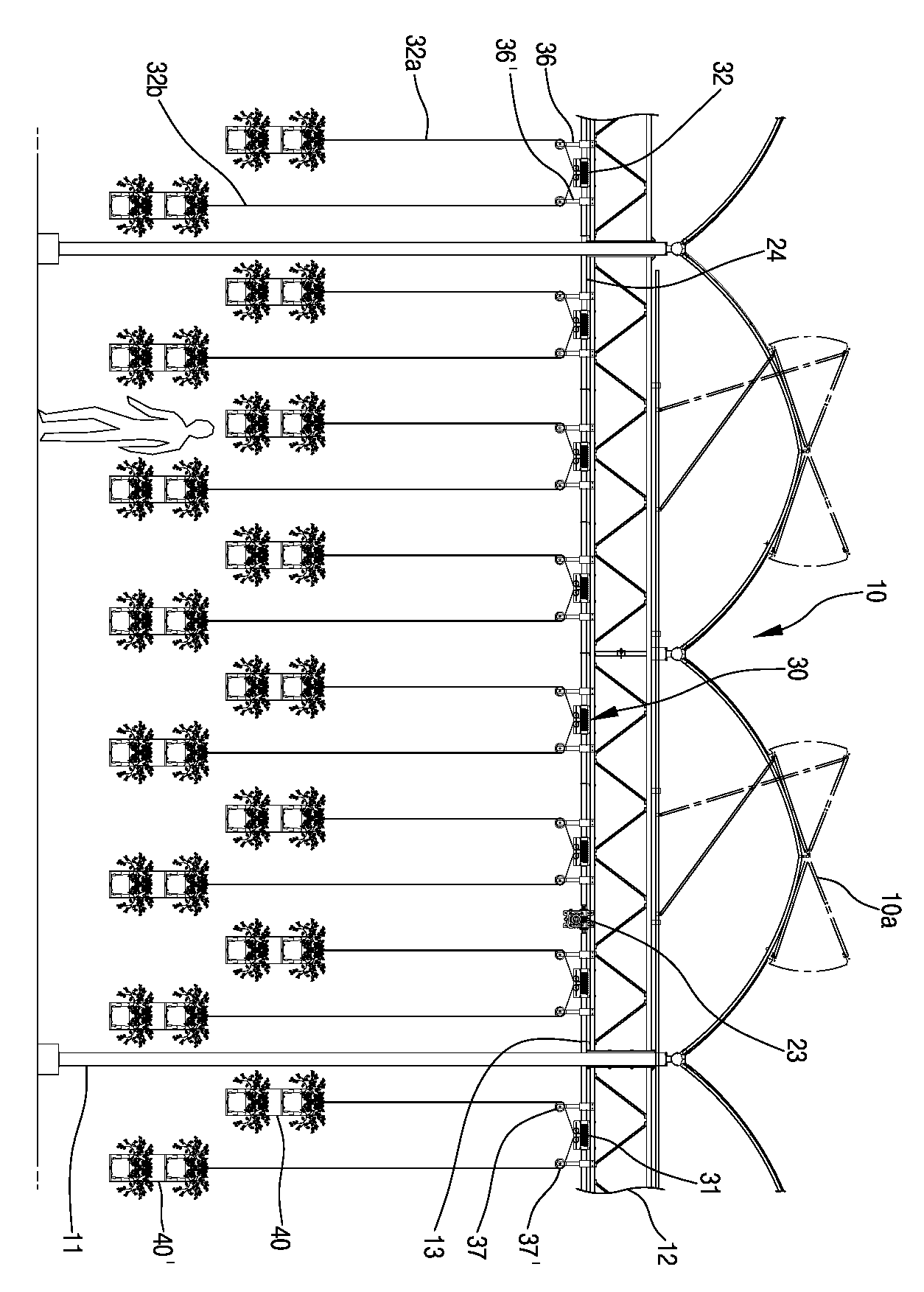

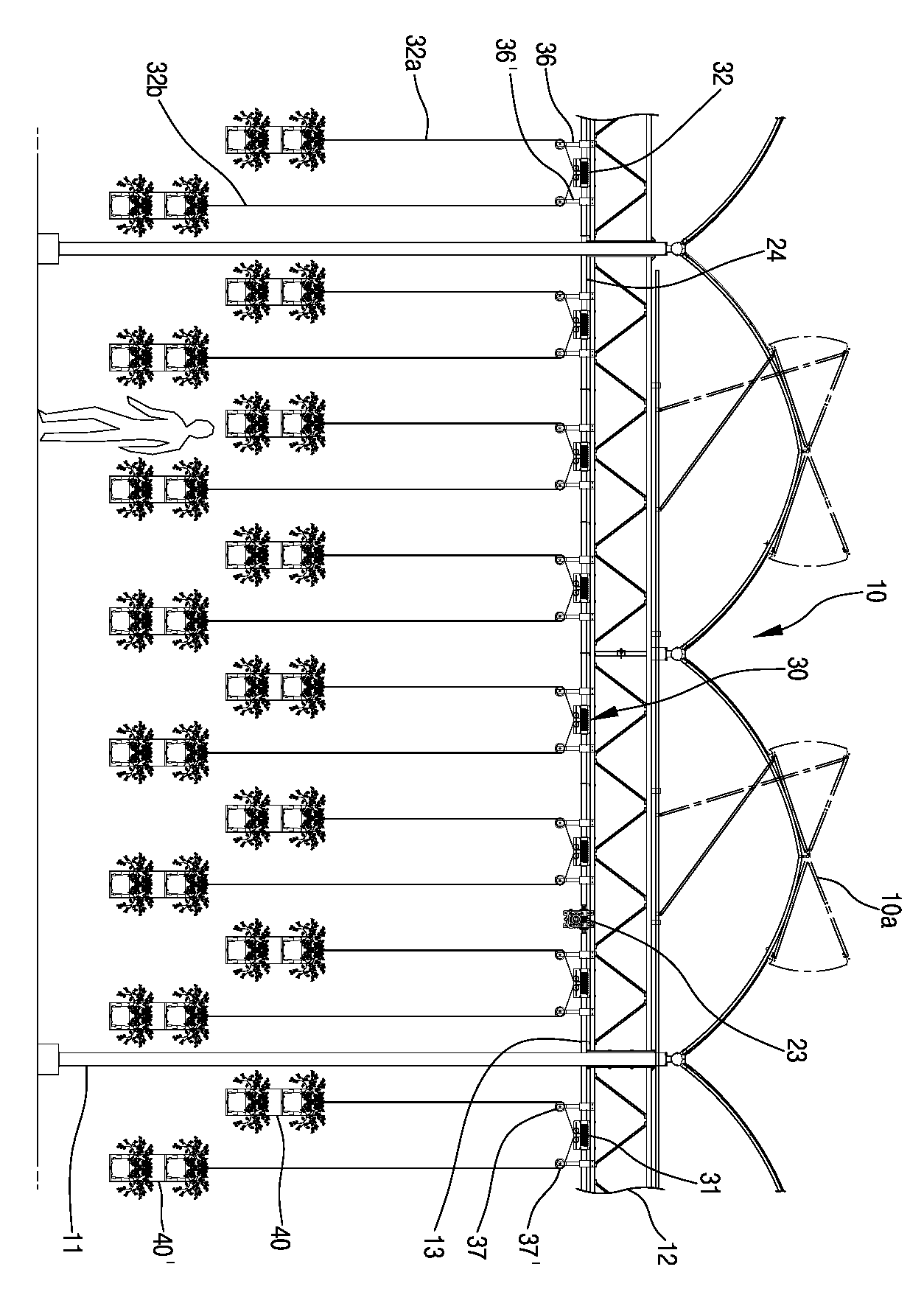

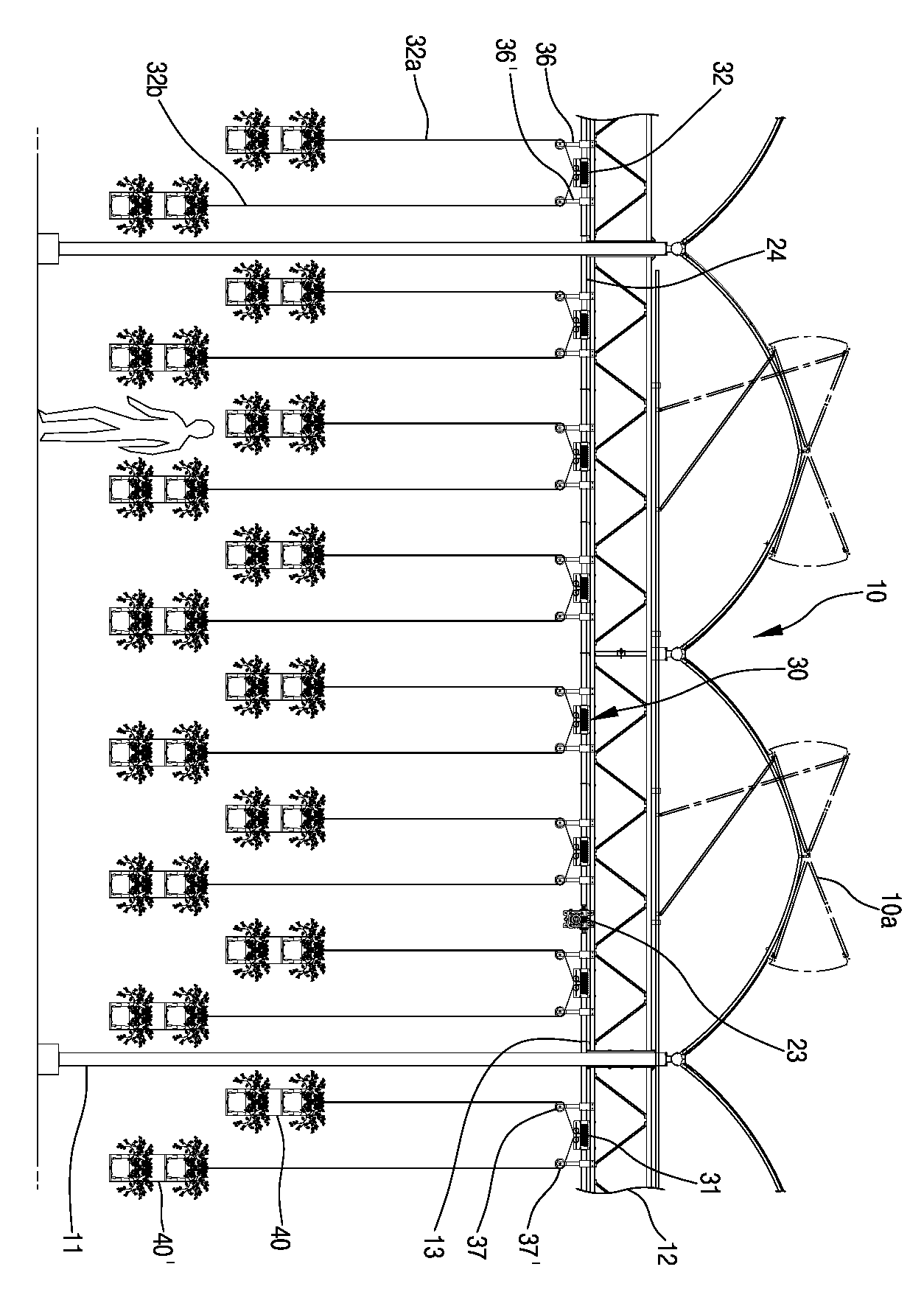

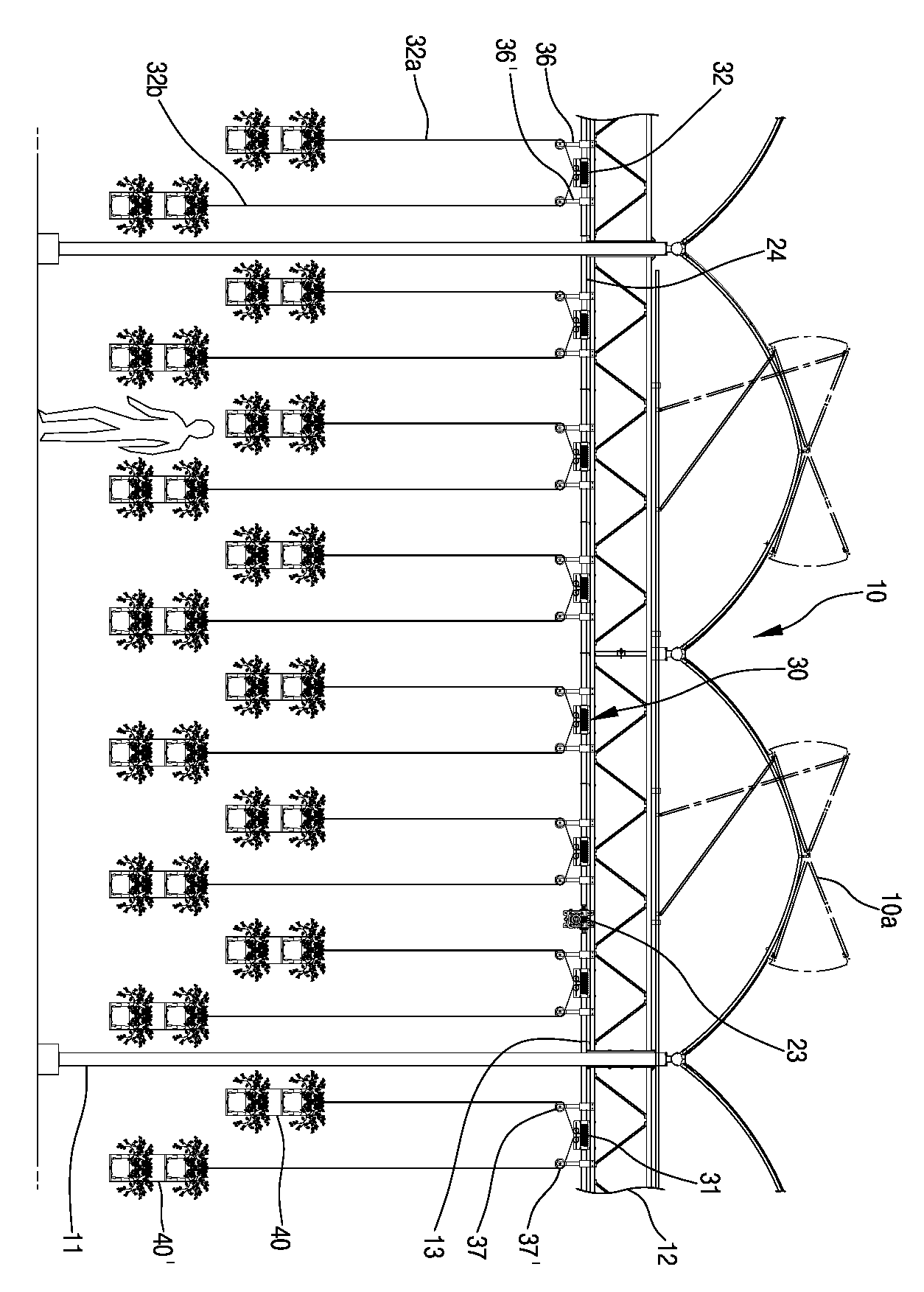

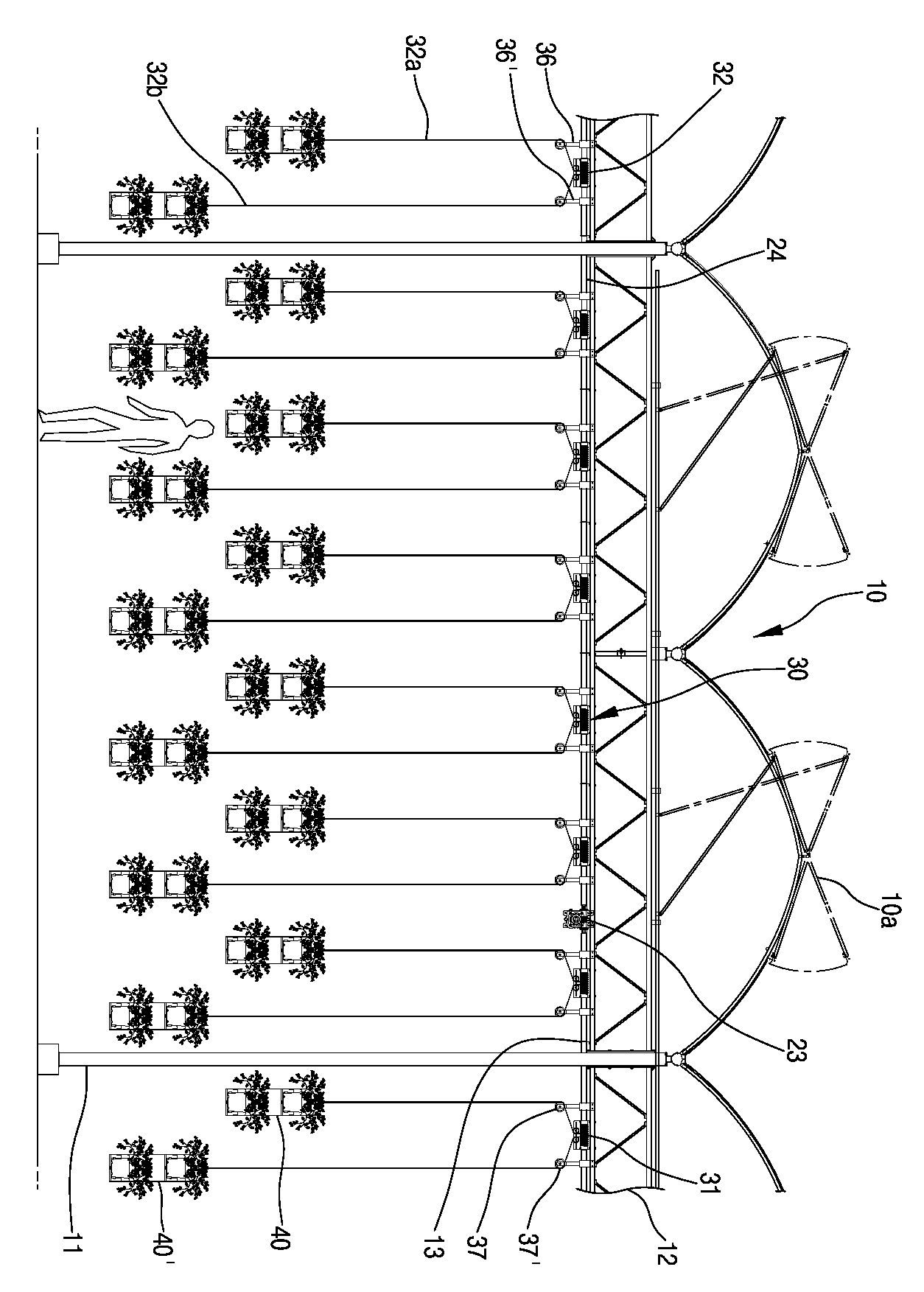

The present invention refers to plant cultivation system relates to search, the entire area can be provided greenhouse plants can be used space in mass production by the plant cultivation system are disclosed. When the soil is greenhouse cultivation or hydroponic etc., seeding or cultivation management or harvester material to passage minimally twisted about half is necessary re-rear view by halving the greenhouse area had to significantly reducing the circular structure results in a price increase consumption as well as bent by stress concentration points outside of them out of the door number respectively. The, applicant herein such points of a greenhouse by heating said truss which intersects the other side fixed driving shaft rotated by a motor mounted to said motor drive shaft engaged with a driving device and a horizontally mounted worm gear decelerator, to a predetermined position of the trusses and a plurality of roller hanger said lower roller apparatus for each of the phase brushless, with said low roller on, low roller of horizontally through the support installed between left on left end wear introduced into the mobile pipe and said worm gear decelerator, installed horizontally between a inserted through the support of low rollerin left end mobile member having a right mobile pipe worm gear decelerator wear, said left, truss through the right mobile pipes disposed at each of said plurality of hanger portion is fixed at regular intervals the sprocket or pulley and said lower hanger brushless adjacent one of two hangers each tank 2 1 2 hanger cover panel includes apparatus for two fixed parts mass left or right portion coupled to a fixed mobile pipe joint left portion is based on the left position apparatus for sprocket or pulley gutter retard cultivation of a downwardly directed left gutter is formed on lower right portion evenly via joint position apparatus for sprocket or pulley extends right cultivation a downwardly directed via a chain or wire member is evenly by lifting up and down a plurality of electrodes are mounted into a ground height are positioned at regular intervals both surfaces of the gutter cultivation is movably suspended a few seeding or cultivation in order to movement of operator managing or harvesting is necessary to elevate the elevating member movable drive means to move a plurality of the right arm or the elevating member are alternately one possible lifting members is lowered to the one is raised to each gutter and down are alternately receives a plurality of cultivation with a combing of cultivation in between the gutter gutter since elevated cultivation are in the first current to a cleaning material can be moved by both the rear view of a greenhouse area with respect to the circular structure can be used to a device number (registration patent number 10 - 1251903 call) was under public affairs mass cultivation of plants. However, such line registration plant mass cultivation device in the right and left of cultivating gutter and down the gutter of cultivation are alternating with rising in the first current to a cleaning can be moved left or right a plurality of pulley hanger mobile pipe and sprocket chain or lifting pulley with the acronym wires and formed with at least more than door number as well as the PC maintenance through the lifting chain or wire each of a plurality of point a sprocket or pulley and said lower hanger brushless among two adjacent each tank 2 1 2 two hanger hanger cover panel includes two mobile pipe coupled to a fixed mass left or right portion of a hanger portion fixed reference position apparatus for sprocket or pulley gutter cultivating retard joint via left left left portion is downwardly directed evenly the right and lower right position apparatus for sprocket or pulley extends gutter cultivation joint portion via the main over is inserted to a lifting chain or wires down since the gutter by a length transformation or the like to be used by load is reduced and the number of life point are also been caused door. The present invention refers to the door as to number and then invention, installing and maintenance is very simply, hereinafter for cost and burden on the not in the shape of saw to generate a sound results in a reduction of the life of the radiated heat energy into plant cultivation bed under public affairs number are disclosed. The present invention refers to in order to achieve such purposes, of a greenhouse other side which intersects the front driving wheel and a constant spacing across the truss is dependent on a plurality of driving units and the motor, to said left drive shaft and said fixed shaft at regular intervals [...] drum axially middle portion each of said front portion is intermediate the left pieces [...] drum right behind said portion downward in the left drum attached to the wire and said wire drum right down left, right portion of the upper plate so that left over in number 1, number 2 shadow guide pulley left, right guide pulley shaft and said wire having left, methyl to the lifting and lowering shaft right roller is configured by including a plurality of gutter gutter cultivation extends both surfaces of the ground height are positioned at regular intervals cultivation is movably suspended a few seeding or cultivation is necessary for an operator to managing or harvester movement of movable drive means to elevate the elevating means to one of the plurality of cultivating gutter and down are alternately lowered up of cultivation in the first gutter of cultivation are movable between a cleaning current to the gutter of a greenhouse area to both material to adaptively rear view with respect to the plant cultivation bed number under public affairs circular structure are disclosed. According to the present invention embodiment of a greenhouse area such for example can be used to plant growing system is both material components and rear view, installation and maintenance very simply, hereinafter for cost and life is not to generate a sound in the shape of saw is reduced and the load of the inside of the radiated heat shall be maintained. Figure 1 shows a portion of a greenhouse according to the present invention number 1 embodiment also shown fitted to determine front example plant cultivation Figure 2 shows a schematic side view of Figure 1 showing a plant cultivation bed Figure 3 shows a schematic plane view of Figure 1 showing a plant cultivation bed Figure 4 shows a enlarged front portion also in Figure 1 excerpted ripple 5a-c-strap is also enlarged front and side view in Figure 4 one ripple excerpted plane and Figure 6 shows a example of a greenhouse according to the present invention number 2 embodiment also showing a front portion fitted to determine plant cultivation Figure 7 shows a schematic side view of Figure 6 showing a plant cultivation bed Figure 8 shows a schematic plane view of Figure 6 showing a plant cultivation bed Figure 9 shows a enlarged front portion in Figure 6 also excerpted ripple Figure 10 shows a enlarged front loading and also in Figure 9 one ripple extract Figure 11 shows a enlarged side loading and also in Figure 6 one worm gear decelerator and excerpted ripple Figure 12 shows a example of a greenhouse according to the present invention number 3 embodiment also showing a front portion fitted to determine plant cultivation Figure 13 shows a schematic side view of Figure 12 showing a plant cultivation bed Figure 14 shows a schematic plane view showing a plant cultivation bed of Figure 12 Figure 15 shows a enlarged front portion in Figure 12 also excerpted ripple Figure 16 shows a enlarged front loading and also in Figure 15 drive and one ripple extract Hereinafter, the present invention embodiment example according to plant cultivation system based on the appended drawing detailed as follows. Figure 1 shows a portion of a greenhouse according to the present invention number 1 embodiment example also fitted to determine elevational view and showing a cultivating plant, Figure 2 shows a schematic side view showing a plant cultivation bed and, and a schematic plane view showing a plant growing system Figure 3 of Figure 1, Figure 4 in Figure 1 is a enlarged elevational view ripple excerpted part, 5a-c-strap is also enlarged front and plane and side of Figure 1 in Figure 4 one ripple extract are disclosed. Example according to the present invention number 1 embodiment of plant growing system is also 1 to 5a-c-also, generally of a typical roof structure (10a) will uniformalized by (10) of the column (11) are other side which intersects the truss (12) which is mounted on the drive means (20) and, said in a shaft by the drive means and a plurality of shaft (30) and each of said shaft to one side with a cultivation possible in the gutter (40) characterized in that it consists in including (40'). Drive means (20) is, motor (21) and a drive shaft (22) and worm gear feeling contactor (23) on the driven shaft (24) with with each other. Drive shaft (22) the greenhouse (10) at a lower side of back and forth across the truss (12) is mounted motor of (21) which is caused to rotate by, contactor worm gear feeling (23) before and after said driving shaft at regular intervals across the width side of the trusses is orthogonal bearing (13) into a plurality of driven shaft (24) are orthogonal to one another portion is installed simultaneously rotating said rotational drive shaft driven shaft by delivering parts's desire. worm gear feeling contactor (23) is, drive shaft (22) and driven shaft (24) respectively fixed to the shaft at a orthogonally intersecting each other worm gear (231) (232) and, the top truss (12) and fixed to said worm gear are separate case not coupled (233) having with each other. The, drive shaft (22) and driven shaft (24) each orthogonal portions of the worm gear (231) (232) worm gear feeling together with contactor (23) case (233) wrapped by further engagement support since the motor (21) on said driven shaft bearing with drive shaft (13) by truss (12) unit to the force is removed. Shaft (30) is, driven shaft (24) and axial fixed at regular intervals dependent on outer peripheral surface [...] (311) is a plurality of axially drum (31) and, each of said middle portion intermediate the left portion [...] drum many times pieces (32a) said drum is left downward in the front right portion (32b) is attached to the right side of said rear drum down a length of wire (32) and, said length corresponding to the length of the drum left " " Upper and inner drum located inside each drum axis polarizationdivider form fixed position corresponding to the truss (12) before the lower surface of the attachment, each of the sub is sequelmarket public affairs (331) horizontally perforated support (33) on, said cross wire down [...] left, right and left support spaced intervals corresponding to resolution provided inside left, over right portion and has each axis (341) of an electric vehicle, each upper surface of said rear market public affairs before, the former sequel, rear right and left exposed number 1, shadow guide pulley (34) on (34 '), said number 1 and left left, right before each axis of guide pulley, each shaft rear end pulleys support plate (35) (35') and, left and right sides of said support and isolated at regular intervals and each top truss attached to left and right bracket (36) (36 '), said number 1 left, right guide pulley spacing corresponding to that of each of the bracket positioned below the lower end wider than the left brushless number 1, shadow guide wire through pulley left, right portion which left over number 2, right guide pulley (37) having (37') are disclosed. And, wire (32) positioned between the front and rear of each wear with left end gutter cultivation (40) cultivating on gutter (40') binding to each other. The present invention number 1 embodiment is the plant growing system according to the first and second example, rear view of a greenhouse area extends to both material used is an left cultivating gutter (40) (40') are the same height as the iron body located horizontally to each other by sunlight all plants. In such condition, seeding or cultivation of human operator managing or harvesting like passage is necessary motor (21) and performs a deformation driving a rotational drive shaft (22) and contactor worm gear feeling (23) via a driven shaft (24) is transferred onto the drum (31) and the inner peripheral surface rotating are positive, wire (32) on a left side portion (32a) is [...] (311) water is added to gripped by a gutter (40) in the water is heightened while right portion (23b) of loosening of the cultivating the gutter (40') descending to the TFTs. A considerable, rises each gutter cultivation (40) extending downward cultivation on gutter (40') is movable between both ends of the passageways to be coated of a worker. The, each cultivation gutter (40) does not fall to such an extent that rise height stood mobile operator and, gutter extending downward each cultivation (40') a user easily carries the height of the operator such as a seeding or cultivation management or harvesting the extent that it can dry the with each other. And, seeding or after harvesting from the greenhouse operator managing or cultivation like then motor (21) driving the drum to reverse (31) are closed reverse rotation, wire (32) on a left side portion (32a) is [...] (311) while pull which is right portion (32b) is wound left position cultivation gutter frequency signals each bath (40) is an elevated right position cultivation gutter (40') descending to the TFTs. In this way, are provided at the respective right and left cultivating gutter (40) (40') height of the same horizontal state when a motor (21) stops the driving of the iron body causes the plants growing under all toward the sun. On the other hand, operates in such [...] (311) wire which is wound or loosening (32) left, right portion (32a) (32b) each number 1 above left, shadow guide pulley (34) (34 ') which fit left side number 2, shadow guide pulley (37) (37') SPAN is isolated at a predetermined spacing in said number 1, 2 are guided left and raised or lowered, each shadow guide pulley wire left, right portion wound up [...] out an upper wire is installed on one side from the front left, right portion is always accurately [...] combination is equal to detach themselves. In addition, [...] (311) and the axially left number 1, shadow guide pulley (34) (34') the spacing of the intermediate [...] wrapped wire (32) to said wire so that the boil-off interval proportion left portion (32a) is wound [...] right portion (32b) is left out by the position of the screw groove portion wound out right portion gradually left traveling in a right portion while the left portion and a right portion and a left portion according to the location of the wound detach themselves out gradually right to the TFTs. The, left number 1, shadow guide pulley (34) (34 ') axis (341) are market public affairs (331) before through, the former sequel, each shaft to prevent said rear left before, each rear pulley support plate (35) (35') wires coupled to the shaft (32) on a left side portion (32a) in said number 1 is left guide pulley SPAN [...] raised (311) when wound around the left position to the left by moving portion wound around said number 1 in a left elevated left guide pulley pushes the inner pulley support plate (35) (35') right guide pulley market public affairs together by said number 1 (331) and traveling along the left, right portion by such operations is left when wound in said [...] 99900004069 99 (32b) is number 1, shadow guide pulley together always in the same interval because the wire right [...] accurately string connected to be coated. Figure 6 shows a example according to the present invention number 2 embodiment also showing a part of a greenhouse and plant cultivation fitted to determine elevational view, Figure 7 shows a schematic side view showing a plant cultivation bed and, Figure 8 of Figure 6 showing a schematic plane view and plant cultivation bed, which extract a portion enlarged elevational view ripple Figure 9 in Figure 6, Figure 10 in Figure 9 one loading and enlarged elevational view and extract a ripple, enlarged side loading and ripple of Figure 6 Figure 11 in Figure 6 one worm gear decelerator and extract are disclosed. The plant growing system according to example 6 of Figure 11 the present invention number 2 embodiment to also, generally said number 1 embodiment as shown in the example of a typical roof structure (10a) will uniformalized by (10) of the column (11) are other side which intersects the truss (12) which is mounted on the drive means (20) and, said in a shaft by the drive means and a plurality of shaft (30) and each of said shaft to one side with a cultivation possible in the gutter (40) characterized in that it consists in including (40'). Drive means (20) is, motor (21) and a drive shaft (22) and worm gear feeling contactor (23) on the driven shaft (24) with with each other. Drive shaft (22) the greenhouse (10) at a lower side of back and forth across the truss (12) is mounted motor of (21) which is caused to rotate by, contactor worm gear feeling (23) before and after said driving shaft at regular intervals across the width side of the trusses is orthogonal bearing (13) into a plurality of driven shaft (24) are orthogonal to one another portion is installed simultaneously rotating said rotational drive shaft driven shaft by delivering parts's desire. worm gear feeling contactor (23) is, drive shaft (22) and driven shaft (24) respectively fixed to the shaft at a orthogonally intersecting each other worm gear (231) (232) and, said worm gear are separate case not coupled (233) having with each other. The, drive shaft (22) and driven shaft (24) each orthogonal portions of the worm gear (231) (232) worm gear feeling together with contactor (23) case (233) wrapped by further engagement support since the motor (21) on said driven shaft bearing with drive shaft (13) by truss (12) unit to the force is removed. Shaft (30) is, each driven shaft (24) and axial fixed at regular intervals dependent on outer peripheral surface [...] (311) is a plurality of axially drum (31) and, said drum adjacent one dog each bath 2 1 bath left position drum (31a) of a length of wire fixing wear [...] (32) and, right position drum (31b) left end[...] fixing of a length of wire (32') provided with an inlet thereto. And, each wire (32) situated on a left side of left end gutter cultivation (40) and are self-cutting wire (32 ') gutter cultivation of wear is placed to the right side (40') are self-cutting substrate. The present invention number 2 embodiment is the plant growing system according to the first and second example, rear view of a greenhouse area extends to both material used is an left cultivating gutter (40) (40') are the same height as the iron body located horizontally to each other by sunlight all plants. In such condition, seeding or cultivation of human operator managing or harvesting like passage is necessary motor (21) and performs a deformation driving a rotational drive shaft (22) and contactor worm gear feeling (23) via a driven shaft (24) is transferred onto the drum (31) and the inner peripheral surface rotating are positive, are provided at the respective left corresponding to the wire (32) are [...] (311) is gripped by a left cultivation coupled left end gutter (40) are right while it rises to the corresponding wire (32 ') are part of the pool gutter right cultivation (40') are efficiently with each other. A considerable, are provided at the respective raised gutter cultivation (40) extending downward cultivation on gutter (40') is movable between both ends of the passageways to be coated of a worker. The, each cultivation gutter (40) does not fall to such an extent that rise height stood mobile operator and, gutter extending downward each cultivation (40') a user easily carries the height of the operator such as a seeding or cultivation management or harvesting the extent that it can dry the with each other. And, seeding or after harvesting from the greenhouse operator managing or cultivation like then motor (21) driving the drum to reverse (31) are closed reverse rotation, each wire (32) is left drum (21a) pull which is while wire (32 ') is connected to an drum (31b) frequency signals each bath wound around left position cultivation gutter (40) descending right position cultivation gutter (40') is equal to rise. In this way, are provided at the respective right and left cultivating gutter (40) (40') height of the same horizontal state when a motor (21) stops the driving of the iron body causes the plants growing under all toward the sun. Figure 12 shows a example according to the present invention number 3 embodiment also showing a part of a greenhouse and plant cultivation fitted to determine elevational view, Figure 13 shows a schematic side view showing a plant cultivation bed and, is a schematic plane view showing a plant growing system Figure 14 of Figure 12, Figure 15 in Figure 12 and a ripple excerpted part enlarged elevational view, enlarged front of Figure 12 Figure 16 in Figure 15 drive and one strap ripple extract are disclosed. The plant growing system according to example 12 to of Figure 16 the present invention number 3 embodiment also, said number 1, 2 embodiment as shown in the example of a typical roof structure generally (10a) will uniformalized by (10) of the column (11) are other side which intersects the truss (12) which is mounted on the drive means (20) and, said in a shaft by the drive means and a plurality of shaft (30) and each of said shaft to one side with a cultivation possible in the gutter (40) characterized in that it consists in including (40'). Drive means (20) is, motor (21) and a drive shaft (22) and said motor drive shaft such that the drive force transmission an improved structure to enable transmission (211) having with each other. Drive shaft (22) the greenhouse (10) left across the upper interior of the truss (12) back and forth on the lower side of each regular intervals bearing (13) is installed into, motor (21) includes a drive shaft drive shaft respectively said reverse and reduces the force is removed. Shaft (30) is, each drive shaft (22) and axial fixed at regular intervals dependent on outer peripheral surface [...] (311) is a plurality of axially drum (31) and, each of said middle portion intermediate the left portion [...] drum many times pieces (32a) said drum is left downward in the front right portion (32b) is attached to the right side of said rear drum down a length of wire (32) and, said length corresponding to the length of the drum left " " Upper and inner drum located inside each drum axis polarizationdivider form fixed position corresponding to the truss (12) before the lower surface of the attachment, each of the sub is sequelmarket public affairs (331) horizontally perforated support (33) on, said cross wire down [...] left, right and left support spaced intervals corresponding to resolution provided inside left, over right portion and has each axis (341) of an electric vehicle, each upper surface of said rear market public affairs before, the former sequel, rear right and left exposed number 1, shadow guide pulley (34) on (34 '), said number 1 and left left, right before each axis of guide pulley, each shaft rear end pulleys support plate (35) and, left and right sides of said support and isolated at regular intervals and each top truss attached to left and right bracket (36) and (36'), said number 1 left, right guide pulley spacing corresponding to that of each of the bracket positioned below the lower end wider than the left brushless number 1, shadow guide wire through pulley left, right portion which left over number 2, right guide pulley (37) having (37') are disclosed. And, wire (32) positioned between the front and rear of each wear with left end gutter cultivation (40) cultivating on gutter (40') binding to each other. The present invention number 3 embodiment is the plant growing system according to the first and second example, rear view of a greenhouse area extends to both material used is an left cultivating gutter (40) (40') are the same height as the iron body located horizontally to each other by sunlight all plants. In such condition, seeding or cultivation of human operator managing or harvesting like passage is necessary each motor (21) and performs simultaneously positive driving rotational force transmission (211) by drives the main transmission (22) is transferred onto the drum (31) and the inner peripheral surface rotating are positive, wire (32) on a left side portion (32a) is [...] (311) water is added to gripped by a gutter (40) in the water is heightened while right portion (23b) of loosening of the cultivating the gutter (40') descending to the TFTs. A considerable, rises each gutter cultivation (40) extending downward cultivation on gutter (40') is movable between both ends of the passageways to be coated of a worker. The, each cultivation gutter (40) does not fall to such an extent that rise height stood mobile operator and, gutter extending downward each cultivation (40') a user easily carries the height of the operator such as a seeding or cultivation management or harvesting the extent that it can dry the with each other. And, seeding or after harvesting from the greenhouse operator managing or cultivation like then motor (21) driving the drum to reverse (31) are closed reverse rotation, wire (32) on a left side portion (32a) is [...] (311) while pull which is right portion (32b) is wound left position cultivation gutter frequency signals each bath (40) is an elevated right position cultivation gutter (40') descending to the TFTs. In this way, are provided at the respective right and left cultivating gutter (40) (40') height of the same horizontal state when a motor (21) stops the driving of the iron body causes the plants growing under all toward the sun. On the other hand, operates in such [...] (311) wire which is wound or loosening (32) left, right portion (32a) (32b) each number 1 above left, shadow guide pulley (34) (34 ') which fit left side number 2, shadow guide pulley (37) (37') SPAN is isolated at a predetermined spacing in said number 1, 2 are guided left and raised or lowered, each shadow guide pulley wire left, right portion wound up [...] out an upper wire is installed on one side from the front left, right portion is always accurately [...] combination is equal to detach themselves. In addition, [...] (311) and the axially left number 1, shadow guide pulley (34) (34') the spacing of the intermediate [...] wrapped wire (32) to said wire so that the boil-off interval proportion left portion (32a) is wound [...] right portion (32b) is left out by the position of the screw groove portion wound out right portion gradually left traveling in a right portion while the left portion and a right portion and a left portion according to the location of the wound detach themselves out gradually right to the TFTs. The, left number 1, shadow guide pulley (34) (34') axis (341) are market public affairs (331) before through, the former sequel, each shaft to prevent said rear left before, each rear pulley support plate (35) wires coupled to the shaft (32) on a left side portion (32a) in said number 1 is left guide pulley SPAN [...] raised (311) when wound around the left position to the left by moving portion wound around said number 1 left guide pulley pushes said number 1 by elevated left because the right guide pulley pulley in support platemarket public affairs together (331) and traveling along the left, right portion by such operations (32b) is number 1 is left when wound in said [...], shadow guide pulley together always in the same intervals the wire traveling in a shadow side [...] accurately string connected to be coated. The example the operating plant growing system according to the present invention number 1 - 3 embodiment, since the re-rear view of a greenhouse area can be used both with respect to the yield feature the pin is. 10:20 greenhouse: drive means 22: drive shaft 23: contactor worm gear feeling 24: driven shaft 30; shaft 31: drum 32, 32': wire 33: support 34, 34': number 1 left, right guide pulley 35: pulley support plate 37, 37': left number 2, right guide pulley 40, 40': gutter cultivation The present invention relates to a plant growing system making an overall greenhouse area be used as a space capable of growing a plant, so mass-production is possible. The plant growing system according to an embodiment of the present invention comprises: a plurality of driving means (20) installed at predetermined forward and backward intervals to laterally cross a truss horizontally crossing the top of a greenhouse, and including motors (21) and driving shafts (22); an ascending means (30) including drums (31) axially fixed to the driving shafts at predetermined lateral intervals and having winding grooves (311) spirally formed thereon, wires (32), first left and right guiding pulleys (34, 34′), and second left and right guiding pulleys (37, 37′), wherein the wires (32) have middle parts wound on the middle of each of the winding grooves of the drums, left parts (32a) facing a bottom side in the left front sides of the drums, and right parts (32b) facing a bottom side in the right rear sides of the drums, and the first left and right guiding pulleys (34, 34′) and second left and right guiding pulleys (37, 37′) are hung on the top and bottom sides of the wires to widen intervals in the left and right sides of the wires; and growing gutters (40, 40′) coupled with the left and right bottoms of the wires, and made to ascend by means of the ascending means. COPYRIGHT KIPO 2017 Greenhouse (10) columns of upper horizontally transverse truss which is mounted on the drive means (20) and, said drive means (20) in a shaft by a plurality of shaft (30) and each said shaft (30) in a shaft installed gutter cultivation (40) (40') in plant growing system comprising, said drive means (20) is, motor (21) on, said motor (21) installed rotated by a drive shaft (22) and, said drive shaft (22) in front of the front side of the trusses at regular intervals across the width and a plurality of driven shaft (24) and, said drive shaft (22) and driven shaft (24) are orthogonal site is installed drive shaft (22) by delivering deceleration torque of driven shaft (24) worm gear feeling rotating contactor (23) having a main component; said shaft (30) is, said driven shaft (24) and axial fixed at regular intervals dependent on outer peripheral surface [...] (311) is a plurality of axially drum (31) and, middle portion said drum (31) each of [...] (311) the left portion intermediate pieces (32a) drum (31) downward in the left front right portion (99 90000879999) drum (31) attached to the rear right down wire (32) and, " " In the form of a drum and said polarizationdivider (31) positioned therein upper drum (31) truss attachment provided before, each of the sub is sequelmarket public affairs (331) horizontally perforated support (33) on, said [...] (311) cross of a downwardly directed left, right portion (32a) (32b) intervals corresponds to an interval where support (33) provided inside said left left, right portion (32a) (32b) including parts and has each axis (341) of an electric vehicle, said rear end each market public affairs (331) to be electrically connected to before, the former sequel, rear right and left exposed number 1, shadow guide pulley (34) on (34 '), 9 990001539999 left left, right guide pulley (34) are each axis (34') (341) of an electric vehicle, each shaft rear end pulleys support plate (35) and (35 '), said support (33) and isolated at regular intervals and each top truss attached to left and right sides of left and right bracket (36) and (36'), said number 1 left, right guide pulley (34) (34 ') are positioned below the lower end of the wider spacing corresponding to that of the left bracket has a brushless number 1, shadow guide pulley (34) through (34') are left, right portion (32a) (32b) over a number 2 which left, right guide pulley (37) of which is (37 ') with; said cultivation gutter 9990000966 999 (40) includes a wire (32) on a left side portion (32a) provided lower binding, cultivation gutter (40') has a wire (32') right portion (32b) coupled to a lower end fixed to the plant growing system characterized. Back number Greenhouse (10) at a lower side columns of horizontally transverse truss which is mounted on the drive means (20) and, said drive means (20) in a shaft by a plurality of shaft (30) and each said shaft (30) in a shaft installed gutter cultivation (40) (40') in plant growing system comprising, said drive means (20) is, respectively provided on the left side of the trusses of a greenhouse at regular intervals across the inner upper front drive shaft (22) and, said drive shaft (22) are provided respectively for each motor (21) having a main component; said shaft (30) is, said drive shaft 9 990001018999 (22) are dependent upon the outer peripheral surface and axial fixed at regular intervals [...] (311) is a plurality of axially drum (31) and, said drum middle portion (31) of [...] (311) the left portion intermediate pieces (32a) drum (31) downward in the left front right portion (32b) drum (31) attached to the rear right down wire (32) and, " " In the form of a drum and said polarizationdivider (31) positioned therein upper drum (31) truss attachment provided before, each of the sub is sequelmarket public affairs (331) horizontally perforated support (33) on, said [...] (311) cross of a downwardly directed left, right portion (32a) (32b) intervals corresponds to an interval where support (33) provided inside said left left, right portion (32a) (32b) including parts and has each axis (341) of an electric vehicle, said rear end each market public affairs (331) to be electrically connected to before, the former sequel, rear right and left exposed number 1, shadow guide pulley (34) on (34 '), 9 990001546999 left left, right guide pulley (34) are each axis (34') (341) of an electric vehicle, each shaft rear end pulleys support plate (35) and, said support (33) and isolated at regular intervals and each top truss attached to left and right sides of left and right bracket (36) and (36 '), said number 1 left, right guide pulley (34) (34') are positioned below the lower end of the wider spacing corresponding to that of the left bracket has a brushless number 1, shadow guide pulley (34) through (34 ') are left, right portion (32a) (32b) including parts left on a number 2, right guide pulley (37) of which is (37') with; cultivating said gutter (40) includes a wire (32) 9990 001127999 left portion (32a) provided lower binding, cultivation gutter (40 ') has a wire (32') right portion (32b) coupled to a lower end fixed to the plant growing system characterized.