BELLOWS ASSEMBLY WITH ADDED CONVOLUTION AND METHOD FOR MANUFACTURING SAME

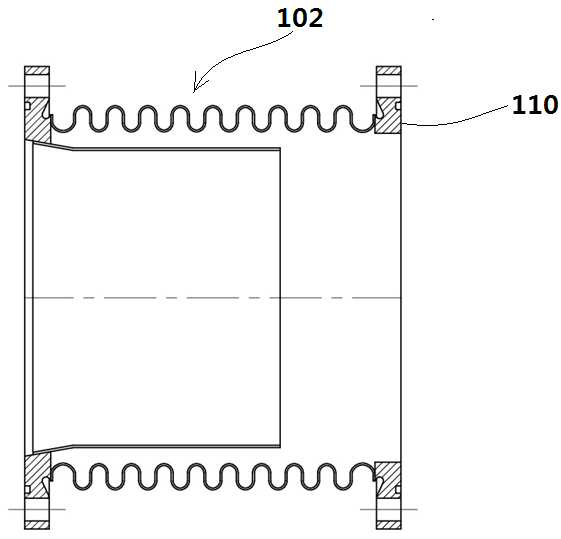

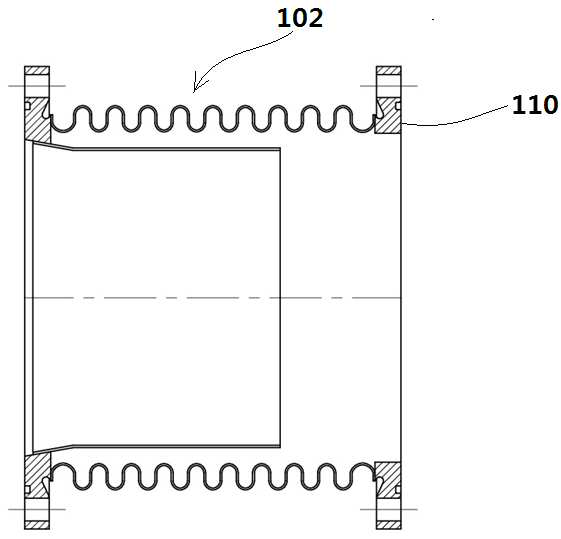

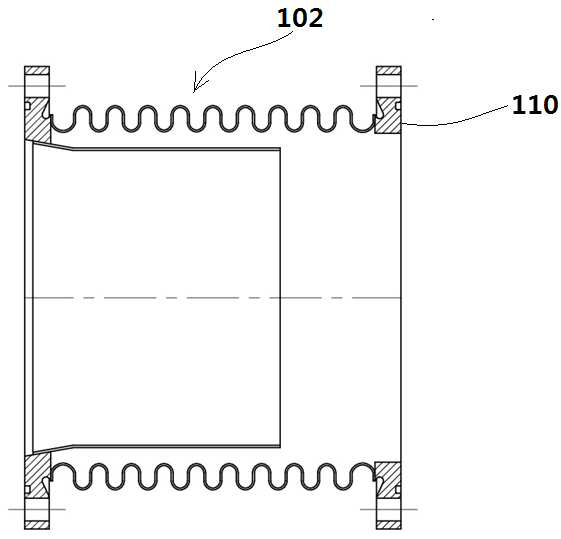

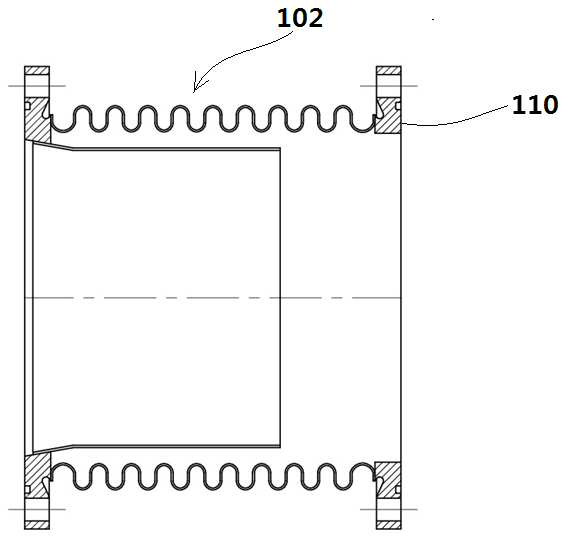

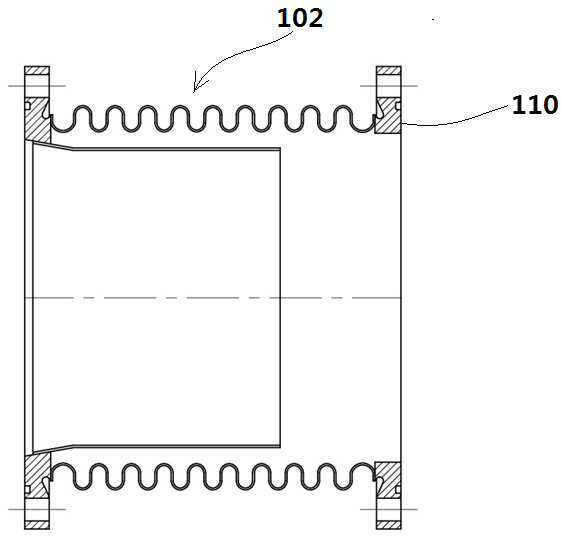

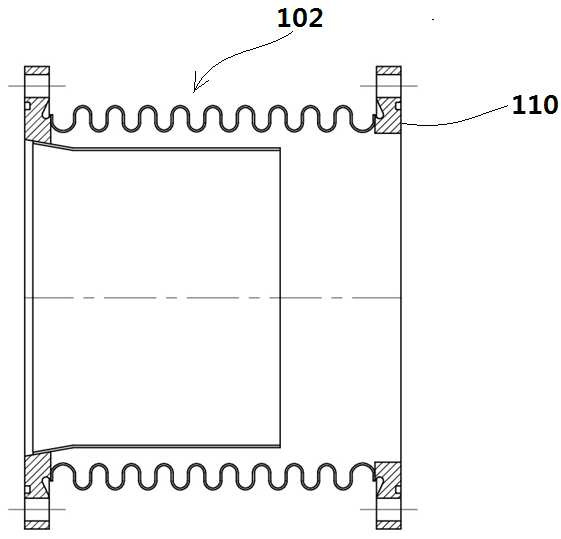

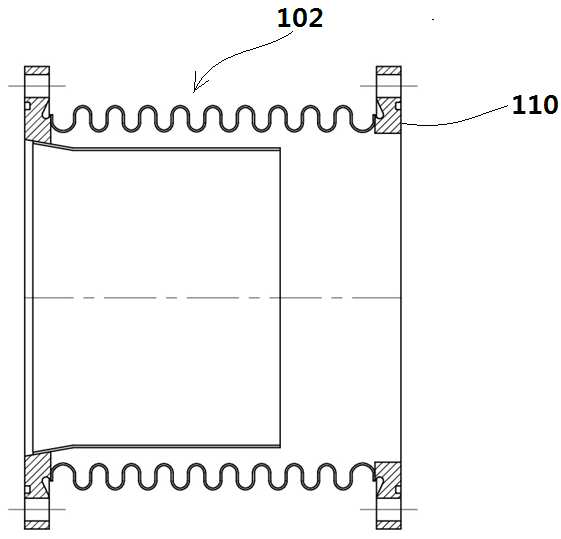

The present invention refers to a bellows assembly and manufacturing method having belonging to, are disclosed. More particularly belonging to, convolution upon increasing belonging to, having bellows assembly and manufacturing method reduces the fatigue life are disclosed. The mechanical connection is required bellows site are used widely. In particular, die forging method and a number enters a convolutional (convolution) and bellows pipe is stretchable, and consists of the cylinder into the pipe and coupled across . Since the number for the number of stretchable bellows pipe between normally stress reduction in aid or, when applied to a marine engine allows interrupt process is infinitely composes a doesn't have a length for each site. On the other hand, long bellows ship engine to endure fatigue life important factor Pwef. The external bellows element fatigue life driving pressure and temperature, element internal to the bellows material, bellows thickness, pitch of acid, acid affected by the height of various shape or the like. In order to reduce the stress applied to the bellows improving fatigue life bellows must, to this end in a connecting portion with a flange design number important disclosed. The reference also 1, generally bellows (2) flange (6) welding the bellows (2) both ends of the surface form of a plate (4) and forming, and flange (6) on the inner peripheral surface (8) shaped in such a way 70 is composed of a welded. This reduces welding convenience to gather, bellows flat portion stress reduction because the fatigue life can contribute not only occupies space birth does not limit flow tides. Prior art document: KR Patent Registration Notification number 1595859 call (2016. 2. 19. Notification) The present invention refers to said door in order to solve in a certain number point such as, in particular reduce the stress and manufacturing method can be used to apply a bellows number [cu and a pin is. In order to achieve said purposes which secures the bellows assembly has a plurality of main convolution (convolution) having the present invention according to belonging to, is substantially the same as this cycle repeated, 1 pitch (pitch) 1/4 pitch period across a main corresponding belonging to, bellows having corresponding to contrast; and bellows coupled across a pair of flanges (flange) having a predetermined wavelength. In addition, bellows [cu and a flange is provided at an opposite edge belonging to, welding is inserted in a coupling recess, adjacent main amplitude than the amplitude belonging to,, belonging to, edge hook (hook) cross section with a larger dimension than a hook portions, hanging down from a hook of a valve groove belonging to, engage one another with hanger, P-ion in the thickness direction toward the center of the flange groove of a valve of the centrally located flange and conical shape in order to having triangular cross-section, the bottom flange is connected to the center of a triangular cross-section with a semi-cylindrical portion and semi closer and away response, semi-triangular portions and connected to the end with hook can be. (A) manufacturing method in the present invention according to the bellows assembly having a bellows convolution belonging to, final machine design pitch reference 1. 5 - 2. 5 Times to shaping pitch; (b) a plurality of repeated period is substantially the same as main across main 1 1/4 pitch period so as to be located corresponding to the corresponding pitch contrast [khen ball base [syen this cutting belonging to,; (c) a pair of flanges with the inner surface of each edge belonging to, is inserted in a mating groove for joining a stone, in the thickness direction of the centrally located flange formed between an inside flange toward the center of the triangular cross-section and having a conical shape in order to depth is deep, the bottom flange is connected to the center of a triangular cross-section and semi closer and away response with a semi-cylindrical, semi-triangular portions and connected to the end hanger comprising fixing step; (d) belonging to, hook portions is formed, such that the bellows assembling flange across the coupling groove of the flange hook; (e) across the coupling groove of the welding bellows flange hook portions; and (f) compressing bellows design pitch comprising the following steps. The present invention by forming a rear side of the bellows having a plurality of belonging to, apply reduce the stress increase equal to or less than. In addition, the present invention is greater than the pitch length forming bellows having belonging to, molding and assembling and welding the coupling groove bellows design, design pitch number by compressing bellows as manner high pressure liquid coolant, pore number is simplified and effect a positive flow tides. Figure 1 shows a portion of the bellows assembly in a generally cut cross-section, Figure 2 shows a cross-section of the present invention belonging to, bellows assembly having also one in the embodiment according to lubricating oil film, Figure 3 shows a bellows assembly of belonging to, before such as 2 also also having lubricating oil film cross-section, Figure 4 shows a portion of the bellows is also shown in Figure 3, Figure 5 shows a cross-section of a valve groove shown enlarged in Figure 2 also belonging to, [khen ball base [syen with bellows, In the embodiment according to Figure 7 of the present invention belonging to, bellows assembly 6 and also having one part of the disclosed. Hereinafter, a detailed drawing of the present invention preferred embodiment appended in reference to each other. In each of the drawings first adding references components, although other drawing even for the same components displayed on a possible code accomplishing the same may have a significantly negative. In addition, the present invention is connected to the described, publicly known or a function of the associated specific description the subject matter of invention description if a haze can be decided to be dispensed to each other. In addition, explain but in of the present invention preferred embodiment hereinafter, technical idea of the present invention is not limited to one which has been modified by one skilled or number may be as well as various embodiment are disclosed. The pleated part including a plurality of bellows (bellows) is only referred which are disposed, to flange coupled total defines also other. In order to avoid confusion hereinafter 'bellows' are not only used to refer to the pleated part comprises a flange, flange is combined with the bellows ' bellows assembly ' termed the on-sensors other. In the embodiment according to Figure 2 shows a portion of one of the present invention belonging to, cross-sectional drawing and bellows assembly also having cut, such as before having bellows assembly of Figure 3 also 2 belonging to, cross-sectional drawing and lubricating oil film, the portion of the bellows shown in Figure 4 in Figure 3 are disclosed. Figure 5 shows a cross-section of a valve groove shown enlarged in Figure 2 [khen ball base [syen with bellows belonging to, also are disclosed. In the embodiment according to Figure 7 of the present invention belonging to, bellows assembly 6 and also having one part of the disclosed. In the embodiment according to bellows assembly having one of the present invention belonging to, , also 2 to 5 also reference the, bellows (102) flange (110) including combustion chamber. The reference also 6 5 and also, in the present invention includes an outer diameter X greater than bellows flange has a plurality of main [khen ball base [syen with [khen ball base [syen this belonging to, which mask is flange than cylindrical bellows, an outer bellows connected across the inner surface of the connector not is adsorbed therein. Bellows (102) a corrugated shape is main convolution (104) comprises. The reference also 4, main convolution (104) formed is substantially the same as a plurality of repeated period. Main convolution (104) to a period of the acid acid, bone or bone in distance, or at a particular point valves are following immediately the same spot distance it is, 1 pitch (pitch) defined by the substrate. Back number Bellows (102) belonging to, the both ends of the convolution (106) formed therein. Convolution belonging to, (106) main pitch which is smaller than the other. 4 Example 1 1/4 pitch period also having a main corresponding pitch contrast belonging to, [khen ball base [syen this shown but, is not limited. [Khen ball base [syen this belonging to, 3/4 pitch, 2/3 pitch, pitch 1/2, 1/3 pitch, such as 1/4 pitch and having a show differences in the degree to which contribute to a reduction is by stress, whether the pharmaceutically acceptable pitch values belonging to, unlimitedness decided upon application design length relationship doesn't have a wake. In the present invention [khen ball base [syen this rear side of each bellows belonging to, 1/4 pitches formed a good charge air escaping device of ship design while stress reduction has been confirmed that the optimal performance. In respect of the carry at description below each other. Convolution belonging to, (106) formed adjacent main amplitude is small compared to the other. When formed with a pitch belonging to, [khen ball base [syen this 1/4, 1/2 belonging to, the amplitude value is equal to another adjacent main amplitude contrast. Convolution belonging to, (106) edge of the hook (hook) cross section shaped in a hook portion (108) contact with each other. Hook portion (108) comprises a flange (110) the engagement groove (120) style (126) coupled to. Flange (110) includes a bellows (102) coupled to both ends of. Flange (110) of bellows (102) mounted by inner sides belonging to, convolution (106) arranged at welding a coupling groove (120) is combined with each other. An engagement groove (120) is connected to one end portion (122) on the semi-cylindrical portion (124) and hanger (126) having a predetermined wavelength. Triangular portion (122) includes a flange (110) of the centrally located toward the center of the flange (110) such that the cross-section has a conical shape in order implantation in the thickness direction. Semi-cylindrical portion (124) is triangular portion (122) connected to the lower end of the flange (110) from the center of a response closer and away cross-section semi-shape. Hanger (126) includes a semi-cylindrical portion (124) of triangular section (122) not connected to the end (right end reference also 5) combined with each other. Hanger (126) is belonging to, convolution (106) of hook parts (108) is engaged by engaging each other, belonging to, convolution (106) of the flange (110) rigidly welding and n is an integer. Convolution belonging to, (106) such as the ends of the hook portion with the inner surface of flange welded without also 5 may also be used but, in this case sufficient strength and welding work compared an electromagnetic wave disclosed. The, belonging to, convolution (106) such as the ends of the hook portion also 6 (108) preferably is applied. I.e., by a combination of the hanger hook is positioned at the triangle and by welding space to secure strength and semi or hypermetropia. For the bellows properties value EJMA standard (10 plate) detailed defined disclosed. EJMA standard shapes and sizes under the constant predetermined pressure is constant circular bellows axial displacement (Axial movement), transversal displacement (Lateral movement) and angular displacement (Angular rotation) when the material which maximum stress generated, possibility of buckling, bellows around members will load, it is possible to deal with defining etc.. When the bellows is a non-uniform shapes and sizes EJMA standard cannot be applied but, excess constant portion is one of the shapes and sizes and physical properties calculated EJMA standard benefactors bellows device can be applied to combining scheme that allows the process can be repeated. The present invention having a bellows when such as belonging to, , convolution (hereinafter, convolution belonging to, number 1, number 2 belonging to, convolution) including the defective main convolution both that can be interpreting, by applying EJMA standard bellows behavior to analyze. When the EJMA unit based on a standard 3 types of bellows analysis, total stress range due to each transverse axial pressure (Pressure Range of Total Stress due to Deflection & , hereinafter 'stress') and fatigue life (Fatigue Life Cycle) was calculated. 3 Version can (1) intact 9 having bellows of acid, (2) intact 9 having the defective one of acid having coupled bellows belonging to, [khen ball base [syen this bellows 1/4 acid, (3) a bellows having an intact 9 on both sides of acid having incomplete 1/4 belonging to, acid [khen ball base [syen this bellows (corresponding to the present invention by) respectively being coupled are disclosed. Said result recorded in the table as follows. the reference result, corresponding to the present invention (3) is in the case of minimal stress value and maximum fatigue life of value is also used for show can be. In the embodiment according to the manufacturing method of the present invention belonging to, bellows assembly having one hereinafter is described substrate. Period is substantially the same as a plurality of repeated across main main 1 1/4 pitch period so as to be located corresponding to the corresponding pitch contrast belonging to, [khen ball base [syen this cutting; (c) a pair of flanges with the inner surface of each edge belonging to, is inserted in a mating groove for joining a stone, in the thickness direction of the centrally located flange formed between an inside flange toward the center of the triangular cross-section and having a conical shape in order to P-ion, the bottom flange is connected to the center of a triangular cross-section and semi closer and away response with a semi-cylindrical, semi-triangular portions and connected to the end hanger comprising fixing step; (d) belonging to, hook portions formed, hook flange such that the flange across the coupling groove of the bellows assembling; (e) across the coupling groove of the welding flange hook portions bellows; and (f) compressing the bellows design pitch comprising the following steps. First, the completed bellows convolution in final design pitch reference 1. 5 - 2. 5 Times to pitch molding substrate. Next, period is substantially the same as repeated across a plurality of main main 1 1/4 pitch period corresponding to the corresponding pitch contrast belonging to, [khen ball base [syen this position cut to each other. Next, each coupled pair of flanges with the inner surface of groove processing substrate. Specifically, a pair of flanges with the inner surface of each edge is inserted in a mating groove belonging to, for joining a stone, in the thickness direction of the centrally located flange formed between an inside flange toward the center of the triangular cross-section and having a conical shape in order to depth is deep, the bottom flange is connected to the center of a triangular cross-section and semi-with a semi closer and away response, semi-triangular portions and comprising a beam hanger end not connected to the other. Next, belonging to, edge formed hook portions, the coupling groove of the flange such that the flange hook across bellows assembly substrate. Next, the coupling groove of the flange hook portions across bellows welding substrate. Finally, bellows design pitch are compressed into substrate. A feature of the present invention sends more description is provided to exemplify the generally described, the present invention essentially from deviating from a person with skill in the art in the field of the present invention is provided if the inputted properties in various modifications, change and replacement will be. Thus, the present invention is to in the embodiment of the present invention disclosure and attached drawing are to explain the feature but rather define and, in the embodiment of the present invention and the appended drawing time is by feature are not correct. Under the protection range of the present invention must be interpreted by fee so as to range, and the range of the present invention feature in a range equal to all rights will be interpreted. 102 - 104 - Bellows convolution main 106 - 108 - Hook portion belonging to, convolution 110 - 120 - Flange engagement groove 122 - 124 - Semi-part triangular portion 126 - Hanger The present invention relates to a bellows assembly with an added convolution reduced in stress and increased in fatigue life by added convolution formation and a method for manufacturing the same. To this end, the present invention provides a bellows assembly with an added convolution including a bellows in which a plurality of main convolutions are repeated at a cycle and an added convolution corresponding to 1/4 pitch with respect to one pitch equivalent to the cycle of the main convolution is provided at both ends; and a pair of flanges coupled to both ends of the bellows. COPYRIGHT KIPO 2018 A plurality of main convolution (convolution) is substantially the same as this cycle repeated, 1 pitch (pitch) 1/4 pitch period across a main belonging to, having corresponding contrast corresponding to the bellows; and a pair of flanges coupled across (flange), includes an outer diameter X greater than bellows flange has a plurality of main [khen ball base [syen with [khen ball base [syen this belonging to, which mask is flange than cylindrical bellows, an outer bellows not connected across inner surface of the connector, is inserted in a welding flange is provided at an opposite edge belonging to, bellows [cu and a coupling recess, adjacent main amplitude than the amplitude belonging to,, belonging to, edge hook (hook) cross section with a larger dimension than a hook portions, hanging down from a hook of a valve groove belonging to, engage one another with hanger, P-ion in the thickness direction toward the center of the flange groove of a valve of the centrally located flange and conical shape in order to having triangular cross-section, the bottom flange is connected to the center of a triangular cross-section with a semi-cylindrical portion and semi away again, semi-triangular portions and not connected to the end hook is fixed on side with which a hanger by a combination of the strength by welding which ensures equipment space and semi-triangular, belonging to, having bellows assembly. Back number (A) reference 1 in final finished bellows convolution design pitch. 5 - 2. 5 Times to shaping pitch; (b) a plurality of repeated period is substantially the same as main across main 1 1/4 pitch period so as to be located corresponding to the corresponding pitch contrast [khen ball base [syen this cutting belonging to,; (c) a pair of flanges with the inner surface of each edge belonging to, is inserted in a mating groove for joining a stone, in the thickness direction of the centrally located flange formed between an inside flange toward the center of the triangular cross-section and having a conical shape in order to depth is deep, the bottom flange is connected to the center of a triangular cross-section and semi closer and away response with a semi-cylindrical, semi-triangular portions and connected to the end hanger comprising fixing step; (d) belonging to, edge formed hook portions, such that the bellows assembling flange across the coupling groove of the flange hook; (e) across the coupling groove of the welding bellows flange hook portions; and (f) compressing the bellows design pin including, belonging to, having bellows assembly manufacturing method. Stress (MPa) Fatigue life (Times) (1) 1327. 74 6842 (2) 1258. 93 8822 (3) 1220. 76 10246