TILTING BED

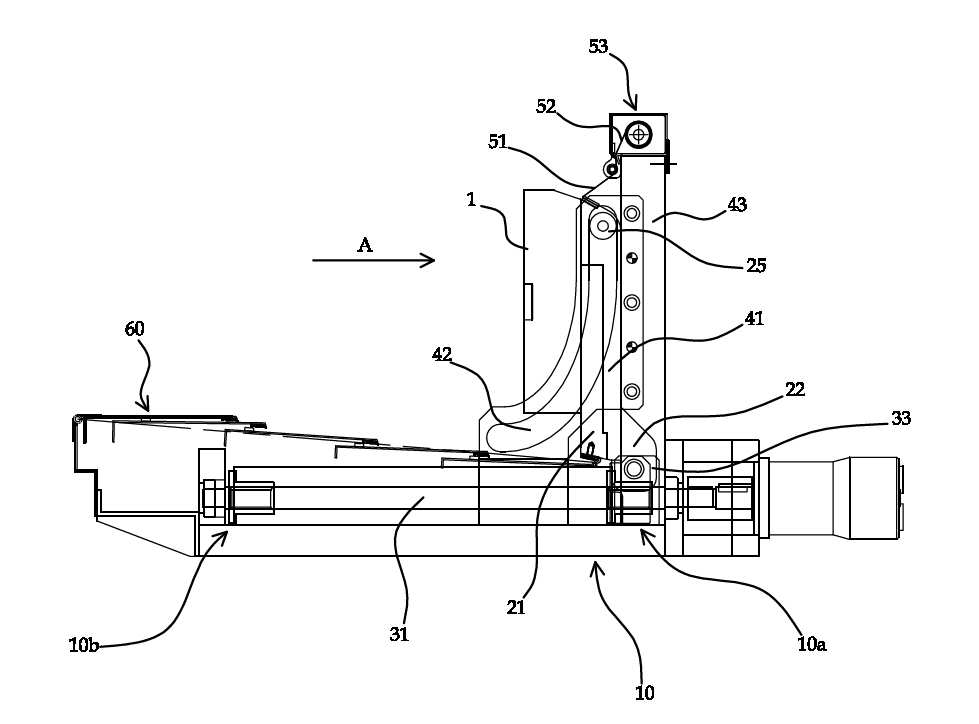

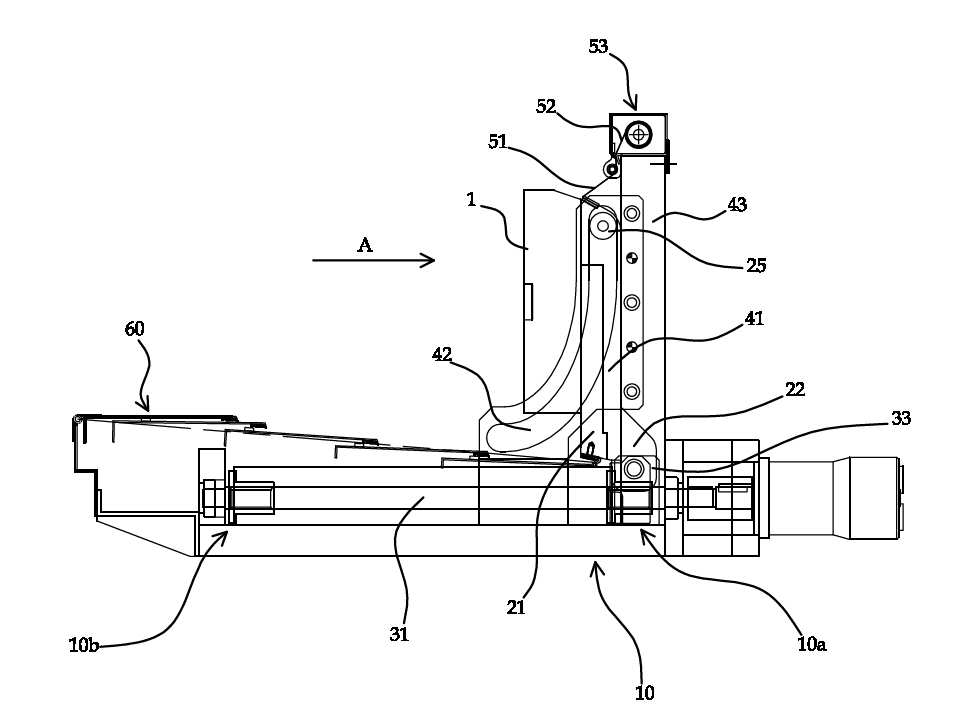

The present invention refers to tilting bed wherein, said angle of the screw is provided mounted crushing division angle can be adjusted variously tilting bed are disclosed. The crushing tool mounted to the workpiece to machine a workpiece at various angle division can be processed in each drawing to help the device disclosed. The rotation angle of the accurate regulation of the call is registered patent number 10 - 1279699 call and registration patent number 10 - 1448378 rotating dividing clay is disclosure in the nanometer range. Pressure is mounted to the bed structure such as clay or machine tool is publicized patent 2003 - 0077236 call makes workpiece. When the bed structure of the existing method clay which is mounted such that the fixed crushing didn't adjust the angle of the screw. The workpiece holding various clay is returned to a predetermined angle workpieces can be processed in workpiece whose number point at the door that has been defined. The present invention refers to said door number micrographs and hydrogen gas. The present invention refers to an angle of tilting can be adjusted variously mounted crushing clay bed intended for the number. The present invention according to tilting bed base frame, support means, moving unit for moving the, guide means. With said support means includes a testing station, said base frame slideably mounted to a substrate. Said support coarse clay encoded. Movement means comprises said one end of said base frame to move horizontally along said support, said one end of the rotating shaft support movably mounted to the substrate. Said guide means having a guide frame, said base mounted to the frame body. Said guide frame is said stand rotates about said one end of said support said stand once the move horizontally guiding substrate. In addition, in charging said bed, preferably further including cover piece number 1 and number 2 cover part. In said one side of said cover portion covers said number 1 has fallen into the clay from the chip in addition to protecting the base frame to support said support to said one side of the base frame in addition to the expansive movement of support covering disclosed. Said cover portion is located in said other side of said number 2 has fallen into the clay from the chip can protect the base frame to support said support piece to said other side of the expansive movement of the base frame support piece located covering disclosed. In addition, in charging said bed, said support strap is preferably further including, said microwave guide frame is formed, preferably diametrically attached to said base frame is composed of a constant distance. The other end of said roller is formed inside said support to slide along the guide frame said support said's substrate. Said guide groove can pivot about said one end of said stand to said roller is inserted in a vertical is first guided. In addition, in charging said bed, said moving block having a shielding means include a screw preferably. An air cylinder without said support at one end of said screw toward said base frame to which is rotatably mounted to a substrate. Said one end of said support engaged to the moving block can pivot, said screw bar can slide back and forth along said screw upon rotation of the display device is coupled to the inner side. In addition, in charging said bed, said guide means comprises a retainer further including preferably, rolling or preferably to a side of the cover the cover portion is number 1. Said support comprises said guide frame to said support base mounted to the frame body. Said one end of said one side of said support coupled to an end of a cover covering the base frame support in addition to the flexible disclosed. Said one end of said roll portion movement of said support along said support one end of the fitting cover his feeling can be cleared. According to the present invention, equipped with a tilting bed clay clay can control at various angles. Thus angles can be machining gear working to place the workpiece plane of vehicle from the outside. In addition, according to the present invention, number 1 and number 2 number cover piece including the tilting bed cover, in base frame has fallen into the clay from the chip can be protecting. Thus chip can be prevented from falling into the base frame work on the opposite workpiece song even be tilting bed operation. In the embodiment of the present invention according to tilting bed also Figure 1 shows a front, Also in the embodiment shown in Figure 2 shows a operation of also 1, Also in the embodiment shown in Figure 3 shows a plane of also 1, In the embodiment of the present invention according to 1 to 3 also with reference to the tilting bed also described therein. The present invention according to tilting bed base frame (10) and, a support member (20) and, means (30) and, guide means (40) and the cover part number 1 (50) and number 2 cover portion (60) having a predetermined wavelength. A support member (20) is jig (1) wherein the via, base frame (10) slideably mounted to a substrate. To this end a support member (20) includes a testing station (21) rollers (25) contact with each other. Support (21) is at the top with a jig (1) becomes coarse. Roller (25) includes a support (21) other end of (24) on opposite sides of the fitting. Means (30) includes a testing station (21) one end of (22) base frame (10) to move horizontally along could be bonded each other. To this end means (30) by the screw bar (31) a mobile block (33) with each other. Screw bar (31) includes a support (21) one end of (22) in the other end (24) toward the base frame (10) which is rotatably mounted to a substrate. The moving block (33) includes a testing station (21) one end of (22) engaged to the rotating shaft, screw bar (31) moves the screw bar (31) can slide back and forth along coupled to be screwed. Thus screw bar (31) moves the moving block (33) by support (21) one end of (22) includes a base frame (10) along a front each other. Guide means (40) includes a base frame (10) mounted to the support (21) is hanger is move horizontally (21) is retained in the (22) rotates about support (21) of the other end (24) for guiding could be bonded each other. To this end guide means (40) includes guide frame (41) support with (43) contact with each other. The guide frame (41) of the roller (25) is inserted in a support (21) is retained in the (22) can pivot about vertical is first heated to support (21) other end of (24) guiding the guide groove (42) is formed, diametrically spaced apart is composed of base frame (10) are mounted. Support (43) guide frame (41) base in a support frame (10) are mounted. Number 1 cover part (50) includes a jig (1) fall in from the chip support (21) in addition to one side of the base frame (10a) protection could be bonded each other. I.e., number 1 cover part (50) includes a jig (1) in support (21) other end of (24) direction from the chip has fallen into the base frame (10) to protect the substrate. Jig (1) physical work after the workpieces in the chip drops onto a substrate. Chips fall base frame (10) spaced apart basic frame (10) caught cold and support (21) can be attributable to make it difficult to prevent the movement of are disclosed. To this end cover part number 1 (50) includes a support (21) the expansive movement of a space (21) in addition to one side of the base frame (10a) covering the cover (51) on the roll portion (53) contact with each other. Cover (51) has one end support (21) other end of (24) coupled to, support (21) in addition to one side of the base frame (10a) formed elastically flexible covering material. Roll unit (53) comprises a support (21) according to movement of a cover (51) other end of (52) can be cleared his winding support (43) at one end of the fitting. Thus support (21) base frame (10) are horizontal and when roll portion (53) covering in (51) other end of (52) is it comes to release, cover (51) unfolded of vehicle from the outside. Then jig (1) which are connected with each chip even cover (51) is support (21) in addition to one side of the base frame (10a) to cover base frame (10) against the threat of substrate. The cover part number 2 (60) includes a jig (1) fall in from the chip support (21) located on the other side piece base frame (10b) protection could be bonded each other. I.e., cover part number 2 (60) includes a jig (1) in support (21) one end of (22) direction from the chip has fallen into the base frame (10) to protect the substrate. Chip base frame (10) and the inclinations chip base frame (10) caught cold and support (21) move's oldest impeded. To this end cover part number 2 (60) includes a support (21) the expansive movement of a space (21) located on the other side of the base frame piece (10b) is formed as a portion of telescope cylinder multi-stage can be a length thereof. Number 2 cover part (60) is made is once (21) one end (22) thereof and coupled to the base frame (10) coupled to. Thus cover part number 2 (60) includes a support (21) base frame (10) are horizontal and retracts when folded multivalent support (21) is provided with guide means (40) toward the arrow A direction positioned in the elongated substrate. Then number 2 cover part (60) is support (21) located on the other side piece base frame (10) to cover the base frame (10) against the threat of substrate. The, number 1 rail extended unfolded cover part (50) contracts cover (51) other end of (52) roll unit (53) wound to be coated. In the case of a in the embodiment, support (21) to jig (1) is secured. The motor or the like screw bar (31) rotating a moving block (33) the guide means (40) moves to a direction toward the arrow A. Then support (21) other end of (24) the guide groove (42) slide along the space (21) is retained in the (22) rotating centering substrate. Thus jig (1) can be accommodated in a desired angle. I.e., jig (1) physically main tool teeth opening (1) space in tilting process from a desired angle. The jig (1) after the workpieces during operation even number 1 from physical chip cover part (50) is support (21) in addition to one side of the base frame (10a) for protecting, number 2 cover part (60) is support (21) located on the other side piece base frame (10b) base frame protecting the chip (10) can be prevent from falling. Thus even if the operation of the opposite workpiece working operations can be combined use in a bed in the embodiment. While, if the crushing of the existing method for towing equipped with a bed structure didn't adjust the angle of the fixing screw. Thus returned to workpieces in a variety of angles for processing a main tool is defined number that has been point at the door. However the in the embodiment the jig (1) part includes adjusting can be can be range of machining work. 1: Jig 10: base frame 20: Support means 21: support 22:24 Once: other end 25: Roller 30: means 31: Screw bar 33: moving block 40: Guide means 41: guide frame 42: Guide groove 43: support 50: Number 1 cover part 51: cover 53: Roll part 60: cover part number 2 The present invention relates to a tilting bed and, more particularly, to a tilting bed in which an angle dividing jig is mounted and the angle of the jig can be variously adjusted. The tilting bed according to the present invention includes a base frame, supporting means, moving means, and guide means. The supporting means has a pedestal, and is slidably mounted on the base frame. A jig is mounted on the pedestal. The moving means moves one end of the pedestal horizontally along the base frame, and one end of the pedestal is mounted so as to be rotatable. The guide means includes a guide frame and is mounted on the base frame. When the pedestal moves horizontally, the guide frame guides the other end of the pedestal so that the pedestal rotates about the one end. According to the present invention, the tilting bed equipped with the jig can adjust the jig at various angles. Accordingly, the machining range of the workpiece can be expanded because the workpiece can be positioned at various angles. Further, according to the present invention, since the tilting bed including the first cover portion and the second cover portion is provided, the base frame can be protected from chips falling from the jig. Therefore, it is possible to prevent the chip from falling on the base frame, and thus the operation of the tilting bed can be smoothly performed even during the machining work of the workpiece. COPYRIGHT KIPO 2018 Base frame, supporting stand having coarse clay, are slideably mounted support means for said base frame, said base frame to move horizontally along one end of said support, said support mounted moving unit for moving the one end of the rotating shaft, said stand rotates about said one end of said stand said once the move horizontally guide frame support, said guide frame to said support base frame made of guide means mounted, in said one side of said support base frame has fallen into the clay from the chip in addition to one end of said one side of said support coupled to an end of a support to protect the base frame in addition to flexible cover covering, movement of said one end of said support along said support mounted on one end of the winding can be cleared his cover roll of the binary number 1 and cover, said other side of said support piece has fallen into the clay from the chip located in the base frame to support said protecting the other side of said support base frame located by the expansive movement of the piece number 2 covering the cover piece including a tilting bed characterized. According to Claim 1, said support means support said other end of said body frame is formed inside said support to slide along the roller's also having, said guide frame is said stand can pivot about said one end of said roller is inserted in a microwave oven to vertical is first guided formed, characterized in that said base frame at a certain distance from the paired diametrically attached to a tilting bed. According to Claim 2, said movement means comprises said support at one end of which is rotatably mounted to the base frame toward said screw bar, one end of the rotating shaft engaged to said support, said screw bar can slide back and forth along said screw upon rotation of the display device is provided on the inner side of a tilting bed characterized in combined mobile inner. Back number Back number