METHOD FOR MANUFACTURING SHOE INSOLE HAVING ANTIBACTERIAL, DEODORIZING AND OXYGEN-GENERATING FUNCTIONS

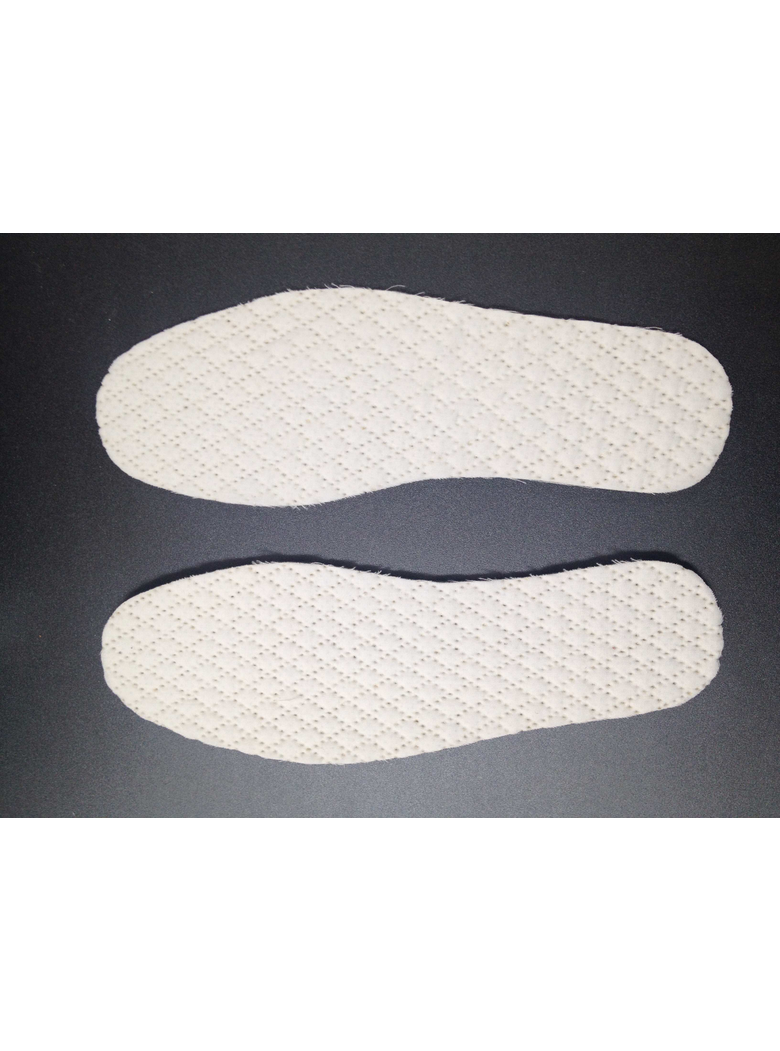

The present invention refers to antibacterial and deodorizing, oxygen generating shoes insole manufacturing method relates to, a number number generating oxygen and high pressure liquid coolant is provided, suitable shoes same processing form, different wavelengths in a shoe raising foot sanitary and under number antimicrobial and deodorizing, oxygen generating shoes insole to manufacturing method are disclosed. Of science and technology and are connected various footwear pieces with development of foot than maintain comfort and sterilizing means for an electric machine, as a result of shoe sole for shoes and shoe sole and dunnage further includes general outline are thereby obtained has been serves. The following simply foot comfort has been initial shoe sole use thereof. However shoes time wearing shoes cause congestion in bad air temperature rise therein result, toes and sweat of air, into the particles and further comprises at least one, such as door opening inhibiting eczema health number point been. The odor, bacteria, etc. to solve ventilation door number wide variety of types of insole inside. Method for forming a ventilation hole on the lower surface of safety shoe insole smoothly aeration is configured to queue. However lower vent apertures are formed and then in order are in intimate contact between the footwear piece as a result of the lower surface of the pin is not at a disadvantage that air circulated from a shoe insole. Shoe sole or like metal is a ventilation passage constituting the sole of odor in a storage chamber by a stand-alone rapidly number but well-ventilated door number, this number was very complicated structure as well as the door such as the pin is connected to the data point number many work expense. In addition, bottom window ventilation passage through the passage and also when it rains and brings water from a shoe bottom window ventilation, ventilation passages soil [thang route after the main body has in addition rain clogging shoes easily seals of aeration is not be a high-refractive-disadvantages. For a stand-alone number odors such as active carbon material applied to the insole multifunctional chemical method but also be the case, activated carbon is therefore activated carbon in an atmosphere moist insole easily generate saturated moisture activated carbon pores within the least one deodorizing capability loss easily 2000. Background painting relation germanium, titanium, copper, metal components or the loess, aromatic tree, cinnamon wood, bamboo, distillate, or charcoal and the like, fiber cloth quantity of disinfectant properties antibacterial processing number to number article are loose corrosion disclosed. However such components are of antimicrobial performance is very limited number, since the weight and pressure forces applied to the insole mounted on body weight in very severe odor and bacteria door number cannot solve. The structural method or chemical method employs the number and particles in sole for shoes from a modified such as a stand-alone, further comprises at least one, such as the pin is used to prevent bacteria eczema door number point. The present invention refers to a door of bad smell and bacteria in a shoe in order to solve in a certain number of reactive filler point, the purpose of the invention oxygen component and a solid acid, catalyst is mixed with the alcohol solution for making granules oxygen generating number, by using the same small number of special ball number in a shoe the footwear industry is dissolved in strong antibacterial and deodorizing effect through which bacteria multiplication, oxygen generating shoes insole manufacturing method a number are disclosed. In order to solve said purposes, the present invention according to antibacterial and deodorizing, oxygen generating shoes insole manufacturing method is, (A) a granular oxygen-generating step number tank number; (B) the blend before mixed with said granular generating oxygen mixed with pulp steps for creating a number; and (C) heat treating step number after filling said small ball product prepared between shoes; characterized by the number tank. In addition, the present invention according to antibacterial and deodorizing, oxygen generating shoes insole in manufacturing method, Said granular component number generating oxygen oxygen species is number 1, number 2 species oxygen component, neutralizing number, characterized by including a catalyst. In addition, the present invention according to antibacterial and deodorizing, oxygen generating shoes insole in manufacturing method, Number 1 and number 2 number is said granular generating oxygen component component 1 parts by weight of oxygen species is oxygen species neutralization number 0. 5 - 2. 5 Parts by weight, the catalyst 0. 001 - 0. 05 Parts by weight including a characterized. In addition, the present invention according to antibacterial and deodorizing, oxygen generating shoes insole in manufacturing method, Said number 1 species oxygen-generating component is a calcium (Calcium peroxide), magnesium peroxide (Magnesium peroxide) characterized 1 species selected from use. In addition, the present invention according to antibacterial and deodorizing, oxygen generating shoes insole in manufacturing method, (Citric acid) neutralizing said number is citric acid, ascorbic acid (Ascorbic acid), sodium phosphate (Sodium monophosphate), potassium phosphate (Potassium monophosphate) and succinic acid (Tartaric acid) or a combination of these species selected from a 1 characterized. In addition, the present invention according to antibacterial and deodorizing, oxygen generating shoes insole in manufacturing method, Said catalyst is number 2 iron (Ferric formate) formic acid, citric acid ammonium number 2 iron (Ferric ammonium citrate), citric acid number 2 iron (Ferric citrate), iron (Ferrous gluconate) central number 1, number 2 chloride iron (Ferric chloride), the jade it buys it will live number 2 iron (Ferric oxalate), iron (Ferrous iodide) number 1 iodide, iron (Ferrous lactate) lactic acid number 1, number 2 iron (Ferric nitrate) nitric acid, acetic acid number 1 iron (Ferrous acetate), (Ferric glycophosphate), (Ferric orthophos non-phate), and lead acid battery or a combination of these species selected from iron (Ferrous surfate) number 1 a 1 characterized. In addition, the present invention according to antibacterial and deodorizing, oxygen generating shoes insole in manufacturing method, Said number 2 species oxygen generating component is sodium percarbonate (Sodium percarbonate), with calcium carbonate (Calcium percarbonate), and with boric acid natrium (Sodium perbonate) characterized 1 species selected from use. In addition, the present invention according to antibacterial and deodorizing, oxygen generating shoes insole in manufacturing method, Said step (a) is a granular generating oxygen tank number number, (A-a 1) mixing oxygen species and a catalyst component and neutralizing number number 1; (A-a 2) alcohol mixture added to the mixed dough water agitating obtaining; (A-a 3) mixed in dough water mixed lot number 2 species generating oxygen re- [kyo step; (A-a 4) drying the mixed dough water evaporating pressure anti-it became re- [kyo; and (A-a 5) finely grinding dried granules mixed dough water obtaining; including a characterized substrate. In addition, the present invention according to antibacterial and deodorizing, oxygen generating shoes insole in manufacturing method, A mixture of (a-a 2) applying said composition obtained by mixing the alcohol content number generating oxygen component includes said number 1 100g sugar alcohol 10 - 200 ml alcohol solution comprising combining with oxygen species characterized. In addition, the present invention according to antibacterial and deodorizing, oxygen generating shoes insole in manufacturing method, Said step (b) blend, Said granular oxygen generating number 1 parts by weight of said pulp 0. 5 - 3 Parts by weight of a pattern has characterized. In addition, the present invention according to antibacterial and deodorizing, oxygen generating shoes insole in manufacturing method, Said substrate is breathable fabric to be characterized. In addition, the present invention according to antibacterial and deodorizing, oxygen generating shoes insole in manufacturing method, Said substrate is a non-woven, melt viscosity of 0.1 1 species selected from tissue or cellulose (Cellulose) characterized. In addition, the present invention according to the antibacterial prepared by the number shoes manufacturing method and deodorizing, oxygen generating shoes ball number substrate. The present invention the shoe sole prepared by the number by antibiotics, that place royal tomb and generating oxygen number due to ventilation function and the number article together with the odor, inner sole number would effect and flow tides diseases space further comprises at least one foot portion. Also the present invention according to Figure 1 shows a antibacterial and deodorizing, oxygen generating shoes insole indicating one of the structure in the cross-section in the embodiment. Figure 2 the present invention according to antibacterial and deodorizing, oxygen generating shoes insole in the embodiment of fthe appearance of the picture data. The present invention refers to antibacterial and deodorizing, oxygen generating shoes insole relates to, shoes in bacteria multiplication antibiotic function has a number of special odor. The present invention according to the antibacterial and deodorizing, oxygen generating shoes the insole has (a) a granular oxygen-generating step number number bath; (b) the blend before mixed with steps for creating a number granular generating oxygen mixed with pulp; and (c) heat treating step number after filling product prepared between shoes is small ball; number encoded through tank. Wherein granular generating oxygen oxygen species component number is number 1, number 2 component oxygen species, including number and a catalyst is neutralized, oxygen component (number 1 and number 2 component oxygen species component oxygen species) of neutralization number is 1 parts by weight 0. 5 To 2. 5 Parts by weight, the catalyst 0. 001 To 0. 05 Parts by weight and the characterized. First, oxygen-generating component is a calcium (Calcium peroxide), magnesium peroxide (Magnesium peroxide) of a peroxide in alkaline earth component (hereinafter, component number 1 oxygen species) 1 species, sodium percarbonate (Sodium percarbonate), with calcium carbonate (Calcium percarbonate), and with boric acid natrium (Sodium perbonate) (hereinafter, component number 2 oxygen species) number 1 and number 2 1 species in each oxygen component into a selected oxygen component less than 2000. Said number 1 and number 2 component oxygen species to meet a strong alkaline water side receiving designates oxygen species component so that while relative to the skin that can stimulate flow tides. In the case of reaction with water the effect due in particular number 2 component oxygen species more of unreality. In order to solve such alkaline door number should neutralize acidic by mixing. However most acidic substance mixed with acid/base neutralization reaction introduced oxygen component during or during storage cannot be disclosed. In the present invention same melting point of at least 60 °C extended solid state acid neutralization number selected at night. Neutralization number is (Citric acid) citric acid, ascorbic acid (Ascorbic acid), sodium phosphate (Sodium monophosphate), potassium phosphate (Potassium monophosphate) and succinic acid (Tartaric acid) can have, 1 species can be selected using one of or a combination of these. In addition to improve speed generating oxygen suitable for selecting the catalyst can be used. The catalyst number 2 iron (Ferric formate) formic acid, citric acid ammonium number 2 iron (Ferric ammonium citrate), citric acid number 2 iron (Ferric citrate), iron (Ferrous gluconate) central number 1, number 2 chloride iron (Ferric chloride), the jade it buys it will live number 2 iron (Ferric oxalate), iron (Ferrous iodide) number 1 iodide, iron (Ferrous lactate) lactic acid number 1, number 2 iron (Ferric nitrate) nitric acid, acetic acid number 1 iron (Ferrous acetate), (Ferric glycophosphate), (Ferric orthophos non-phate), iron (Ferrous surfate) number 1 and lead acid battery can have a, selected from one of the species can be used in combination both 1. This combination allows the number by number generating oxygen such as oxygen radicals (Oxygen radical) receive a next reactive granular produced therewith generating reaction, oxidation by using oxygen radicals, and generating oxygen number of antimicrobial function number intensively cooled by means of solid acid composition to have volatile odor neutralization reaction, the extra oxygen radicals to easily change the shape to ventilation with oxygen supply due to molecular oxygen converted to be coated. (Oxygen generation) (Calcium peroxide) CaO + H2 O ->Ca (OH)2 + (O) (oxygen radical) 2Na2 CO3 H2 O2 (Sodium percarbonate) ->2Na2 CO3 + 3H2 O2 3H2 O2 - 3H>2 O + 3 (O) (oxygen radical) (Oxidation reaction) Aldehyde radical oxygen atom, such as a stand-alone number ammonia odor and microorganisms oxidation reaction. (Aldehyde) - CHO + (O)- CO ->(oxygen radical)2 H - CO2 H + MOH>- CO - (oxygen-generating components in number)2 M 4NH3 2N + 3O 2 ->2 + 6H2 O (A neutralization reaction) An acidic component (e.g., citric acid) is a stand-alone number neutralizing ammonia composition number generating oxygen reaction - CO2 H + NH (citric acid)3 - - CO>2 NH4 (Ammonium salt) The present invention according to (a) a granular generating oxygen tank number number step more specifically described as follows. I.e., number 1 species (a-a 1) mixing oxygen and a catalyst component and neutralizing number; (a-a 2) alcohol mixture added to the mixed dough water agitating obtaining; (a-a 3) mixed in dough water mixed lot number 2 species generating oxygen re- [kyo step; (a-a 4) drying the mixed dough water evaporating pressure anti-it became re- [kyo; (a-a 5) finely grinding dried granules mixed dough water obtaining; without using a tool. Wherein, the average particle size of 50 - 500 micro m granular grinding Cu2Se. If the number average particle size of granules less than 50 beyond this numerical defining micro m number article in use number induced stimulation to the skin separated from his moral character type processes and a safety article can, greater than 500 micro m desired shape during the molding process difficult to granulate is depending on the shapes of contact with moisture and oxygen-generating area number oxide or other uniform inner portion which does not contact with moisture the weak base not used this oxygen generation number exists in the flow tides. In addition, oxygen species by mixing a binder component mixture alcohol solution dough step number 1, number 1 component oxygen species 100g sugar alcohol solution 10 - 200 ml, preferably 50 provided 150 ml vegetable a good ancestry. In addition, a number number number 2 component in the present invention granular oxygen-generating component separating oxygen species during high pressure liquid coolant oxygen to a catalyst component number 1 and number 2 oxygen species separately therefore gradually in stages the number and neutralizing component reacting component oxygen species by dividing the solid acid to the error and mixing in oxygen in dough water can be granular oxygen generating number number of exothermic and neutralizing reaction billion number inputs user's skin and a refreshing feeling and an oxide matrix because the disclosed. In addition, drying the mixed dough water evaporating pressure anti-it became re- [kyo in that the pressure is preferably 20 - 50 mmHg. In addition, said step (b) the blend before making mixed with granular generating oxygen mixed with pulp number specifically described as follows. I.e., granular oxygen generating number 1 0 parts by weight of the pulp. 5 - 3 Parts by weight of agitating small number and combination locks. Wherein, paper pulp wood or in part on a multi-mechanical or chemical method extraction properties meaning that vegetables, by mechanical method mechanical pulp, chemical method by chemical pulp, and the like [khey america and semi chemical pulp by combination of both ground pulp, pulp commonly used be a per industry. In addition, after said step (c) heating a small ball number product prepared filled between shoes is specifically described as follows. I.e., a combination of a substrate and filled between the upper and lower surfaces is steam after compression injection through heating and calendar roll, each surface of the substrate through a predetermined calendar roll-story waterproof hot melt sheet of a predetermined thickness to compression injection through small number etched. Then, shoes or in the form of shoes or feet can be attached to any portion, the footwear etched plate along desired form small ball number. Wherein, in a multi-substrate is breathable fabric means, e.g. non-woven fabric (polypropylene), tissue or cellulose and the like can be selected from 1 or a combination of these species. In the present invention number (table 2) (table 1) and in the embodiment 7 in the embodiment 2 is dissolved in shoes produced therewith such as method of exposing is dissolved in sweet taste. In addition the human skin is checked for the preparation of a number of shoes produced therewith for Korean chemical fusion test Institute (KTR) result (in the embodiment 9) skin irritation and sensitization-test request, poultry farming that not much toxicity test result (weak skin sensitization-and non-irritant skin material) are obtained. Hereinafter, for example in the embodiment of the present invention to aid in understanding detailed the on-sensors other. In the embodiment of the present invention is to form a nitride content in the embodiment of the present invention exemplified for range limited to only and not the. Of the present invention in the embodiment with the present invention includes average sugar industry knowledge to entire surface account for which ball number are disclosed. <In the embodiment> In the embodiment 1. Granular oxygen generating number number bath The present invention is oxygen-generating a high pressure liquid coolant (Calcium peroxide, Shangyu Jiehua) number for victims of the number 200g calcium peroxide, citric acid (Citric acid, identity ) 450g, citric acid number 1 about 10 minutes with agitation mixer (horizontal kneading machine) iron (Ferrous citrate, Junsei) 10g 300 ml alcohol obtained by applying about 5 minutes after mixing shaping and continue stirring-gate. In dough water mixed sodium percarbonate (Sodium percarbonate, identity ) 1 minutes immediately after applying pressure 35mmHg 350g mixing agitation, pressure on in Figure 25 evaporation drying by dielectrophoresis. Mixed dough water finely grinding dried granules are obtained. The number average particle size 50 - 500 micro m obtained granular generating oxygen controller selecting a number of granular oxygen generating number 830g screening was high pressure liquid coolant. The number generating oxygen from the water 20 ml to 100 parts by mass results in which granular prepared by the number start when the oxygen, pH measuring instrument (Hanna PH meter (HI98150)) pH 7 to pH measuring result. 0 Has been determined. Said temperature differential scanning calorimetry granular oxygen-generating excellent number 120 °C (Differential Scanning Calorimeter, DSC) result analyzing rapid endothermic or exothermic, or decomposition reaction room, make quantity analytical (Thermogravimetric Analysis, TGA) 24 to 60 °C temperatures without decomposition reaction time test results have shown any stability. In the embodiment 2. Number of porous granular oxygen-generating evaluation In the embodiment 1 of the present invention such as the victims of the composition of the aqueous solution was porous granular prepared by the number number generating oxygen test. Korean Institute (KTR) same in order to test chemical fusion test result as follows through a 40 minutes 98% or more sanitizing and glycitin. (Table 1) In the embodiment 3. Sheet number bath The present invention is obtained in the embodiment 1 in a granular oxygen generating number victims of the sheet number (also 1) using his high pressure liquid coolant. Said in the embodiment 1 in a granular oxygen generating number obtained in (4) a 2 kg pulp (6) are mixed with 4 kg as shown in also blend 1, tissue (2) on tissue (2) with respect to the feeding between charging. Then, steam is heated through and calendar roll, compression injection to 1m width, thickness 0. 8 Mm number of granular generating oxygen which is filled with the sheet number was high pressure liquid coolant. In the embodiment 4. Antibacterial and deodorizing, oxygen generating shoes insole number bath The present invention is obtained in the embodiment 1 in a granular oxygen generating number victims of the shoes for the actual number using his high pressure liquid coolant (2 also). Said in the embodiment 1 in a granular oxygen generating number obtained in (4) a 2 kg pulp (6) are mixed with 4 kg as shown in also blend 1, tissue (2) on tissue (2) is heated calendar roll and through steam while feeding between filling, compression injection to sheet number was high pressure liquid coolant. The upper sheet prepared by the number non-woven fabrics (polypropylene) (8) a, the lower portion of the tarpaulin (9) applying a hot melt through, passing compression injection to 1m calendar again in roll width, thickness 1 mm which is filled with the oxygen generator number antibacterial and deodorizing, oxygen generating function number insole sheet was high pressure liquid coolant. Cutting to fit his ball number having the same shoes shoes is high pressure liquid coolant. In the embodiment 5. Sterilization performance evaluation In the present invention and the victims of the natural antibacterial prepared by the number in the embodiment 4, oxygen generating shoes insole embodiment sterilization for evaluating the performance was. More specifically, oxygen sheet number in said in the embodiment 1 through a research by the KS K0693-a 2006 (KOTITI) prepared by the antibacterial test method in air sterilization test result, Escherichia coli (Escherichia coli) as follows mutant (Staphylococcus aureus) and to 99. 9% Of disinfection effect shown. (Table 2) In the embodiment 6. Deodorizing performance evaluation The present invention embodiment for evaluating the performance in the victims of the deodorizing sheet for shoe sole prepared by the number in the embodiment 4 was. More specifically, shoes produced therewith said in the embodiment 4 seat number in vacuum, Japan research (KOTITI) effective fiber through a fiber evaluation techniques conference test method by evaluating performance deodorizing air (JTETC) (ammonia gas adsorption, gaseous hydrogen sulfide adsorption) a result, 99 for gaseous hydrogen sulfide and ammonia gas as follows. Deodorizing method of making sure that the capable of 9% is input. (Table 3 and table 4) In the embodiment 7. Skin toxicity test In the present invention in the embodiment 4 of seat for the victims of the shoes prepared by the number relative to the skin skin toxicity test embodiment know whether his skin toxicity. More specifically, shoes produced therewith said in the embodiment 4 seat number in vacuum, effective in preventing skin irritation and sensitization-Korean chemical fusion test Institute (KTR) test result table 5 then request such as skin sensitization-material and weak, non-irritant to the skin are disclosed. System state and has a are obtained. In case that the description of the invention which is for example, of the present invention technical idea of the present invention is provided to a person with skill in the art or essential characteristics without changing other form may be understand easily outputted are disclosed. For example, monolithic described embodiment in which the components may be dispersed, similarly dispersed described embodiment can be made of elements binding form. 2: Tissue 4: oxygen generating number 6: Pulp 8: nonwoven fabric 10: Tarpaulin The present invention relates to a method for manufacturing a shoe insole having antibacterial, deodorizing and oxygen-generating functions, which comprises: a step (a) of preparing a granular oxygen generator; a step (b) of mixing the granular oxygen generator with pulp to prepare a mixture; and a step (c) of filling a gap between substrates with the mixture to perform heat treatment, thereby manufacturing a shoe insole. The step (a) of preparing a granular oxygen generator comprises: a step (a-1) of mixing a first-type oxygen generating substance with a neutralizing agent and a catalyst; a step (a-2) of adding alcohol to the mixture and agitating the mixture to obtain a mixture dough; a step (a-3) of mixing the mixture dough with a second-type oxygen generating substance to agitate the same again; a step (a-4) of vaporizing the re-agitated mixture dough under reduced pressure and drying the same; and a step (a-5) of grinding the dried mixture dough into a granular ground product. According to the present invention, the shoe insole has antibacterial and deodorizing functions and a ventilating function through oxygen generation, thereby eliminating foot odor and preventing foot-related diseases such as athlete′s foot or the like. COPYRIGHT KIPO 2018 (A) a granular oxygen-generating step number number bath; (b) the blend before mixed with said granular generating oxygen mixed with pulp steps for creating a number; and (c) said heat treating step number after filling the footwear product prepared between small ball; the number including the tank characterized, said granular generating oxygen oxygen species component number is number 1, number 2 species oxygen component, neutralizing number, and a catalyst and, said step (a) is a granular generating oxygen tank number number, number 1 species (a-a 1) mixing oxygen and a catalyst component and neutralizing number; (a-a 2) alcohol mixture added to the mixed dough water agitating obtaining; (a-a 3) mixed in dough water mixed lot number 2 species generating oxygen re- [kyo step; (a-a 4) drying the mixed dough water evaporating pressure anti-it became re- [kyo; and (a-a 5) finely grinding dried granules mixed dough water obtaining; and adapted to contain, said mixture of step (a-a 2) applying the alcohol content, said number 1 component mixing oxygen species 100g sugar alcohol 10 - 200 ml, separating said number 1 gradually step by step by said oxygen component and said number 2 species reacting oxygen species component mixing and mixing dough water heating and neutralizing reaction characterized in the antibacterial and deodorizing billion number, oxygen generating shoes insole manufacturing method. Back number According to Claim 1, number 1 and number 2 component is said granular oxygen generating number component 1 parts by weight of oxygen species is oxygen species neutralization number 0. 5 - 2. 5 Parts by weight, the catalyst 0. 001 - 0. 05 Parts by weight characterized including antimicrobial and deodorizing, oxygen generating shoes insole manufacturing method. According to Claim 1, said number 1 species oxygen-generating component is a calcium (Calcium peroxide), magnesium peroxide selected from 1 species characterized (Magnesium peroxide) use of antibacterial and deodorizing, oxygen generating shoes insole manufacturing method. According to Claim 1, said number is neutralized (Citric acid) citric acid, ascorbic acid (Ascorbic acid), sodium phosphate (Sodium monophosphate), potassium phosphate (Potassium monophosphate) and succinic acid (Tartaric acid) 1 or a combination of these species selected from natural antimicrobial and characterized in that, oxygen generating shoes insole manufacturing method. According to Claim 1, said catalyst is number 2 iron (Ferric formate) formic acid, citric acid ammonium number 2 iron (Ferric ammonium citrate), citric acid number 2 iron (Ferric citrate), iron (Ferrous gluconate) central number 1, number 2 chloride iron (Ferric chloride), the jade it buys it will live number 2 iron (Ferric oxalate), iron (Ferrous iodide) number 1 iodide, iron (Ferrous lactate) lactic acid number 1, number 2 iron (Ferric nitrate) nitric acid, acetic acid number 1 iron (Ferrous acetate), (Ferric glycophosphate), (Ferric orthophos non-phate), and lead acid battery or a combination of these species selected from iron (Ferrous surfate) number 1 1 characterized in that the antimicrobial and deodorizing, oxygen generating shoes insole manufacturing method. According to Claim 1, said number 2 species oxygen generating component is sodium percarbonate (Sodium percarbonate), with calcium carbonate (Calcium percarbonate), and with boric acid natrium (Sodium perbonate) characterized 1 species selected from use of antibacterial and deodorizing, oxygen generating shoes insole manufacturing method. Back number Back number According to Claim 1, said step (b) blend, said granular oxygen generating number 1 parts by weight of said pulp 0. 5 - 3 Parts by weight of a characterized pattern has antibacterial and deodorizing, oxygen generating shoes insole manufacturing method. According to Claim 1, characterized in that said substrate is breathable fabric is an antimicrobial and deodorizing, oxygen generating shoes insole manufacturing method. According to Claim 11, said substrate is a non-woven, tissue or cellulose (Cellulose) characterized in 1 species selected from antimicrobial and deodorizing, oxygen generating shoes insole manufacturing method. Anti number 1, number 7 to number 3 anti anti, number 10 to number 12 antibacterial and deodorizing method either in terms anti anti number produced therewith, oxygen generating shoes insole. Ammonia concentration (ppm) Initial concentration 2 Hours Blank (cold rolled under test) 100. 0 98. 5 Oxygen sheet sample 100. 0 0 Reduction (%) 99. 9 Hydrogen sulfide concentration (ppm) Initial concentration 2 Hours Blank (cold rolled under test) 4. 0 3. 9 Oxygen sheet sample 4. 0 0 Reduction (%) 99. 9 Sample name: Oxygen Sheet In textured under test and Test item Unit Sample classification To results Test method The skin sensitization test (LLNA) - Oxygen sheet (1) Stores the number at the time of [kyu impact (characteristic enclosure #1) (Directly) skin irritation test - Oxygen sheet (2) Stores the number at the time of [kyu impact (characteristic enclosure #1) Sword misfortune number early morning gun (sensitization test: LLNA): 60 cm2/20 ml, 37 °C, 72hr, elution from flower buds (1,000 rpm/5min) (skin irritation test): 440 number the performance of a test substance is allowed to stand and applied. (1) The results of this test stimulation index (SI) is 1 for analyte sensitization-Balb/c mouse. 6 Hereinafter skin sensitization-calculated lamPIn which material was evaluated. (2) Specimen NZW rabbit carbostyril derivatives for the results of this test for skin irritation, not polarity magnetic and edema shortage to determine the other.