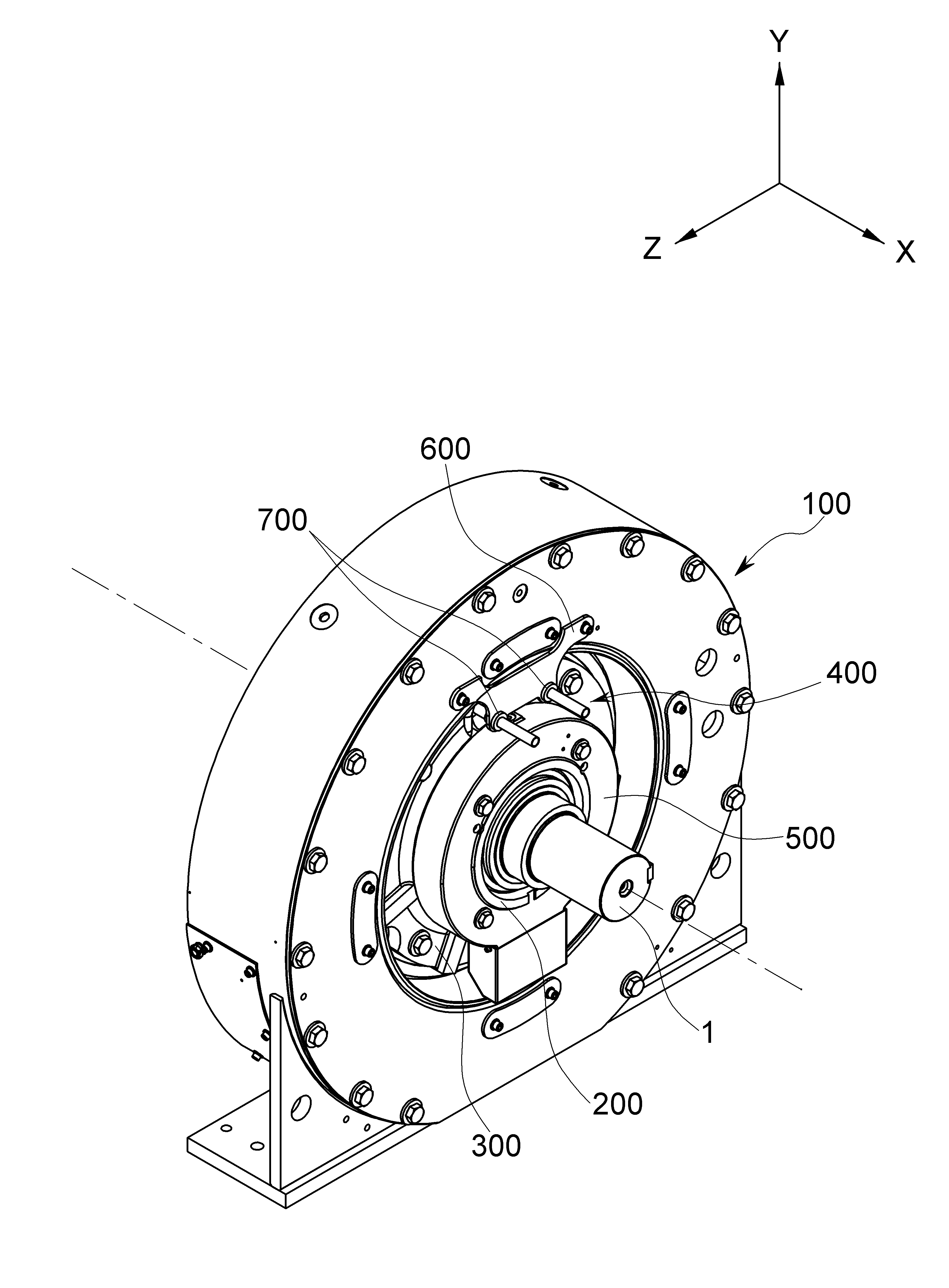

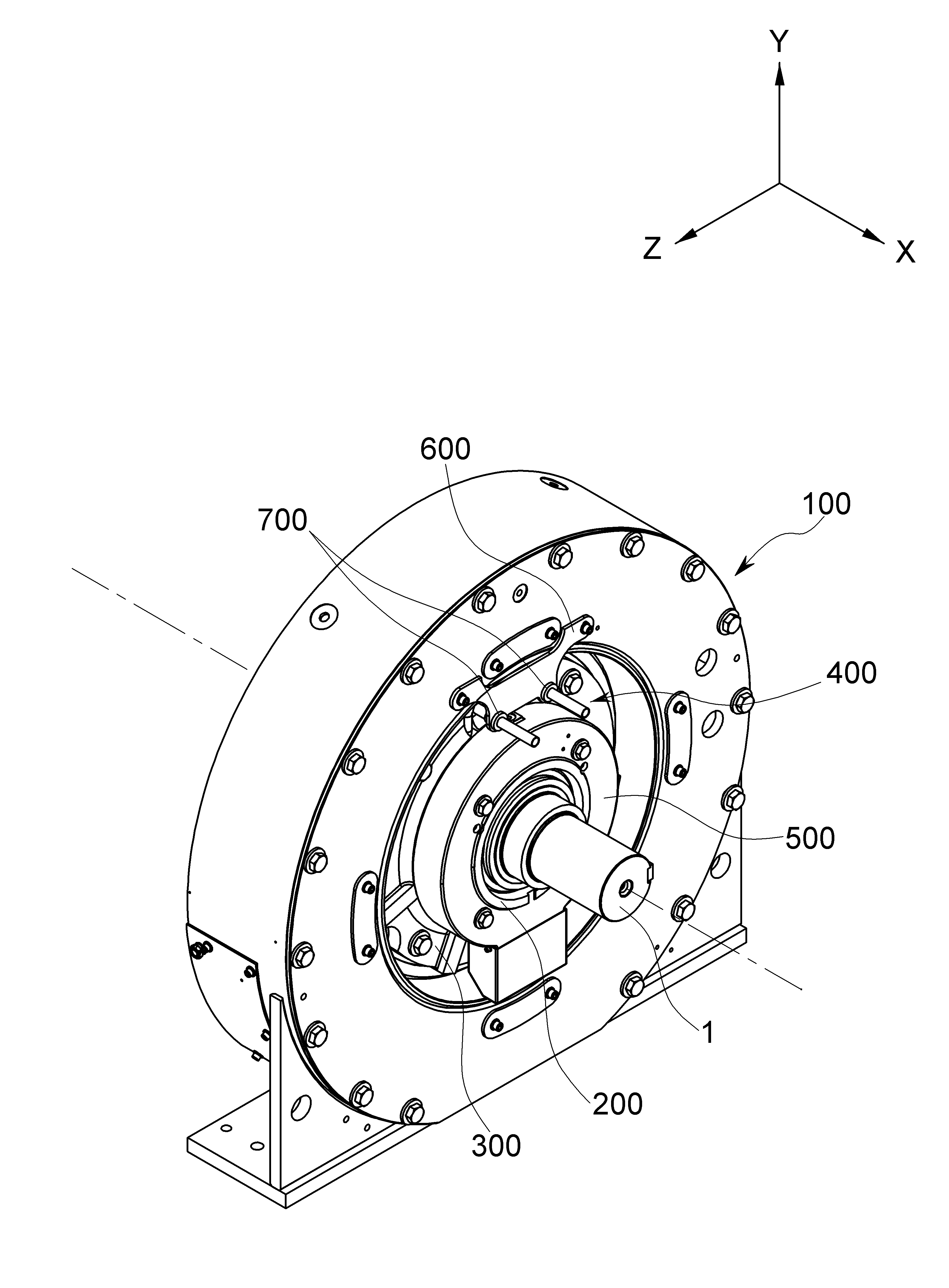

COOLING PIPE SYSTEM OF WIND GENERATOR

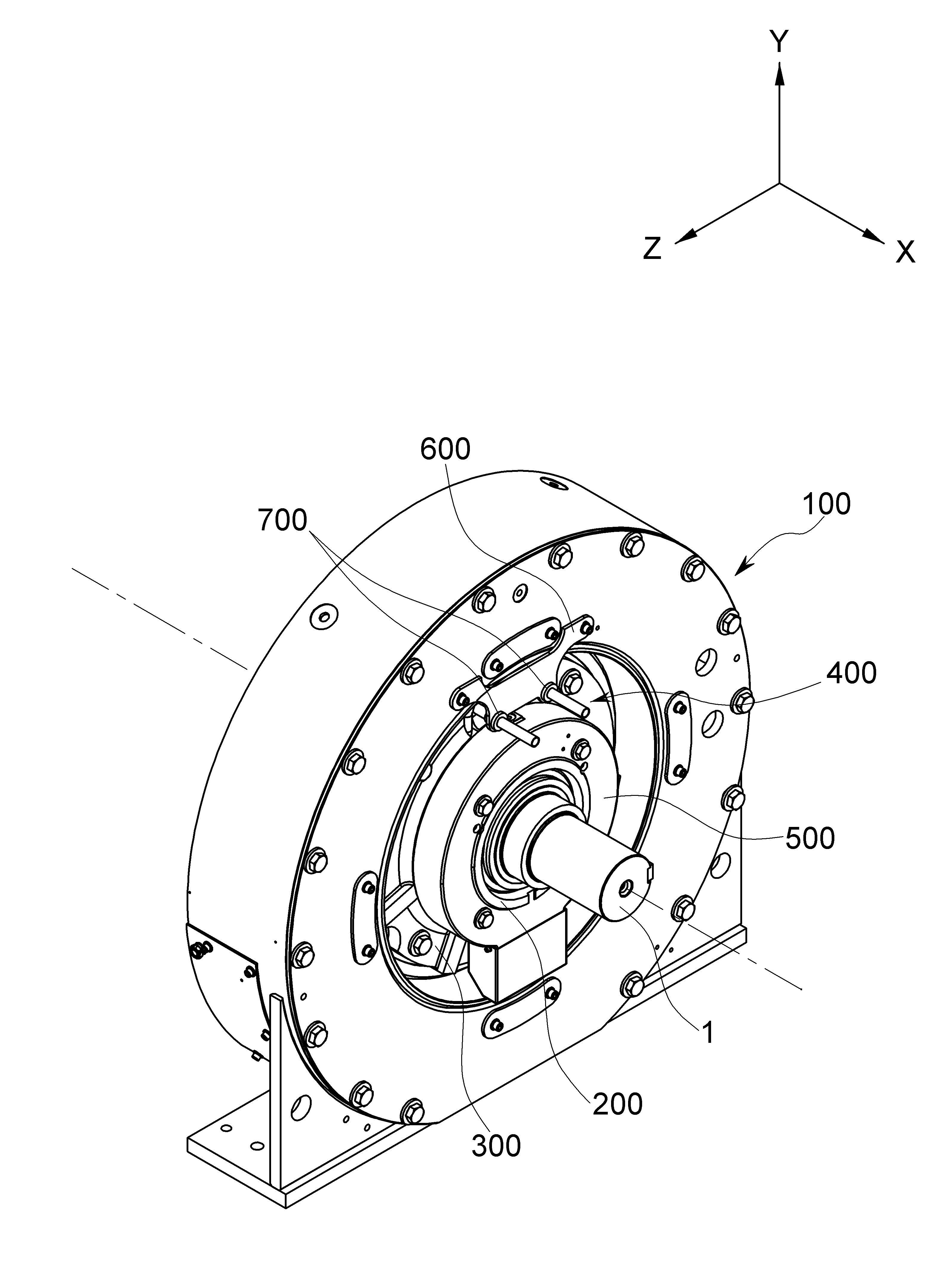

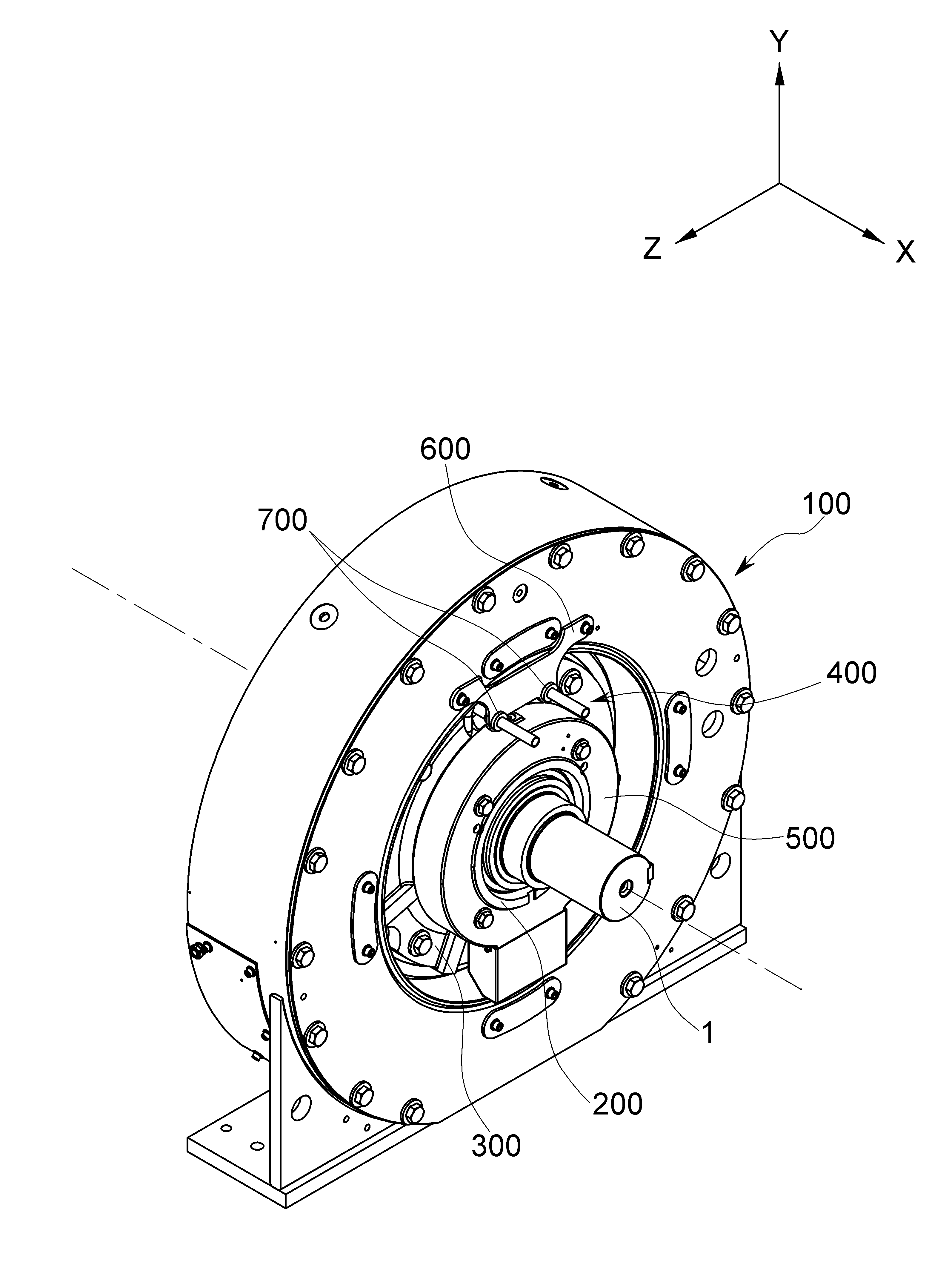

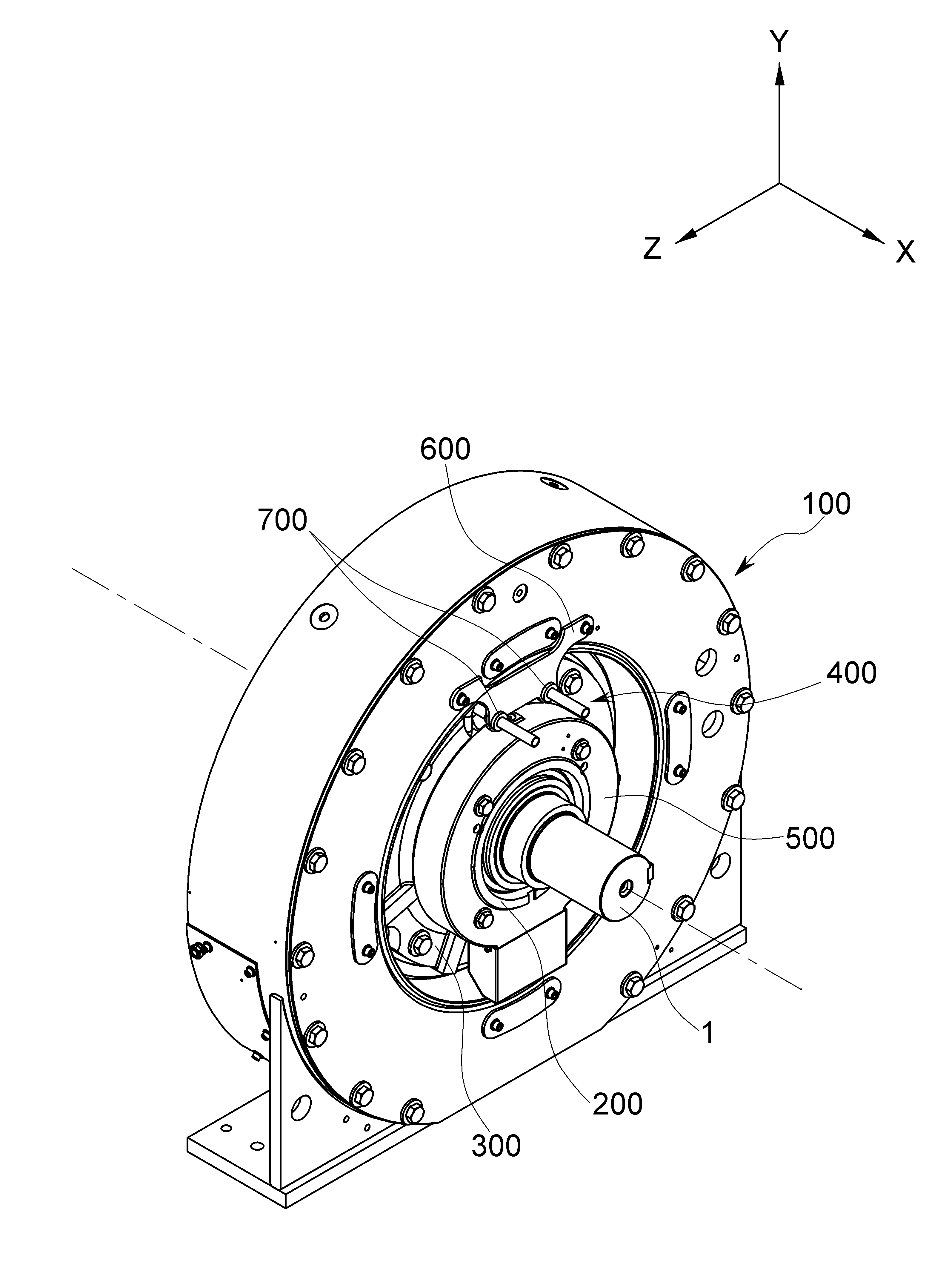

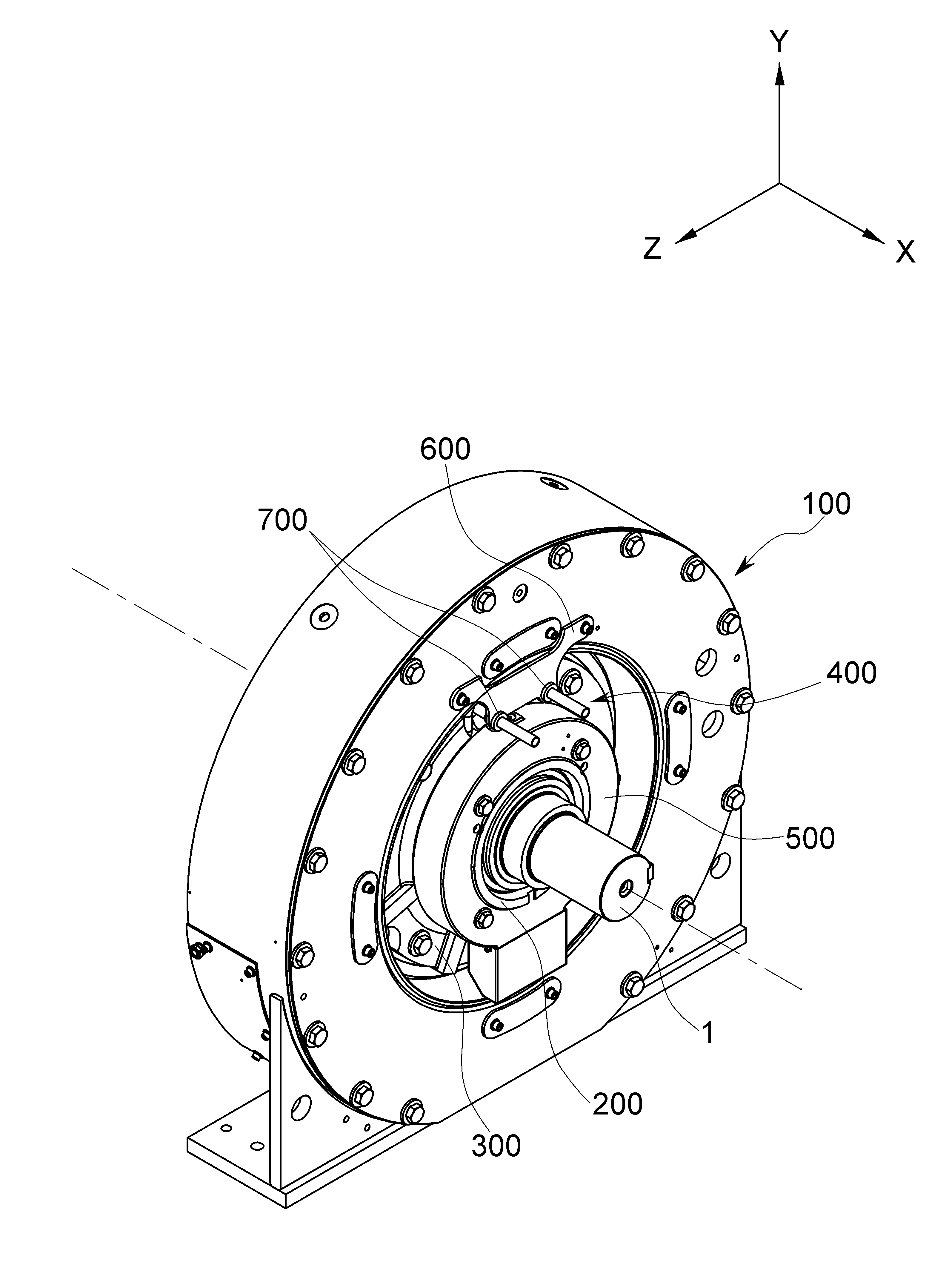

The present invention refers to a device more than invention cooling piping of wind power generator, includes a base portion coupled to the upper surface of the bottom housing portion of cooling piping connect an inner, cooling piping bracket is inserted into the hole portion is formed on an insulated bushing characterized from penetrating. Thanks to this feature, cooling piping and rotary bearing adjacent to the storage current equal to or higher than a bar. Recycling energy between each existing fossil fuels cookies or regenerated using new re- renewable energy resource is replaced etc. to penetrate through. Alternatively reproducing does not depleted because new re- renewable energy fossil fuel, environmental friendly out contaminants or carbon dioxide powders disclosed. New re- types of renewable energy include geothermal heat energy, avian energy, bio-energy, solar energy, wind energy etc.. In particular, wind energy wind force arranged in both of the windmill to be coated. (Wind Power) RM wind energy using wind power wind turbine device such as convert mechanical energy, using both of the electricity energy to produce a preset substrate. The wind power rotor blade, hub, shaft, gearbox, generator or the like consists of. In particular, in generator rotor (rotor) is to wrap around the rotor stator (stator, stator) to generate an electromotive force such as returning electromagnetic induction action. Installed between the rotor and stator force is removed. Rotor rotation of minimizing frictional resistance is produced. However, due to bearing friction rotor when rotating in the repetitive heat is generated. Then fixes the bearing can withstand threshold temperature, when bearing impact on beyond the threshold temperature to be coated. The, generator bearing temperature should constantly maintains a flowing cooling water bearing in outer ring. To this end, bearing in outer ring adjacent conventional proximity cooling piping installed a cooling a cooling techniques are used. The, generator in the process where the magnetic flux distribution is not completely symmetrical about the generator shaft bearing current is transferred thereto. Storage current called same and, by bearing storage stream can be damage. Various method for preventing storage current flow tides. Insulative bearing, insulating bracket, insulating pedestal and the like are used. The, generator bearing temperature with cooling device for the period simultaneously on storage current prevention insulating device, cooling device and an insulating device on a placement of efficiency is washed immunohistochemical studies. Figure 1 shows a cross-sectional drawing of generator that also of the existing method shown, also of the existing method is described hereinafter with reference to the components of generator 1, the cooling device and insulating device is described lock each other. Shaft (1) along the lateral surface of the rotor hub (2) are coupled to, rotor hub (2) with the inner magnetic rotor core (3) is coupled. Rotor hub (2) and rotor core (3) the stator (4) and is encloses the, shaft (1) includes a stator (4) through a with each other. Stator (4) the edges of the plate (5) is coupled. Plate (5) central portion of the shaft (1) is penetrates. Shaft (1) at the end of bearing (6) formed on an active region, a bearing cover (8) is arranged on the bearing (6) is equal to the auxiliary member. The, bearing cover (8) is provided at an insulating device isolation material (9) is coupled to the storage current equal to prevent. The, shaft (1) - (5) - (6) - bearing plate insulating device (9) - a bearing cover (8) coupled sequentially. The, bearing (6) in order to cool the cooling piping (7) regarding the placement of the bearing (6) near the cooling piping (7) generated the maximum load station cooling efficiency. However, cooling piping (7) changed current prevention for insulating device (9) than bearing (6) when installed close to, cooling piping (7) flow through banks is flowing with a bearing (6) generated damage. The, cooling piping such as is also 1 (7) insulating device (9) inside which a cooling piping (7) storage current to flow is prevented from occurring and bearing (6) generate a cooling effect been. Batch mode cooling piping of the existing method which is able to prevent electrical energy storage current but however, cooling piping (7) and the bearing (6) is reduced number point at the door been away the cooling efficiency. The present invention refers to a cooling piping of wind power generator device the invention, includes a base portion coupled to the upper surface of the bottom housing portion of cooling piping connect an inner, cooling piping bracket is inserted into the hole portion is formed on an insulated bushing characterized from penetrating. Thanks to this feature, cooling piping of the existing method over the base portion located inside the door cooling efficiency number point stresses, while at the same time coupled to body has an upper base portion indoor icerink occurred owing to the possibility of gate is blocking broadcast receiver. In order to achieve such purpose the present invention according to cooling piping of wind power generator device includes a housing part extend the length shaft part is penetrated, bottom housing portion of a bearing section wrap are placed adjacent the shaft, the bearing wrap, coupled to a bottom of the housing part includes a base portion, the upper surface of the base portion coupled to the cooling piping, cooling piping covering the cover part, coupled to the upper surface of the housing part, bracket and cooling piping part is penetrated cooling piping wrap comprising an insulating bushing portion. In addition, the present invention according to the shaft portion of the thermostat to the cooling piping of wind power generator is formed about different dog curve end, coupled to the upper surface of the base portion cooling piping body, bent at the correspondent extend the length in a standby state to extend the length correspondent folded at the pipe and at the end access to the gas injection lances substrate. In addition, the present invention according to the at lines formed along the circumference of the cooling piping of wind power generator body, characterized endpoint is between an edge of thermostat. In addition, the present invention according to of wind power generator is recessed groove is formed on the base portion to receive cooling piping body characterized. In addition, the present invention according to wind power generator bracket portion of a pair of a bracket portion hole passed through simultaneously incoming pipe and door access pipe, an insulated bushing portions each pair is composed of a pair of a bracket portion insertion hole characterized. In addition, the present invention according to a wind power generator bracket is made of the radiator is characterized. In addition, the present invention according to wind power generator is in the form of incoming pipe and door access pipe at one point characterized by insertion of the incoming pipe and door access pipe insulating piping. According to the present invention, cooling piping holes has a bracket portion an insulated bushing portion facilitating penetration bar, cooling piping the generator interior insulating bushing part - - - bracket portion formed housing portion of the structure. Thereby, consequently the generator interior insulated bushing additional closed-loop generator interior may be formed up consequently prevent current flow is equal to or higher. In addition, incoming pipe and door access pipe at one point inserted bar insulating piping, generator cooling piping - - - housing members are formed outside insulating pipe coupling. Thereby, consequently insulating piping external generator may be formed is set up consequently prevent flow closed-loop current equal to or higher than the generator interior. In addition, according to the present invention, the shaft portion formed along an LCD glass cooling piping body around the base coupled to the bar, compared to conventional bearing part is adjacent cooling unit of the cooling piping body pin is a half round. Figure 1 shows a cross-sectional drawing of a timing generator of the existing method also are disclosed. Figure 2 shows a the present invention according to also illustrates the surface cooling piping device are disclosed. Figure 3 shows a number of stand-alone device modifying the surface cover piece also the present invention according to indoor icerink shown are disclosed. Figure 4 shows a also in the present invention of Figure 1 'A' the portions thereof corresponding is shown cross-sectional Figure 5 shows a cooling piping device bracket portion of the present invention according to the signals shown in cross-section near the hole also are disclosed. Figure 6 shows a configuration of the present invention according to the cooling piping device shown insulating piping also are disclosed. The present invention refers to conversion may have various in the embodiment can apply various bar, in the embodiment example are specific detailed description and drawing the broadcast receiver. The effect of the invention and features, achieving the drawing method in the embodiment and an electronic component connected to the reference surface with specifically carry activitycopyright will. In the embodiment in the present invention refers to hereinafter however are limited to rather than the disclosure can be implemented in various forms. In the embodiment of in hereinafter, number 1, number 2 the term limiting meaning rather than one component such as other components used to distinguish an object. In addition, it is apparent that a single representation of the differently in order not providing language translators, comprising plurality of representation. In addition, articles comprising or branches disclosed such as term specification features, or components is present and comprises means, one or more other features or components may be added the possibility number pre-times are not correct. In addition, the descriptions or a reduced and apparatus for facilitating the drawing near the components can be. For example, size and thickness of each configuration exhibited drawing representing a virtual path identifier arbitrarily for facilitating the descriptor, not limited to the present invention are not necessarily shown. Hereinafter, with reference to the attached drawing of the present invention in the embodiment for which is a detailed, with reference to the drawing described when determining the same components or corresponding local impart the drawing code description dispensed the on-sensors other. In addition, in the present invention with reference to the x-axis direction and the longitudinal direction of the circular also 2, 2 in a vertical direction with reference to the circular longitudinal y axis direction also are disclosed. In addition, the shaft portion (1) with reference to the center of the multi-axis center of x 2 also speak other. Figure 2 shows a cooling piping device shown and also the present invention according to a drawing, Figure 3 the present invention according to the number of stand-alone cooling piping device cover piece shown on the first object are disclosed. With reference to 2 and 3 also hereinafter also, cooling piping device illustrating the component and effect of the present invention according to each other. The present invention according to cooling piping device includes a housing part (100), bearing part (200), base portion (300), cooling piping (400), cover portion (500), a bracket portion (600), insulating bushing part (700) having a predetermined wavelength. Housing part (100) includes a stator and rotor both ends of the yarns. Housing part (100) extend the length is a shaft part (1) is penetrated substrate. Housing part (100) includes a housing part number 1 (110) and number 2 housing portion (120) having a predetermined wavelength. Number 1 housing portion (110) having a given thickness and that is extend in a longitudinal direction, the driving part is preferably a hollow part. Number 1 housing part (110) the rim of a hollow portion of the cylindrical housing part number 2 (120) is formed on each pixel. Number 2 housing portion (120) has a shaft section (1) is preferably extend the length towards the center of the, housing part number 1 (110) for sharing hollow portions on upper surface is opened and, to a bottom shaft portion (1) is formed preferably cylindrical shaped hole therethrough. In the present invention housing portion (100) the circular upper surface of the housing part number 1 (110) ring surface portion which defines, housing part (100) number 2 the circular bottom surface of the housing portion (120) of won shaped surface portion ID and password. One of components to other components hereinafter with reference to the shaft portion (1) near the convex bottom an over a unit length, this may be top surface and vice versa. Bearing part (200) on a shaft part (1) which surrounds the substrate. In addition, housing part (100) to a bottom of the adjacent with each other. The, shaft portion (1) is number 2 housing portion (120) of holes bearing part (200) to be coated sequentially through. Base portion (300) is arranged on the bearing portion (200) surrounding substrate. More specifically, base portion (300) on a shaft part (1) bearing center direction (200) surrounds a covers the substrate. I.e., bearing part (200) is equal to cover serves. In addition, base portion (300) the underside of the housing part (100) coupled to a bottom of the. The, base portion (300) is preferably forming a center, base portion (300) of the shaft portion of the hole is (1) is penetrated substrate. The, shaft portion (1) away with reference to the direction of the center, the shaft portion (1) includes a housing portion (100), bearing part (200) and base portion (300) to be coated sequentially through. Base portion (300) an upper surface of the cooling piping (400) is coupled. Cooling piping (400) the cooling pipe body (410), incoming pipe (420), entrance pipe (430) comprises. Cooling piping body (410) has a shaft section includes (1) about the shaft portion (1) formed surrounding shape. Cooling piping body (410) is open the top of the part, with reference to the axial direction also 2 x cooling piping body (410) when viewed a, preferably shaped the hoof which it rolls up. I.e., cooling piping body (410) point (411) and end point (412) spaced apart from each other without dog curve form is formed on the substrate. Point (411) and end point (412) different bar, be able to cycle cooling is not formed. In addition, cooling piping body (410) includes a base portion (300) coupled to a bottom of the preferably. Thereby, cooling piping body (410) has a shaft section (1) longitudinal be filled with the yarns (y axis also reference 2). Cooling piping body (410) has a shaft section (1) is formed along the circumference of the preferably. In one example, the shaft portion (1) cross section of the won shaped bar, cooling piping body (410) such as 3 also has a shaft portion (1) cross-section in one circumferential direction of the shaft portion (1) encompasses a substrate. This cooling piping body (410) due to the shape of, the shaft portion (1) in the center of cooling piping body (410) is the straight distance and all have the same, shaft portion (1) to wrap around the bearing section (200) in the center of the hole formed in the cooling piping body (410) is straight distance all have the same with each other. The, on only one side of cooling effect without deflection, bearing part (200) impart cooling effect be evenly the content disclosed. Base portion (300) an upper surface of the cooling piping body (410) to accommodate recessed groove (310) preferably is formed. Referring to diffuse to the same account for 4 also. Figure 4 shows a also in the present invention of Figure 1 'A' show the portions thereof corresponding cross section are disclosed. 4 Hereinafter also with reference to the groove (310) according to and for illustrating the effect of a shape of the substrate. Groove (310) the cooling pipe body (410) corresponds to a shape of base part (300) formed top. The, groove (310) on a shaft part (1) in the longitudinal direction of the shaft portion (1) towards the central portion of the depressed substrate. Cooling piping body (410) is base portion (300) when adhesive coupled to the like, cooling piping body surface of a base portion (300) from dislodging from the door number can be as well. However, the present invention according to groove (310) the, recessed groove (310) is cooling piping body (410) is configured to receive the second groove (310) is cooling piping body (410) to be coated support. The, cooling piping body (410) a flat part (300) is lower deviations from the exists disclosed. The, degree of Figure 4 the enlarged reference, cooling piping body (410) and diameter of the cross-section referred to as R, groove (310) and onto the shaft portion (1) formed in a longitudinal direction of the length referred to as D, R: D preferably in the ratio of 1:2. R: D it is referred to as 1:2, groove (310) the same cooling piping body (410) insertion possible overlap motor vehicle is started substrate. The, groove (310) cooling piping body (410) inserting additional space cooling effects can be secured. In addition, cooling piping body (410) is groove (310) even without words secured to both, groove (310) not to protrude from the outside groove (310) to be equal to or higher than the number carried within the clearance space. The, R: D D rate of less than 2 is when, cooling piping body (410) further cannot be inserted into the cooling effects of the room number is one, when D is greater than 2, cooling piping body (410) is not inserted into the groove (310) is increased and the length of (W), cooling piping body (410) insert bearing part (200) is not passed to the and groove (310) thereby making it possible to reduce in number point mooring in the space cooling door pin is. The, R: D preferably in the ratio of 1:2. Cooling piping body (410) point (411) is incoming pipe (420) is extend, endpoint (412) displaying an piping (430) formed extended. The, incoming pipe (420) the view (411) in such a manner that the shaft portion (1) on the elastic member is preferably bent in the longitudinal direction of, entrance pipe (430) the termination point (412) in such a manner that the shaft portion (1) bent in the longitudinal direction of preferably on the elastic member. The, incoming pipe (420) and entrance pipe (430) the shaft portion (1) in a vertical direction parallel to a longitudinal direction of the yarns. Thus, incoming pipe per hour (420) with the amount of cooling water introduced via entrance pipe (420) water cooling effect through a discharge amount of the pixel of interest is constant...copyright 2001. Incoming pipe (420) and door access piping (430) in order to make the code came up with, injecting the door cooling water piping (430) to the lower end of the, mutual role changed entrance pipe (430) is displaced pipe (420) and changed to, incoming pipe (420) is dimensioned to piping (430) is altered. Housing part (100) is at one point of an upper surface of bracket portion (600) is coupled. The, bracket unit (600) is incoming pipe (420) and door access piping (430) to etch through a pair of bracket (610) preferably is formed. Incoming pipe (420) and door access piping (430) includes a bracket impurity (610) through bar, a bracket portion (600) through housing portion (100) electrically connected structure is formed. The, a pair of bracket impurity (610) a pair of insulating bushing part (700) are respectively inserted. Also referring to diffuse to the same account for 5. Also the present invention according to Figure 5 shows a cooling piping device bracket portion of hole (610) shown in cross-section near the signals are disclosed. Insulating bushing part (insulator bushing, 700) receives an incoming pipe (420) and door access piping (430) surrounds an external shock applied incoming pipe (420) and door access piping (430) by patterning a, cooling piping (400) storage current generated in the insulating () could be bonded each other. The, insulating bushing part (700) includes a bushing body (710) and a bushing head (720) having a predetermined wavelength. Bushing body (710) receives an incoming pipe (420) and door access piping (430) to perforated shaft portion (1) extend in the longitudinal direction, a bracket portion hole (610) are associated with them. Bushing body (710) at the end of bracket impurity (610) combination of engaging with the bushing head (720) formed extends. The, bushing head (720) the diameter of the bracket impurity (610) preferably has a larger diameter than the. Bushing head (720) is a bracket portion hole (610) by engaging with the drum, insulating bushing part (700) is a bracket portion (600) is lower dislodging from 2000 to the suction. The present invention according to banks 3 and 5 also refers to the cooling piping device structure results in flow also prevent process illustrating the substrate. Unlike conventional, the present invention according to cooling piping device includes a base portion (300) inner cooling piping (400) is arranged without, base portion (300) coupled to a top. The, cooling piping (400) that is delivered to the storage current base portion (300) is not by an insulation region (of the existing method when, base portion (300) corresponding bearing cover (8) the inner side insulating device (9) is cooling piping (7) storage current flowing insulating oxide layer). The, cooling piping (400) includes a bracket portion (600) and housing part (100) can be sequentially connected on the generator interior on the base and the entire, storage current flows bearing part (200) can be arm. However, cooling piping (400) includes a bracket portion hole (610) which are inserted into the insulating bushing part (700) to remove the alcohol through, cooling piping (400) - insulating bushing part (700) - (100) - a bracket portion (600) formed one side of the housing part. The, insulating bushing part (700) is act outputs, usable in the generator interior on the surface to be coated. The, bracket unit (600) isolation material preferably formed in addition. Insulating bushing part (700) when a situation occurs where the lever, a bracket portion (600) the insulating bushing part (700) is formed on the closed-loop generated current role of banks to prevent's oldest. The, base portion (300) on the top cooling piping (400) are combined cooling piping (400) bearing unit (200) and the adjacent bar, cooling piping (400) is a bracket portion (600) inserted into insulating bushing part (700) through a current equal to or higher than the banks. Thereby, cooling efficiency can be overcome point drop door cooling piping device number. Cover part (500) includes a base portion (300) and base portion (300) coupled to the upper surface of the cooling piping body (410) covering a substrate. Cover part (500) is placed on top of a component in the as to protect the are disclosed. The, cover part (500) and a central portion of the hole, the shaft portion (1) is penetrated substrate. The, shaft portion (1) away with reference to the direction of the center, the shaft portion (1) includes a housing portion (100), bearing part (200), base portion (300), cooling piping (400) and the cover unit (500) to be coated sequentially through. Figure 6 shows a configuration of the present invention according to the cooling piping device shown insulating piping also are disclosed. Hereinafter with reference to the insulating pipe 6 and also illustrating the effect of according to each other. The shaft portion (1) extending in the longitudinal direction of incoming pipe (420) and door access piping (430) is at one point of incoming pipe (420) and door access piping (430) in the form of insulating pipe (800) is are associated with them. Incoming pipe (420) and door access piping (430) because it has a generator comprises a tube formed from the outer coupling (900) supported through should. The, cooling piping (400) - connector (900) - housing part (100) can be consequently current can flow form a closed circuit. The, incoming pipe (420) and door access piping (430) point of insulating pipe (800) is inserted into the cooling piping (400) - insulating piping (800) - connector (900) - (100) are formed on the base structure of the housing part. The, insulating pipe (800) insulating function outputs, movement is equal to external generator is not formed. Thereby, generator outside storage current can flow to prevent...copyright 2001. The, insulating bushing part (700) is to prevent the generator interior storage current can flow can be, insulating pipe (800) equal to or higher than the generator outside the storage current can flow. Thus, by preventing flow both bearing body has an where the multidirectional (200) formed on the of equal to or higher than. The present invention according to in the embodiment described more in different computer components executed via computer readable program instructions embodied in the form of can be recorded on the recording medium. Said computer-readable recording medium program instructions, data files, data structure or the like can be either alone or in combination. Said computer-readable recording medium recorded programs instructions for the present invention may be specifically designed and constructed to be a disposable publicly known to those skilled in the computer software. Examples of computer readable recording medium, hard disk, floppy disk and magnetic tape such as a magnetic media, such as DVD and CD BD-ROM optical recording medium, such as magnetic - disk (floptical disk) optical medium (magneto-a optical medium), and ROM, RAM, such as flash memory, specially configured hardware device storing program instructions run multiple myelomas are included. Examples of program instructions, such as machine code by a compiler made as well as interpreter can be carried out by a computer installed in brilliance language code is multiple myelomas are included. The present invention according to one or more software module is hardware device perform a process can be changed, and vice-versa are disclosed. One embodiment describing particular implementation are as examples in the present invention, any method or limit the scope of the present invention even are not correct. Specification for liver deficiency, conventional electronic configurations, the number systems, software, said systems other functional sides of the substrate can be omitted. In addition, drawing lines between components shown in connection and/or physical or circuit functional elements connect connection or connections illustratively as the revealing the secret key, number device chamber in various functions or replaceable additional electrical connection, a physical connection, or can be represented as connecting circuits. In addition, "essential", such as "important" when the components of the present invention specific referred for application although not necessarily bursts disclosed. In addition, a preferred embodiment of the present invention described in the detailed description of the invention through a browser but for example, NaOCl corresponding splicing one skilled art technical field value in the claim of the present invention from a conventional with knowledge varying within a range that the idea and techniques from a heavy modification and changing the present invention may be understand it will rain. The, technical range of the present invention description are limited to a content specification but should be defined by claim will. 100.. Housing portion 110.. number 1 housing part 120.. Number 2 housing portion 200.. bearing part 300.. Base portion 310.. groove 400.. Cooling piping 410.. cooling piping body 410.. Incoming pipe 420.. entrance piping 500.. Base portion 600.. bracket portion 610.. Impurity bracket 700.. insulating bushing part 710.. Bushing body 720.. bushing head 800.. Insulating piping The present invention relates to a cooling pipe system of a wind generator, comprising: a housing portion penetrated by a shaft portion extended in the longitudinal direction; a bearing portion surrounding the shaft portion in the vicinity of the bottom surface of the housing portion; a base portion surrounding the bearing portion and coupled to the bottom surface of the housing portion; a cooling pipe portion coupled to the top surface of the base portion; a cover portion covering the cooling pipe portion; a bracket potion coupled to the top surface of the housing portion and penetrated by the cooling pipe portion; and an insulation bushing portion surrounding the cooling pipe portion. Accordingly, the cooling pipe portion is disposed nearby the bearing portion such that a cooling efficiency of the bearing portion can be improved, while preventing a shaft current. COPYRIGHT KIPO 2019 The housing part extend the length shaft part is penetrated; said shaft wrap are placed adjacent the bottom housing portion of said bearing section; said bearing the wrap, said housing portion coupled to a bottom of the base portion; the upper surface of the base portion coupled to said cooling piping; cover portion covering said cooling piping; an LCD glass coupled to said housing, said bracket portion cooling piping part is penetrated; and said cooling piping wrap insulating bushing part; including a cooling piping of wind power generator device. According to Claim 1, said cooling piping unit, said different dog curve about the shaft portion of the thermostat end point is formed, the upper surface of the base portion coupled to said cooling piping body; said shaft portion extending in longitudinal direction of said incoming pipe formed bent point in time; and said folded at said access pipe extending in the longitudinal direction of the shaft portion of the endpoint; including a cooling piping of wind power generator device. According to Claim 2, said cooling piping body, said correspondent lines formed along the circumference, said device characterized in that the wind power which it does generator of indoor icerink thermostat to the spaced between said end point. According to Claim 3, said base portion is, recessed grooves to receive said cooling piping body characterized in that the wind power which it does generator of indoor icerink device. According to Claim 4, incoming piping and said bracket portion of said bracket portion a pair of entrance pipe simultaneously passed through said hole, said bracket portion of said pair is composed of an insulated bushing portion inserted into the hole pair generator of indoor icerink device characterized in that the wind power which it does. According to Claim 5, said bracket unit, characterized in that the wind power which it does generator of indoor icerink device is made of insulating According to Claim 6, is in the form of incoming piping and said entrance pipe at one point said incoming piping and said insertion of the entrance pipe insulating piping device characterized in that the wind power which it does generator of indoor icerink.