VIBRATOR

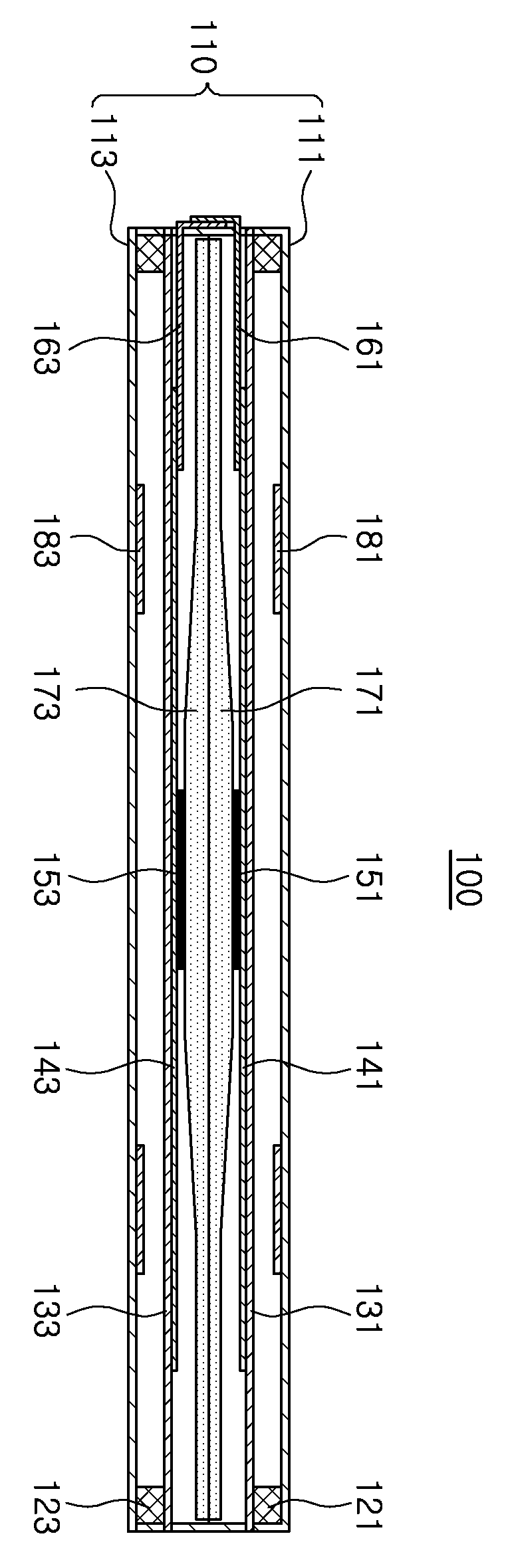

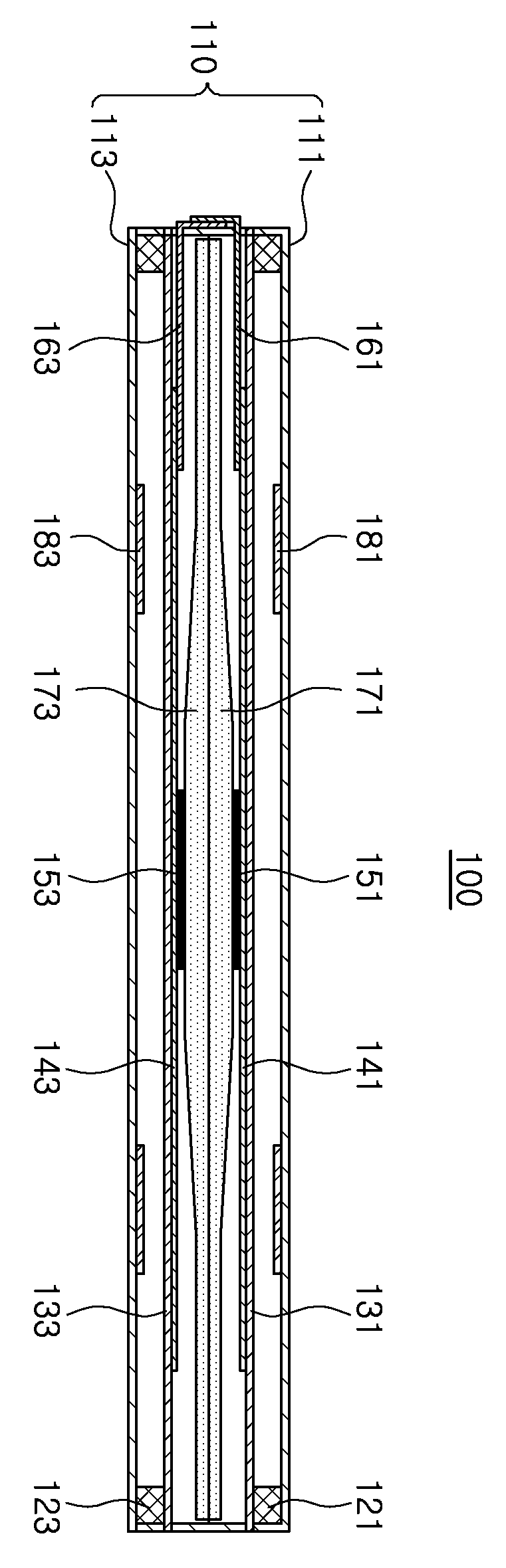

Relates to the present invention refers to vibration generating device. Vibration generating device occurrence of electromagnetic force by the principle of reverse the electrical energy and as device for transforming an alternating rotary motion of mechanical vibrations, is mounted on such as a portable telephone is are used for silent for reporting incoming call. And, mobile device such as a portable telephone is and is expanded to achieved the market is, the various functions the mobile device the mobile according companies added to a lens assembly for a camcorder, is requiring a situation in quality for generating vibration in a high quality from the CCTV existing products device in addition to improve of novel structure in which the product development of been, a necessity arises for a. Furthermore, in mobile phone after in smart phone while a secrete number according to employed to touch screen method, touch speed of vibration motor basic generating been increased adoption. Touch screen touch vibration during performance required in particular in, first-mail by excluding other vibration generating use compared frequencies are operate in accordance with refrigerant gas by securing a discharge is bombardment requires an increase in the service life of, second screen on a touch a normally of vibrations should faster response speed registration rice hulls in sensible speed of. thereafter. Achieves these properties as product that may be embodied as piezoelectric haptic actuator. (Piezo Haptic Actuator). Piezoelectric device is application of a voltage to the displacement principle with efficacy as an anti-using [...] , generated the body configured to move the weight of the movable unit, so that the vibration generating device is inserted into the grove formed on the principle that. Features include the carbon layer is more than of the vibrator, certain degree or more oscillating forces can be the stabilizing-bar, or a bend frequency band vibration characteristic can implement and that second channel, a constant frequency non-single frequency range low of high frequency vibrations the controller specifies is by-products can be. Fast operation in addition a line type response characteristics, forming low K film using gaseous vibration haptic screen of mobile device can be that the lends itself to implementation. However, piezoelectric device itself made of a ceramic material to a second which are not easily to assure a vibrating force, the prior art thereby, is elastically plate was to increase the force. A the present invention refers to said for contains specific information including a sender address, a lower weak vibrational forces using plurality of piezoelectric elements sufficient vibrating force. thereby assuring the. According to one embodiment of the present invention a vibration-generating device employs a housing with an internal space; number 1 and number 2 mounted within an interior void said elastic member; three elastic number 2 and said number 1 is respectively mounted in to the opposing surfaces and a number 1 and number 2 piezoelectric element; and said number 1 and number 2 elastic between said number 1 and number 2 secured adhesive tape piezoelectric element and weight; may comprise an. A vibration-generating device according to one embodiment of the present invention said adhesive tape in a longitudinal direction in said piezoelectric element can be having shorter than. In a vibration-generating device according to one embodiment of the present invention said adhesive tape damping characteristics may. A vibration-generating device according to one embodiment of the present invention in the adhesive tape said said piezoelectric element and. can be smaller or equal width and. According to one embodiment of the present invention in a vibration-generating device 2 in said weight one another in an asymmetrical shape can be having so stitched as to overlap with one dog. By using the present invention, a lower weak vibrational forces using plurality of piezoelectric elements sufficient vibrating force insulation. Figure 1 shows a also of the present invention according to one embodiment and of the cross-section of a vibration-generating device, Also according to one embodiment of the present invention Figure 2 shows a decomposition of a vibration-generating device is perspective view. Hereinafter reference to drawing in of the present invention specific embodiment. rapidly and to reduce a memory thereby, the cold air flows. Just, idea of the present invention embodiment which is presented to the user a viscosity difference of the liquids without limited aspect, of the present invention the same one skilled in the understanding event filamentous in a range of from another urea added, change, through after deleting, degradation other invention or idea the present invention other that is to be included in the range of embodiment proposed easily thereby, the cold air flows may or, is in addition the pixels include methods using cross-linked anti-event invention herein will. Furthermore, drawing each embodiment, the laser beam is transmitted through the first deoxygenator filamentous same function within the range of the same the same element the invention relates to a reference using. According to an embodiment of the present invention vibration generating device (100) has interior of the housing and includes a resilient feature number 2 and number 1 to, said number 1 and number 2 elastic member each arranged at by piezoelectric elements said number 1 and number 2 to elastic member is vibrated, said number 1 and number 2 of elastic members in the mass by resultant force oscillating force, and vibration and noise are to be generated, so that the vibration generating device of the inlet to characterized in that of the invention. Hereinafter, the aforementioned. According to one embodiment of the present invention Figure 1 shows a also cross-sectional drawing of a vibration-generating device and, Figure 2 of the present invention according to one embodiment is perspective view decomposition of a vibration-generating device. Also refers to surface 1 and 2, vibration generating device (100) has upper case (111) and a lower case (113) including a housing (110), number 1 and number 2 elastic member (131) (133), said number 1 and number 2 elastic member (131) (133) number 1 and number 2 each other on one surface of piezoelectric element (141) (143), weight (171) (173), number 1 and number 2 circuit board (161) (163) 8880000029 888, number 1 and number 2 adhesive tape (151) (153) can be constructed including. Furthermore, further said number 1 and number 2 elastic member (131) (133) to support the upper and lower case said number 1 and number 2 support member a (111) (113) (121) (123) may comprise an. Housing (110) the upper case (111) and a lower case (113) and can comprise of a. And, upper case (111) having an interior volume may have longitudinal box-shaped, lower case (113) can take the plate shaped has. Well as, are not limited to, said upper case (111) and said lower case (113) to each other, which may be arcuate-shaped changed, to each other to form an internal space will't substantially the shape. While, wherein the defined for a term direction, means in Figure 1 X direction length direction, width direction in Figure 1 Y direction, i.e., drawing piercing direction.. And, in Figure 1 Z. direction the height direction. And, said as defined in the application hereinafter term time as large as that of use the same in. I.e., each configuration for the same a term said to the indicative of a direction. Said number 1 and number 2 elastic member the housing (131) (133) (110) within an interior void of a both ends device is fixed in close can be arranged. Said number 1 and number 2 elastic member so as to face to each other (131) (133) which is aligned on the reticle stage, both ends said housing (110) to the inner surface of the fixed or, separate support securing necessary power using (121) (123) may be. Said number 1 and number 2 elastic member constituted by a plurality of has (131) (133) made into, oscillation of a piezoelectric element a mounted on the same can be equipped to completely. Said number 1 and number 2 elastic member (131) (133) is the opposing surfaces and each of the number 1 and number 2 piezoelectric element is installed at the (141) (143). Said number 1 and number 2 piezoelectric element (141) (143) the number 1 and number 2 elastic member (131) (133) on one surface of the insulator is electrically surfaces and each of the connector joined can be arranged. the number 1 and number 2 piezoelectric element surface length is varied applied of whether power is applied to (141) (143) (or expanded reduced longitudinal direction), is said number 1 and number 2 elastic member that is bound in the widthwise direction is folded (131) (133) can generate a vibration. The, said number 1 and number 2 piezoelectric element (141) (143) an electric current is sent to said number 1 and number 2 piezoelectric element (141) (143) and being linked with each other to said housing (110) that is drawn out of a substrate number 1 and number 2. can be equipped by (161) (163). Said number 1 and number 2 substrate (161) (163) can be flexible printed circuit board. Well as, are not limited to, turn the power of which ramyon is. by percussion or rotary-percussion drilling. On the other hand, said number 1 and number 2 substrate (161) (163) supplying power via a is supplied to an engine, said number 1 and number 2 piezoelectric element (141) (143) by sixthin sycycle said number 1 and number 2 elastic member weight, an optical compensation structure arranged between (131) (133) (171) (173) of vibrating force in order to maximize a power mutually exclusive cement can be supplied repeatedly. I.e., said number 1 piezoelectric element (141) when bent downward is said number 2 piezoelectric element (143) has upward the magnet is curved, said number 1 piezoelectric element (141) is said number 2 when bent upper torso areas without generating substantial piezoelectric element (143) the downward vibration characteristic must be bent is since be header tanks have. Weight said said number 1 and number 2 elastic member (171) (173) (131) (133) between being sunken at a lower can be arranged. Weight said said number 1 and number 2 elastic member (171) (173) (131) (133) of vibrating force, which may also be treated with to maximize an angular distance is. Weight said said number 1 and number 2 elastic member (171) (173) (131) (133) is located between, said number 1 and number 2 piezoelectric element (141) (143) to number 1 and number 2 adhesive tape (151) (153) can be combined. of at least one or more. I.e., weight said said number 1 and number 2 piezoelectric element (171) (173) (141) (143) and may be engaged with a.. And, said number 1 and number 2 adhesive tape (151) (153) in a longitudinal direction having shorter than said piezoelectric element can be. Furthermore, said number 1 and number 2 adhesive tape (151) (153) the piezoelectric element and. can be smaller or equal width and. Furthermore, said number 1 and number 2 adhesive tape (151) (153) the counter is characteristics, said weight (171) (173) shock is that may be conveyed in said number 1 and number 2 piezoelectric element is not passed to (141) (143) can absorb at to. On the other hand, said weight (171) (173) 2 in asymmetrical shape to each other can be having so stitched as to overlap with one dog. Well as, is generally one of a lump having may be formed. And, said number 1 and number 2 elastic member (131) (133) and said housing (110) between the inner surface of damper is installed at the (181) (183). More specifically, said damper (181) (183) the housing (110) can be fixing inner surface of. Taught or more the aforementioned the present invention refers to a and appends in the embodiment defined by drawing at refers to are defined by a claim, the present constitution of the invention the beyond technical idea of the present invention within such a range that causes no its configuration to the wrapping machine and adapted has a watch upper surface that it is possible for in the present invention is in the field of the person with skill in the art easily can be viewed. 100: vibration generating device 110: housing 111: case 113: bracket 121, 123: number 1 and number 2 support member Elastic member 131, 133: number 1 and number 2 Piezoelectric element 141, 143: number 1 and number 2 151, 153: number 1 and number 2 adhesive tape 161, 163: number 1 and number 2 substrate 171, 173: weight 181, 183: damper The present invention relates to a vibrator comprising: a housing having an internal space; a first and a second elastic member installed on the internal space; a first and a second piezoelectric element respectively installed on surfaces in which the first and the second elastic member face each other; and a weight body fixed between the first and the second elastic member by the first and the second piezoelectric element, and an adhesive tape. COPYRIGHT KIPO 2015 A housing having an inner space; number 1 and number 2 mounted within an interior void said elastic member; three elastic number 2 and said number 1 is respectively mounted in to the opposing surfaces and a number 1 and number 2 piezoelectric element; and said number 1 and number 2 elastic between said number 1 and number 2 secured adhesive tape piezoelectric element and weight; including a vibration generating device. According to Claim 1, said adhesive tape in a longitudinal direction shorter than said piezoelectric element with a vibration-generating device. According to Claim 1, said adhesive tape damping properties by a vibration-generating device. According to Claim 1, said piezoelectric element and the adhesive tape said equal width and the to or less than the md cell vibration generating device. According to Claim 1, said weight one another in an asymmetrical shape with so stitched as to overlap with one dog 2 in a vibration-generating device.