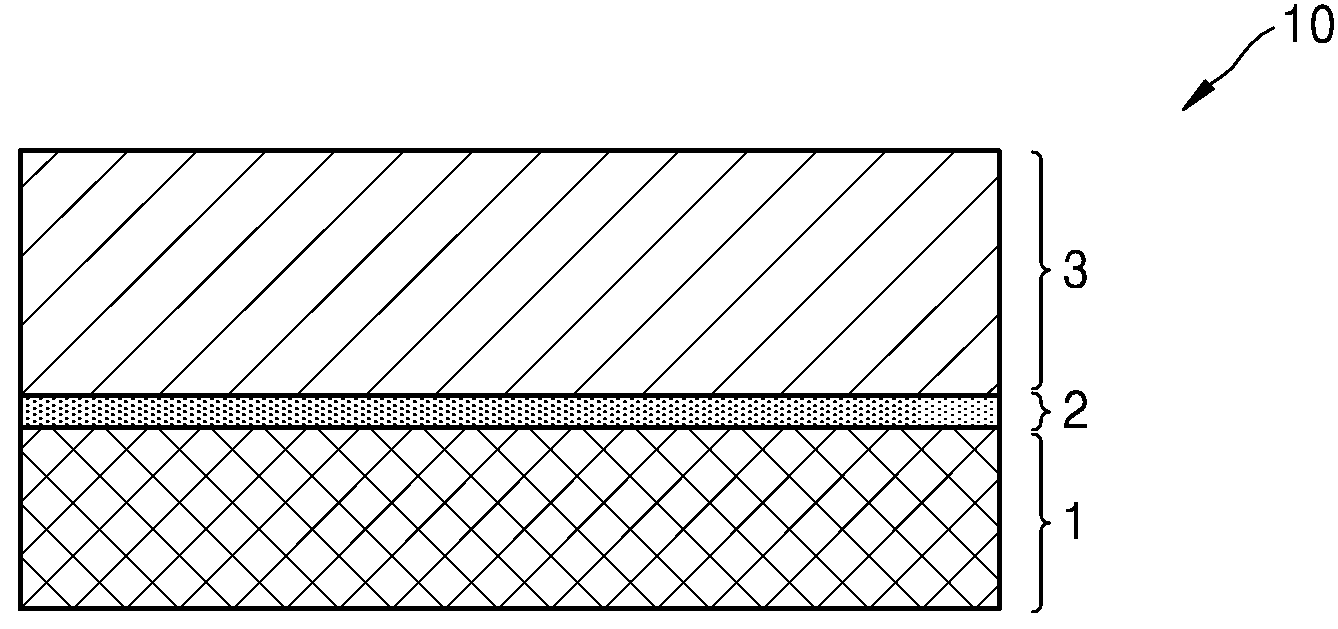

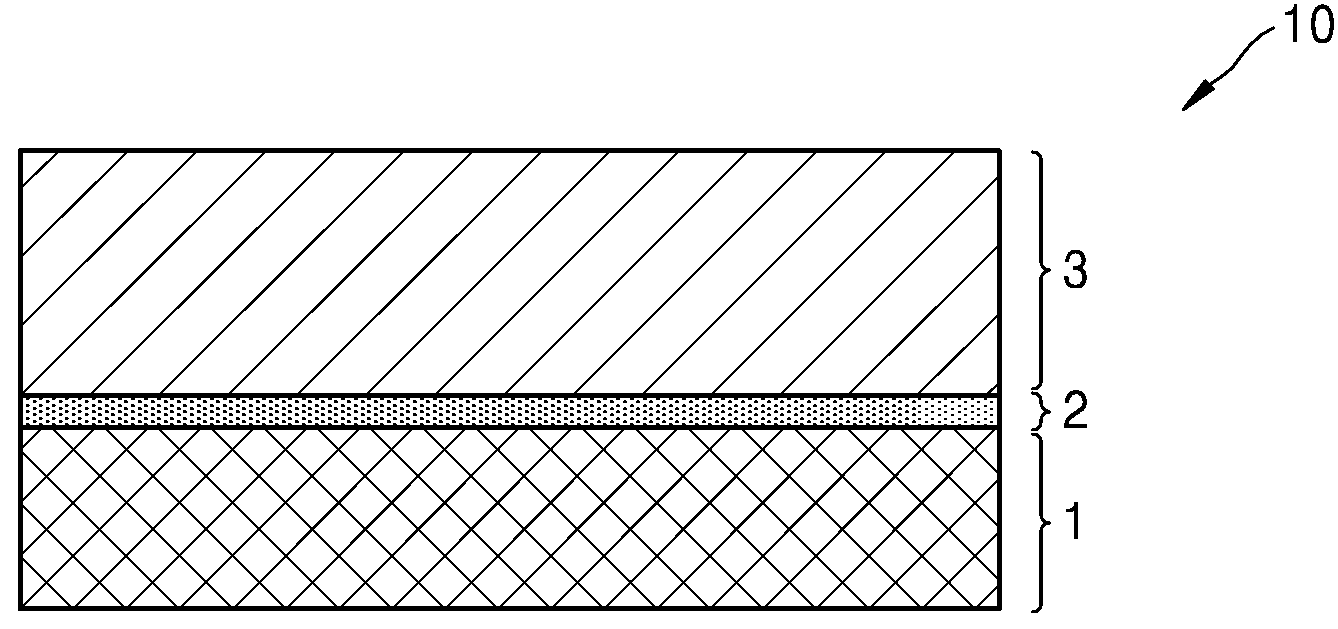

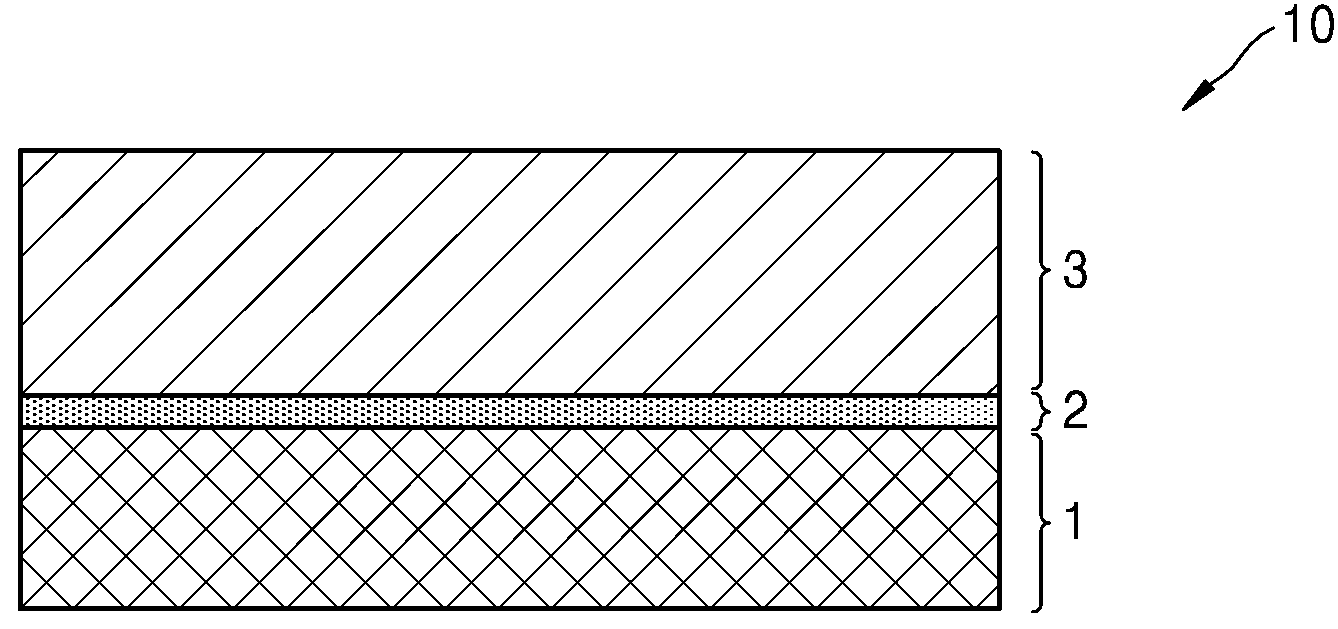

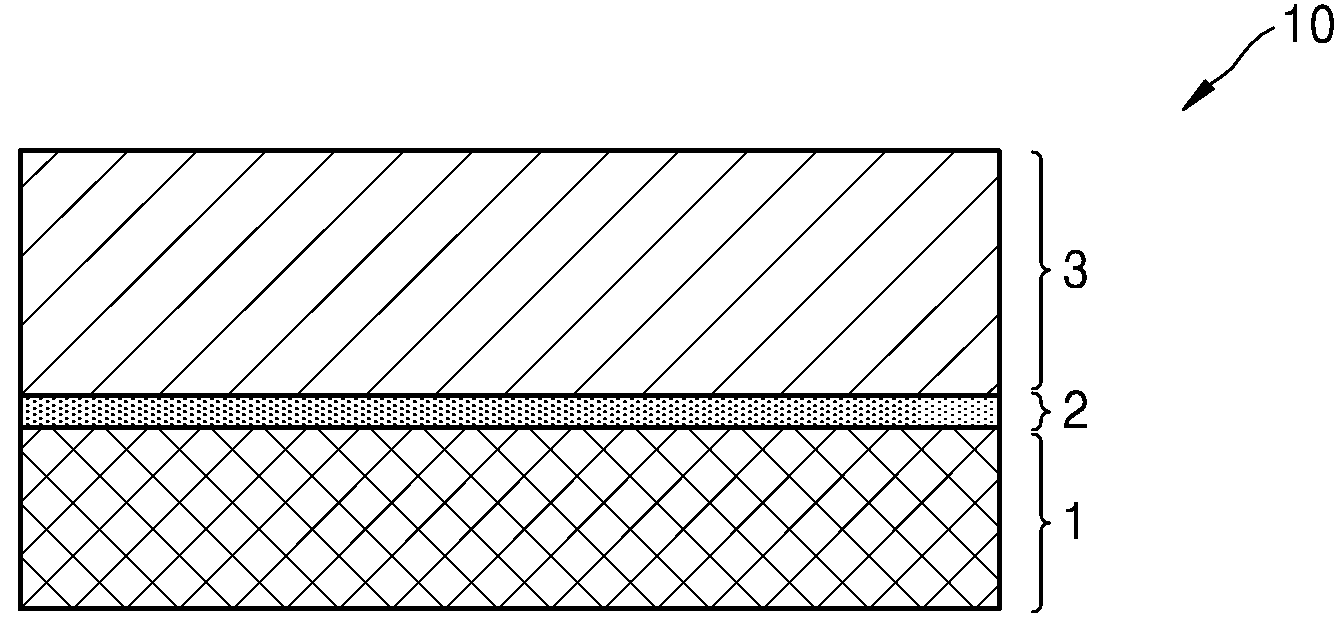

POSITIVE ELECTRODE ACTIVE MATERIALS, SECONDARY BATTERIES INCLUDING SAME AND MANUFACTURING METHOD THEREOF