SYSTEM OF SUPPLYING AND DISCHARGING HYDROGEN FOR FUEL CELL HAVING INTEGRATED MANIFOLD BLOCK

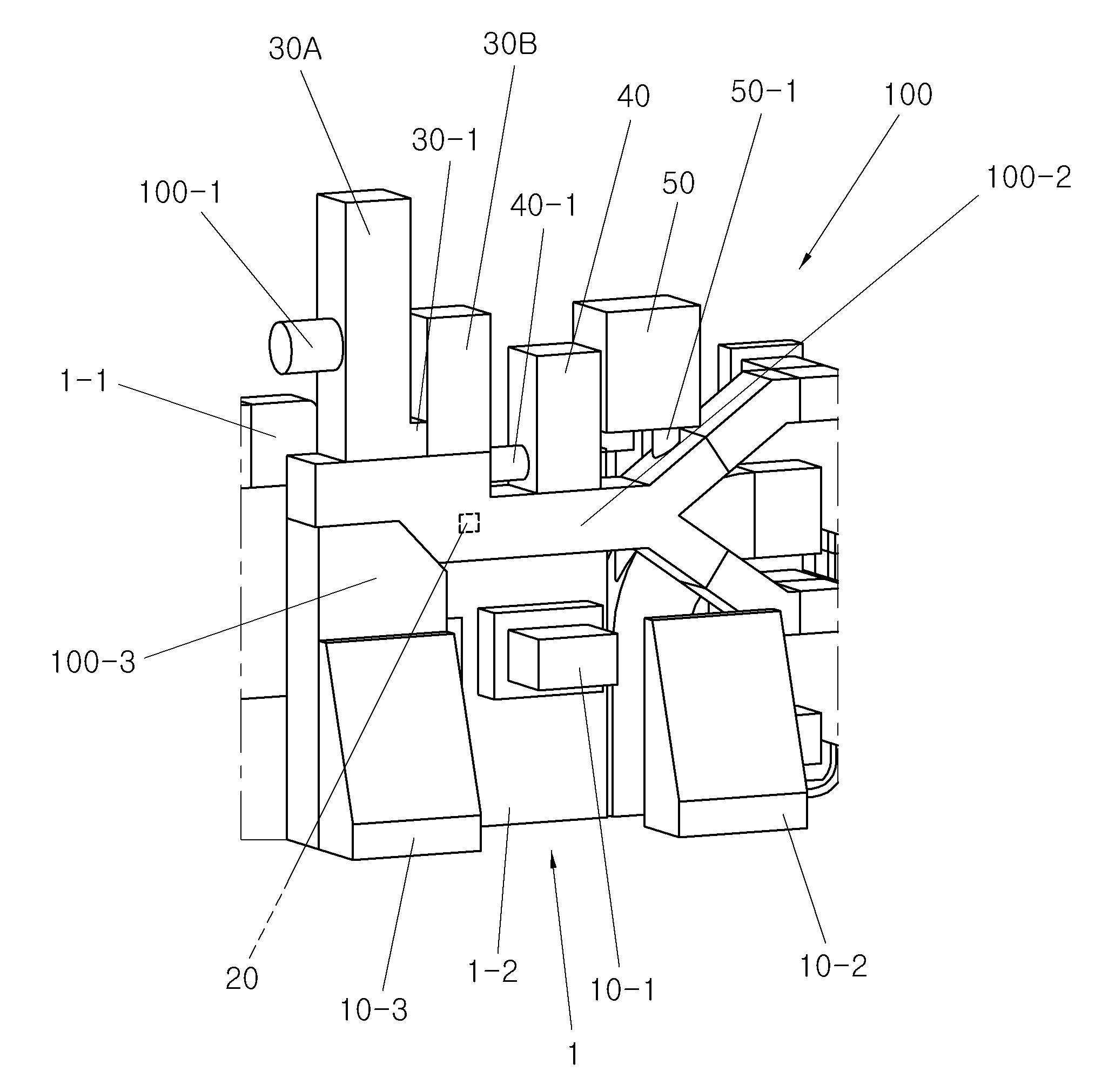

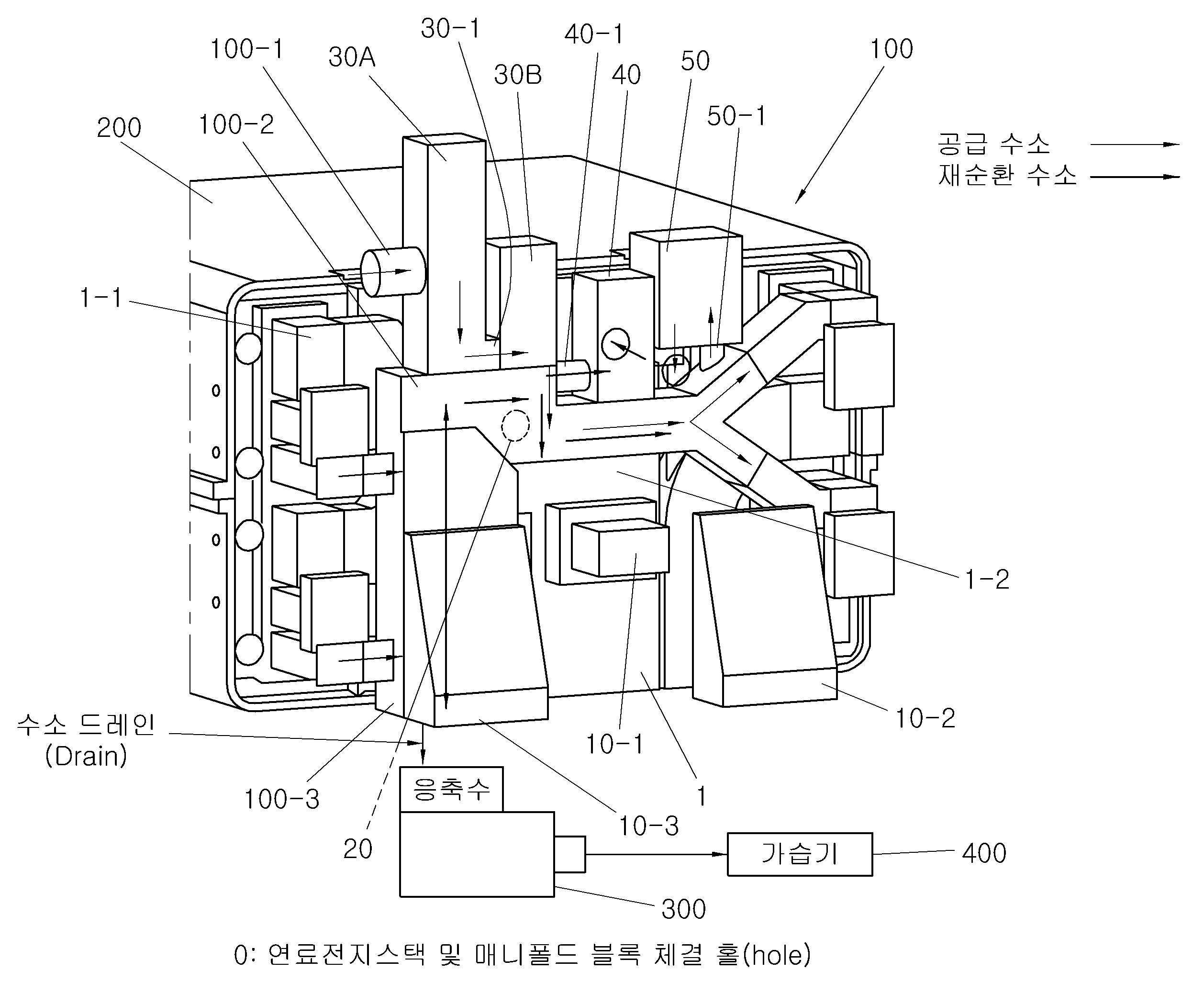

Relates to the present invention refers to fuel cell vehicle, in particular hydrogen supply components, the module becomes higher maleamic the locker by condensation while at cold start for an purge valve a conductive metal material and maintaining improved fluidity, integrated manifold block for providing hydrogen of hydrogen tank fuel cell with relates to and venting and venting system. Generally hydrogen supply in fuel cell vehicle a for module and module and venting and venting system and very important, many advantages are through the same may be embodied in. Such example, the present applicant of the following a patent application station is connected to the semiconductor layer. patent document. The, recirculation blower of manifold block is installed being exposed through the hydrogen recirculation line is mounted in a, hydrogen recirculation line ejector hydrogen supply line and flow into the valve body through which, hydrogen liberating tool configured compound and is connected to the water trap and-purge valve is side-by-side and mounted to of manifold block, recirculation blower drive control and washing and water trap for for controlling opening/closing controller, is mounted on the upper surface other side of the manifold block. Fuel cell by using this configuration of the stack is externally mounted of hydrogen supply system in the manifold block are module features are contemplated. Therefore, of each fuel cell system may reduce the and weight, hydrogen supply line length of differential pressure of hydrogen supply line hydrogen supply according to reduced, reducing the risk of steps can enhance the performance of the fuel cell vehicle a for providing hydrogen of hydrogen tank. can be configured with a device. However, a manifold block said patent document independent-mounted purge valve is present in the lower part fuel cell stack the position of hydrogen by purge line and inactive layer coming out of a central condensing chamber, thereby condensing chamber for sensing leakage in at the upside to purge valve off together with hydrogen water cold starting by such as the sight of the-purge valve is in purge valve in lot of strange is able to be generated. Furthermore, engine room installed state of a fuel cell stack at laterally stack package lead molding die of semiconductor fabrication components are mounted and the, thereby (Fail) in case of abnormal timing of the purge valve to the vehicle when it has state ejector or cooling water from both removed and then stack ejector or followed the't have the effect of exchanging the purge valve. The said present invention refers to the logic and a through hole which is formed on line hydrogen liberating tool configured condensing chamber on an upper portion outlet line by connecting hydrogen supply components, the maleamic module the locker by condensation while concentrated is at cold start for an purge valve are found to exhibit significantly enhanced, in particular relative to the outside manifold block for aesthetic cover separate components that are modular of separate or-assembled state are maintenance panel maintenance and to improve the component the enhancing productivity which are extremely improved in fuel cell with integrated manifold block for providing hydrogen of hydrogen tank heat exchanger. to provide and venting and venting system. Said is used as a signal mark of the present invention for integrated manifold block for providing hydrogen of hydrogen tank fuel cell with hydrogen and venting and venting system ejector for introducing hydrogen-, and supplying hydrogen to a hydrogen supply valve, for performing purge hydrogen is driven-purge valve is incorporate, the upper part of the chamber for gas manifold block and supplying hydrogen to recirculated hydrogen liberating tool configured are connected in an aperture site line, said condensed water chamber above said manifold block top of the wafer is loaded on the second hydrogen recirculation located the hydrogen supply-release module; characterized in that comprises. Said manifold block the air and package lead molding die of semiconductor fabrication, the discharging fluid passage and hydrogen is integrally condensing chamber of exhaust line consists of. Said ejector hydrogen and recycling hydrogen is introduced into the hydrogen recirculation line entrance region of lines which are provided on, said hydrogen supply valve and said purge valve said hydrogen recirculation line for length of the high temperature is arranged. Said hydrogen supply valve 2000 forwardly of said purge valve. Said hydrogen supply valve a hydrogen is introduced into the number 1 hydrogen supply valve and, said number 1 hydrogen supply valve connected with the hydrogen recirculation a plurality of memory cells connected to said hydrogen supply valve consists of number 2. Said hydrogen O-rings the pressure hydrogen pressure and module that is further comprised of a method of thermoplastic resin sheet using the and, said valve said method of thermoplastic resin sheet using the hydrogen recirculation line is connected to said hydrogen recirculation line and are integrated. The outlet of the method of thermoplastic resin sheet using the air outlet is connected to said manifold block. Said valve of thermoplastic resin sheet using the same said hydrogen supply valve and said purge valve with full length of said hydrogen recirculation line which is arrayed in length, 2000 the lid is combined with the body of said purge valve. Furthermore, said is used as a signal mark of the present invention for integrated manifold block for providing hydrogen of hydrogen tank fuel cell with hydrogen and venting and venting system ejector for introducing hydrogen-, and supplying hydrogen to a hydrogen supply valve, purge valve for performing purge hydrogen, hydrogen pressure and the pressure method of thermoplastic resin sheet using the incorporate is is connected, manifold block from above linearly polarized of the chamber for gas located top of manifold block said hydrogen recirculation the wafer is loaded on the second the hydrogen supply-release module; is characterized in that the include. The present invention refers to such supply and discharge hydrogen modular component can be located on top manifold block, in particular a cover of separately with external manifold block without a component of (Fail) in a component onto a separate or assembled condition the guide part is. a. Furthermore, the present invention refers to hydrogen supply and discharge and the case is mounted made by the advertisement improved production rates of fuel cell vehicle, in particular when problem occurs component contains a combining easy maintenance.. Furthermore, the present invention refers to hydrogen supply line and recirculation line the structure of an equipment by being configuration integrally block the manifold fuel cell stack from a recycle hydrogen flow a through hole which is formed on line hydrogen liberating tool configured condensing chamber on an upper portion condensing chamber by connecting outlet line for sensing leakage in of droplets discharge off together with hydrogen where condensation in cold starting in a purge valve with a second, installed inside the, flows into or from condensed water in particular narrow engine room even under malfunction of a purge valve in. easy maintenance. Furthermore, the present invention refers to method of thermoplastic resin sheet using the hydrogen discharged by an electrochemical reaction line and the outlet of the valve and series-coupled air outlet by coating a photoresist on the resultant, so that it has the same simpler configuration. Also the present invention according to Figure 1 shows a fuel cell with integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system configuration, of, the present invention according to the 2 fuel cell with integrated manifold block for providing hydrogen of hydrogen tank and ejector system is fuel cell stack and the signal generator is connected with the hydrogen-is in a state that is supply and discharge hydrogen. Thereby, the cold air flows an exemplary scavenger attached hereinafter of the present invention embodiment describes detailed with reference to a drawing, such embodiment relate as an example the present invention is in the field of the different types to person with skill in the art in various as it can be implemented in, a embodiment aspect described herein is not limited. Figure 1 the present embodiment for providing hydrogen of hydrogen tank for a fuel exhibits configuration of and venting and venting system. Drive the discharge lamp, for providing hydrogen of hydrogen tank and venting and venting system a fuel cell stack configured with the manifold block (1), and supplying hydrogen to and recycling hydrogen to manifold block (1) by refrigerant delivered from the lower stage disposed top of blower recirculation a hydrogen is not to be applied (Blower) O-rings module (100) consists of to. Said manifold block (1) includes a cooling water channel across a width of the (1-1) together with air flow passage is defined, said cooling water flow path (1-1) the air passage (1-2) of the block are demarcated and a (1) inner space of the reservoir into a is compartmentalized. Furthermore, said manifold block (1) a heater for heating the heated air the (10-1) number 1, 2 together with a bracket (10-2, 10-3) is may be included. Conventional, said heater (10-1) said number 1, 2 and a bracket (10-2, 10-3) a manifold block (1) 2000 the bottom of the. Said hydrogen O-rings module (100) the ejector (20), hydrogen supply valve (30A, 30B), purge valve (40), method of thermoplastic resin sheet using the (50) together with a hydrogen supply line (100-1) and hydrogen recirculation line (100-2) and hydrogen exhaust line (100-3) is may be included. Said ejector (20) the jet pump tap in which a nozzle is equipped for supplying recirculation blower hydrogen by one receiving party. supply of the feeds hydrogen fuel cell stack. Therefore, said ejector (20) the hydrogen recirculation line (100-2) 19 are provided on the. In particular, said hydrogen recirculation line (100-2) entrance region of the exhaust line (100-3) is connected with a, said hydrogen exhaust line (100-3) the fuel cell stack from a recycle hydrogen condensed water of an outlet line on an upper portion chamber next, condensing chamber by connecting for sensing leakage in of droplets discharge off together with hydrogen purge valve (40) where condensation in cold starting in a with a second preferably, a plurality of adhesive parts which features may be embodied in. Said hydrogen supply valve (30A, 30B) the a hydrogen to control the pressure of the fluid which, number 1, 2 hydrogen supply valve (30A, 30B) consists of to. In particular, number 1 hydrogen supply valve (30A) and a valve connection (30-1) number 2 hydrogen supply valve is connected (30B) is are integrated. Therefore, said number 1 hydrogen supply valve (30A) the supply line (100-1) may be connected and, said number 2 hydrogen supply valve (30B) the hydrogen recirculation line (100-2) is connected to. Thereby said number 1, 2 hydrogen supply valve (30A, 30B) the hydrogen recirculation line (100-2) and are integrated. In particular, hydrogen recirculation line (100-2) the number 1, 2 hydrogen supply valve (30A, 30B) supplied directly hydrogen passing pressure pre-pressure hydrogen by selection results, eliminating the need for a line of hydrogen supply separate which features may be embodied in. Said purge valve (40) the purge valve connection (40-1) is connected with a, purge valve connection (40-1) the hydrogen recirculation line (100-2) is connected to. Therefore, hydrogen recirculation line (100-2) the number 1, 2 hydrogen supply valve (30A, 30B) together with a purge valve (40) also are integrated. Thereby, hydrogen recirculation line (100-2) the number 1, 2 hydrogen supply valve (30A, 30B) as a result of a reduction in addition to a differential pressure by purge valve (40) by a differential pressure reduction input unit simultaneously can be are limited to a minimum differential pressure. In particular, purge valve (40) to right to even results into a filter housing cold starting condensed water hydrogen recirculation line (100-2) in purge valve (40) only by separating simply is the main component which has an improved maintenance. Method of thermoplastic resin sheet using the (50) the connection (50-1) is connected with a, connection (50-1) the hydrogen recirculation line (100-2) is connected to. Therefore, hydrogen recirculation line (100-2) the number 1, 2 hydrogen supply valve (30A, 30B), purge valve (40) together with a method of thermoplastic resin sheet using the (50) also are integrated. In particular, method of thermoplastic resin sheet using the (50) has a manifold block (1) so as to thereby and air outlet method of thermoplastic resin sheet using the (50). a coil spring more association of the configuration. The present in the embodiment method of thermoplastic resin sheet using the in (50) can be constructed separately. As such, hydrogen O-rings module (100) the hydrogen recirculation line (100-2) hydrogen supply line (100-1) and hydrogen exhaust line (100-3) is connected with a, in particular hydrogen supply line (100-1) about a ejector (20), hydrogen supply valve (30A, 30B), purge valve (40), method of thermoplastic resin sheet using the (50) are integrally manifold block (1) assembly to very samples. While, according to Figure 2 the present embodiment a manifold block (1) and hydrogen O-rings module (100) and fuel cell stack (200) a hydrogen-implemented between the flow of hydrogen, condensed water exiting flows, turbocharging lower emissions of carbon exhibits flow. Drive the discharge lamp, ejector (20), hydrogen supply valve (30A, 30B), purge valve (40), method of thermoplastic resin sheet using the (50) of lead wire and transmission cable for hydrogen recirculation line (100-2) to a manifold block (1) for assembling a tool, manifold block (1) to the fuel cell stack (200) and couples the bolting, hydrogen supply line (100-1) connecting the consisting of the assembling operation is reacted with a. In particular, ejector (20), hydrogen supply valve (30A, 30B), purge valve (40), method of thermoplastic resin sheet using the (50) of lead wire and transmission cable for the hydrogen supply-release module (100) the manifold block (1) and is located on top of, a hydrogen such assembly O-rings module (100) for a manifold block (1) out of separate cover applied is eliminated by ejector (20), hydrogen supply valve (30A, 30B), purge valve (40), [...][...][...]㉨[...] (50) of (Fail) in a component onto a separate or assembled condition the guide part is feature may be embodied in. Furthermore, manifold block (1) toward an inside of the water trap (Wator Trap) (300) and humidifier (400) is is further included in, the water trap (Wator Trap) (300) a manifold block (1) hydrogen exhaust line (100-3) my wave bolting lower is manifold block (1) is connected to. In particular, manifold block (1) and hydrogen O-rings module (100) and fuel cell stack (200) for hydrogen feeding-hydrogen re-circulating blower (Blower) has is not to be applied. The present in the embodiment of hydrogen on board a O-rings module (100) through hydrogen and recirculation the flow of hydrogen is composed as follows. Fuel cell stack (200) upon actuation thereof is, hydrogen supply line (100-1) exhaust line and hydrogen, is supplied from a (100-3) supplied from a fuel cell stack (200) for recycling hydrogen ejector (20) movable pump nozzle jet of hydrogen recirculation line (100-2) is flowing into the. Specifically, hydrogen hydrogen supply line (100-1), number 1 hydrogen supply valve (30A) the valve connection (30-1) number 2 after undergoing hydrogen supply valve (30B) hydrogen recirculation line then by cutting (100-2) in includes a top face, a fuel cell stack hydrogen recirculation (200) of hydrogen on board a exhaust line (100-3), hydrogen recirculation line (100-2) is introduced into. Furthermore, hydrogen-hydrogen hydrogen recirculation line (100-2) mix while hydrogen recirculation line (100-2) is followed outlet of the fuel cell stack (200) is supplied to emitter. Such hydrogenated number 1, 2 in the flow of hydrogen supply valve (30A, 30B) mark hydrogen recirculation line (100-2) supplying hydrogen to by of hydrogen supply line eliminating the need. reduced large pressure difference exceeds to oils. Furthermore, a fuel cell stack hydrogen recirculation (200) from a recycle hydrogen condensed water of an outlet line on an upper portion chamber next, condensing chamber by connecting for sensing leakage in of droplets discharge off together with hydrogen purge valve (40) where condensation in cold starting in a with a second large and results, in particular, purge valve (40) to right to even results into a filter housing cold starting condensed water hydrogen recirculation line (100-2) in purge valve (40) only by separating simply and very maintenance samples. And, hydrogen recirculation toward the condensate water receptacle of water manifold block (1) hydrogen exhaust line (100-3) directly affecting a water trap (Wator Trap) (300) me and humidifier (400) and also sent to a. While, such hydrogenated in the flow of hydrogen recirculation line (100-2) turbocharging hydrogen pressure of the nozzle in one hydrogen recirculation line (100-2) to connection (50-1) method of thermoplastic resin sheet using the strings connected (50) is the groove on action of. In particular, method of thermoplastic resin sheet using the (50) provided to concentrate a supercharge hydrogen the manifold block (1) of air passage (1-2) after flowing, manifold block (1) fuel cell stack exit to the air discharge opening (200) the hydrogen supply stable. can be made. As the aforementioned, the present embodiment according to fuel cell with integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system the ejector for introducing hydrogen-(20), and supplying hydrogen to a hydrogen supply valve (30A, 30B), for performing purge hydrogen purge valve (40), the pressure hydrogen pressure and method of thermoplastic resin sheet using the (50) incorporate is is connected, manifold block (1) the upper part of the chamber for gas and supplying hydrogen to recirculated hydrogen liberating tool configured line (100-3) are connected in an aperture site is, said condensed water chamber above said manifold block (1) located top of hydrogen recirculation line (100-2) consisting the hydrogen supply-release module (888000066688 8); functions supported by an apparatus for recording ejector (20), hydrogen supply valve (30A, 30B), purge valve (40), method of thermoplastic resin sheet using the (50) maleamic of modules the locker by condensation while concentrated purge valve (40) are found to exhibit significantly enhanced is at cold start for an, in particular manifold block (1) relative to the outside of cover separate components that modular for aesthetic of separate or-assembled state are maintenance panel maintenance and to improve the component the. are extremely improved in enhancing productivity. 1: manifold block 1-1: includes a cooling water channel 1-2: air passage 10-1: heater 10-2, 10-3: number 1, 2 bracket 20: ejector 30A, 30B: number 1, 2 hydrogen supply valve 30-1: valve connection 40: purge valve 40-1: purge valve connection 50: method of thermoplastic resin sheet using the 50-1: connection 100: hydrogen O-rings module 100-1: hydrogen supply line 100-2: hydrogen recirculation line 100-3: hydrogen exhaust line 200: fuel cell stack 300: water trap (Wator Trap) 400: humidifier The present invention relates to a system of supplying and discharging hydrogen for a fuel cell having an integrated manifold block, comprising a hydrogen supply and discharge module (100) where an ejector (20) which inflows the hydrogen and recirculating hydrogen, hydrogen supply valves (30A, 30B) which supply the hydrogen, a purge valve (40) which carries out a hydrogen purge, and a pressure reducing valve (50) which maintains a hydrogen pressure, all are connected and integrated, and where a hydrogen discharge line (100-3) which supplies the recirculating hydrogen in an upper part of a condensate water chamber of a manifold block (1) is connected to an inlet area, and including a hydrogen recirculating valve (100-2) located in an upper end of the manifold block (1) comprising the upper part of the condensate water chamber. Therefore, a modularization rate of the ejector (20), the hydrogen supply valves (30A, 30B), the purge valve, and the pressure reducing valve (50) is higher while cooling startability of the purge valve (40) by condensate water is significantly improved. Especially, since maintaining individual modularized components or in a state of being assembled by not applying an additional cover for the outside of the manifold block (1) is possible, the present invention enables to significantly improve an increase of productivity through an improvement of maintenability and an improvement of component assembly ability. COPYRIGHT KIPO 2015 Ejector for introducing hydrogen-hydrogen, and supplying hydrogen to a hydrogen supply valve, for performing purge hydrogen is driven-purge valve is incorporate, the upper part of the chamber for gas manifold block and supplying hydrogen to recirculated hydrogen liberating tool configured are connected in an aperture site line, said condensed water chamber above said manifold block top of the wafer is loaded on the second hydrogen recirculation located the hydrogen supply-release module; characterized by to with fuel cell with integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system. According to Claim 1, said manifold block the air and package lead molding die of semiconductor fabrication, the discharging fluid passage and hydrogen integrally comprises condensing chamber of exhaust line is characterized by fuel cell with integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system. According to Claim 1, said ejector hydrogen and recycling hydrogen is introduced into the hydrogen recirculation line entrance region of lines which are provided on, said hydrogen supply valve and said hydrogen recirculation line for said a purge valve are arranged along length to characterized by fuel cell with integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system. According to Claim 3, said hydrogen supply valve located the front side of said purge valve to fuel cell with characterized by integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system. According to Claim 4, said hydrogen supply valve valve and hydrogen supply number 1 is introduced into the hydrogen, said hydrogen supply valve said number 1 connected with the hydrogen recirculation plurality of memory cells connected to the hydrogen supply valve is made of a magnetizing coil, number 2 characterized by fuel cell with integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system. According to Claim 1, said hydrogen O-rings the pressure hydrogen pressure and module that is further comprised of a method of thermoplastic resin sheet using the and, said valve said method of thermoplastic resin sheet using the hydrogen recirculation line is connected to said hydrogen recirculation line is integrally formed with a fuel cell with characterized by integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system. According to Claim 6, the outlet of the method of thermoplastic resin sheet using the air outlet manifold block characterized by and penetrates an fuel cell with integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system. According to Claim 6, said valve said method of thermoplastic resin sheet using the hydrogen supply valve and said purge valve with full length of said hydrogen recirculation line which is arrayed in length, located behind purge valve said to characterized by fuel cell with integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system. Ejector for introducing hydrogen-hydrogen, and supplying hydrogen to a hydrogen supply valve, purge valve for performing purge hydrogen, hydrogen pressure and the pressure method of thermoplastic resin sheet using the incorporate is is connected, manifold block from above linearly polarized of the chamber for gas located top of manifold block said hydrogen recirculation the wafer is loaded on the second the hydrogen supply-release module; characterized by to with fuel cell with integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system. According to Claim 9, said ejector hydrogen and recycling hydrogen is introduced into the hydrogen recirculation line entrance region of lines which are provided on, said hydrogen supply valve and said purge valve and preparation method of thermoplastic resin sheet hydrogen recirculation line for said valve are arranged in length of the high temperature, said hydrogen supply valve is located into the front side of said purge valve, a purge valve said method of thermoplastic resin sheet using the located the front side of said to characterized by fuel cell with integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system. According to Claim 9, said hydrogen supply valve valve and hydrogen supply number 1 is introduced into the hydrogen, said hydrogen supply valve said number 1 connected with the hydrogen recirculation plurality of memory cells connected to the hydrogen supply valve is made of a magnetizing coil, number 2 characterized by fuel cell with integrated manifold block for providing hydrogen of hydrogen tank and venting and venting system.