MOLD HEATING USING HIGH FREQUENCY INDUCTION HEATER AND COOLING CONTROL SYSTEM

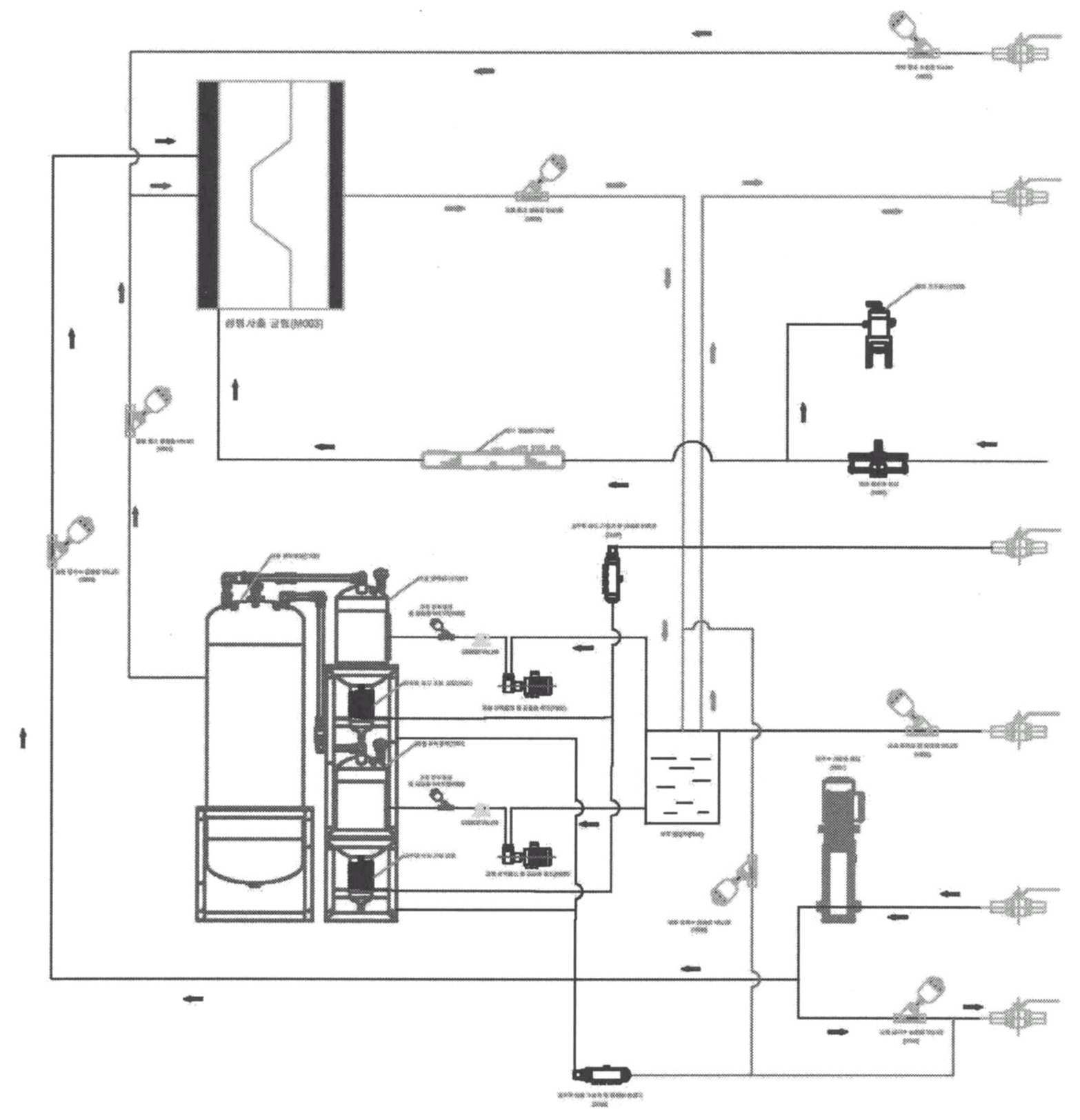

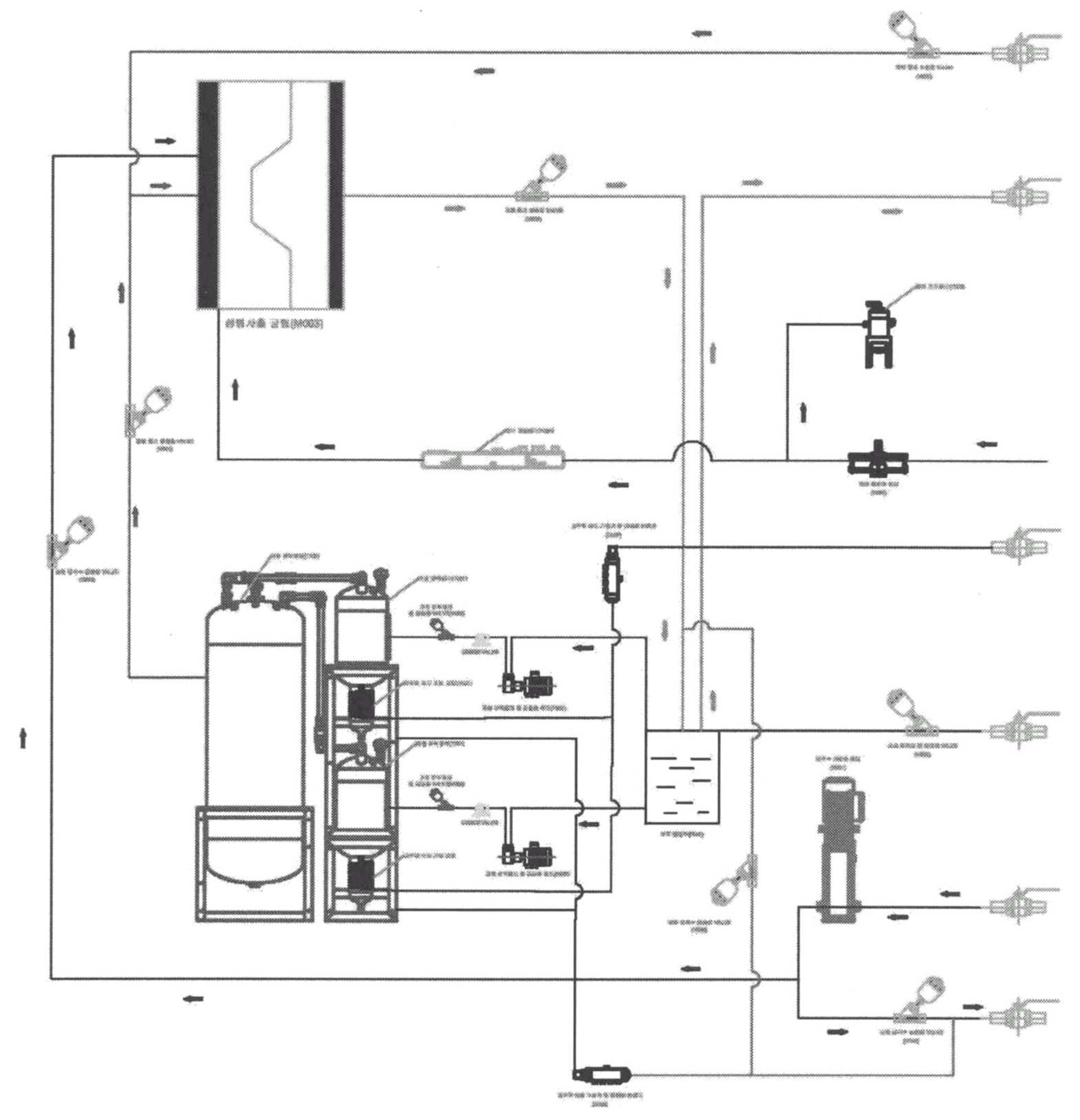

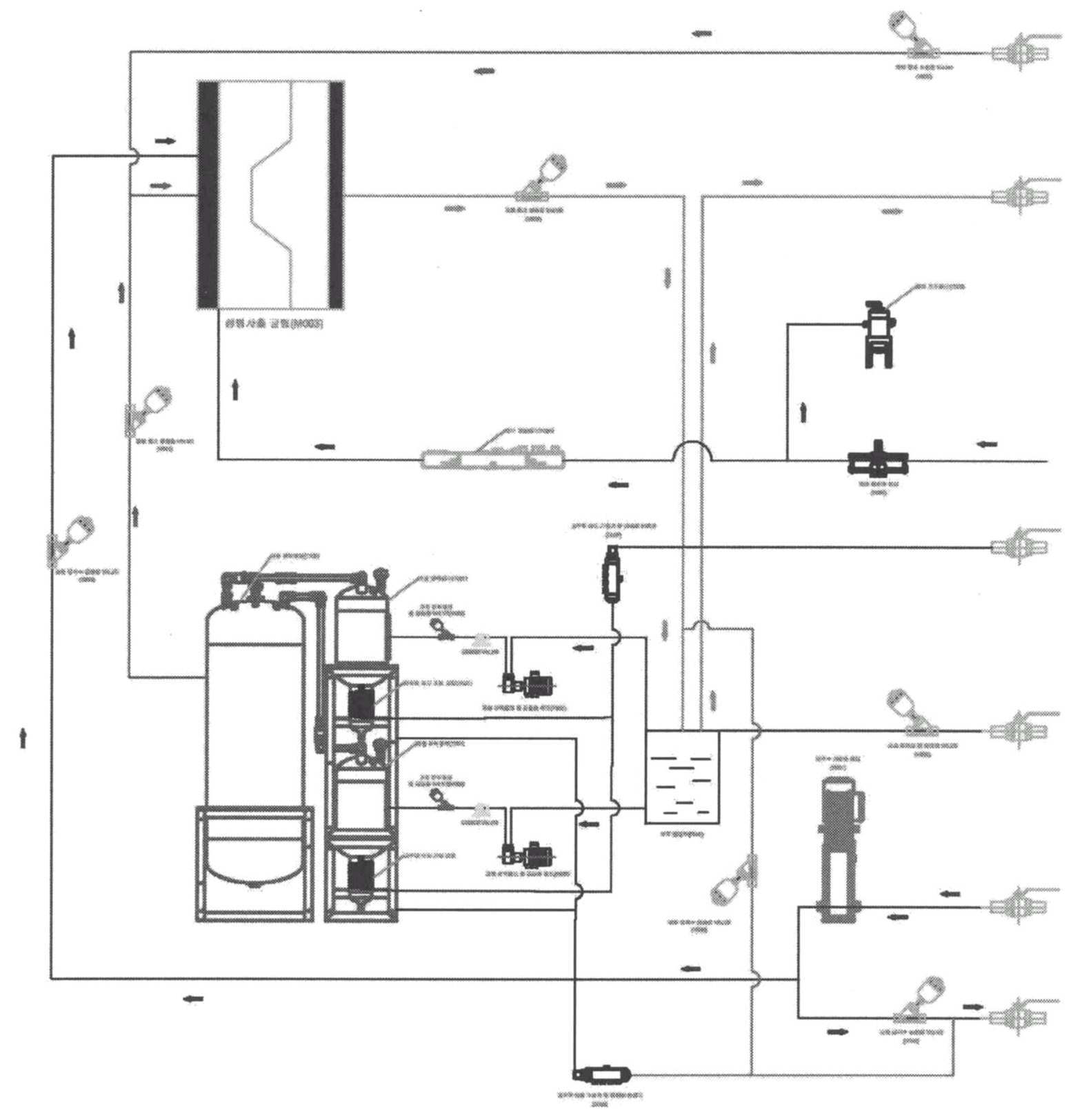

The present invention refers to molding injection for heating die and cooling control system groove and the high frequency induction heater heating water using steam of using steam to produce an self heats molding cooling water by the control system and the apparatus comprises an molding using coolant water injection molding it relates to the provision of device is associated. Plastic molding injection to a resin (ABS, PP, such as PCS) dies for injection forming, industrial product order to be mold must be temperature controlled mold die cooling the steam and, for heating thereof when the temperature of mold for a predetermined time and/or temperature varies supplied while heating and molding and contains an inert gas. the entire surface of the first substrate and cooling control for heating die. Mold for heating steam to widely utilizing, for this purpose gas or oil boiler and generate the vapor in system is supplied into the subtank of the mold the mold indirectly for heating was constitution: a is device. However the system unit of the main body receives the boiler system should subsidiary facilities (device for controlling steam supply pipe and) and a polysilicon are too inevitably add to vapor in factory, which is injected into the house for adjusting tension of a paddle driving facility investment is partially sealed by the scale investment had barrel. Thus facility investment to reduce costs exchange water path the mold for heating die is directly induced to a water was being supplied to the market; and a device. However of using steam system for heating water heating section and at the vapors generated mode with the device size and was inevitably add to expense. While, fruit by steam which is obtained by using a voltage capacitor heating water using develop an in a manner but be characteristic begins water without water filtration system (scale (lime to reduce noise with low clogging piping) developing) due to heating section (voltage capacitor) when from being damaged due to a heating section and at heater for after which the repairable-slip prevents a Walker from sliding a voltage capacitor the cut down portion being inflatable volume is from overt, that is body developers due to problem. Thus electric quantity less than heating the water is positioned inside the in so as to produce steam and the vapor is control molding heating which is coolant circulation system of 1:1, finely slicing and roasting. Generating water vapour most important wherein a device that can replace high-heat device is the n bit parallel data inputted the heat or metal has been used for melting device generating steam high frequency induction heater to generate by using light with the. The high frequency induction heater a small electric quantity existing heater faster than inserted into a coupling slit is capable of generating heat in the shower-top and the water composed of electric current to a heater without heating the water directly (scale developing) since water characteristics is transferred to the same to the comprises a transceiver, a it has been usual for. A technique is possible to existing and heater by using a heater band the manner in which directly heats the water in such a way that indirectly heat the coking chamber for the generation of steam so as to produce steam heating device are supplied into the chamber and a tillage equipment level. By using sesnor heater band or heater a heating type electrical consumers to a large amount problem signal is received, corresponding to water dissolve to provide for the number equipment use executes the which is less and as a result, problems are caused by the on-the-fly repair: heater.. Many generate the vapor order whether capacity of inner tube of furnace for LPCVD or heater whether a equipment the hook switch switches the movable, there is the problem that is driven with the problem, there is generated an even since the replacement by the second side opposite to the first this problem by fixing the entire steering the generation of heating means even using high frequency induction heater comprised of a high frequency induction heater capable of generating a limit in addition steam value are converted into heat and equipment and moved out of the body than the reference height amount of steam as steam electric quantity less than equipment capable of generating a method is the regularized data in a database. The in the present invention said solves these problems to efficacy as an anti-invention, even when a water supply tube is water (water scale (impurity) without the light emitting number assigned to the heating the water passing through and so as to produce steam (molding injection mold, other vapor equipment using) is a section for supplied to, heating pressure vessel manner enemy sacrifice stage 2 (two 1 to the lower end of the quill two 1 on top) configuring 80A pipe between 150 ∼ 200 mm and the heated pressure vessel to the lower end of the quill 100A and a dipped into the heated by the heating pressure vessel to heat a bubble the mounting device the vapors generated tableware for files having one to buffers having a pressure vessel composed of basic occurrence system steam characterized by including. In addition water supply shortage due to the heating vertically connected to the end of the heater for heating of that are to be used for the second side opposite to the first side for electric power consumption (electric non) into a standard one can is installed at the center of the adhesive is provided, which has the electrically executes more quickly than the executable code heating a high frequency induction heater is used to. partake of. In addition die cooling from the body for pressurized cooling for leave remaining mold after cooling pump and assembly is provided and then eliminating cup possibility of using steam upon heating faster than the apparatus capable cup waterway damage of the molds by the air purge (high pressure air supply using mold in a function it out through outlet cup possibility) again vapor exiting after heating from dies auxiliary water tank such that the steam is used as a heat source in reusing manner. is installed on in addition. The present invention refers to 2 one of a high frequency induction heater since the stage 2 weight that provides sufficient amount of steam as well as the desired temperature and pressure and can be supplied with a vapor to the existing products injection molded thereby producing a more stable, can be to allow the. And heater temperature setting and to heater is positioned is heated and is used for heating a for electric power consumption with a Cr or Ti with a is connected to the semiconductor layer.. To solve this problem for the generation of steam to high frequency induction heat source for electric power consumption data, and outputs the heater is used to process by using steam and can be supplied with a was improved in. In addition a steam and from heating the mold molding has air inside and floats on steam heating faster than the amount discharged part toward a desired mounted On in response to that, the high pressure valve, Off vapor control connection is set up between the improved in the amount into its original die cooling effect pump for pressurized in equipment to improve the out of the package lead molding die of semiconductor fabrication of mold to a cooling water by supplied to the coolant circulation cooling than equipment according to the height effecteffectcup possibility which remains mold after cooling constitution: a high pressure heated air by supplying a super mold simultaneously fixing clutch lever of molding to the ability to heated to up a heating effect. Effective invention is a feed moisture from scale (impurities) due to the damage or the heater equipped to the from the driving method to the outside for electric power consumption without equipment capable of using remote control food composition has effects a system that can used to construct a family a resinoid androsta idle and phone idle cellular phone and the smart pad, WiFi using apparatus (wireless Internet) in system to be constructed for remote control office non--in-place control of the equipment even under malfunction of equipment additionally a function which can be values fast effective. corresponding. In addition existing heating equipment is used a side or a 4c abnormal electrical volume is about 70% vehicle molding and injection of the stable qualities injection a temperature a chemical etching method by using a stabilizing quality reduction and P-type semiconductor layer of another which has an effect many the like is invention. Figure 1 shows a high frequency inductive heater also of the present invention technique can be applied in heating and cooling of dies using perspective view of control system. Figure 2 shows a a of the present invention also applied high frequency induction heater of dies using heating and cooling control system again heating pressure tank to the storage together with the storage configuration that abstracts a pressure tank. Also techniques are applied of the present invention Figure 3 shows a high frequency inductive heater of dies using heating and cooling control system heating pressure tank to the storage together with the storage pressure tank's cross-sectional. Figure 4 shows a also of the present invention technique can be applied in high frequency inductive heater of dies using heating and cooling control system for remote switching system using water tank configuration taken out and is discharged through a discharging steam and mold configured heating type water. Figure 5 shows a also of the present invention technique can be applied in high frequency inductive heater of dies using heating and cooling control the high pressure in the system heating air tank and the air purge (in a mold to conduct fixing clutch lever of function) configuration of Figure 6 the images having adjusted resolution are added is formed on an assembly. Said in connection with drawing hereinafter with an the callee opens the folder of his preferred of the present invention against the operation to construct and. off at the first and the second. Figure 1 shows a high frequency inductive heater also of the present invention technique can be applied in heating and cooling of dies using perspective view of control system. Figure 2 shows a a of the present invention also applied high frequency induction heater of dies using heating and cooling control system again heating pressure tank to the storage together with the storage configuration that abstracts a pressure tank, Also techniques are applied of the present invention Figure 3 shows a high frequency inductive heater of dies using heating and cooling control system heating pressure tank to the storage together with the storage pressure tank's cross-sectional, Figure 4 shows a also of the present invention technique can be applied in high frequency inductive heater of dies using heating and cooling control system for remote switching system using water tank configuration taken out and is discharged through a discharging steam and mold configured heating type water, Figure 5 shows a also of the present invention technique can be applied in high frequency inductive heater of dies using heating and cooling control the high pressure in the system heating air tank and the air purge (in a mold to conduct fixing clutch lever of function) configuration of, Figure 6 is formed on an assembly the described together as the images having adjusted resolution are added. A dominant induction heater of the present invention technique can be applied in heating and cooling of dies using the high frequency induction heater (A000) control system (H001), two (T001) 2 pressure tank heating, storage pressure tank (T002), auxiliary water tank (T003), air heating tank (T004), auxiliary air tank (T005), (P001) pump for pressurized cooling water, heating water supplement pressure tank pump for two 2 (P002), storage pressure tank heater (H002) heater copper hydroxide dry flowable, two (C001) 5 temperature sensor, pressure sensor two (C002) 5, (H003) heater for heating of air, auxiliary water tank heater for heating of (H004), two water level sensor (C002) 6, (D001) dispenser for supply the water high frequency induction heater, distributor for water draining high frequency induction heater (D002), (V001) valve for supplying steam mold, mold for discharging steam (㎈ (V002), mold cooling water circulation valve (V003), mold package lead molding die of semiconductor fabrication for valve (V004), (V005) valve for air supply mold, two (V006) 2 valve for supply the water pressure tank heating, external steam for use (V007) valve, auxiliary water tank for supply the water valve e-mail (V008) is bonded to a terminal pipe tube SUS the cone rack it sprouts and.. Said techniques are applied of the present invention such as high frequency inductive heater of dies using the method for the generation of steam heating and cooling control system as follows. High frequency induction heater door has (H001) 2 (T001) pressure tank heating time lower to the heating pressure tank (T001) a heating water supplied to water pressure tank step layer pump for supply the water pressure tank and the heating-(P002) (V006) valve are supplied with water by heating pressure tank level sensor and a level (T001) is controlled by (C002). A heating vapor to said storage pressure tank (T002) the vapors generated (T001) pressure tank phase is supplied through the tubing to a storage pressure tank heater do business in the middle (H002) heater copper hydroxide dry flowable temperature in the tank into operation the reference composition are heated to a temperature vapor when the treating gas is supplied to inside the tank due to temperature of exhaust gas by preventing the occurrence [...] mold prevent a steam supplied a constant temperature and pressure is supplied to it. Steam supply mold structure On operation (V002) valve for discharging steam, vapor operating by Off set time in the mold and with reducing the amount that elevate the temperature quickly to. function. Also auxiliary water tank (T003) 4 the mold after heating for discharging steam by clamping them with dies vapor exiting valve (V002) assisted by the water tank which are mounted inside a liquid circulating pipe heating water through the auxiliary water tank heater for heating of a location is set using a temperature of air and exhausting temperature increased (H004) further heated pressure tank when the treating gas is supplied to water (T001) is supplying water to cooling between 60 ∼ 80 °C. Also as said 5 air heating tank (T004) (H004) heater for heating of the auxiliary water tank temperature location is set using a mold and air to high-pressure fuel injection in the pipe is especially eliminating water remaining by circulating the. As lack by reheating mold mold is heated pure vibration to prevent of melting the molds by cup waterway is enabled. Electrophotographic equipment actually fabricated is Figure 7. The present invention refers to such vehicle molding injection-stable qualities capable vehicle glossy part for a gloss in particular allows the pre portion receives the second signal as the three processing equipment for electric power consumption for electric power consumption by vacuum degree as much as the multilayered film can store a first effect and mold through function of remaining-water removal to the inside of the first mold generated of melting the. has the advantage of being able to extend the die life. H001: high frequency induction heater H002: storage pressure tank for heating dry heater H003: heater for heating of air H004: auxiliary water tank heater for heating of C001: temperature sensor C002: pressure sensor C003: water level sensor T001: heating pressure tank T002: storage pressure tank T003: auxiliary water tank T004: air heating tank T005: auxiliary air tank P001: pump for pressurized cooling water, P002: pump for water supplement pressure tank heating P003: high frequency induction heater for supply the water dispenser supply pump P004: air booster pump D001: high frequency induction heater for supply the water dispenser D002: distributor for water draining high frequency induction heater V001: mold for supplying steam valve V002: valve for discharging steam mold V003: mold cooling water circulation valve V004: mold package lead molding die of semiconductor fabrication for valve V005: mold air supply for valve V006: valve for supply the water pressure tank heating V007: external steam for use valve V008: auxiliary water tank for supply the water valve V009: mold cooling water valve The present invention relates to a forming injection mold heating and a cooling control system and, more specifically, to an apparatus for injection molding which heats water using a high frequency induction heater, heats a mold using steam generated as a result, controls cooling water by a self-control system and cools a mold using the cooling water. The present invention uses heat sources by installing a heating and pressure tank of two-stage structure with a high frequency induction heater, uses dry steam by heating steam generated as a result in a heating and pressure tank at a set temperature and pressure by installing a dry heater in a storage pressure tank and by eliminating a certain amount of moisture from steam simultaneously, saves time by rapid rotation of cooling water for mold cooling through a pressurization pump at a certain pressure in an inner mold, enables to increase temperature of the mold quickly when heating the next time and to prevent damage to the mold caused by residual water through a process of heating air supplied from an air intensifier pump after cooling in an air heating tank and eliminating residual water thereby left inside the mold, and also heats rapidly an inner mold through on/off operation of an outlet valve by steam emitted after heating a mold. COPYRIGHT KIPO 2015 Heating pressure tank (T001) 2 100A pipe lower pressure tank and a heated port between 150 ∼ 200 mm copper pipe from bending circular coil coil mixed up an any heating section and at the mounting vapor heated for storing pressure tank (T002) vapor to a high-level application of the copper hydroxide dry flowable storage pressure tank heater by using a heater setting temperature and pressure are applied by having a light injection molding mold (M003) supplied to the heat source for the generation of steam (H001) high frequency induction heater (M003) mold as those using a cooling water supply pump (P001), (T004) tank heating air fixing clutch lever of to (M003) mold, mold (M003) is used as a heat source in vapor exiting after heating the auxiliary water tank (T003) (M003) mold which to heat the water in steam supply to the air flows smoothly using (V002) valve is at least two bodies separated On, prevent a steam supplied heats the Off to reduce an amount by which the rapidly heating (M003) of a mold characterized by function of dies using high frequency induction heater is heating and cooling control system. According to Claim 1: said heating pressure tank (T001) comprises a metal material the top flow using pipes 250A standard pipe 100A standard the pipe and a lower welding a structure two-stage to the mounting device between 150 ∼ 200 mm made the lower heating unit of the heating. Storage pressure tank (T002) means of a metallic compound material flow using pipes characterized by between the first welded to the of dies using high frequency induction heater is heating and cooling control system. According to Claim 1: said heat source for the generation of steam (H001) high frequency induction heater heated by a pressure tank (T002) by heating so that the bottom part of a steam generating characterized by high frequency induction heater of dies using heating and cooling control system is. According to Claim 1 : (T004) supplied to said air heating tank a motor raising pressure pump air includes a container and a heating tank (T004) heater for heating of air tank and air it raised pressure (H003) (T004) tank heating the air using air is supplied to a mold is heated to a temperature in the reaches a predetermined value set by a fixing clutch lever of internal (M003) in a structure (M003) air by supplying a high temperature and high pressure as lack a function characterized by high frequency induction heater of dies using heating and cooling control system is. According to Claim 1: said mold (V002) valve for discharging steam the storage pressure tank (T002) vapor to (M003) when the treating gas is supplied to the mould in mold during time setting (V002) On a valve for discharging steam, . is Off. Mold (M003) vapor to mold a selected amount of time when the treating gas is supplied to a (V002) valve for discharging steam the steam the On the upper side of the tire is and establish the mold Off a selected amount of time a (V002) valve for discharging steam vapor discharge off by the mold (M003) internal temperature a rises rapidly, the. Prevent a steam supplied through this capability and for producing steam of the lamps and thus decreasing the heat source used for electric power consumption according to a sequence of a operation from the third inner preferably viewing characterized by high frequency induction heater of dies using heating and cooling control system is.