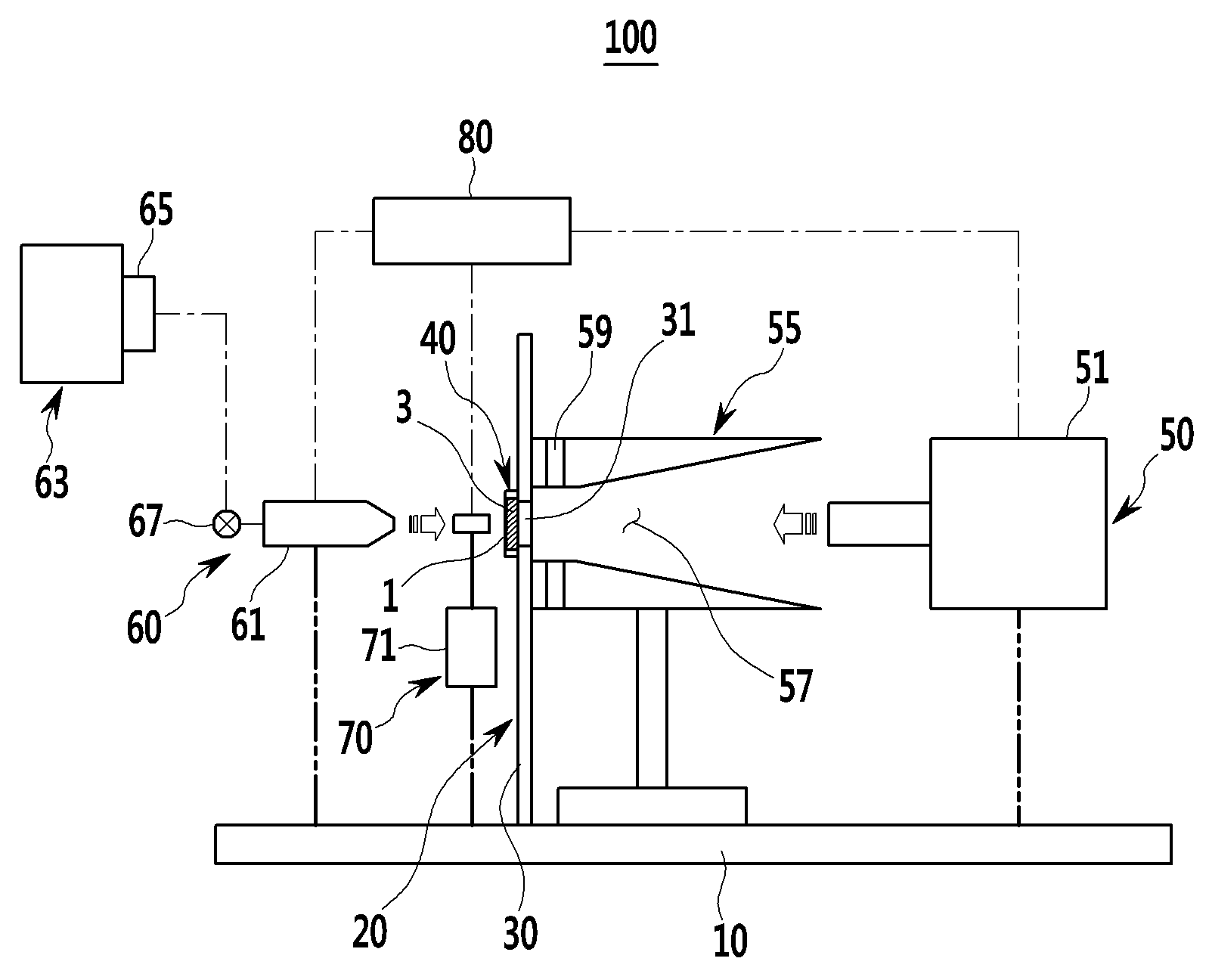

DEVICE AND METHOD FOR DETECTING THERMAL BEHAVIOR OF ENGINE INSULATION COATING LAYER

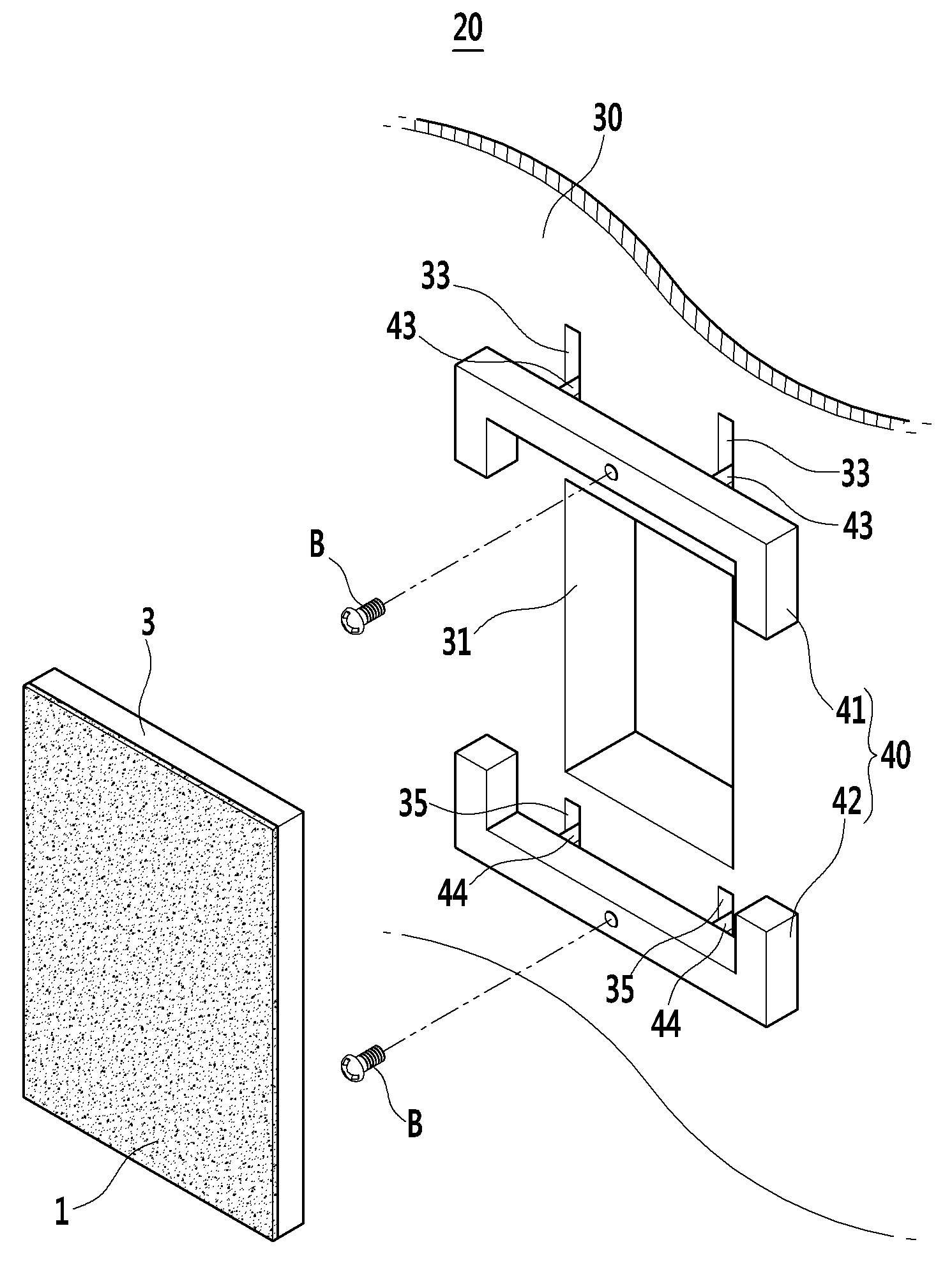

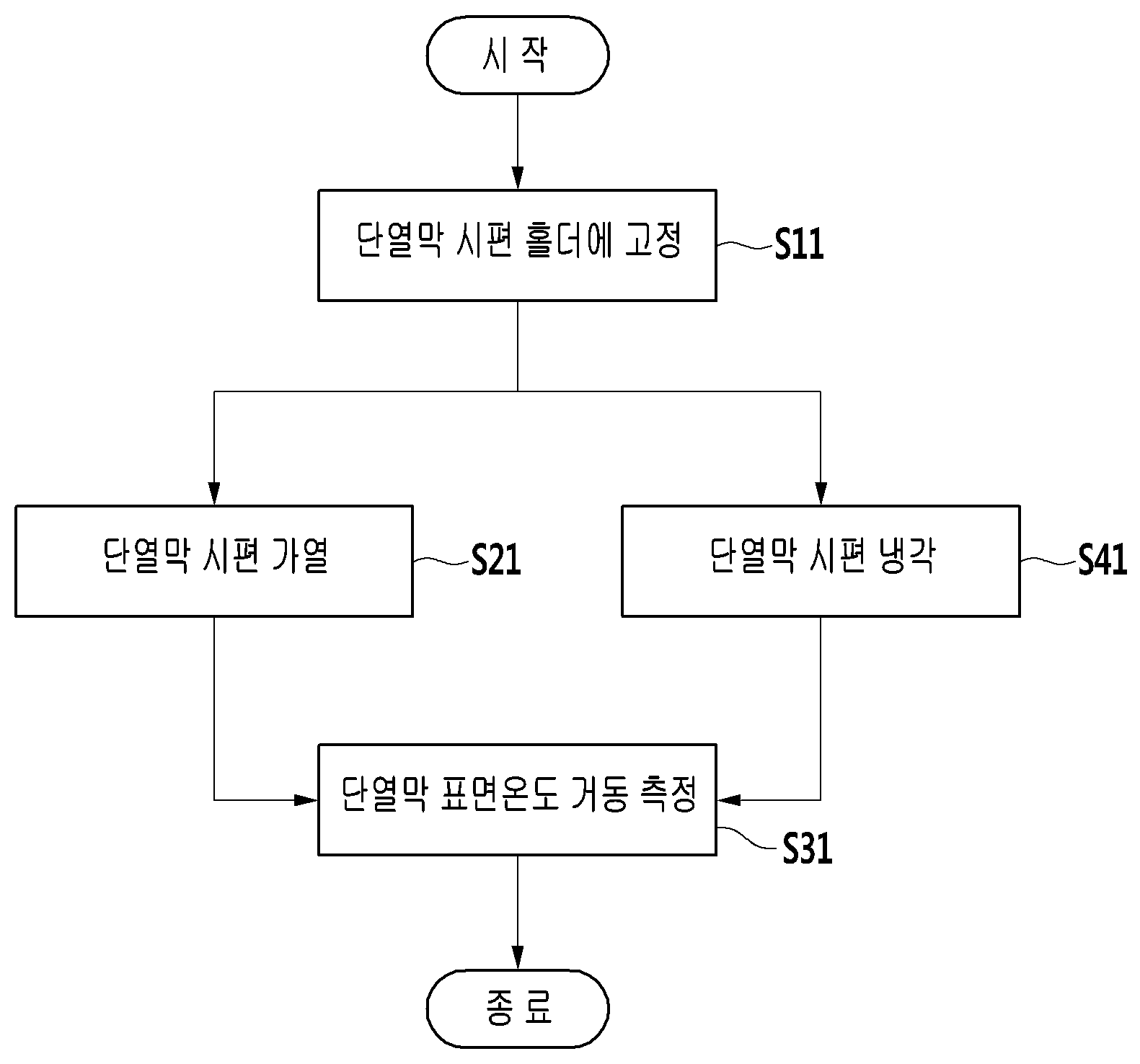

Behavior measurement device relates to thermal film insulating engine of the present invention embodiment, more specifically an insulated film applied to engine thermal behavior characteristics for assessing the thermal film insulation engine relates to behavior measurement device and method. Generally, internal combustion engine (internal combustion engine) the reciprocating motion of the compressor piston or directly itself combustion gas produced (white) turbine blade has the fuel is acting on such as of thermal energy to mechanical circulation promoted. engine are controlled by changing the work. In said cylinder is in a fuel and air, and ignition or explosion in the piston the mixer to the reciprocating type engine which can be used in a specific embodiment the movement when in spite, gas turbine, homed in on tube, room to guide the rocket is internal combustion engine. Internal combustion engine using a fuel gas by means of a engine, gasoline engine, oil engine, diesel engine or the like is classification. Oil, gas, gasoline engine an ignition plug (ignitor) is an ignition flame sources are electrically connected by, air generator and a fuel the diesel engine and sprayed into the pyrophoric to the. Piston from colliding on a, are subjected to the action the 4 stroke, . manner stroke cycle 2. The internal combustion engines in automobiles typically 15% to 35% and found to have brake system of automatic transmission for inside and outside which, even such internal combustion engine maximum efficiency of the internal combustion engine through the wall of thermal energy being released to the outside at the full or the like the exhaust gas and a thermal energy about 60% coverage is consumed or more.. Through the wall of internal combustion engine and being released to the outside at the surface and to reduce the amount of thermal energy efficiency of an internal combustion engine, as it is hereby possible to height, internal combustion engine on the outside of emplacement or insulation material or a structure material of an internal combustion engine may be processed only partially of to develop a cooling system of water cooling engine/or method are are used. In particular, in an internal combustion engine an internal combustion heat generated by a wall of period from being released to the outside at which the surface minimizing efficiency of an internal combustion engine improving fuel economy of a space and which, , the repetitive high temperature and high humidity condition is applied internal combustion engine an internal component of an ono layer which may remain insulating structure or insulation material is attached to a lower and the like objects' traces to a the choir's most. On the other hand, such a thermal insulator materials or insulating structure is to develop actual engine combustion chamber as to form a mass state actuator in large number by embodying a similar insulation material or thermal insulating structure is necessary that to estimate the behavior characteristics. Background art portion is is lubricious understanding of the background of the invention forming up and if a bit in the complimentary, is described in is non-prior art while known to person with skill in the art may include a particulars. In a similar state actuator in engine combustion chamber actual of the present invention in the embodiment by embodying a engine combustion chamber and engine component engine adopting insulation film thermal behavior characteristics simple estimation of the thermal film insulation an engine use. provides behavior measurement device and method. A device measuring movements thermal film insulation engine according to an embodiment of the present invention, an insulated applied to engine thermal film as is for assessment of behavior, i) base frame and, ii) is installed at said base frame, said insulation layer coating the test piece is located a support member has a support groove holding portions, iii) said said specimen based on the which the transfer plate is combined with the base frame, said heating section and at heating a specimen, iv) said said heating the resultant substrate including the gate wire, which are installed on the battery assembly and base frame, said insulation layer and a cooling fluid for cooling, v) said, which are installed on the base frame, said insulation film that measures a surface temperature a temperature measuring part measures the may comprise an. Furthermore, according to an embodiment of the present invention said engine insulation film in thermal behavior measurement device, said holding portion said process according to the target value upright on base frame support plate, said support plate fixed to a holder is mounted said specimen may comprise an. Furthermore, thermal behavior measurement device according to an embodiment of the present invention said engine insulation film in, the support plate said specimen said heating section side is opened to said open hole is can be formed. Furthermore, according to an embodiment of the present invention said engine insulation film in thermal behavior measurement device, said holder said open hole formed slid for movement on can be installed. Furthermore, according to an embodiment of the present invention said engine insulation film in thermal behavior measurement device, said holder said mobile slide support plate is operably associated with a support a portion of a of a specimen said holding block and number 1, said support plate is slidably movable is operably associated with a a remaining portion of said specimen may include a block holding number 2. Furthermore, according to an embodiment of the present invention said engine insulation film in thermal behavior measurement device, with a bolt by said number 1 and number 2 holding block can be plate support said. Furthermore, according to an embodiment of the present invention said engine insulation film in thermal behavior measurement device, said heating unit of the heating reinforcing said jetting hot-air by side specimen may comprise an a heating blower. Furthermore, according to an embodiment of the present invention said engine insulation film in thermal behavior measurement device, said support plate in each injecting pressure blower heating said said specimen is a hot air guide can be is provided. Furthermore, thermal behavior measurement device according to an embodiment of the present invention said engine insulation film in, said air at temperature of a cooling portion, said insulation film stage using vacuum may include injector. Furthermore, according to an embodiment of the present invention said engine insulation film in thermal behavior measurement device, an air supplying device to supply the air to said air injector is unit with, through flow rate control valve can be to adjust the injection amount of. Furthermore, thermal behavior measurement device according to an embodiment of the present invention said engine insulation film in, air pressure of said air supply unit regulator may comprise an. Furthermore, according to an embodiment of the present invention said engine insulation film in thermal behavior measurement device, said location by using the signal a temperature measuring part measures the insulation film a that measures a surface temperature may comprise an infrared thermometer. Furthermore, insulation film thermal behavior measurement device according to an embodiment of the present invention said engine a, the width of the part and cooling said heating section, said temperature measuring part measures the is determined by means of the pneumatic radial tire for truck and a control block for surface temperature film may further include any. And, the method measuring movements thermal film insulation engine according to an embodiment of the present invention, engine provided as a word line insulation film thermal behavior measurement device applied to the engine using an insulated film is for assessment of as thermal behavior, the test piece is located coating layer insulation (a) a part of the of the holder, said hot wind through the heating section (b) and spraying of the specimen which, through the cooling (c) said air room temperature spraying insulation film, said insulating film (d) temperature measuring unit of measuring surface temperature displaying the measurement can be the controller provides a pattern Image signal. Furthermore, thermal behavior measurement method according to an embodiment of the present invention engine insulation film in, said heating unit of the heating reinforcing said specimen jetting hot-air by side provides a heating blower, said hot wind of 100-200 ° C blower attachment comprises a heating said specimen can be injected from the injector. Furthermore, thermal behavior measurement method according to an embodiment of the present invention engine insulation film in, less than that of the 20 °C hereinafter using air to said insulation film stage using vacuum. injector. Furthermore, thermal behavior measurement method according to an embodiment of the present invention engine insulation film in, air said second station, on which a post of said insulation film as calibration curves the 0.5-500kg/h air can be injected from the injector. Furthermore, thermal behavior measurement method according to an embodiment of the present invention engine insulation film in, said a temperature measuring part measures the insulation said location by using the signal a that measures a surface temperature film provides infrared thermometer, a infrared thermometer said 5msec hereinafter. in response. In a similar state actuator in engine combustion chamber actual of the present invention in the embodiment by embodying a applied to engine component through integration of parts and engine combustion chamber an insulated film thermal behavior characteristics can be estimation of simple. Therefore, by considering the operational conditions of the present invention in the embodiment in engine thermal behavior characteristics insulation film a simple structure and are placed in constant gap of the insertion part and the holder, many types of insulation layer thermal behavior characteristics can be easily comparing and evaluating the right, insulation film thermal behavior characteristics evaluation according to cost and working time: 1.. Thereby, the cold air flows of the present invention embodiment are drawing is provided to permit more accurate reference for at the, drawing a appends the technical idea of the present invention limited to. is not but should of subsequent analysis. Figure 1 shows a thermal film insulation engine according to an embodiment of the present invention also shown is roughly behavior measurement device is configured block. Also Figure 2 shows a thermal film insulation engine according to an embodiment of the present invention behavior measurement device shown holding portions and are applied to. plane from the. Behavior measurement thermal film insulation engine Figure 3 according to an embodiment of the present invention to explain the method is flow-chart. Hereinafter, with reference to a drawing based on a text content of the focuses of the present invention embodiment in the present invention is in the field of the person with skill in the art easily embodiment. as further described can be. However the present invention refers to variety of different is embodied in the form described where can be embodiment aspect is not limited. The present invention thereby unambiguously direct the described described for the portion that are independent of and, throughout the specification the same, or similar, is made by the identical is so the reference code. Shown in drawing each configuration size and thickness for facilitating of arbitrarily representing sleeve regulates the described, shown in the present invention necessarily drawing which not limited to, various portions and area of a porous ceramic so that its wall thickness for securely presenting showed thus expanding the. And, the description of the name of a code constructed in a systematic way that number 1, number 2 at respective it, and have the same relationship configuration for mapping unit into, necessarily of the following in the description of the sequence limited to not. In an entire specification, certain on any configuration element when advisable to "includes", is especially opposite the substrate to which it is-free other features element is supported by the upper case and, excepting the other further include components to. meaning that it may be set. Furthermore, is specification "... Unit "," ... Means "," ... Part "," ... Member " a set of terms, such as at least one functional, operating to an up/down in a generic, . units. Figure 1 shows a thermal film insulation engine according to an embodiment of the present invention also shown is roughly behavior measurement device is configured block. Also 1 with a, thermal film insulation engine behavior measurement device (100) according to an embodiment of the present invention the high temperature and high humidity condition is applied which can be applied/or the motor of the vehicle or insulation material thermal insulating structure is for assessment of behavior characteristics is. For example, thermal film insulation engine according to an embodiment of the present invention behavior measurement device (100) of the engines the interior of a combustion chamber in temperature of the upper surface of the piston according to gas temperature 1 within cycle conductivity low thermal capacity and low thermal in varying engine insulation film has the properties of being (1) (hereinafter in. is for the sake of convenience "insulating film") thermal behavior characteristics can be applied in assessment of. This insulation film (1) low heat conductivity and less than pulse in accordance with a timer capacity mechanical properties tolerant against light and heat, etc. layer, a part of the, by reducing thermal energy from being released to the outside at improving fuel economy of a and engine efficiency, there can be may to coating layer. Wherein, said insulation film (1) various the inner surface or the of the engine between a casing and an inner component for example, intake valve, exhaust valve, cylinder head and piston or the like can be formed coating. Behavior measurement thermal film insulation engine according to an embodiment of the present invention said device (100) communicates the true engine combustion chamber in a similar state actuator in by embodying a applied to engine component through integration of parts and engine combustion chamber an insulated film (1) thermal behavior characteristics simple estimation of the. purpose: an. To this end according to an embodiment of the present invention said engine insulation film thermal behavior measurement device (100) has with an essentially, base frame (10), holding portions (20), heating section (50), a cooling portion, (60), temperature measuring part measures the (70) the control section (80) includes, according comprising. off at the first and the second. In of the present invention in the embodiment, said base frame (10) in the various arrangements elements hereinafter be described as supported, one frame or more frames are alternately located in the may. Said base frame (10) the components to support various bracket, bar, rod, plate, housing, case, block, the auxiliary elements such as color, comprises a. However, said accessory elements are each components base frame (10) an annealing process is for mounting on a, of the present invention in the embodiment in exceptional but where said accessory elements base frame (10) in. them. In of the present invention in the embodiment, said holding portions (20) in the film an insulating bar (1) the test piece is located the coating (3) for fixing a to, base frame (10) is inserted into the pin grooves. Wherein, said specimen (3) which no limitation in size, made of same engine component, one surface of a film includes a heat insulator (1) the coating formed. Also Figure 2 shows a thermal film insulation engine according to an embodiment of the present invention behavior measurement device shown holding portions and are applied to. plane from the. Also refers to surface 1 and 2, based on a received said holding portions of the present invention embodiment (20) has a base frame (10) installed in a support plate (30) and, support plate (30) a holder (40) includes. Said support plate (30) a plate form base frame (10) is provided mounted on one side of the side. Said support plate (30) the fixed sample (3) heating section be described more from the back (50) side is opened to open hole (31) is formed. And, said holder (40) has the test piece (3) back onto the support plate (30) for fixed to, the support plate (30) unit hole (31) formed to vertically guide is provided. Such holder (40) the carrier plate (30) is operably associated with slid for movement on specimen (3) a support a portion of a of number 1 holding block (41) and, support plate (30) is operably associated with slid for movement on specimen (3) a remaining portion of a number 2 holding block (42) 10 includes. Said number 1 holding block (41) a specimen (3) portion of (edge portion as to based drawing) a blocks, which in the form of approximately "U", open hole (31) is the upper edge of rail slot number 1 (33) the up-and-down direction along the guide is provided. Said number 2 holding block (42) a specimen (3) other portion (edge portion lower when based drawing) a blocks, which in the form of approximately "U", open hole (31) the lower edge a number 2 rail slot (35) the up-and-down direction along the guide is provided. Wherein, said number 1 holding block (41) the number 1 rail slot (33) connected to the number 1 a slidably joined to (43) is formed, said number 2 holding block (42) the number 2 rail slot (35) connected to the number 2 a slidably joined to (44) is formed. In this case, said number 1 and number 2 holding block (41, 42) a specimen (3) of line and the connected to the number 1 and number 2 (43, 44) through the number 1 and number 2 rail slot (33, 35) along the mobile slide in the vertical direction and can be. And, said number 1 and number 2 holding block (41, 42) with a bolt (B) supported by plate (30) to bag to, sample (3) of line and the between at least the pair of slide in the vertical direction and, bolt (B) supported by plate (30) can be fixed to. Also with a 1, said heating section based on a received of the present invention embodiment (50) the engine in th combustion chamber a high temperature environment (expansion stroke) for the implementing a, insulation film (1) the test piece is located the coating (3) sufficient for heating a. I.e., said heating section (50) operating status and the engine within a combustion chamber surface temperature of internal as to form a mass that while retaining the air, by heat for implementing a similarly the heat insulation film (1) the test piece is located the coating (3) is heating a. Said heating section (50) has a holder (40) the test piece is located fixed to (3) based on the, base frame (10) .the transfer plate is combined with the. Such heating section (50) has the test piece (3) side jetting hot-air by a heating blower (51) includes. Said heating blower (51) air into housing includes a suck-in motorcycle (such as hot wire) air through the are heated and, thus a predetermined inclination angle specimen (3) include an injection side is made. Such heating blower (51) has air ventilation temperature of specimen which variably regulating thelength of range 100-200 ° C (3) can be jetting hot-air by in. On the other hand, said stay plates (30) the heating blower (51) in each injecting pressure is open hole (31) for specimen through the (3) air ventilation to guide (55) is provided with. Said hot air guide (55) for a separate support through the base frame (10) is provided on. Said hot air guide (55) the heating blower (51) of hot air jet, hole open at a side of ratio close to (31) inside the flat portions are perpendicular to the side the small hot air induction (57) to each other, to form a.. Wherein, said open hole (31) is coated on a hot air guide (55) the edges of the two hot air induction (57) through which specimen (3) air ventilation an inner an outer surface of the body unit and an outlet for supplying air (59) to each other, to form a.. Also 1 with a, based on a received said a cooling portion, of the present invention embodiment (60) the in engine combustion chamber valve piston, intake through a valve to an actuator for air room temperature with an atmospheric internal for the implementing a, specimen (3) on insulation film (1) .the surface can be cooled. I.e., said a cooling portion, (60) operating status and the engine within a combustion chamber surface temperature within a combustion chamber cooled by the intake air as to form a mass state similarly to implement specimen (3) on insulation film (1) is be cooled. Said a cooling portion, (60) has the test piece (3) based on the, heating section (50) corresponding to base frame (10) .the transfer plate is combined with the other. Such a cooling part (60) has down the substrate using air to specimen (3) on insulation film (1) and is injected pump apparatus, (61) includes. Said pump apparatus, (61) a standby specimen fan and the motor are positioned in (3) on insulation film (1) and spraying of the. purpose: an. Such pump apparatus, (61) specimen using air to the 20 °C hereinafter (3) on insulation film (1) can be injected from the injector. Wherein, said pump apparatus, (61) an air supplying an air supplying device unit (63) and are connected. Said air supply unit (63) as long as the compressed air the tank for storing the may include, air supply unit (63) on the air pressure of regulator (65) may be is provided. And, said pump apparatus, (61) (air injection amount) on the air the feed rate of flow rate control valve for regulating the (67) can be is provided. Such pump apparatus, (61) has flow rate control valve (67) through 0.5-500kg/h injection amount which variably regulating thelength of in a range of insulation film (1) .the valve is capable of injecting the air. Also 1 with a, said temperature measuring part measures the based on a received of the present invention embodiment (70) has a heating section (50) and cooling part (60) by heating and cooling an insulated film (1) of is intended to. Said temperature measuring part measures the (70) has a base frame (10) a bar, insulation film (1) non-contact behavior surface temperature of measurement can be conducted by a infrared thermometer (71) includes. Wherein, said infrared thermometer (71) the, in engine combustion chamber 1 cycle (crank 2 rotation) time since proportional to engine rpm, for example 600rpm: 200msec, 3000rpm: 40msec, 6000rpm: since satisfied by 20msec, the largest of cycle 1 4 minimum perform at one or more data thereby assuring the response of 5msec hereinafter. rate is required. Such temperature measuring part measures the (70) has sugar in the surveillance industry widely known a processing solution is supplied as a publicly known art infrared thermometer, the present specification in which more detailed consistency of their configuration dispensed to the described. Also with a 1, said control unit based on a received of the present invention embodiment (80) which has a low overall device (100) or the overall operation for control, a bar in heating section (50), a cooling portion, (60) and temperature measuring part measures the (70) controls the operation of. Wherein, said control unit (80) has a heating section (50) for clearing nozzles of blower (51) a polyolefin, controlling by controlling the hot air temperature, a cooling portion, (60) the air injector (61) flow control valve of (67) for controlling the air injection amount a leakage of oil to the, temperature measuring part measures the (70) of infrared thermometer (71) is determined by means of the insulation film (1) surface temperature of can be display. Hereinafter, stored in a table form said thermal film insulation engine behavior measurement device (100) according to an embodiment of the present invention engine using insulation film thermal behavior measurement method that will otherwise precede the drawing and a disclosure of the following drawing. rapidly and to reduce a memory reference to. Behavior measurement thermal film insulation engine Figure 3 according to an embodiment of the present invention to explain the method is flow-chart. Also with a 3 also to 1, of the present invention in the embodiment first insulation film in (1) the test piece is located the coating (3) back onto the support plate (30) a portion of a wall of the hole (31) locating the side, thereof open hole (31) through the hot air guide (55) for inhibiting gene expression induction (57) facing the side positions the.. In this state, in holder of the present invention in the embodiment (40) of number 1 and number 2 holding block (41, 42) for specimen through the (3) back onto the support plate (3) fixed to (step S11). Not to standardize the number 1 and number 2 holding block (41, 42) for specimen (3) of line and the in the moving magnets in the vertical direction and, bolt number 1 and number 2 (B) through the holding block (41, 42) back onto the support plate (30) fixed to to. Wherein, said number 1 and number 2 holding block (41, 42) a specimen (3) of line and the connected to the number 1 and number 2 (43, 44) through the number 1 and number 2 rail slot (33, 35) along the mobile slide in the vertical direction and can be. And, said number 1 and number 2 holding block (41, 42) a specimen (3) the upper edge of portion and lower edge portion are inserted to be connected to the-, bolt (B) through the support plate (30) can be fixed to. Said specimen such as (3) of the holder (40) fixed on the state in engine in th combustion chamber of the present invention in the embodiment for implementing a a high temperature environment the heating section (50) for clearing nozzles of blower (51) through the hot wind specimen (3) specimen the injection side (3) heating a (step S21). I.e., said heating section (50) for clearing nozzles of blower (51) the engine operating status and within a combustion chamber surface temperature of internal as to form a mass that while retaining the air, by heat for implementing a similarly the heat insulation film (1) the test piece is located the coating (3) in jetting hot-air by the specimen (3) heating the. In this case, said heating blower (51) of a injected from the hot air guide (55) for inhibiting gene expression induction (57) along the derived, open hole (31) side test specimen (3) is supplied to emitter. Specimen and (3) an inner of a hot air guide (55) outlet of (59) is to one. Wherein, said heating blower (51) operation of the control section (80) the greater the length of time controlled by, blower heating thereof (51) has air ventilation temperature of specimen which variably regulating thelength of range 100-200 ° C (3) can be jetting hot-air by in. Which affords to a process, based on a received temperature measuring part measures the of the present invention embodiment (70) of infrared thermometer (71) the heating blower (51) the test piece is located heated by (3) insulation film on (1) surface temperature of. a non-contact measurement behavior (step S31). The infrared thermometer (71) as responding speed of the 5msec hereinafter insulation film (1) for measuring the change in surface temperature of.. Furthermore, control unit (80) has an infrared thermometer (71) is determined by means of the insulation film (1) surface temperature of the display. On the other hand, in engine combustion chamber valve piston in of the present invention in the embodiment, intake through a valve to an actuator for internal air room temperature with an atmospheric in order to render a cooling portion, (60) of pump apparatus, (61) through the room temperature (20 °C hereinafter) using air to specimen (3) insulation film on (1) a jet to the insulation film (1) cooling to (step S41). I.e., said a cooling portion, (60) of pump apparatus, (61) the engine operating status and within a combustion chamber surface temperature within a combustion chamber cooled by the intake air as to form a mass state similarly to implement specimen (3) insulation film on (1) the air by spraying spray material insulation film (1) to cooling. In this case, said pump apparatus, (61) an air supply unit (63) in regulator saved state to (65) while pressure is adjusted by compressed-air as to insulate film (1) the injection side. At this time said pump apparatus, (61) operation of the control section (80) the greater the length of time controlled by, air injector (61) has flow rate control valve (67) through 0.5-500kg/h injection amount which variably regulating thelength of in a range of insulation film (1) .the valve is capable of injecting the air. Which affords to a process, based on a received temperature measuring part measures the of the present invention embodiment (70) of infrared thermometer (71) such as the S31 timepoints as for the adjustment phase, a cooling portion, (60) cooled by thermally insulating film (1) surface temperature of the lens to behavior. Furthermore, control unit (80) has an infrared thermometer (71) is determined by means of the insulation film (1) surface temperature of the display. Until now such as described above wherein thermal film insulation engine according to an embodiment of the present invention behavior measurement device (100) according to method and, in a similar state actuator in actual engine combustion chamber by embodying a applied to engine component through integration of parts and engine combustion chamber an insulated film (1) thermal behavior characteristics can be estimation of simple. Therefore, by considering the operational conditions engine of the present invention in the embodiment in insulation film (1) a simple structure and thermal behavior characteristics are placed in constant gap of the insertion part and the holder, many types of insulation film (1) ensure thermal behavior characteristics can be easily comparing and evaluating the right, insulation film (1) thermal behavior characteristics evaluation according to cost and working time: 1.. Over but are disclosed of the present invention in the embodiment, the technical idea of the present invention that are presented in specification confirmation, if the limited aspect embodiment, skilled in the art for understanding technical idea of the present invention the same technical idea in a range of from, additional component, changing, deleting, example, in adding a by other embodiment proposes easily thereby, the cold air flows or may be, is advisable to that it lies in a range rights in addition of the present invention will. 1.. insulation film 3.. specimen 10.. holding portions 20.. base frame 30.. support plate 31.. open hole Rail slot 35.. number 2 rail slot 33.. number 1 40.. holder 41.. number 1 holding block 42.. number 2 43.. number 1 connected to the holding block Connected to the heating section 50.. 44.. number 2 51.. heating blower 55.. hot air guide 57.. hot air induction outlet 59.. 60.. 61.. pump apparatus, a cooling portion, 63.. 65.. regulator air supply unit 67.. 70.. temperature measuring part measures the flow rate control valve 71.. infrared thermometer 80.. control unit B... Bolt Disclosed is a device for detecting the thermal behavior of an engine insulation coating layer. The device for detecting the thermal behavior of an engine insulation coating layer is provided to evaluate the thermal behavior of an insulation coating layer applied to an engine. The device includes a base frame, a holding part which is installed on the base frame and fixes a sample coated with the insulation coating layer, a heating part which is formed on one side of the base frame based on the sample and heats the sample, a cooling part which is formed on the other side of the base frame by corresponding to the heating part and cools the insulation coating layer, and a temperature measuring part which measures the surface temperature of the insulation coating layer. COPYRIGHT KIPO 2016 An insulated film applied to engine thermal behavior for assessing the behavior measurement device as thermal film insulation engine, base frame; said base frame is installed at, said insulation layer coating the test piece is located a support member has a support groove holding portions; said said specimen based on the which the transfer plate is combined with the base frame, said specimen heated; said said heating the resultant substrate including the gate wire, which are installed on the battery assembly and base frame, said insulation layer a cooling fluid for cooling part; and said, which are installed on the base frame, said insulation film that measures a surface temperature a temperature measuring part measures the; thermal film insulation engine including a behavior measurement device. According to Claim 1, said holding portion, said upright on base frame support plate process according to the target value, said said support plate fixed to a holder is mounted to a specimen engine characterized by including insulation film thermal behavior measurement device. According to Claim 2, the support plate said specimen said heating section side is opened to said open hole is formed, said slide formed hole open said holder is provided movable insulation film characterized by engine thermal behavior measurement device. According to Claim 3, said holder, said support plate is operably associated with is slidably movable, a support a portion of a of a specimen said holding block and number 1, said support plate is operably associated with is slidably movable, a a remaining portion of said specimen holding block number 2 engine characterized by including insulation film to thermal behavior measurement device. According to Claim 4, holding block with a bolt by said number 1 and number 2 secured in a support plate engine characterized by said insulation film thermal behavior measurement device. According to Claim 1, said heating unit of the heating, said specimen jetting hot-air by side to a heating blower for a thermal film insulation engine characterized by including behavior measurement device. According to Claim 3, said heating unit of the heating reinforcing jetting hot-air by side said specimen includes a heating blower, said support plate in each injecting pressure blower heating said said specimen is a hot air guide for installing the insulation film characterized by engine thermal behavior measurement device. According to Claim 1, less than that of the, room temperature using air to said insulation film characterized by engine including injector stage using vacuum insulation film to thermal behavior measurement device. According to Claim 8, an air supplying device to supply the air to said air injector is unit with, flow rate control valve through an amount of injection is, air said air supply unit including a regulator to control the pressure of the fluid to thermal film insulation engine characterized by behavior measurement device. According to Claim 1, said a temperature measuring part measures the, insulation said location by using the signal that measures a surface temperature film to an infrared thermometer engine characterized by including insulation film thermal behavior measurement device. According to Claim 1, the width of the part and cooling said heating section, said temperature measuring part measures the is determined by means of the insulation film surface temperature to a control block for engine characterized by further including insulation film thermal behavior measurement device. Claim 1 engine insulation film thermal behavior measurement device applied to the engine using an insulated film insulation engine for assessing the thermal behavior behavior measurement method as thermal film, insulation layer coating the test piece is located of the holder a part of the; heating section through which said hot wind and spraying of the specimen; cooling through the room temperature air spraying said insulation film; said insulation film temperature measuring unit of measuring surface temperature measured value display an engine insulation film thermal behavior measurement method. According to Claim 12, said heating unit of the heating reinforcing said specimen jetting hot-air by side provides a heating blower, said hot wind of 100-200 ° C blower attachment comprises a heating said specimen and is injected characterized by engine insulation film thermal behavior measurement method. According to Claim 12, less than that of the 20 °C hereinafter using air to said insulation film provided to injector stage using vacuum insulation film characterized by engine thermal behavior measurement method. According to Claim 14, as calibration curves the second station, on which a post 0.5-500kg/h of said air said air insulation film insulation film characterized by the spraying of water engine thermal behavior measurement method. According to Claim 12, said a temperature measuring part measures the insulation said location by using the signal a that measures a surface temperature film provides infrared thermometer, a infrared thermometer said 5msec hereinafter that it satisfies in response behavior measurement method characterized by thermal film insulation engine.