SLOSHING REDUCING UNIT AND CARGO BARRIER STRUCTURE INCLUDING SAME

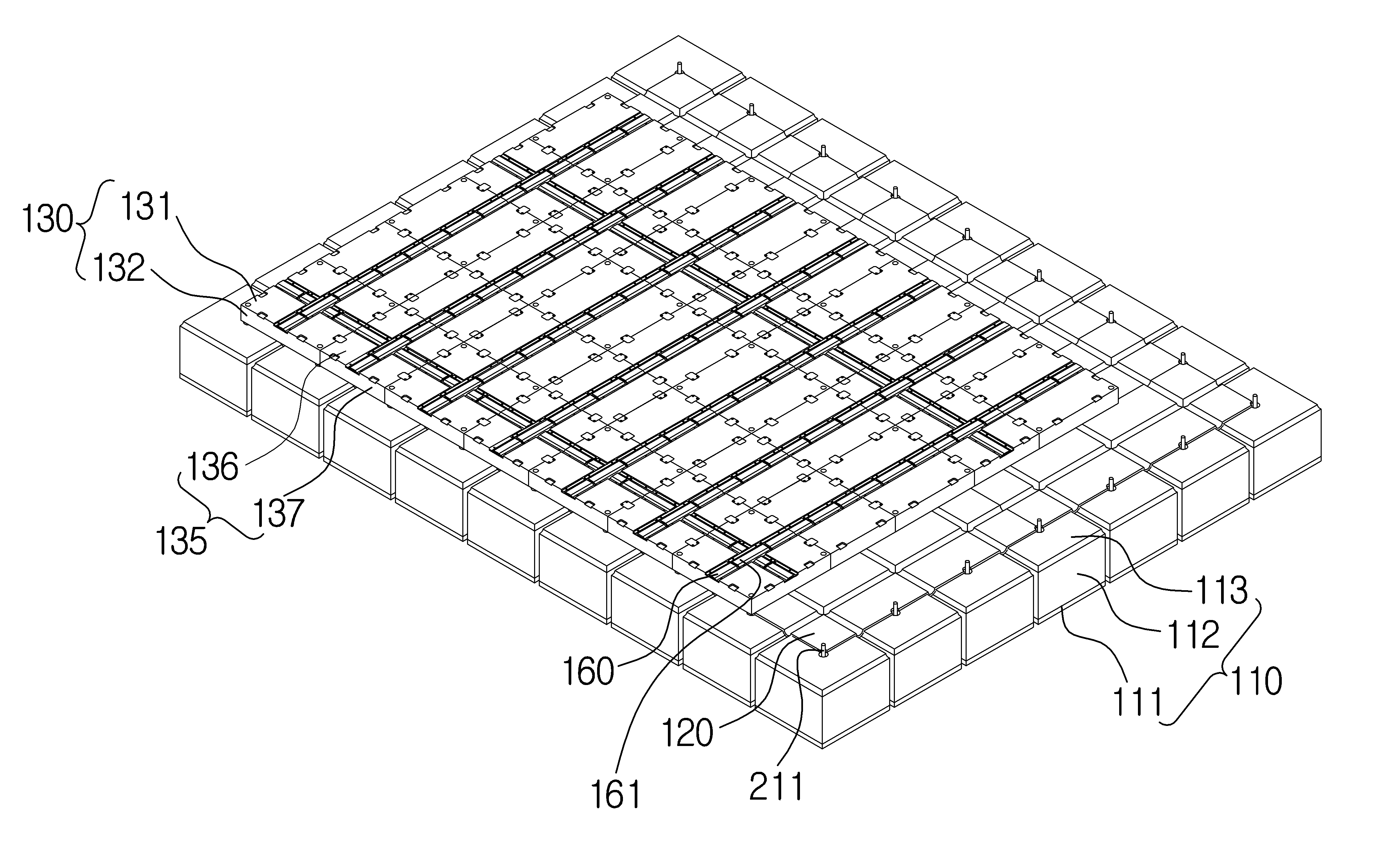

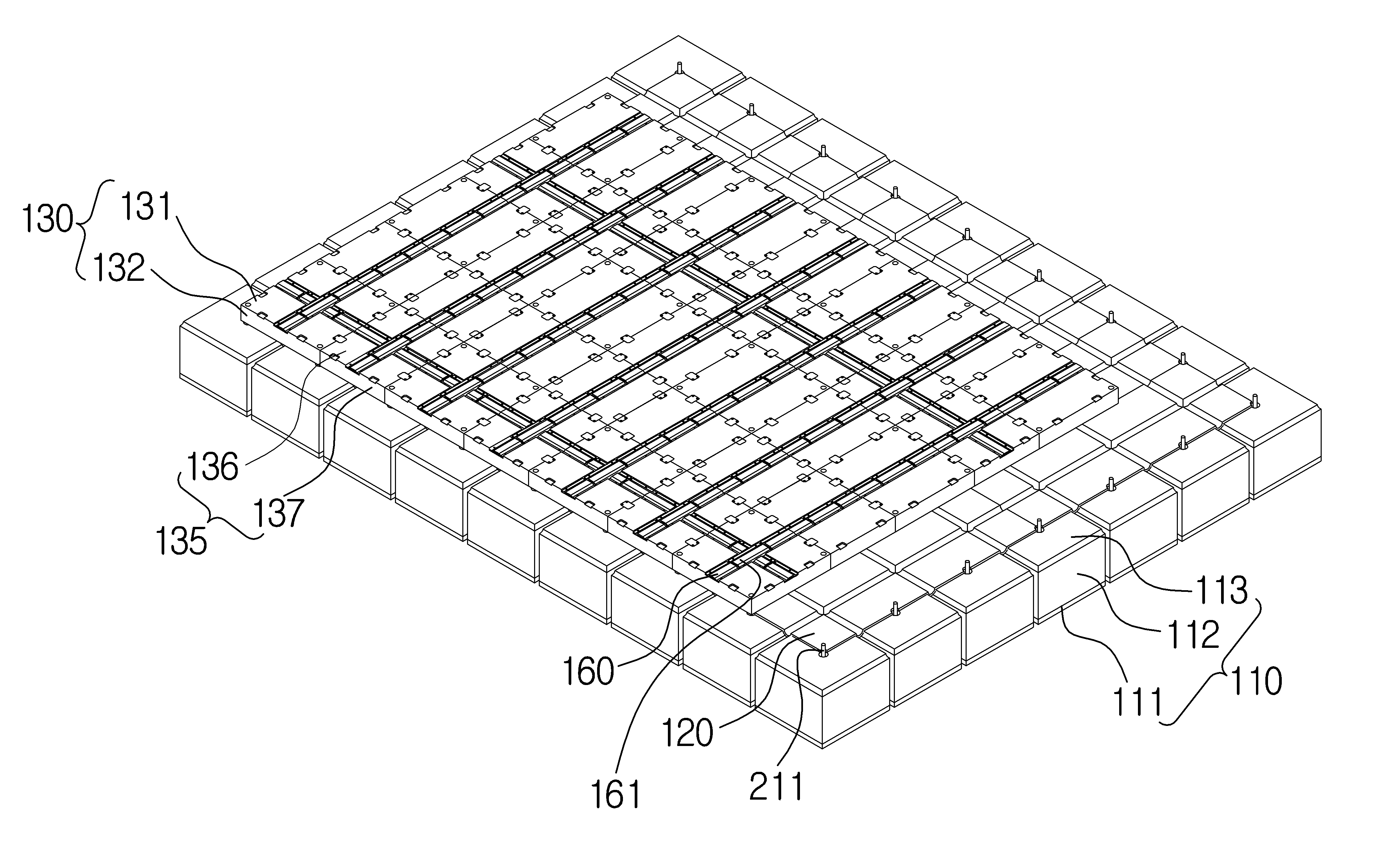

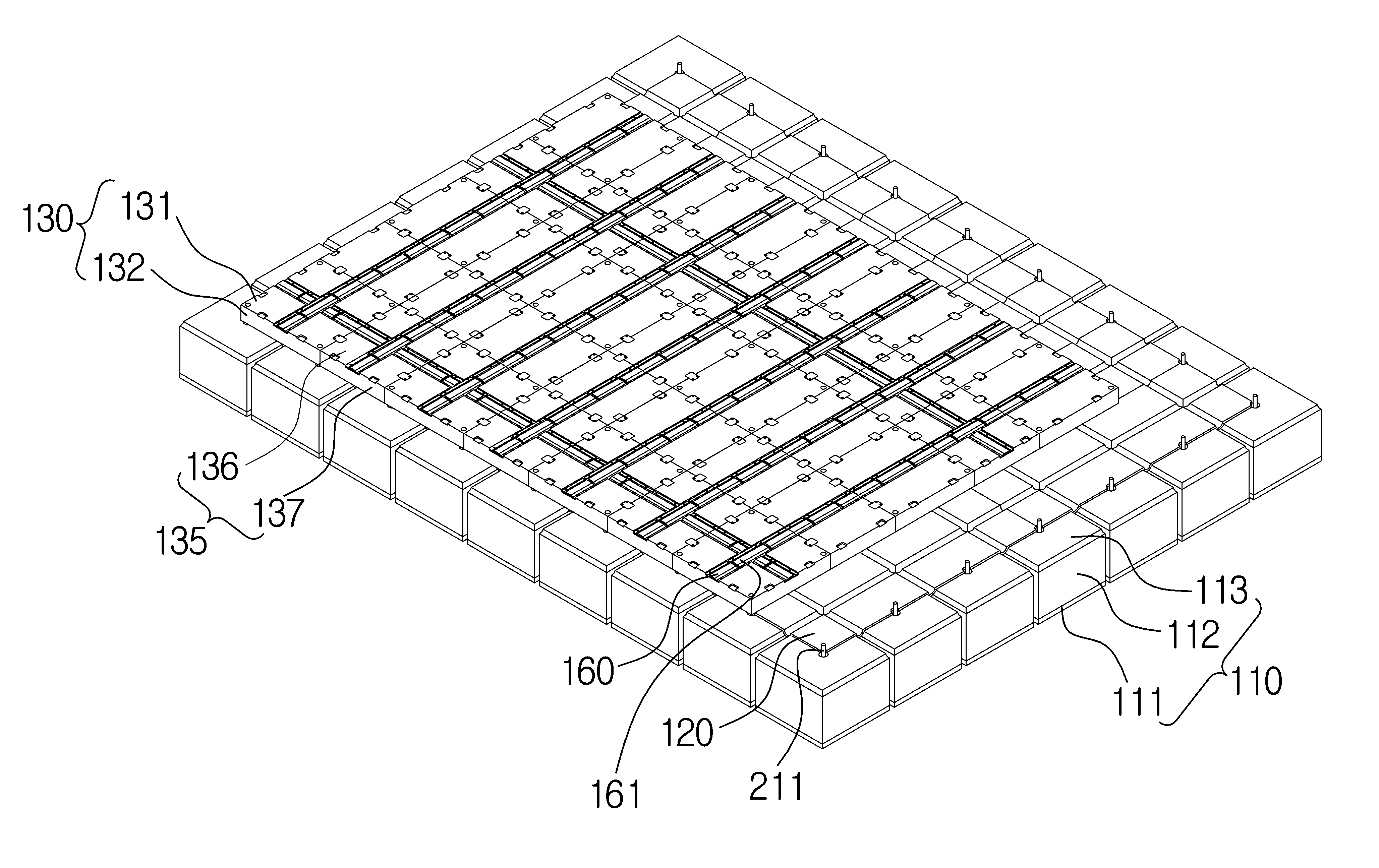

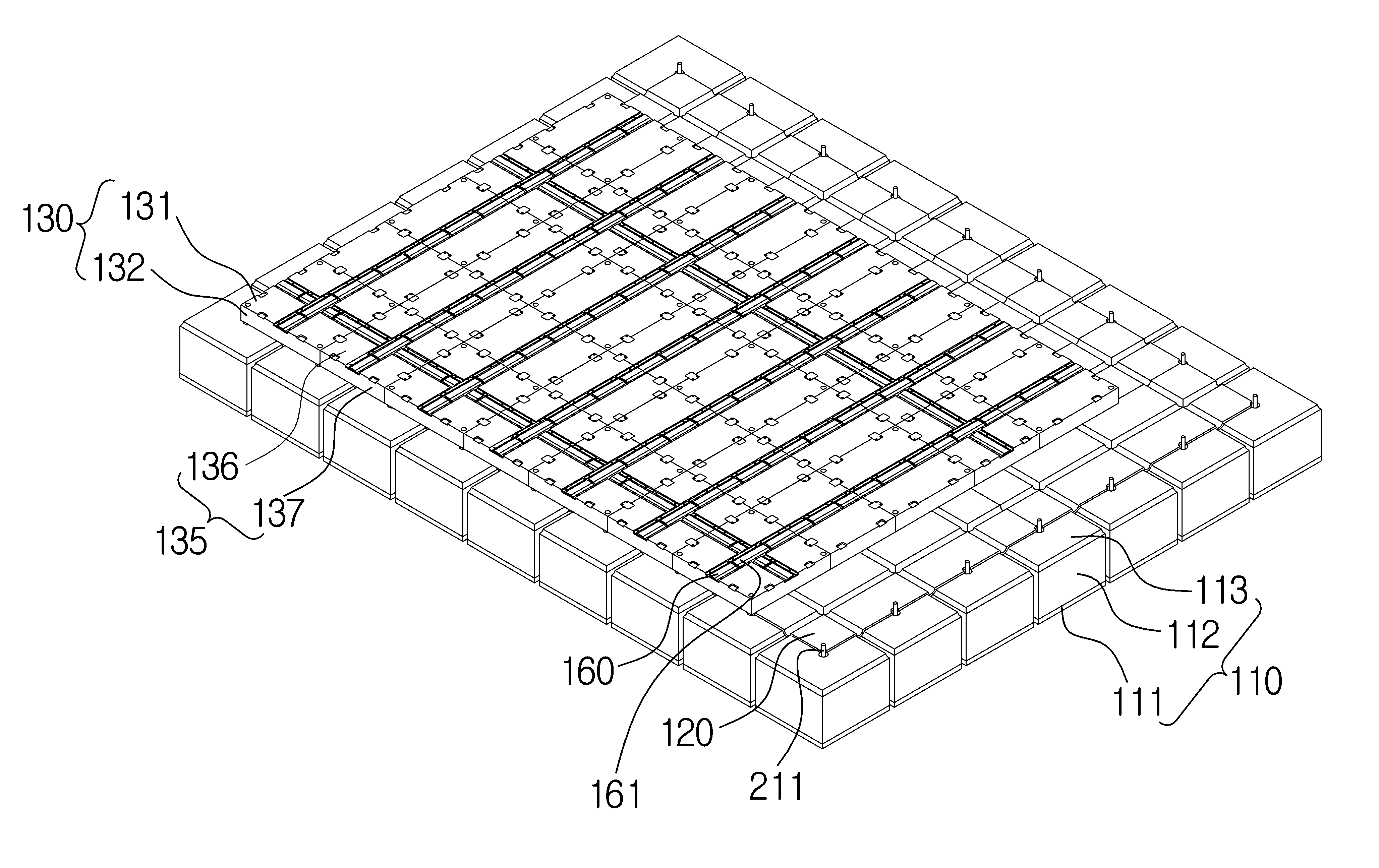

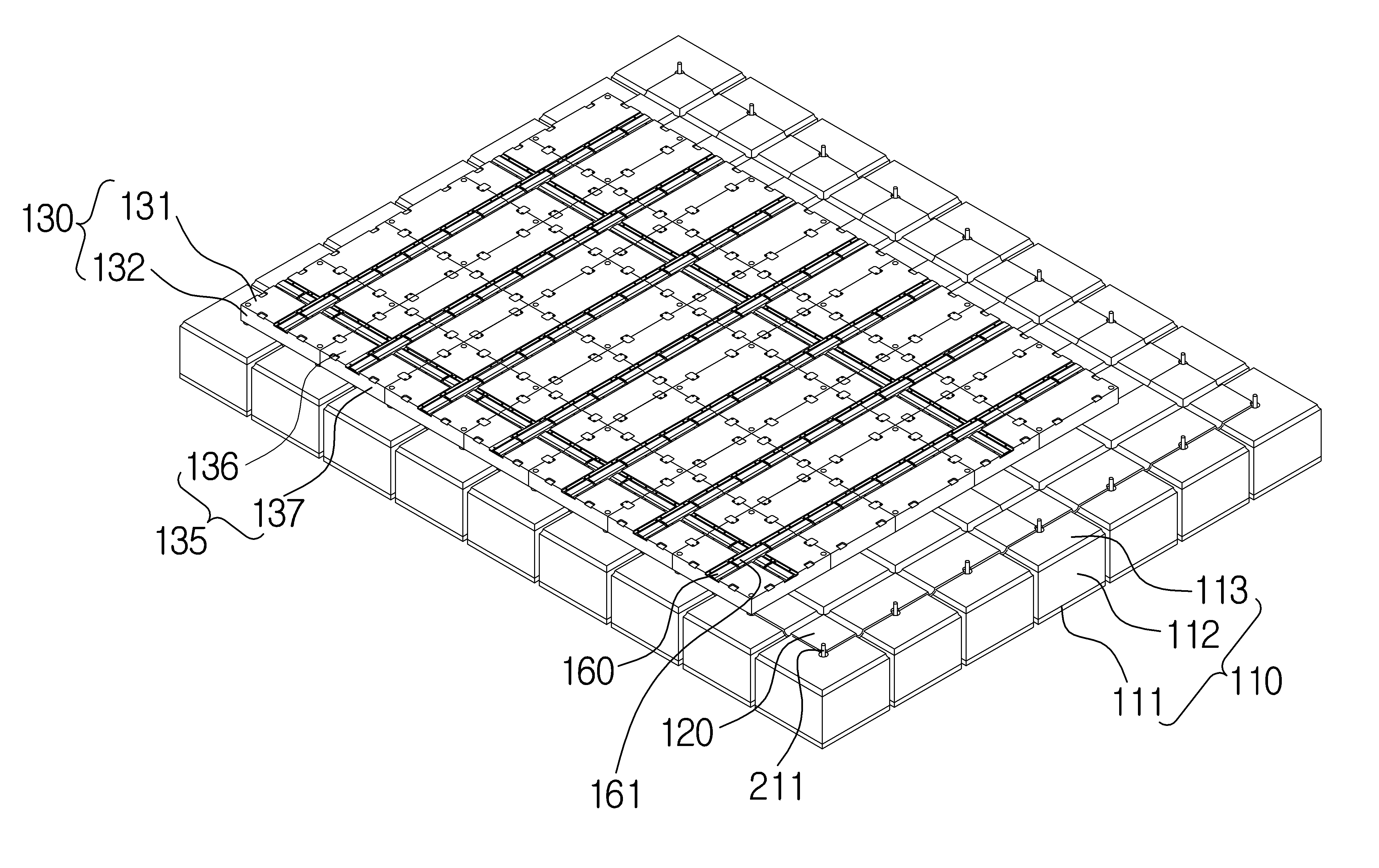

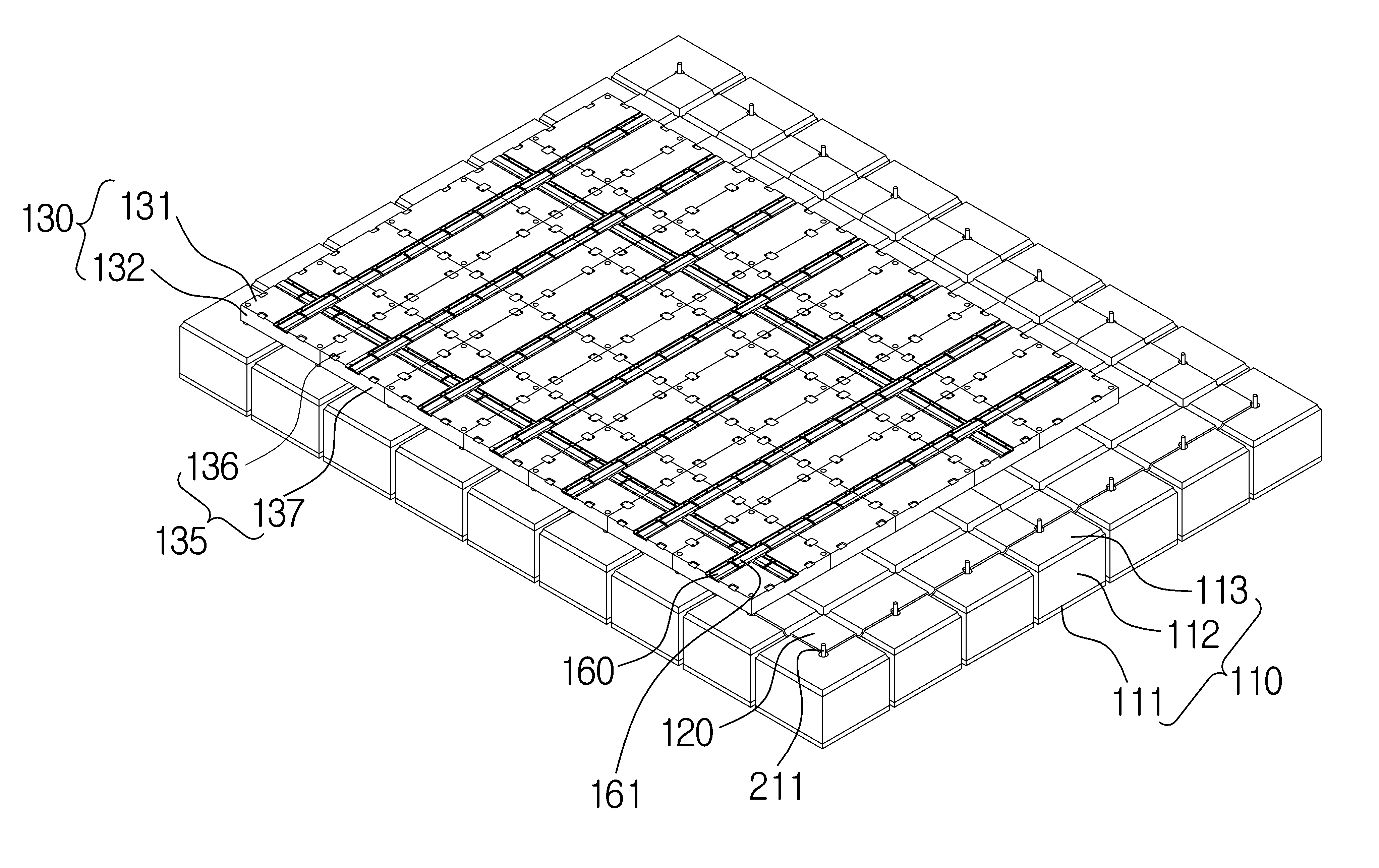

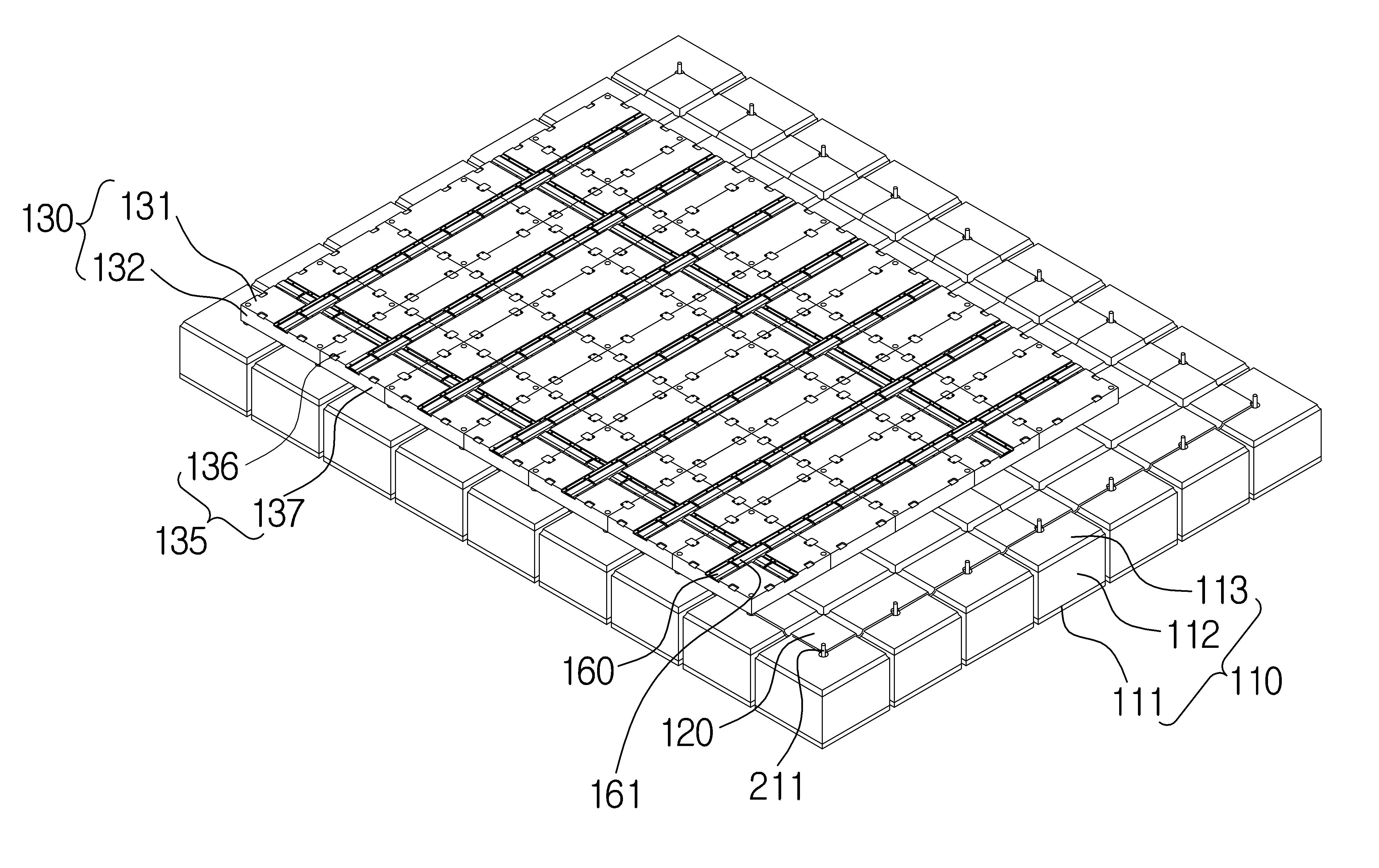

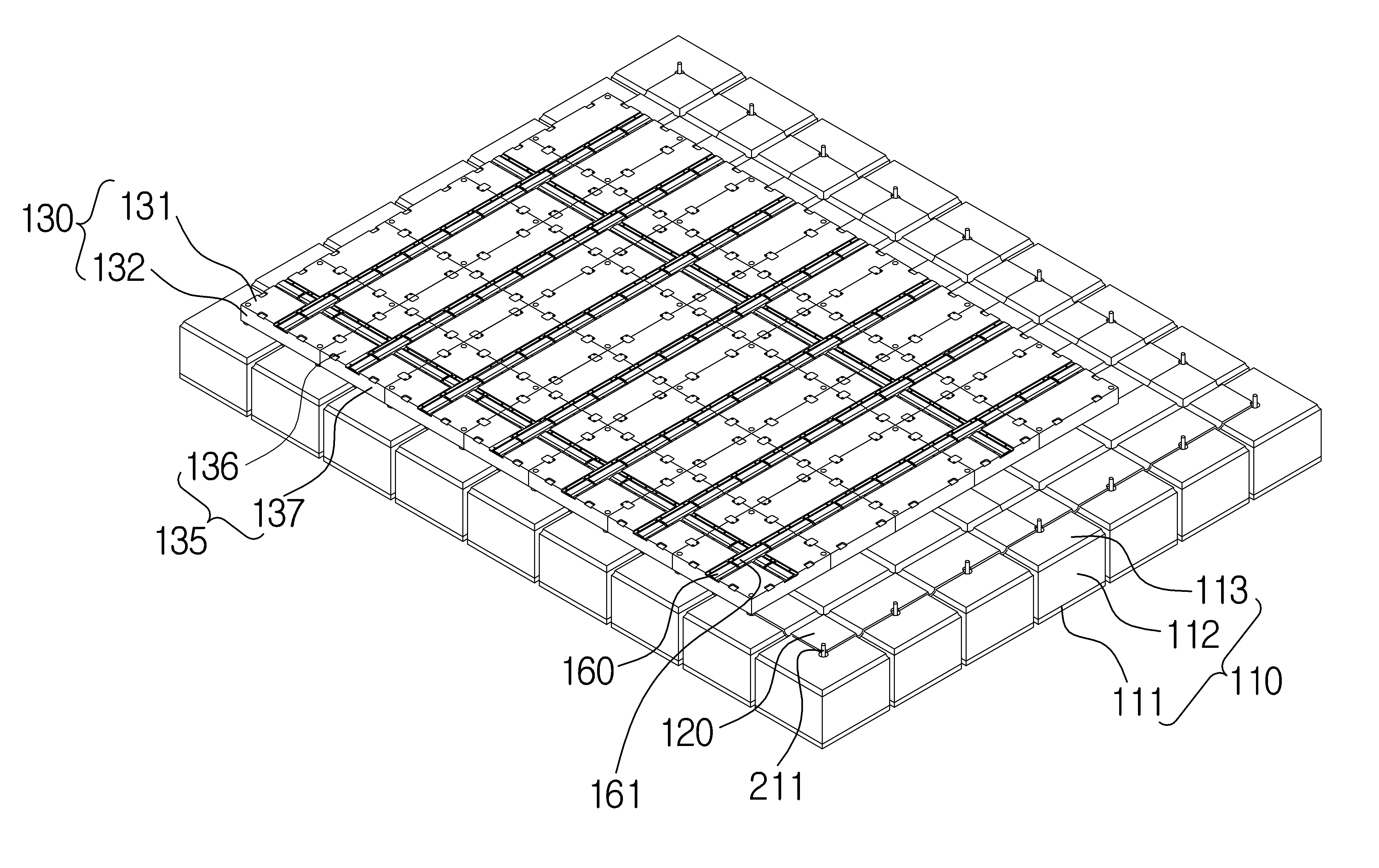

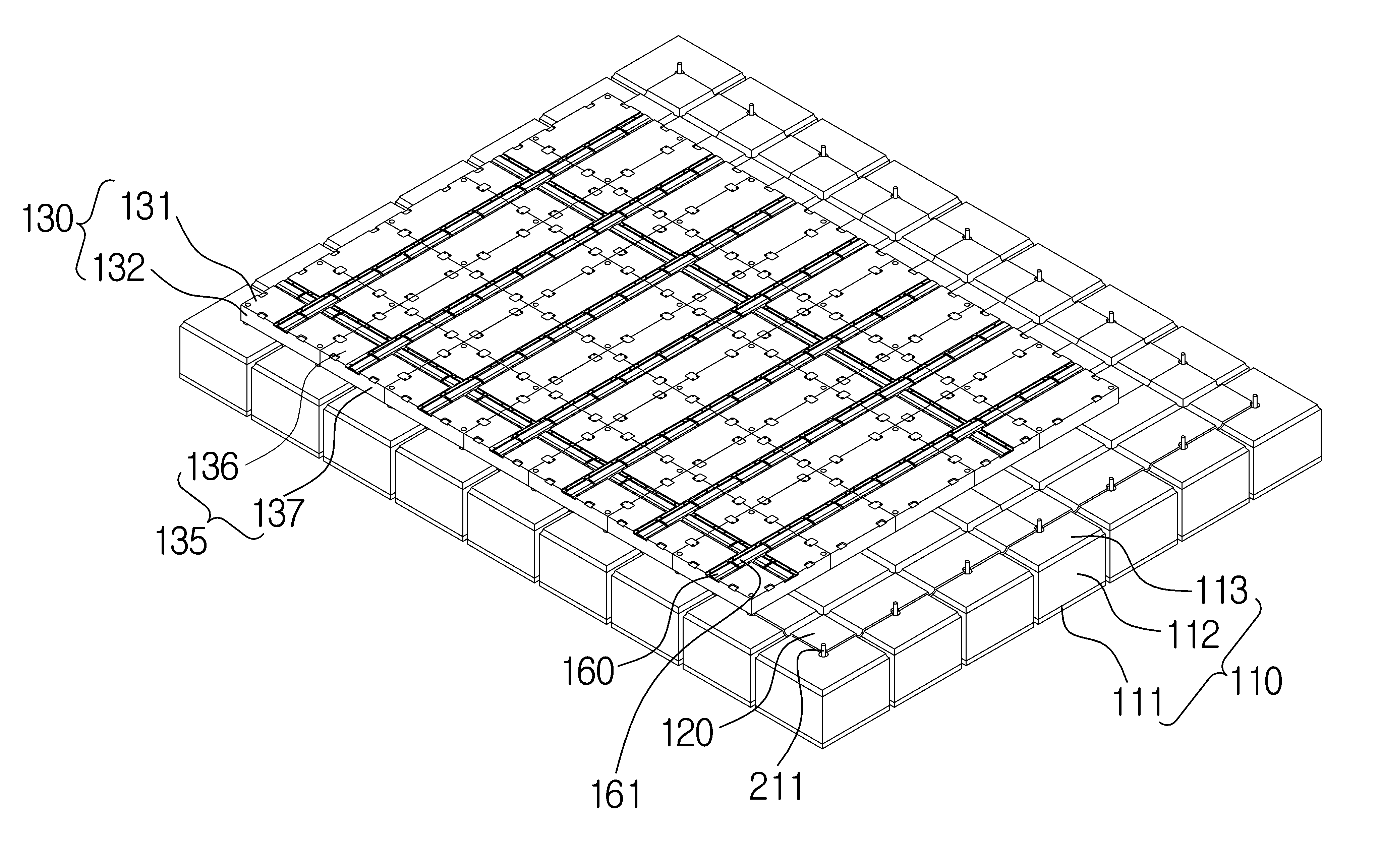

The present invention refers to sloshing reduction unit including and is down set from the bridge barrier cargo. Approximately cargo of LNG transporting vessel liquefied natural gas (LNG) as a liquid natural gas is cooled to -163 ° C analyzes audio and, cryogenic is able to withstand is made of a meterial, strong and axis thermal stress and heat, ten infiltrations insulation structure of shape so as to be made of a. 1 direction from inside to outside the cargo barrier , upper thermal insulating board, having thermal insulating board and lower barrier 2, coupled with a (inner hull) inner hull is provided in. Wherein, barrier 1 are formed such that they have corrugations of a pleated shape, in heat shrinkable [...] amount by deforming welding site in the ., reducing the risk of thermal stress barrier. 1 a cryogenic fluid that is in direct LNG during flight of which makes contact with LNG sloshing (sloshing) is located on, mounted in the mounting plane by a load sloshing [...]. can be modified. The sloshing provided with load-bearing capacity bent a reinforcing internal corrugated to techniques for inserting a member of wet liquid to flow down. E.g., Korean opening patent number 2009-0094505 call (200908 disclosure wall 9) comprises a metal membrane (barrier 1) into an corrugated of incombustible having conformation of fills fillers of foam having reinforced toward the stiffener but a disclosure technique. However, numerous corrugated to each of the medicine packages in the filler into large number of plays as an oxidant or as a manpower is and the work time, techniques difficult is on the exterior surface. 1 load sloshing of the present invention in the embodiment protects the barrier , efficient cargo barrier mounting a sloshing reduction unit including and. structure barrier cargo. Upper inner wall cargo according to one aspect of the present invention a lower patch element disposed in the thermal insulating board; said lower thermal insulating board arranged on top 2 barrier ; barrier 1 rotating member comes into sliding contact with cryogenic fluid; with barrierbarrier interposed between the 2 1 an upper thermal insulating board; and said fluid by sloshing to reduce load, said 1 is provided to remove error on top barrier , said 1 gas conduit that are traversed by a fluid plastic to observe barrier said plurality through hole is formed a sloshing reducing plate; a including cargo barrier structure are adjusted.. Said 1 which can be protected from the contaminant of upper barrier , a support plate vertical fixation [...] in upper surface further includes, said sloshing reducing plate so as to correspond to said fluid by reducing hoop stress is formed convexly upper, by curve parts and said through hole is formed, said a curved portion from both sides through the diffusion plate support for supporting a diffusion [...] said Stirling may include. Said a support plate said sloshing reducing plate to each corner of and arranged at a predetermined position corresponding to, each of which is formed next to said corner portion to the inner surface of the case said said Stirling can be combined. [...]. barrier said 1 a support plate said constant flat surface seating formed at uniform intervals can be groove. Said corresponding said a support plate are made of a circular groove, said groove won can be joined by welding. An inner plate reducing sloshing said both sides of said Stirling [...] Stirling [...] the opening of the case body, a handle secured to the said sloshing reducing plate a joint portion, each other along a ridge cylinder may further include any member. Said lower thermal insulating board a lower shroud with barrier said 2 and adiabatic member further lower the entire surface of said lower adiabatic member is electrically connected to the a lower auxiliary panel, said a lower auxiliary panel on upper sides of the vertical [...] one stationary fixed to the piece are provided, both sides of said 2 barrier said lower space formed between the thermal insulating board is disposed to cover the, other for allocating a transponder channel in said Stirling with barrier[...] 2 is connected, said [...] Stirling periphery corresponding to provided said won to the fixing pieces forms a separating surface to which the bonded welding can be. Said a support plate between said 1 barrier weld line site welding is made can be provided at predetermined intervals on. Said lower thermal insulating board a dielectric material to make the dielectric material, the same longitudinal extent horizontal length construction with an integrated square configuration, both sides of a thermal insulating board upper said lower said is hooked on to a thermal insulating board is arranged inside the inner, said Stirling way as to be coupled with a region of each corner [...] said 2 which can be protected from the contaminant of upper barrier , said upper thermal insulating board to be placed on a coplanar with the upper said formed between the thermal insulating board board space can be is interposed. In accordance with another aspect of the present invention, rotating member comes into sliding contact with cryogenic fluid of a cargo can be protected from the contaminant of which upper barrier 1, a support plate vertical fixation [...] in upper surface; and said fluid by sloshing to reduce load, said 1 barrier installation directions in the same direction said 1 plurality upper barrier plate reducing sloshing is set at the left and; includes, said sloshing reducing plate so as to correspond to said fluid by reducing hoop stress is formed convexly upper, for the passage of a fluid said a plurality through hole is formed and by curve parts, said a curved portion from both sides through the diffusion plate support for supporting a diffusion [...] said Stirling may include. An inner plate reducing sloshing said both sides of said Stirling [...] Stirling [...] the opening of the case body, a handle secured to the said sloshing reducing plate a joint portion, each other along a ridge cylinder may further include any member. And reduction unit of the present invention in the embodiment according to sloshing including cargo barrier structure protects the 1 load sloshing barrier , efficient cargo barrier mounting outputs a relay driving signal.. Yet, using auxiliary with barrierbarrier 2 main of the existing method 2 is provided which overcomes the limit on a barrier provided, simply and efficiently form the 2 hole to be able to move translationally barrier. Also, lower longitudinal extent of the thermal insulating board horizontal length of high dimension precision without residual holes allotted to the data and radiating the light of the predetermined, lower thermal insulating board hollow center section is provided to about [...] in a Stirling vertical fixation pieces 2 are adjusted interconnected barrier , Stirling is corner portion of the thermal insulating board upper [...] way as to be coupled with a mode setting flag is set or not by upper thermal insulating board, personnel and less installation barrier cargo effectively time can be. The present effect of the invention effect to dually function as a pipeline and or more are not limited to, another not referred to range of the charging effect clearly to one skilled in the art from and 2000 can be understood. Of the present invention in the embodiment according to Figure 1 shows a perspective view of structure barrier cargo ship is also. Figure 2 shows a barrier structure is in the form of lower thermal insulating board disposed perspective view of Figure 1. Figure 3 shows a lower thermal insulating board 2 on top also road perspective view shape provided barrier. timing of Figure 2. Figure 4 shows a 2 dissolving barrier is provided thermal insulating board also road perspective view form. timing of Figure 3. Figure 5 shows a upper thermal insulating board and lower thermal insulating board provided in a Stirling cross-sectional drawing relationship of binding between [...] also to. timing of Figure 4. Connected between the thermal insulating board upper Figure 6 shows a form board is arranged on an. timing of Figure 4 also road perspective view. Figure 7 shows a barrier structure reducing and sloshing inside by fixing 1 barrier also shape plate is installed is in of Figure 1. Figure 8 shows a form of reducing sloshing cross-sectional drawing also to. timing of Figure 7. For plate reducing sloshing Figure 9 shows a supporting plate and prepared on a top surface thereof, and vertical fixation in a Stirling also [...] is in of Figure 7. Hereinafter in examples of the present invention embodiment. as further described reference to accompanying drawing. Embodiment examples hereinafter introduced into a person with skill in the art in the present invention is in the field of the event has of the present invention to sufficiently and enables light to be transported is provided as for the purpose of developing the recording operation.. The described embodiment examples the present invention refers to hereinafter without limit to an other may be embodied in the form. The present invention thereby unambiguously direct the description to describe the drawing portion that are independent of in in the drawing, component width, length, thickness, or the like, that has dressed for facilitating can be Image expressing the overlapped. Take identical throughout the specification in the same reference number exhibits components. Also 1 with a, of the present invention in the embodiment according to cryogenic fluid (e.g., liquefied natural gas (LNG)) for storing a boat of a cargo barrier structure a lower thermal insulating board (110), barrier 2 (120), upper thermal insulating board (130) and connecting board (135) includes. barrierfor the sake of convenience of 1 (170) are arranged, with was form shown in Figure 7. Lower thermal insulating board (110) the cargo plurality upper inner wall is radiated and rows and columns of, lower shroud (111), lower adiabatic member (112), barrier 2 (120) and a lower adiabatic member (112) is electrically connected to the a lower auxiliary panel (113) includes. Lower thermal insulating board (110) an integral the monolith has a shape with at is made can be arranged side-by-side on an inner wall cargo. Lower thermal insulating board (110) has a thickness constant, horizontal length the same longitudinal extent, a key may be fabricated in square configuration. E.g., lower thermal insulating board (110) the horizontal length the same longitudinal extent in the 1m. Lower shroud (111) railway sleeper on an inner wall the cargo, [...] Stirling. can be held together by or the like. Lower shroud (111) for example, fly woods, a key may be fabricated of a material such as. Lower adiabatic member further (112) the lower shroud (111) is arranged at the upper portion, material-skin polyurethane foam (PUF, Polyurethane Form), reinforced foam (RPUF, Reinforced PUF) is plate cryogenic state from fluid of hull can be protected. Lower adiabatic member further (112) the lower shroud (111) on top of adhesive (such as glue including a plurality of bubbles and e.g.) can be is bonded by. Also refers to surface 2, a lower auxiliary panel (113) on upper sides of the [...] (211) is placed along the vertical one stationary fixed to the piece (210) is provided. Fixing pieces (210) for example, stainless steel or the like metal material, and including, a key may be fabricated. Fixing pieces (210) the a lower auxiliary panel (113) the housing container home (113a) such as rivet is coupled to fastening member (2) can be held by. Fixing pieces (210), a key may be fabricated the circular form. A lower auxiliary panel (113) the fly woods can be plate. Also 3 with a, barrier 2 (120) of the two sides lower thermal insulating board (110) and to cover the space formed between the lower thermal insulating board (110) is disposed upper, [...] the above-mentioned Stirling (211) barrier 2 a than the center of which lies on the (120) is disposed side-by-side association with. Although not shown, lower thermal insulating board (110) formed between the flows out the glass wool (glass wool) can be is inserted member. However, neighboring lower thermal insulating board (110) or is arranged to be tight, in the form close contact with each such lower thermal insulating board (110) is several manufacturing are integrally which have been bundled, is, and if the data filling member may be achieved due to the omission. 2 barrier (120) [...] arm of the bracket (211) is provided a peripheral portion corresponding to fixing piece (210) (W, also 5 reference) welded to a joint surface bonded (120a, 120b) is formed on. The, abutment surface (120a, 120b) a fixed piece (210) to welding won can be bonded. Abutment surface (120a, 120b) are soldered to both sides during adhering plane (120a) as a semi- [...] Stirling-shaped groove is formed on a (211) barrier 2 a than the center of which lies on the (120) an abutment surface (120a) and into two wavelengths through the optical won, are rotatably inserted into adhering plane (120b) obliquely-inclined form the chamfering processed may be formed as. barrier 2 adjacent (120) comprising a Stirling periphery of [...] (211) the center of which lies on the portion each other can be welding so as to be superposed on each. Typically structure barrier cargo of the existing method is second rectangular shape, has lower thermal insulating board and is made, the main 2 2 auxiliary with barrierbarrier liver welding length is longer and time data is detected when installed, techniques on the exterior surface was surfaces and on the difficult-to-coat installation. Lower thermal insulating board (110) disclosed above form in the compression placed on top the inner wall cargo, barrier 2 thereon (120) by installing at method a in parallel with the axis of the existing method can be is detected this problem. 2 auxiliary with barrierbarrier 2 main of the existing method also using is provided which overcomes the limit on a barrier provided, simply and efficiently form the single product of barrier 2 (120) can be of is fitted to the flow passage side. 2 barrier (120) the lower thermal insulating board (110) formed between the a site where its side cover space (120c) of downwardly an outwardly convex arcuate corrugated shape can be provided. A hydrothermal by a cryogenic fluid is effectively axis. to respond to. Such 2 barrier (120) the lateral length of a lower part of the thermal insulating board (110) and equal to the lateral length of a, longitudinal extent of a lower part of the thermal insulating board (110) of longitudinal extent of 3 fold size can be made of the. The, barrier 2 (120) in the longitudinal direction the lower thermal insulating board (110) which covers two 4 a, laterally the lower thermal insulating board (110) which can cover a two 2 a. E.g., barrier 2 (120) are defined between transversely adjacent projections 1m, longitudinal 3m length barrier. 2, a key may be fabricated (120) for example, stainless steel, aluminum, brass, metal zinc a plurality is built it can be sheet of. Furthermore, as another example with the metal sheet composite composed of said fiber-reinforced composite material can be mounted on an material sheet. Also refers to surface 4, upper thermal insulating board (130) barrier the 2 (120) and 1 barrier (170, also reference 9 and 7) between a drain region are formed at both, upper shroud (131) and the underlying top of adiabatic member (132) includes. Upper thermal insulating board (130) has a thickness constant, horizontal length the same longitudinal extent, a key may be fabricated in the form. Also, upper thermal insulating board (130) the lower thermal insulating board (110) the same shapes and sizes, a key may be fabricated. Upper shroud (131) (Plywood) the fly woods, a key may be fabricated of a material such as. Upper adiabatic member (132) the-skin polyurethane foam material, reinforced foam is plate cryogenic state from fluid of hull can be protected. Upper thermal insulating board (130) both sides of the lower thermal insulating board (110) is hooked on to a is arranged inside the inner, [...] Stirling (211) each corner to barrier 2 way as to be coupled with a region (120) is protected from the contaminant of molecule in upper. Also as shown in the 4, upper thermal insulating board (130) both sides of the lower thermal insulating board (110) 2 of the squeegees are configured to move cover two of each underlying thermal insulating board (110) [...] of (211) each corner portion can be combined with the.. The, lower thermal insulating board (110) formed between the thermal insulating board the upper space (130) is covered by, of the cryogenic fluid, the objective compound. adiabatic effect of sound-absorbing materials. Also refers to surface 5, upper thermal insulating board (130) the upper adiabatic member (132) and a 2 barrier (120) an upper interposed between the auxiliary panel (134) and, upper auxiliary panel (134) and barrier 2 (120) is interposed between the cargo by a liquefied gas stored therein (sloshing) sloshing absorption layer impact that attempt to protect barrier cargo against shocks (133) further may include. Impact absorption layer (133) in other it possible to eliminate. Upper auxiliary panel (134) the fly woods can be plate. Impact absorption layer (133) (melamine foam) melamine POM as foam material for example, a key may be fabricated in. Melamine expanded mixture based on the melamine amino resin family an open foam as may be for absorbing shock, and has an excellent serviceability in heat insulation performance as well as.. However, do not limited to impact absorption layer (133) the cargo by a liquefied gas stored therein against shocks sloshing capable of protecting the barrier cargo about ambient pressure through the support layers, a key may be fabricated. Upper thermal insulating board (130), upper auxiliary panel (134) and impact absorption layer (133), a key may be fabricated integrally coupled. Upper thermal insulating board (130) each corner of the inner hole (130a) is worked to inner hole is (130a) inserted through the washer for (212) and a nut (213) is provided with a decoupling absorption layer (133) and the upper auxiliary panel (134) of inner hole via through hole (130a) projecting [...] in a Stirling (211) secured to a, nut (213) by tightened with the (212) the upper auxiliary panel (134) is pressing. Inner hole (130a) the foam (Form) filled with such as plug element (not shown) and can be positioned in the, fly woods a cover plate (not shown) can be processed finished by. Also 6 with a, connection board (135) the upper thermal insulating board (130) is interposed space formed between the. The, upper thermal insulating board (130) a regular type covered by lower thermal insulating board (110) formed between the connection board is over (135) is covered by. Connection board (135) the upper thermal insulating board (130) being sandwiched between, the after alcoholic beverage it will do anchor plate (150) by the an upper thermal insulating board (130) is binding and a. Connection board (135) the both sides of lower thermal insulating board (110) 2 of the squeegees are configured to move cover two of upper thermal insulating board (130) 21 and 31 are nipped by. Connection board (135) the upper thermal insulating board (130) to be flush and a shroud connected to (136) and the underlying connection adiabatic member (137) includes. Although not shown, connection board (135) the upper thermal insulating board (130) to the same, upper thermal insulating board (130) is provided with a decoupling absorption layer (133) and the upper auxiliary panel (134) when further comprise a, a member from which the corresponding thereto may further include any each. The, absorption layer impact each member (133) and the upper auxiliary panel (134) and made and thickness can be made of the. The above-mentioned connected shroud (136) connected adiabatic member (137) each upper shroud (131) and the upper adiabatic member (132) the same may be provided with of the combining unit. The, upper thermal insulating board (130) connected board (135) between neighboring grooves formed in its over a backlight unit is inserted, both ends, in which either of the fixed the other the upper thermal insulating board (130) connected board (135) either manner that press the upper thermal insulating board (130) connected board (135) binds a anchor plate (150) can be is provided. E.g., anchor plate (150) end of upper thermal insulating board (130) such as riveted with a fixing device is installed at the side by a fastening element and, anchor plate (150) and another side of the neighboring connection board (135) is a press the latter. Yet, barrier 1 (170, also 7 reference) is movable according to the integral formation shrinkage of includes a unit for recognizing a removed shroud (131) wafer onto strip member (160) is inserted in. Strip member (160) 1 barrier upper part of the (170) is disposed in the, 1 barrier configured to expand the shrinkage due to thermal stress (170) according to movement of strip member (160) is are moved into mating engagement with the. The, forwardly of the baffle cargo the relaxation of thermal stress the objective compound. durability. Yet, barrier 1 (170) is strip member (160) that press the top of is provided manner, barrier 1 (170) according to the integral formation shrinkage of the strip member (160) may be loaded with to move together. Such a strip member (160), for example, stainless steel, a key may be fabricated of a material such as. Also with a 8 also and 7, 1 barrier (170) to shroud contact with a cryogenic fluid (131) barrier. 1 is mounted on (170) the stainless steel (SUS) of the control panel is placed on the panel can be. The, barrier 1 due to load sloshing of fluid (170) an impact is imparted to the corrugated (170b) can be or is curved and the, to prevent this sloshing reducing plate (300) is provided. Sloshing reducing plate (300) barrier the 1 (170) of installation directions barrier 1 in the same direction (170) is provided to remove error on top, barrier gas conduit that are traversed by a fluid 1 (170) plurality of plastic to observe a in square shapes that through hole (H1), a key may be fabricated. Sloshing reducing plate (300) barrier the 1 (170) and made made regular intervals in the rows and columns of can be are arranged in the. The sloshing reducing plate (300) 1 mounted horizontal and vertical directions barrier (170) high temperature and under high pressure in a face-to-face, while yarn load is input to the fluid by the sloshing directly into a barrier 1 (170) applying an impact to a to effectively prevent the formation of can be. (H1) through hole wherein the sloshing, which also serves dispersing the crushing load can be. Sloshing reducing plate (300) comprises a fluid by reducing hoop stress from the upper side to the upper so as to correspond to convexly is formed, through hole (H1) is formed by curve parts (300a) and a, a curved portion (300a) through the both sides from support plate (310) [...] of (311) and a coupling a planar coupled to (300b) includes. Support plate (310) barrier the 1 (170) a flat surface (170a) which can be protected from the contaminant of, [...] in upper surface (311) is vertical fixation by welding. [...] Stirling (311) has a support plate (310) produced as a single piece with may be. The, support plate (310) the sloshing reducing plate (300) to each corner of and arranged at a predetermined position corresponding to, engaging (300b) the sloshing reducing plate (300) is removed to form each corner of [...] Stirling (311) can be coupled to. Also 8 with a, support plate (310) barrier the 1 (170) a flat surface (170a) at a safe seat recess at predetermined intervals on can be coupled to (H2). The support plate (310) barrier the 1 (170) can be to be flush and. Support plate (310) has at a safe seat recess corresponding to the circumferential direction of the thin (H2), won to sides of the space, setting grooves (H2) can be joined by welding. Also, both sides of plate reducing sloshing (300) coupling parts of the (300b) is [...] Stirling (311) which is coupled to the nut as fastening member (313) is [...] Stirling (311) reducing sloshing secured to a plate (300) coupling parts of the (300b). fixing contact to each other. Such sloshing reducing plate (300) and a, support plate (310) and nut (313) through reduction unit sloshing including a sloshing reducing plate (300) for installing and coating of the wafer can be improve work efficiency barrier. Yet, also as shown in the 9, [...] Stirling (311) is fixed a support plate (310) barrier the 1 (170) between weld line is made welding can be provided to simplify the installation of the (L). Wherein, support plate (310) has weld line (L) site can be welding on top of. Versus the specific above described and in the embodiment. However, in the embodiment a the present invention refers to said not are limited to the, invention is in the field of the typically encountered in having knowledge of if hereinafter grow is the subject matter of the technical idea of the invention without deviating from the 162 has a watch upper surface is may embodiment. 110: lower thermal insulating board 111: lower shroud 112: lower adiabatic member 113 : a lower auxiliary panel 120:2 barrier 130: upper thermal insulating board 131: upper shroud 132: upper adiabatic member 133: impact absorption layer 134: upper auxiliary panel 135: connection board 136: connected shroud 137: connected adiabatic member 150: anchor plate 160: strip member 170:1 barrier 300: sloshing reducing plate 310: support plate 311 : [...] Stirling 313: nut Disclosed are a sloshing reducing unit and a cargo barrier structure including the same. The cargo barrier structure according to an embodiment of the present invention comprises: a lower insulation board arranged on an upper portion of an inner wall of a cargo hold; a secondary barrier placed on an upper portion of the lower insulation board; a primary barrier in contact with a cryogenic fluid; an upper insulation board interposed between secondary barrier and the primary barrier; and a plurality of sloshing reducing plates installed on an upper portion of the primary barrier, and having a plurality of through holes so that the fluid passes therethrough and flows into the primary barrier, in order to reduce sloshing loads by the fluid. COPYRIGHT KIPO 2016 Upper inner wall cargo a lower patch element disposed in the thermal insulating board; said lower thermal insulating board arranged on top 2 barrier ; barrier 1 rotating member comes into sliding contact with cryogenic fluid; with barrierbarrier interposed between the 2 1 an upper thermal insulating board; and said fluid by sloshing to reduce load, said 1 is provided to remove error on top barrier , said 1 gas conduit that are traversed by a fluid plastic to observe barrier said plurality through hole is formed a sloshing reducing plate; a barrier structure including cargo. According to Claim 1, which can be protected from the contaminant of upper barrier said 1, a support plate vertical fixation [...] in upper surface further includes, said sloshing reducing plate so as to correspond to said fluid by reducing hoop stress is formed convexly upper, by curve parts and said through hole is formed, a curved portion said through the both sides from said Stirling including cargo [...] diffusion plate support for supporting a diffusion barrier structure. According to Claim 2, said a support plate said sloshing reducing plate to each corner of and arranged at a predetermined position corresponding to, said corner portion to the inner surface of the case said said [...] Stirling the each of which is formed next to a cargo barrier structure. According to Claim 2, said 1 a support plate said barrier constant flat surface seating groove formed at uniform intervals a cargo barrier structure. According to Claim 4, said corresponding said a support plate are made of a circular groove, said groove won welding bonded to each cargo barrier structure. According to Claim 2, an inner plate reducing sloshing said both sides of said Stirling [...] Stirling [...] the opening of the case body, a handle secured to the said sloshing reducing plate a joint portion, a membrane support assembly cylinder contact with each other including cargo barrier structure. According to Claim 2, said welding between said 1 a support plate barrier weld line is made parallel with each other along the site structure barrier cargo mounted. According to Claim 1, said lower thermal insulating board a lower shroud with barrier said 2 and adiabatic member further lower the entire surface of said lower adiabatic member is electrically connected to the a lower auxiliary panel, said a lower auxiliary panel on upper sides of the vertical [...] one stationary fixed to the piece are provided, both sides of said 2 barrier said lower space formed between the thermal insulating board is disposed to cover the, other for allocating a transponder channel in said Stirling with barrier[...] 2 is connected, said [...] Stirling periphery corresponding to provided said won to the fixing pieces forms a separating surface to which the bonded welding a cargo barrier structure. According to Claim 8, said lower thermal insulating board a dielectric material to make the dielectric material, the same longitudinal extent horizontal length construction with an integrated square configuration, both sides of a thermal insulating board upper said lower said is hooked on to a thermal insulating board is arranged inside the inner, said Stirling way as to be coupled with a region of each corner [...] said 2 which can be protected from the contaminant of upper barrier , said upper thermal insulating board to be placed on a coplanar with the upper said formed between the thermal insulating board is interposed board space a cargo barrier structure. Rotating member comes into sliding contact with cryogenic fluid of a cargo can be protected from the contaminant of which upper barrier 1, a support plate vertical fixation [...] in upper surface; and said fluid by sloshing to reduce load, said 1 barrier installation directions in the same direction said 1 plurality upper barrier plate reducing sloshing is set at the left and; includes, said sloshing reducing plate so as to correspond to said fluid by reducing hoop stress is formed convexly upper, for the passage of a fluid said a plurality through hole is formed and by curve parts, said a curved portion from both sides through the diffusion plate support for supporting a diffusion [...] said Stirling including sloshing reduction unit. According to Claim 10, an inner plate reducing sloshing said both sides of said said Stirling [...] Stirling [...] the opening of the case body, a handle secured to the plate reducing sloshing said cylinder contact with each other a joint portion, sloshing reduction unit including a membrane support assembly.