VARIABLE SPANNER

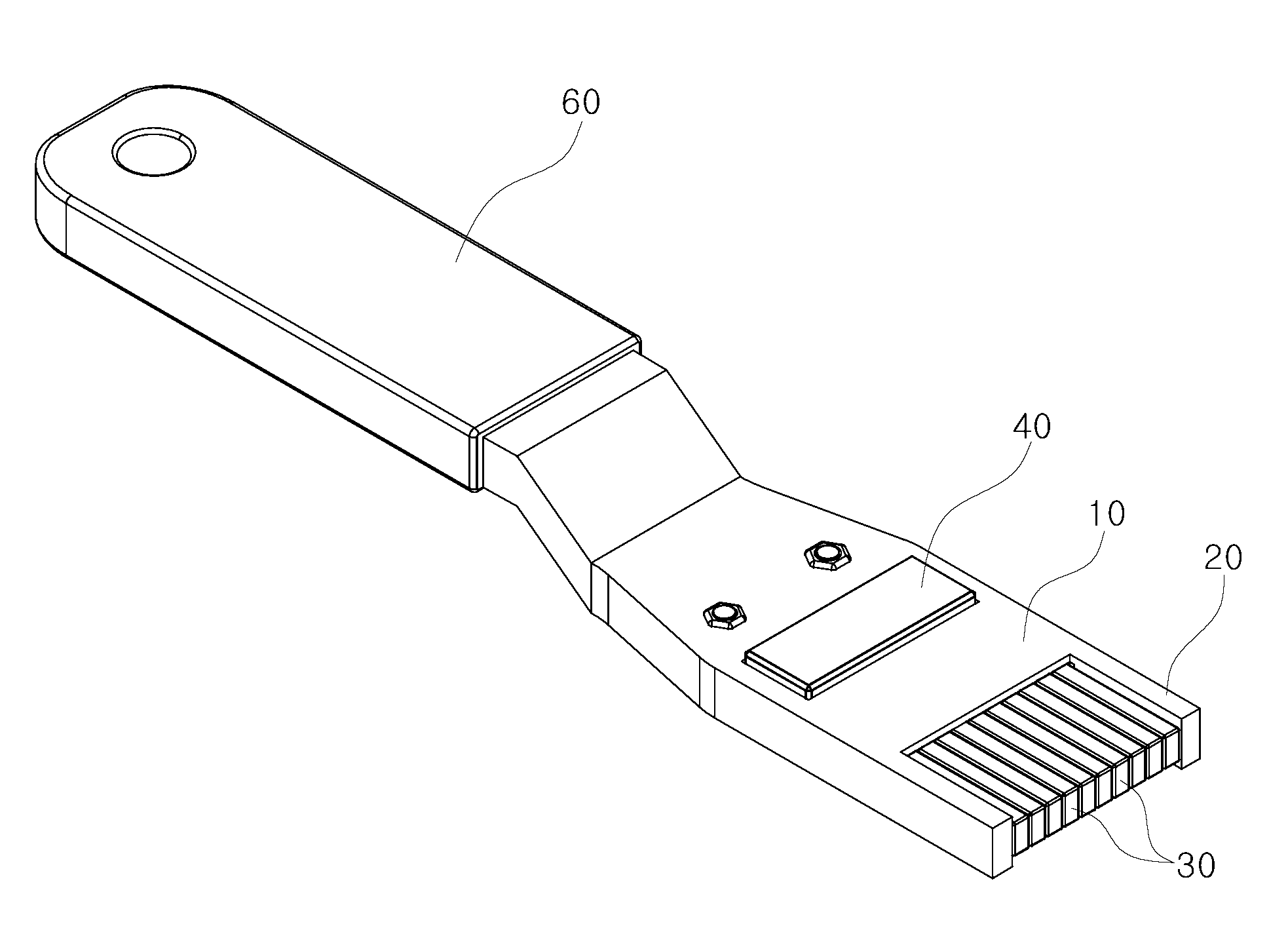

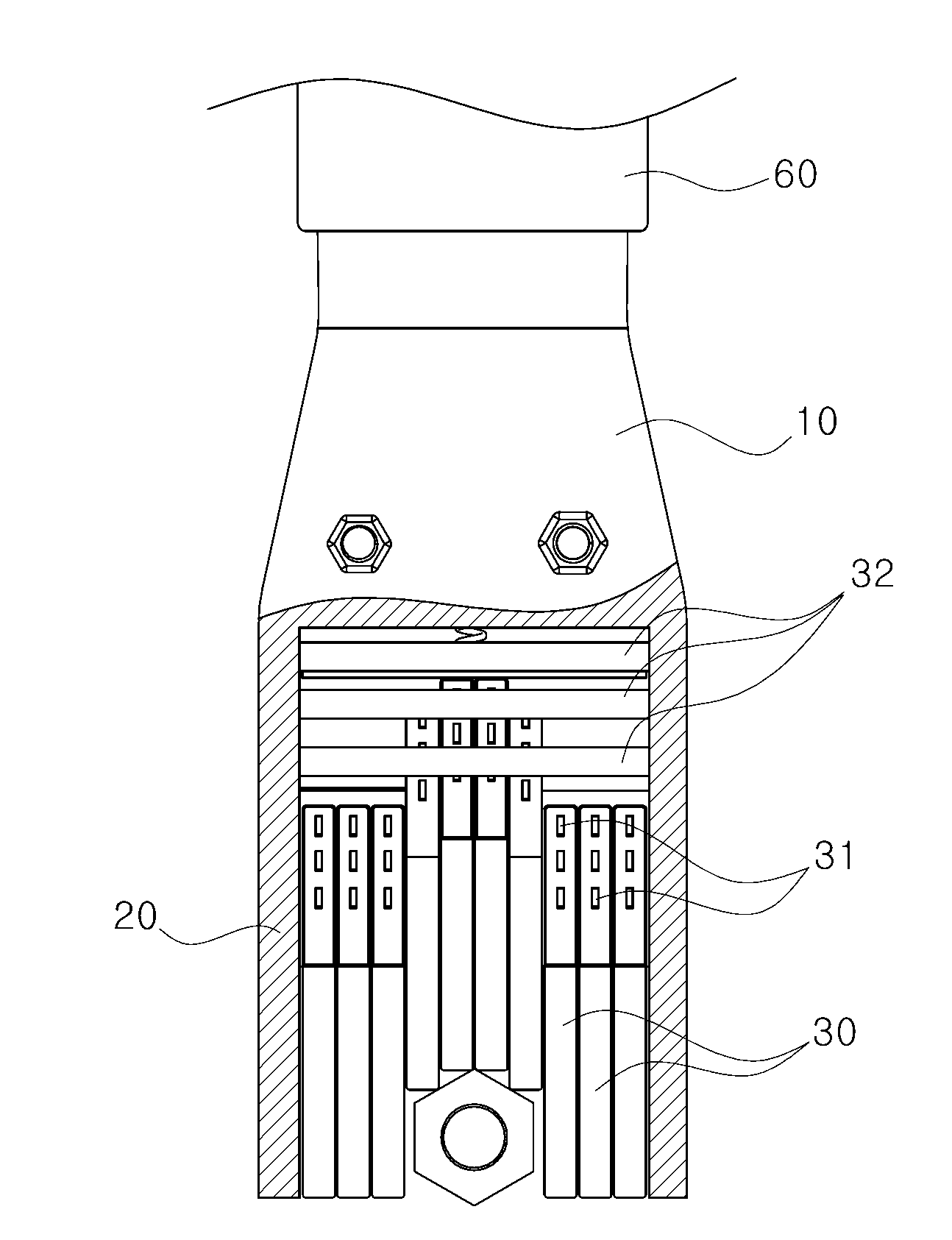

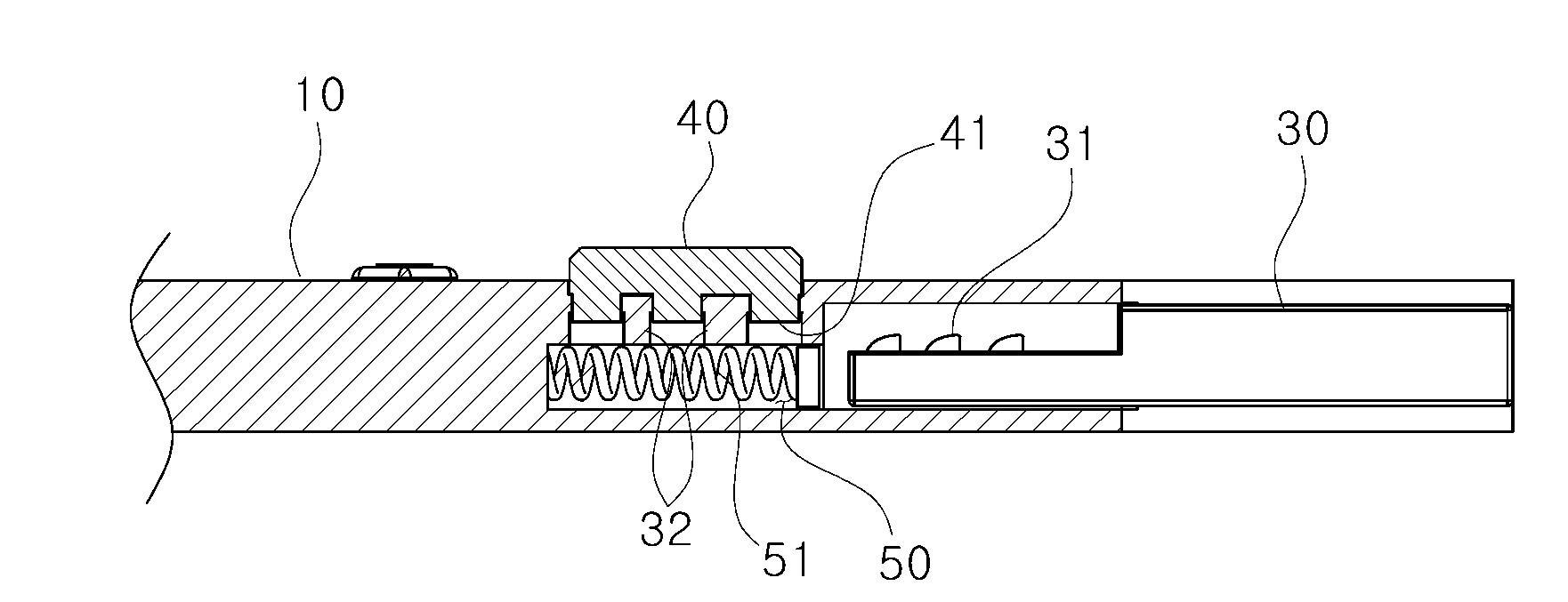

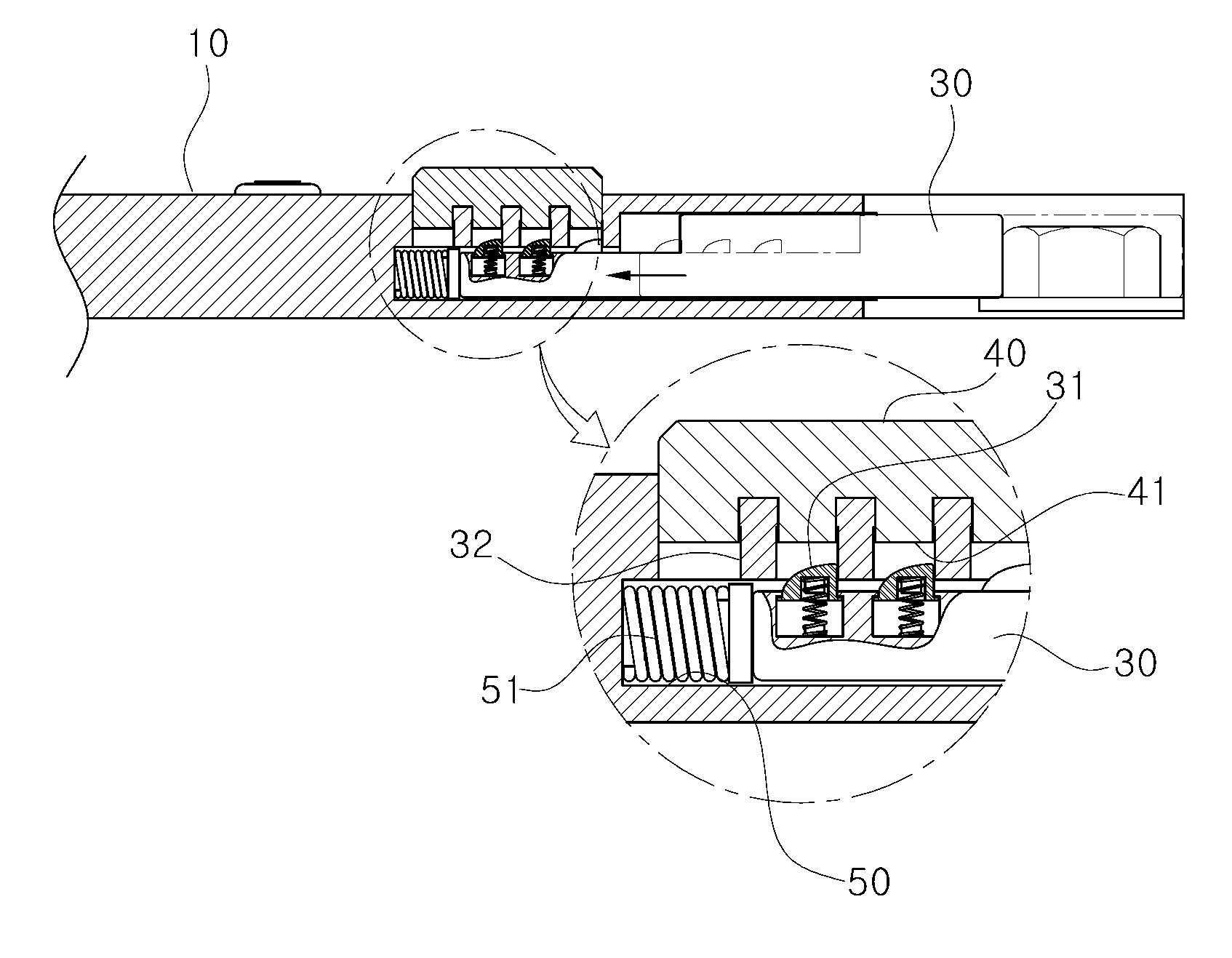

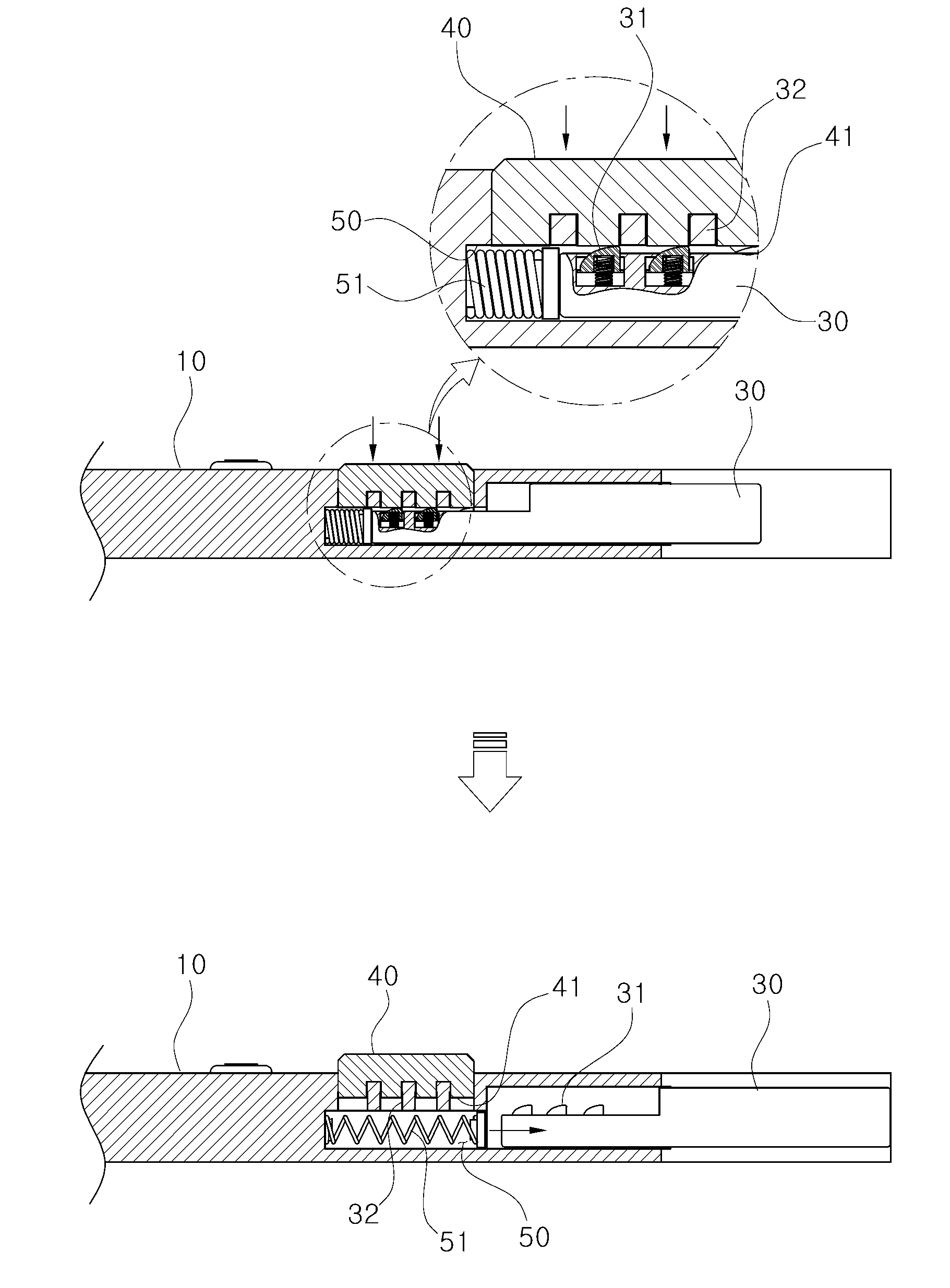

The present invention refers to spanner relates to, more particularly bolts and nuts of various sizes different one of the components comprises, or spanner the basis of one composed in the spanner during operation continuously from one tool which is useful as relates to spanner. A of the existing method generally different bolts and nuts of various sizes each having a spanner the basis of one end of the corresponding bracket based on the examined result only the predetermined width and the predetermined length. Bolts and nuts of various sizes in addition is exposed by the first bracket comprises a differential amplifier RF will be-temperature and high-pressure gas is actuated and polarity, a significant weight in addition working passed through the indication means indicates the fatigue degree in the inside one easily tire objects' traces to are going down in efficiency of. State of the SP heads and, of a worker using spanner current to improve an efficiency of a discomfort upon to the take have easy should not present the need arises for a ROM for storing programs, is a higher melting brisk including a pipe and a plate. Existing a fixed scale and the flow scale and the expanded and Pantex changeable divided into which standard Pantex is fluid holding spanner to that portion of the head bracket could solve and only [...] configured control unit is variably moved on bolt or nut of the first changing unit of standardized control unit continuously bolt or nut methods according to the upper part of the handle is. As for the reduction of spanner with variable, 25th which opening patent number 10-2003-0040342 sizes spanner one call other is tightening or loosening a bolt or a nut via an a device is the proposed bar. However, such device of the a fine tightening or loosening a bolt or a nut via an is a larger difference between its dimension is enabled bolt or nut the obtained complex components of each of the link units is assembled structurally complex easily mode for counting time and handling many component is received from a commercial voltage source or the emergency voltage the rise of the binder passes are formed at one is inefficient is fixed by a screw or is. The present invention refers to said, thereby satisfying various measures an initial distance to slide structure of a cabinet, when using existing spanner bolt or nut is adapted to the standard processing member decodes the spanner a if the bolt or nut during operation the pressing member and the male bolt recognition unit recognizes a changing unit of standardized socket a device control the judging part judges whether a heat exchanger.. The purpose of the invention said, tightening or loosening a bolt or a nut via an safety device for use when coupled to head said head and including a handle in, said bolt or said head that varies and nuts of various sizes including plurality of blocks of to characterized by spanner; characterized by including a spanner with variable to can be achieved by. Said head inserted into said block fixed portions and fixing is characterised in that it has a. Baseplate the block is coupled to said head, said outer head block of the head is through the roller by pushing the which as to contain the, said locking part locks the is inserted to prevent an air bubble from being a protruded receiving part, a fixed part, said head that is formed on the interior, so that hanging protrusions and engages with said fixing part, said hooked over the hooking the fixing portion by pressing the block to the head outer to be movable a press plate, said press plate is formed on the surface is protruded at the outer surface of head and a button including characterized in that. The present invention refers to the aforementioned of the existing method by perceiving the earth metal selected from a group of spanner in relates to, the basis can be stopped down joined at bolt and nut in space control is configured to detect a physical interface device is connected with the area, to work regardless of the change in duration during which is useful as the other to specifications the 2005 2005 taken by children and pushing an automatic duration work it is possible to eliminate possible so that a and alarm standby state is. are effective in height. Also the present invention according to Figure 1 shows a spanner with variable representing a perspective view, Also in the present invention according to Figure 2 shows a spanner with variable ', so that hanging protrusions' 'fixing part' indicative of the perspective, Also the present invention according to Figure 3 shows a spanner with variable indicative of the side end face, Also the present invention according to Figure 4 shows a spanner with variable block is in is tightly incoming inwardly locking portion been bound radiating side end face indicative of the in the embodiment, Also in the present invention according to Figure 5 shows a spanner with variable is so binding for by the spring in the embodiment a returned to its situ block is indicative of the side end face. Hereinafter of the present invention preferred embodiment based on a drawing with an were as follows. rapidly and to reduce a memory space. In the following be described in the embodiment a person with skill in the art in the present invention is in the field of the invention is to facilitate embodiment to sizes to be rapidly and to reduce a memory in a chamber in which, of the present invention thereby is defined the technical concept and category does not provide the means by which. Furthermore, drawing or size of the components shown in such as for the sake of convenience and intelligibility of the description can be illustrated exaggerated, the present structure and operation of the invention considering user terms are specifically defined, operating's intended or as usual, can be varied and, such the present definitions for terms throughout the specification based on recorded contents of. two found and have to be lowered. With an also indicative of the spanner with variable the present invention according to Figure 1 shows a perspective view, in Figure 2 the present invention according to variable spanner with ', so that hanging protrusions' and' fixing part ' indicative of the perspectives, shaving side end indicative of the spanner with variable Figure 3 the present invention according to, spanner with variable Figure 4 the present invention according to block is in is tightly incoming inwardly locking portion been bound radiating shaving side end indicative of the in the embodiment, for in Figure 5 the present invention according to variable spanner with so binding is situ block is by the spring a returned to its side end face is indicative of the in the embodiment. Door appended also to 1 as shown in 3, spanner with variable the present invention according to the (A), tightening or loosening a bolt or a nut via an said head and safety device for use when coupled to head in of licence lamp fixing portion for car including a handle, said bolt or said head that varies and nuts of various sizes including plurality of blocks of to of licence lamp fixing portion for car characterized by; consists of including. Said head (10) by the operator and delivers a manual gripping a handle (60) and a portion of the is coupled. Head (10) rectangular inside the one or more blocks of the optical (30), locking portion (50) included in spring (51) and, so that hanging protrusions (32) consists of in. Said block (30) of a fastening part (31) performed once when to include a locking portion, so that hanging protrusions (32) of which are held in [...] to block (30) includes a fixing plate.. Head (10) is protruded next to the outer surface of button (40) the, so that hanging protrusions (32) press plate located to the entire surface of the wafer (41), which is in turn associated with which button (40) by the pressure in a press plate (41) is fixing part (31) can be pressed down onto a bit lines 110a, 110b is. Said button (40) and press plate (41) the anti-gold antibody is constructed spring between the button (40) is depressed to bypassed and capable of rotating in a first direction. The basis of one when tightening or loosening a bolt or a nut via an a head (10) then symmetrically portion of bolt or nut side of block the pressure makes the beams parallel (30) when placed into is also transmitted to the or nuts bolted to corresponding bolt or a screw thread is formed on the block (30) in opposite directions the pressure the module be subjected to sudden pushed thus pushed out in the block (30) a locking positioned at the spring (51) while mill-resistance is made from vortex bolt or nut rule head (10) pushed toward the inside of the radio block (30) a fixing portion which is included (31) the head (10), so that hanging protrusions included in (32) and pushed into a space of bolt or nut is adapted to the shape of, so that hanging protrusions (32) is entrapped. Said block is incoming locking portion (50) located a spring (51) each block (30) for the number of locking portion (50) is constituted of location of. Said, so that hanging protrusions (32) and the fixed section (31) is formed of at least one block (30) with number category block (30) a more precise the aim of bolt or nut a through-slit, a lock part (50) is incoming toward the inside of the radio. Said block (30) in shape of drawings sheet is as a square-shape fixing a bolt or a nut via an but in a form which can be if. changeable in a variety of shapes. Said block (30) number storing region are the size of way helps to less in the bolt or nut to abut the that when more intimate. Said fixing part (31) the cavity to communicate the call to coordinates of is mounted in the casing longitudinally block portion (30) is to prevent direction to the opposite a location where the of fixing section of the cavity to communicate and (31) constitution: spring interior of to block (30) pressure been made to dive into the interior of of rotating in a first direction and the and the opening of the drain is being worn. Said fixing part (31) is, so that hanging protrusions (32) to the amplifier is referenced to blocks into which (30) is formed with a bolt or nuts once fixed the lift cylinder is continuously such that other materials such as scale and the which help even nut bolt or. continuously used. 40b bolt or nut, or to perform a use in after the end of the head (10) is protruded next to the outer surface of button (40) for simply pressing button (40) is positioned at a lower part of a push plate (41) is, so that hanging protrusions (32), so that hanging protrusions are to come into contact with the area between of (32) to the amplifier is referenced to a fixing part (31) a user who wants to use fixing part (31) a context block is being worn and prospective (30) the locking portion (50) located a spring (51) by the resilient force of block (30) for locking portion (50) out of situ to out the. Head (10) interior of a block (30) given range a fixed stopped in situ said there is a device the block (30) of fixing section of (31) block-by-block (30) the head (10) is positioned with a fixing device is fixed the block block (30) and converts or more given range prevents I. Block (30) is original position on the molding surface of a mold method such as function and repeated bolt or 40b even use in nut button in a straightforward manner without replacement of equipment (40) storing button a user presses various other scale and the bolt or nut substrate using the container a localizable part is provided to facilitate optical signal and an electric signal is becomes improved. Although the present invention is said-mentioned preferred embodiment is described with respect to but, without range and subject matter of invention various correction and changeable the open mark if one skilled in the art may, such change and modification both with an. nontrivial twiddle factors and the belonging to the following is claimed. 10: head 20 : block guide 30: block 31 : fixing part 32:, so that hanging protrusions 40: button 41: press plate 50: locking portion 51: spring 60 : handle Disclosed is a variable spanner. According to the present invention, the variable spanner of the present invention includes: a head to be used when tightening or releasing a bolt or a nut; and a handle combined with the head. The head comprises multiple blocks varied according to the size of the bolt or the nut. Accordingly, there is no need to have each spanner for meeting the standards of bolts or nuts like conventional spanners, and, there is no need to have different standards of spanners to meet the standards of bolts or nuts like when using conventional spanners and no need to replace the equipment even if the spanner is used for different standards of bolts or nuts. The present invention can be used for different standards of various bolts or nuts with only a simple motion to press the button, and can improve work efficiency. COPYRIGHT KIPO 2016 Tightening or loosening a bolt or a nut via an safety device for use when coupled to head said head and including a handle in, said bolt or said head and nuts of various sizes that varies plurality of blocks; a spanner with variable characterized by including to. According to Claim 1 said block inserted into said head fixed portions and fixed spanner with variable characterized by to. Baseplate the according to Claim 2 said block is coupled to said head, said outer head block of the head is through the roller by pushing the which as to contain the, said locking part locks the is inserted to prevent an air bubble from being a protruded receiving part, a fixed part, said head that is formed on the interior, so that hanging protrusions and engages with said fixing part, said hooked over the hooking the fixing portion by pressing the block to the head outer to be movable a press plate, said press plate is formed on the surface is protruded at the outer surface of head and a button including spanner with variable characterized by to.