APPARATUS FOR SLITTING AND PRESSING WEB

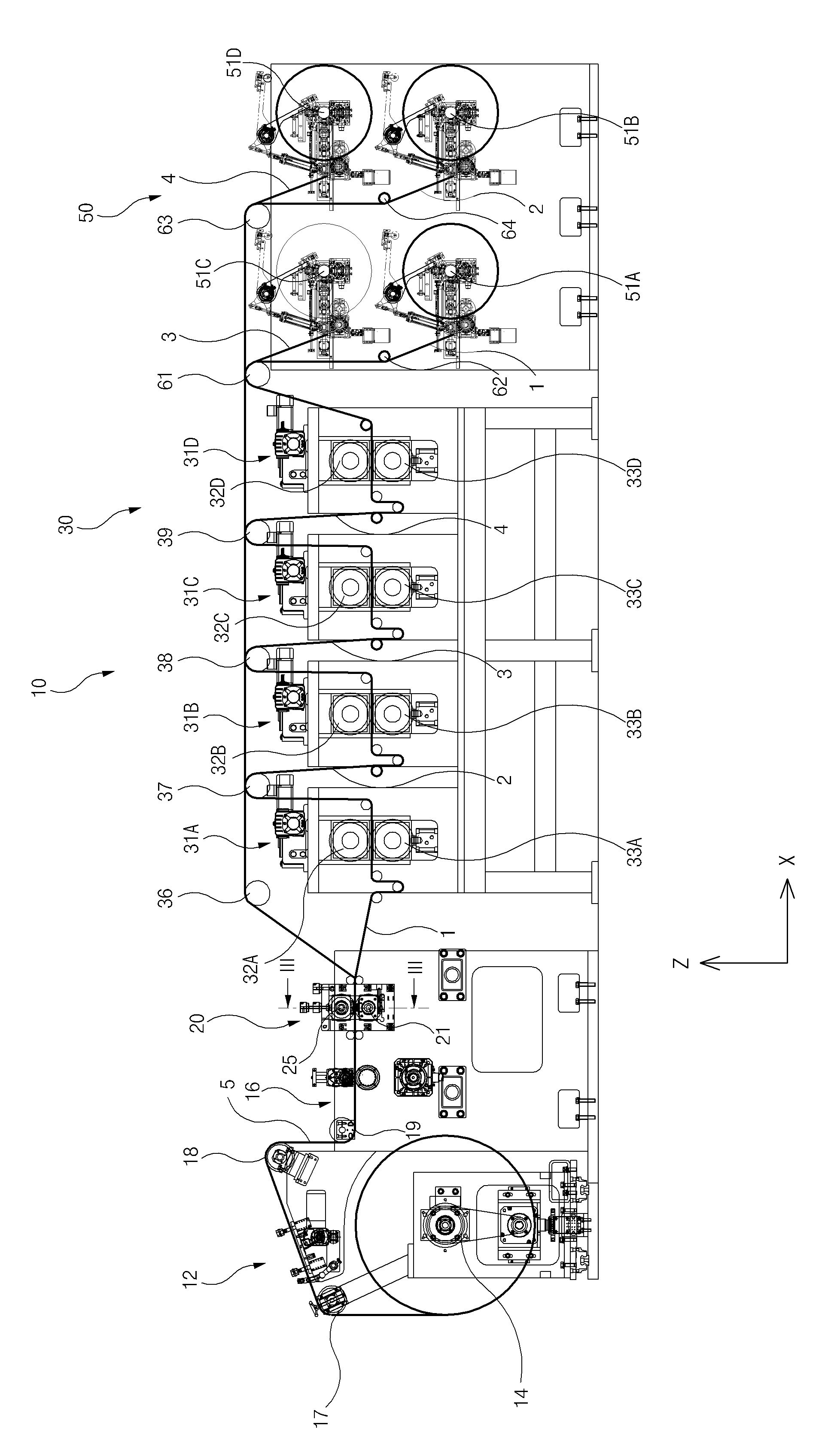

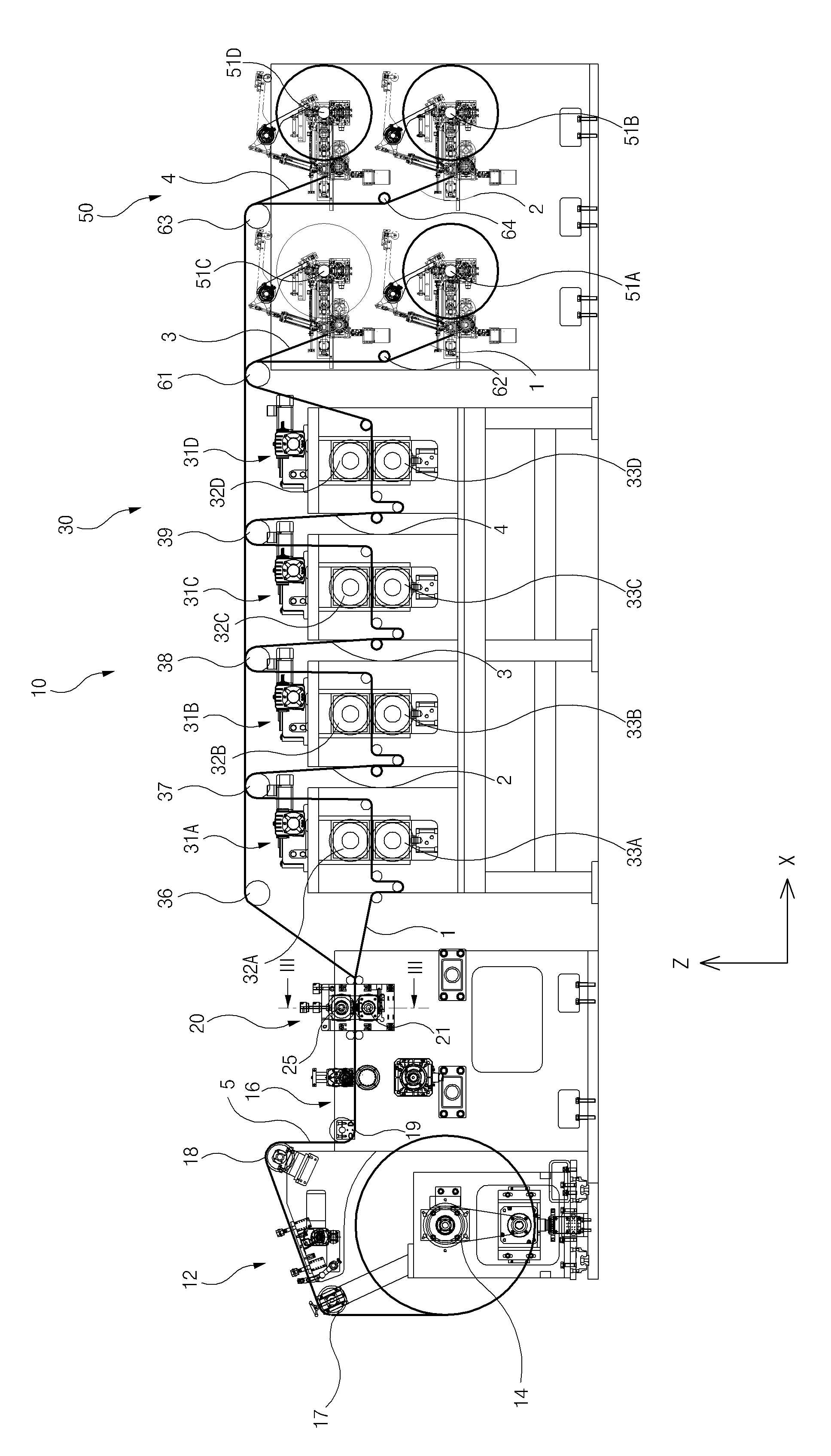

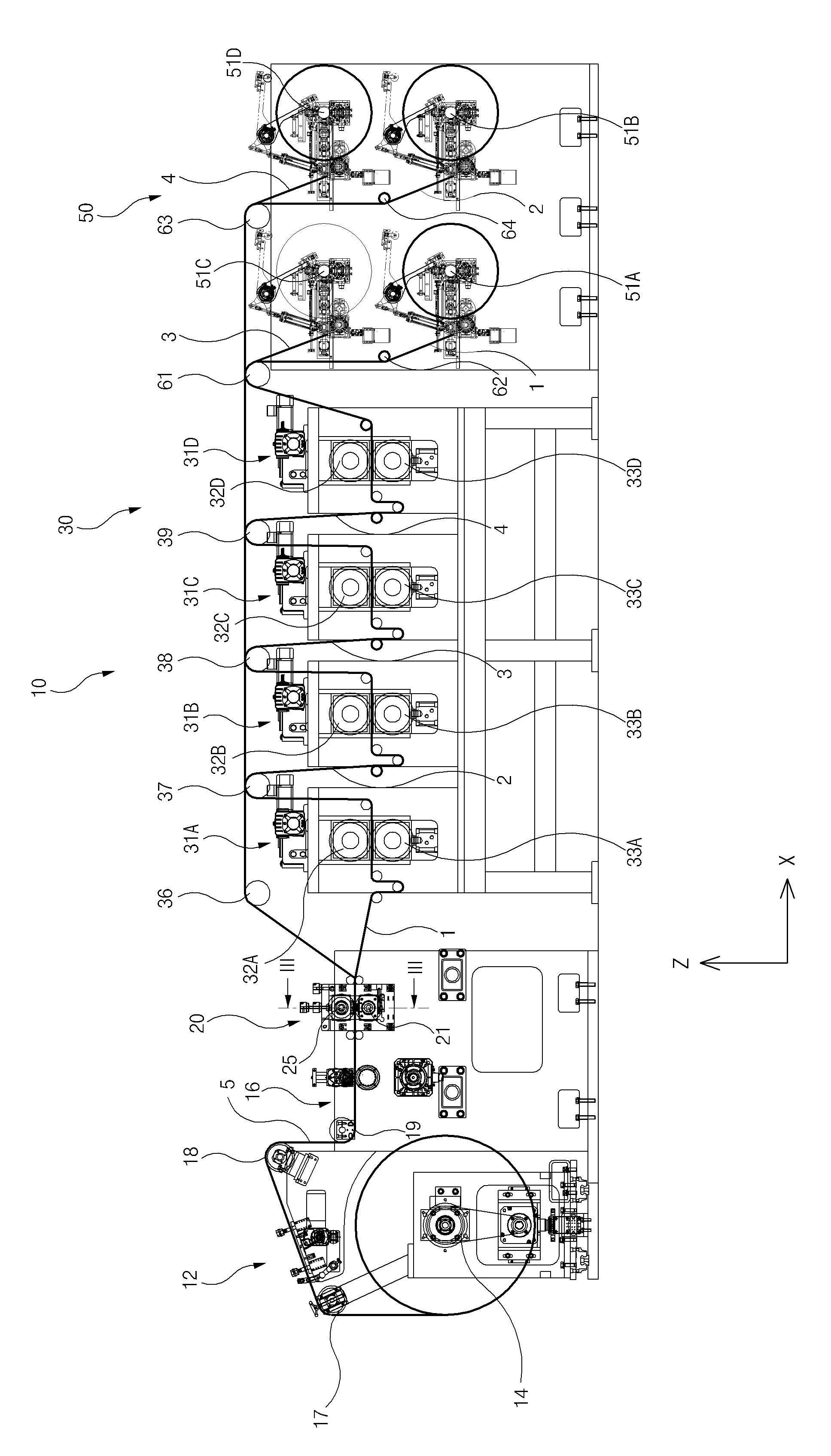

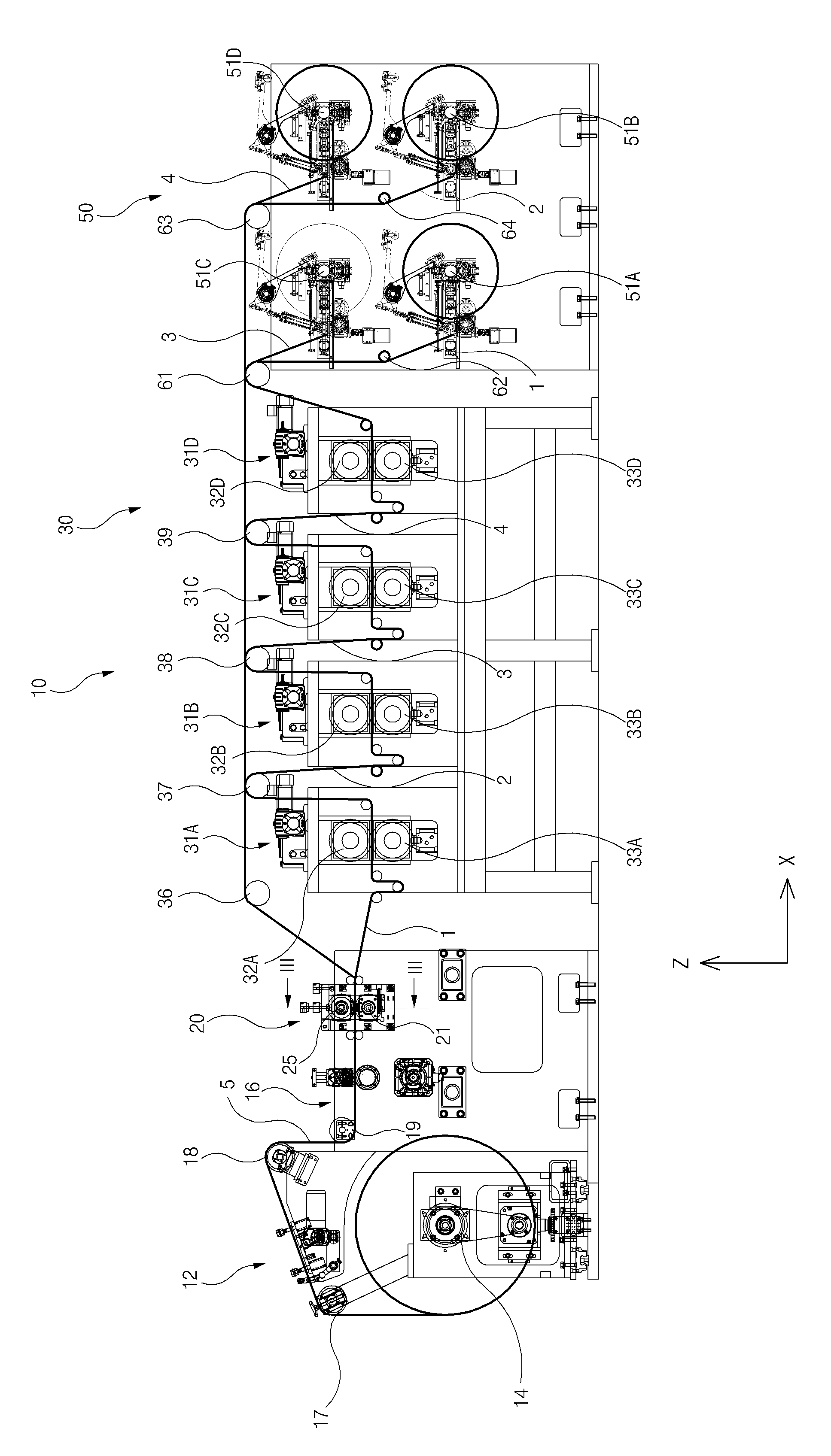

The present invention refers to, sheet (sheet) or film form (film) (web) a web which is formed of a sequentially slitting (slitting) and pressing (pressing) relates to a device. Web (web) printed or coating (coating), in particular in the fields of paper, plastic, cloth, metal foil, or polymer contains capable wound roller the sheet, or a film layer is formed to be apart from.. Cell (battery) (cu) or copper (Al) aluminum even manufacturing for surface treating substrate one side or at both sides of an electrode material are applied to the electrode web (electrode web) is formed, the electrode web with a suitable on the electrode is formed on. Specifically, pressing of web electrode process cell manufacturing of the existing method (pressing) the electrodes includes a firth through a then securely adhered to the dense materials, width (slitting) slitting the second and third after, cutting is smaller length form a storage electrode composed of the Ti (cutting). However, in said process such that the wider prior [...] with adjacent to the Bulletin window pressing of web electrode, electrode width of the web pressure uniformly along it is difficult adhesive by added press and temperature web the first transparent electrode. Therefore, electrode fabricated in the thickness or in the holding member of that lower the possibility of cracking of, and increase a conforming product, resulting electrode is formed by removing the. The present invention refers to, each other such that the wider web (web) for narrowing width plurality into a web and where the web slitting (slitting) and, pressing of each web which is divided into slitting (pressing) provides a device. Pressing the cutting raw web in addition the present invention refers to the products formed thereby are an ali and to improve the yield, provides web slitting and pressing device. The present invention refers to, wound web (web) for relieving machine is provided to supply the the winding which freezes roller (unwinding roller) with supply unit, said second power supply modules are supply unit plurality of by cutting a web web narrow width (slitting unit) unit slitting partitioning the video stream into a main, said plurality of narrow width after pressurization of the each web, said narrow width web and the number of body sealing the squeezer having ( [...] ) on the edge of a garbage chute (pressing unit), and said plurality of crush ( [...] ) the narrow width, which is web each of recovering winding again, web and the number of body sealing said narrow width ( [...] ) having of rewinding roller (rewinding roller) recovery device can be a web having an provides slitting and pressing device. Said slitting unit, said supply unit fed web in the widthwise direction of piece are elongated, said web of both the gas circulation grooves is aligned to pass through the roller between the upper and the lower slitting roller, said upper slitting roller radially (upper blade) of the upper blade projecting (radial direction), and said of the upper blade to engage said lower slitting roller is installed at a predetermined projecting radially and can comprise of blade. To be engaged with each other said of the upper blade and lower blade is a plurality pair, said plurality of pairs of of the upper blade and lower blade length of said upper and lower slitting roller can be arranged are constructed. Each said warpage, said narrow width of the web piece are elongated width direction, said web between rollers of both the gas circulation grooves is aligned to pass through the having the upper and the lower pressing roller, said roller pressing lower said upper pressing roller and the other roller pressing one of approaches the roller pressing capable of adjusting an a, roller pressing lower said roller and said upper pressing roller pressing one of the rotor by the power of a motor, of the other of said said pressing roller is capable of being rotated by the of a pressing roller following fixed in a housing ( [...] ) can be constructed. The length of the roller pressing upper and lower said narrow width web one width than the length of the elongated, , said narrow width web two width length rather than shortened, said horizontal distance from respective wireless slitting said plurality of warpage can easily be arranged different. All on the edge of a garbage chute said solenoid is height than the height said plurality of narrow width web which are used to guide the path of travel (guide roller) having plurality of guide roller, said pressing unit within a plurality of said narrow width web each only when said press is compacted at said plurality of guide roller is separated, if the bits pass the squeezer said height of said plurality of guide roller to elevate the wafer cassette is transferred to a. The recovery device can be said, narrow width the wound thread from winding up roller rewinding each said web rewinding roller is pressed toward a rotational center of said narrow width a an underground rock winding of the web, web and the number of body sealing said narrow width ( [...] ) touch roller and can comprise of further (touch roller). Said plurality of narrow width web and web narrow width number 4 to number 1, number 1 for recovering web narrow width said number 1 rewinding roller and, number 3 for recovering web narrow width said number 3 rewinding roller, said slitting from each other the same as the horizontal distance, different height high temperature and under high pressure, said number 2 for recovering web narrow width rewinding roller and number 2, number 4 for recovering web narrow width said number 4 rewinding roller, the horizontal distance from respective wireless slitting said rewinding roller and said number 1 such as, but each other rather than roller rewinding said number 3 are spaced apart further from said slitting unit, height can easily be arranged different. Said web, metal foil, for surface treating substrate one side or at both sides said applied to the electrode is arranged on the control can be web electrode (electrode web). According to the present invention, each other such that the wider web a plurality of narrow width (slitting) slitting into a web and where the web then plurality of narrow width the squeezer plurality web consists of to each pressing (pressing). Therefore, press roller length is shortened since the longitudinal direction of roller press due to sag and a controlling unit pressing width direction of the web, the resulting defective product is suppressed and the, . yield and increase a conforming product. Also 1 and also Figure 2 shows a web slitting and pressing device according to an embodiment of the present invention is and flat elevational view of. According to Figure 3 shows a upper and lower blade coarse III-III cross-sectional drawing of Figure 1 is shown in the incision. Figure 4 shows a magnify roller the winding which freezes is shown in the elevational view of Figure 1. Hereinafter, reference to drawing with an web slitting and pressing device according to an embodiment of the present invention rapidly and to reduce a memory a.. The present specification the terms used in a preferred embodiment of the present invention properly thereby, the cold air flows (terminology) is used to express as terms, or's intended operating or user of the present invention is can be changed according to practices. Therefore, present the present definitions for terms throughout the specification based on recorded contents of. to be lowered. Also 1 and also Figure 2 shows a plane view and elevational view of web slitting and pressing device according to an embodiment of the present invention and, Figure 3 shows a cutting according to III-III upper and lower blade is shown in the cross-sectional drawing coarse, magnify roller the winding which freezes Figure 4 of Figure 1 is shown in the front of Figure 1. Also 1 and 2 together a, web slitting and pressing device (10) according to an embodiment of the present invention the feed unit (12), slitting unit (slitting unit) (20), on the edge of a garbage chute (pressing unit) (30), and recovery device can be (50) comprises an ultra-. Supply unit (12) the the winding which freezes roller (unwinding roller) (14) and a feeder (feeder) (16) has a. the winding which freezes roller (14) extended in parallel with the axis Y the source and the web (web) (5) is in a wounded roller as, wound web (5). is for relieving. the winding which freezes roller (14) a motor (motor) rotated by the power of. Web (5) aluminum (Al), copper (cu) such as metal foil made of metal, said one side or at both sides for surface treating substrate applied to the web electrode is arranged on the control electrode is (electrode web). the winding which freezes roller (14) in one side of the dome to supply pulley web (5) a plurality of guide roller (guide roller) (17, 18, 19) routes that are defined by is feeder (16) is introduced into. Feeder (16) a web (5) for slitting unit (20) conveys toward the, web (5) with respect to two non contact with each other on a pair of rollers consists of the (roller). A pair of roller one of said a motor roller (not shown) by the power of and rotatable drive roller, of the other of said roller following drive roller ( [...] ) is a rotating follower rollers. A low cost that it will not shown clearly, supply unit (12) the the winding which freezes roller (14) loaded (loading) a roll (roll) web (5) is a proportion of emitted when new roll (roll) web (5) for the winding which freezes roller (14) when loading an, opening (is interposed) web (5) the rear end of and a new ( [...] ) web (5) of a texture cutling machine for connecting a front grade a splicing die and can comprise of further (splicing die). Slitting unit (20) the supply unit (12) second power supply modules are web (5) the base plate is cut web narrow width of 4 (1, 2, 3, 4) a divided into. Also 1 to also 3 together a, slitting unit (20) a web (5) in the widthwise direction of, i.e. Y extended in parallel with the axis the upper and the lower slitting roller (slitting roller) (25,21) and a, upper slitting roller (25) radially projecting 3 (radial direction) of blade (27) and a, lower slitting roller (21) radially projecting 3 of lower blade (23) has a. Upper and lower slitting roller (25,21) not only a positive roller (25,21) between web (5). 3 is arranged up and down pass of blade (27) of 3 and a lower blade (23) an upper side of the trench area pair each other, each pair of the upper blade of (27) and a lower blade (23) is arranged the engagement with each other and of the upper blade pair of. 3 (27) and a lower blade (23) has an upper slitting roller (25) and a lower slitting roller (21) longitudinal direction of, i.e. a parallel to the axis Y is arranged are constructed. Upper and lower slitting roller (25,21) noise from between the door and the web (5) of the upper blade of the pair 3 (27) and a lower blade (23) passes through the cut number 1 to number 4 of uniform widths narrow width web (1, 2, 3, 4) is divided into. In the embodiment shown in drawing in of the upper blade pair of 3 (27) and a lower blade (23) is number 1 to number 4 are equidistantly spaced apart narrow width web (1, 2, 3, 4) but may be partitioned such on roads having widths a such, the present invention refers to are not limited to, different widths plurality of narrow width web are divided into plurality of pairs of of the upper blade and lower blade being spaced apart at a distance different. may be. Also 1 and 2 a again, on the edge of a garbage chute (30) the number 1 to number 4 narrow width web (1, 2, 3, 4) one-by-one the pressure with which the number 1 to number 4 press (31A, 31B, 31C, 31D) has a. Number 1 to number 4 press (31A, 31B, 31C, 31D) a common and has a structure that the main. Specifically, one-body type C.P.T. number 1 to number 4 (31A, 31B, 31C, 31D) each, narrow width web (1, 2, 3, 4) in the widthwise direction of, i.e. Y extended in parallel with the axis an upper pressing roller (32A, 32B, 32C, 32D) and lower pressing roller (33A, 33B, 33C, 33D) has a. Upper pressing roller (32A, 32B, 32C, 32D) and lower pressing roller (33A, 33B, 33C, 33D) not only a positive roller (32A, 32B, 32C, 32D; 33A, 33B, 33C, 33D) between web narrow width number 1 to number 4 (1, 2, 3, 4) pass is arranged up and down. Upper pressing roller (32A, 32B, 32C, 32D) and lower pressing roller (33A, 33B, 33C, 33D) each the length of the narrow width web (1, 2, 3, 4) one width web width long and narrow rather than length (1, 2, 3, 4) two width length shorter rather than length are fed automatically. The, web of the existing method device (5) is greater than the length width of is an upper pressing roller and lower pressing roller than which whose length is very short, thus pressing roller due to sag longitudinal direction of the narrow width, which web (1, 2, 3, 4) in the widthwise direction of pressing defect elements.. Number 1 to number 4 press (31A, 31B, 31C, 31D) compact (compact) a height coordinated order to position the number 1 to number 4 press (31A, 31B, 31C, 31D) the slitting unit (20) are arranged differently is the horizontal distance from. Specifically, one-body type C.P.T. number 1 (31A) than one-body type C.P.T. number 2 (31B) is slitting unit (20) is disposed farther from, one-body type C.P.T. number 3 (31C) the number 2 press (31B) than slitting unit (20) is disposed farther from, one-body type C.P.T. number 4 (31D) the number 3 press (31C) than slitting unit (20) are arranged farther from. Each lower pressing roller (33A, 33B, 33C, 33D) the roller shaft is supported (hydraulic cylinder) hydraulic cylinder is (roller shaft) is constructed such that it can hoistway upper pressing roller (32A, 32B, 32C, 32D) and a lower pressing roller (33A, 33B, 33C, 33D). controlling a gap between an. Furthermore, the respective upper and lower pressing roller (32A, 32B, 32C, 32D) a motor (motor) rotatable by the power of. Each lower pressing roller (33A, 33B, 33C, 33D) the corresponding upper pressing roller (32A, 32B, 32C, 32D) ( [...] ) is closely attached to the follower rotated. In this configuration number 1 to number 4 narrow width web (1, 2, 3, 4) has upper pressing roller (32A, 32B, 32C, 32D) and a lower pressing roller (33A, 33B, 33C, 33D) are closed together (nip) a nip which is then allowed to pass through the same pressed tightly against one web (5) and high than, conductive metal foil to applied. but not density of electrode material. Just, of the present invention each press (31A, 31B, 31C, 31D) configuration of the above described are not limited to, for example, lower roller pressing upper positive relative to roller pressing interval of roller may be the lateral side or the upper side, for gap control roller driving roller and roller to may be roller such as is. On the edge of a garbage chute (30) the number 1 to number 4 press (31A, 31B, 31C, 31D) is height than the height of number 1 to number 4 narrow width web (1, 2, 3, 4) which are used to guide the path of travel plurality of guide roller (guide roller) (36, 37, 38, 39) has a. On the edge of a garbage chute (30) in web narrow width number 1 to number 4 (1, 2, 3, 4) to be opposed mutually to support the one-body type C.P.T. number 1 to number 4 (31A, 31B, 31C, 31D) only when is compacted at said plurality of guide roller (36, 37, 38, 39) is separated a, corresponding press (31A, 31B, 31C, 31D) if the bits pass the a plurality of said guide roller (36, 37, 38, 39) is performed on raised to height of. On the edge of a garbage chute (30) in web narrow width number 1 to number 4 (1, 2, 3, 4) surfaces of a specifically path of, slitting unit (20) from vented number 1 narrow width web (1) one-body type C.P.T. the number 1 (31A) formed by adhering the, web narrow width number 4 to number 2 (2, 3, 4) the upwardly performed on the one-body type C.P.T. number 1 (31A) for guide roller of upper (36) through the X axis positive direction. parallel to the sprung blade. Number 1 press (31A) from vented number 1 narrow width web (1) the upwardly performed on the one-body type C.P.T. number 2 (31B) for guide roller of upper (37) through the X axis positive direction and parallel to the sprung blade, web narrow width number 2 (2) the guide roller (37) in a below, passes through a one-body type C.P.T. number 2 (31B) flows in to, number 3 and number 4 narrow width web (3,4) the guide roller (37) through the X axis positive direction. parallel to the sprung blade. Number 2 press (31B) from vented number 2 narrow width web (2) the upwardly performed on the one-body type C.P.T. number 3 (31C) for guide roller of upper (38) through the X axis positive direction and parallel to the sprung blade, number 3 narrow width web (3) the guide roller (38) in a below, passes through a one-body type C.P.T. number 3 (31C) flows in to, web narrow width number 1 and number 4 (1,4) the guide roller (38) through the X axis positive direction. parallel to the sprung blade. Number 3 press (31C) from vented number 3 narrow width web (3) the upwardly performed on the one-body type C.P.T. number 4 (31D) for guide roller of upper (39) amount of axis X through the recovery device can be parallel to the (50) running on the toward the, number 4 narrow width web (4) the guide roller (39) in a below, passes through a number 4 press (31D) flows in to, number 1 and number 2 narrow width web (1,2) the guide roller (39) amount of axis X through the recovery device can be parallel to the (50) is performed on toward the. Number 4 press (31D) from vented number 3 narrow width web (4) the recovery device can be (50) for upward toward the is performed on. Also 1, also 2, and 4 together a, recovery device can be (50) the number 1 to number 4 rewinding roller (51A, 51B, 51C, 51D) and a, number 1 to number 4 touch roller (touch roller) (56A, 56B, 56C, 56D) has a. Number 1 to number 4 rewinding roller (51A, 51B, 51C, 51D) has a pressing unit (30) made of compression through the number 1 to number 4 narrow width web (1, 2, 3, 4) retrieves the winding again one-by-one. Number 1 to number 4 rewinding roller (51A, 51B, 51C, 51D) that is responsible for the for shrinking a rotary rotated by the power of motor. Number 1 to number 4 touch roller (touch roller) (56A, 56B, 56C, 56D) the number 1 to number 4 rewinding roller (51A, 51B, 51C, 51D) number 4 to number 1 the wound thread from winding up narrow width web (1, 2, 3, 4) for rewinding roller (51A, 51B, 51C, 51D) is pressed toward a rotational center of of number 1 to number 4 narrow width web (1, 2, 3, 4) of winding of the fluid bag for a shower head, web and web sites fibers from gapping or from unsealing a the anti-reaction layer. Specifically, each touch roller (56A, 56B, 56C, 56D) each rewinding roller (51A, 51B, 51C, 51D) lever spaced from a rotation center of the rotational center (54A, 54B, 54C, 54D) rotatable relative to the supported touch roller lever (53A, 53B, 53C, 53D) to an end one side of is supported rotatably. Touch roller lever (53A, 53B, 53C, 53D) equalize the amount of heat emitted to end hydraulic cylinder (hydraulic cylinder) is connected to cylinder or pneumatic (air cylinder), said cylinder by the driving force of touch roller lever (53A, 53B, 53C, 53D) the rotated clockwise or counterclockwise the, the touch roller (56A, 56B, 56C, 56D) the rewinding roller (51A, 51B, 51C, 51D) move near to and away from.. Rewinding roller (51A, 51B, 51C, 51D) a narrow width web (1, 2, 3, 4) being wound up with begins the touch roller lever (53A, 53B, 53C, 53D) are rotated better view with touch roller (56A, 56B, 56C, 56D) is rewinding roller (51A, 51B, 51C, 51D) in addition, the, rewinding roller (51A, 51B, 51C, 51D) a narrow width web (1, 2, 3, 4) are wound around concavo off little by little touch roller lever (53A, 53B, 53C, 53D) rotation in an anticlockwise direction the touch roller (56A, 56B, 56C, 56D) is rewinding roller (51A, 51B, 51C, 51D) which away off little by little from, narrow width web (1, 2, 3, 4) is wound around narrow width web is wound roll (roll) is completed, rewinding roller (51A, 51B, 51C, 51D) in narrow width said, separates out roll of the web can be touch roller lever (53A, 53B, 53C, 53D) and a touch roller (56A, 56B, 56C, 56D) is. is moved up to advantages of the chain double-dashed line. Number 1 to number 4 rewinding roller (51A, 51B, 51C, 51D) within a limited space with a compact (compact) in order to, number 1 and number 3 rewinding roller (51A, 51C) the slitting unit (20) the horizontal distance from each other the same as the, different height is disposed. Furthermore, number 2 and number 4 rewinding roller (51B, 51D) the slitting unit (20) the horizontal distance from each other such as, but number 1 and number 3 rewinding roller (51A, 51C) rather than slitting unit (20) are spaced apart further from, different height is disposed. Recovery device can be (50) in web narrow width number 1 to number 4 (1, 2, 3, 4) surfaces of a specifically path of, web narrow width number 1 (1) the on the edge of a garbage chute (30) is forced from number 3 rewinding roller (51C) for guide roller of front (61) passing downward through a running on the rewinding roller number 1 (51A) for guide roller of front (62) number 1 through the rewinding roller (51A) to be wound onto the spool. Number 2 narrow width web (2) on the edge of a garbage chute the (30) is forced from number 3 rewinding roller (51C) for guide roller of front (61) (+) amount axis X through the direction of and parallel to the sprung blade, number 4 rewinding roller (51D) for guide roller of front (63) number 2 passing downward through a running on the rewinding roller (51B) for guide roller of front (64) number 2 through the rewinding roller (51B) to be wound onto the spool. Number 3 narrow width web (3) the on the edge of a garbage chute (30) is forced from number 3 rewinding roller (51C) for guide roller of front (61) number 3 through the rewinding roller (51C) to be wound onto the spool. Number 4 narrow width web (4) the on the edge of a garbage chute (30) is forced from number 3 rewinding roller (51C) for guide roller of front (61) (+) amount axis X through the direction of and parallel to the sprung blade, number 4 rewinding roller (51D) for guide roller of front (63) number 4 through the rewinding roller (51D) to be wound onto the spool. Web slitting and pressing device (10) the each other such that the wider web (5) a plurality of narrow width web (1, 2, 3, 4) then (slitting) slitting in, plurality of narrow width web (1, 2, 3, 4) a plurality the squeezer (31A, 31B, 31C, 31D) consists of to each pressing (pressing). Therefore, press roller (32A, 32B, 32C, 32D; 33A, 33B, 33C, 33D) narrow width length of web (1, 2, 3, 4) corresponding to length of short because the press roller (32A, 32B, 32C, 32D; 33A, 33B, 33C, 33D) due to sag longitudinal direction of the narrow width, which web (1, 2, 3, 4) in the widthwise direction of pressing and a controlling unit, the resulting defective product is suppressed and the, . yield and increase a conforming product. Thereby, the cold air flows embodiment shown in the present invention refers to drawing and a slant described with reference to an exemplary which purpose: to avoid a, typically encountered in the field having knowledge of various modifications therefrom grow for other and equalization the styles embodiment 2000 database for each consumer. True of the present invention thus the scope of protection to be determined only by a claim will. 1, 2, 3, 4: narrow width web 10: web slitting and pressing device 12: supply unit 14 : the winding which freezes roller 20: slitting unit 30:on the edge of a garbage chute 31A, 31B, 31C, 31D: press 50: recovery device can be 51A, 51B, 51C, 51D: rewinding roller 56A, 56B, 56C, 56D: touch roller Disclosed is an apparatus for slitting and pressing a web, which slits a wide web into a plurality of narrow webs and presses each of the webs obtained through the slitting. The disclosed apparatus for slitting and pressing a web comprises: a feed unit which includes an unwinding roller adapted to unwind and feed a wound web; a slitting unit which slits the web, fed by the feed unit, into a plurality of narrows webs; a pressing unit which includes the number of presses adapted to press the narrow webs, respectively, and to be equal to the number of the narrow webs; and a withdrawal unit which includes the number of rewinding rollers adapted to withdraw the pressed narrow webs through winding and to be equal to the number of the narrow webs. COPYRIGHT KIPO 2016 Wound web (web) for relieving machine is provided to supply the the winding which freezes roller (unwinding roller) with supply unit; said supply unit second power supply modules are web by cutting a plurality of narrow width (slitting unit) unit slitting partitioning the video stream into a main web; said plurality of narrow width after pressurization of the each web, said narrow width web and the number of body sealing the squeezer having ( [...] ) on the edge of a garbage chute (pressing unit); and, said plurality of crush ( [...] ) the narrow width, which is web each of recovering winding again, web and the number of body sealing said narrow width ( [...] ) of rewinding roller (rewinding roller) recovery device can be with; with a second gate insulation layer characterized by web slitting and pressing device. According to Claim 1, said slitting unit, said supply unit fed web in the widthwise direction of piece are elongated, said web of both the gas circulation grooves is aligned to pass through the roller between the upper and the lower slitting roller; said upper slitting roller radially projecting (radial direction) of the upper blade (upper blade); and, said lower slitting roller of the upper blade to engage said radially projecting blade is installed at a predetermined; characterized by the prior art including deterioration of film web slitting and pressing device. According to Claim 2, to be engaged with each other said a plurality pair of the upper blade and lower blade is, of the upper blade and lower blade plurality of pairs of said upper and lower slitting roller in the longitudinal direction of said are arranged in spaced apart relation to a characterized by web slitting and pressing device. According to Claim 1, each said warpage, said narrow width of the web piece are elongated width direction, said web between rollers of both the gas circulation grooves is aligned to pass through the having the upper and the lower pressing roller, said roller pressing lower said upper pressing roller and the other roller pressing one of approaches the roller pressing capable of adjusting an a, roller pressing lower said roller and said upper pressing roller pressing one of the rotor by the power of a motor, of the other of said said pressing roller is capable of being rotated by the of following a pressing roller ( [...] ) characterized by rotation of the web slitting and pressing device. According to Claim 4, the length of the roller pressing upper and lower said narrow width web one width than the length of the elongated, , said narrow width web two width length rather than shortened, said plurality of warpage is the horizontal distance from respective wireless slitting said differently arranged characterized by web slitting and pressing device. According to Claim 5, all on the edge of a garbage chute said solenoid is height than the height said plurality of narrow width web which are used to guide the path of travel (guide roller) having plurality of guide roller, said pressing unit within a plurality of said narrow width web each only when said press is compacted at said plurality of guide roller is separated, if the bits pass the squeezer said height of said plurality of guide roller characterized by advancing raised to web slitting and pressing device. According to Claim 1, the recovery device can be said, narrow width the wound thread from winding up roller rewinding each said web rewinding roller is pressed toward a rotational center of said narrow width a an underground rock winding of the web, web and the number of body sealing said narrow width ( [...] ) touch roller (touch roller); to having a web characterized by slitting and pressing device. According to Claim 1, said plurality of narrow width web and web narrow width number 4 to number 1, number 1 for recovering web narrow width said number 1 rewinding roller and, number 3 for recovering web narrow width said number 3 rewinding roller, said slitting from each other the same as the horizontal distance, different height high temperature and under high pressure, said number 2 for recovering web narrow width rewinding roller and number 2, number 4 for recovering web narrow width said number 4 rewinding roller, the horizontal distance from respective wireless slitting said rewinding roller and said number 1 such as, but each other rather than roller rewinding said number 3 are spaced apart further from said slitting unit, to make the size small by aligning differently height characterized by web slitting and pressing device. According to Claim 1, said web, metal foil, for surface treating substrate one side or at both sides said applied to the electrode is arranged on the control electrode (electrode web) provided that the web characterized by web slitting and pressing device.