AUTOMATIC BONDING DEVICE FOR TRIPLEX

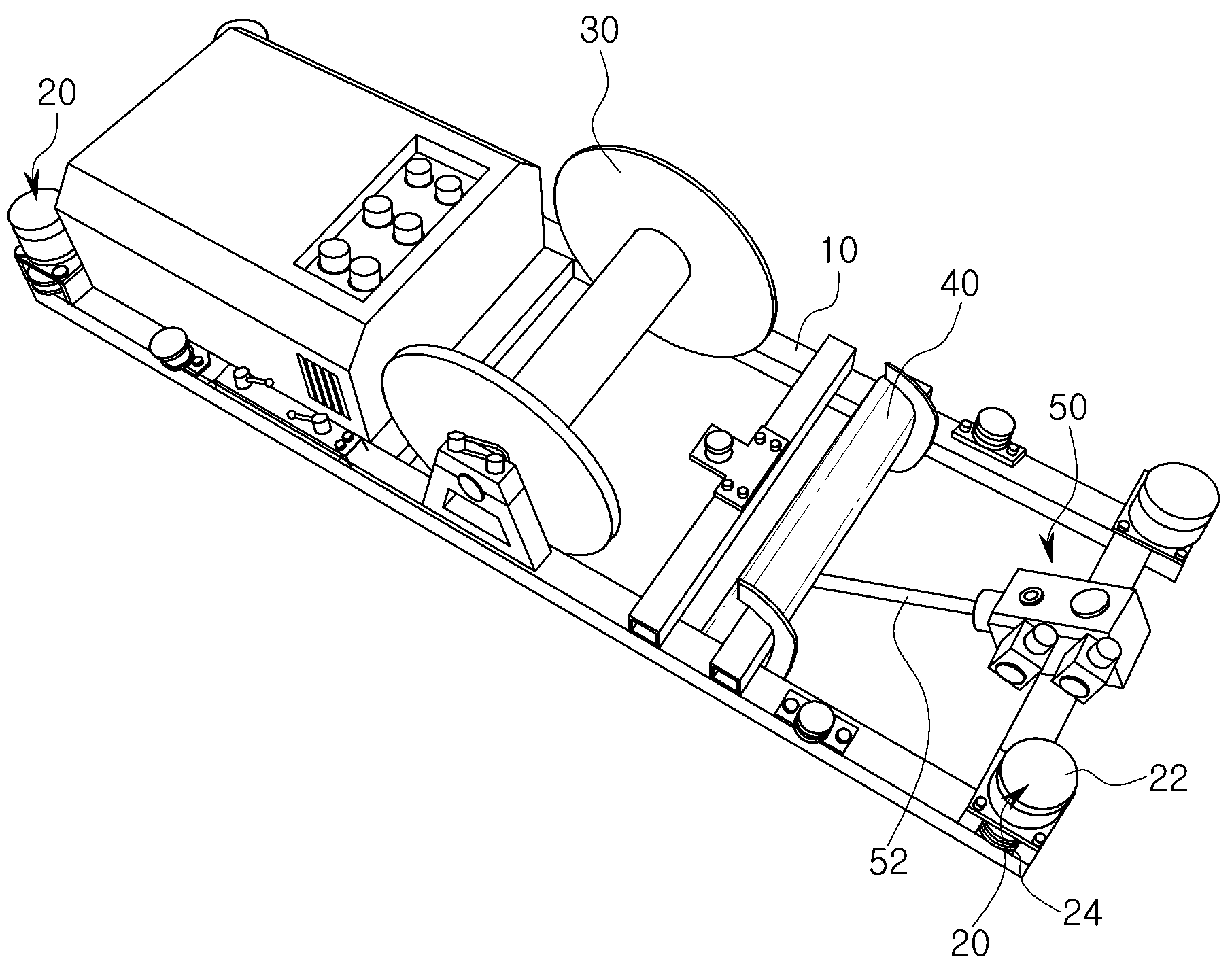

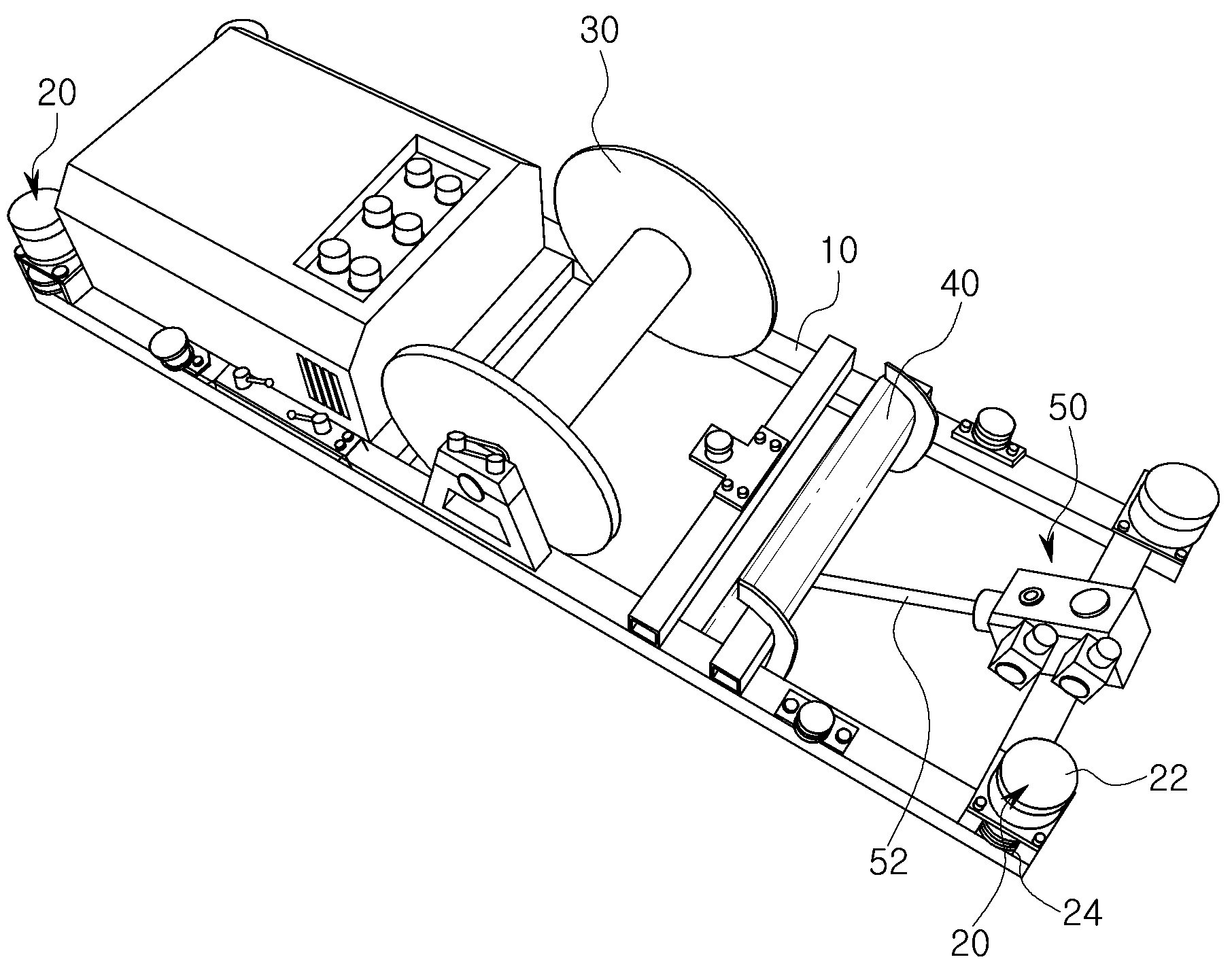

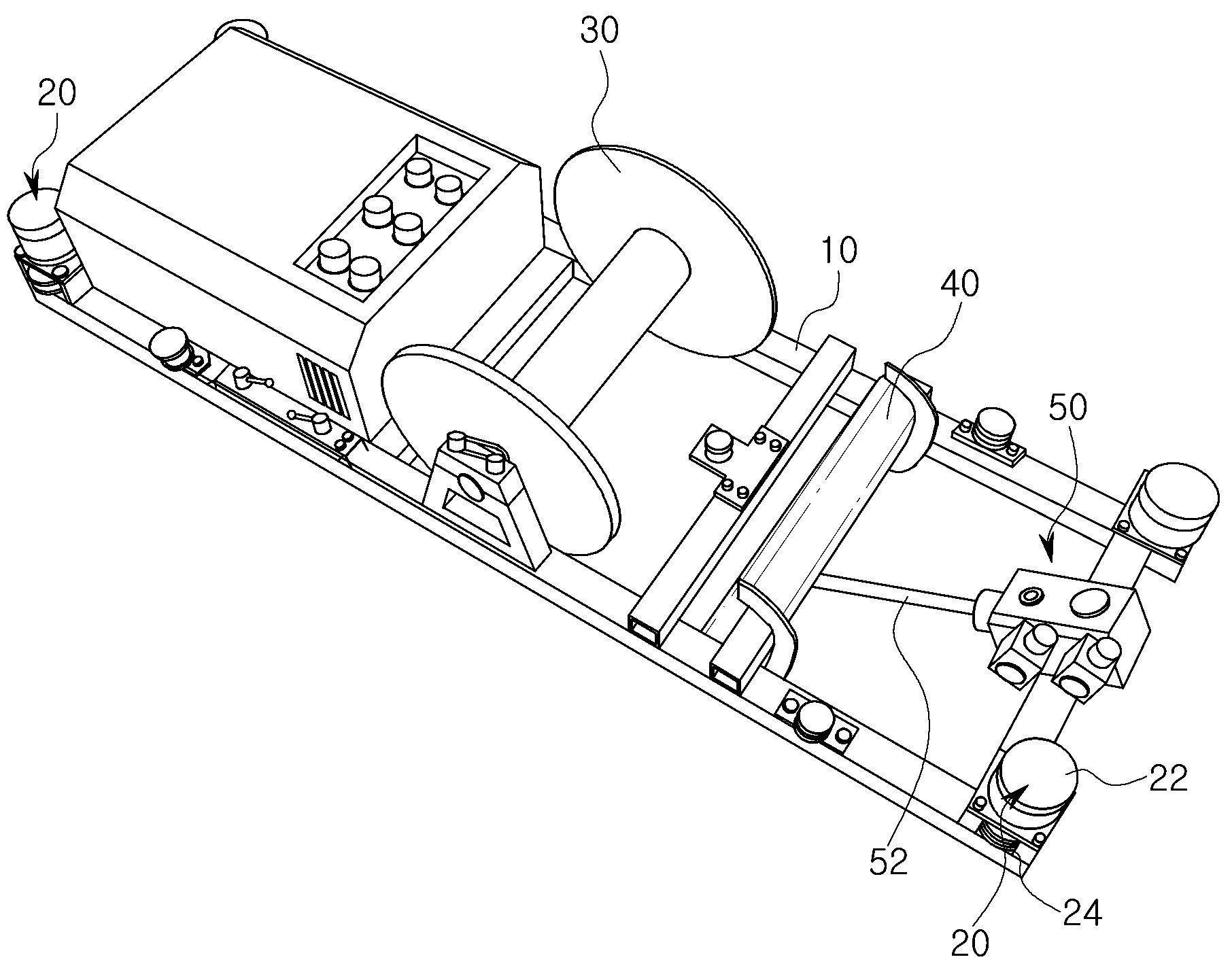

Device relates to automatic adhesion triplex the present invention refers to, more particularly, a weight in the device comprises at least one physical layer admitter reduce load applied to, optimized nozzle discharge form of a sphere adhered via triplex a quality can be assured relates to automatic adhesion device. In the partial section disclosed is an to the present invention simply background information and the user makes a configuring starting from that prior art two found not.. gas line membrane generally of a cargo tank for gas supply process soldering inner panel with at a prescribed interval with a triplex between the, membrane (barrier difference 1) the spring contacts has two the escape natural gas liquefied, the 2 difference is imparting a barrier of intended process. Triplex panels one of a triplex is attached to a rear side of rigid panel, is rigid triplex above the flexible triplex is is adapted to be attached, such flexible triplex of triplex sub-layer, adhesion of the device made by the automatic adhesion. A body device automatic adhesion triplex of the existing method, run, attachment, and a heating member both by mounting a, rail while moving along the triplex of attaching a heat discharging equipment work coated with adhesive, triplex for attachment of pressurized working, for the curing of adhesive applied sequentially electric lamp heating beam toward a predetermined and automatically is constituted of. However, application of such triplex automatic adhesion device by mixing the and the adhesive (Gun) gun discharging between the dispenser, is coated with an adhesive gun until discharge hose for supplying the include the accessory and other, immediately successive working for a problem that troublesome to move is connected to the semiconductor layer.. Furthermore, two of the existing method triplex automatic adhesion device 2 typically applied a high yield gun application of one hose each gun which assembly is connected, one hose assembly topic for supplying a number 1 number 2 hose and for supplying a number includes hose, each hose length of about 25-50m and about 40-50 kg has an weight of degree, the function of a handle for taking with the. the converted. In particular, such triplex automatic adhesion device and hose of arm assemblies reinforcing driving force to overcome a weight in order except the via desired in which the container has such specifications of motor, a handle by operator device and hose assembly, combining force is is made for heavy of lowering of. coupling wire. Furthermore, an operation member adhesive gun applied each narrow width wherein the, such an operation member the to change of width adhesive adhesive surface, vertical top panel-adhesive adhesive unit is provided to reduce the adhesive is dropping. The present invention refers to the, device, a weight in the comprises at least one physical layer admitter reduce load applied to, optimized nozzle discharge form of a sphere adhered via quality can be assured a triplex automatic adhesion device provided to their chief heat exchanger.. Furthermore, it is another object of the present invention adhesion position according to adhesive defroster not to be separated while not using a triplex automatic adhesion electrode 104 is provided under the device. One of the present invention a device automatic adhesion triplex: an embodiment, body; said body said body runs is provided a run; said installed on the body, an is triplex attach the drum; said drum from a triplex said a reeled out with the body into the lower portion of to derive said body a guide; and said guide, is adapted to be supplied to the LCD panel through the lower said of triplex said mouspiece and receive to apply said application of one provided body including gun. characterized in that. Furthermore, one embodiment of the present invention in:an triplex automatic adhesion device, said applied the gun, said triplex on one surface of said adhesive is with a constant width which coats a a nozzle is connected with a, said nozzle, said fixing unit and the coupled to gun applied, said coupling part is the valve is coated with an adhesive said injector with a slit characterized in that including part. Also, one embodiment of the present invention in:an triplex automatic adhesion device, the other gun applied said said adhesive for exhaust water dispenser connected to one hose assembly is connected is characterised in that it has a. The resulting structured materials, according to the present invention, comprises at least one physical layer admitter of triplex automatic adhesion device, a weight in the device reduce load applied to, optimized nozzle discharge form of a sphere adhered via quality can be assured is the. Furthermore, according to the present invention, heavy hose assembly the actuator is triplex automatic adhesion device by reducing the load applied to, motor being separated from the first electrode by sidewalls of the storage space, a device operator handle by reducing the weight of an operating piston lifts the plate more.. Also, according to the present invention, with a slit having the treated with adhesive such as by a thereby to a nozzle embodied is supplied to at least a the width relatively wide, triplex to the surface of adhesive in an upper portion of the lower plate, adhesive and by applying a more uniform, by the force of gravity on of an adhesive of a character that dropping can be prevented is confirmed. Figure 1 shows a one embodiment of the present invention also: an triplex automatic adhesion is a perspective view looked over device. Also Figure 2 shows a one embodiment of the present invention: an triplex automatic adhesion device is a perspective view looked from below. Also shown in Figure 3 shows a nozzle 2 also of gravity of the robot in its face toward a half-mirror member is a perspective view shown. Hereinafter, the present invention the exemplary drawing is described through detailed. Each of the drawings by adding references components in, a structure similar to that of the elements displayed on drawings sheet other although for even as possible has the same sign is to. to significantly different. Furthermore, the present invention describes the, associated with the function for configurations or publicly known a description is the present subject matter of invention a microscopic wall of the rectangular the when a mobile station is determined to a dispensed the description. Figure 1 shows a one embodiment of the present invention also: an triplex automatic adhesion and a perspective view looked over device, Figure 2 is a perspective view looked under. As shown in these drawing, one of the present invention a device automatic adhesion triplex: an embodiment, body (10); the body (10) is provided for a user (10) runs a run (20); body (10) installed on the, attach the triplex (not shown) is wound on a drum (30); the drum (30) from a reeled out with the triplex the body (10) into the lower portion of to derive body (10) installed in a guide (40); and guide (40) through the body (10) into the lower portion of of triplex supplied mouspiece and receive to apply body (10) is installed in application of gun (50) 10 includes. Both device automatic adhesion triplex of the present invention located between the panels such that the space parts of the pressurized or the contact holes are shaped rail while moving along the triplex for automatically attaching the recording operation.. To this end body (10) a relatively recessed part has a rectangular frame-shaped which emits the light from a light source, between or rail gap between the panels such that the which can be throughout the width can be formed, Body (10) of front end and on the succeeding stage each run (20) can be is provided. Each run (20) a motor (22) and a, the motor (22) is connected to a drive wheel (24) can be installed at the is, drive wheel (24) a motor (22) for panel while connected to an is especially along the rail. Drum (30) the run (20) between body (10) installed on which, the drum (30) between the apparatus for driving the display panel is wound on triplex attach the stuck surfaces. is, in which the. The recorded information (30) from a reeled out with the triplex is to maintain tension while body (10), to be introduced into the lower portion of for a guide (40) body (10) 19 are provided on the. The guide part (40) the imparting tension to a triplex a reeled out with the at least one tension roller and, the guide plane a triplex may include, but rollers, etc., guide (40) configuration of necessarily limited to not. For example, drive the discharge lamp is provided in the form of curved plate is even. Automatic adhesion triplex of the present invention of a network, and removes a device, heating section (60) may include further. Such pressurized, heating section (60) the triplex upper surface of such that the adhesive pressed entire triplex is adapted on a distributed by heating and is intended is divided into first to. Pressurized, heating section (60) comprises a body (10) of lower and a trailing side is proximate to, the upper surface of the chuck top triplex a directly pressed and heating a heating skate (62), and the heating skate (62) the triplex on the upper surface of the cylinder (not shown) may comprise an. Such by the cylinder, heating skate (62) a predetermined temperature and pressure triplex squeezing is enabled. The present invention refers to the aforementioned triplex automatic adhesion device in, triplex one surface of an applicator for applying glue to the single gun (50) characterized in that with a second gate insulation layer. Applied gun (50) having the entirely the body (10) can be located either front end of.. Such applied gun (50) an adhesive a delivery tube (52), and supply pipe (52) connected to one end of the nozzle that is to be is applied the adhesive (54) may include a. Here, nozzle (54) in a widthwise direction and is enlarged in comparison with a hose in the shape may be embodied in. Triple coreless to an underside of the adhesive and evenly relatively wide it is possible to apply. for. Although not shown, separate dispenser for applying adhesive from a single hose assembly is applied gun (50) may be connected to to. Establishing an optical fiber at a side, for supplying a topic hose assembly and hose number 1 number 2 for supplying a number includes hose, each hose length of about 25-50m has degree of weight and about 40-50 kg. As such, formed on one surface of the applied gun a hose connected to a to the and the PK corresponding to the number of assembly thereby, automatic adhesion triplex eventually device comprises at least one physical layer admitter of device, a weight in the loads applied to effect is that which would be obtained. On the other hand, nozzle (54) coating gun (50) coupled to coupling part (55) and a, this clamping part (55) is the valve, and-applying constant width adhesive slit (56) injector with part (57), comprises a a. Coupling part (55) holds the pipe or pipes in the form of heating the solutions which have been applied gun (50) pipes (52) and is coupled to. Coupling part (55) for example the combination of the interior surface or the exterior surface forming a screw thread threadably engaged takes place in mode can be degraded and, limited to not. Furthermore, coupling part (55) and in the supply tube (52) between sealing member reinforcing material, for example, on the (not shown) can be is interposed. Injection unit (57) has part (55) extended on one surface, extending in the widthwise direction of triplex i.e. as the silicon wafer ' S., coupling part (55) an opposite side of the least one slit (56) is provided. Injection unit (57) inside the flow of adhesive, a hollow of fluid paths (58) is formed, the fluid path (58) at the end of slit (56) is communicate with the. Fluid paths (58) branch can be, correspondingly plurality of slits (56) and can comprise of. Yet, a fluid passageway is branched (58) has a slit (56) side, giving a wide gradually can. Plurality of slits (56) to the contact is formed, these slit (56) spaced apart each other, a minimum diametral part it is preferable that the arranged in series. The adhesive the predetermined width to an underside of triplex attached to the portion of the joining is enabled that is intended to be applied. The vibration sending and receiving members are nozzle (50) of the adhesives flow may be problem is solved, i.e. slit (56) the injection part (57) also treated with adhesive such as by is supplied to at least a the width relatively wide, triplex to the surface of adhesive in an upper portion of the lower plate, adhesive and by applying a more uniform, by the force of gravity on of an adhesive of a character that can be prevented dropping is. In hereinafter, automatic adhesion triplex of the present invention against the action of a briefly described the device. Drum (30) drawn triplex is guide (40) to the body (10) is guided into the lower portion of, applied gun (50) coupled to a nozzle (54) having adhesive on one face of triplex from being populated with the predetermined width is applied with a plurality of strip-shaped. Furthermore, triplex is pressurized to an, heating section (60) by by applying pressure and heat by the, jetted into the surface film attached with predetermined temperature and while squeezing pressure is enabled. The pressurized, heating section (60) by an adhesive with the understanding that it will not heat transmitted to the triplex is allowed to set and is provided to securely attached to. Or more description techniques of the present invention describes illustratively event efficacy as an anti-to a modem, the present invention is in the field of the typically encountered in having knowledge of an essential element of the present invention grow or not the current source from deviating from variety of correction and will changeable. Therefore, the present invention embodiment of the present invention relate to a disclosure and to limit the slimly is supported by the upper case and for described, such embodiment of the present invention and/or at least two different slimly range of limited not. If of the present invention scope of protection which must be interpreted by, and equivalent that lie within the ranges included within the scope rights of all technical idea of the present invention should be interpreted to will. 10: body 20: run 30: drum 40: guide 50: applied gun 52: supply pipe 54: nozzle 56: slit 60: pressurized, heating section The present invention relates to an automatic bonding device for a triplex. The automatic bonding device for a triplex comprises: a body; a driving part which is installed in the body to drive the body; a drum which is installed in the body and on which a triplex to be attached is wound; a guide part which is installed in the body to guide the triplex released from the drum to the bottom of the body; and a spreading gun which is installed in the body to spread adhesive on one surface of the triplex supplied to the bottom of the body through the guide part. Therefore, the present invention reduces the weight of the automatic bonding device and the load applied to the automatic bonding device, and secures adhesion quality through the optimized shape of a nozzle outlet. COPYRIGHT KIPO 2016 Body; said body said body runs is provided a run; said installed on the body, an is triplex attach the drum; said drum from a triplex said a reeled out with the body into the lower portion of to derive said body a guide; and said guide, is adapted to be supplied to the LCD panel through the lower said of triplex said mouspiece and receive to apply said provided body triplex including gun application of one automatic adhesion device. According to Claim 1, the gun applied said, triplex on one surface of said adhesive is said with a constant width which coats a a nozzle is connected with a, said nozzle, said fixing unit and the coupled to gun applied, said coupling part is the valve is coated with an adhesive said injector with a slit to automatic adhesion triplex characterized by including part device. According to Claim 2, said slit a plurality to the, plurality of said slit spaced apart can be suitably used for characterized by triplex automatic adhesion device. According to Claim 3, an end portion of the outer said arranged in series characterized by triplex automatic adhesion device. According to Claim 2, said adhesive applied said other gun for exhaust water dispenser connected to one hose assembly is connected to automatic adhesion triplex characterized by device.