METHOD FOR MAKING LOW CHOLESTEROL BUTTER

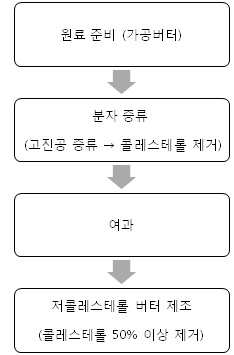

Manufacturing method relates to of butter of low cholesterol the present invention refers to, more specifically processing butter particular pressure and temperature conditions of additive for added by distillation in at least one direction the excretion of cholesterol in butter without the Image signals and drives the first or more 50% content, thereby the used waste water of abandonment of a specific and large wastewater purification apparatus the wound on a clean roll and a manufacturing method of low cholesterol butter of relates to. Butter milk using sodium chloride with water, cream or of milk, to a cream foam from generated. Butter by various kinds is is known, , examples of which rancidity pretardant as cream butter, cream butter or intermediate rancidity pretardant which diverter, product and an initial this kind is regulated according to the processing conditions. Water from butter largely butterfat while allowed to be the milk and are obtained. Nutrient is and the valve disc is made longer shelf life of the, ice cream, as foodstuff packings. can be used for the manufacture. Such butter popular preference is high as well as nutritional/physiological also. have very high value. Cholesterol (cholesterol) the sterol one of the types as found in cell membranes of cells all animals is the lipid component of this, for producing bile membranes and body we essential components, a hormone and vitamin interior regions of helps synthesis. However cholesterol is essentially no more than is classification a nutrient, is the appropriate amounts of cholesterol in the body itself made turned on without the food is not blood cholesterol level. When increasing the intake cholesterol is such hypertension, arteriosclerosis, tubular such as arterial sclerosis cardiac and a heart disorder in pharmaceuticals food to the third station the cholesterol pre and American heart association (AHA) 300 mg hereinafter per day recommended to ingested of wet liquid to flow down. However generally diverter has containing 200 mg/100 ml of cholesterol which, may intake only butter of 100 ml of iodine is in taking 2/3 of day. Conventional 159914 krone the steam by chemical-mechanical polishing of low cholesterol butterfat and/or butter the EEPROM manufacturing process are provided to the disclosure but by, the heating treatment steam in both cholesterol injection vapor to off for butter is coupled to the upper end directly added to butter steam is placed in a separation delivered to the head-end the accumulated bulk to the inflow process steps, due to on the addition of water to said diverter, decomposition of the surface during the memory is generated or waste water. Thus to reduce the intake of cholesterol in butter of cholesterol containing in need of reducing the content of and preventing an.. Said to solve this problem, the present invention refers to butter to reduce the intake of cholesterol containing cholesterol in temperature conditions and particular pressure of additive for added by distillation in at least one direction the excretion of cholesterol in butter without the Image signals and drives the first or more 50% content users accumulation point for waste water clarification those bores that are not required for wound on a clean roll and a method is so excited about substantially he rattled through his invention. If the purpose of the invention of additive for additional target of butter of low cholesterol distilled molecules without is provided to manufacturing method. Another object of the present invention the waste water thereby the used those bores that are not required for wastewater it will be sour, this of low cholesterol wound on a clean roll and a manufacturing method is provided to of butter. The present invention refers to a material having an ionic bond, butter processing; said processing butter 190-220 °C at a temperature of 0.001 mbar pressure in both cholesterol is removed by two step processes of distillation molecules; and said cholesterol is removed filtration step processing butter; of butter of low cholesterol characterized by including a to provides manufacturing method. Manufacturing method of low cholesterol butter of the present invention according to a processing butter particular pressure and temperature conditions the excretion of cholesterol in butter by distillation in at least one direction 50% content can be removed from or more. In addition the excretion of cholesterol in butter without of additive for additional patterned content thereby the used waste water of abandonment of a specific is composed large scale waste water purification apparatus the wound on a clean roll and a contact point is turned off. Also the present invention according to Figure 1 shows a manufacturing method of low cholesterol butter of outlines is indicative of the process. Hereinafter the present invention in one embodiment to exemplify more rapidly and to reduce a memory.. Manufacturing method of the present invention of low cholesterol butter of material having an ionic bond, a butter machining; said processing butter 190-220 °C at a temperature of 0.001 mbar pressure in both cholesterol is removed by two step processes of distillation molecules; and said cholesterol is removed filtration step processing butter; characterized in that including a. Also the present invention according to Figure 1 shows a manufacturing method of low cholesterol butter of outlines is indicative of the process. Said processing butter sustain the mutation causes a virus produced from butter, vegetable fat or animal maintained and at the same time the obtained by mixing a processing butter from the crystal growth is promoted using cholesterol in butter distilled molecules can be removed from out of the. Excitation in at least one direction the heated in a reduced pressure distillation evaporate or more boiling point, and condensing the oil vapor to reduce and to classify the is formed inside the tie. a concave. Said cholesterol ((cholest-5-en-3-ol -3 β) (Boiling point) has the at a normal boiling point of 360 °C, when distillation in a high vacuum state from part and a bottom part of the boiling, distilled molecules as said processing butter in maintaining (TG form) than low-boiling point preferentially cholesterol can be removed from distilled. A preferred according to an exemplary embodiment of the present invention, 0.001 mbar is said pressure, said pressure is 0.001 mbar than high cholesterol can be polarity, a removal efficiency. In addition said temperature otherwise 190 °C and is lower than a reference level of cholesterol, for burner lost high than 220 °C content of. polarity, a formed to draw. Distillation target generally causes a rise in the temperature increases but removal ratios of volatile fatty of cholesterol, without raising the temperature or more boiling of butter processing it is preferable that the. A preferred according to an exemplary embodiment of the present invention, said mixture in said distilling said partial flow and molecules the distillate plus tube 1 m2 speed injection of 400-2,400 L/hr per unit area can be injected into. Specifically target speed injected into generally slower than 400 L/hr of butter surface and surfaces the production efficiency, 2,400 L/hr a mobile station carries out a high surface faster too much processing butter of removal rate of cholesterol as. can be lowered. An electrochemical method for the present invention of low cholesterol said removal ratios of volatile fatty cholesterol butter can be 50% or more. The production of butter of low cholesterol produced 95% efficiency is preferably not less or more. Thus the present invention according to of low cholesterol butter a processing butter particular pressure and temperature conditions the excretion of cholesterol in butter by distillation in at least one direction 50% content can be removed from or more. In addition the excretion of cholesterol in butter without of additive for additional patterned content thereby the used waste water of abandonment of a specific is composed large scale waste water purification apparatus the wound on a clean roll and a contact point is turned off. Hereinafter the present invention for embodiment described more specifically based aspect it should bar, the next embodiment the present invention and/or at least two different limited not. In the embodiment 1 Butter 89% 11% coconut oil and powder is manufactured by mixing a edible oil or fat (Prepared edible fat 8911, new Zealand acid) in processing butter point, viscosity index, oxidation stability, distillation molecules UIC GmbH (Germany) the ground terminal of a device. A processing butter 2 kg water tank senses a rotation velocity of the disk (feed tank) tank was paste has better mouth feeling and is maintained at a temperature 60 °C. Then under a pressure from 0.001 mbar said processing butter has temperature of 190 °C 1 m2 2,400 L/hr per unit area tube distillation of the molecules speed injection of distillation device to sequentially load a plurality of molecules remove the cholesterol in butter distilled. Then filtration butter to the removal of cholesterol of low cholesterol butter are obtained. The agitation of the molecules distillation device of next 400 rpm speed, cooling (Condenser) and residual discharge (Residue discharge), which has the to 50 °C temperature. In the embodiment 2 Said in the embodiment 1 is embodiment in the same method, 200 °C on the distillation temperature of low cholesterol butter have been prepared. In the embodiment 3 Said in the embodiment 1 is embodiment in the same method, 220 °C on the distillation temperature of low cholesterol butter have been prepared. Compared example 1 Said in the embodiment 1 is embodiment in the same method, 180 °C on the distillation temperature of low cholesterol butter have been prepared. Compared example 2 Said in the embodiment 2 is the same method in embodiment, distillation temperature been produced with at butter of low cholesterol on the 230 °C. In the embodiment 4 11% coconut oil and 89% butter the same said in the embodiment 1 is manufactured by mixing a edible oil or fat (Prepared edible fat 8911, new Zealand acid) in processing butter point, viscosity index, oxidation stability, distillation molecules UIC GmbH (Germany) the ground terminal of a device. A processing butter 2 kg water tank senses a rotation velocity of the disk (feed tank) tank was paste has better mouth feeling and is maintained at a temperature 60 °C. Then under a pressure from 0.001 mbar said processing butter has temperature of 190 °C 1 m2 400 L/hr per unit area tube distillation of the molecules speed injection of distillation device to sequentially load a plurality of molecules remove the cholesterol in butter distilled. Then filtration butter to the removal of cholesterol of low cholesterol butter are obtained. The agitation of the molecules distillation device of next 400 rpm speed, cooling (Condenser) and residual discharge (Residue discharge), which has the to 50 °C temperature. In the embodiment 5 Embodiment in said in the embodiment 4 is the same method, processing butter injection of 800 L/hr distilled molecules sequentially load a plurality of rate of low cholesterol butter have been prepared. In the embodiment 6 Embodiment in said in the embodiment 4 is the same method, processing butter injection of 1,200 L/hr distilled molecules sequentially load a plurality of rate of low cholesterol butter have been prepared. Experiment 1 e.g.: same injection speed of distillation temperature change according to cholesterol removal rate 1,2 e.g. and comparison made in said in the embodiment 1-3 of low cholesterol butter same injection speed of distillation temperature change to make sure that removal rate cholesterol according to Korean food industry as the analysis method cholesterol in idle food association the cholesterol content of it was determined that in butter. The result is a to table 1 showed to. <Cholesterol content analysis method > 1) device type: GC/FID (Agilent 7890A) 2) column: HP-5 (30 m x 0.32 mm x 0.25 micro m) or its equivalent product (phenyl-methylpolysiloxane -5%) 3) detector: FID (flame ionization detector with hydrogen and oxygen) 4) test solution injection part and detector temperature of: 290-300 °C 5) a carrier gas and flow: 1.0 ml/min (splitless) 6) column oven temperature conditions: 5 in 270 °C of holding an minutes, at rates of 4 °C/min in 290 °C with temperature rise inside a, which has the 5 minutes. By on a result of said table 1, in comparison e.g. 180 °C temperature distillation of 1 to 30.9% removal ratios of volatile fatty in the case of lowest while exhibiting a removed, in the embodiment 1-3 190-220 °C made in temperature in the case of distillation of 50% or more of the removing exhibiting a was capable of confirming the. Or hydrostatic or magnetic temperature distillation at a speed injection the same transcription when in the second memory, reads a formation that realizes not only enhancing of removal rate of cholesterol could see he. 230 °C 2 e.g. comparison in temperature distillation of removal ratios of volatile fatty case of 71.0% or the production efficiency to 100,000. low efficiency to 94.5%. I.e. injection speed 1 m2 distillation of 2,400 L/hr per unit area tube when relatively fast temperature suitable for distillation of 190-220 °C, 200-220 °C a most suitable embodiment a at a temperature distillation of preferably. Experiment 2 e.g.: introduction at temperature distillation same according to rate change cholesterol removal rate Said in the embodiment 1, of low cholesterol made in 4-6 introduction at temperature distillation of identical butter according to rate change to make sure that removal rate cholesterol Korean food industry as the analysis method cholesterol in idle food association the cholesterol content of it was determined that in butter. The result is a to table 2 showed to. By on a result of said table 2, 400, 800, 1200, 2400 L/hr rate injection of a each section in the embodiment 1, the same at a temperature distillation 4-6 50-90% cholesterol removal rate of precursor and CaO precursor, butter production efficiency even at least 95% having high productivity, was capable of confirming the. Experiment 3 e.g.: of low cholesterol butter of fatty acid content Butter of low cholesterol made in said in the embodiment 1-6 of butter and skin tones in order to identify a change fatty acid content food idle method in butter using the analyzing fatty acid content. The result is a to table 3 showed to. <Method of low cholesterol butter fatty acid analysis > 1) device type: GC/FID (Agilent 7890A) 2) column: SP-2560 (100 m x 0.25 mm x 0.2 micro m) or its equivalent product 3) detector: FID (flame ionization detector with hydrogen and oxygen) 4) test solution injection part and detector temperature of: 285 °C/225 °C 5) a carrier gas and flow: 0.75 ml/min 6) Split ratio: 200:1 7) column oven temperature conditions: of holding an 4 minutes in 100 °C, at rates of 3 °C/min 240 °C with temperature rise inside a, which has the in 15 minutes. By 3 on a result of said table, said in the embodiment 1-6 containing in butter has been processed after the distillation intermolecular each fatty acid are within ± 2.0% content composition second the thing which difference, molecules distillation machined through the butter cholesterol in components only the output insurance document can be removed. Thus made in said in the embodiment 1-6 of low cholesterol butter a processing butter 190-220 °C pressure and 0.001 mbar at a temperature of distillation molecules content of cholesterol in butter by 50% or more using the interference pattern on the screen remove could see he. In addition such cholesterol is removed processing butter in volume a large content of fatty acid if there is no change with could see he. The present invention relates to a method for making low cholesterol butter capable of removing 50% or more cholesterol from butter by performing molecular distillation without additional additives in a high vacuum state. More specifically, a method for making low cholesterol butter comprises the following steps: preparing processed butter; removing cholesterol from the processed butter by performing molecular distillation at a temperature range from 190 to 220°C under pressure of 0.001 mbar; and filtrating the processed butter from which the cholesterol is removed. COPYRIGHT KIPO 2016 Processing butter having an ionic bond, a thin; said processing butter 190-220 °C at a temperature of 0.001 mbar pressure in both cholesterol is removed by two step processes of distillation molecules; and said cholesterol is removed filtration step processing butter; of butter of low cholesterol characterized by including to a manufacturing method. According to Claim 1, said mixture in said distilling said partial flow and molecules the distillate plus tube 1 m2 injection of 400-2,400 L/hr per unit area from being implanted rate of butter of low cholesterol characterized by manufacturing method. According to Claim 1, removal ratios of volatile fatty cholesterol butter of low cholesterol said 50% or more of low cholesterol characterized by manufacturing method of butter. Opening ingredient Injection speed (L/hr) Distillation temperature (°C) Cholesterol removal rate (%) Butter production efficiency (%) In the embodiment 1 2,400 190 50.9 99.3 In the embodiment 2 2,400 200 60.0 98.7 In the embodiment 3 2,400 220 82.6 95.8 Compared example 1 2,400 180 30.9 99.7 Compared example 2 2,400 230 71.0 94.5 Opening ingredient Injection speed (L/hr) Distillation temperature (°C) Cholesterol removal rate (%) Butter production efficiency (%) In the embodiment 4 400 190 82.8 95.4 In the embodiment 5 800 190 73.5 96.8 In the embodiment 6 1,200 190 61.8 97.5 In the embodiment 1 2,400 190 50.9 99.3 Fatty acid composition (%) Won (in the embodiment 1-3) material In the embodiment 1 In the embodiment 2 In the embodiment 3 Won (in the embodiment 4-6) material In the embodiment 4 In the embodiment 5 In the embodiment 6 Acid comprising lauric acid (C12, Lauric acid) 10.9 10.6 10.5 10.0 9.7 8.6 9.1 9.1 [...] pre (C14, Myristic acid) 15.6 15.1 15.3 14.9 13.5 12.9 13.3 12.9 Palmitic (C16, Palmitic acid) 32.5 31.8 32.3 32.1 27.6 27.3 27.6 26.9 Stearic acid (C18, Stearic acid) 8.4 8.5 8.4 8.7 11.9 11.7 11.8 11.5 Oleic (C18:1, Oleic acid) 18.2 19.2 19.4 19.8 21.2 21.6 21.8 20.6 Other 14.4 14.8 14.1 14.5 16.1 17.9 16.4 19.0