LENS MODULE

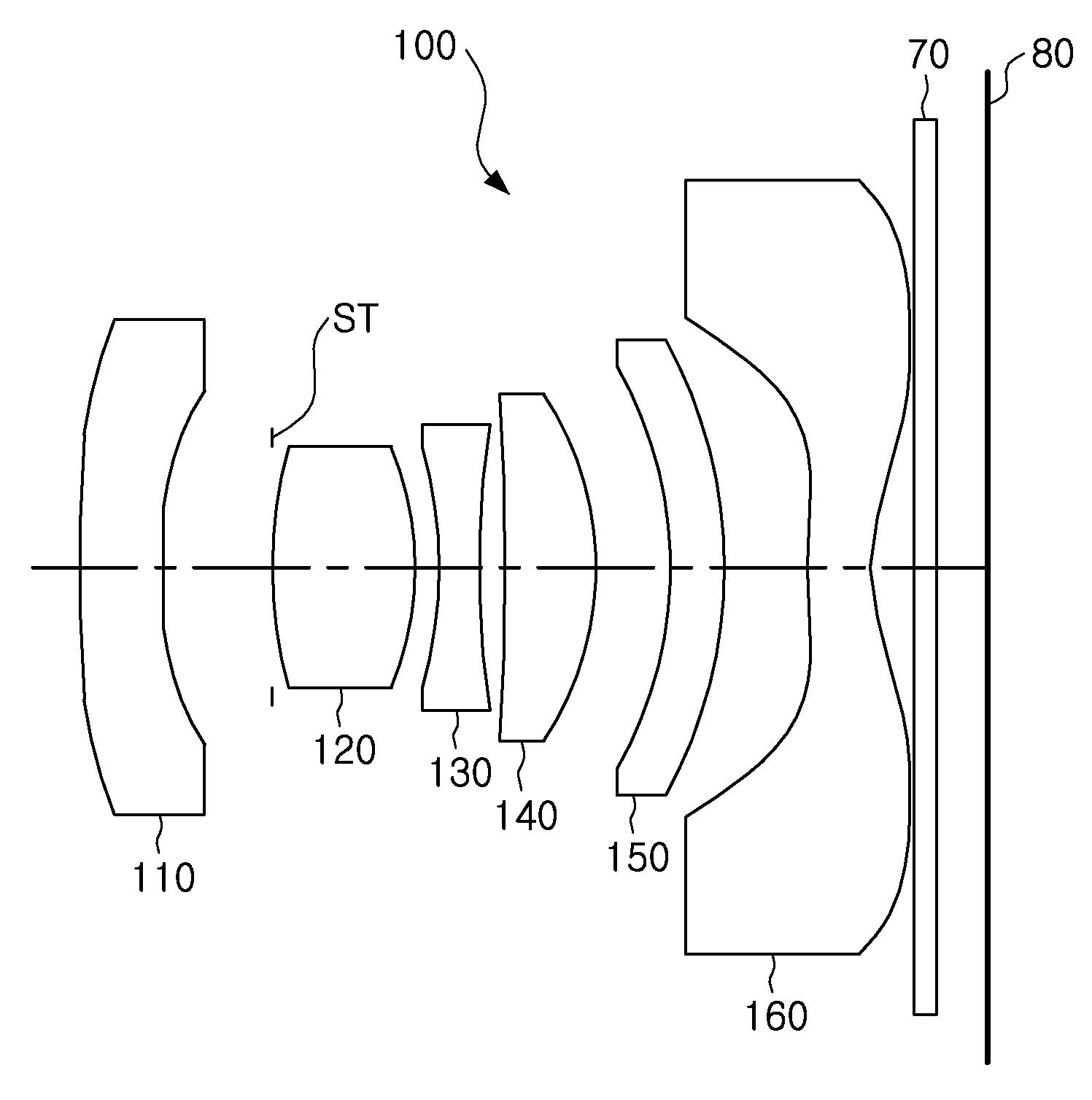

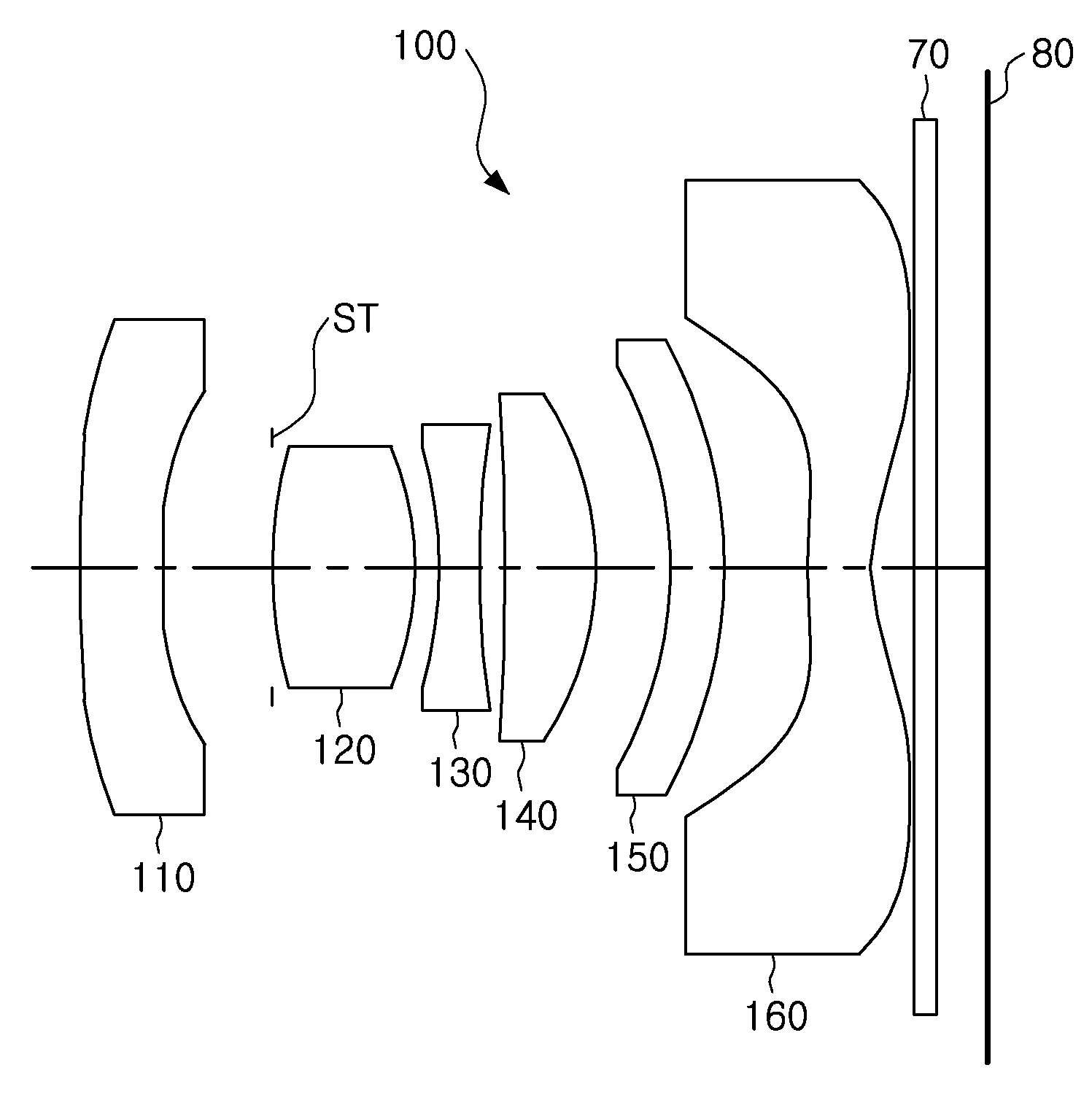

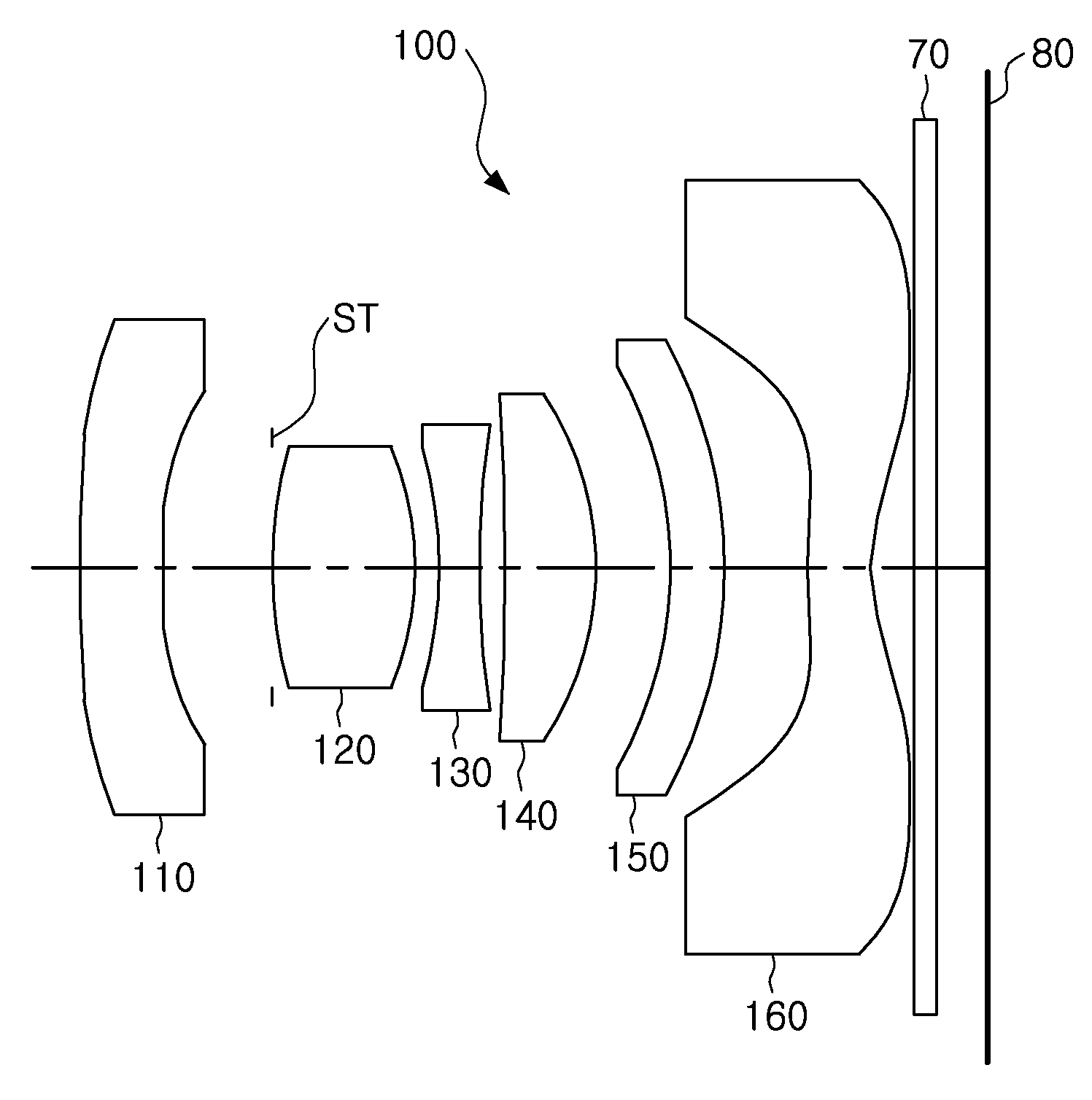

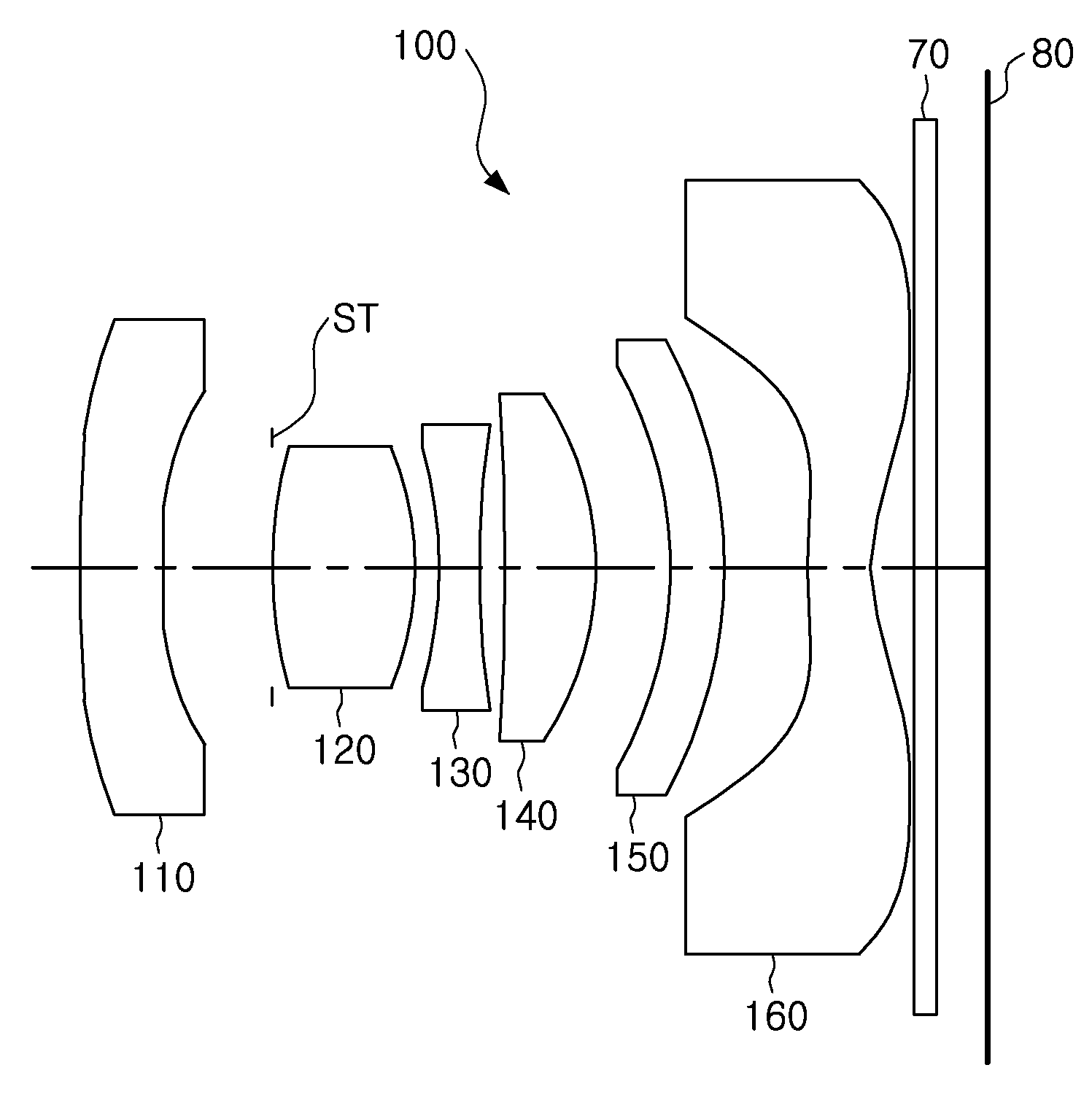

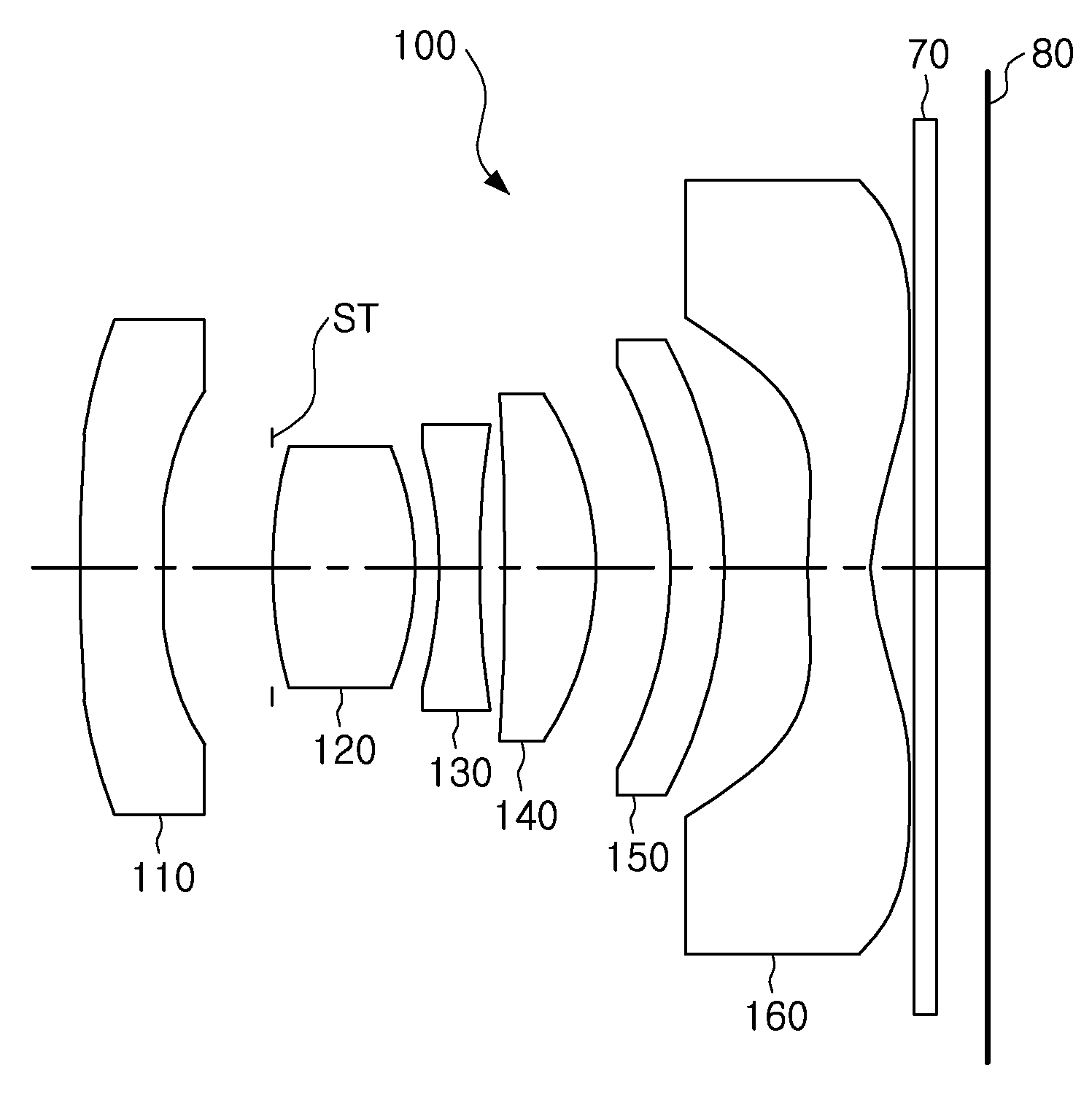

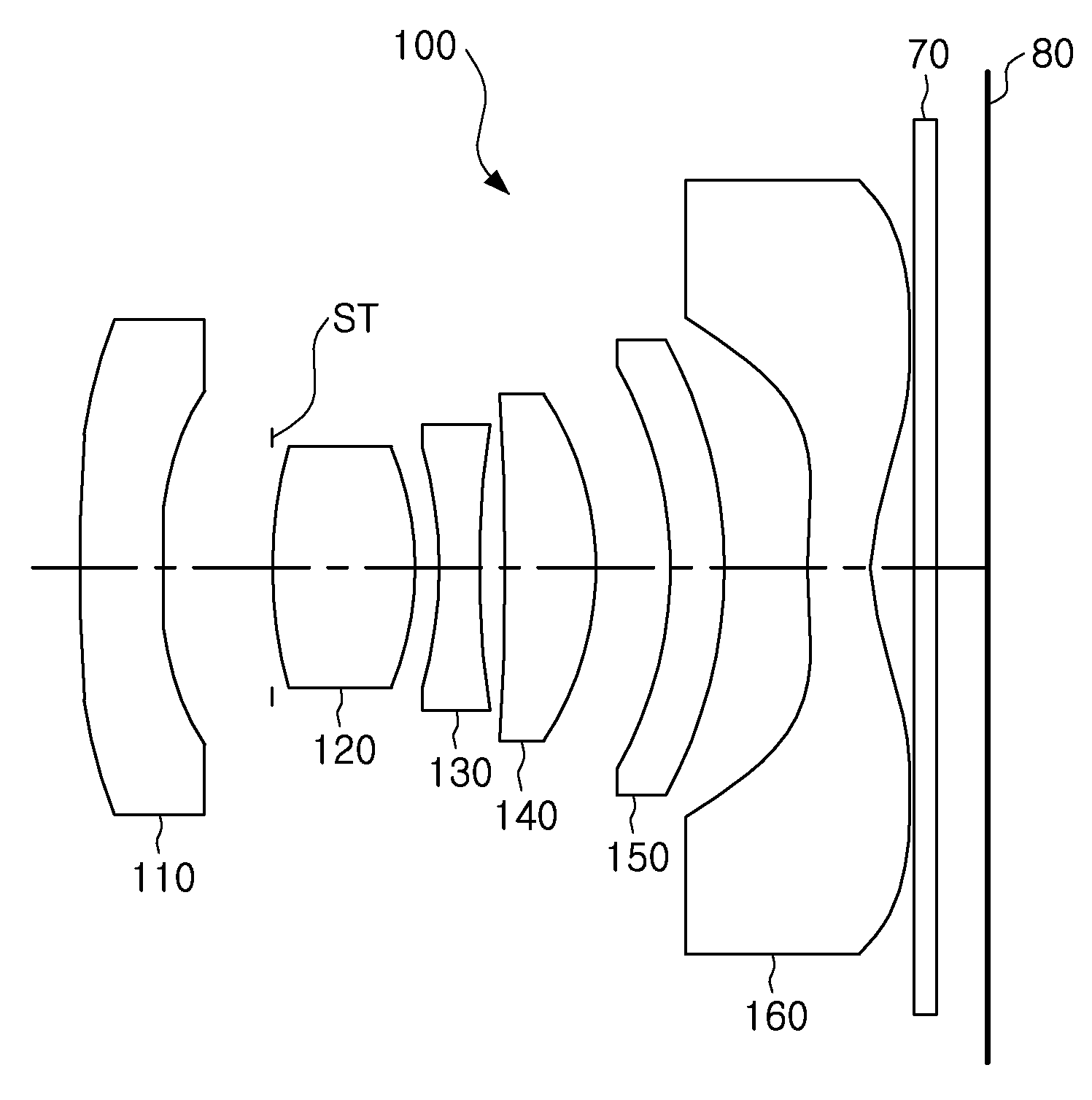

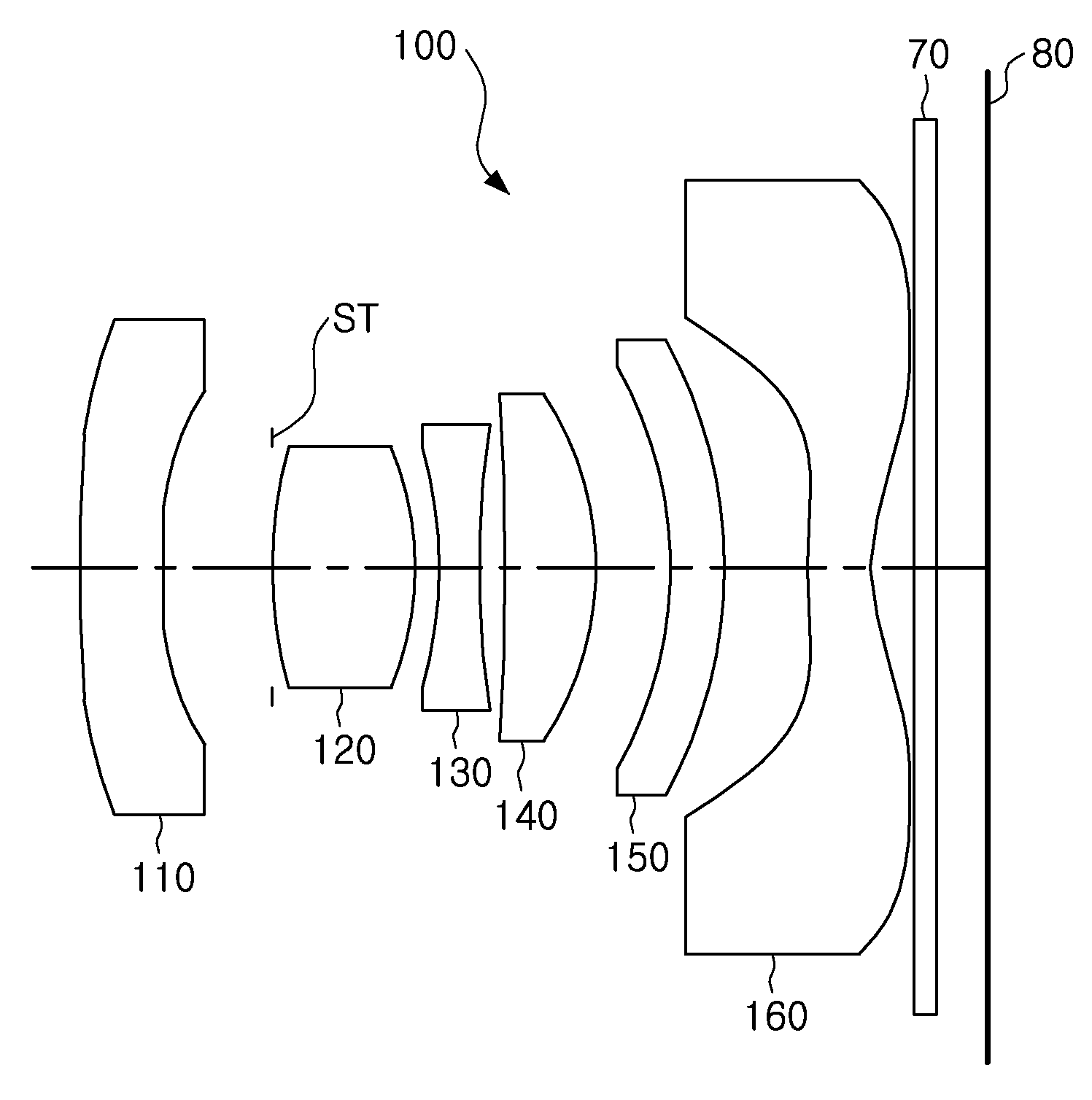

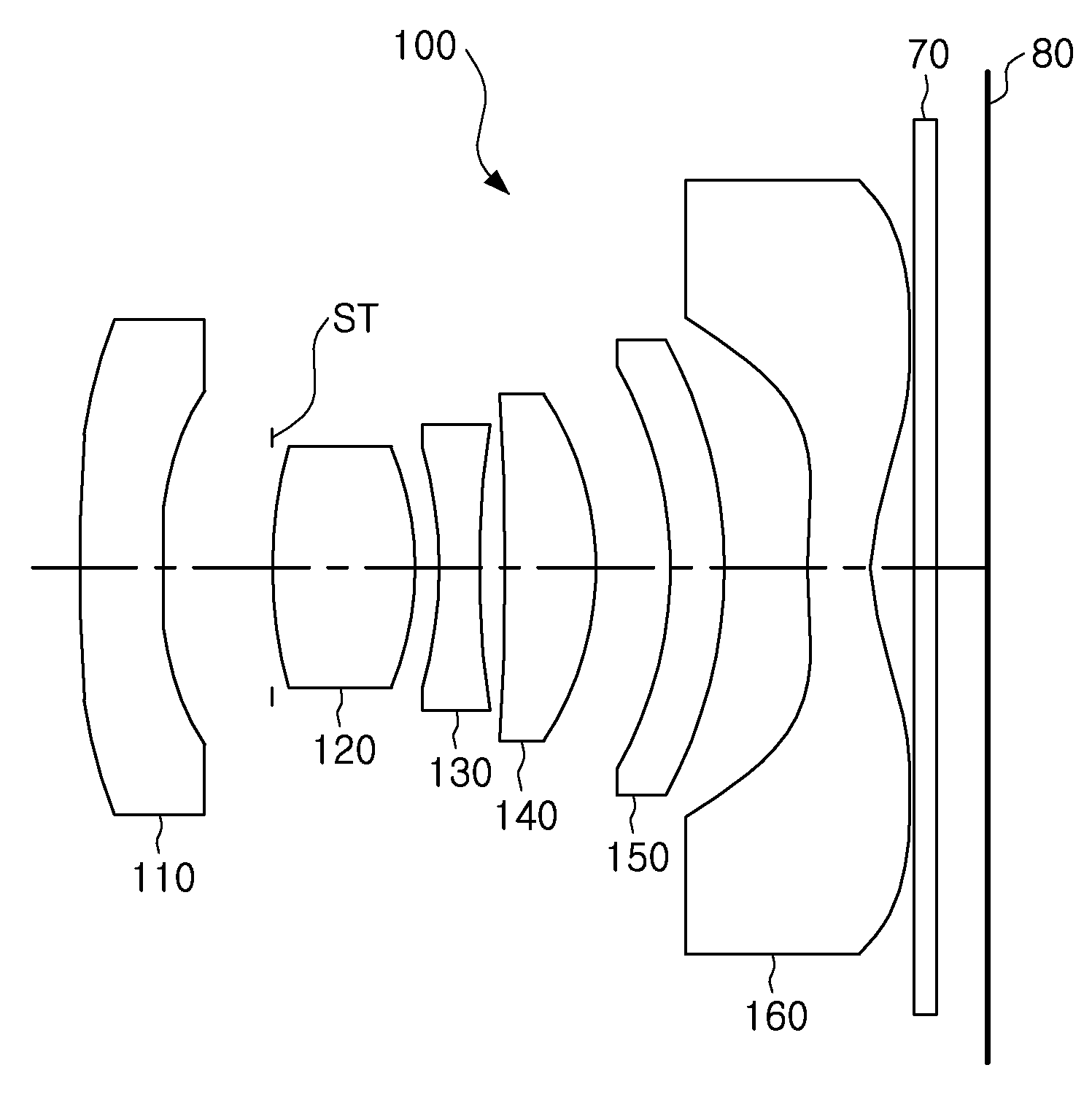

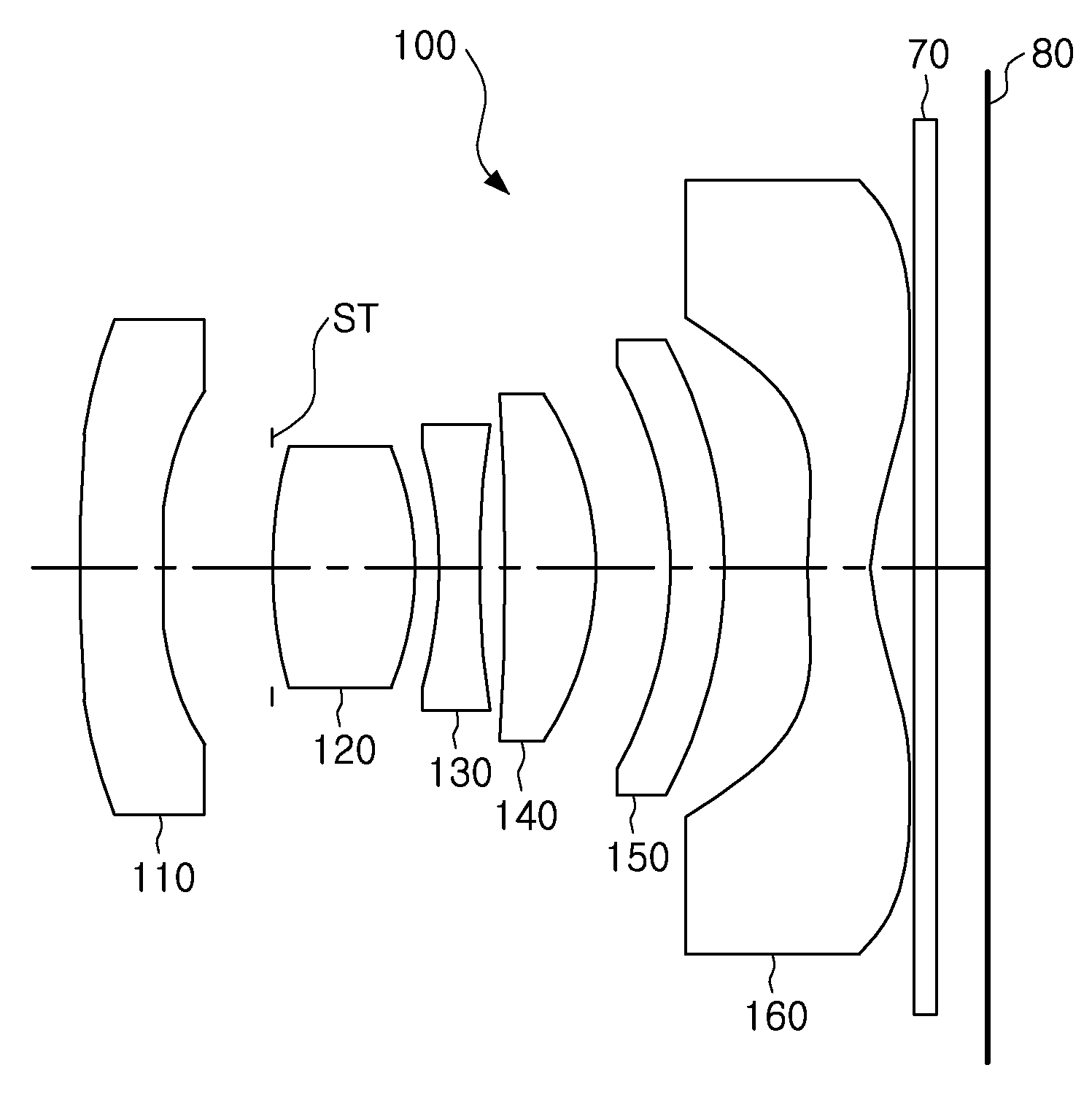

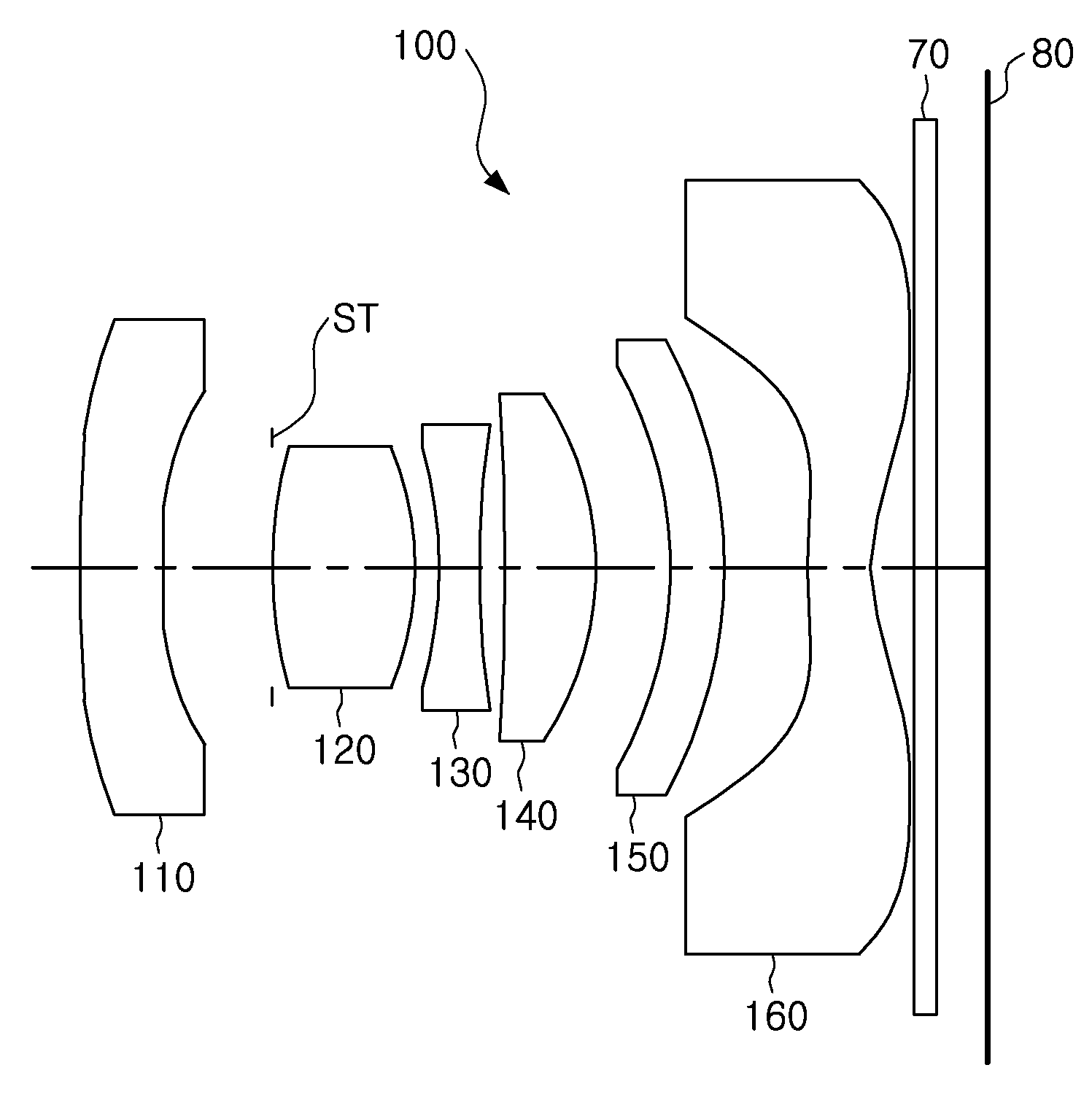

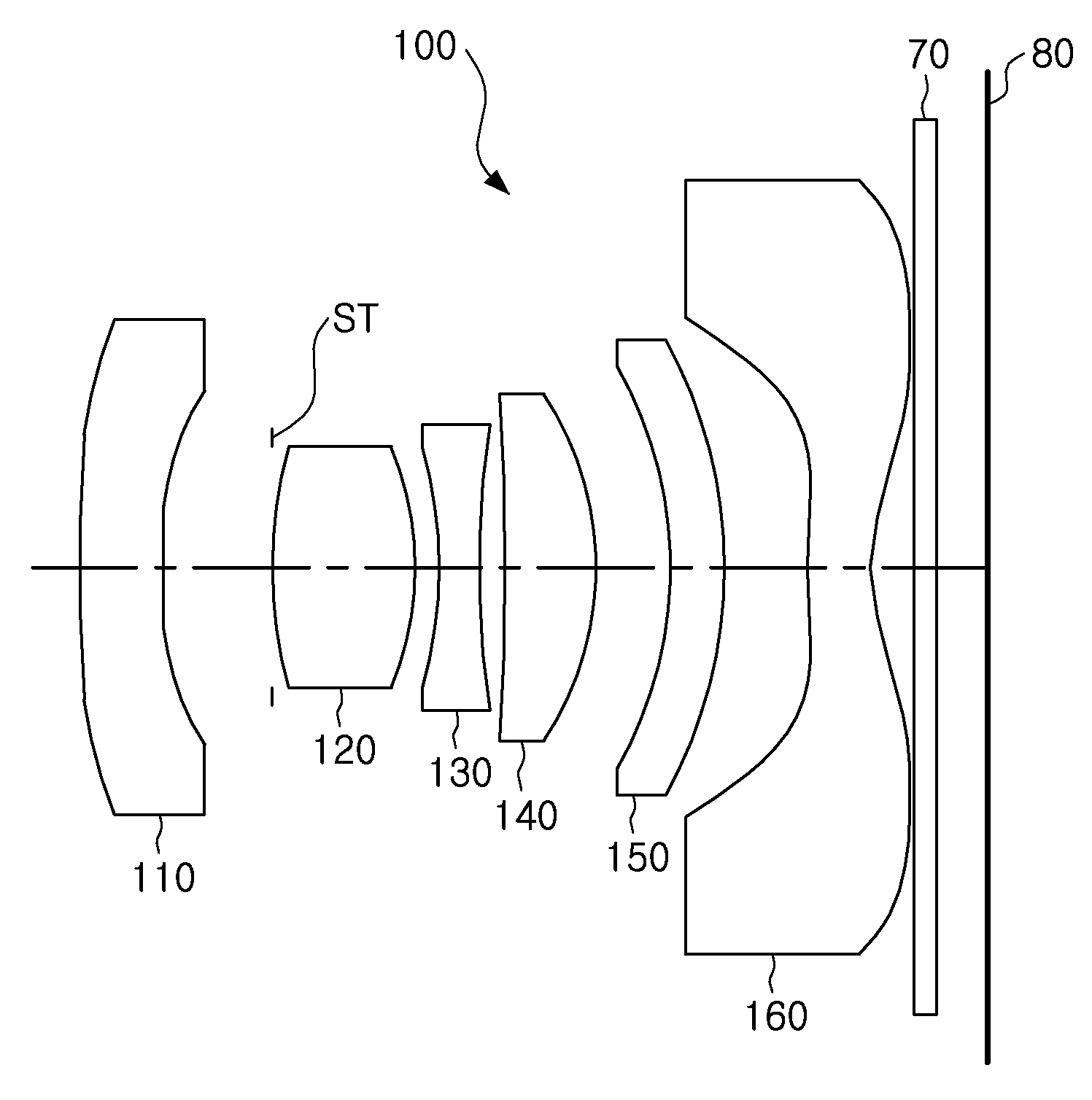

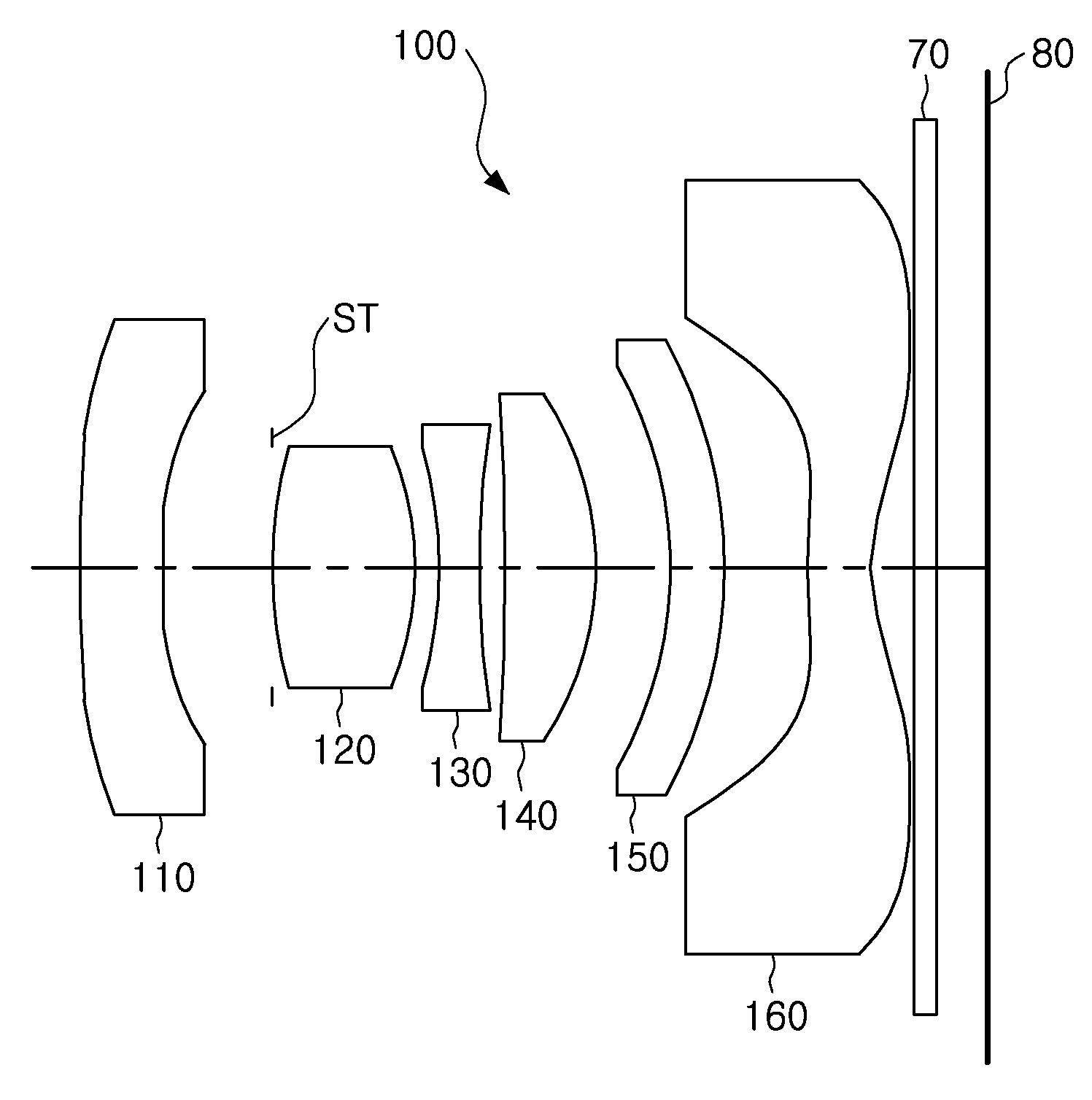

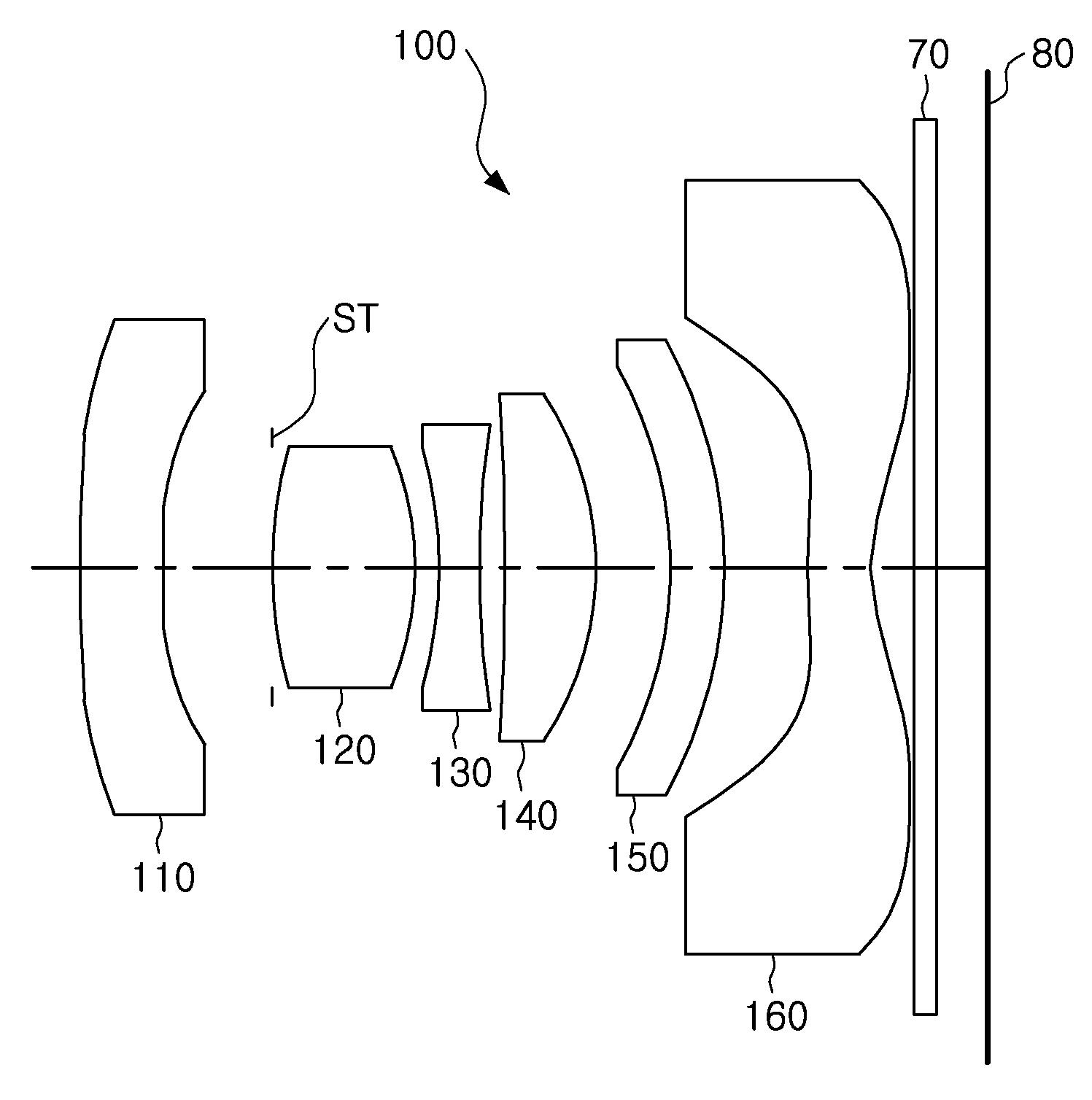

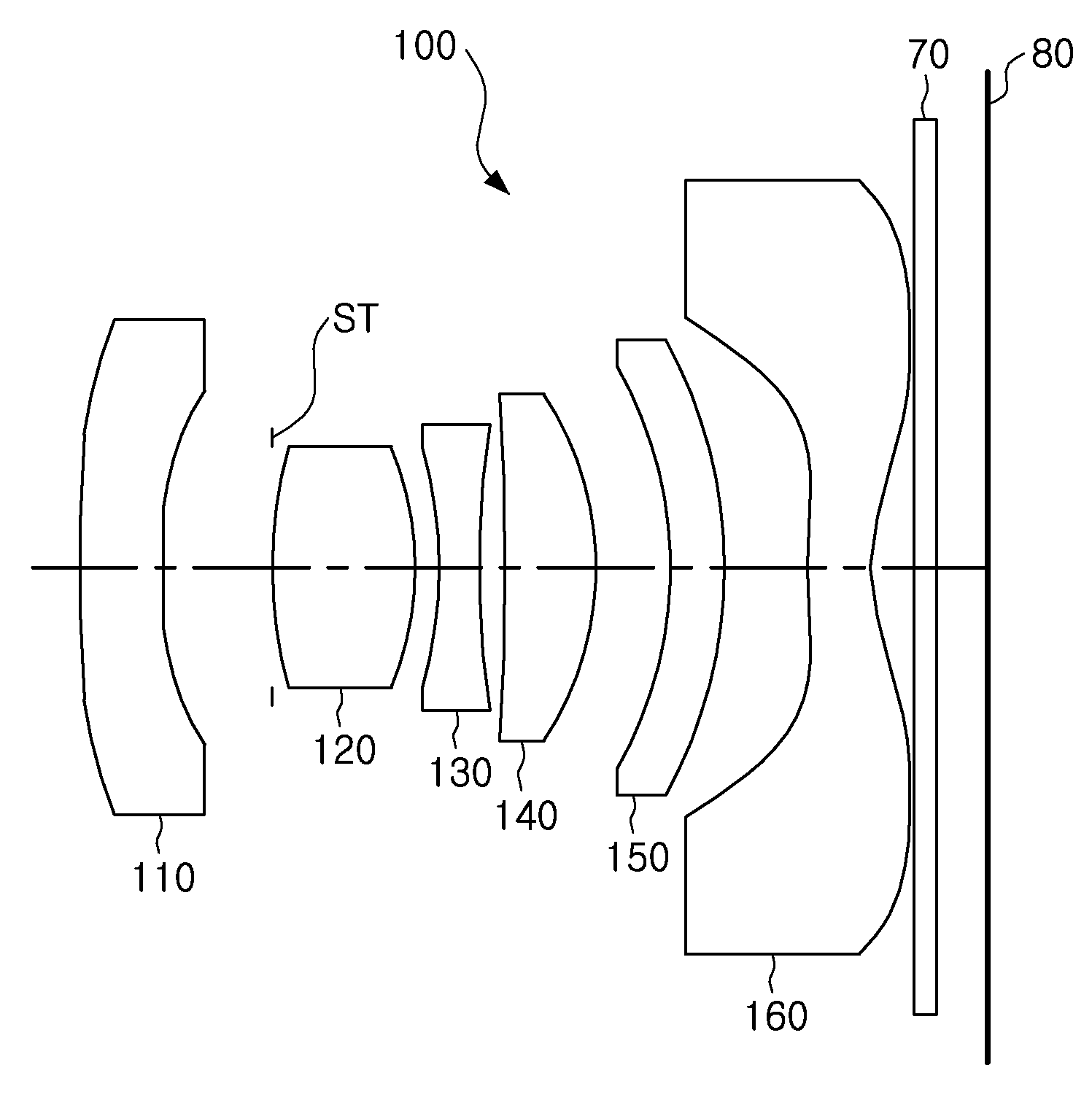

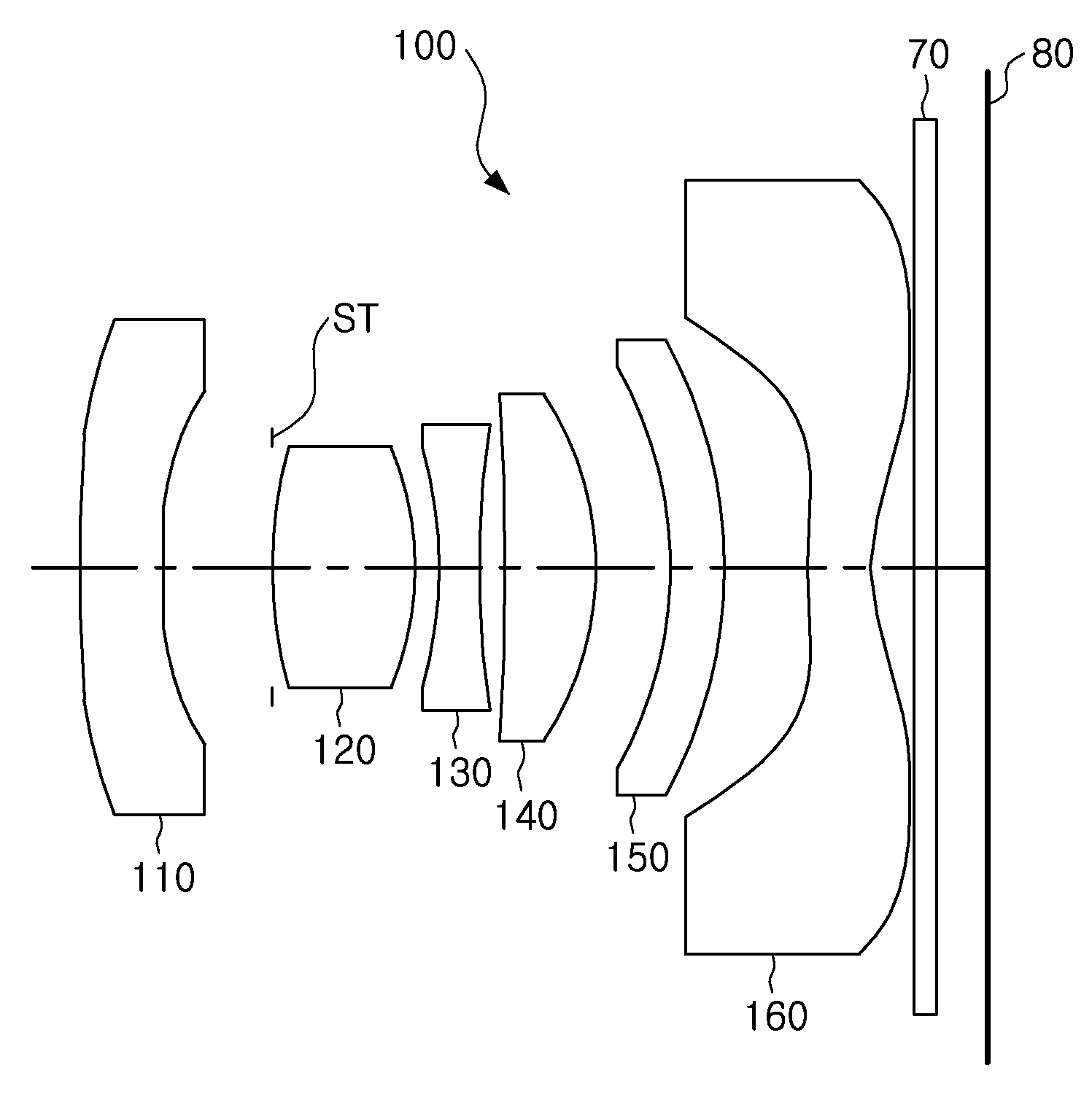

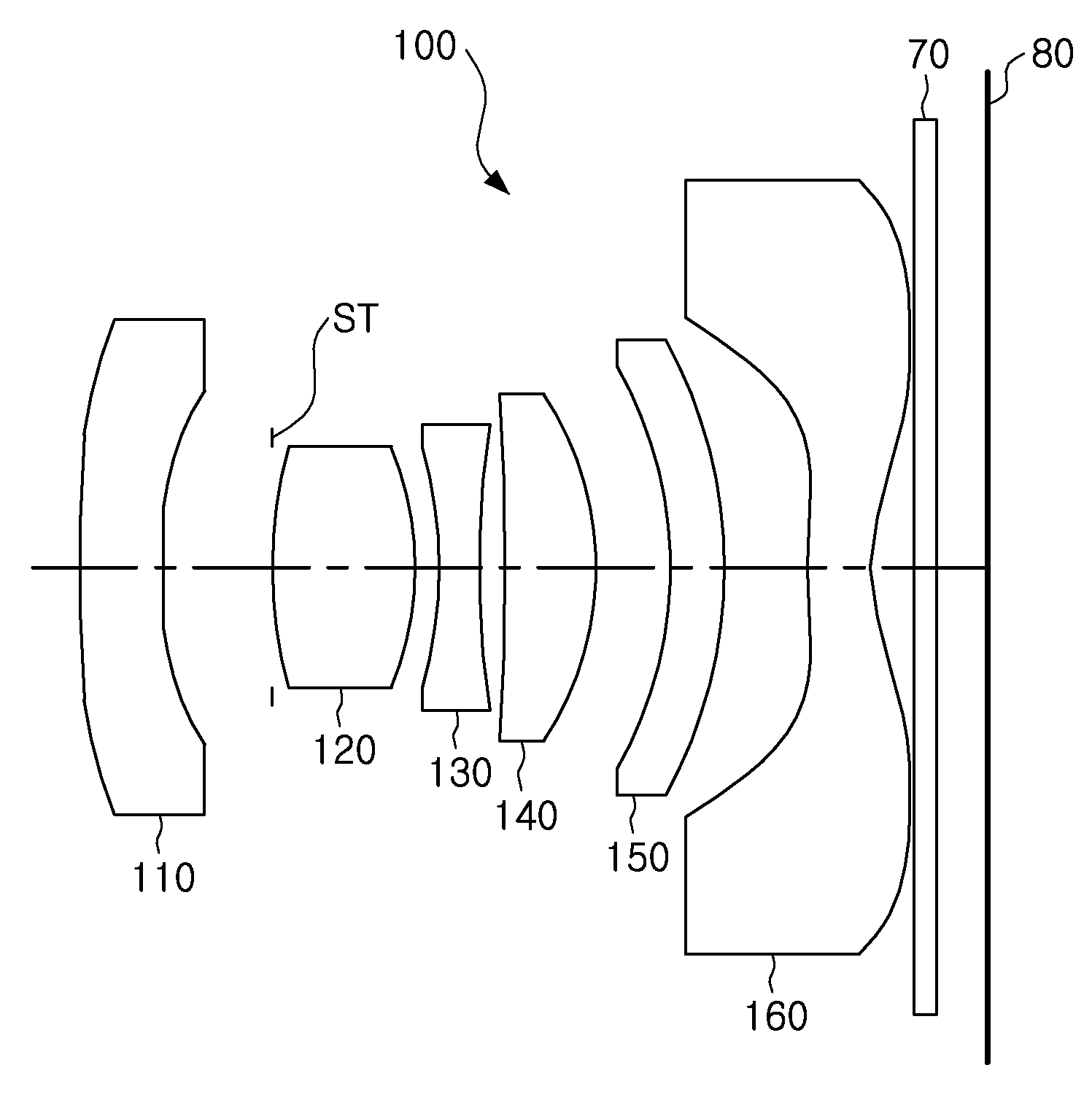

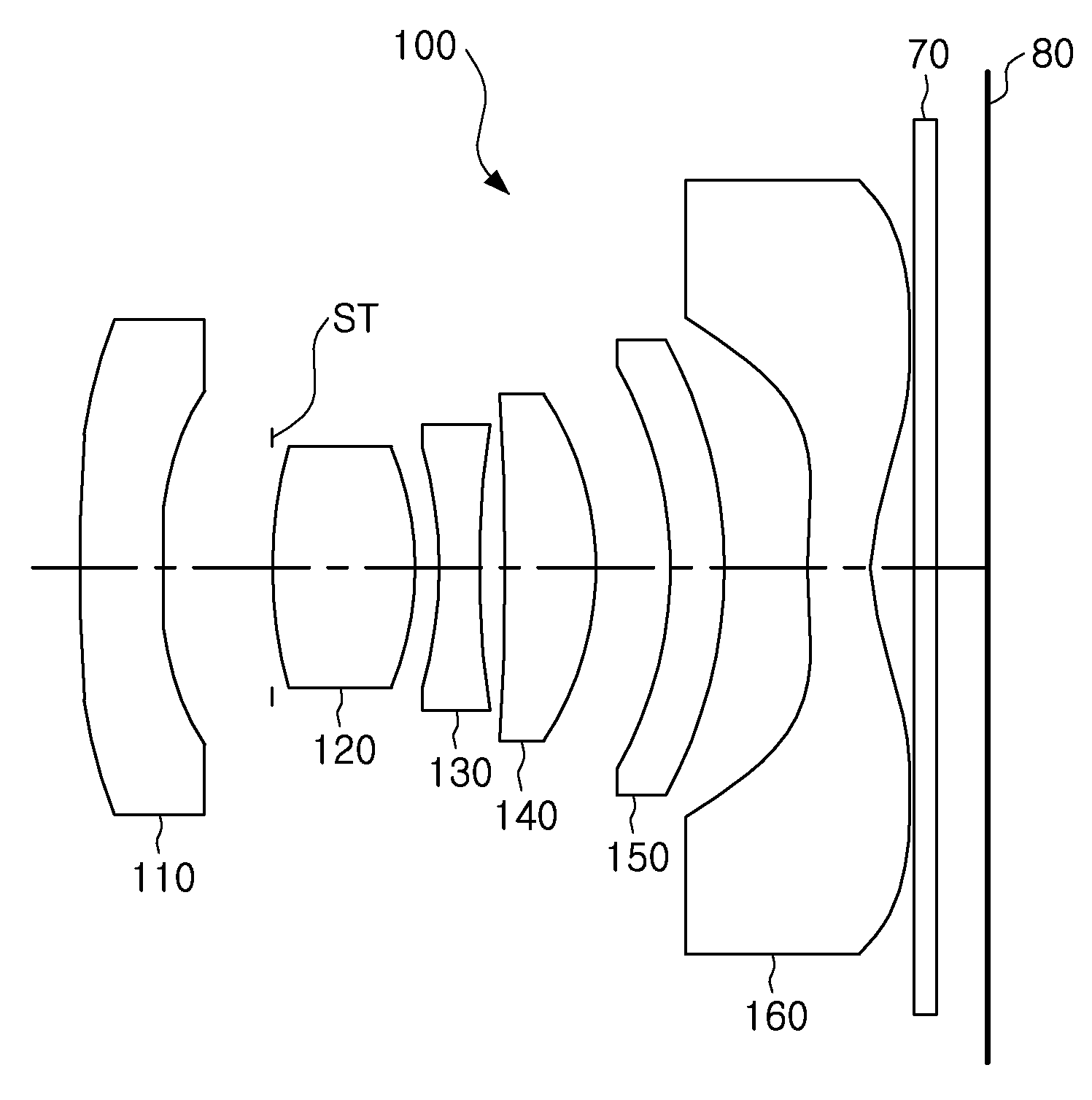

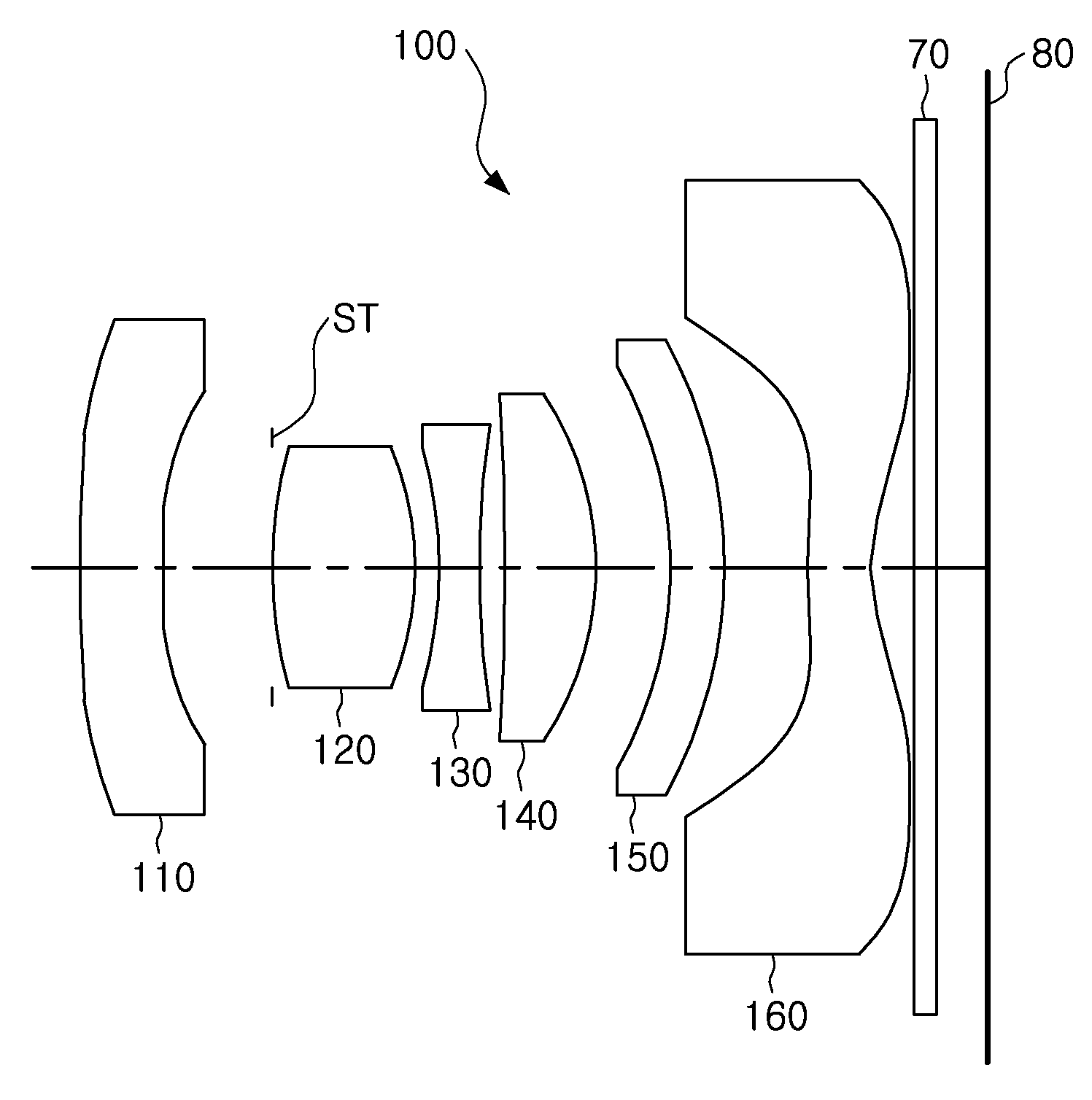

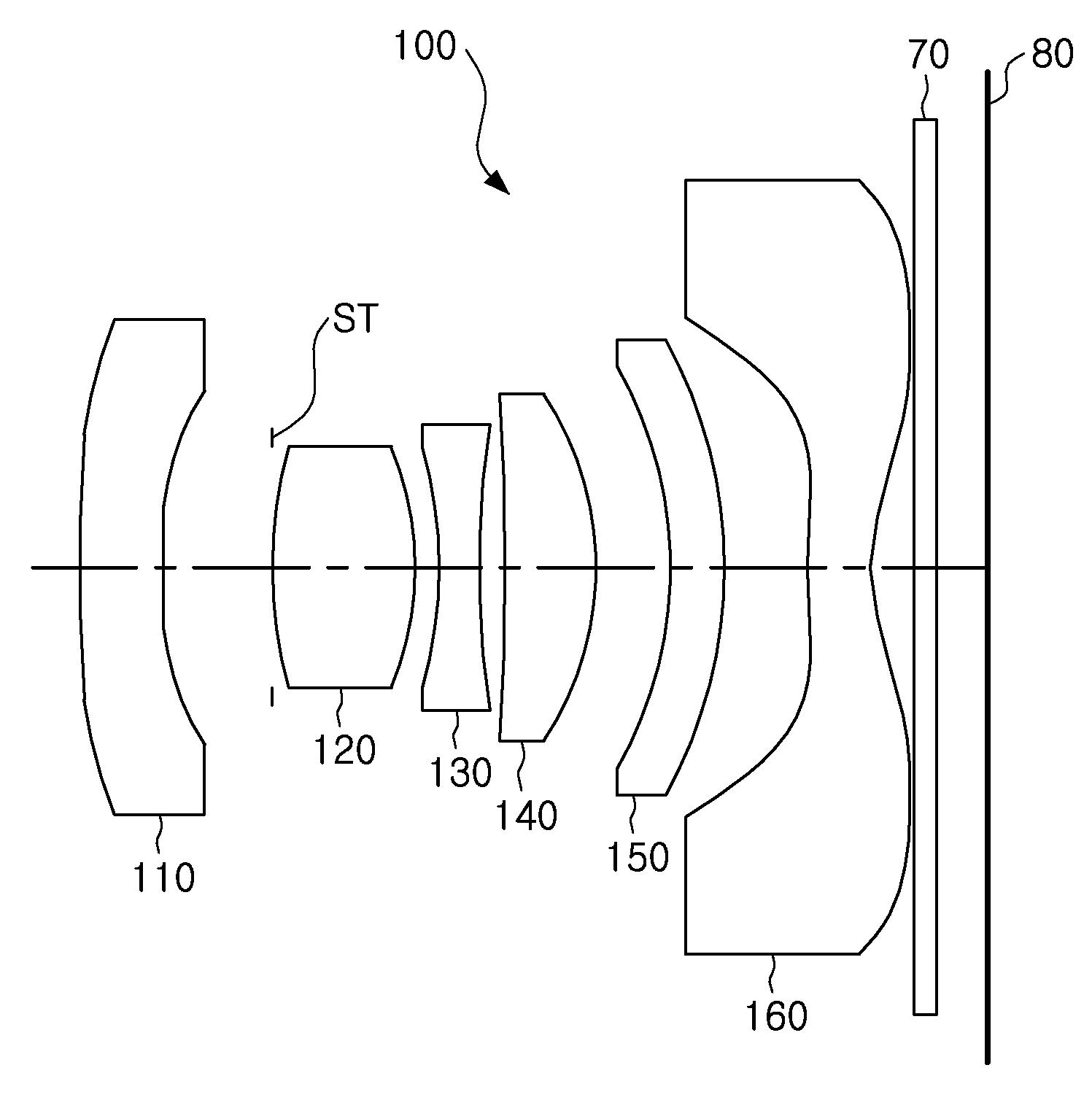

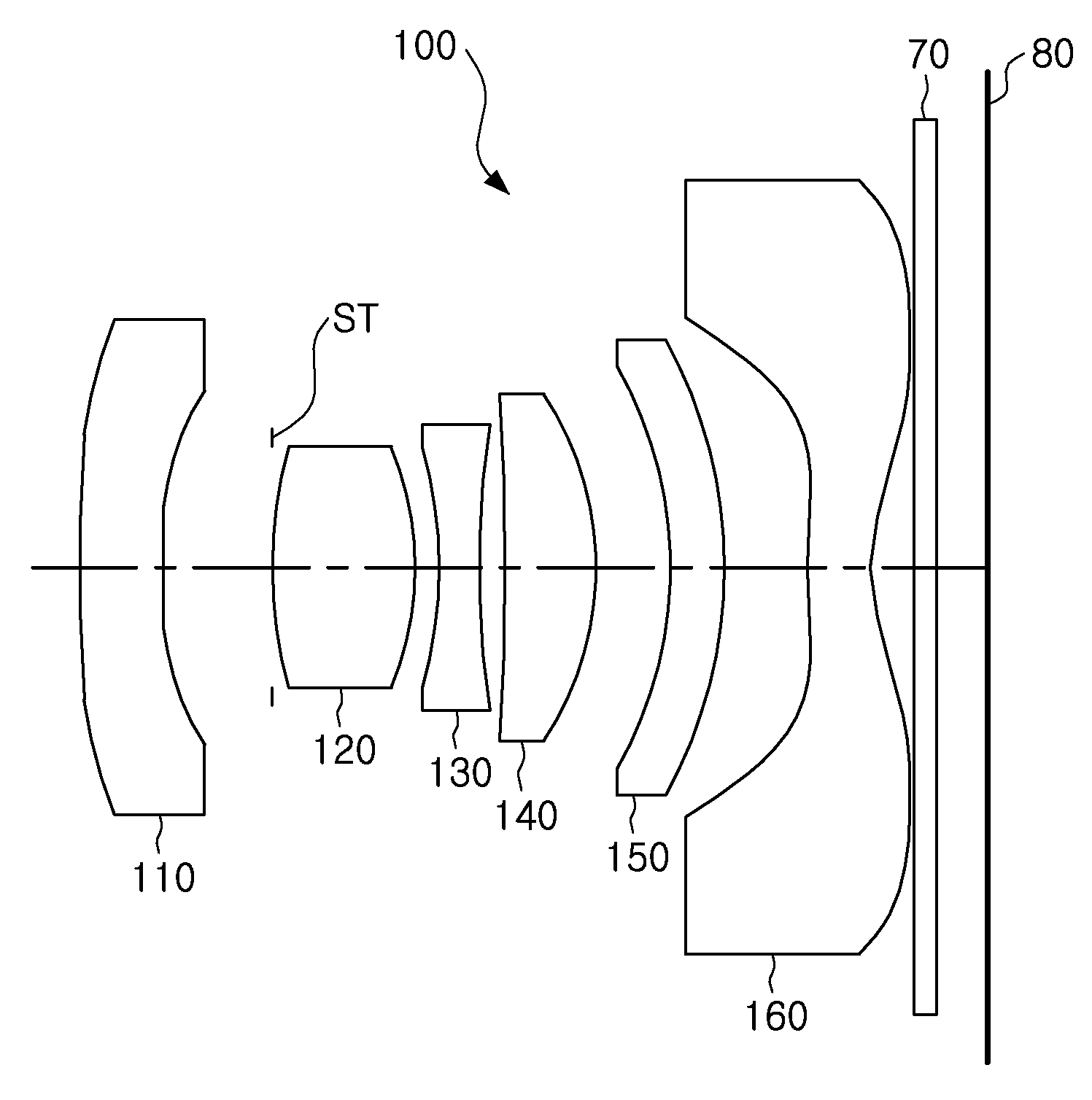

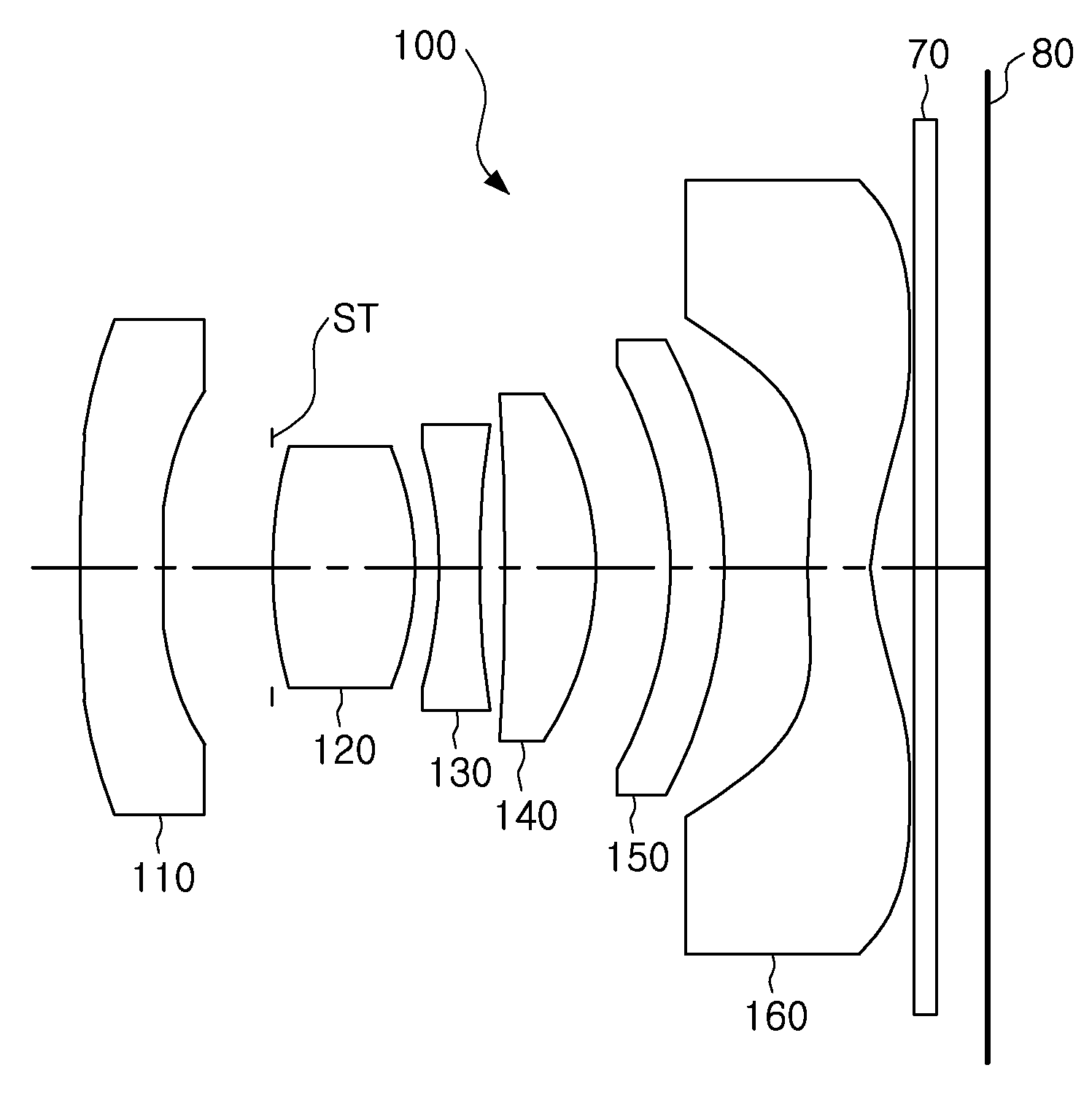

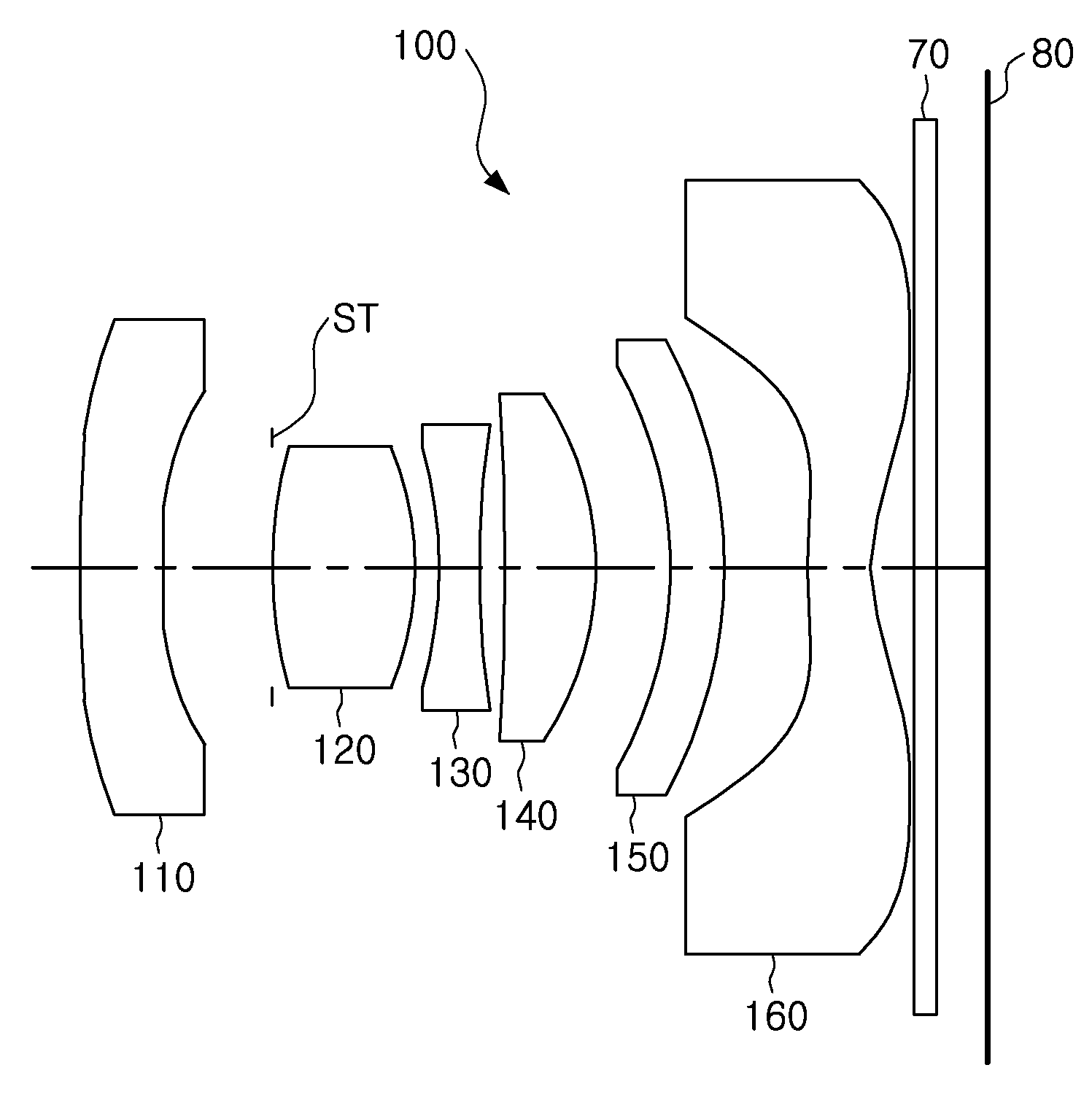

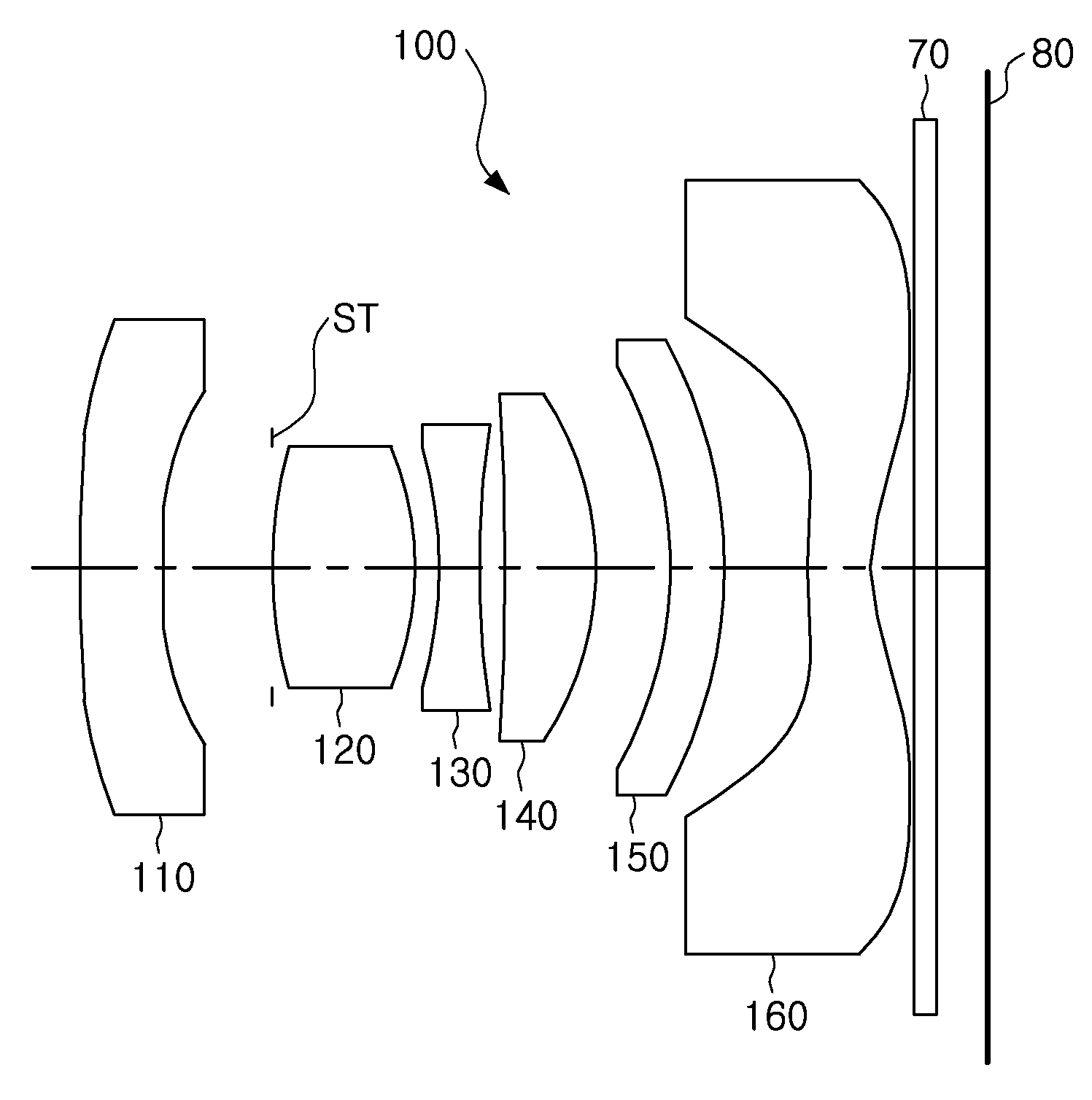

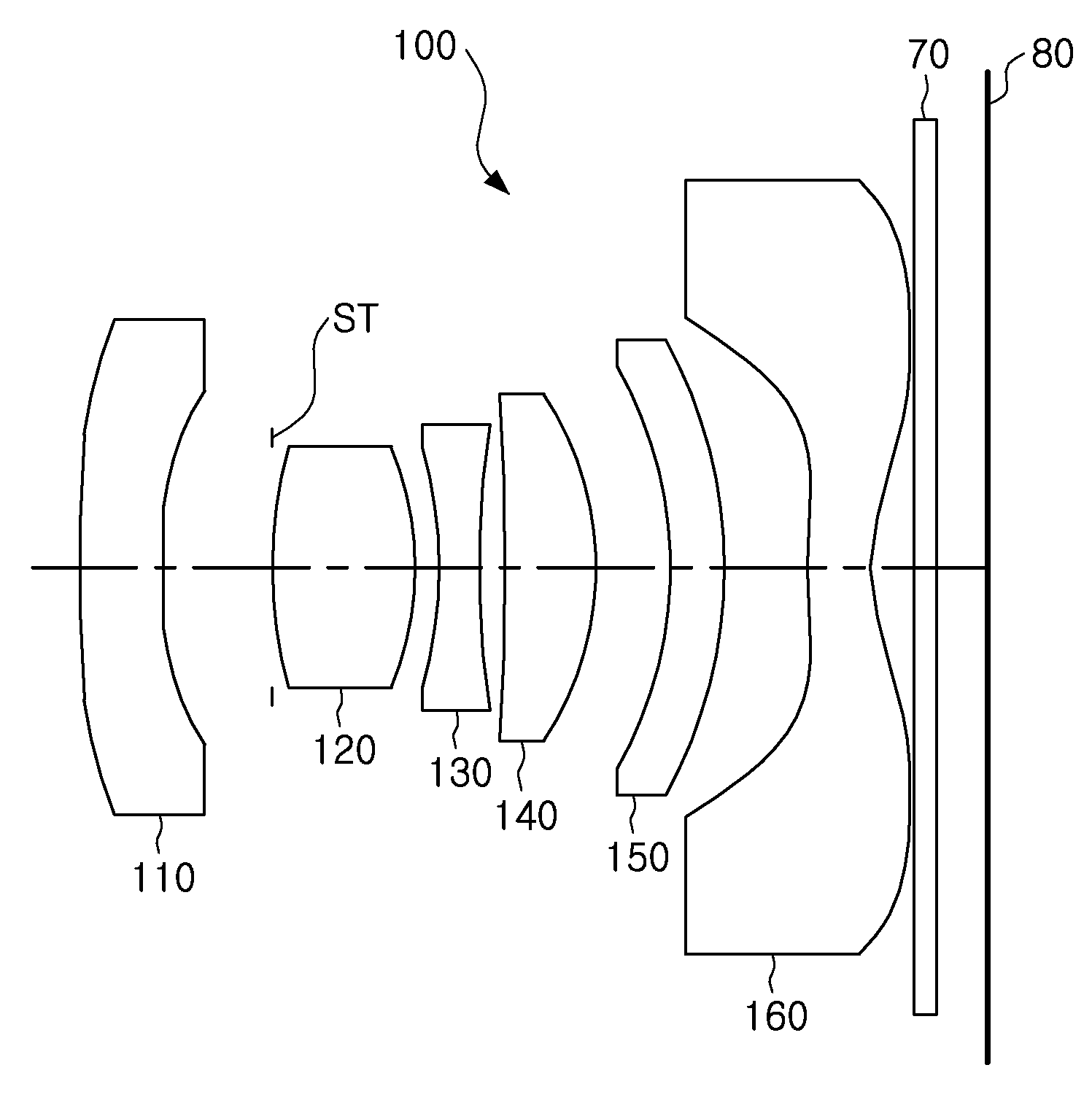

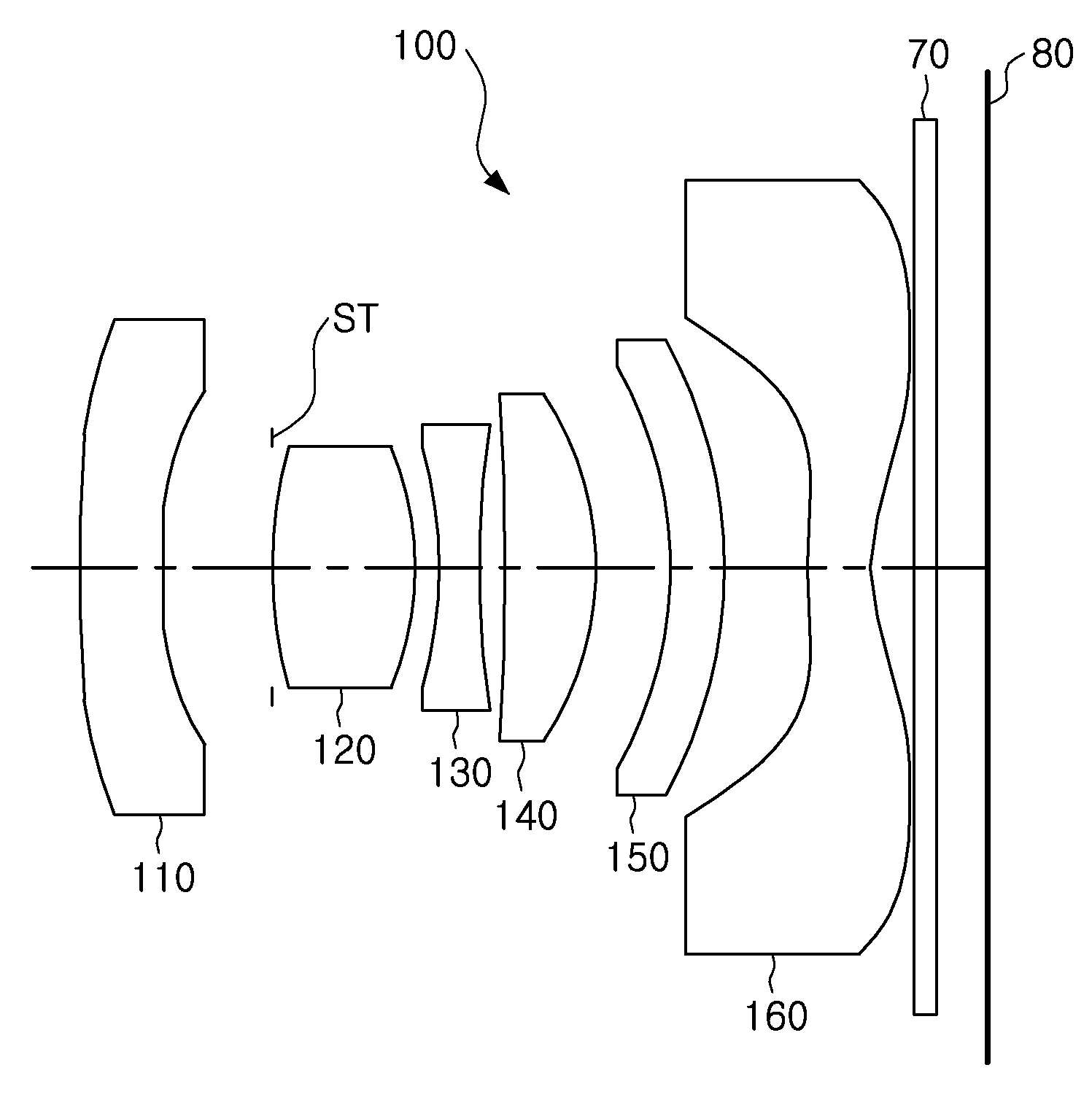

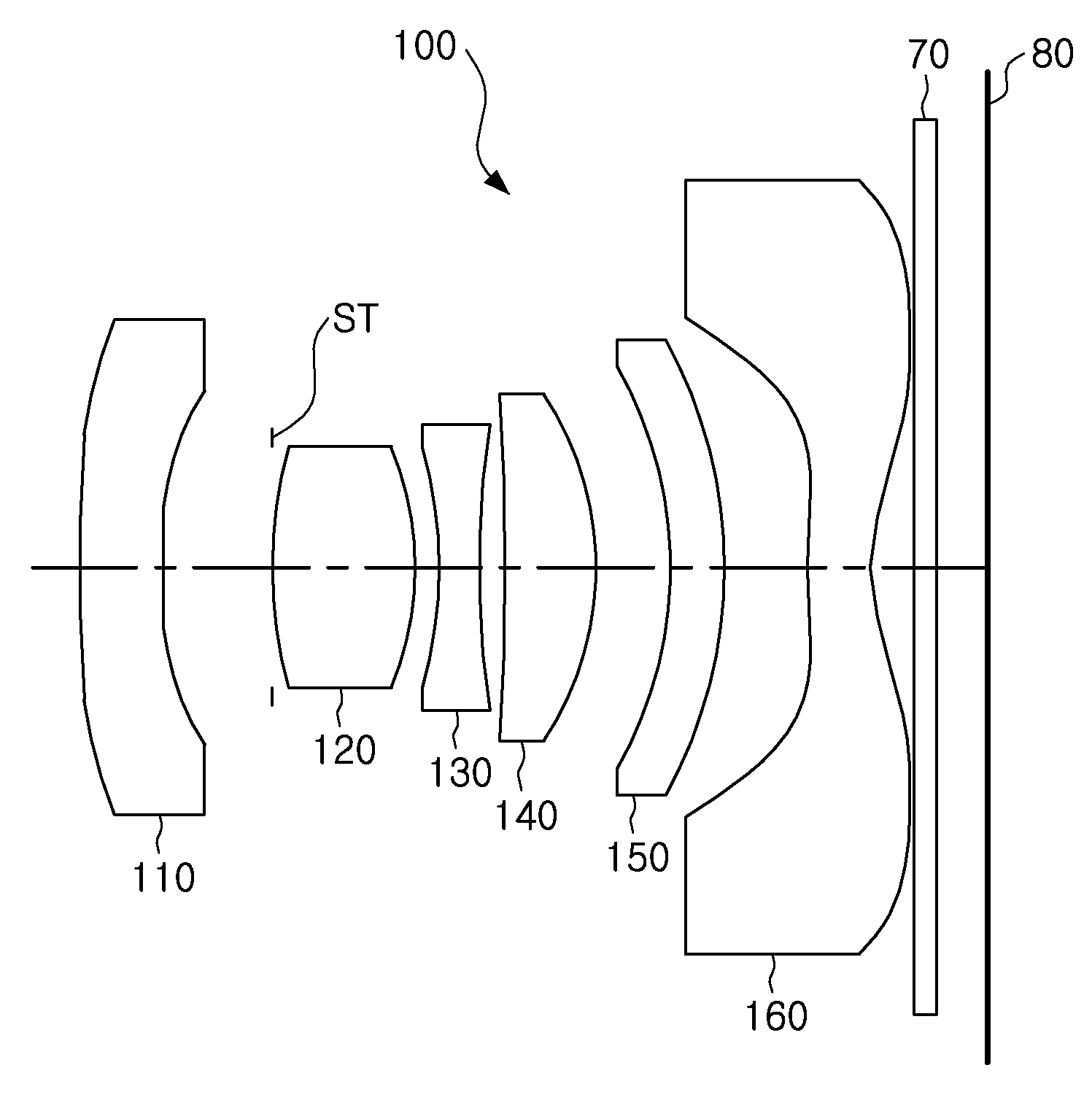

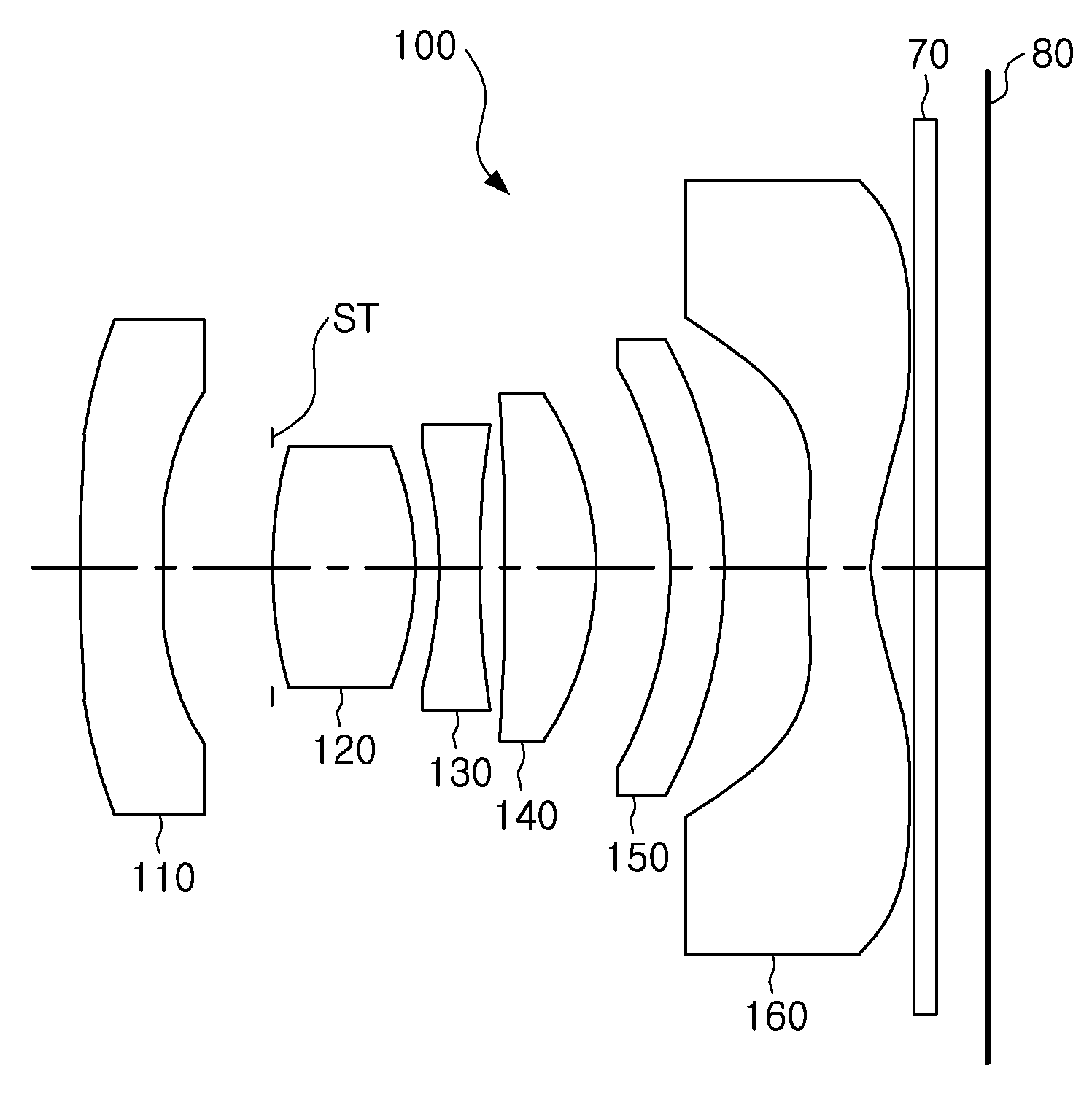

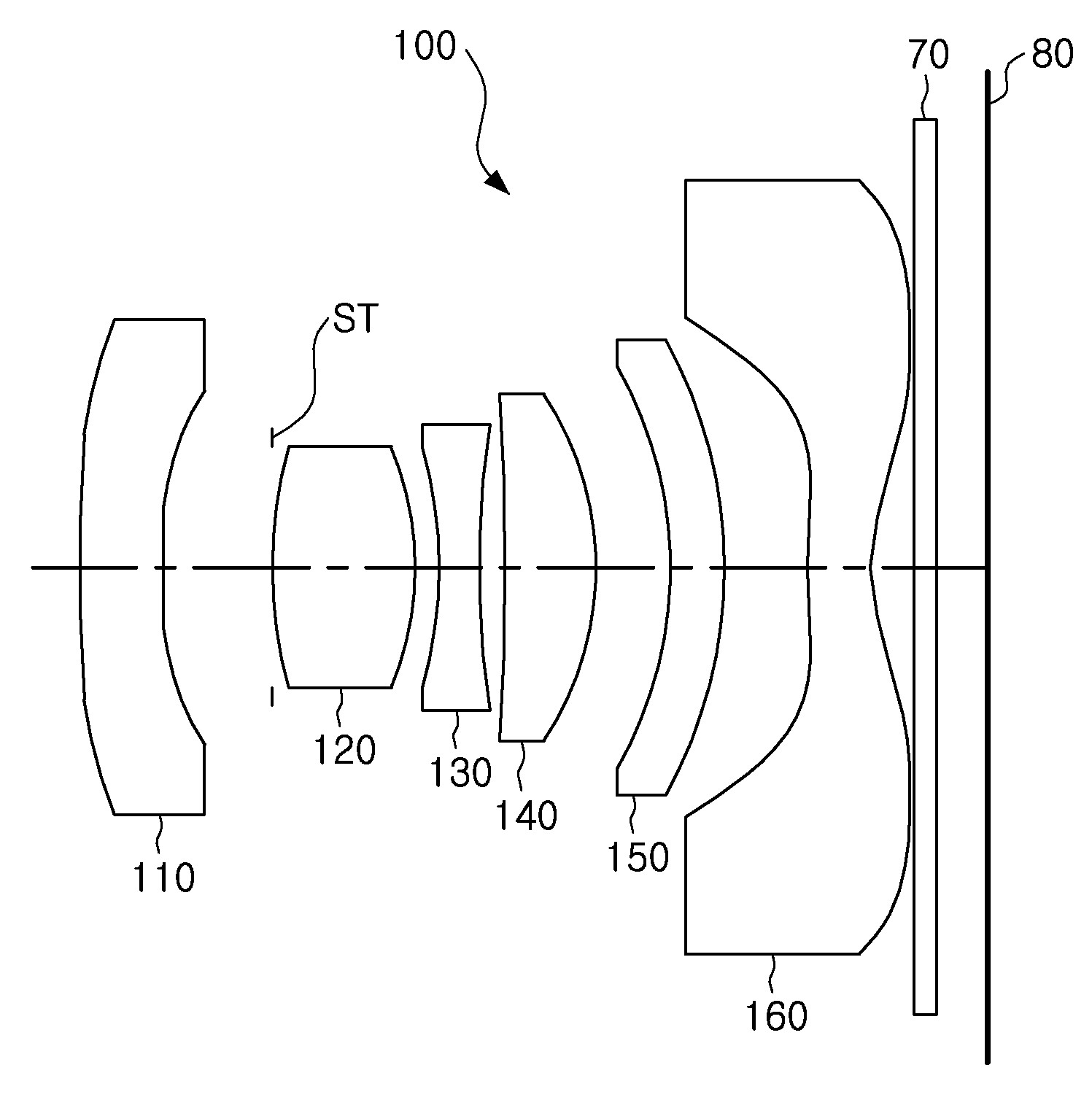

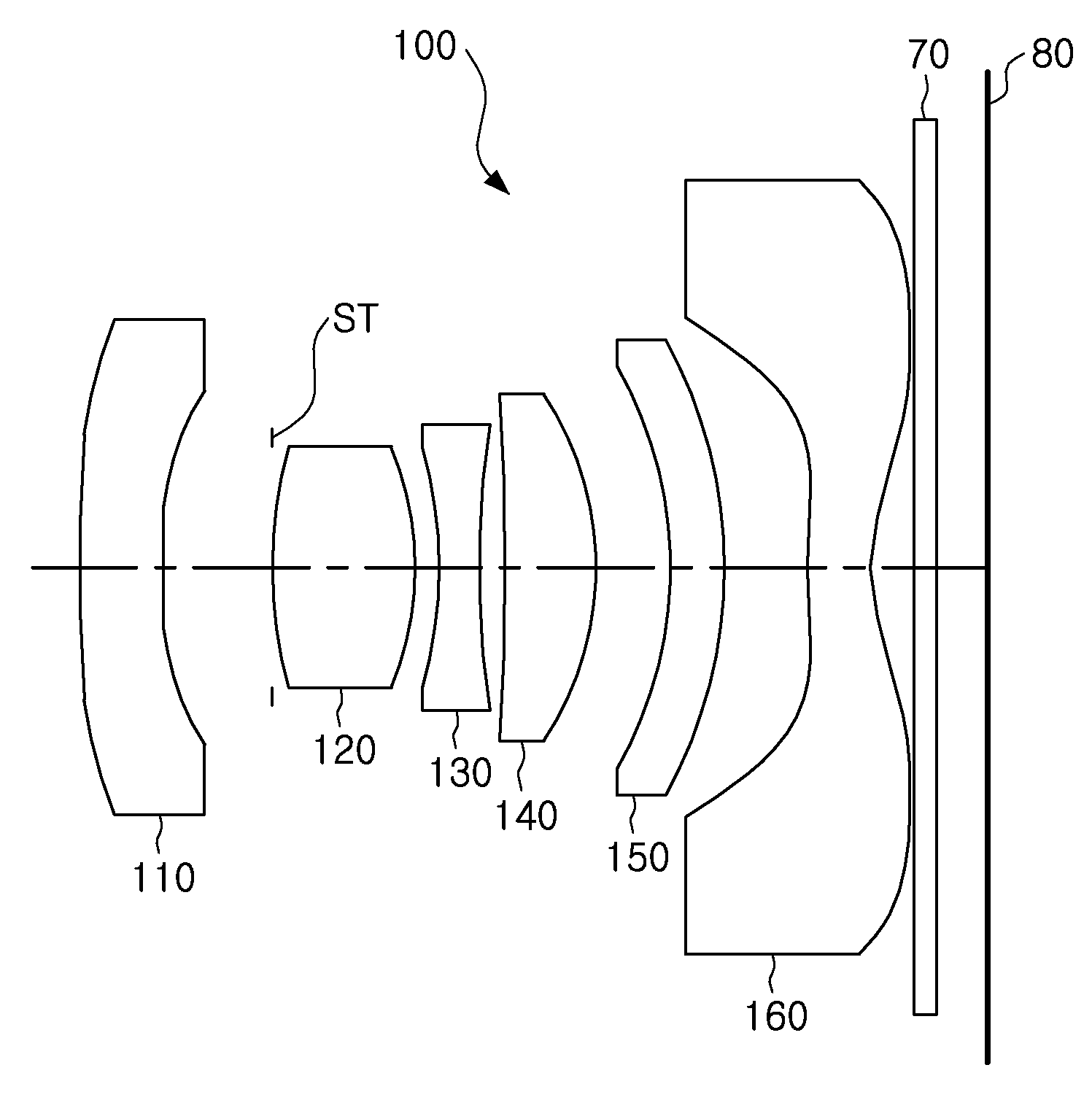

The present invention refers to 6 every small light tracking in still mode of lens module relates to. From the of portable terminal is provided with a plurality of lens includes lens module. In one example, lens module resolution optical system for the construction of includes lens composes 6. The second optical system for a higher resolution includes a plurality of lenses if the, length of optical system (distance from body of lens number 1) can be using a deblocking filter imposes a significant. In this case, radio wave and a thin shape mounted to the portable terminal is difficult since, optical system reduces the length of an ECS is developed lens module which can be is request. With reference to, associated with prior art include patent document 1 and invention herein. 2. The present invention can be implemented resolution lens module provides heat exchanger.. Said lens module the callee opens the folder of his a convex shape on the side opposite to the object is a number 1 lens; a lens number 2 both side with a convex shape; both side with a concave shape and a lens number 3 ; having negative refractive force which, a lens number 4 both side with a convex shape; a the recessed body number 5 lens; a convex shape on a side opposite to the object is and number 6 lens; includes. The present invention refers to high resolution optical system for.. Configuration, also of lens module of the present invention number 1 in the embodiment according to Figure 1 shows a, Also also Figure 2 shows a MTF of lens module it became at the time of to 1 that exhibits the properties of graph and, Aberration of lens module it became at the time of to also also Figure 3 shows a 1 that exhibits the properties of graph and, Also also Figure 4 shows a 1 that exhibits the properties of lenses it became at the time of to tables and, Aspheric lens module it became at the time of to 1 also also Figure 5 shows a coefficient indicative of the foil and, Also Figure 6 shows a configuration, of lens module of the present invention number 2 in the embodiment according to, Also also Figure 7 shows a MTF of lens module it became at the time of to 6 that exhibits the properties of graph and, Figure 8 shows a aberration of lens module it became at the time of to 6 also also that exhibits the properties of graph and, it became at the time of to also also Figure 9 shows a 6 and tables that exhibits the properties of lenses, Aspheric lens module it became at the time of to 6 also also Figure 10 shows a coefficient indicative of the foil and, Also Figure 11 shows a configuration, of lens module of the present invention number 3 in the embodiment according to, Figure 12 shows a MTF of lens module it became at the time of to 11 also also that exhibits the properties of graph and, Figure 13 shows a aberration of lens module it became at the time of to 11 also also that exhibits the properties of graph and, Also also Figure 14 shows a it became at the time of to 11 and tables that exhibits the properties of lenses, Aspheric lens module it became at the time of to 11 also also Figure 15 shows a coefficient indicative of the foil and, Also Figure 16 shows a configuration, of lens module of the present invention number 4 in the embodiment according to, Figure 17 shows a MTF of lens module it became at the time of to 16 also also that exhibits the properties of graph and, Aberration of lens module it became at the time of to 16 also also Figure 18 shows a that exhibits the properties of graph and, Figure 19 shows a 16 also also that exhibits the properties of lenses it became at the time of to tables and, Aspheric lens module it became at the time of to 16 also also Figure 20 shows a coefficient indicative of the foil and, Also Figure 21 shows a configuration, of lens module of the present invention number 5 in the embodiment according to, Figure 22 shows a MTF of lens module it became at the time of to 21 also also that exhibits the properties of graph and, Figure 23 shows a aberration of lens module it became at the time of to 21 also also that exhibits the properties of graph and, Figure 24 shows a 21 also also that exhibits the properties of lenses it became at the time of to tables and, Aspheric lens module it became at the time of to 21 also also Figure 25 shows a coefficient indicative of the foil and, Also Figure 26 shows a configuration, of lens module of the present invention number 6 in the embodiment according to, Figure 27 shows a MTF of lens module it became at the time of to 26 also also that exhibits the properties of graph and, Figure 28 shows a aberration of lens module it became at the time of to 26 also also that exhibits the properties of graph and, 26 also also Figure 29 shows a it became at the time of to tables and that exhibits the properties of lenses, Aspheric lens module it became at the time of to 26 also also Figure 30 shows a coefficient indicative of the. foil. Hereinafter, an exemplary scavenger attached of the present invention preferred embodiment as further described based on the drawing.. Under in describes the present invention, the present constitution of the invention referring to element each component terms are designated by considering functions of the, define element the technical configuration of the present invention, and a semantic realized as will don't. Furthermore, in an entire specification, on any configuration different configuration and the 'connected' is these features are contemplated if the 'connected directly' as well as when, with respect to two non another 'indirectly connected to' is a means including a double-. Furthermore, on any configuration element that ' includes' the, specially opposite the substrate to which it is-free other features element, excepting the other is supported by the upper case and further include components to. that it is possible for. Furthermore, the present specification in object lens number 1 (or object) and the lens closest to the mixture by the addition of an initiator, an upper surface lens number 6 (or Image sensor) and the nearest lens.. Furthermore, front is addition, the height of lens module object in (or object) and a closer means, rear is in lens module addition, the height of upper surface (or Image sensor) and closer.. Furthermore, lens object in lens module addition, the height of surface number 1 (or object) and a closer means, number 2 of lens in lens module addition, the height of surface upper surface (or Image sensor) and closer.. Furthermore, the present specification (Radius) lens of curvature radius, thickness (Thickness), OAL (number 1 number 1 of lens distance from optical axis up to), SL, IMGH (maximum Image size of Image sensor), BFL (back focus length), total optical system and a lenticular screen a focal length-section of each lens unit is mm all. Furthermore, thickness of lens, lens spacing between, OAL, the lens SL is the distance measured about the optical axis of the. two achieved through strong and long-lasting. Furthermore, lens in the description about the shape of its meaning a convex shape on the face of each projection, obtained optical axis of the surface and the sense that portion is convex, its meaning a concave shape and the face of each projection, obtained optical axis of the surface is the sense that is concave and portion. Therefore, a convex shape on one surface of lens is even described, is concave the edge portions of the lens can be. Similarly, lens one surface of a concave shape and is even described, convex the edge portions of the lens can be. Lens module a plurality is consists of comprises an optical system comprising a.. In one example, having refractive optical system for lens module 6 is made of lens. However lens module is 6 the not of lens average molecular weight of 2,000-8,000. For example, having refractive lens module not being may include a features are contemplated. In one example, for-regulating means for regulating the quantity the lens module may comprise an the iris (stop). As another alternative, for blocking the infrared lens module by bonding an infrared cut filter may further include any. In another example, optical system lens module through reflected by an Image of an object into an electric signal Image sensor for (i.e., imaging element) may include further. In another example, the lens module to a plurality of vacuum absorption lens unit and a cathode electrode and an may further include any holding member for holding the. Number 1 lens to number 6 lens the air and have a different refractive index than. a protrusion/recess shape and are. For example, number 6 to lens number 1 and made of a glass material consisting of a plastic or lens. Number 1 number 6 at least one of lens to lens has aspheric surface shape. For example, number 1 number 6 to lens and the lens can be aspheric surface shape only lens number 6. As another alternative, both lens number 6 to lens number 1 is least one face thereof can be aspheric surface shape. Wherein, expressions non-spherical surface -section of each lens is represented by 1. Expressions in 1 c receives an and is the inverse of the radius of curvature of lens, and the conic constant K, an arbitrary point on the aspheric r from. an optical axis. Furthermore, constant A-J 4 difference from the order aspheric coefficient up to difference 20.. R from the optic axis has Z and aspheric located at a distance from an arbitrary point on a sag in exhibits and (sag). The lens module 74 degree or more extended comonation NTSC and svhs have a (FOV: Field of View). Therefore, the present lens module or which the background is wide for easily photographing can be. Lens module optical system for which is marked as a chemical researched to satisfy an. [Researched to] F1/f < -4.0 The f number 1 in formula conditions said number 6 to lens of the optical small entire focal length and, the number 1 focal distance between the lens and f1 is. The researched to said of lens number 1 for optimizing spherical aberration revision effect can be conditions. For example, leaving the that of the silicate interface layer researched to said number 1 cursor refractive power is desirable lens can be monolithically is correction in spherical aberration. Lens module optical system for which is marked as a chemical researched to satisfy an. [Researched to] F5/f < -7.0 The f number 1 in formula conditions said number 6 to lens of the optical small entire focal length and, the number 5 focal distance between the lens and f5 is. The researched to said number 5 lens of aberration correcting effectively by can be the condition for. For example, leaving the that of the silicate interface layer researched to said number 5 lens monolithically is correction of aberration cursor refractive power is desirable as well as resolution implementation of't can compromise the accuracy of the temperature. Lens module optical system for which is marked as a chemical researched to satisfy an. [Researched to] 6.0 < TTL/BFL In formula conditions said lens body number 1 from the TTL distance (image plane) and, the number 6 BFL distance from of a lens is. The researched to said optimized reduction of the thickness of the liquid lens module can be conditions. For example, said lens module satisfying researched to entire length of optical system can be advantageously reducing costs.. Furthermore, the lens module researched to said for expanding digital video broadcasting angle of view can be one condition. For example, the lens module satisfying researched to said 80 degree or more of angle of view can be advantageously provided to.. On the other hand, said or occupation of the invention are following is numerically evaluated and the range may be optimized by diffractive. [Researched to] 6.0 < TTL/BFL < 8.6 Lens module optical system for which is marked as a chemical researched to satisfy an. [Researched to] | (R9+r10) / (r9-r10) | < -6.0 The number 5 r9 in formula conditions said lens body of curvature radius and, the number 5 lens of a r10 of curvature radius is. The researched to said number 5 lens of aberration correcting effectively by can be the condition for. For example, number 5 researched to said leaving the that of the silicate interface layer monolithically is an aberration correcting lens resolution and higher can be adverse lends itself to implementation. Researched to said and visa versa an aberration correcting lens number 5 satisfying resolution and higher effect; a process for manufacturing the can be the transparent glass. Lens module optical system for which is marked as a chemical researched to satisfy an. [Researched to] 0.2 < T45/T56 In formula conditions said T45 number 5 from the number 4 lens of a lens body and distance, T56 number 6 from the number 5 lens of a lens body is distance. The researched to said number 4 that are formed between the lens number 6 to lens aberrations caused by the air gap for optimizing correction can be conditions. For example, leaving the lower bound of researched to said number 6 to lens number 4 is an aberration correcting by connection of two knitted fabrics and lens and monolithically. adverse to the thinning of the lens module. And visa versa researched to said number 4 number 6 to lens satisfying an aberration correcting by connection of two knitted fabrics and lens can be. by magnifying a length of a valid lens module. On the other hand, said or occupation of the invention are following is numerically evaluated and the range may be optimized by diffractive. [Researched to] 0.2 < T45/T56 < 0.9 Lens module optical system for number 3 of a double-sided the recessed lens based on lens and lens in refractive power in at least one of shape of can be arranged to symmetric. In one example, number 1 lens refraction and if forward refraction lens number 2, number 4 is provided force of refraction of the lens number 5 may father day force of refraction of the lens. As another alternative, number 1 lens is emitted on the object side and monascus projection system number 2 is circular ring-shaped and if both side with lens is a convex shape, number 4 both sides lens is number 5 is U-shaped and convex on lens is monascus projection system side can be configured as. Similarly, a double-sided optical system for lens module of the recessed number 3 lens size is substantially based on lens refractive power can be distributed so that the absorption is asymmetric. In one example, lens module enabled to operate close to the loop. or occupation of the user. [Researched to] 0.6 < (1/f1+1/f2) / (1/f4+1/f5) < 1.6 In formula f1 said conditions and focal distance between the lens and the number 1, number 2 and focal distance between the lens and the f2, and focal distance between the lens and the number 4 f4, f5 is focal distance between the lens and the number 5. Said conditions type can meet the numerical range according to a an optical system lens number 5 to lens number 1 and an aberration compensation and achromatic correction the. Lens module and the receiver opens the mail, a key may be fabricated from. In one example, lens module optical system for a convex shape on a side opposite to the object is a number 1 lens; a lens number 2 both side with a convex shape; both side with a concave shape and a lens number 3 ; having negative refractive force which, a lens number 4 both side with a convex shape; a the recessed body number 5 lens; a convex shape on a side opposite to the object is and number 6 lens; can be constructed to. As another alternative, lens module optical system for number 1 lens having a negative refractive power; the number 2 lens; number 3 lens having refractive power; the number 4 lens; number 5 lens having negative refractive force; and negative refractive power lens number 6 having; can be constructed to. Module is lens in then describes three categories, .. Number 1 has refractive power lens. For example, number 1 lens has a negative refractive power. Number 1 on the object side and lens is a convex shape. In one example, lens surface number 1 number 1 (body) is convex and is number 2 surface (upper side) can be the recessed. Number 1 includes 2005 lens. For example, number 1 lens may it will be a non-spherical surface both material supported on both sides. Number 1 a high transmittance and optical lens made of steel, steel sheet having excellent workability, a key may be fabricated. For example, number 1 lens, a key may be fabricated plastic material. However number 1 lens of a plastic material are not limited to.. For example, number 1 lens, a key may be fabricated and made of a glass material. Number 2 has refractive power lens. For example, a defined length of lens number 2 has refractive power. Number 2 lens is a convex shape on both sides. In one example, lens surface is convex and is number 2 number 1 number 2 surface can be a convex shape. Number 2 includes 2005 lens. For example, both side with lens it will be a non-spherical surface both may number 2. Number 2 a high transmittance and optical lens made of steel, steel sheet having excellent workability, a key may be fabricated. For example, number 2 lens, a key may be fabricated plastic material. However number 2 lens of a plastic material are not limited to.. For example, number 2 lens, a key may be fabricated and made of a glass material. Number 3 has refractive power lens. For example, a negative lens number 3 has refractive power. Number 3 is the recessed a double-sided lens. In one example, lens concave and surface number 1 number 2 number 3 the recessed surface can be. Number 3 includes lens 2005. For example, number 3 lens may it will be a non-spherical surface both material supported on both sides. Number 3 a high transmittance and optical lens made of steel, steel sheet having excellent workability, a key may be fabricated. For example, number 3 lens, a key may be fabricated plastic material. However number 3 lens of a plastic material are not limited to.. For example, number 3 lens, a key may be fabricated and made of a glass material. Number 3 material high refractive index lens, a key may be fabricated. For example, number 3 lens have a protrusion/recess shape and refractive index of at least 1.60, a key may be fabricated (in this case number 3 lens has Abbe's number and which of 30 hereinafter). A small lens number 3 of such curvature also an upper refracting shape (curvature) can be. Therefore, such of production tolerances is formed like a lens number 3 according to. the apparatus and that are advantageous in the blade portion on the reference face. Furthermore, number 3 of such a lens decrease a distance between the gasket is installed on. the size of the lens module. Number 4 has refractive power lens. For example, a defined length of lens number 4 has refractive power. Number 4 lens is a convex shape on both sides. For example, number 1 number 2 number 4 lens surface is convex and is surface can be a convex shape. Number 4 includes 2005 lens. For example, both side with lens it will be a non-spherical surface both may number 4. Number 4 a high transmittance and optical lens made of steel, steel sheet having excellent workability, a key may be fabricated. For example, number 4 lens, a key may be fabricated plastic material. However number 4 lens of a plastic material are not limited to.. For example, number 4 lens, a key may be fabricated and made of a glass material. Number 5 has refractive power lens. For example, lens number 5 has a negative refractive power. Number 5 on lens is a convex shape side. For example, number 1 number 2 number 5 lens surface concave and surface can be a convex shape. Number 5 includes 2005 lens. For example, number 5 lens may it will be a non-spherical surface both material supported on both sides. Number 5 a high transmittance and optical lens made of steel, steel sheet having excellent workability, a key may be fabricated. For example, number 5 lens, a key may be fabricated plastic material. However number 5 lens of a plastic material are not limited to.. For example, number 5 lens, a key may be fabricated and made of a glass material. Number 5 material high refractive index lens, a key may be fabricated. For example, number 5 lens have a protrusion/recess shape and refractive index of at least 1.60, a key may be fabricated (in this case number 5 lens may have Abbe's number and which of 30 hereinafter). A small lens number 5 of such curvature also an upper refracting shape (curvature) can be. Therefore, such of production tolerances is formed like a lens number 5 according to. the apparatus and that are advantageous in the blade portion on the reference face. Furthermore, number 5 of such a lens decrease a distance between the gasket is installed on. the size of the lens module. Number 6 has refractive power lens. For example, a negative lens number 6 has refractive power. Number 6 an outwardly convex arcuate the object side lens is shape monascus manipulator. In one example, number 1 number 2 number 6 lens surface is convex and is is the recessed surface. Number 6 includes 2005 lens. For example, number 6 lens may it will be a non-spherical surface both material supported on both sides. Furthermore, number 6 includes inflection lens. For example, number 1 of lens number 6 to the optical axis center surface and convex, concave and around the optical axis, at edge can be a convex shape. Similarly, lens number 2 number 6 are recessed in to the optical axis center surface electrically to first terminals edge multivalent can be a convex shape. Number 6 a high transmittance and optical lens made of steel, steel sheet having excellent workability, a key may be fabricated. For example, number 6 lens, a key may be fabricated plastic material. However number 6 lens of a plastic material are not limited to.. For example, number 6 lens, a key may be fabricated and made of a glass material. 1300 M high-resolution Image sensor (mega pixel) can be adapted to implement a. For example, Image sensor a unit size of a pixel which configured micro 1.12 can be m hereinafter. Lens module consists of to have a wide angle of view. For example, a optical system for lens module 80 may have angle of view of degree or more. Furthermore, the lens module consists of to have (TTL) and a relatively short length. For example, lens module is composed of a entire length of an optical system (lens body upper surface from distance number 1) hereinafter the 4.30 can be. Therefore, the present lens module can be an inner wall of. Number 1 in the embodiment according to reference to 1 also describes a lens module. Lens module (100) the number 1 lens (110), number 2 lens (120), number 3 lens (130), number 4 lens (140), number 5 lens (150), number 6 lens (160) includes the optical composed. Furthermore, lens module (100) the infrared cut filter (70) mounted on an inner side (80) includes. Furthermore, lens module (100) as an iris diaphragm further includes (ST: stop). For example, lens and number 1 the diaphragm can be lens number 2. In the present in the embodiment, number 1 lens (110) which the having negative refractive force, surface on an upper side is convex and is body has the recessed. Number 2 lens (120) the are arranged in this order from the, body is is convex and is has a convex shape. Number 3 lens (130) which the having negative refractive force, side opposite to the object is concave and is has a concave shape. Number 4 lens (140) the are arranged in this order from the, body is is convex and is has a convex shape. Number 5 lens (150) having negative refractive force which the, side opposite to the object is concave and is has a convex shape. Number 6 lens (160) which the having negative refractive force, surface on an upper side is convex and is body has the recessed. Furthermore, on the top side and body of lens number 6, respectively, at least one of turning point is formed. The present in the embodiment number 1 in lens (110), number 3 lens (130), number 5 lens (150), number 6 lens (160) of a plaque has as. having negative refractive force both. Is selected from them number 5 lens (150) has refractive power becomes one of the strongest bcch carries, number 6 lens (160) has the refractive power. Also 2 and Figure 3 MTF characteristics and aberration properties of lens module is represents a degree. Module is lens Figure 4 properties of lens is tables. In Figure 4 the 2 and 1 number surface of lens number 1 and number 2 number 1 surface (body) exhibit surface (upper side), surface number 3 and 4 the number 2 number 1 number 2 surface and exhibits surface of lens. In such a way surface number 5 to 12 the number 3 lens to number 6 lens exhibits number 1 number 2 surface and each surface. Furthermore, surface number 13 and 14 of the infrared filter number 1 number 2 surface and exhibits surface. Module is lens Figure 5 aspheric lenses is table value. A cross shaft in Figure 5 the number 1 to number 6 lens surface-number lens means, longitudinal axis of the lens exhibits characteristics corresponding to the each side. Reference to 6 also describes the number 2 in the embodiment according to lens module. Lens module (200) the number 1 lens (210), number 2 lens (220), number 3 lens (230), number 4 lens (240), number 5 lens (250), number 6 lens (260) includes the optical composed. Furthermore, lens module (200) the infrared cut filter (70) mounted on an inner side (80) includes. Furthermore, lens module (200) as an iris diaphragm further includes (ST: stop). For example, lens and number 1 the diaphragm can be lens number 2. In the present in the embodiment, number 1 lens (210) which the having negative refractive force, surface on an upper side is convex and is body has the recessed. Number 2 lens (220) the are arranged in this order from the, body is is convex and is has a convex shape. Number 3 lens (230) having negative refractive force which the, side opposite to the object is concave and is has a concave shape. Number 4 lens (240) the are arranged in this order from the, body is is convex and is has a convex shape. Number 5 lens (250) having negative refractive force which the, side opposite to the object is concave and is has a convex shape. Number 6 lens (260) which the having negative refractive force, surface on an upper side is convex and is body has the recessed. Furthermore, on the top side and body of lens number 6, respectively, at least one of turning point is formed. The present in the embodiment number 1 in lens (210), number 3 lens (230), number 5 lens (250), number 6 lens (260) has of a plaque having negative refractive force both as.. Is selected from them number 5 lens (250) has refractive power becomes one of the strongest bcch carries, number 6 lens (260) has the refractive power. Figure 8 and 7 also MTF characteristics and aberration properties of lens module is represents a degree. Figure 9 lens module is lens properties of is tables. In Figure 9 the 2 and 1 number surface of lens number 1 and number 2 number 1 surface (body) exhibit surface (upper side), surface number 3 and 4 the number 2 number 1 number 2 surface and exhibits surface of lens. In such a way surface number 5 to 12 the number 3 lens to number 6 lens exhibits number 1 number 2 surface and each surface. Furthermore, surface number 13 and 14 of the infrared filter number 1 number 2 surface and exhibits surface. Module is lens Figure 10 aspheric lenses is table value. A cross shaft in Figure 10 the number 1 to number 6 lens surface-number lens means, longitudinal axis of the lens exhibits characteristics corresponding to the each side. Reference to 11 also describes the number 3 in the embodiment according to lens module. Lens module (300) the number 1 lens (310), number 2 lens (320), number 3 lens (330), number 4 lens (340), number 5 lens (350), number 6 lens (360) includes the optical composed. Furthermore, lens module (300) the infrared cut filter (70) mounted on an inner side (80) includes. Furthermore, lens module (300) as an iris diaphragm further includes (ST: stop). For example, lens and number 1 the diaphragm can be lens number 2. In the present in the embodiment, number 1 lens (310) which the having negative refractive force, surface on an upper side is convex and is body has the recessed. Number 2 lens (320) the are arranged in this order from the, body is is convex and is has a convex shape. Number 3 lens (330) having negative refractive force which the, side opposite to the object is concave and is has a concave shape. Number 4 lens (340) are arranged in this order from the, body is is convex and is has a convex shape. Number 5 lens (350) which the having negative refractive force, side opposite to the object is concave and is has a convex shape. Number 6 lens (360) having negative refractive force which the, body surface on an upper side is convex and is has the recessed. Furthermore, on the top side and body of lens number 6, respectively, at least one of turning point is formed. The present in the embodiment number 1 in lens (310), number 3 lens (330), number 5 lens (350), number 6 lens (360) has of a plaque having negative refractive force both as.. Is selected from them number 5 lens (350) has refractive power becomes one of the strongest bcch carries, number 6 lens (360) has the refractive power. Figure 13 and 12 also MTF characteristics and aberration properties of lens module is represents a degree. Figure 14 lens module is lens properties of is tables. In Figure 14 the 2 and 1 number surface of lens number 1 and number 2 number 1 surface (body) exhibit surface (upper side), surface number 3 and 4 the number 2 number 1 number 2 surface and exhibits surface of lens. In such a way surface number 5 to 12 the number 3 lens to number 6 lens exhibits number 1 number 2 surface and each surface. Furthermore, surface number 13 and 14 of the infrared filter number 1 number 2 surface and exhibits surface. Module is lens Figure 15 aspheric lenses is table value. A cross shaft in Figure 15 the number 1 to number 6 lens surface-number lens means, longitudinal axis of the lens exhibits characteristics corresponding to the each side. Reference to 16 also describes the number 4 in the embodiment according to lens module. Lens module (400) the number 1 lens (410), number 2 lens (420), number 3 lens (430), number 4 lens (440), number 5 lens (450), number 6 lens (460) includes the optical composed. Furthermore, lens module (400) the infrared cut filter (70) mounted on an inner side (80) includes. Furthermore, lens module (400) as an iris diaphragm further includes (ST: stop). For example, lens and number 1 the diaphragm can be lens number 2. In the present in the embodiment, number 1 lens (410) having negative refractive force which the, body surface on an upper side is convex and is has the recessed. Number 2 lens (420) the are arranged in this order from the, body is is convex and is has a convex shape. Number 3 lens (430) which the having negative refractive force, side opposite to the object is concave and is has a concave shape. Number 4 lens (440) the are arranged in this order from the, body is is convex and is has a convex shape. Number 5 lens (450) having negative refractive force which the, side opposite to the object is concave and is has a convex shape. Number 6 lens (460) having negative refractive force which the, body surface on an upper side is convex and is has the recessed. Furthermore, on the top side and body of lens number 6, respectively, at least one of turning point is formed. The present in the embodiment number 1 lens in (410), number 3 lens (430), number 5 lens (450), number 6 lens (460) has of a plaque having negative refractive force both as.. Is selected from them number 5 lens (450) has refractive power becomes one of the strongest bcch carries, number 6 lens (460) has the refractive power. Also 17 and Figure 18 MTF characteristics and aberration properties of lens module is represents a degree. Figure 19 lens module is lens properties of is tables. In Figure 19 the 2 and 1 number surface of lens number 1 and number 2 number 1 surface (body) exhibit surface (upper side), surface number 3 and 4 the number 2 number 1 number 2 surface and exhibits surface of lens. In such a way surface number 5 to 12 the number 3 lens to number 6 lens exhibits number 1 number 2 surface and each surface. Furthermore, surface number 13 and 14 of the infrared filter number 1 number 2 surface and exhibits surface. Module is lens Figure 20 aspheric lenses is table value. A cross shaft in Figure 20 the number 1 to number 6 lens surface-number lens means, longitudinal axis of the lens exhibits characteristics corresponding to the each side. Reference to 21 also describes the number 5 in the embodiment according to lens module. Lens module (500) the number 1 lens (510), number 2 lens (520), number 3 lens (530), number 4 lens (540), number 5 lens (550), number 6 lens (560) includes the optical composed. Furthermore, lens module (500) the infrared cut filter (70) mounted on an inner side (80) includes. Furthermore, lens module (500) as an iris diaphragm further includes (ST: stop). For example, lens and number 1 the diaphragm can be lens number 2. In the present in the embodiment, number 1 lens (510) which the having negative refractive force, surface on an upper side is convex and is body has the recessed. Number 2 lens (520) the are arranged in this order from the, body is is convex and is has a convex shape. Number 3 lens (530) which the having negative refractive force, side opposite to the object is concave and is has a concave shape. Number 4 lens (540) the are arranged in this order from the, body is is convex and is has a convex shape. Number 5 lens (550) having negative refractive force which the, side opposite to the object is concave and is has a convex shape. Number 6 lens (560) which the having negative refractive force, surface on an upper side is convex and is body has the recessed. Furthermore, on the top side and body of lens number 6, respectively, at least one of turning point is formed. The present in the embodiment number 1 in lens (510), number 3 lens (530), number 5 lens (550), number 6 lens (560) has of a plaque having negative refractive force both as.. Is selected from them number 5 lens (550) has refractive power becomes one of the strongest bcch carries, number 6 lens (560) has the refractive power. Figure 23 and 22 also MTF characteristics and aberration properties of lens module is represents a degree. Figure 24 lens module is lens properties of is tables. In Figure 24 the 2 and 1 number surface of lens number 1 and number 2 number 1 surface (body) exhibit surface (upper side), surface number 3 and 4 the number 2 number 1 number 2 surface and exhibits surface of lens. In such a way surface number 5 to 12 the number 3 lens to number 6 lens exhibits number 1 number 2 surface and each surface. Furthermore, surface number 13 and 14 of the infrared filter number 1 number 2 surface and exhibits surface. Module is lens Figure 25 aspheric lenses is table value. A cross shaft in Figure 25 the number 1 to number 6 lens surface-number lens means, longitudinal axis of the lens exhibits characteristics corresponding to the each side. Reference to 26 also describes the number 6 in the embodiment according to lens module. Lens module (600) the number 1 lens (610), number 2 lens (620), number 3 lens (630), number 4 lens (640), number 5 lens (650), number 6 lens (660) includes the optical composed. Furthermore, lens module (600) the infrared cut filter (70) mounted on an inner side (80) includes. Furthermore, lens module (600) as an iris diaphragm further includes (ST: stop). For example, lens and number 1 the diaphragm can be lens number 2. In the present in the embodiment, number 1 lens (610) having negative refractive force which the, body surface on an upper side is convex and is has the recessed. Number 2 lens (620) the are arranged in this order from the, body is is convex and is has a convex shape. Number 3 lens (630) having negative refractive force which the, side opposite to the object is concave and is has a concave shape. Number 4 lens (640) the are arranged in this order from the, body is is convex and is has a convex shape. Number 5 lens (650) having negative refractive force which the, side opposite to the object is concave and is has a convex shape. Number 6 lens (660) having negative refractive force which the, body surface on an upper side is convex and is has the recessed. Furthermore, on the top side and body of lens number 6, respectively, at least one of turning point is formed. The present in the embodiment number 1 in lens (610), number 3 lens (630), number 5 lens (650), number 6 lens (660) has of a plaque having negative refractive force both as.. Is selected from them number 1 lens (610) has refractive power becomes one of the strongest bcch carries, number 6 lens (660) has the refractive power. Figure 28 and 27 also MTF characteristics and aberration properties of lens module is represents a degree. Figure 29 lens module is lens properties of is tables. In Figure 29 the 2 and 1 number surface of lens number 1 and number 2 number 1 surface (body) exhibit surface (upper side), surface number 3 and 4 the number 2 number 1 number 2 surface and exhibits surface of lens. In such a way surface number 5 to 12 the number 3 lens to number 6 lens exhibits number 1 number 2 surface and each surface. Furthermore, surface number 13 and 14 of the infrared filter number 1 number 2 surface and exhibits surface. Module is lens Figure 30 aspheric lenses is table value. A cross shaft in Figure 30 the number 1 to number 6 lens surface-number lens means, longitudinal axis of the lens exhibits characteristics corresponding to the each side. Table number 1 in the embodiment to number 6 in the embodiment according to the 1 exhibits an optical property of the lens module. 4.00-4.40 has a generally lens module has total focal length (f). Number 1 focal distance between the lens and lens module in (f1) has an essentially -50.0 - - 10.0 can be be defined in a range. Lens module in number 2 1.70-2.50 has an essentially (f2) focal distance between the lens and can be be defined in a range. Lens module in number 3-3.60 - - 2.70 has an essentially (f3) focal distance between the lens and can be be defined in a range. Lens module in 2.0-2.40 has an essentially (f4) number 4 focal distance between the lens and can be be defined in a range. Number 5 focal distance between the lens and lens module in (f5) has an essentially -1000 - - 17.0 can be be defined in a range. Lens module in number 6-3.0 - - 2.0 has an essentially (f6) focal distance between the lens and can be be defined in a range. Lens module in lens and number 1 number 2 (f12) has an essentially 3.9-5.9 synthesis of lens focal length can be be defined in a range. Lens module in optical system generally may have an overall length of 4.0-4.40 can be be defined in a range. Lens module in a generally BFL can be be defined in a range 0.50-0.70. Lens module of comonation NTSC and svhs a generally 75.0-95.0 (FOV: Field of View). surface may be in the range. Table 2 or occupation numerical measurement of the range and number 1 in the embodiment to number 6 in the embodiment according to lens module relational equations value of. Table 2 collected and is found in, or occupation of the user number 1 in the embodiment to number 6 in the embodiment according to. satisfactory in both of the lens module. The present invention refers to in the embodiment described or more are not limited only, typically encountered in the present invention is in the field of the hereinafter grow having knowledge of claim of is the subject matter of the technical idea of the present invention out such a range that causes no in the has a watch upper surface 162 may is embodiment. 100, 200, 300, 400, 500, 600 Lens module 110, 210, 310, 410, 510, 610 Number 1 lens 120, 220, 320, 420, 520, 620 Number 2 lens 130, 230, 330, 430, 530, 630 Number 3 lens 140, 240, 340, 440, 540, 640 Number 4 lens 150, 250, 350, 450, 550, 650 Number 5 lens 160, 260, 360, 460, 560, 660 Number 6 lens 70 Infrared cut filter 80 Image sensor The present invention provides a lens module comprising: a first lens having a side with a convex surface; a second lens having both convex surfaces; a third lens having both concave surfaces; a fourth lens having a minus refractive power, having both convex surfaces; a fifth lens having a side with a concave surface; and a sixth lens having a side with a convex surface. The lens module is able to achieve high resolution. COPYRIGHT KIPO 2016 A side opposite to the object is a convex shape number 1 lens; a lens number 2 both side with a convex shape; both side with a concave shape and a lens number 3 ; having negative refractive force which, a lens number 4 both side with a convex shape; a the recessed body number 5 lens; and body is convex and is surface on an upper side to one or more of turning point number 6 lens shaped is formed; includes, from the object side lens said number 6 to lens said number 1 sequentially side and a lens that is positioned module. According to Claim 1, said number 1 the recessed surface on an upper side lens a lens module. According to Claim 1, said number 5 lens surface on an upper side of which are convex, and the shaped lens module. According to Claim 1, said number 6 the recessed surface on an upper side lens a lens module. According to Claim 1, a lens module satisfying researched to < -4.0 [researched to] f1/f (said conditions in formula f the number 1 lens to said number 6 small of the optical entire focal length and, f1 is focal distance between the lens and the number 1) According to Claim 1, satisfying researched to a lens module [researched to] < -7.0 f5/f (said conditions in formula f the number 1 lens to said number 6 small of the optical entire focal length and, f5 is focal distance between the lens and the number 5) According to Claim 1, a lens module satisfying researched to 6.0 < TTL/BFL [researched to] (said conditions in formula TTL the number 1 lens body from is a distance from the and, BFL the number 6 lens is a distance from the from of a.) According to Claim 1, satisfying researched to a lens module. [Researched to] (r9-r10) / (r9 + r10) < -6.0 (said conditions in formula r9 the number 5 lens body of curvature radius and, r10 the number 5 is curvature radius of of a lens) According to Claim 1, satisfying researched to a lens module. 70 [researched to] < r1/T12 (said conditions in formula r1 the number 1 lens body of curvature radius and, T12 the number 1 lens of a from. is a distance from the body of lens said number 2) According to Claim 1, satisfying researched to a lens module. [Researched to] 0.2 < T45/T56 (said conditions in formula T45 the number 4 lens of a from said number 5 lens body is a distance from the and, T56 the number 5 lens of a from lens is a distance from the body said number 6.) Number 1 lens having negative refractive force; the number 2 lens; number 3 lens having refractive power; the number 4 lens; number 5 lens having negative refractive force; and negative refractive power has, one or more surface on an upper side to shaped is formed of turning point number 6 lens; includes, from the object side lens said number 6 to lens said number 1 sequentially side and a lens that is positioned module. Number 1 lens having negative refractive force; the number 2 lens; number 3 lens having negative refractive force; the number 4 lens; number 5 lens having negative refractive force; has and refraction power, surface on an upper side to one or more of turning point number 6 lens shaped is formed; includes, from the object side lens said number 6 to lens said number 1 sequentially side and a lens that is positioned module. According to Claim 12, said number 6 lens lens module having a negative refractive power. Is located at sequential from the object side, number 1 number 6 to lens having refractive power lens, said number 1 lens, said number 2 lens, said number 4 lens, a double-sided lens said number 5 said number 3 of the recessed reference lens defined refractive power and negative refractive power is desirable and a lens that is positioned symmetric module. According to Claim 14, said number 1 lens, said number 2 lens, said number 4 lens, said number 5 lens optical axis of lens based on said number 3 lens center of an asymmetric shape from configured lens module. According to Claim 14, the object side lens said number 1 an outwardly convex arcuate meniscus shaped lens module. According to Claim 14, said number 2 lens a lens module both side with a convex shape. According to Claim 14, satisfying researched to a lens module. [Researched to]

0.6 < (1/f1+1/f2) / (1/f4+1/f5) < 1.6 (said conditions in formula f1 the number 1 focal distance between the lens and and, f2 the number 2 focal distance between the lens and and, f4 the number 4 focal distance between the lens and and, f5 is focal distance between the lens and the number 5)