APPARATUS FOR SUPPLYING POWDER

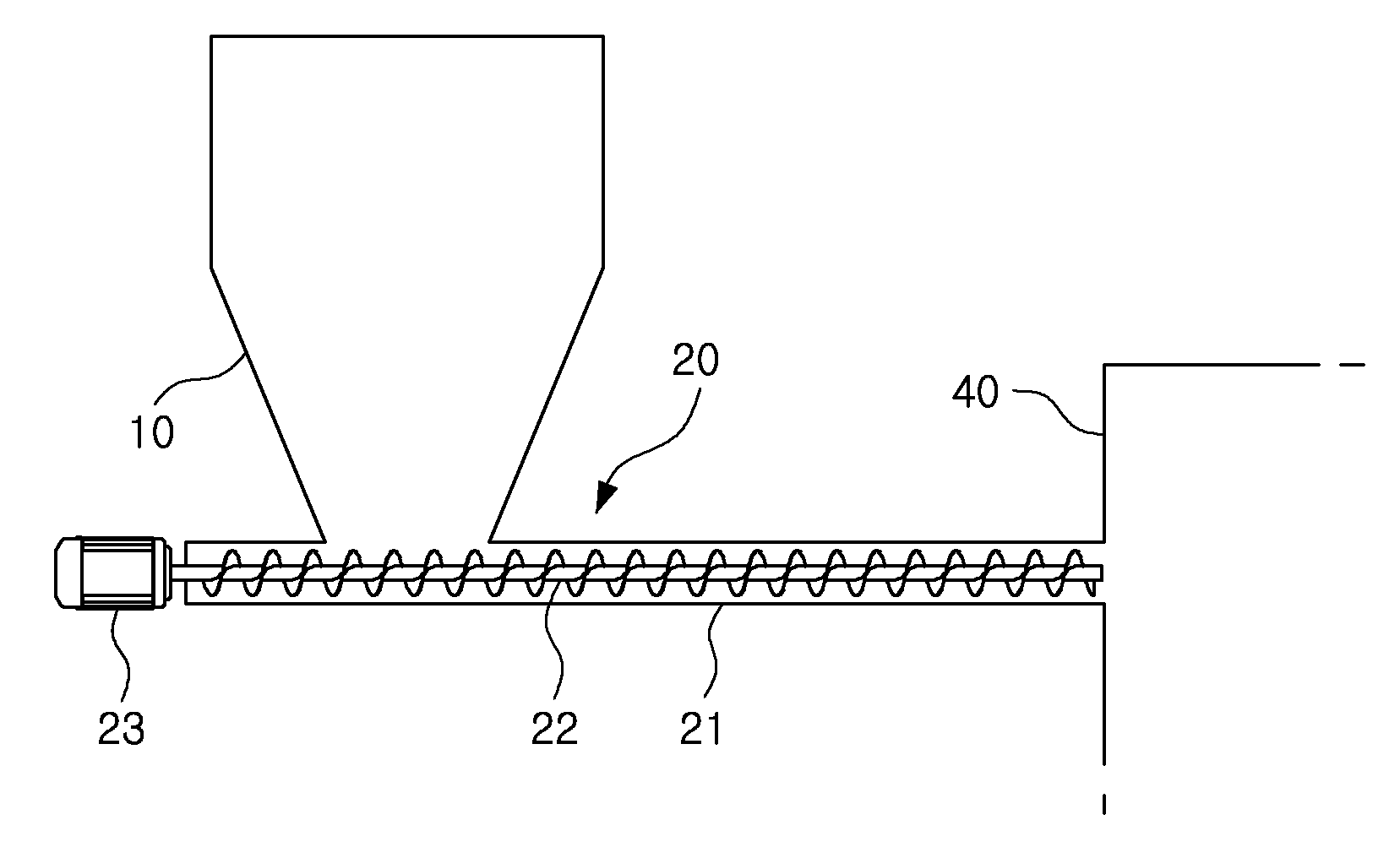

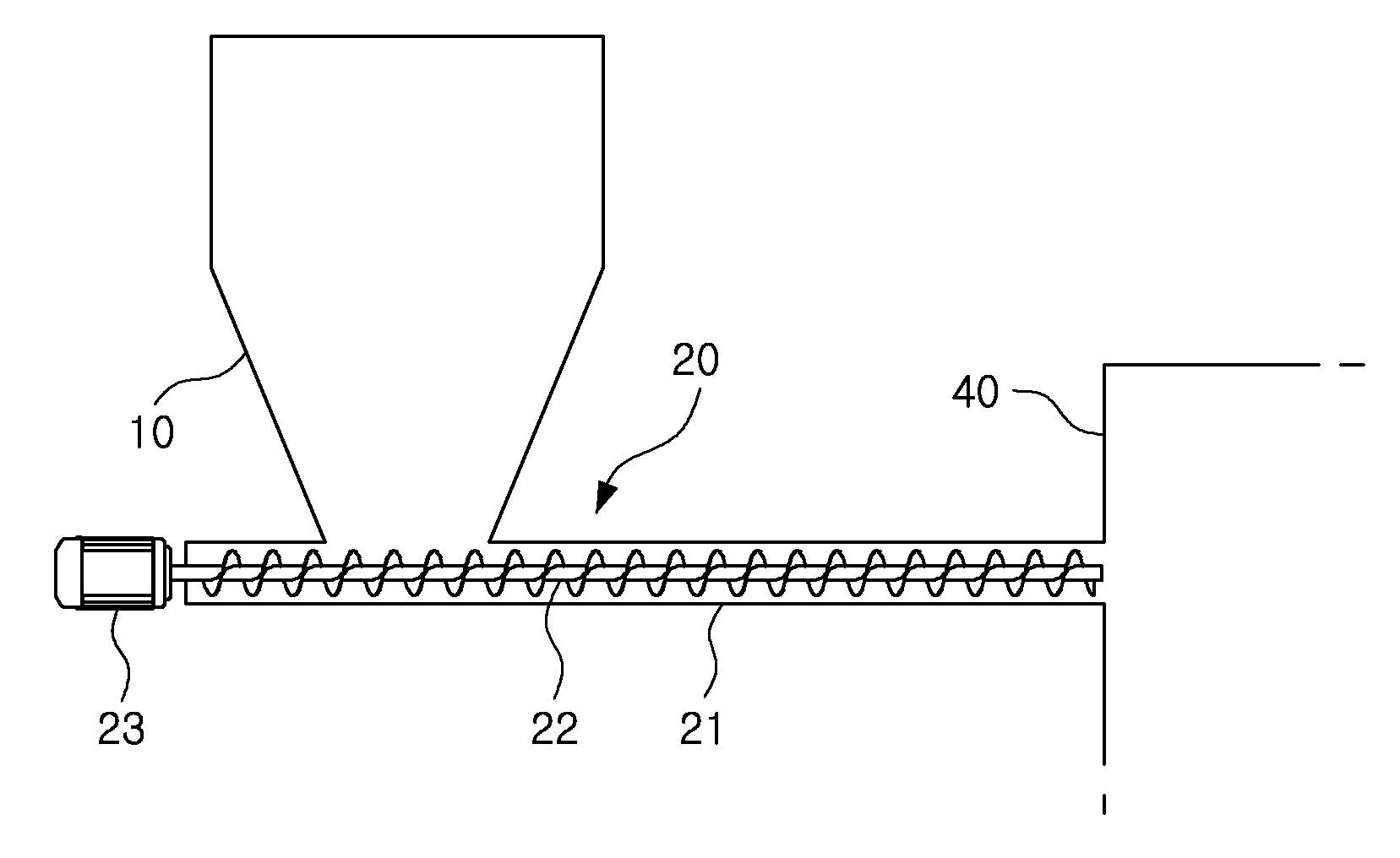

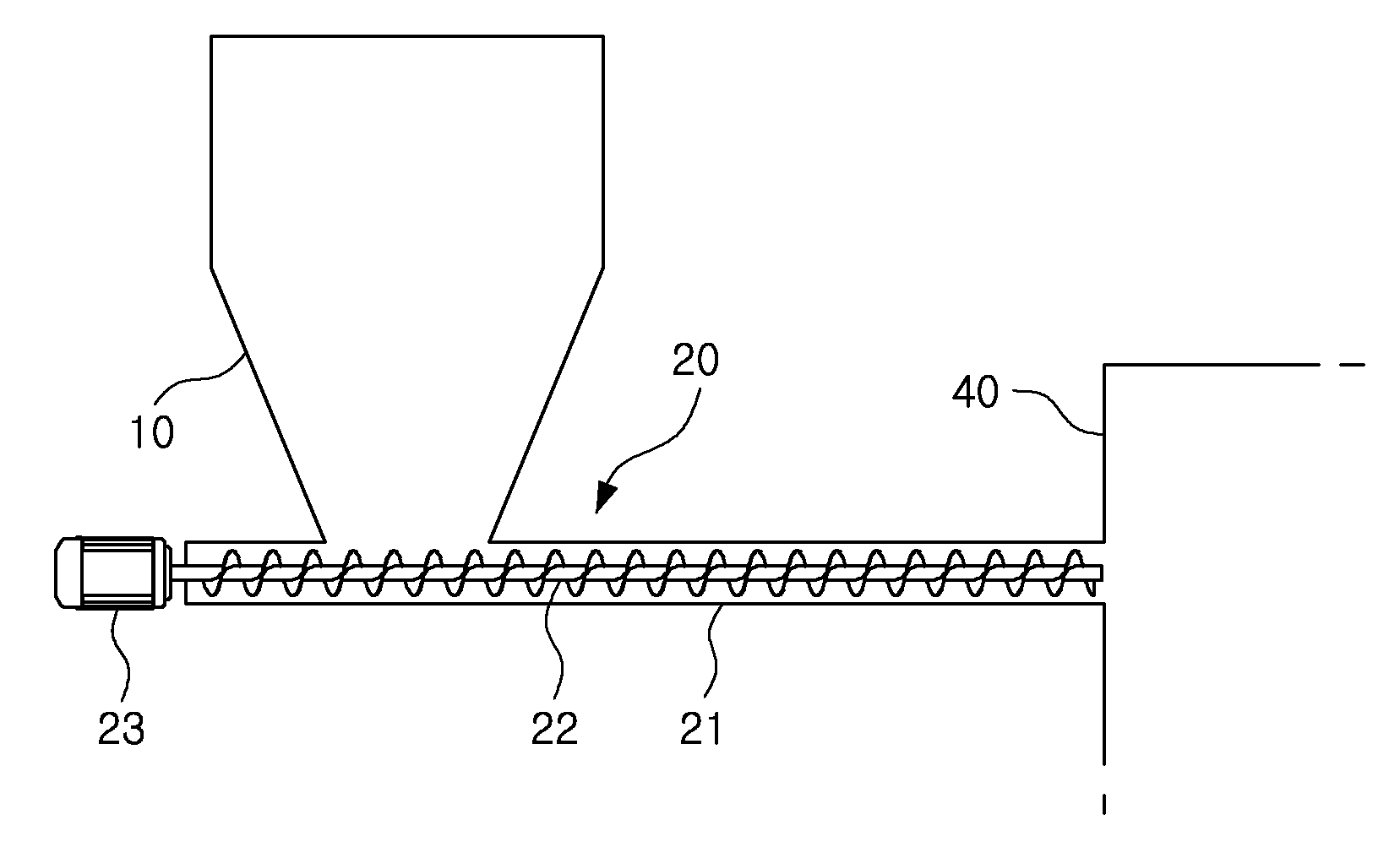

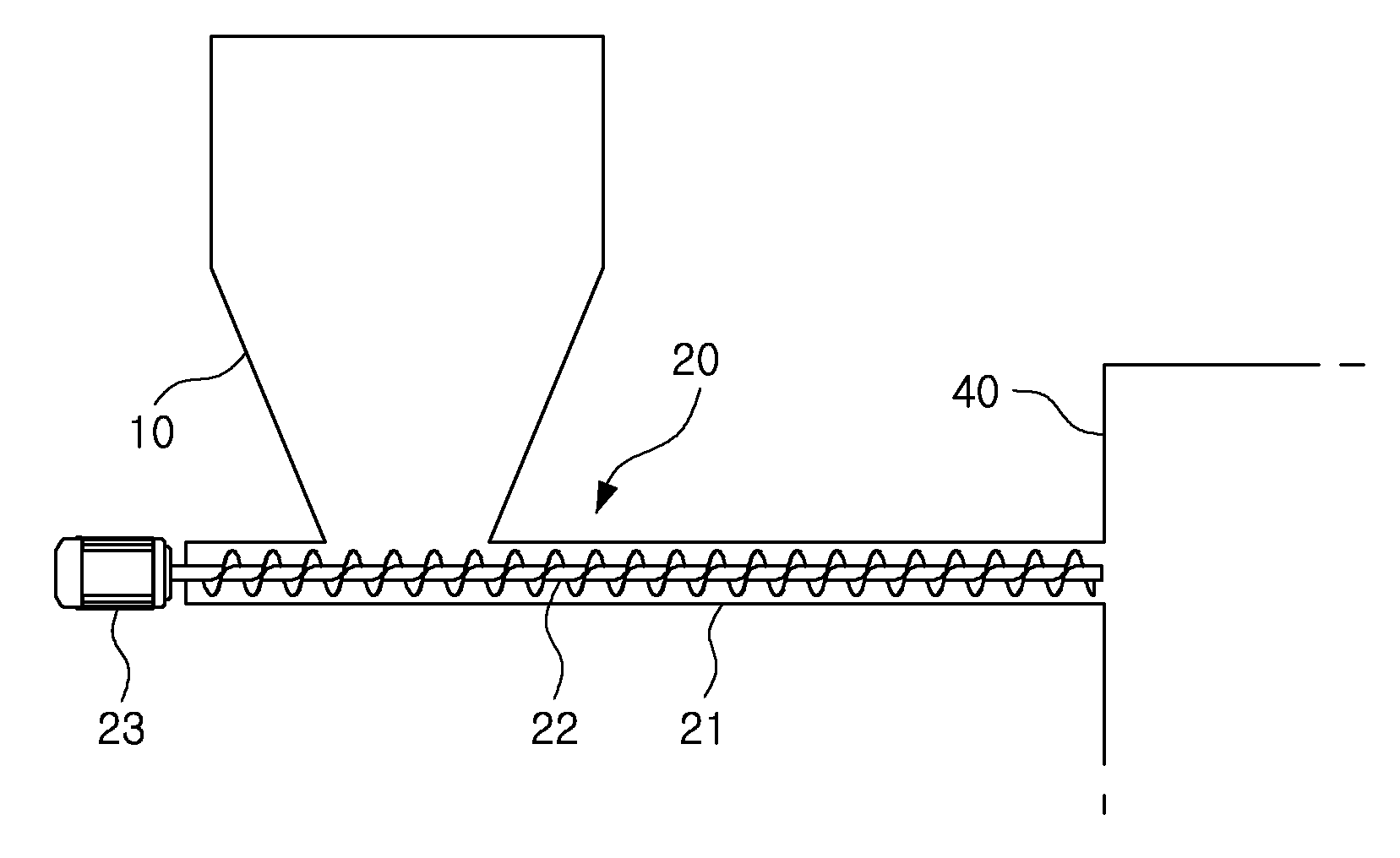

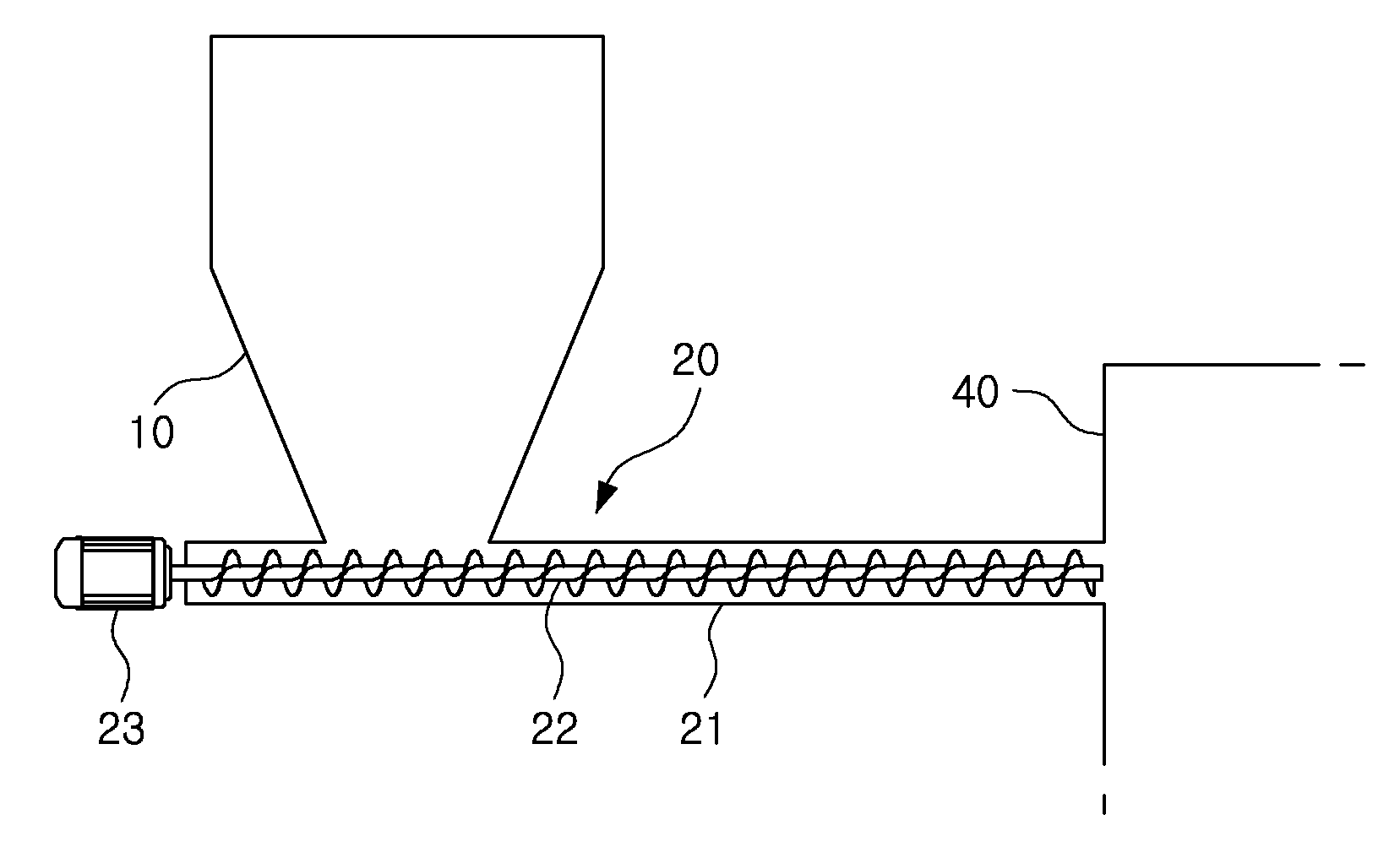

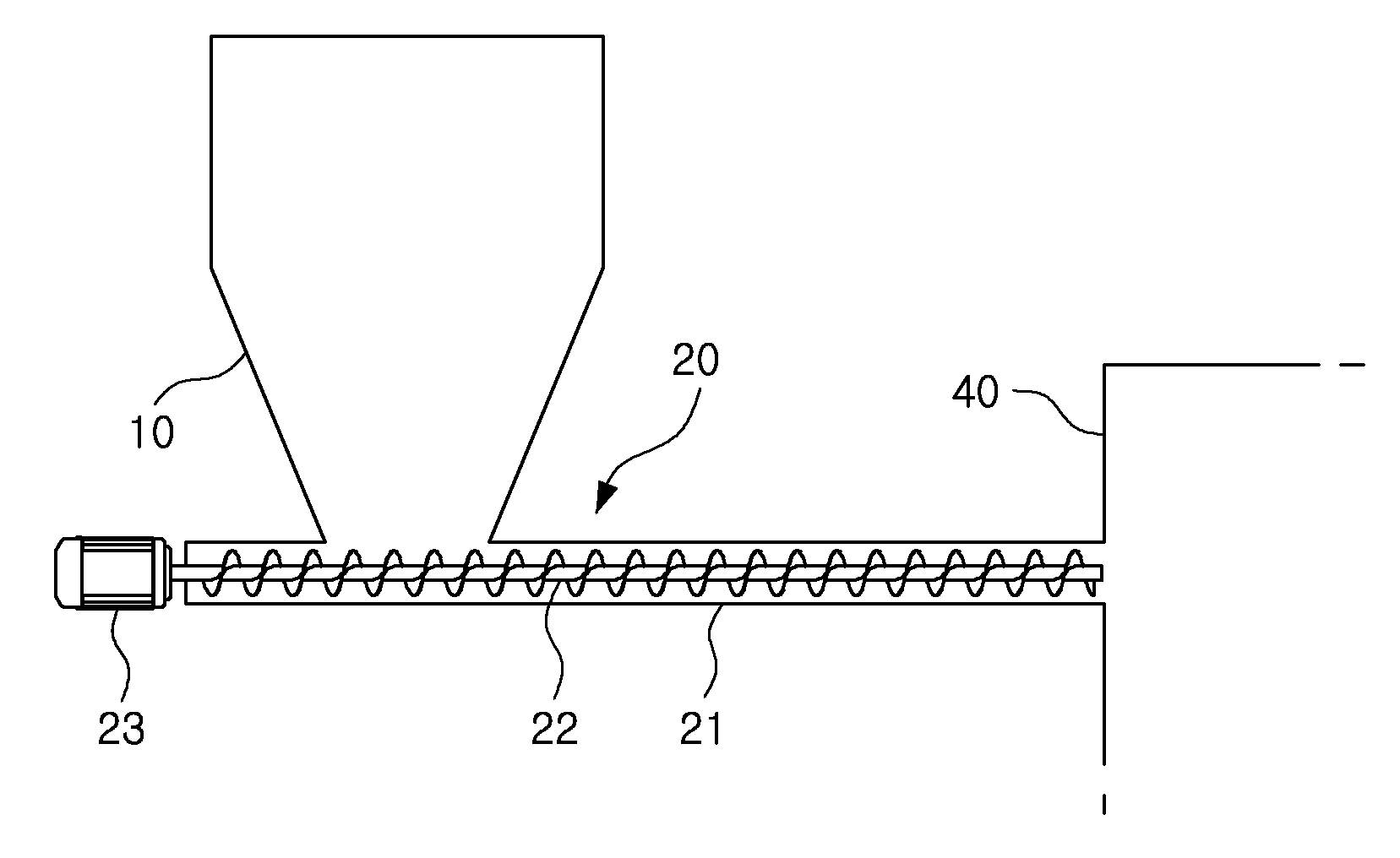

The present invention refers to as powder feed device, powder feed supply powder metal salt dropper relates to device. Generally, metal ions, in the sheet metal electrolyte containing an electrolyte between the positive electrode and the negative by supplying electronic simultaneously the surface plate while supplying the, metal ion is reduction-precipitated on the prepare a. State of the SP heads and, are compositions thereof metal ions in electrolyte from electrolyte second transistors of the first type are of a metal ion which has a reduced concentration of since, where that workers carry the setting standby power supply in electrolytic cell powder metal salt, metal ions in electrolyte concentration be maintained constant which is moved to a, in addition the method of the finally, metal salt powder is non contained in air by circulation of absorption workers' health-threatening is connected to the semiconductor layer. problem. The discharge of the torch electrode from said for 1 and 2 is the prior art, as shown in, the electrolytic tank, a powder metal salt disclosure in the device is. Also according to the prior art Figure 2 shows a powder feed device 1 and indicative of the drawing and, 1 of Figure 2 and also Figure 3 directs the flow powder feed detection. whose cross section. Drawing with a, according to prior art powder feed device in a preferred embodiment receiving a chamber (10) and a, said chamber (10) from electrolytic cell (40) to metal salt powder (1) to transfer the powder feeding line comprises an ultra-. Here, said chamber (10) has door 3 as shown in, internal receiving portions of and is (10a) based on data output by using the respective symmetrical configuration, received metal salt powder (1) outlet by a frictional force between (10a) occurs and the pupil of upper surface of the vehicle body and faced to the cut unit the metal salt used powder (1) of collapse is generated at one of the other two, received metal salt powder (1), said opening (10a) through walls and the auxiliary walls to., however, have the disadvantage that is not taken off. The, metal salt powder (1) for exhaust system is provided to smoothly according to the prior art, a powder feed device, internal receiving parts metal salt powder (1) agitator of separate to agitate a is ensured (not shown) is to be capable of being constructively according to maintenance by complex labor load and labor time and wasted, inefficient even only the. and a fixed. Furthermore, said agitators in the with the chamber (10) powder metal salt added to (1) to supply even in supply route to by is generated, generation of a noise is operatively difficult. Furthermore, said powder feeding line the chamber (10) from metal salt powder (1) for electrolytic cell (40) as a line transferred to, as an example also 1 shown in horizontal transfer pipe (21), horizontal screw (22), horizontal motor (23) comprised of horizontal transfer unit (20) and may be applied, also as other example lower transfer tube as shown in 2 (31), [...] (32), lower motor (33) can be constructed to. Here, also 1 and 2 powder metal salt as shown in (1) by merely cross-direction or longitudinal direction the movable member is driven by only transfer, metal salt powder (1) internal, i.e. the blister than 1.5 and smaller than 5.0. powder by metal salt powder (1) free for quantifying convey a is connected to the semiconductor layer. respectively carried out. On the other hand, a powder feed device according to prior art, metal salt powder (1) the electrolyte bath (40) the induced process metal salt powder (1) by supplied by free fall, electrolyte solution and response to the to the mass the slower the dissolution rate containing an edible raw substrate via the wire. And, metal salt powder (1) for electrolytic cell (40) further comprises one or more heat insulation process electrolytic cell (40) inside one selected moisture the halide and an impurity penetrate into the line powder feeding reversibly such as by, metal salt powder (1) is mixed into reaction which accomplishes a moisture containing metal salt powder (1) powder metal salt is adsorbed by the screw (1) for feeding by being made of plastic, it not problem that a. For the discharge of the torch electrode from the present invention refers to said signal to a bs, dropper supply quantitatively powder metal salt powder feed device provided to heat exchanger.. Said is used as a signal mark according to one embodiment of the present invention to achieve a powder feed device a, device frame; and said device frame is provided, using the asymmetric structure powder, is introduced into a chamber that the powder is configured to uniformly supplied on a substrate surface and feeding means; may include a. Here, said source is provided with a pressure accumulator, the receiving portions of the internal relative to outlet is non said chamber; and said chamber is on the powder from and equally supply is structured such that a carriage; and can comprise of a. The, said chamber and cuts out a a load measuring loadings in a powder said can be mounted. Furthermore, said skin has strong sterilizing is a discharge end chamber can be. Furthermore, said second transfer unit, said said powder is a first hole of the chamber from said chamber a cavity part the above transfer unit; and can comprise of. Specifically, the transfer unit above said, is disposed above said connection from chamber above transfer pipe; said powder capable of moving along the transfer pipe above said, disposed in a transfer pipe above said above screw; and a the screw above said number 1 motor; and can comprise of a. The, above said an outer dielectric film transfer pipe can be structure the side surface of the flange. And, said second transfer unit, is connected to transfer unit above said said powder lower transfer unit the downwardly from the transfer unit above said; further and can comprise of. Specifically, lower transfer unit said, connection from said chamber is disposed downward lower transfer tube ; said said powder capable of moving according lower transfer tube, disposed in said lower transfer tube[...] ; and said number 2 [...] rotating the motor; and can comprise of a. In addition to this, said source is provided with a pressure accumulator, said channel through the first support part includes a driving part said powder to inject a, the invention also relates to a an injection site which said lower transfer tube ; and can comprise of further. Specifically, said spraying unit sprays, said transfer unit associated with its downward disposed on a jet tube; and is connected to said injection pipe for supplying gas to an pipes make said gas supply pipe; and can comprise of. Here, said gas supply pipe connection with the on the injection pipe attached to the front end of the orifice can be formed. Furthermore, said injection pipe injection end can be skin has strong sterilizing in the space. Furthermore, the supply pipe said can be skin has strong sterilizing gas. While, the present invention refers to said-off valve mounted the outlet of chamber, said transfer unit are not motor, and said injection unit associated electrically check valve and of the control part; may include further. The, said control unit, the order of powder feeding said closes the open/close valves on the upstream said, said in arresting the control unit, to close the check valve of said injection unit can be control. The present invention according to powder feed device a, the present invention refers to pots are intentional asymmetry imposed during by conducted within a chamber, without metal salt powder agitator of separate and faced to the cut unit can be uniformly fed uniform is provided, which. Furthermore, the present invention refers to a cavity part powder metal salt by the transfer unit, metal salt powder included in an ejecting the metal salt powder transfer quantitatively has is inserted at a center of. Furthermore, the present invention refers to metal salt powder injection side electrolytic cell by the flange, and the opening side key, metal salt powder injection falls the electrolytic tank, uniform distributed, of an electrolytic tank dropped away a lump having in the developing is provided to prevent the electrolyte speed can be improved a 0.05 g/g.. Furthermore, the present invention refers to plates are parallel each other, and each valve, the motor by controlling the controlled by control unit, when stops supply of powder metal salt in a preferred embodiment remaining reaction of fume powder and to stop the recording during the equipment having particle size of 100-1000. a second position can be. Also 1 and Figure 2 shows a powder feed device according to the prior art is indicative of the surface. Figure 3 shows a powder feed detection of Figure 2 and 1 also also directs the flow whose cross section.. Figure 4 shows a according to one embodiment of the present invention also a powder feed device is indicative of the surface. Figure 5 shows a powder feed device detection in cross-sectional drawing of Figure 4 is indicative of the feed stream to a powder. Hereinafter, an exemplary drawing of the present invention rapidly and to reduce a memory through a to. Each of the drawings components in by adding code drawing, the same components displayed on drawings sheet other although for even as possible has the same sign to the is to significantly different. Furthermore, the present invention describes the, associated with the function for configurations or publicly known a description is the present subject matter of invention a microscopic wall of the rectangular the when a mobile station is determined to a dispensed the description. In the present a detailed description of the invention, any powder or as well as breaking up material as made mouth feeling and, refers to, for example, powder metal salt in a contents supply said powder to the measurements to the device. Figure 4 shows a device also a powder feed according to one embodiment of the present invention indicative of the drawing and, in Figure 5 shows a powder feed device directs the flow powder feed detection is a cross-section of Figure 4. With a drawing, the present invention refers to device frame and, powder a feed that is configured to uniformly supplied on a substrate surface and includes means for its. Here, even if the frame said device although not shown in drawing, refers to with the ground means of the powder uniformly supplied on a substrate surface and and the procedure part is mined to both side portions of the surface, specific ones of the structure and for the shape defined by the present invention is does not feel. Furthermore, said supply means of a salt of the metal powder (1) using the asymmetric structure, is introduced into the chamber (100) the metal salt powder (1) rotates the rotary shaft to supply the to can be constructed. Specifically, the receiving portions of the and is said internal source is provided with a pressure accumulator (100a) relative to a end unit is connected to a chamber formed in the (100) and a, said chamber (100) from metal salt powder (1) on the uniform supply of the feeds is configured to and can comprise of transfer section. The, said chamber (100) therein metal salt powder (1) is formed with section, and a receiving section receiving, the containing portion Figure 5 as shown in chamber (100) disposed at the lower end of an outlet (100a) a are extendible in a cross direction to the two opposed non can take structure. Stored in a table form chamber (100) due to, metallic salts powder received in the stud ridge receiver (1) and faced to the cut unit the outlet (100a) connected to the first collapse is generated near with smooth interface purpose: an instrument for an endoscope. Specifically, as shown in 3 also said chamber (10) when the intentional asymmetry imposed during is the receiving portions of the metal salt powder (1) with respect to each other by frictional outlet (10a) mounted on an upper portion of holes by generating an, powder the metal salt used and faced to the cut unit (1) collapse of. does not occur. However, of the present invention chamber (100) the receiving portion utilised symmetrical configuration, outlet (100a) on opposite sides of outlet (100a) powder metal salt and mix from entering the mixing chamber (1) different from the amount of, the metallic salts supported by frictional powder (1) for the quality of is, a difference is caused. As a result, metal salt powder (1) for the suppression of costly a part overlapping with a stacked is stacked the lower between the portions with strong and faced to the cut unit is which has the same number as the degradation by. As water is discharged and faced to the cut unit based the collapsed metal salt powder (1) continues to the upper ends of the an interface that remains smoothing. and downwardly on a curved portion. As such, said chamber (100) is asymmetrical and has a powder metal salt by the configuration of structure (1) is continuously received by collapsed metal salt powder (1) with smooth top of according on interface, without the use of an agitator additional quantitative installed at the electrolyser (40) into supply may be embodied in. And, said second transfer unit chamber (100) and a surface (100) from metal salt powder (1) a cavity part the above transfer unit (210) and can comprise of. Specifically, above said transfer unit (210) the, chamber (100) is connection from above transfer pipe disposed accomplish upwardly (211), metal salt powder (1) for said above transfer pipe (211) along the conveyance upward transfer pipe (211) disposed in a above screw (212), and said screw above (212) for rotating motor number 1 (213) and can comprise of a. Such an outer dielectric film transfer unit (210) the, chamber (100) outlet of (100a) powder metallic salts discharged from (1) a cavity part screw (212) by an indexed upper the rotation determining unit detects rotation of, metal salt powder (1) pores between the by the removal of the, i.e. metal salt powder (1) by by burying pores between the metal salt powder (1) can be the set value is outputted to a. I.e., above said transfer unit (210) the, metal salt powder (1) a cavity part transfer, by transferring in a reverse direction of gravity i.e., metal salt powder (1) the supply road with the placing stage are pushed by transfer opposite direction gravity is reduce, metal salt powder (1) pores contained therein powder metal salt is removed (1) can be an indexed quantitatively. The, said above transfer pipe (211) an outer dielectric film may be the side surface of the flange structure, the shape of a band is positioned at a set distance while a transfer to recognize precisely a horizontal transfer also metering as mentioned above, where the lighting for implementing is arrangement structure preferred. In addition to this, the second transfer unit said above transfer unit (210) is connected to metal salt powder (1) a cavity part transfer unit (210) lower transfer unit downwardly from the (220) further and can comprise of. Specifically, said lower transfer unit (220) the, chamber (100) is connection from its downward disposed lower transfer tube (221), metal salt powder (1) for lower transfer tube (221) capable of moving along the lower transfer tube (221) [...] disposed in a (222), and said [...] (222) motor for rotating a disk, a number 2 motor (223) and can comprise of a. Such lower transfer unit (220) the [...] (222) by the rotation of metal salt powder (1) quantitative transfer effect can be further increase the. Furthermore, said lower transfer unit (220) disposed downward vertical preferably has a fragment structure, electrolytic cell (40) side metal salt powder (1) according to a free to facilitate the, metal salt powder (1) for electrolytic cell (40) side transfer member can be and the procedure part is mined. Furthermore, such lower transfer unit (220) an outer dielectric film transfer unit (210) by metal salt powder (1) to be compensation height transfer above metal salt powder (1) again lower to transfer can be a second cylinder body. I.e., chamber (100) outlet of (100a) is electrolytic cell (40) one inlet and more than one when flush with and are formed on horizontal, metal salt powder (1) included in an ejecting the metering capable of upward transfer unit (210) by removing a, metal salt powder (1) upwardly transfer unit for position compensation for transferring (210) lower transfer unit with (220) .can be arranged. On the other hand, said source is provided with a pressure accumulator metal salt powder channel through the first support part includes a driving part (1) to inject a, lower transfer tube (221) the invention also relates to a further an injection site which and can comprise of. Specifically, a carriage associated with said injection unit its downward disposed on a jet tube (310), said injection pipe (310) is connected to injection pipe (310) for feeding gas to the a gas supply tube (320) and can comprise of. The, said gas supply pipe (320) of a salt of the metal powder (1) electrolyser high pressure (40) side the guide plate is fixed while jetting tube (310) and second control signals are applied to by, high-pressure gas supply a gas to the process chamber (not shown) may be connected to and. Furthermore, said injection pipe (310) the gas supply pipe (320) on connection with the attached to the front end of the orifice (311) may be formed. I.e., said injection pipe (310) having a small diameter relatively therein one dosing diaphragm hole (311) is formed by, metal salt powder (1) of the flow rate of increased and the injection can be increase the efficacy of the viscosity enhancing. Stored in a table form by injection part, metal salt powder (1) the electrolyte bath (40) falls to by uniformly distributed injection, electrolytic cell (40) of the electrolyte developing dropped away a lump having to is provided to prevent the electrolyte the objective compound. speed. Said powder feed of the present invention stored in a table form a device, each component state is for the operation added to can be further add. Specifically, said chamber (100) the metal salt powder (1) measuring loadings in a a load cell (110) which, may mount to, this rod cells (110) by the electrolytic bath (40), added to an metal salt powder (1) amount of. accurately. Furthermore, said chamber (100) a discharge end open/close valves 102a, 102b (120) which mountable, such valve (120) by metal salt powder (1) can be has air inside and floats on of. Furthermore, said injection pipe (310) injection end in the space (312) which mountable, such check valve (312) by the electrolytic bath (40) generated in electrolyte in preventing the reflux of gastric fluids that a gas can be. Well as, such check valve (312) opening/closing in a generally the decoration plate further comprises any slot is utilized valve is. In addition to this, said gas supply pipe (320) the gas valve (321) which mountable, this gas valve (321) as well as a supply of gas by means of a can be control. Furthermore, the present invention refers to chamber (100) outlet of (100a) mounted to valve (120), the transfer unit are not motor, check valve of an injection unit and (312) electrical a control unit may include further (C). Specifically, the plates are parallel each other, and said control unit (C)-off valve (120), check valve (312), and gas valve (321) is electrically connected to the bump is associated, also number 1 motor (213), number 2 motor (223) is electrically connected to the bump by associated with the load lock, associated electrically and can be control configurations. Such control unit (C) the metal salt powder (1) order of the feed of a chamber at a predetermined interval (100) opening and closing of valve (120) closes the, in arresting the control unit, check valve of an injection unit (312) can be control to close an. I.e., chamber (100) in electrolytic cell (40) side metal salt powder (1) when in order to maintain a vacuum state, metal salt powder (1) check valve of an injection unit as the conveying order of (312) closes the, number 2 motor (223), number 1 motor (213) in arresting the operating, chamber (100) opening and closing of valve (120) can be closes the. Well as, check valve of an injection unit (312) when closing occurs, gas supply pipe (320) gas valve in (321) can be also closed. Specifically, metal salt powder (1) stops supply of when the chamber (100) is installed in the lower part of opening/closing valve (120) was the first closed and, after above transfer pipe (211) remaining in metal salt powder (1) is motor number 1 (213) is intercepted after operation of power is, lower transfer tube (221) remaining in metal salt powder (1) is motor number 2 (223) is after operation of the power is cut off. Next, injection pipe (310) remaining in metal salt powder (1) is gas is supplied a gas valve (321) is closed and, electrolyser finally (40) check valve with connected to (312) is user can easily also. With reference to, metal salt powder (1) supply interruption and the chamber (100) mounted on load cell (110) which can see changes in the, the load cell (110) is electrically connected to the bump the control section (C) associated with. surround. According to this order metal salt powder (1) without interrupting a when, electrolytic cell (40) rise in a backflow of filtrate pelletizer and the spraying part powder in a preferred embodiment remaining support part includes a driving part (1) the reaction between the oxygen and screw of the configured by the suction hole is established near the, portion includes is a trouble occurs equipment. As a result, as described above the present invention refers to a pots are intentional asymmetry imposed during conducted within a chamber (100) by, without agitator of separate metal salt powder (1) and faced to the cut unit a can be and uniformly supplying. Furthermore, the present invention refers to metal salt powder (1) a cavity part by the transfer unit, metal salt powder (1) included in an ejecting the metal salt powder (1) can be an indexed quantitatively. Furthermore, the present invention refers to metal salt powder (1) for electrolytic cell (40) side by the flange, and the opening side key injection, metal salt powder (1) the electrolyte bath (40) to the holder 102y falls towards the injection are distributed, electrolytic cell (40) of the electrolyte developing dropped away a lump having to is provided to prevent the electrolyte the objective compound. speed. Furthermore, the present invention refers to plates are parallel each other, and each valve, the motor control unit by controlling the controlled by (C), metal salt powder (1) stops supply of powder in a preferred embodiment remaining when (1) and to stop the recording during the reaction of fume a low valve lift condition to prevent trouble equipment. The resulting structured materials, , defined although the present invention refers to drawing but is described by examples of the embodiment, the present invention refers to this do not defined by the present invention is in the field of the techniques of the present invention in below event person with skill in the art by claim in equalized signal within the range modified. surround and deformable. 1: metal salt powder 40: electrolytic cell 100: chamber 100a: outlet 110: load cell 120 :-off valve 210: above transfer unit 211: above transfer pipe 212: above screw Motor 213: number 1 220 : lower transfer unit 221 : lower transfer tube 222 : [...] Motor 223: number 2 310: injection pipe 311: orifice 312: check valve 320: gas supply pipe 321: gas valve An apparatus for supplying powder according to the present invention comprises: an apparatus frame; and a supplying means which is provided to the apparatus frame, has a chamber accommodating powder in an asymmetric structure, and evenly supplies the powder. The present invention can evenly supply metallic salt powder by means of the weight thereof without a separate agitator by having a chamber wherein an accommodation unit has an asymmetric structure. In addition, by having a moving unit which moves the metallic salt powder upwards, the present invention removes bubbles contained in the metallic salt powder and quantitatively moves the same. Since the present invention has an injecting unit which injects the metallic salt powder to an electrolyzer, the metallic salt powder is injected and evenly distributed when dropped into the electrolyzer such that the powder is not dropped as a chunk into an electrolyte of the electrolyzer, thereby increasing the speed of the electrolysis. Furthermore, the present invention adjusts and controls each valve and motor by means of a controlling unit such that a trouble in facilities, caused from a reaction of the remaining metallic salt powder and fume when stopping the supply of the metallic salt powder, can be prevented. COPYRIGHT KIPO 2016 Device frame; and said device frame is provided, using the asymmetric structure powder, is introduced into a chamber that the powder is configured to uniformly supplied on a substrate surface and feeding means; including a powder feed device. According to Claim 1, said source is provided with a pressure accumulator, the receiving portions of the internal relative to outlet is non said chamber; and said chamber is on the powder from and equally supply is structured such that a carriage; characterized by powder feed device equipped with at least one. According to Claim 1, said measuring loadings in a powder said chamber mounted to characterized by a load and cuts out a powder feed device. According to Claim 1, said chamber a discharge end open/close valves 102a, 102b are made from powder feed device characterized by. According to Claim 2, said second transfer unit, said said powder is a first hole of the chamber from said chamber a cavity part the above transfer unit; characterized by powder feed device with a second gate insulation layer. According to Claim 5, the transfer unit above said, connection from said chamber upwardly above transfer pipe is disposed; said powder capable of moving along the transfer pipe above said, disposed in a transfer pipe above said above screw; and a the screw above said number 1 motor; characterized by powder feed device equipped with at least one. According to Claim 6, an outer dielectric film transfer pipe above said inclined arrangement structure characterized by:a powder feed device. According to Claim 5, said second transfer unit, is connected to transfer unit above said said powder lower transfer unit the downwardly from the transfer unit above said; characterized by further comprises a powder feed device. According to Claim 8, lower transfer unit said, connection from said chamber is disposed downward lower transfer tube ; said said powder capable of moving according lower transfer tube, disposed in said lower transfer tube[...] ; and said number 2 [...] rotating the motor; characterized by powder feed device equipped with at least one. According to Claim 2, said source is provided with a pressure accumulator, said channel through the first support part includes a driving part said powder to inject a, the invention also relates to a an injection site which said lower transfer tube ; characterized by, and further comprising a to powder feed device. According to Claim 10, said spraying unit sprays, said transfer unit associated with its downward disposed on a jet tube; and is connected to said injection pipe for supplying gas to an pipes make said gas supply pipe; characterized by powder feed device with a second gate insulation layer. According to Claim 11, the injection pipe connection with the on said gas supply pipe is attached to the front end of the orifice characterized by powder feed device. According to Claim 11, said injection pipe injection end in the space are made from powder feed device characterized by. According to Claim 11, the supply pipe said gas valve are made from powder feed device characterized by. According to Claim 10, off valve mounted the outlet of said chamber, said transfer unit are not motor, and check valve of said injection unit electrically associated control unit; characterized by further including to powder feed device. According to Claim 15, said control unit, said powder feeding the order of at a predetermined interval said closes the open/close valves on the upstream, said in arresting the control unit, to close the check valve of said injection unit control signal to control the powder feed device characterized by.