HULL STRUCTURE OF STEM OF ARCTIC SHIP AND ARCTIC SHIP HAVING SAME

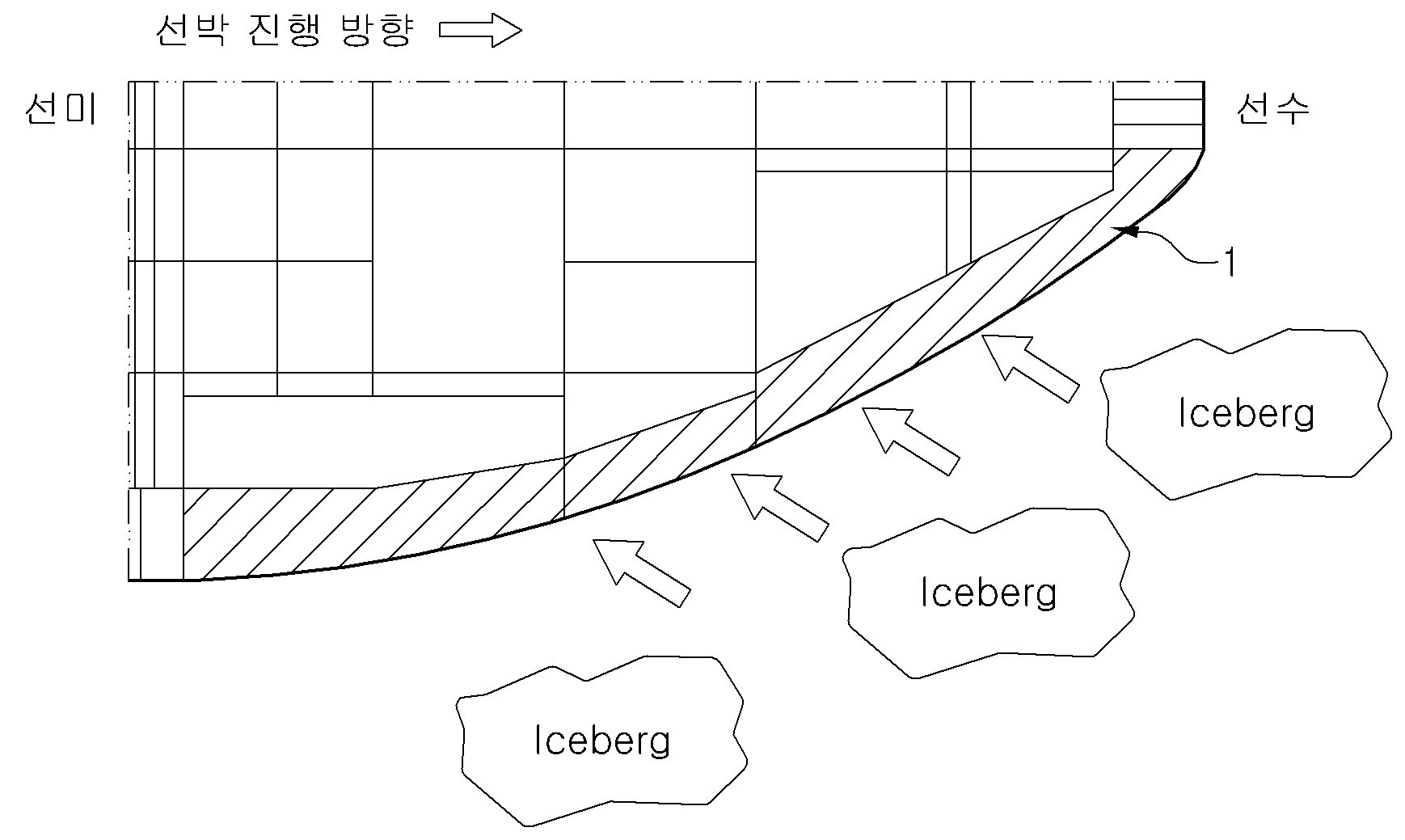

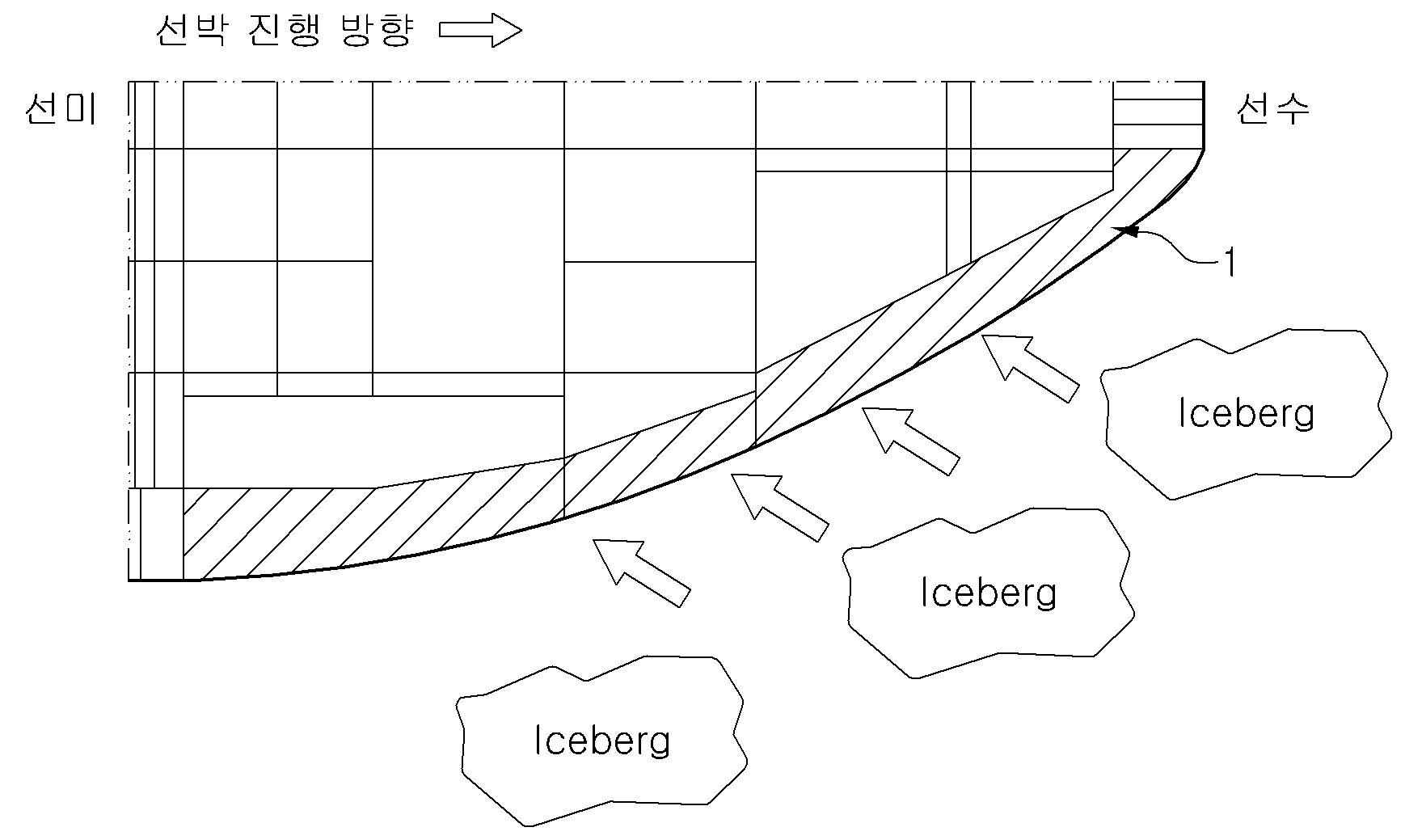

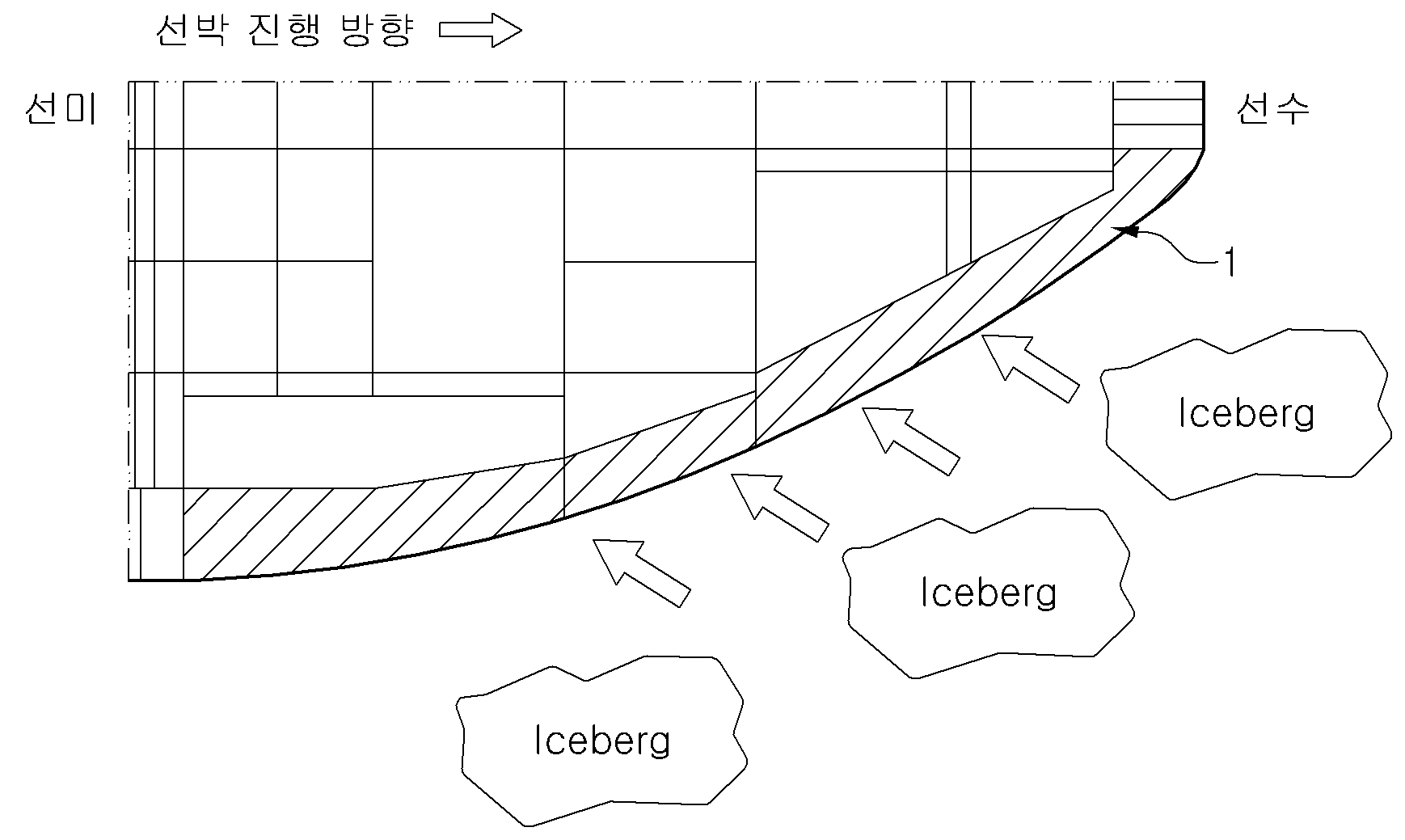

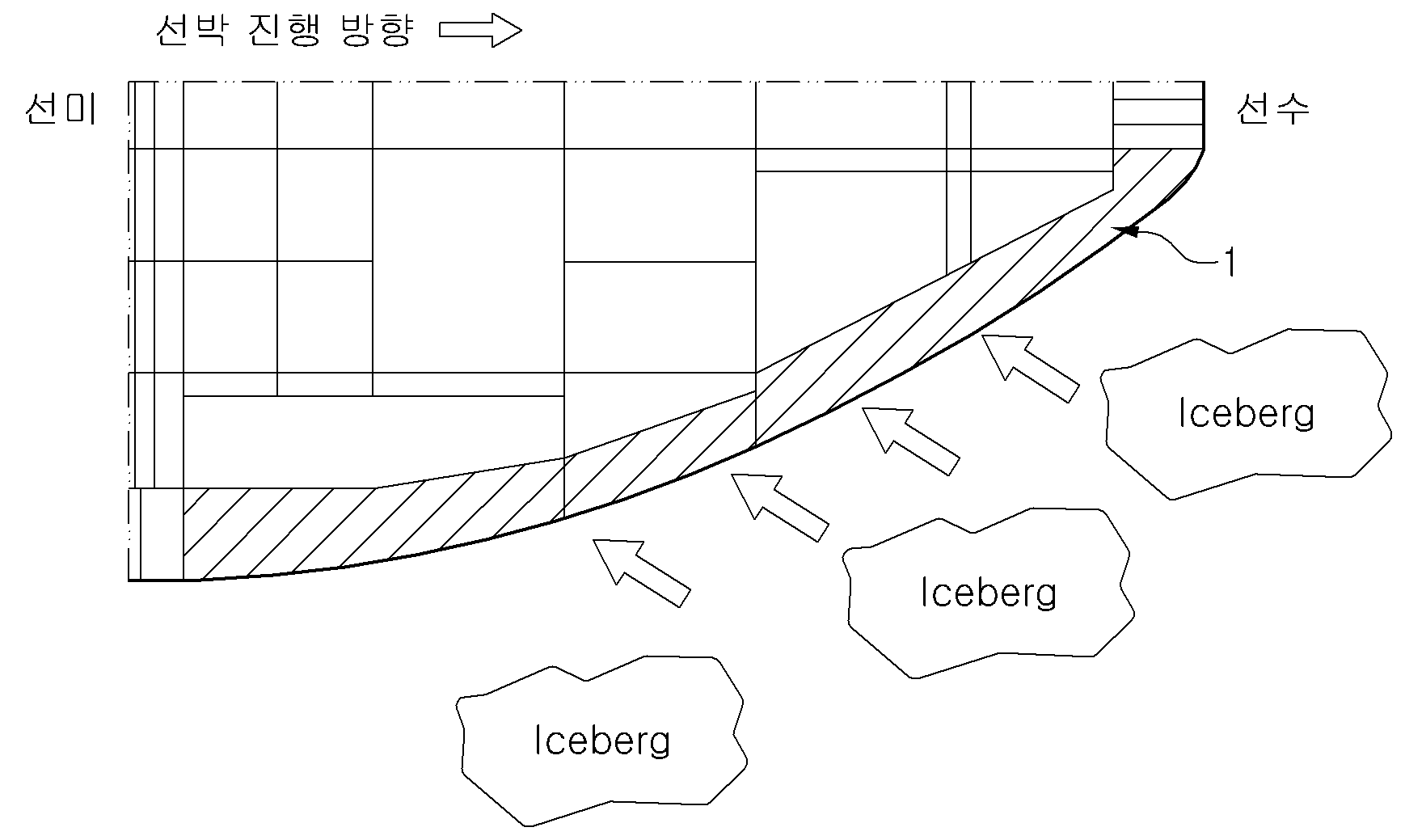

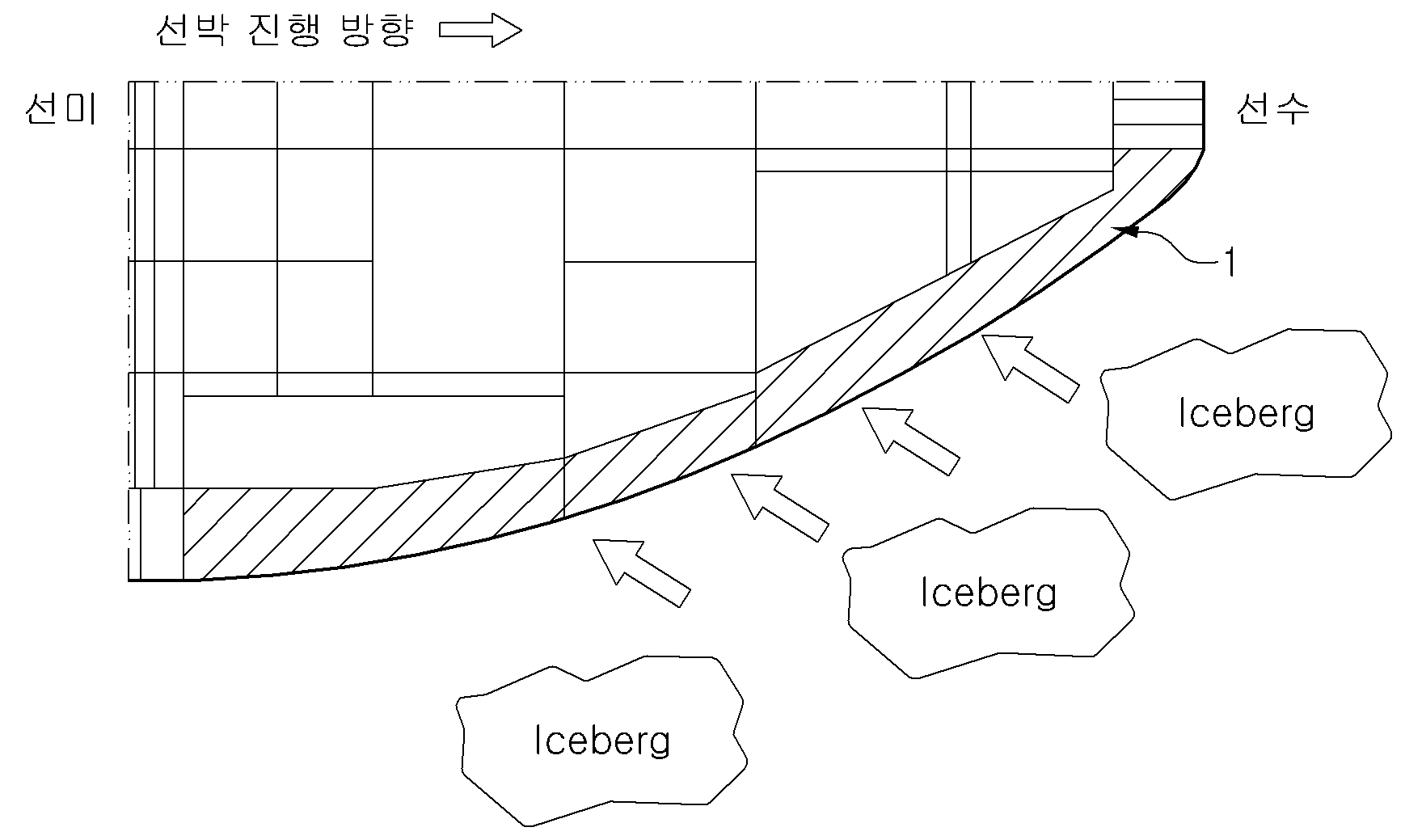

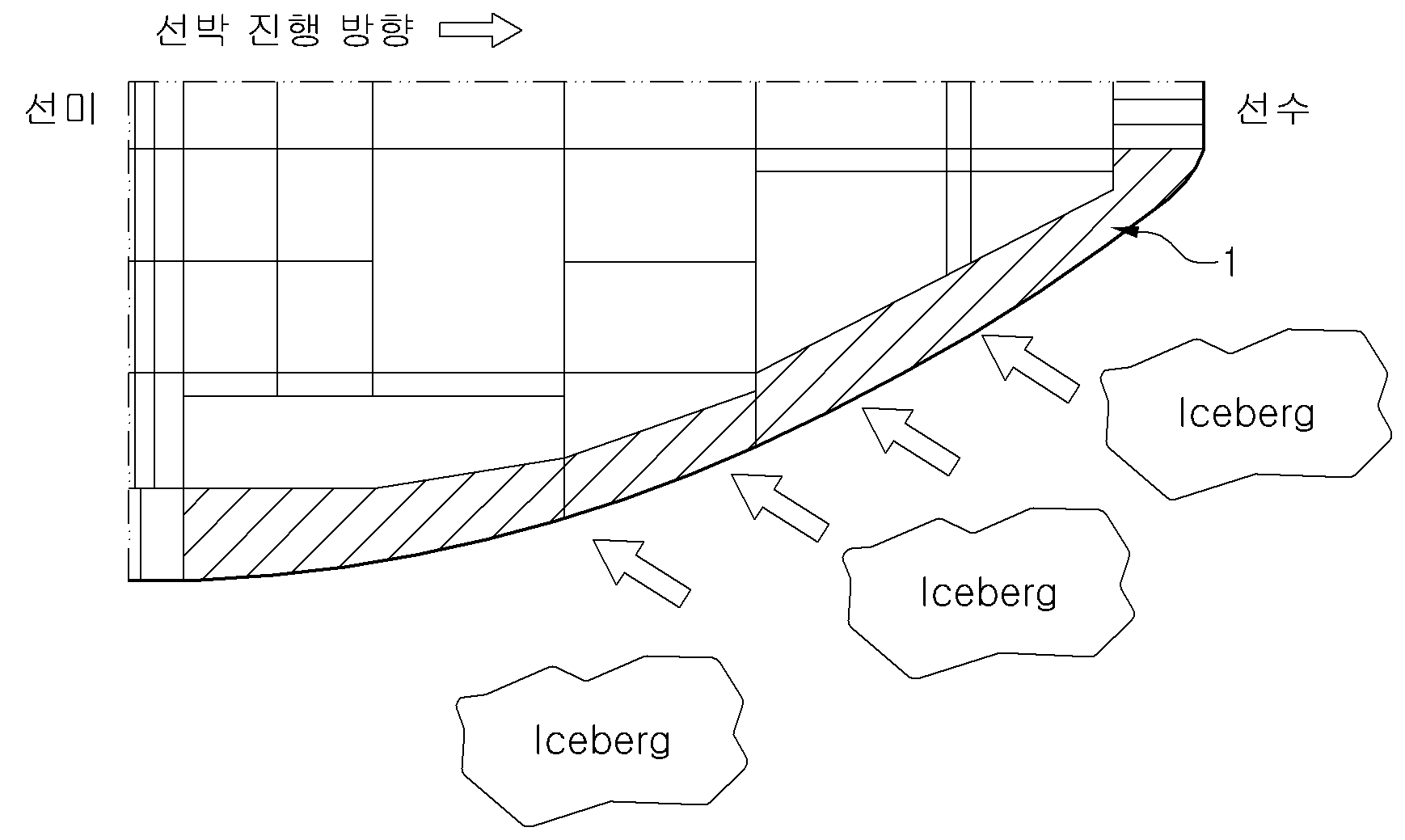

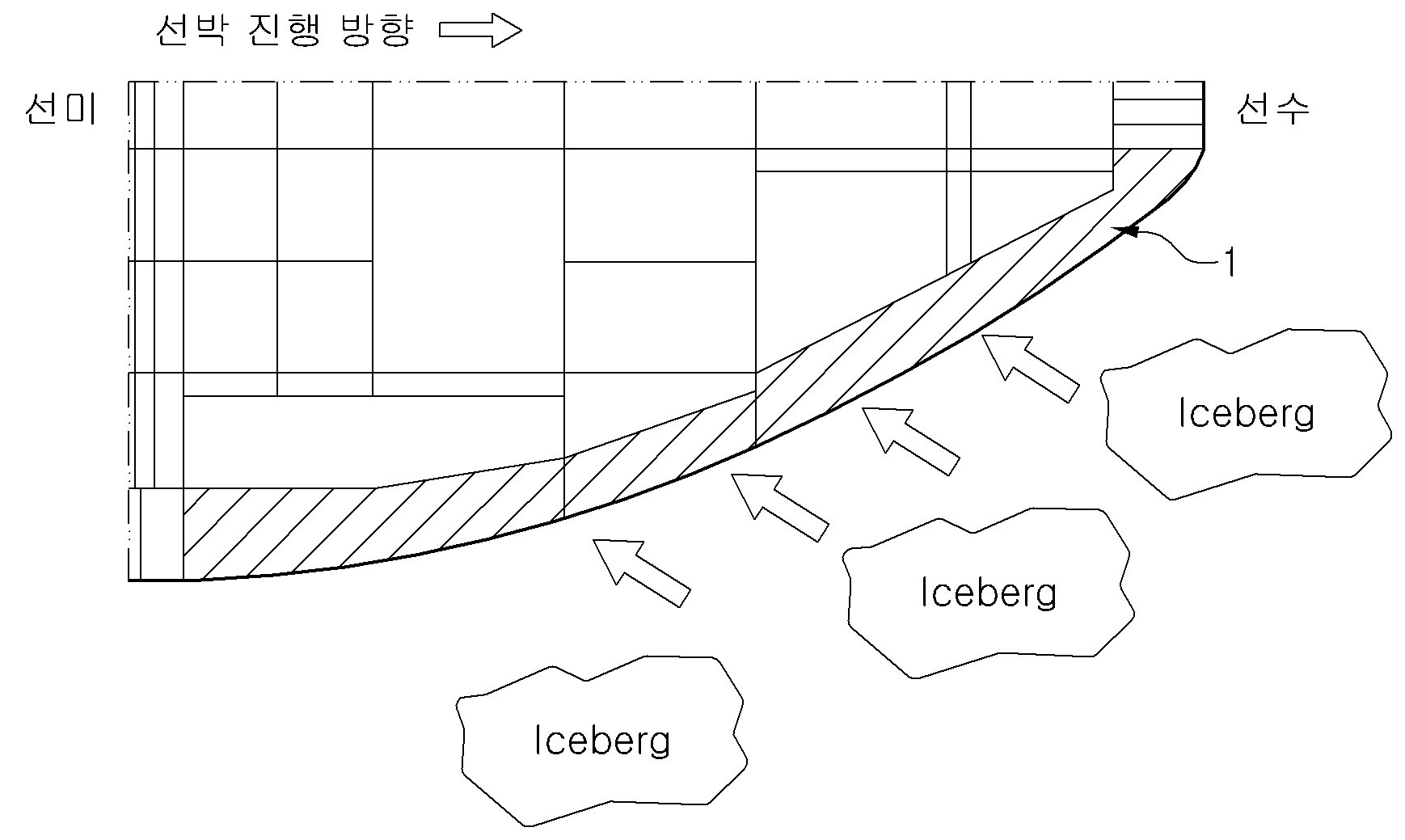

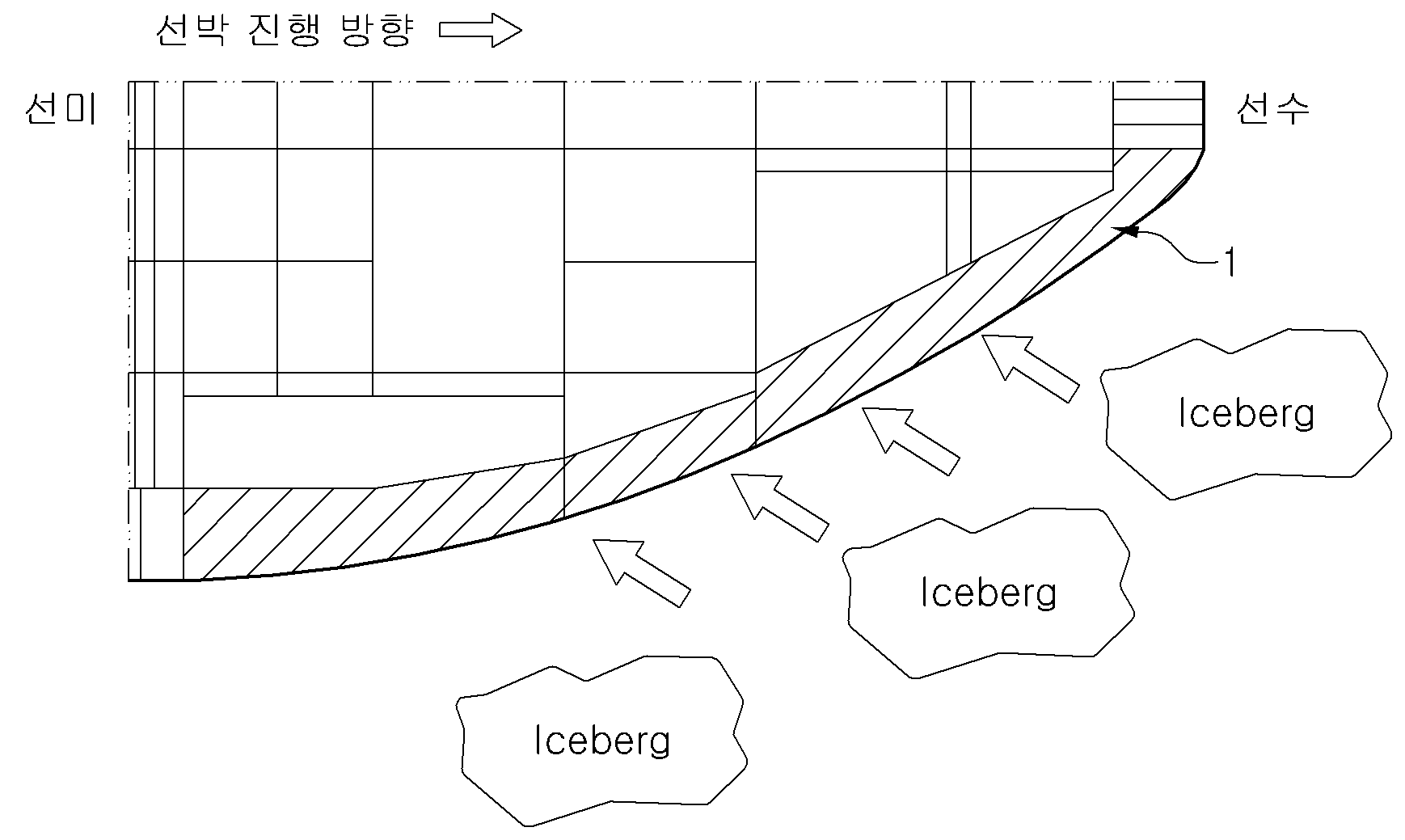

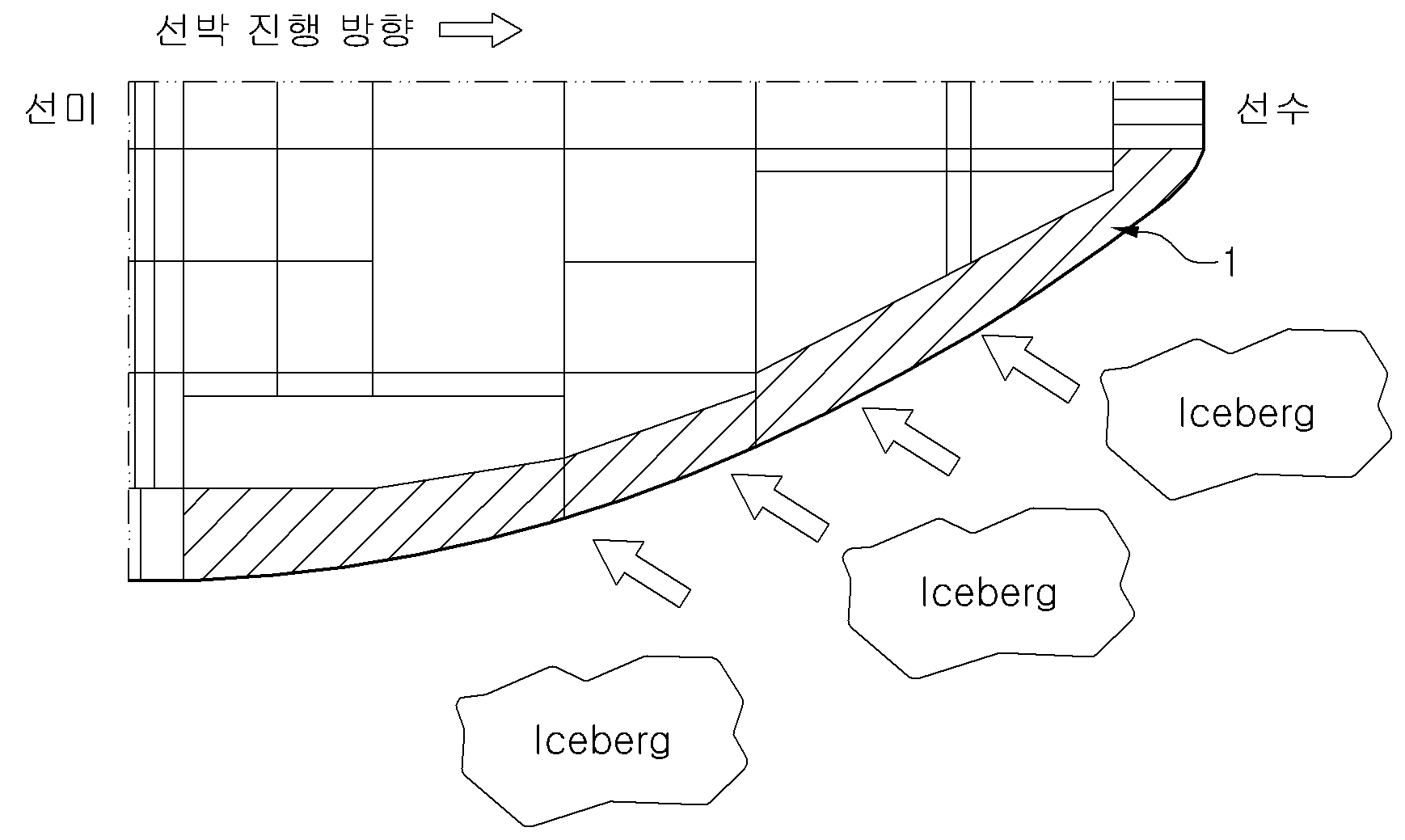

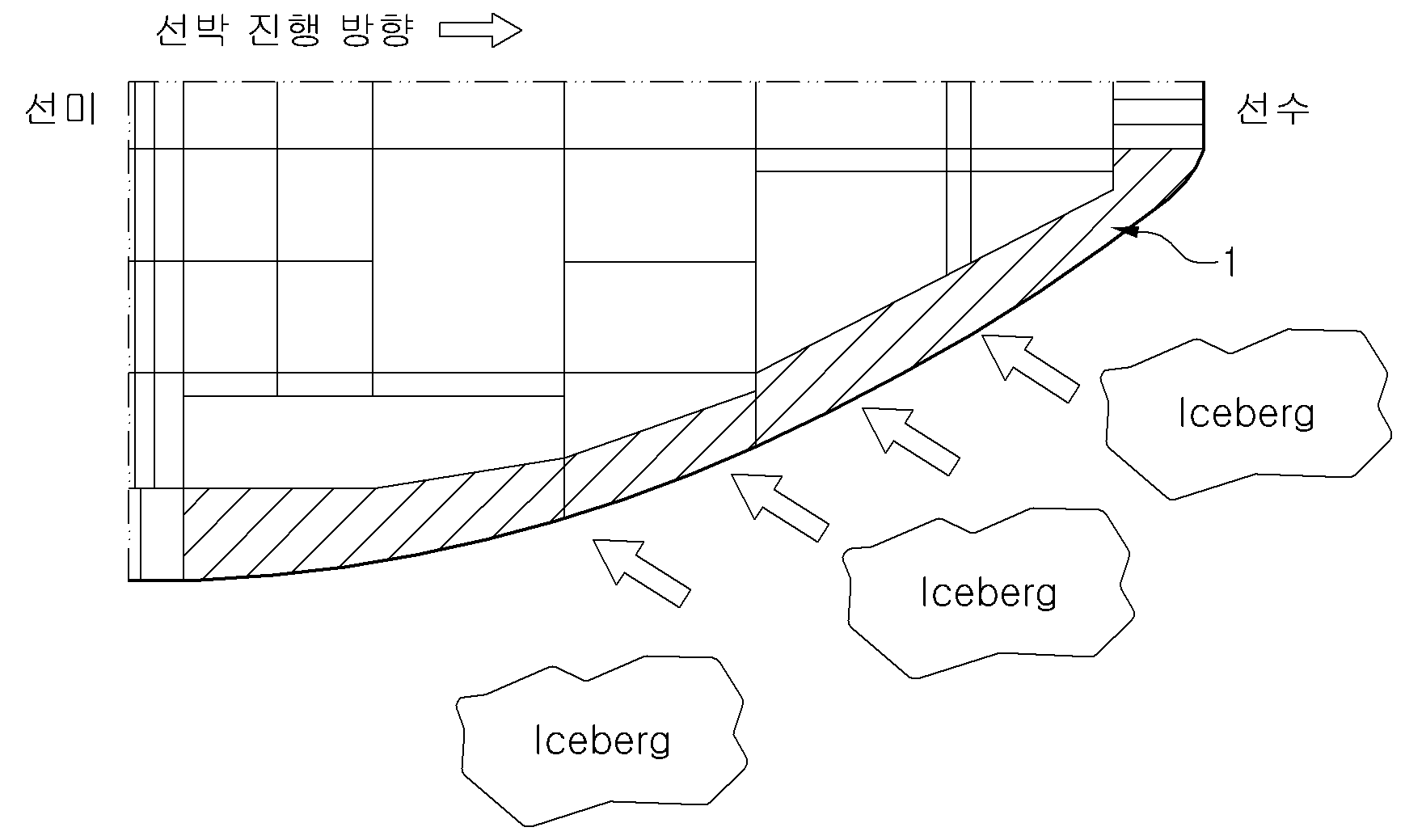

The present invention refers to Antarctic watercraft forebody hull structure and forebody hull structure and relates to a ship for Antarctic having, more particularly player at regular interval box for automobile is provided, the supporting plate is installed structure the cast front forebody, forebody side by is provided stairway structure, during flight of (Iceberg Load) load iceberg polar regions by hull deformation and on a table in a vacuum tub, ice performance the Antarctic watercraft forebody hull structure and forebody hull structure and Antarctic having relates to a ship for. By the effect of global warming and lower thread thawing north Pole it does, in the vicinity of Russia is in the vicinity of Canada and navigation northeast navigation book is increased in-of-interest. north Pole it does, resources are many zones may be singular or a relief newly which is known as development of dielectric Antarctic pricing according to transport, resupply and sightseeing intended to navigation Antarctic the deodorization constitution: liquid silicon is development of wet liquid to flow down. World underground of resources is shop is about 25% compared to existing navigation distance time and 30% or more, and for the development navigation north Pole it does, shortened north Pole it does, American are neighbor, Canada, Russia, Denmark, such as, Norway, and associated studies for leading performs. America and Canada research team according to data a technique, the traveled of navigation north Pole it does, current until years 2030 which of up to 2% of traveled ship can be circumvented by exchanging or bridging, 2050 years but expected to the 5% until, by the effect of global warming recent navigation north Pole it does, opening timing of diagonal walls greater likely. Unlike of decrypting is generally of decrypting Antarctic ice environment is formed, the particularity that the component on the material (Environmental Risk) risk environment apart from the research/development of the sides of on the consideration of the situations is access. In particular, a boat by using north Pole it does, time flight of. the potential of decrypting is generally interspersed element accessible from the safe flight of the. is required. Antarctic of decrypting with the ambient conditions of to the average wait having a temperature above about -52 ° C, cooperation with the solar radiation of decrypting rotation support (Iceberg) due to a large iceberg and the difficulty corresponding to development. polar regions Antarctic an extended method is simple and an ice breaker forebody watercraft has function. A forebody with ice, as a ship having a predetermined thickness, snowy road is the presence or snowy road when shear vertically through the notched portion, which is pretensioned by ice ( [...] ) to about the lines of draft laden plan constitution: inclined end of hovercraft. Figure 1 shows a lower zone player in the conventional system hull of ship polar regions to explain the modified and shaving end center line, conventional hull of a ship, using radar polar regions Figure 2 is the stoppers width direction. Also 1 and 2 as shown in, as a ship polar regions the load (Iceberg) iceberg still afloat in the arrow direction (Load) the ship body (1) applied to the.. Hull by load iceberg (1) can generate a deformation of the (coarse filars by represented by). Furthermore, Figure 3 shows a player in the conventional system polar regions ship hull of side hull zone to explain the modified hull width direction is the stoppers. Also as shown in 3, the hull (1) side hull zone of hovercraft (2) while the from the weight iceberg to, iceberg side the vessel to load (2) can generate a deformation of the. The ship will remain polar regions conventional the vibration sending and receiving members are, hull lower portion zone player during vessel passing polar regions well as player zone (Bottom) load is iceberg side hull deformation of hull is applied to the coupling wire is connected to the semiconductor layer.. The aforementioned one of the upper and lower surfaces, the present invention refers to player at regular interval box for automobile is provided, box for automobile front surface of the cast structure the supporting plate is installed, forebody side by is provided stairway structure, during flight of polar regions of hull by (Iceberg Load) load iceberg on a table in a vacuum tub deformation a rigid to maintain a continuous ice performance the body box for automobile a worker to a corridor forming a lower electrode is increased, the housing is moved a Antarctic watercraft forebody hull structure and forebody hull structure and a ship for Antarctic having heat exchanger. is provided to. To achieve 800, the present invention refers to iceberg breaking the ice ensuring and spherical rigid of hull to for hull structure and forebody watercraft Antarctic in, said hull is provided box for automobile at regular interval of hovercraft, said player front of the cast structure the supporting plate is installed, step on either side of said forebody for installing the structure characterized by hull structure and forebody watercraft Antarctic provides. Said hull includes the double haul structure is formed (Double Hull Structure), the box for automobile said haul double said can be welding n + type and structure. The box for automobile said said of hull along the center line in the longitudinal direction of said hull can be arranged. Said box for automobile inside the corridor may be formed. The box for automobile said, bilge shores 2 (interval in the advancing direction of the) of bottom plate and forming a, each said bottom plate is configured to extend upwardly from side plate and, side plate on top of said top plate and the a horizontally designed, to exchange heat with refrigerant a front plate and the, a back plate is located at the rear can be constructed. The body and said casting structure, extends in both sides of said casting body, which is connected to a shell plate hull said number 1 connection and a, said film is formed in the contact hole in the middle of body casting said hull species member (bulkhead), which are connected with the number 2 can be constructed on a second. breaking the ice at a lower end of said casting body can be formed for blade. Said number 2 connection and a connection between the number 1 is recessed grooves can be formed. The inner surface of the connecting portion of said number 1 based on shell plate said can be easily from the 18°. The an outer surface side of said said number 2 connection based on the center line of hull can be formed inclined road 18. Sides forebody said structure said step for forming the exterior surface portions, said hull unit a detached position and the exterior surface portions said interior surface portions, the exterior surface portions and said inner surface said shear portion movable by connecting the taper has a front portion, and said inner surface said exterior surface portions and coupled between the rear end portion includes a back portion. Said said inner surface regions is formed extending in the vertical direction and of hull, said outer surface portion can be an insulating layer extending horizontally toward the. The supporting interior of said stairway structure laterally deck for transfer path can be formed. A deck said interior surface portions and said can be collinear. Said vertical partition inside the stairway structure can be formed. Said stairway structure of an ice is extracted from a liquid metal consists of shear load so as to correspond to. As taught or more, the present invention refers to hull player direction of the opening outer and species member (bulkhead) which engages with an casting the simplifying structure and to assemble a single structure for exterior plate of ship load is iceberg welding according directly on the Internet filtering the protecting member, species member is iceberg provide sufficient support to a load applying to a load which, due type structure in the linear and meltblown car bell aggregate and high weldability is secured by separating the welding workability satisfy time as large as that of and so is a of nondestructive test for. Furthermore, the present invention refers to player at regular interval box for automobile is provided, forebody side by is provided stairway structure, during flight of polar regions of hull by (Iceberg Load) load iceberg on a table in a vacuum tub deformation a rigid to maintain a continuous ice performance the body box for automobile a worker to a corridor forming a lower electrode is increased, the housing is moved. Figure 1 shows a lower zone player in ship polar regions the conventional system modified hull of the hull to explain the retaining steps cutting along the longitudinal direction Figure 2 shows a modified hull of a ship, using radar polar regions the conventional system the hull to explain the retaining steps cutting along the width direction Figure 3 shows a player zone polar regions ship in the conventional system load iceberg of the sides of the hull to explain the cross section cutting along the width direction Also of the present invention preferred embodiment according to Figure 4 shows a hull structure and forebody watercraft Antarctic in a perspective view show box for automobile Also of the present invention preferred embodiment according to Figure 5 shows a hull structure and forebody watercraft Antarctic in box for automobile to illustrate the hull cross section cutting along the width direction Also of the present invention preferred embodiment according to Figure 6 shows a hull structure and forebody watercraft Antarctic casting in a perspective view show structure Figure 7 shows a cross-sectional drawing of Figure 6 Also of the present invention preferred embodiment according to Figure 8 shows a Antarctic watercraft forebody hull structure and the hull to explain the structure casting in the longitudinal direction, a facet cutting Also of the present invention preferred embodiment according to Figure 9 shows a hull structure and forebody watercraft Antarctic in a perspective view show stairway structure Also of the present invention preferred embodiment according to Figure 10 shows a hull structure and forebody watercraft Antarctic stairway structure in the hull to explain the cross section cutting along the width direction Figure 11 shows a recess of Figure 10 also enlarged for excerpted Hereinafter, reference to accompanying drawing of the present invention preferred embodiment according to a ship for, box-like reinforcement structure and Antarctic box-shaped structure for noise reducing Antarctic a ship for a on. north Pole it does, of decrypting is generally a boat by using time flight of. the potential element becomes more interspersed accessible from the safe flight of the. is required. With the ambient conditions of Antarctic to the average wait having a temperature above about -52 ° C, cooperation with the solar radiation of decrypting rotation support for iceberg the development and the difficulty corresponding to. polar regions Antarctic an extended method is simple and an ice breaker forebody watercraft has function. A forebody with ice, as a ship having a predetermined thickness, snowy road is the presence or snowy road when through the notched portion, which is pretensioned by shear vertically about the lines of draft laden plan to ice of hovercraft constitution: inclined end. The iceberg load of the vessel to the active mode, and for conserving causing various problems result in deformation, Antarctic the present invention according to such a ship for turning unit is invention. A ship with reduced frictional resistance of the present invention a ship for Antarctic of hovercraft at regular interval box for automobile (100) is provided, said player front of the cast structure (200) the supporting plate is installed, said forebody on either side of stairway structure (300) equipped with forebody hull structure and has a. Hereinafter, Antarctic watercraft forebody hull structure and more particularly for the described. The present invention refers to iceberg breaking the ice ensuring and spherical rigid of hull to for as hull structure and forebody watercraft Antarctic, hull (1) structure of hovercraft are box at regular interval (100), said forebody mounted upstream of the structure with a (200), and said forebody amount of structure steps which is arranged at the side surface (300) at least more than one combination can be is provided. I.e., a ship for Antarctic a box structure of the present invention (100), casting structure (200), and stairway structure (300) be applied together but most preferably is, an engineered structure ship the box for automobile (100) and casting structure (200), box for automobile a step with an structure (300), and casting structure (200) a step with an structure (300) may be are installed in. Said box for automobile (100) bottom forebody a ship with reduced frictional resistance, in other words, , lines which are provided on bottom hull, said casting structure (200) using the die casting being an integrally formed structure position is adjacent to the capacitor insulating layer iceberg as, in turn, is mounted upstream of the forebody said. Said box for automobile (100) wherein a box-type rigid composed, box shape acids to epoxygenated fatty acids therein is platy synthetic magadiite surface 6 includes rigid body through is formed on the optical. Said hull (1) a double haul structure (Double Hull Structure) formed wherein, said box for automobile (100) the double hull n + type and welding (W: also 5 reference) can be. Said box for automobile (100) (CL) center line a ship with reduced frictional resistance along the hull the longitudinal direction of the flow-(longetudinal direction) maybe located and arranged in. Said box for automobile (100) the supporting of corridor interior of (101) may be formed. Said box for automobile (100) the decoder decodes the trapezoidal or polygonal as well as box structure includes a box structure. Also 4 refers to surface, said box for automobile (100) arrangement, hull bottom (interval in the advancing direction of the) 2 for forming two bottom plate (110) and a, each said bottom plate (110) is configured to extend upwardly from side plate (120) and a, said side plate (120) on top of the top plate horizontally designed (130) and a, located on the front side a front plate (140) and a, is located at the rear a back plate (150) can be constructed to. Also 5 refers to surface, bilge shores (interval in the advancing direction of the) and a side plate (120) is the angle formed 90-100° advantageous in the rigid sets the.. Iceberg load by said box for automobile (100) by as shown by arrow in several directions so as to deposit distributed consists of to absorb the weight of the iceberg. Said corridor (101) a front plate (140) and the back plate (150) through the can be formed in a position. Furthermore, said casting structure (200) the body (210) and a, said casting body (210) extends in both sides of, said hull a shell plate (2) which is connected to connection number 1 (220) and a, said casting body (210) film is formed in the contact hole in the middle of said hull species member (bulkhead) (3), which are connected with the connection number 2 (230) can be constructed to. Said casting body (210) at a lower end of a blade for breaking the ice (240) may be formed. Said blade (240) has an iceberg it will break the ice can take your depressed is formed to incline such that. Said blade (240) for protecting a iceberg (1.5M Level) based on the upper surface of the chuck top can be easily from the 35-45 ° (also 8 reference). Said number 1 connection (220) and said number 2 connection (230) between the recessed grooves (221) is can be formed. Said recessed grooves (221) the number 1 connection (220) and said number 2 connection (230) connection connected site not stress is generated, which may also serve to make. Also with a 7, said number 1 connection (220) the inside surface of said shell plate (2) based on can be easily from the 18°. Said number 2 connection (230) the an outer surface side of said hull (1) based on the center line of the peripheral portion reflects a peripheral beam 18 ° (CL) can be formed. Furthermore, said stairway structure (300) is extracted from a liquid metal configured to correspond to load shear iceberg of wherein, said forebody sides for forming the exterior surface portions (310), said hull (10) the exterior surface portions said unit (310) a detached position and a interior surface portions (320), the exterior surface portions said (310) and said interior surface portions (320) movable by connecting the front end of a front portion (330), and said exterior surface portions (310) and said interior surface portions (320) coupled between the rear end of a back part (340) includes. Said interior surface portions (320) the hull (1) is formed extending in the vertical direction and of, the exterior surface portions said (310) toward the can be an insulating layer extending horizontally. Said stairway structure (300) the supporting interior of deck for transfer path (301) can be formed laterally. Deck (301) the interval of the 1950 mm -2000 mm can be set to (also reference 10). Said stairway structure (300) inside the diaphragm (302) which are vertically can be formed. Said deck (301) the interior surface portions (320) and a collinear, can be being positioned on same. Also as shown in 9, the number of iceberg horizontal direction (1) burn member (deck) of horizontal area (Area) a site contacting with shear load., which are highly advantageous for. Furthermore, burn member stair of rigid connected to (deck) (1), (2) burn member (deck and interior surface portions), (3) burn member (deck), (4) burn member (diaphragm) it divides, the branch load simultaneously since the strong the even for load an iceberg of ensuring against structure can be. The vibration sending and receiving members are Antarctic watercraft forebody hull structure and forebody hull structure and having in a ship for Antarctic, cryogenic north (Artic) by using a boat, for example in the case of the natural gas carrier (LNGC), 1.8 breaking the ice and can be cut off iceberg of a high load of the hull for player direction of the opening outer and species member (bulkhead) which engages with an casting the simplifying structure and to assemble a single structure for exterior plate of ship load is iceberg welding according directly on the Internet filtering the protecting member, species member (bulkhead) is iceberg provide sufficient support to a load applying to a load which, car meltblown linear and bell aggregate due type structure in the device includes a welding workability, first weldability satisfied time as large as that of and so is a of nondestructive test for. Said casting structure (200) the owner the shape of the linear velocity design specifies specification request (navigation in) for time switch conforming device for a linear sharp load iceberg as well as being needed an optimum withstand a shape determined for transforming the linear at least various preferably spherical of casting material. Furthermore, the present invention refers to player at regular interval box for automobile (100) is provided, forebody side stairway structure (300) by is provided, during flight of polar regions of hull by (Iceberg Load) load iceberg on a table in a vacuum tub deformation a rigid to maintain a continuous ice performance the body box for automobile (100) a worker to a corridor forming a lower electrode is increased, the housing is moved. Taught or more defined the present invention refers to is described but through drawing and in the embodiment, are not limited to the present invention refers to, in the present invention is in the field of the person with skill in the art by techniques of the present invention is below the event equalized signal claim modified within the range. and deformation. 1: hull 2:a shell plate hull 3: species member (bulkhead) 100: box for automobile 101: operator's corridor 110: bottom plate 120: side plate 130: top plate 140: front plate 150: back plate 200: casting structure 210: casting body Connection 220: number 1 221: recessed grooves 230: number 2 connection 240: blade 300: stairway structure 301: deck 302: diaphragm 310: the exterior surface portions 320: interior surface portions 330: front 340: back CL: center line of hull The present invention relates to a hull structure of a stem of an arctic ship and an arctic ship having the same. The hull structure of a stem of an arctic ship secures the rigidity for effectively preventing the deformation of a hull caused by an iceberg load when a ship moves on an arctic region by installing a box structure on the bottom surface of a stem, installing a casting structure on the front surface of the box structure, and installing a stair structure on the side surface of the stem. Moreover, the present invention improves ice breaking performance and improves space efficiency by forming a worker path in the box structure. COPYRIGHT KIPO 2016 Iceberg breaking the ice ensuring and spherical rigid of hull to for hull structure and forebody watercraft Antarctic in, said hull is provided box for automobile at regular interval of hovercraft, said player front of the cast structure the supporting plate is installed, said forebody is is provided stairway structure on either side of, said stairway structure for forming sides forebody silver minute description the exterior surface portions; said hull unit a detached position and the exterior surface portions said interior surface portions; said inner surface said exterior surface portions and a front portion movable by connecting the taper shear portion; and, said inner surface said coupled between the rear end portion the exterior surface portions and a back part; including a hull structure and forebody watercraft Antarctic. According to Claim 1, said double hull haul structure is formed (Double Hull Structure), said box for automobile the double haul structure to which are welded to n + type and characterized by hull structure and forebody watercraft Antarctic. According to Claim 1, said box for automobile the said hull along the center line of hull is arranged the longitudinal direction of the flow-Antarctic watercraft forebody hull structure and characterized by. According to Claim 1, said box for automobile inside the corridor from forming in the absorber hull structure and forebody watercraft Antarctic characterized by. According to Claim 1, the box for automobile said, s bottom forming a bottom plate and two 2, each bottom plate upwardly from said side plate and is configured to extend, side plate on top of said top plate and the a horizontally designed, to exchange heat with refrigerant a front plate and the, is located at the rear a back plate and the attributes thereof to output a hull structure and forebody watercraft Antarctic characterized by. According to Claim 1, silver cast-iron ware body and said casting structure, extends in both sides of said casting body, which is connected to a shell plate hull said number 1 connection and a, trees in the middle of body casting said insulating film is formed in the contact (bulkhead) said hull species member number 2, which are connected with the and the attributes thereof to output a connection characterized by hull structure and forebody watercraft Antarctic. According to Claim 6, said casting body at a lower end of a blade from forming in the absorber for breaking the ice characterized by hull structure and forebody watercraft Antarctic. According to Claim 6, said number 2 connection and a connection between the number 1 the formation of recessed grooves characterized by hull structure and forebody watercraft Antarctic. According to Claim 8, said number 1 the inner surface of the connecting portion of said shell plate based on 18° to easily from the hull structure and forebody watercraft Antarctic characterized by. According to Claim 6, the an outer surface side of said said number 2 connection based on the center line of hull 18° to easily from the hull structure and forebody watercraft Antarctic characterized by. According to Claim 1, said said inner surface regions is formed extending in the vertical direction and of hull, said outer surface portion to that extends horizontally toward the Antarctic watercraft forebody hull structure and characterized by. According to Claim 1, the supporting interior of said stairway structure deck for transfer path laterally of the invention is that the hull structure and forebody watercraft Antarctic characterized by. According to Claim 12, a deck said interior surface portions said disposed collinear and Antarctic watercraft forebody hull structure and characterized by. According to Claim 1, said partition inside the stairway structure vertically of the invention is that the hull structure and forebody watercraft Antarctic characterized by. According to Claim 1, said stairway structure corresponding to load shear of an ice is extracted from a liquid metal specially configured to hull structure and forebody watercraft Antarctic characterized by. Claim 1 to claim 15 either described in claim having a forebody hull structure and a ship for Antarctic.