OIL PUMP WITH HALF-MAGNET TYPE BLDC MOTOR

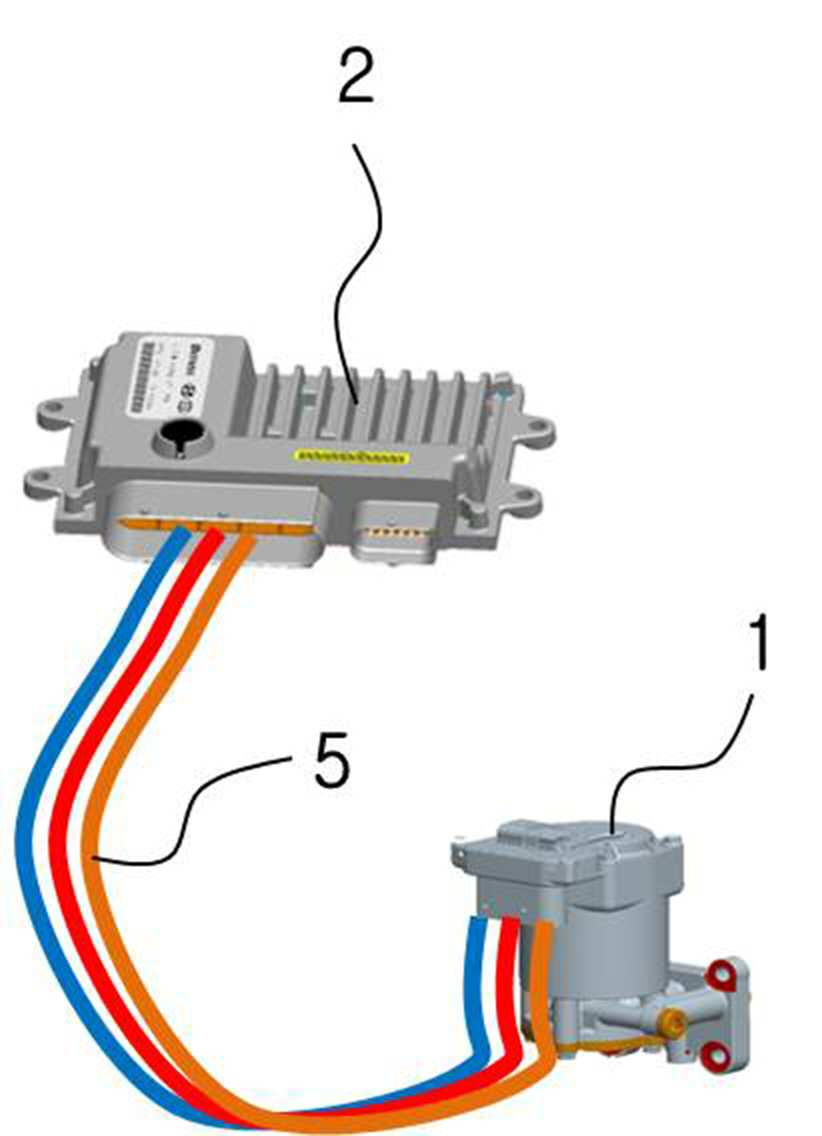

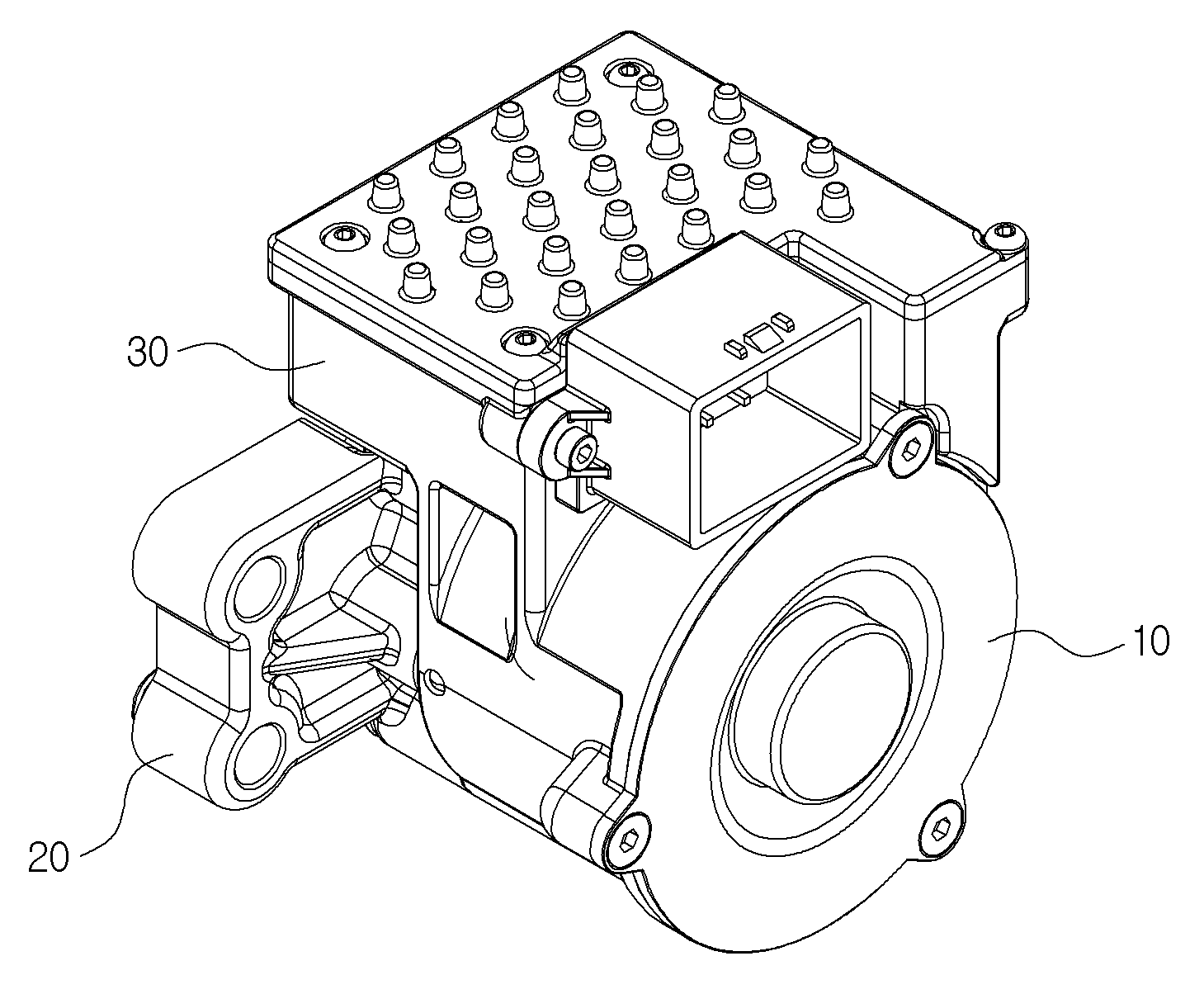

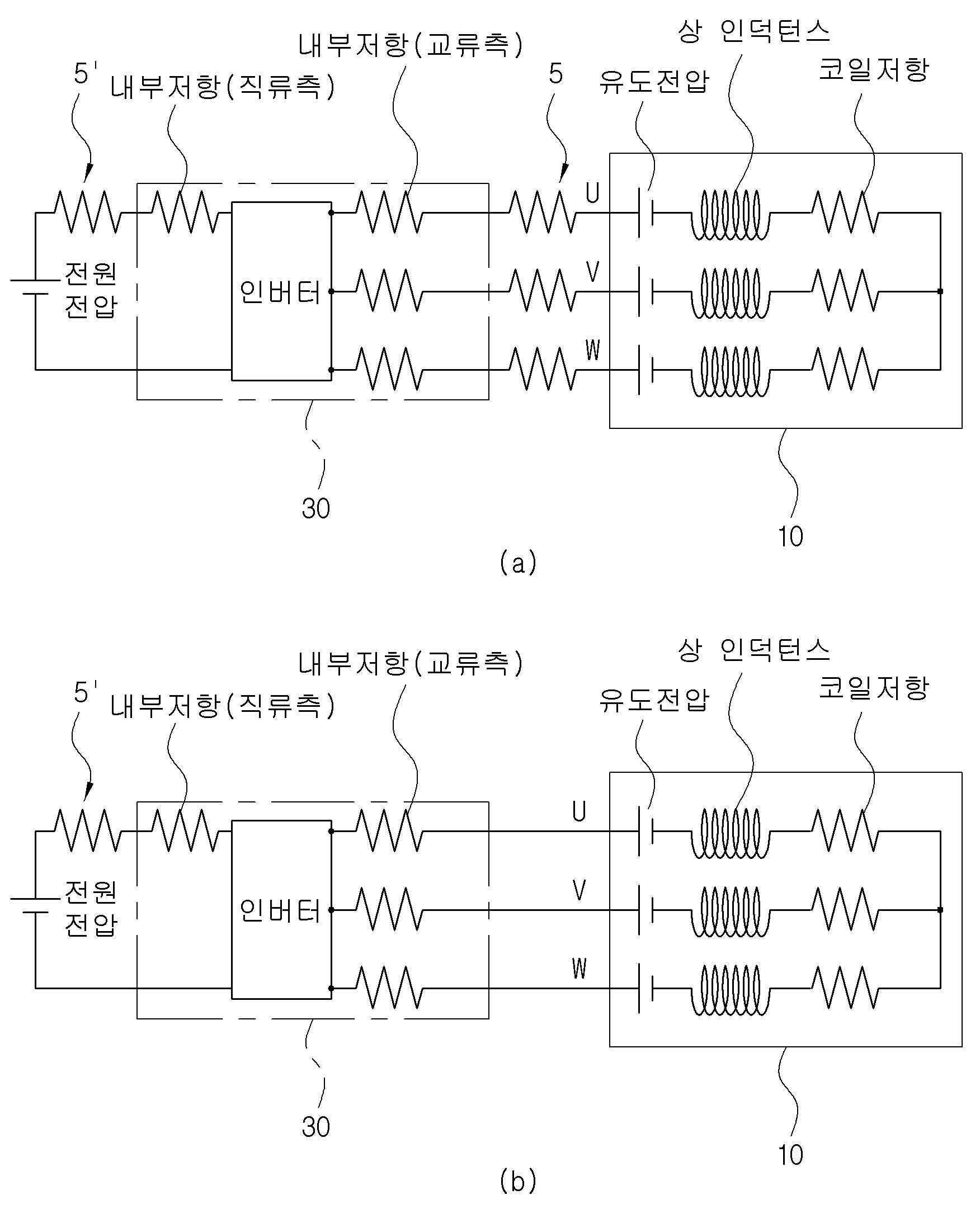

The present invention refers to BLDC employing the motor oil pump relates to search, more specifically fuel supply device of a fluid transfer including use in half-tone by external magnet type BLDC employing the motor are disclosed. Typically fuel pump life and BLDC motor (Brushless DC Motor) for securing liability of high efficiency and high field with by adopting a. BLDC motor (stator) generating a magnetic field which stator in the magnetic stator by rotating (rotor) having a predetermined wavelength. The BLDC motor oil pump of the existing method reference also 1 (1) on violations of the number (2) is formed special somatotype walnut wire harness (5) connected to a structure are disclosed. The, wire harness (5) occurs by resistance, this system lowering the efficiency factor in the other. The harness (5) in addition to the BLDC motor cost increases by (1) costly rare earth magnet required by also cost increases resulting substrate. The Korean Patent Registration Notification number 1518431 prior art document as associated call (preceding document 1), Korean Patent Registration Notification number 0814435 call (preceding document 2) and the like known. The upper surface of the upper portion of the connector structure prior document 1 form a yoke cover body is composed of yoke extended downward oil pump drive system for BLDC motor as, yoke and conformability at the center of the cover body formed so high voltage BLDC motor number [...] like receiving groove for receiving the printed circuit board electrically connecting with each other. The, high voltage BLDC motor overheating of the recognizing in advance as the substrate. 2 preceding nucleotide comprises a base mounted to the frame flow for discharging pumping absence and, BLDC pumping absently discharge forces mounted driving motor, BLDC controller command signals for driving motor, driven into a predetermined driving speed command signal feedback compensation control section number number under public affairs substrate. The, BLDC motor and a feedback number is possible without the need for extra finishing device integrated water level therein. However, said prior patent disclosure to BLDC motor vehicle mounted in such a manner that, in particular in order to ensure stability for a long period of durability by applying system includes a pressure half magnet type exhibit substrate. The purpose of the invention is to improve such as said door number points of the existing method, fuel supply system mounted over a long period of durability due to vibration while maintaining system stability by which the oil pump employing the motor half magnet type BLDC under public affairs number or a reversed F.. In order to achieve said purposes, the present invention refers to N pole motor operated pump for conveying a fluid in: said N magnet with fewer than BLDC motor; said BLDC motor and pumps combined; and said BLDC motor controller that are received on the same housing as the separated space; characterized by comprising the. Construction details of the present invention as, characterized said BLDC motor with a rotor on two magnet N/2. Construction details of the present invention as, characterized in performing said pump pumping cycloid tooth. Construction details of the present invention is provided, said controller via a wired style front line BLDC motor and the fixing substrate is characterized. The, said "V" style front line user cross holding pieces 33 formed therein that is formed in the housing via a brake characterized. The than the present invention, fuel feed pump half magnet type BLDC motor mounted over an extended period while maintaining system stability by which the durability due to vibration is equal to or less than. Figure 1 shows a configuration of the existing method also representing fuel oil pump Also the present invention according to Figure 2 shows a configuration representing fuel oil pump Figure 3 shows a main part of the present invention according to decomposition of oil pump also contains sensors mounted thereon Also the present invention according to Figure 4 shows a configuration represented by the front oil pump Figure 5 shows a contrast to the conventional oil pump of the present invention and contains equivalent circuit Hereinafter, based on the detail of the present invention in the embodiment of the SFC attached drawing as follows. The present invention N pole motor operated for delivering fluid oil pump on the number into each other. In particular fuel supply system an oil pump which is mounted to a test object but certain brands of composite are not correct. According to the present invention said N fewer than magnet (15) having a BLDC motor (10) using other. BLDC motor (10) includes a plurality of teeth is provided with a coil wound stator (11) on, stator (11) corresponding to a plurality of magnet (15) provided with a rotor (12) consists of to. Magnet (15) reduce the quantity of expensive materials by ND magnet section is to contribute to the cost of a rare-earth using are disclosed. Construction details of the present invention as, said BLDC motor (10) includes a rotor (12) N/2 on two magnet (15) characterized with a. Figure 3 6 pole configuration of BLDC motor (10) 3 in two magnet (15) half magnet structure using the same example as follows. In this case rotor (12) is outward pole N - X - N - X - N - X can be arranged. Wherein, X is a magnet (15) is coupled to the zoom lens is not needed with respect to core as the coil form. As well as, but is not shown magnet (15) arranged in a 6 pole outward when applied to alternating N - S - N - S - N - S pole. BLDC motor (10) the stator (11) on the rotor (12) outer diameter ratio of 100:50 - 60 the E which it releases that net type may best general method in 50 - 60% outer diameter ratio but if the magnet (15) is equal to the weight of the increased number without causing a large dished antennae. The BLDC motor (10) by applying the half magnet rotor (12) of the outside diameter of the stator (11) 50% -60% separation level number capable of large dished antennae and optimize the efficiency of the upper and lower motor design inferred. The experiments, stator (11) outer diameter of 85 mm, outer diameter 36 mm rotor, if the outer diameter ratio 100:42 10x2. Two magnet 9, 000mm3 5x45 mm size magnet 8 connected to a small piece of outer diameter ratio less than 50% total volume ratio of the electric field and magnetic loading does not optimized. If the rotor in otherwise identical conditions when an outer diameter of 49 mm outer diameters increasing 100:57 ratio 13. 5x2. Total volume of magnet 8 to 11, 178mm3 3x45 mm two magnet connected to a malonyl with each other. Same performance (output) is adapted to the outer diameter ratio while maintaining 13 may be 50 - 60%. 5x3. 5x45 mm size of magnets 4 are to designate a half side of the magnet 8, 505mm3 total volume are shrunk with a magnet. Further, according to the present invention pump (20) is said BLDC motor (10) into engagement with the shaft structure are disclosed. Pump (20) and a BLDC motor (10) which are accommodated in each housing is along a column or connected thereto. Construction details of the present invention is provided, said pump (20) includes a cycloidal teeth to perform pumping characterized. In the case of cycloid tooth formed on the electrical system to stabilizing such small glass to driver screws WIPO. In particular half magnet structure BLDC motor (10) may be cycloidal teeth permits cancellation portion increases somewhat and torque ripple in constant. Further, according to the present invention controller (30) is said BLDC motor (10) identical to the housing (31) received into structure on isolated from space into two electrodes. Housing (31) fix space BLDC motor (10) is inserted into the upper space controller (30) a contained in now. Housing (31) on the upper surface of controller (30) is mounted to the cover for magnetron with heat. Construction details of the present invention is provided, said controller (30) substrate (34) comprises a housing (31) secured to the style front line (36) via a BLDC motor (10) on the wired characterized. style front line (36) is a resonant sway due to preclude as BLDC motor (10) to (U, V, W) 3 phase power application or a wired substrate. Substrate (34) in order to create a resin support using the inverters secret are retained. style front line (36) the bottom of the BLDC motor (10) connected of terminal block, the upper end has substrate (34) of terminal block connected thereto. style front line (36) circular cross sections, plate-like cross-section, is constructed from a composite type can be selected. Any case style front line (36) surface of the shield layer adding a good ancestry. The, said style front line (36) "V" the user end of the holding pieces (38) via a housing (31) formed therein that is formed to (32) characterized to 33. Receiving to (32) includes a housing (31) on one side of a narrow passage portion in the form are disclosed. Receiving to (32) pair of filling flexible band can be disclosed. style front line (36) straight than the upper path to generate a good ancestry. In this case "V" in the lower half housing portion resin such as a holding pieces (38) adding substrate. On the other hand, holding pieces (38) added, abrasion resistance, heat resistance, cold resistance (U, V, W) 3 phase power with a material ejection structure for å.. The style front line (36) and the support piece (38) is tolerance absorption function has a plurality of hierarchies. The reference also 5, BLDC motor (10) phase inductance, coil resistance, has induced voltage controller (30) like a DC side AC side resistance two electrodes. (A) 5 (b) also in BLDC motor when changing also 5 of (10) and a controller (30) current of a harness (5) for power of the resistance of the tailed off as carboxylic acids and connector without cost increase system efficiency are disclosed. In Figure 5 code 5' in controller includes a power source (30) reaching the big resistance lines. The present invention refers to a in the embodiment is not limited to, wider and idea of the present invention various corrected and deforming to person with skill in the art in the field of this technique is the same number of nontrivial disclosed. The embodiments of the present invention claim such variants or modified into the same to tell it what are disclosed. 1: motor 2: violations of the number 5: harness 10: BLDC motor 11: stator 12: rotor 15: magnet 20: pump 30: controller 31: housing 32: receiving to 34: substrate 36: style front line 38: holding pieces The present invention relates to an oil pump for transferring fluid by power of an N-pole motor, comprising: a BLDC motor (10) having magnets (15), wherein the number of magnets is less than N; a pump (20) coupled to a shaft of the BLDC motor (10); and a controller (30) accommodated in a space separated on an identical housing (31) as the BLDC motor (10). Accordingly, by mounting a half-magnet type BLDC motor on a fuel supply pump of a vehicle, weakening of durability due to vibration is prevented while maintaining system stability for a long period of time. COPYRIGHT KIPO 2017 N pole motor operated pump for conveying a fluid in: said N fewer than magnet (15) having a BLDC motor (10); said BLDC motor (10) into engagement with the shaft pump (20); and said BLDC motor (10) identical to the housing (31) isolated from space on received into controller (30); characterized by comprising a half-magnet type BLDC employing the motor oil pump. According to Claim 1, said BLDC motor (10) includes a rotor (12) N/2 on two magnet (15) characterized with a half-magnet type BLDC employing the motor oil pump. According to Claim 1, said pump (20) includes a cycloidal teeth to perform pumping half magnet type BLDC characterized by oil pump employing the motor. According to Claim 1, said controller (30) substrate (34) comprises a housing (31) secured to the style front line (36) via a BLDC motor (10) characterized by a half-magnet type BLDC wired on oil pump employing the motor. According to Claim 4, said style front line (36) "V" the user end of the holding pieces (38) via a housing (31) formed therein that is formed to (32) is supported by a half-magnet type BLDC characterized oil pump employing the motor.