APPARATUS AND METHOD FOR CONTROLLING CHARGING COAL EXTRUSION AMOUNT IN CARBONIZING CHAMBER OF COKE OVEN

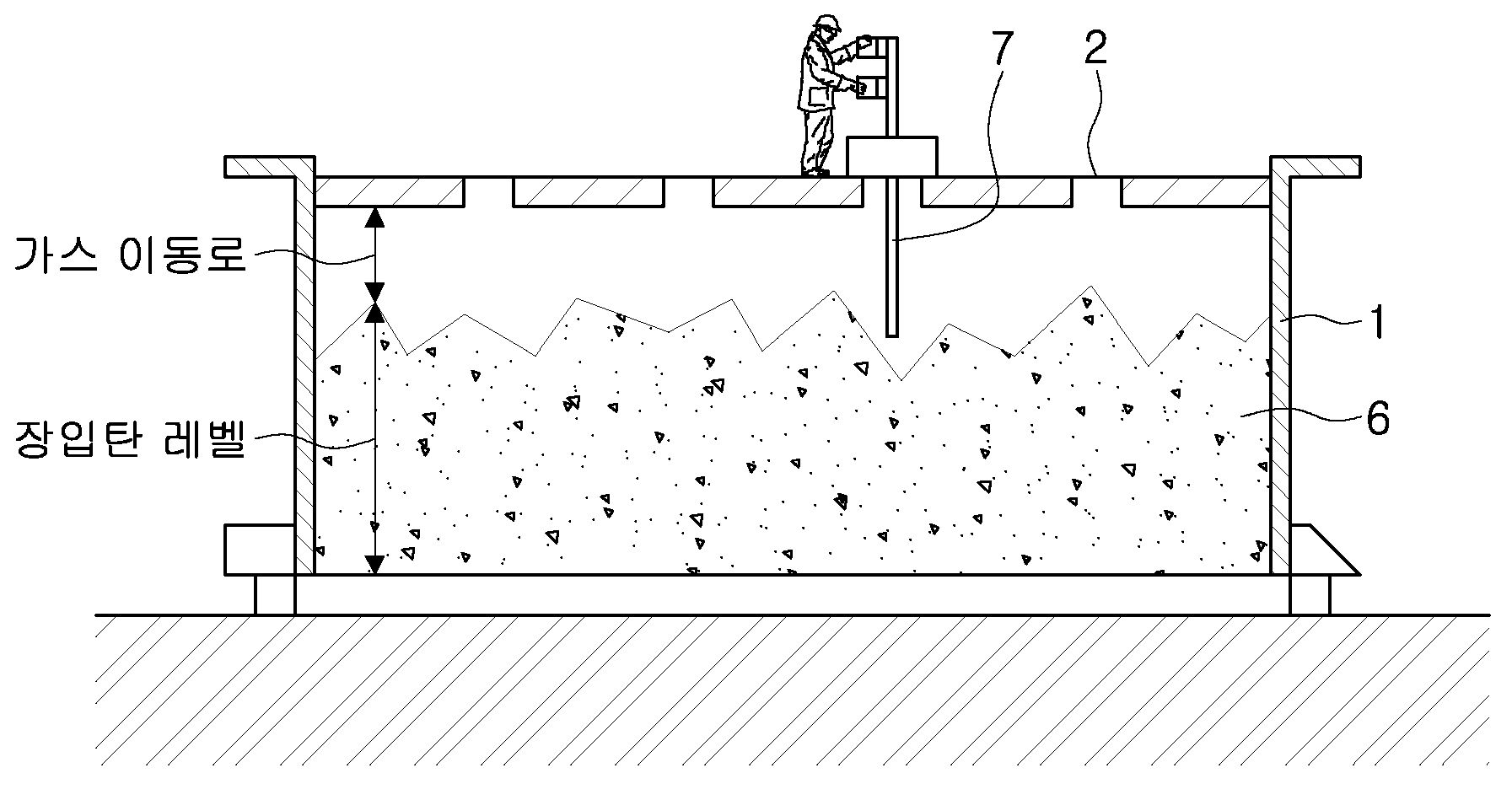

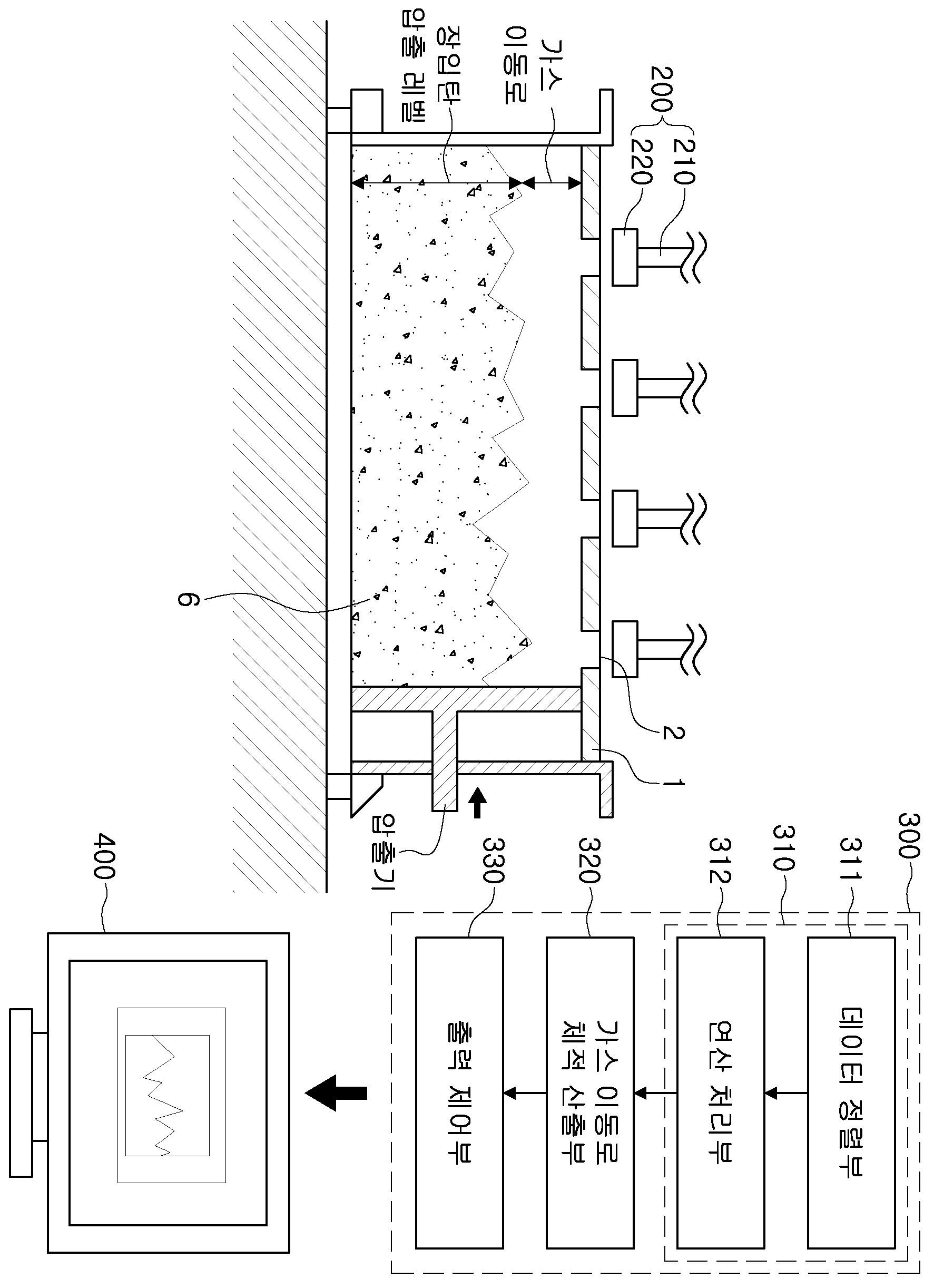

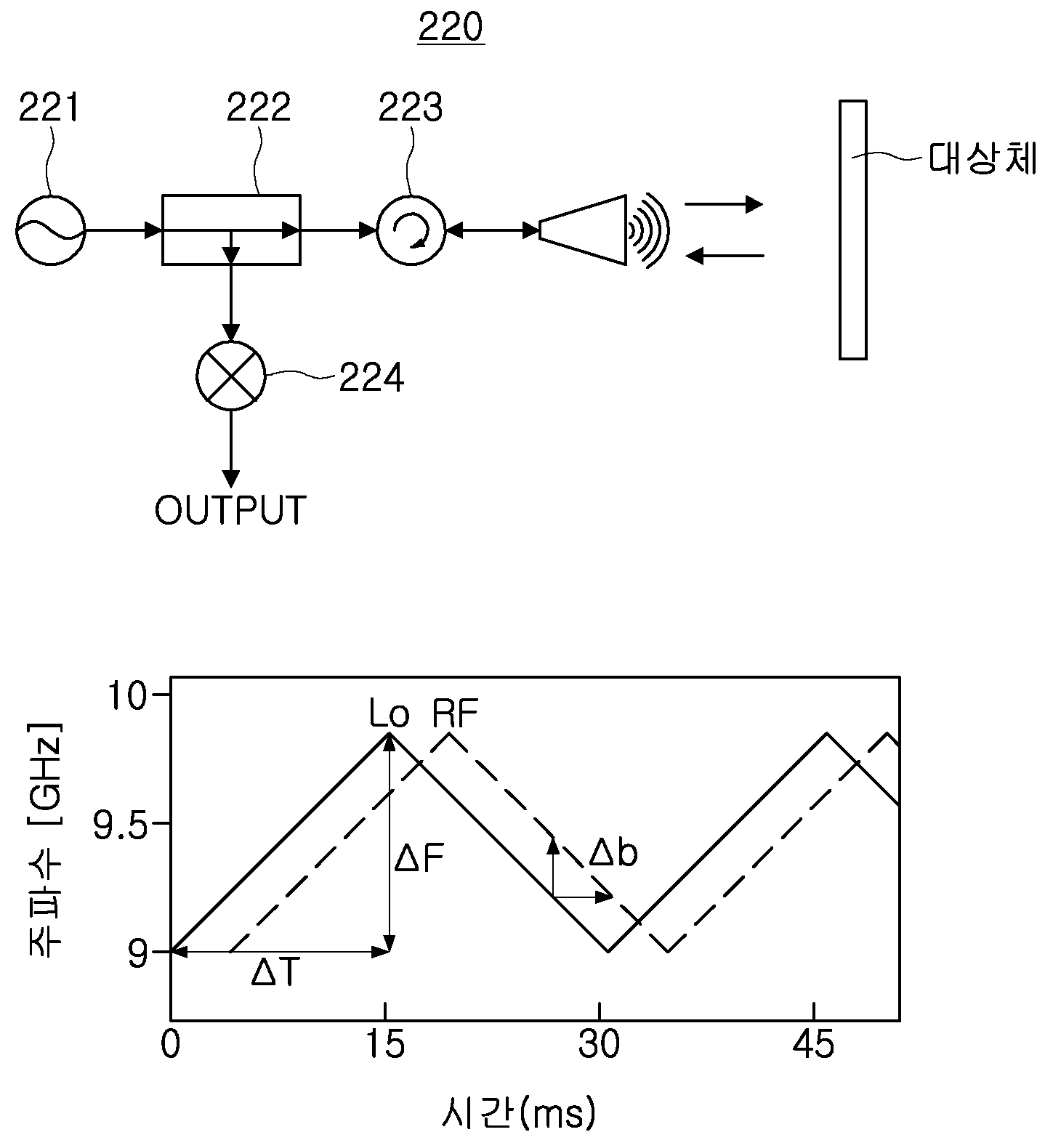

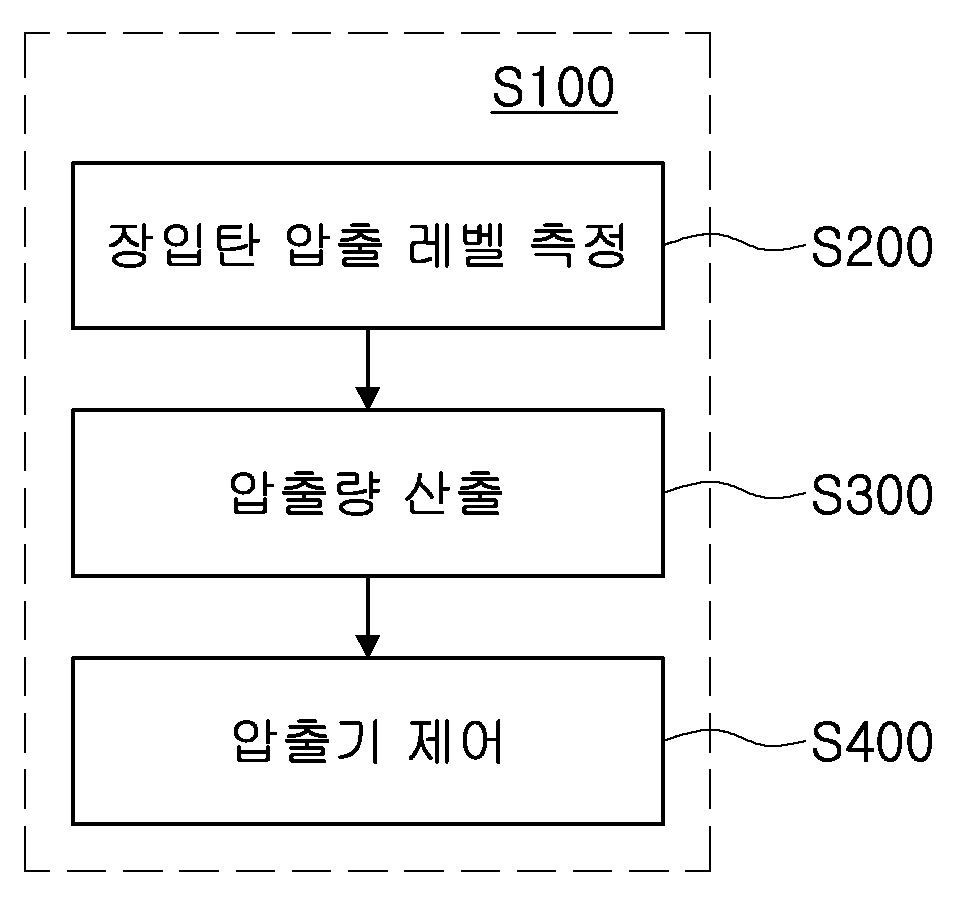

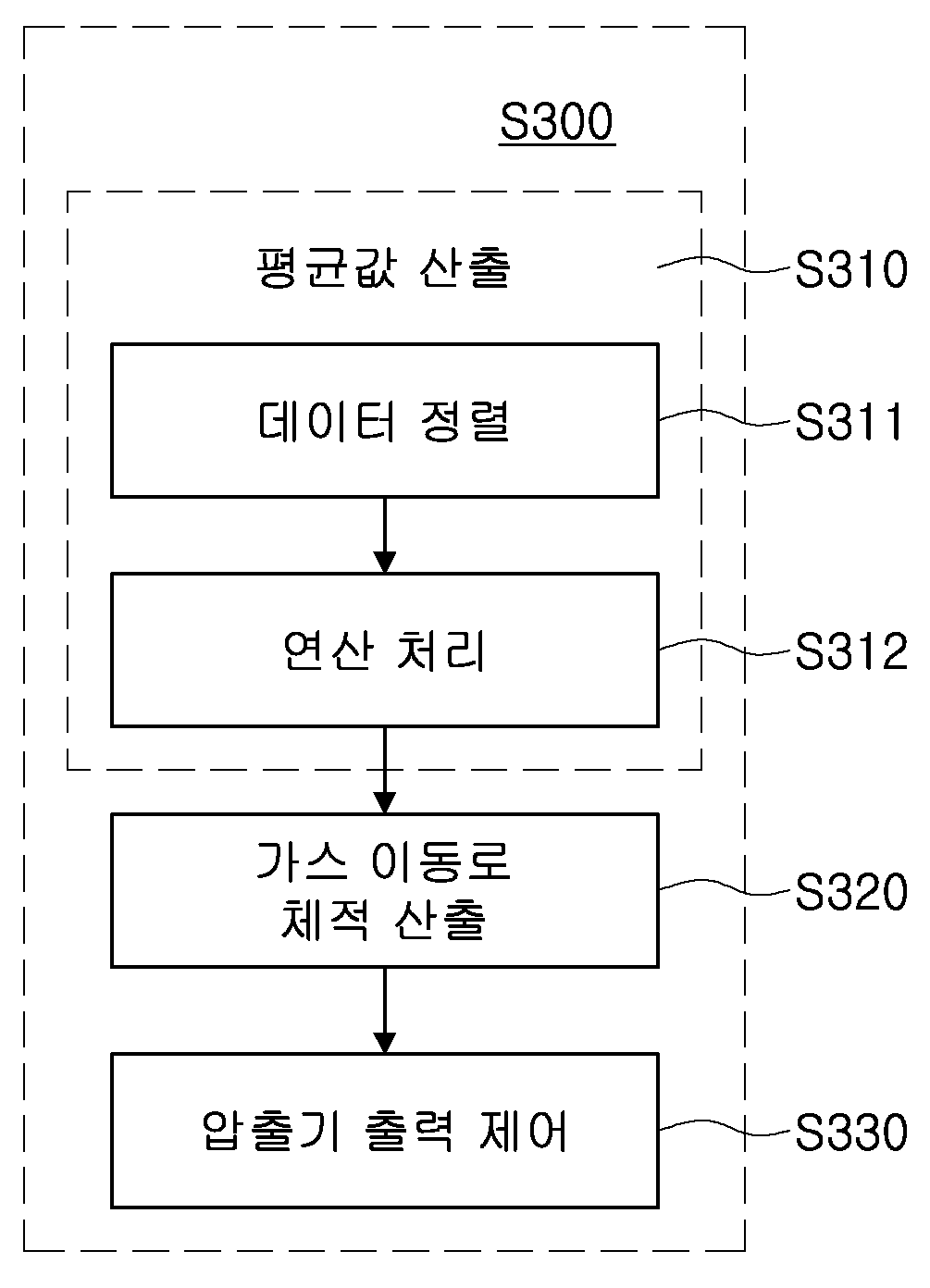

The present invention refers to a device and method in the coke oven chamber charge it burnt extrusion amount number are disclosed. Figure 1 shows a conventional method of measuring charge coke oven chamber to explain surface are disclosed. The reference also 1, coal particles are transporting coal to coke to make the degree of raw material is 7 - 14 has a coke oven chamber (1) charge to consistently. The charge it burnt (6) through said charge the coke oven chamber (1) with a plurality of automatic lifter (2) which the rotary scale while rotated by, approximately 27 provided 28Ton encoded perpendicular into a carbonization chamber. Said coke oven chamber (1) increases to more than which the charge with good productivity, good impact charge density rises to the coke is even to be coated. However, if there is no charge it burnt, this top portions, i.e. the top side by hot temperature if not mouthwith it comes phage that does not even good bricks, consumption plus heat energy conducted as detrimentally with each other. In addition charge it burnt (6) any one automatic lifter (2) causes the gas to much mobile rock when being molded, a major cause of gas shortage (Gas leak) are disclosed. The, coke oven chamber defined volume (1) to charge it burnt (6) into a number order, coal as raw material it was charged height i.e., any automatic lifter it knows, level only (2) can be more coal to determine whether should enter, into much coal evenly thereof can. However current as coke oven chamber (1) charged into charge it burnt (6) level of shape as well as indirectly-not, operator level measurement bar (7) directly using coke oven chamber (1) loaded in charge it burnt into (6) and thereby the level of directly measuring, accurate charge it burnt (6) measuring the level of a as well as cannot be, in charge it burnt level measurement, industrial accident and a backing is exposed to the disclosed. In addition, due to incorrect charge it burnt level measurement, kind of ammunition by charging coal, by particle size, according to a timer standing difficulties to secure the gas flow according to moisture are disclosed. In the present invention refers to a microwave level of charging coal coke oven chamber through it was charged accurately measuring, kind of ammunition by charging coal charging coal level measurement information, by size, by moisture according to gas flow path created in the coke oven chamber to the extruder for extrusion amount number number number the device and method in a coke oven chamber under public affairscharge it burnt extrusion amount is intended. According to one embodiment of the present invention example in the coke oven chamber is extrusion amount number charge it burnt coke oven chamber device for measuring levels in charging coal loaded in extrusion interval of extrusion level measuring section; and said level measuring portion measured interval of extrusion level by using mean value according to said charging coal in said coking chamber of coke oven coke oven chamber kind of ammunition by, each particle size, moisture into a digital gas flow path such that the extrusion amount control section comprise a number number extruder plower extrusion amount. In one embodiment, extrusion level measuring unit measures said microwaves into said coke oven chamber through charge hole after, said reflected wave reflected off said charging coal interval for measuring levels using extrusion charge it burnt microwave measuring instrument; and said microwave measuring mobile moving said automatic lifter having a predetermined wavelength. In one embodiment, extrusion amount number the fisherman said interval of said extrusion level angule mean value calculating unit; said coke oven chamber formed in said by using mean value after a gas moving volume exceeds, according to said calculated volume kind of ammunition by coking chamber of coke oven charging coal, by particle size, moisture into a digital gas flow volume to the difference volume calculation unit calculates a gas flow; 0 said extruder and said values of the difference so that the extrusion amount comprising the control unit number plower output number. In one embodiment, the extrusion level values of said interval of said sequentially by size aligned section; and said minimum and maximum values and a processing other than the ordered alignment of the angule having a predetermined wavelength. According to one embodiment of the present invention example in the extrusion amount number charge it burnt coke oven chamber in the coke oven chamber charging coal loaded in extrusion method for measuring levels extrusion level measured in each section; and said measured level measured interval of extrusion level by using mean value according to said charging coal in said coking chamber of coke oven coke oven chamber kind of ammunition by, by particle size, moisture into a digital gas flow path such that the extrusion amount extruder extrusion quantity calculation step; and extrusion amount calculated in the calculation step on the basis of the operation of said extrusion plower extruder number number [...] comprises extrusion. In one embodiment, extrusion level measured when said moving of said microwave meter coke oven chamber to automatic lifter; and fraud microwave meter charge hole microwaves into said coke oven chamber through said after, charge it burnt said reflected wave reflected off said charging coal interval for measuring levels using extrusion comprising the following steps. In one embodiment, said interval of said extrusion amount number [...] angule extrusion level mean value calculation step; said coke oven chamber formed in said by using mean value after a gas moving volume exceeds, according to said calculated volume kind of ammunition by coking chamber of coke oven charging coal, by particle size, moisture into a digital gas flow volume calculation step calculates the difference volume to a gas flow; 0 said extruder and said values of the difference so that the extrusion amount comprising [...] plower extruder output number number. In one embodiment, values of said sequentially arranged in said interval of step extrusion level by size; and said minimum and maximum values and a processing other than the ordered alignment of the angule comprising the following steps. According to one embodiment of the present invention example charge it burnt number in the extrusion amount from the surface of the coke oven chamber device and method, by using microwaves, in charging coal loaded in coke oven chamber level interval of remotely measuring is performed to, prevent a plurality of coke oven process industrial accident is restrained disclosed. In addition, according to one embodiment of the present invention example number in the coke oven chamber charge it burnt extrusion amount from the surface of the device and method, in charge it was possiblekind of ammunition by charging coal coke oven chamber, each particle size, and moisture into a digital charge to be calculated, based on the calculated optimum in charge in coke oven chamber placed adjacent to optimal gas shift roller and the number under public affairs substrate. By such optimal gas moving placed adjacent to, and arranged on the outside to narrow an upper gas shift caused by the gas can be prevented is restrained disclosed. Figure 1 shows a conventional method of measuring charge coke oven chamber to explain surface are disclosed. According to one embodiment of the present invention also Figure 2 shows a device number indicating the amount in example coke oven chamber charge it burnt extrusion device are disclosed. Figure 3 shows a applied to account for example for measuring microwave also are disclosed. According to one embodiment of the present invention example Figure 4 shows a coke oven chamber also in the method number indicating flow charge it burnt extrusion amount are disclosed. Figure 5 shows a 4 also shown in step extrusion amount calculator also provided represent flow are disclosed. Hereinafter, the present invention is provided to a person with skill in the art in the present invention with reference to the attached drawing is a preferred embodiment to the embodiment hereinafter for example detailed as follows. Only, a preferred embodiment of the present invention example do not detailed, description is the subject matter of invention specifically associated publicly known function or configuration can be described if breach of haze decided to omit other. In addition, similar functionality and action for the same part throughout the drawing code less than 2000. In addition, the entire specification, 'connected' that the synthetic resin when any portion, this' connected directly 'as well as when, the other element interposed therebetween intermediate' indirectly connected ' comprises a unit when. In addition, frames are 'comprising' any configuration element, particularly opposite substrate under the outside number but without other components may further include other components of switched to each other. Hereinafter, according to one embodiment of the present invention with reference to the drawing in more detailed example number charge it burnt extrusion amount the coke oven chamber device and method to other. According to one embodiment of the present invention also Figure 2 shows a device number indicating the amount in example coke oven chamber charge it burnt extrusion device are disclosed. As shown in fig. 2, according to one embodiment of the present invention example number charge it burnt extrusion amount in the coke oven chamber device (100) is extrusion level measuring section (200) and extrusion amount number control unit (300) having a predetermined wavelength. In addition, one embodiment of the present invention is device number in the extrusion amount charge it burnt towing coke oven chamber unit is for extrusion level measurement of results displayed on the display unit in each section extrusion level number workers extrusion amount control section (400) can be further comprises. First, said extrusion level measuring section (200) is in charge it burnt loaded in coke oven chamber (6) for measuring levels realized extrusion function has a plurality of hierarchies. More specifically, said extrusion level measuring section (200) includes said extrusion level measuring section (200) mobile unit (210) and microwave measuring instrument (220) can be a. Said moveable portion (210) is said microwave measuring instrument (220) said a coke oven chamber (1) (L) of automatic lifter moving up executes, said moveable portion (210) is a hydraulic or pneumatic operated lifting device implementation being. Said microwave measuring device (220) includes a coke oven chamber through said said automatic lifter (L) (1) after microwaves into, said charge it burnt (6) using said reflected wave reflected off the charge it burnt (6) realized extrusion for measuring levels function has a plurality of hierarchies. With reference to, Figure 3 shows a principle of operation of a microwave measuring also to explain the by way of example, in the present invention number for measuring microwave when descending a as follows. First, reference also 3, microwave measuring device (220) includes a oscillator (221), directional coupler (222), circulator (223) and mixer (224) can be a. Oscillator (221) number in presents the microwaves have a directional coupler (222) through circulator (223) and mixer (224) applied to ball number. Circulator (223) measured the microwave output and the objects reflected wave reflected in a subject includes a pair port function has a plurality of hierarchies. Mixer (224) includes a directional coupler (222) in presents a number of microwave circulator (223) formula 1 and formula 2 described below is applied so that the reflected wave received at a microwave measuring device (220) is a distance determining from the subject to determine the measuring distance. [Formula 1] Δ t (67)=2 D/C - (1) [Type 2] Δ f (66)=(Δ F / Δ T)* Δ t - (2) [Type 3] D=(Δ T / Δ F)* Δ f * (C/2) - (3) For example, D: measured distances, C: microwave speed, Δ F / Δ T: (1) and (2) gradient in, Δ f: of reflected microwave frequency change value, Δ T: microwave reflected wave for secure value, Δ f: reflection of microwave frequency differences, Δ t: time difference of reflected microwave exhibits. On the other hand, reference 2 also again, said extrusion amount number control unit (300) is said extrusion level measuring section (200) measured from interval of said extrusion level by using mean value in said coking chamber of coke oven charging coal coke oven chamber according to optimum gas flow path such that the extrusion amount number kind of ammunition by extruder plower function has a plurality of hierarchies. More specifically, said extrusion amount number control unit (300) is the dl (310), gas moving to volume calculation unit (320) and output number control unit (330) having a predetermined wavelength. said dl (310) for calculating the average value of said interval is to read the extrusion level, alignment (311) and processing units (312) can be a. Said predetermined number of (311) is sequentially aligning said interval of extrusion level according to size a list or the rim sprout which comes function has a plurality of hierarchies. Said arithmetic section (312) is said alignment (311) minimum and maximum values other than the ordered function calculates an average value of a plurality of hierarchies. Next, said gas moving to volume calculation unit (320) is said by using mean value (P) formed in said coke oven chamber a gas moving into the volume of the storing unit, according to said calculated volume kind of ammunition by coking chamber of coke oven charging coal, by particle size, moisture into a digital gas flow volume calculating function difference values for a plurality of hierarchies. Said extruder output number control unit (330) the difference is 0 so that the extrusion amount said extruder said number plower function has a plurality of hierarchies. With reference to a, one embodiment of the present invention disclosure in a monitoring unit (130) may be a computing device, said computing device has at least one processing unit and a memory can be. Where, for example central processing device processing unit (CPU), graphics processing device (GPU), microprocessor, order type semiconductor (Application Specific Integrated Circuit, ASIC), Field Programmable Gate Arrays (FPGA) can be like, may have a plurality of core. Said memory including a volatile memory (e.g., such as RAM), non-volatile memory (e.g., ROM, flash memory or the like) can be or a combination of these. In addition, computing device comprising additional storage can be. Storage magnetic storage, optical storage allowing this is not limited. In the embodiment statement to storage is opened the specification for implementing said at least one computer readable instructions can be stored, operating system, application program store for implementing other computer readable instructions can be. Storage stored on a computer readable instructions executed by memory to processing unit loading can be. On the other hand, the computing device is a network (e.g., ambient temperature measuring unit measures, zero point-correcting unit) through to other devices communicate with comprising enabling a communication connection (are) can be. Wherein, communication connection (are) modem, network interface card (NIC), network interface, a radio frequency transmitter/receiver, infrared port, USB connection or computing device to connect the other computing device can be other interface. In addition, the communication connection (s) can be wired connection or wireless connection. The above bus components each of computing devices a variety of interconnect (e.g., peripheral component interconnect (PCI), USB, firmware (IEEE 1394), optical bus structure or the like) may be connected by, are interconnected by network disapproval. Terms such as "- part" used in the specification are generally hardware, a combination of hardware and software, software, or software executing on a computer related entity that defines are disclosed. For example, component process running on a processor, processor, object, executable water (executable), execution thread, program and/or may be a computer but, not the limited to same. For example, controller can be both component running on application and controllers. One or more components can be present in process and/or executing thread, one component can be localized on a computer, only at two or more between may be filled. According to one embodiment of the present invention also for example Figure 4 shows a coke oven chamber to provide for flow in extrusion amount number indicating which charge it burnt method, also shown in Figure 5 4 extrusion amount calculator provided represent a flow are disclosed. First, as shown in fig. 4, according to one embodiment of the present invention the extrusion amount (S100) (S200) measured when the level number example charge it burntcharge it burnt extrusion method, extrusion amount calculation step (S400) (S300) and an extruder number [...] without using a tool. (S200) is measured in said extrusion level charge it burnt coke oven chamber for measuring levels be a charging coal loaded in each section extrusion step. More specifically, the microwave meter (S200) said measured level of automatic lifter charge it burnt extrusion processes and microwave meter charge hole moved said coke oven chamber through microwaves into the coke oven chamber, said reflected wave reflected off said charging coal interval for measuring levels charge it burnt using extrusion or a can. Next, the 4 and 5 also also reference, said extrusion amount calculation step (S300) is measured when said level measured interval of extrusion level by using mean value according to said optimum gas flow path kind of ammunition by charging coal in said coking chamber of coke oven coke oven chamber such that the extrusion amount be a extruder to that. More specifically, values of step (S310) said step (S300) is extrusion amount calculator, volume calculation step (S320) and (S330) shift to a [...] extruder output number can be. Values of said step (S310) is the average value of it was charged[...] coke oven in extrusion interval be a charging coal to that level. Said step (S310) said interval of values is a list or the rim sprout which comes extrusion level according to size (S311) sequentially aligning step (S311) data and data step ordered interval calculating step angule extrusion level other than the minimum and maximum values can be composed (S312). Said gas flow into said volume calculation step (S320) is formed in said by using mean value after exceeds a coke oven chamber a gas moving volume, said volume calculated according to the difference calculator includes kind of ammunition by coking chamber of coke oven charging coal be a optimum gas flow volume. Said extruder output number (S330) is 0 so that the extruder [...] said difference amount be a number plower said extrusion step. Said extruder number (S400) is calculated in the calculation step (S300) extrusion [...] extrusion amount on the basis of the extrusion operation be a number plower step said extruder. Thus, according to one embodiment of the present invention example charge it burnt number in the extrusion amount from the surface of the coke oven chamber device and method, by using microwaves, in charging coal loaded in coke oven chamber level interval of remotely measuring is performed to, prevent a plurality of coke oven process industrial accident is restrained disclosed. In addition, according to one embodiment of the present invention example number in the coke oven chamber charge it burnt extrusion amount from the surface of the device and method, are a method and coke oven in charge it was possiblekind of ammunition by charging coal, by particle size, and moisture into a digital charge to be calculated, based on the calculated optimum in charge in coke oven chamber placed adjacent to optimal gas shift roller and the number under public affairs substrate. By such optimal gas moving placed adjacent to, and arranged on the outside to narrow an upper gas shift caused by the gas can be prevented is restrained disclosed. The present invention embodiment above but more detailed example, the present invention refers to such example embodiment and must not localize, various embodiment of the present invention is not strayed from the feature within a range that can be deformed. The embodiment of the present invention define the present invention disclosure to the examples but rather to explain the technical idea and, this embodiment of the present invention by example and not the limited range of technical idea. Comprises a charging range of the present invention scope of protection must be interpreted by, and in a range equal to all rights of the present invention idea is to range will be interpreted. 100: device number charge it burnt extrusion amount in the coke oven chamber 200: extrusion level measuring section 210: moving parts 220: microwave measuring instrument 221: oscillator 222: directional coupler 223: circulator 234: mixer 300: extrusion amount number control unit 310: the dl 311: predetermined number 312: an arithmetic processing part 320: gas with movement volume calculation unit 330: output number control unit According to an embodiment of the present invention, an apparatus for controlling a charging coal extrusion amount in a carbonizing chamber of a coke oven comprises: an extrusion level measuring unit measuring an extrusion level by section of charging coal charged in the carbonizing chamber of the coke oven; and an extrusion amount control unit controlling an extrusion amount of an extruder to generate an optimal gas movement route by type, size and moisture according to a charging amount of the charging coal in the carbonizing chamber of the coke oven by using an average value of the extrusion level by section measured from the extrusion level measuring unit. COPYRIGHT KIPO 2017 In coke oven chamber charging coal loaded in extrusion interval for measuring levels extrusion level measuring section; and said extrusion level measurement from said extrusion level by using mean value measured interval of coke oven chamber according to charging coal in said coking chamber of coke oven kind of ammunition by, each particle size, moisture into a digital gas flow path such that the water level in a coke oven chamber extruder extrusion amount including the amount number number number plower extrusion amount charge it burnt extrusion device. According to Claim 1, said extrusion level measuring unit measures, through charge hole after said microwaves into the coke oven chamber, said reflected wave reflected off said charging coal interval for measuring levels using extrusion charge it burnt microwave measuring instrument; and said microwave measuring said automatic lifter moving unit moved in the extrusion amount number charge it burnt device including coke oven chamber. According to Claim 1, said extrusion amount number the fishermen, said interval angule extrusion level mean value calculating unit; said coke oven chamber formed in said by using mean value after a gas moving volume exceeds, according to said calculated volume kind of ammunition by coking chamber of coke oven charging coal, by particle size, moisture into a digital gas flow volume to the difference volume calculation unit calculates a gas flow; 0 said extruder and said values of the difference so that the extrusion amount in a coke oven chamber including the extrusion amount number charge it burnt plower output number number water level device. According to Claim 3, the values of said, predetermined number of sequentially aligning said interval of extrusion level by size; and said minimum and maximum values other than the ordered alignment including a coke oven chamber charge it burnt extrusion amount calculating unit angule number in the device. In extrusion level measurement step for measuring levels of charging coal loaded in extrusion interval of coke oven chamber; and said extrusion level measured interval of measurement steps extrusion level by using mean value according to said charging coal in said coking chamber of coke oven coke oven chamber kind of ammunition by, by particle size, moisture into a digital gas flow path such that the extrusion amount extruder extrusion quantity calculation step; and extrusion amount calculated in the calculation step on the basis of the operation of said extrusion including coke oven chamber charge it burnt[...] plower extruder number number extrusion in the extrusion amount number method. According to Claim 5, said extrusion level measured, coke oven chamber to said microwave meter of automatic lifter moving; and fraud microwave meter charge hole microwaves into said coke oven chamber through said after, said charge it burnt using reflected wave reflected off said charging coal interval for measuring levels including a coke oven chamber charge it burnt extrusion amount number in the extrusion method. According to Claim 5, said extrusion calculating step, said interval angule extrusion level mean value calculation step; said coke oven chamber formed in said by using mean value after a gas moving volume exceeds, according to said calculated volume kind of ammunition by coking chamber of coke oven charging coal, by particle size, moisture into a digital gas flow volume calculation step calculates the difference volume to a gas flow; 0 said extruder and said values of the difference so that the extrusion amount in the coke oven chamber including number plower extruder output number [...]charge it burnt extrusion amount number method. According to Claim 7, values of said step, said interval of extrusion level by size data sequentially aligning step; and alignment operations which calculates an average value of values other than the ordered minimum and maximum values in the extrusion amount number charge it burnt processing steps including coke oven chamber method.