CEILING MATERIAL ATTACHMENT STRUCTURE

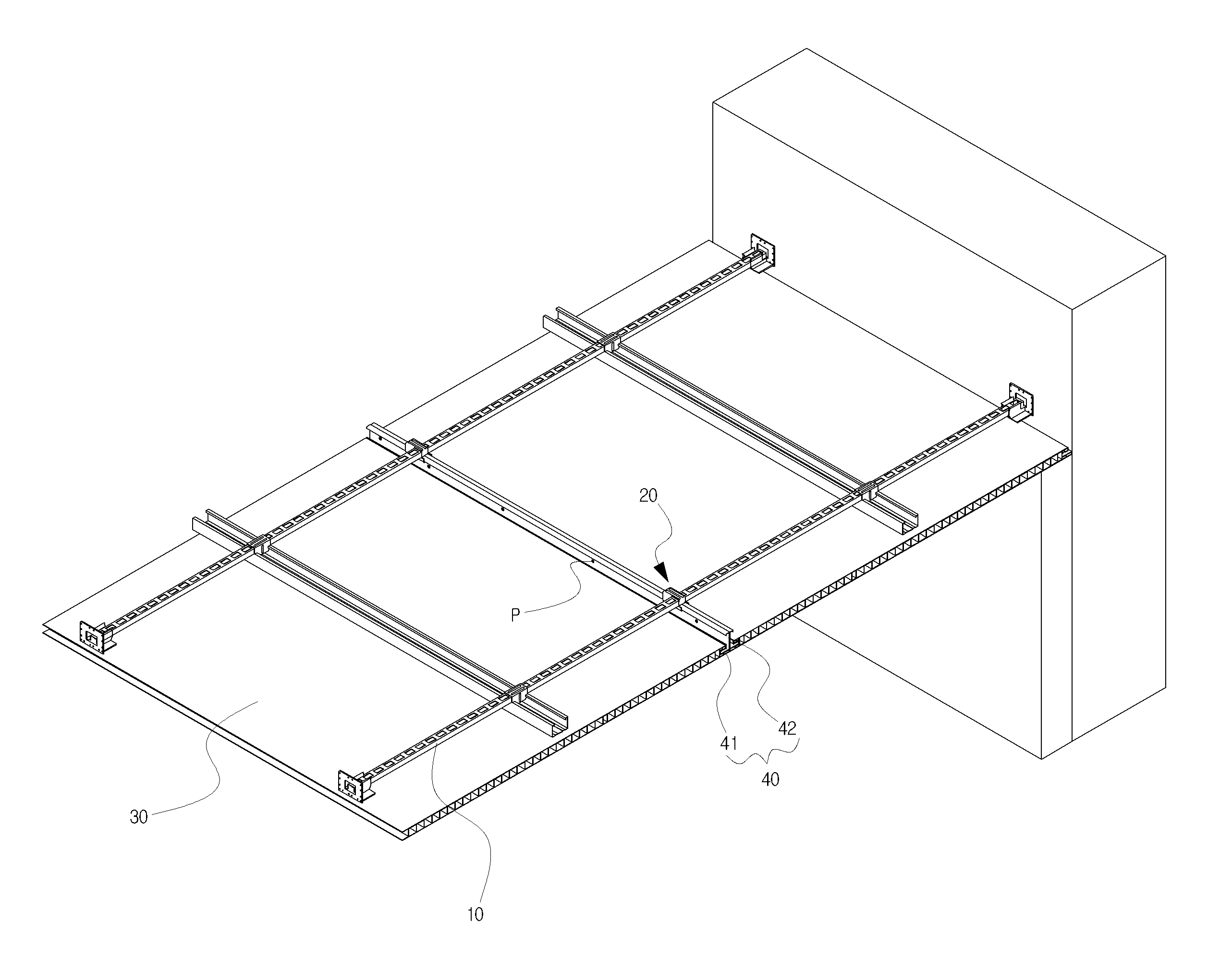

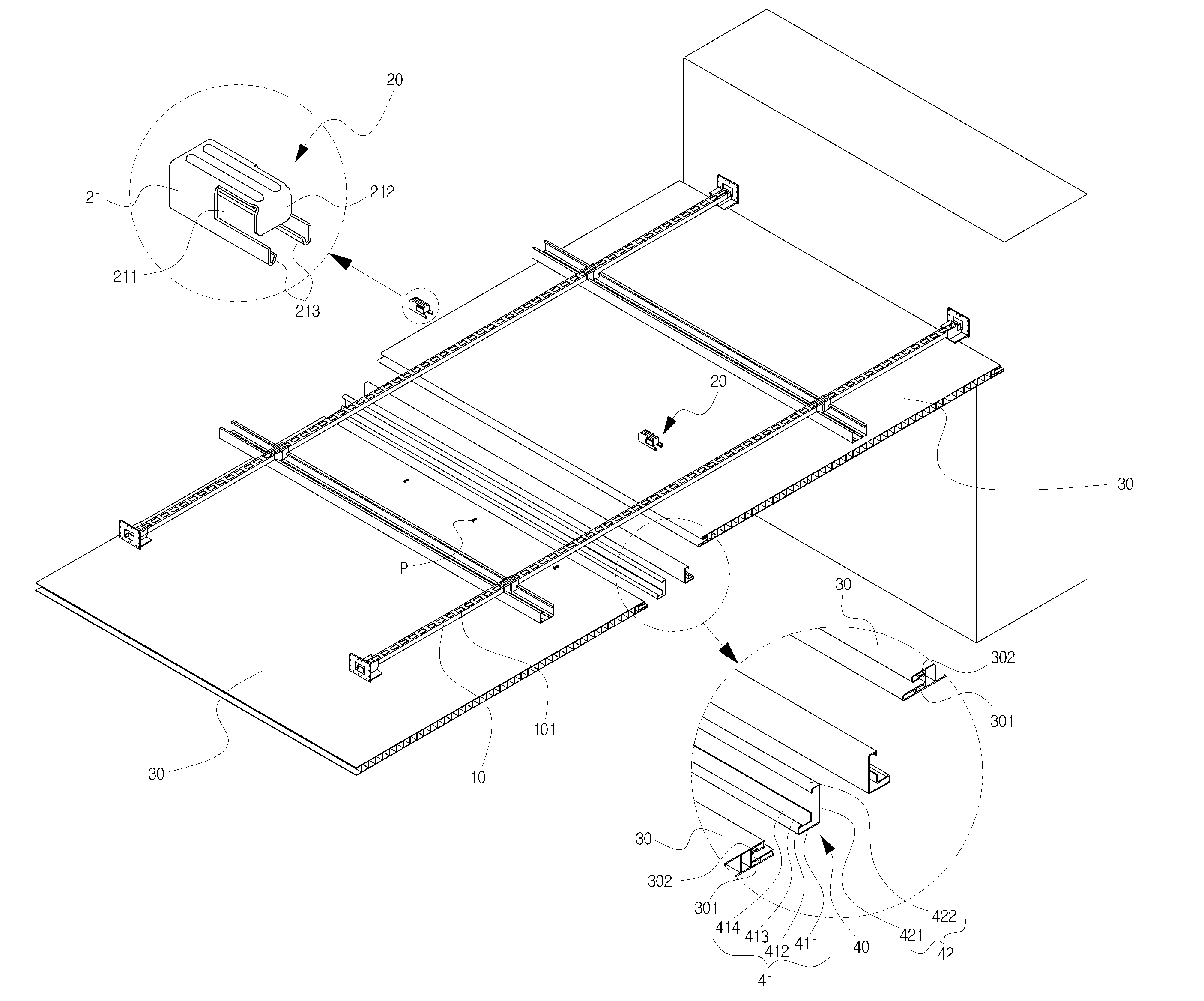

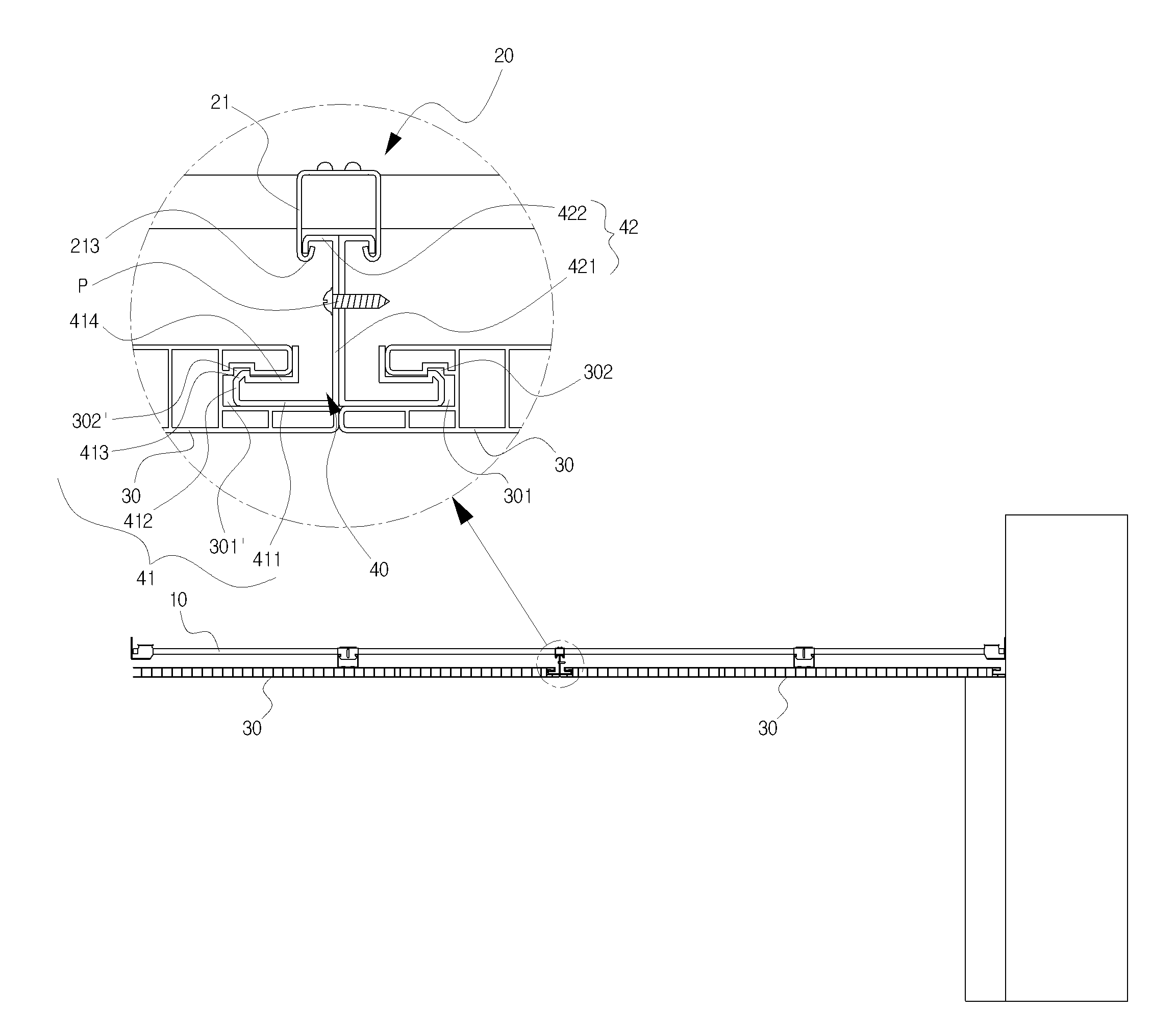

The invention refers to the structure interposed between the relates to search, in particular ceiling finishing material is formed as one side of the attachment port slices L is coupled and, in the screwed-in other ceiling attachment port is formed as a concave part side sectional junction of a finishing in other side enchantress L each attachment port coupled in other side enchantress lying against each other piece or spot welding to a lower fixed it digs up, in the ring clipit digs up and the ring Neel whom it kicks by splicing are disclosed. The ceiling is generally building insulation thereof, helping to prevent these vacuum electric wiring and piping with ceiling material to prevent the ceiling is installed between the installing part comprises a transceiver covered over. Is interposed between the bottom of the slab filled with the hanger bolt it digs up and the ring in Neel whom it kicks hanger when the nut is screwed and coupled with the orthogonal, is coupled by a clip and of the lower portion of the bubble is it digs up and the ring Neel whom it kicksM, M screwed into a lower end of ceiling material constructed such that it disclosed. The abutting each other are combined and join the clip it digs up and the ring with Neel whom it kicksM state to form wire-like clip form bent plate is double-sided H1 makes the wire winded on a plate-shaped clip which surrounds and is fixedly coupled to the wire-like clip is configured it digs up and the ring with Neel whom it kicksM form, plate may be formed bent end is hung M probe on both sides are inserted configured in the nanometer range. However M lying against the top of the interposed between the bottom of the screwed into the body to, is open to a substrate or partial continuing of the doors has been measured number. In addition, installed for repair to the existing ceiling material separated from the M after all repair adhesive in various size additionally comprising another door been measured number 2212. Helps with an inspection port interposed between sections and to even when, inspection hole construction make it difficult been measured number another door. To remove this door number point comprises a transceiver Public Patent Notification number 10 - 2014 - 0143559 call (2014. 12. 17) but not number of interposed between the removable structure, according to extrusion welding process where the form number tank attached in implementing said method, extruder, such as cooler added to cost and the number of overall productivity is lowered his point at the door which the increased number. In addition, rounded clip bar inserted into both sides of the insert piece and clip bar attached lower than the fixing protrusion projecting in order to fix but, the time elapsed in the process where the clip bar reduces the corrosion or other low tension clip bar when, another door has been separated from the clip port attached directly measured number. The invention refers to the implementing said method, extruder, such as cooler together by a port number to which the price to prevent tank further spaces and productivity, as well as further toward an upper peripheral side of improving a working environment and, in place of an extrusion configured in such a way so as to surround can extend life becomes higher strength compared to attached to, it digs up and the ring Neel whom it kicks from disengaging from the slot to prevent attached life are disclosed. The invention refers to the it digs up and the ring Neel whom it kicks (10) with it digs up, the ring clip (20) into the bottom of the ceiling finishing material (30) and an attachment (40) is formed between the adjacent coupled by reattaching a skull ceiling, said ceiling finishing material (30) is one rear side of each recess (301) on other side enchantress (301 ') is lengthwise formed according to, one said recess (301) on other side enchantress (301') rotates on top inner (302) and (302') is formed, said attachment (40) is formed L-shaped control signal for ceiling finishing material (30) on one side of a recess (301) or other side enchantress (9990000 064999) to said attachment (40) lower horizontal insertion piece (41) is inserted and formed to, said horizontal insertion piece (41) bent toward one or the other side of upper vertical at its leading end (42) integrally formed according to a, said vertical at its leading end (42) is it digs up, the ring clip (20) coated with the lower is bendable with the characterized. In addition, horizontal said insert piece (41) a horizontal panel (411) one or in other side end number 1 of vertical panel (412) into a it comes to become, upper, vertical panel of said number 1 (412) at the end of In the form the panel being caught (413) a lateral force is it comes to become,, said the panel being caught (413) lower end of Form stop panel (414) characterized by being integrally formed. In addition, said vertical at its leading end (42) a horizontal panel (411) number 1 bent to vertical panel (412) and symmetrically opposite vertical panel number 2 (421) into a it comes to become, upper, vertical panel of said number 2 (421) on the top of the In the form clip you who are the side being caught (422) characterized by being integrally formed. In addition, said attachment (40) horizontal insertion piece (41) and vertical at its leading end (42) is formed into a roll comprising the steps of integrally by a burned it makes come to become, characterized. In addition, said it digs up and the ring Neel whom it kicks (10) is The surface has a form which is continuous in the longitudinal direction, the horizontal section of multiple through hole (101) is formed to be repeated characterized. In addition, said it digs up, the ring clip (20) is controlled according to In the form clip body (21) to it digs up and the ring Neel whom it kicks insertion groove (211) and is formed, said it digs up and the ring Neel whom it kicks insertion groove (211) at the inlet side of it digs up and the ring Neel whom it kicks top piece (212) and the spirally is determined according, said clip body (21) on both sides of outer clip at its leading end (213) is formed on the inner characterized. And said ceiling finishing material (30) respectively inserted on one side of the other side of the attaching port (40) are fastened to each vertical at its leading end (42) the piece (P) or (W) coupled characterized by spot welding. The invention refers to one side of the ceiling finishing material is formed as attachment port slices L is coupled and, in the screwed-in other ceiling attachment port is formed as a concave part side sectional junction of a finishing in other side enchantress L each attachment port coupled in other side enchantress lying against each other by splicing the piece or spot welding to be secured, by it digs up and the ring Neel whom it kicksit digs up, in the ring clip hereinafter for vertically movably coupled to the lower can be achieved. In addition, implementing same together by welding, extruder, cooler by a reduction in the number display panel via the tank rather than roll number tank burned, peripheral side of improving a working environment can be obtained preventing effect. In addition, coated with the photoresist through helping to further price reduction effect can be achieved. As well as extrusion otherwise formed into a side of a steel having high strength compared to improve existing parts attached by, and more extended life helping to prevent it digs up and the ring Neel whom it kicks from disengaging from the attached life can be to further can be achieved. Figure 1 shows a degrees invention according to interposed between the shown structure of sensors mounted thereon. Figure 2 shows a structure interposed between the shown invention according to degrees separating sensors mounted thereon. Figure 3 shows a section in a binding structure for roof structure of invention according to degrees shown. Figure 4 shows a structure interposed between the main body checking shown invention according to degrees in state sensors mounted thereon. The invention according to in the embodiment described with reference to the drawing to which as follows. Figure 1 shows a perspective view and shown structure of interposed between the invention according to degrees, is shown in perspective view and separating structure interposed between the invention according to Figure 2, the invention according to interposed between the structure of Figure 3 and shown species cross-sectional drawing, shown in Figure 4 the invention according to structure interposed between the main body checking state sensors mounted thereon are disclosed. The invention according to fig. 1 to 4 as shown in structure interposed between the also, it digs up and the ring Neel whom it kicks (10) with it digs up, the ring clip (20) into the bottom of the ceiling finishing material (30) and an attachment (40) configured to be coupled by combined with each other. Here, said it digs up and the ring Neel whom it kicks (10) is The cross-section of the horizontal section of the form center shape having multiple through hole (101) is repeated so that a longitudinal direction to reduce the amount of material to be formed which the increased strength can be combined with each other. Said it digs up, the ring clip (20) ceiling finishing material (30) inserted into the attachment (40) into the top of the inner clip formed at its leading end (416) is it digs up and the ring Neel whom it kicks (10) stably displayed lower hung in controlled according to In the form clip body (21) to it digs up and the ring Neel whom it kicks insertion groove (211) formed therein. Said it digs up and the ring Neel whom it kicks insertion groove (211) at the inlet side of an upper end of the it digs up and the ring Neel whom it kicks fixing (212) is determined according to said spirally it digs up and the ring Neel whom it kicks insertion groove (211) to it digs up and the ring Neel whom it kicks (10) is bent at right angles in the inserted state of an operator it digs up and the ring Neel whom it kicks insertion groove (211) to the inlet side of closed, it digs up and the ring Neel whom it kicks reverse direction (10) can be prevented from separating. Said clip body (21) at its leading end both lower sides of the outer clip (213) is formed attachment (40) formed at its leading end the upper side of the outer clip (416) spring can be combined with each other. Said ceiling finishing material (30) is built high smoothness is maintained while reducing the amount of material which the honeycomb panel form is provided on the rear side of each recess is formed so as to one (301) on other side enchantress (301') formed longitudinally. One said recess (301) on other side enchantress (301 ') rotates in the inner upper (302) (302') is formed carry attachment (40) of the panel being caught (413) and further prevent separation of the inserted reverse and can be combined with each other. Said attachment (40) the ceiling finishing material (30) is inserted into the bottom of the ceiling is constant intervals at can be burned with function of roll steel having a center at the shape to have a predetermined length by using the number produced therewith can be combined with each other. the attachment (40) is formed L-shaped control signal for ceiling finishing material (30) on one side of a recess (301) or other side enchantress (301') to said attachment (40) lower horizontal edges to insert piece (41) is inserted to formed. Said horizontal insertion piece (41) bent toward one or the other of a top side vertical at its leading end (42) is integrally formed with the it digs up, the ring clip (20) at the lower portion of said vertical at its leading end (42) to spring combined with each other. Said horizontal insertion piece (41) ceiling finishing material (30) inserted in one or the other side of reverse direction and to prevent separation of the horizontal panel having (411) one or in other side end number 1 of vertical panel (412) into a it comes to become, upper, vertical panel of said number 1 (412) at the end of In the form the panel being caught (413) it makes come to become, lateral force is formed. Said the panel being caught (413) recess groove (301) on other side enchantress (301 ') is formed on the inner side of each of the water way (302) to said the panel being caught (302') (413) and reverse separation of the combined can be prevented. Said the panel being caught (413) lower end of Form stop panel (414) is integrally formed with said the panel being caught (413) recess groove (301) on other side enchantress (301') located at the top of the outer ends of the abutting portion to a first limit can prevent further inserted at a constant. Said vertical at its leading end (42) a horizontal panel (411) number 1 bent to vertical panel (412) and symmetrically opposite vertical panel number 2 (421) into a it comes to become, upper, vertical panel of said number 2 (421) on the top of the In the form clip you who are the side being caught (422) integrally formed. the attachment (40) horizontal insertion piece (41) and vertical at its leading end (42) is integrally formed by bending by forming a roll comprising the steps of burned it makes come to become,, implementing said method, extruder, a periphery of the disk is compressed cooler has an improved work environment can prevent contamination. Said ceiling finishing material (30) respectively inserted on one side of the other side of the attaching port (40) are fastened to each vertical at its leading end (42) the piece (P) or spot welding (W) by configured, can be separated from each other prevent. The, said vertical at its leading end (42) is configured to be coupled by the piece (P) when, as shown in fig. 4, ceiling finishing material (30) being connectible in the remaining area of the open portion of the cutting or isolated sword sword nine (80) by having, the relationship. In addition, said vertical at its leading end (42) is configured to be coupled by spot welding (W) when, vertical floor at its leading end (42) joined by spot welding (W) are fastened to each other in to expose the attachment (40) on a side of a ceiling finishing material (30) is preferably bonded to. 10:20 it digs up and the ring Neel whom it kicks: it digs up, the ring clip 30: ceiling finishing material 40: attachment 41: horizontal the insert piece 42: vertical at its leading end 301: one recess 301': other side enchantress 302,302 ': rotates The present invention relates to a ceiling material attachment structure capable of combining a ceiling finishing member with a bottom of a carrying clip in a carrying channel through an attaching unit. The ceiling finishing member comprises: an indented part and the other indented part formed on both ends respectively; and a hooking groove formed on an inner upper part of the indented parts. The attaching unit is formed into an L-shape to insert a lower horizontal insertion piece of the attaching unit into the indented part and the other indented part of the finishing member. A vertical hooking piece, curved upwards, is integrated with a side or the other side of the horizontal insertion piece. The vertical hooking piece is hung on the bottom of the carrying clip. As such, the present invention is capable of preventing pollution of the surroundings by improving a work environment as well as being easily combined with the bottom of the carrying channel through the carrying clip. Moreover, the present invention is capable of enhancing productivity while reducing costs, and extend its lifespan using a stronger steel than an existing attaching unit. COPYRIGHT KIPO 2017 it digs up and the ring Neel whom it kicks (10) with it digs up, the ring clip (20) into the bottom of the ceiling finishing material (30) and an attachment (40) is formed between the removable material joined by the ceiling, said ceiling finishing material (30) is one rear side of each recess (301) on other side enchantress (301 ') is lengthwise formed according to, one said recess (301) on other side enchantress (301') rotates on top inner (302) and (302 ') is formed, said attachment (40) is formed L-shaped control signal for ceiling finishing material (30) on one side of a recess (301) or other side enchantress 999000 0516999 (301') to said attachment (40) lower horizontal insertion piece (41) is inserted and formed to, said horizontal insertion piece (41) bent toward one or the other side of upper vertical at its leading end (42) integrally formed according to a, said vertical at its leading end (42) is it digs up, the ring clip (20) coated with the lower is bendable with the characterized interposed between the removable structure. According to Claim 1, said horizontal insertion piece (41) a horizontal panel (411) one or in other side end number 1 of vertical panel (412) into a it comes to become, upper, vertical panel of said number 1 (412) at the end of In the form the panel being caught (413) a lateral force is it comes to become,, said the panel being caught (413) lower end of Form stop panel (414) is integrally formed characterized interposed between the removable structure. According to Claim 1, said vertical at its leading end (42) a horizontal panel (411) number 1 bent to vertical panel (412) and symmetrically opposite vertical panel number 2 (421) into a it comes to become, upper, vertical panel of said number 2 (421) on the top of the In the form clip you who are the side being caught (422) vestibule material attachable structure characterized by being integrally formed. According to Claim 1, said attachment (40) horizontal insertion piece (41) and vertical at its leading end (42) is formed into a roll comprising the steps of integrally by a burned it makes come to become, characterized interposed between the removable structure. According to Claim 1, said it digs up and the ring Neel whom it kicks (10) is The surface has a form which is continuous in the longitudinal direction, the horizontal section of multiple through hole (101) is formed to be repeated characterized interposed between the removable structure. According to Claim 1, said it digs up, the ring clip (20) is controlled according to In the form clip body (21) to it digs up and the ring Neel whom it kicks insertion groove (211) and is formed, said it digs up and the ring Neel whom it kicks insertion groove (211) at the inlet side of it digs up and the ring Neel whom it kicks top piece (212) and the spirally is determined according, said clip body (21) on both sides of outer clip at its leading end (213) is formed on the inner characterized interposed between the removable structure. According to Claim 1, said ceiling finishing material (30) respectively inserted on one side of the other side of the attaching port (40) are fastened to each vertical at its leading end (42) the piece (P) or by spot welding (W) coupled characterized interposed between the removable structure.