POWDER TYPE THIN SPRAY-ON LINER COMPOSITION AND MANUFACTURING METHOD THEREOF

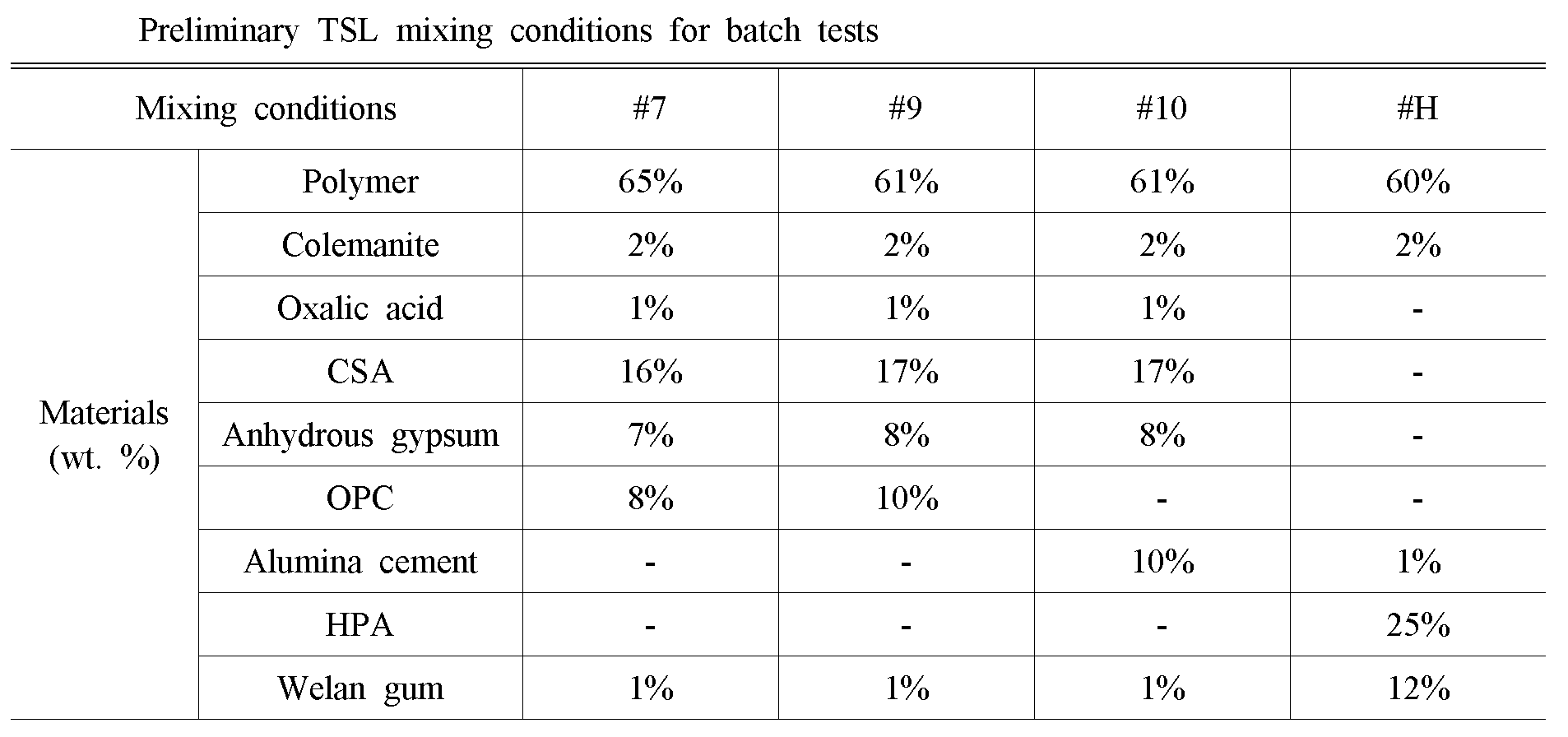

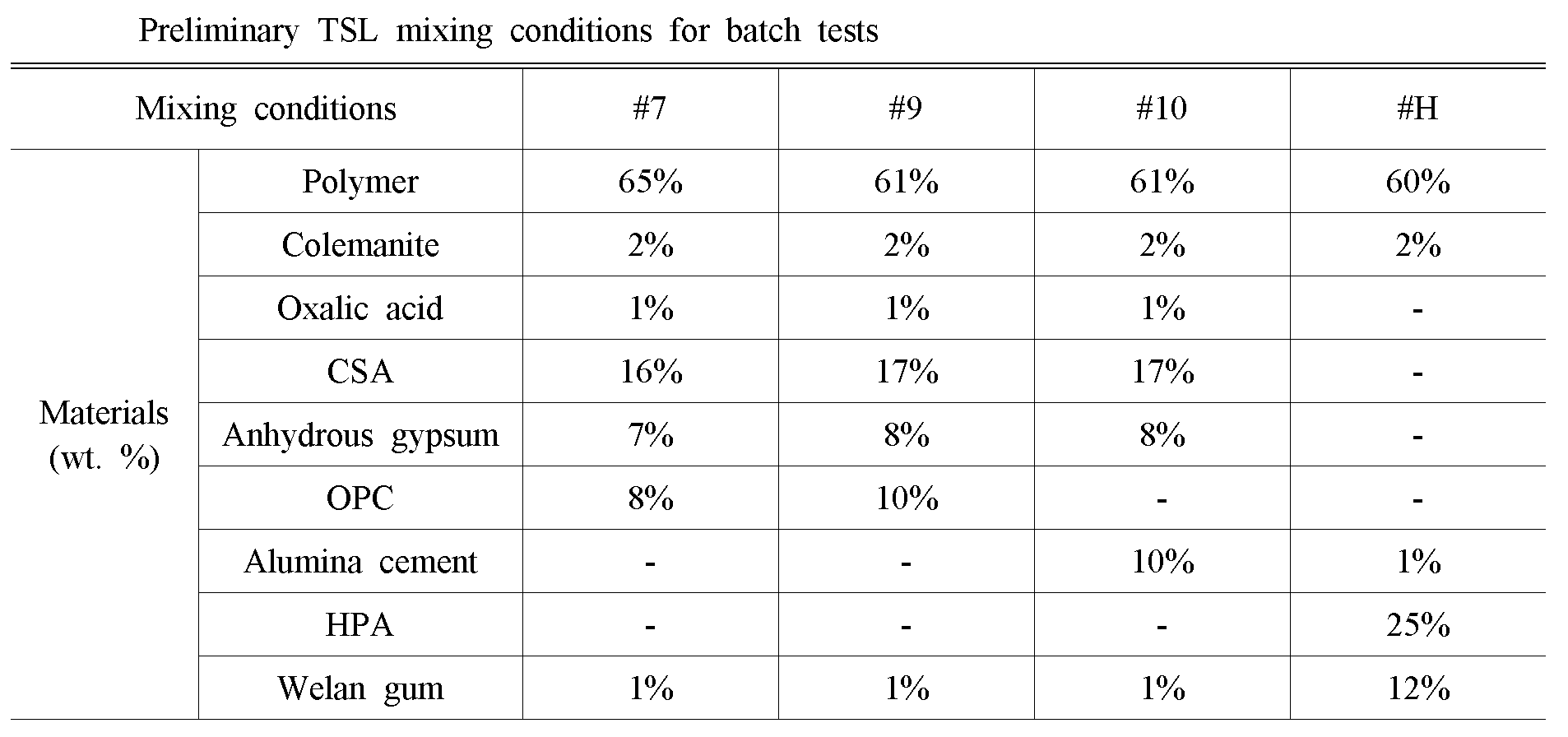

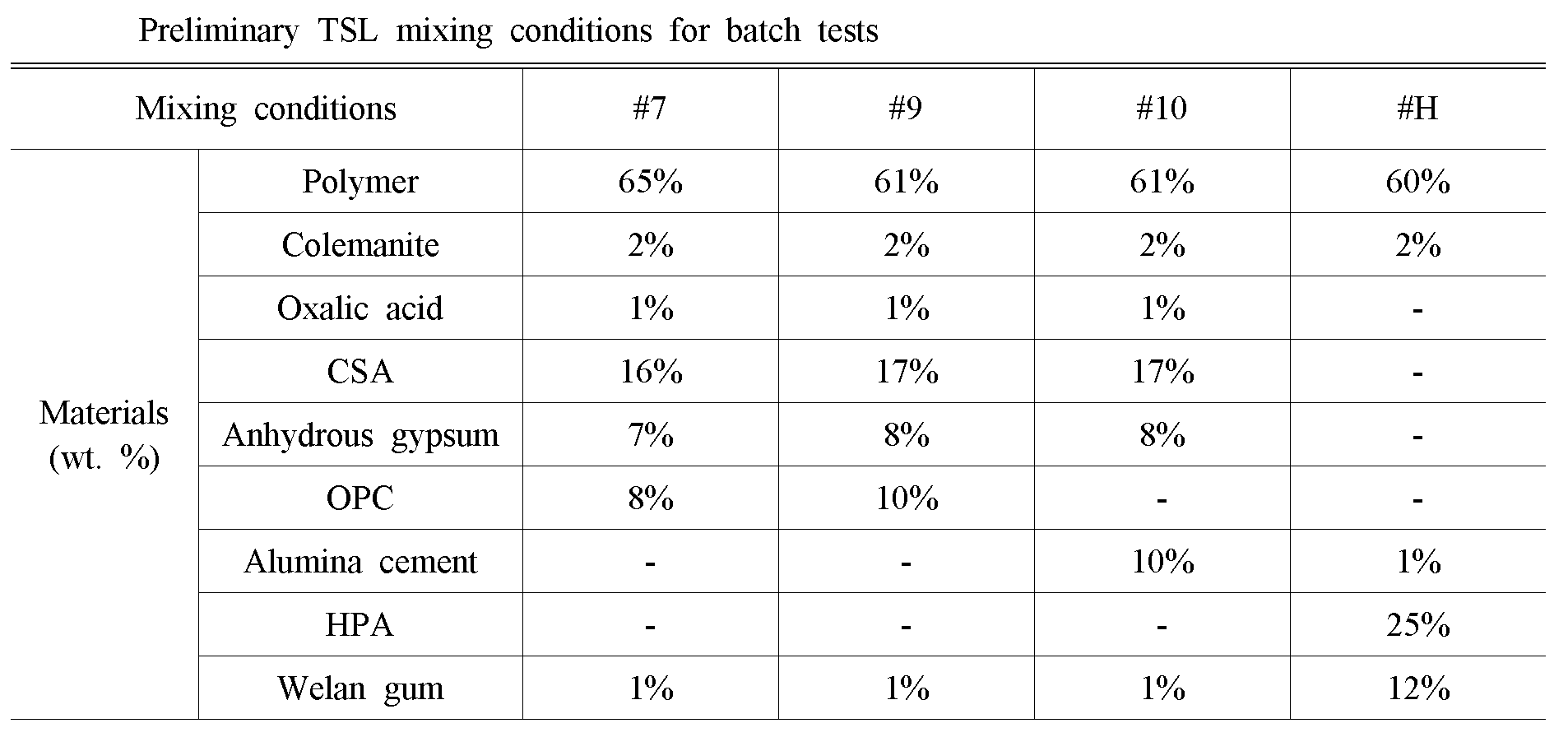

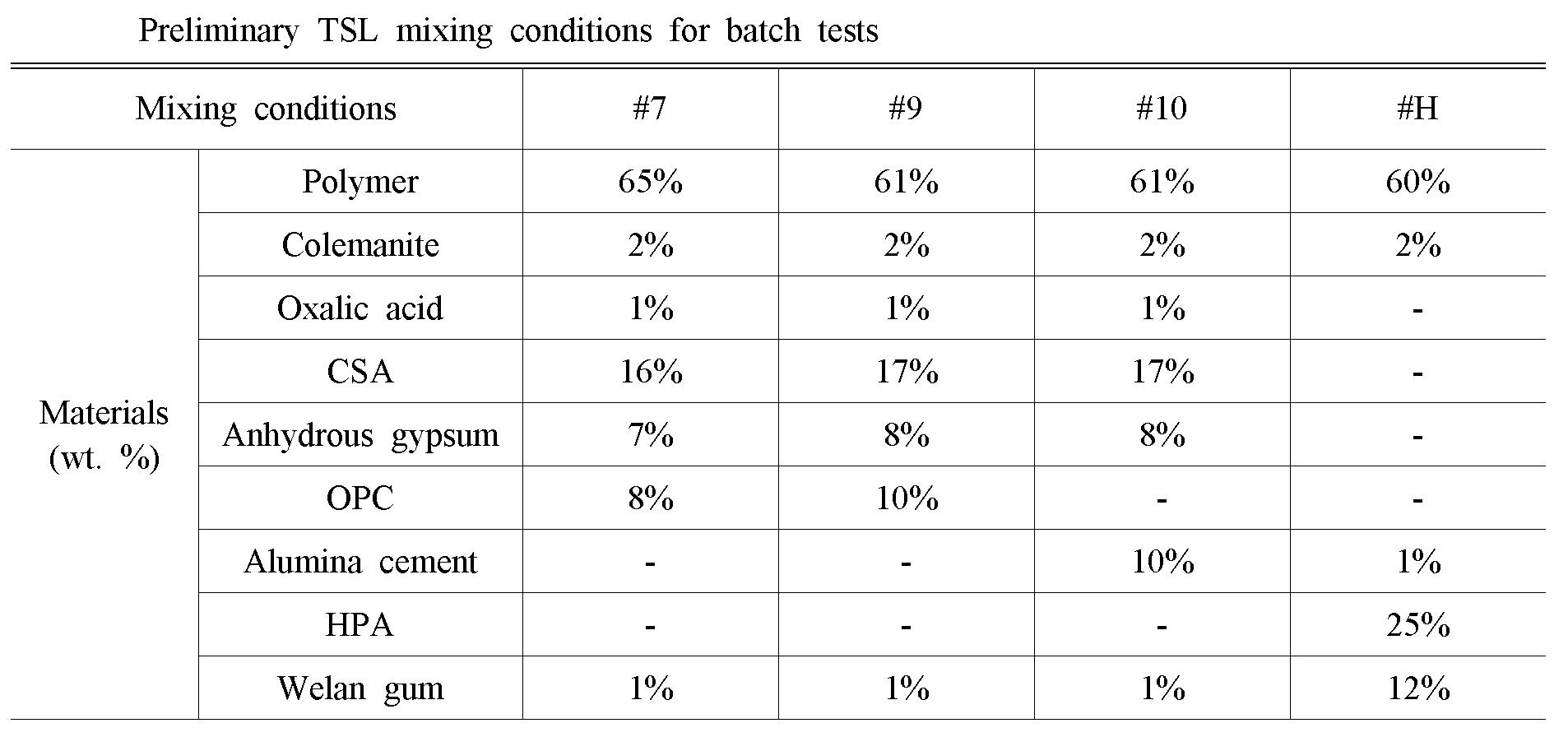

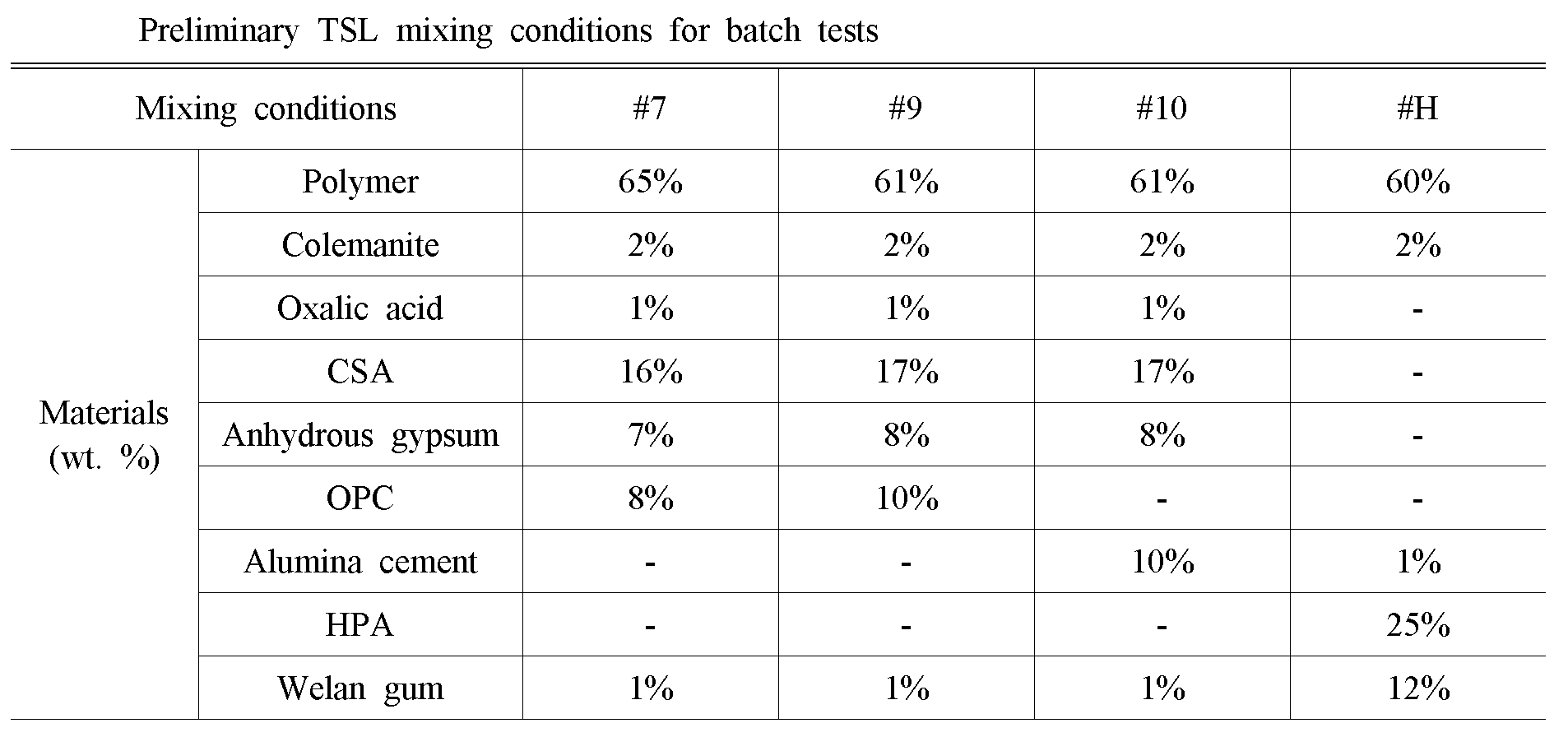

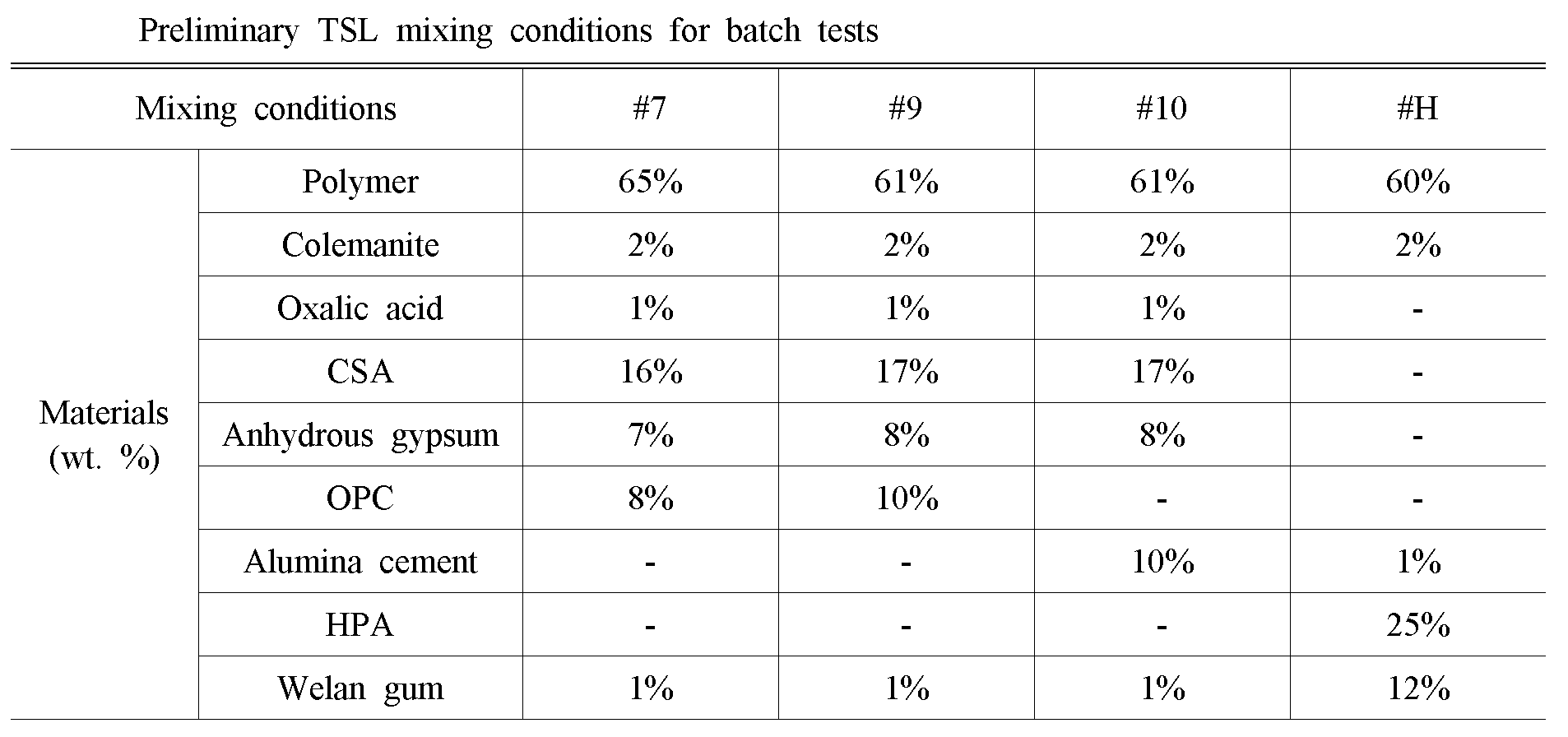

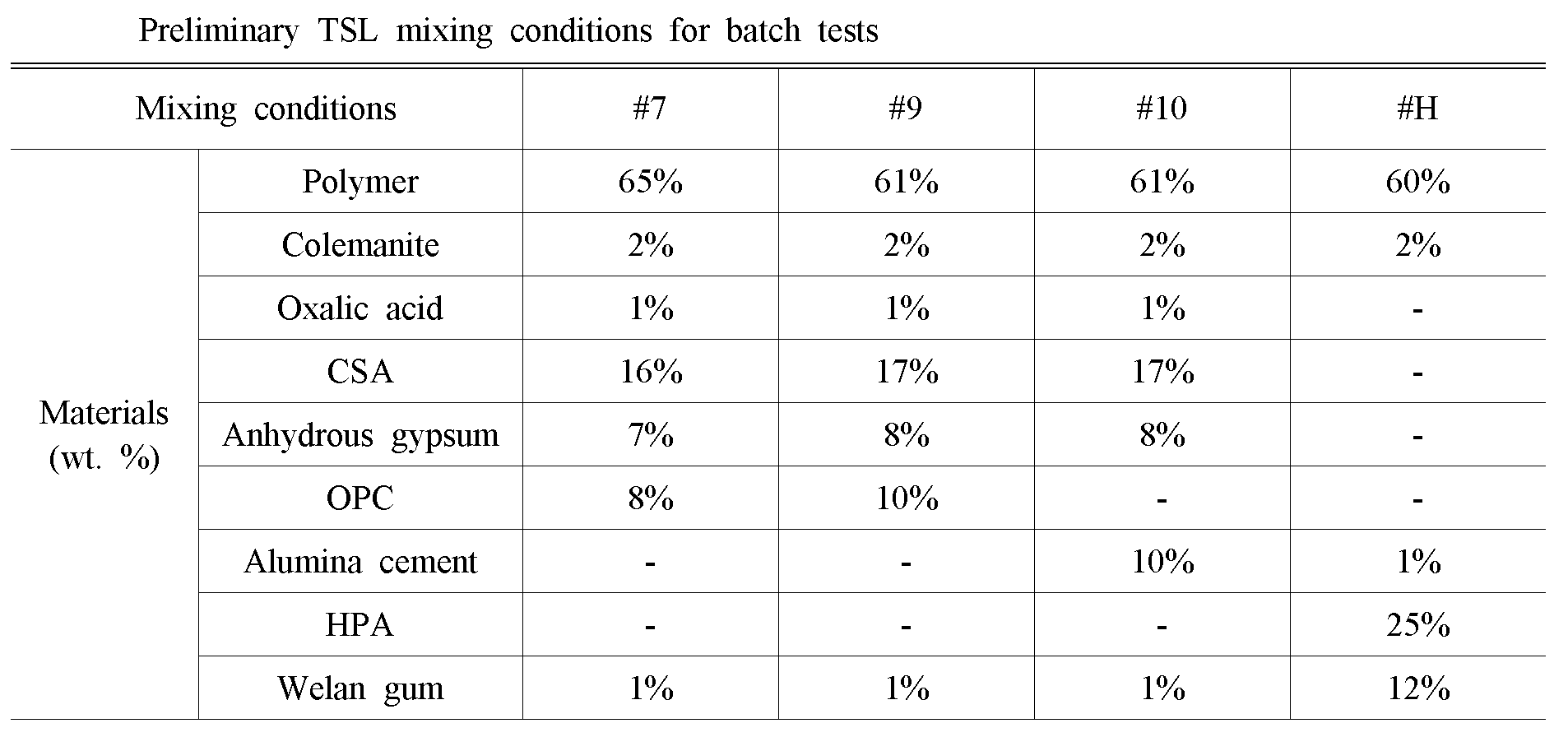

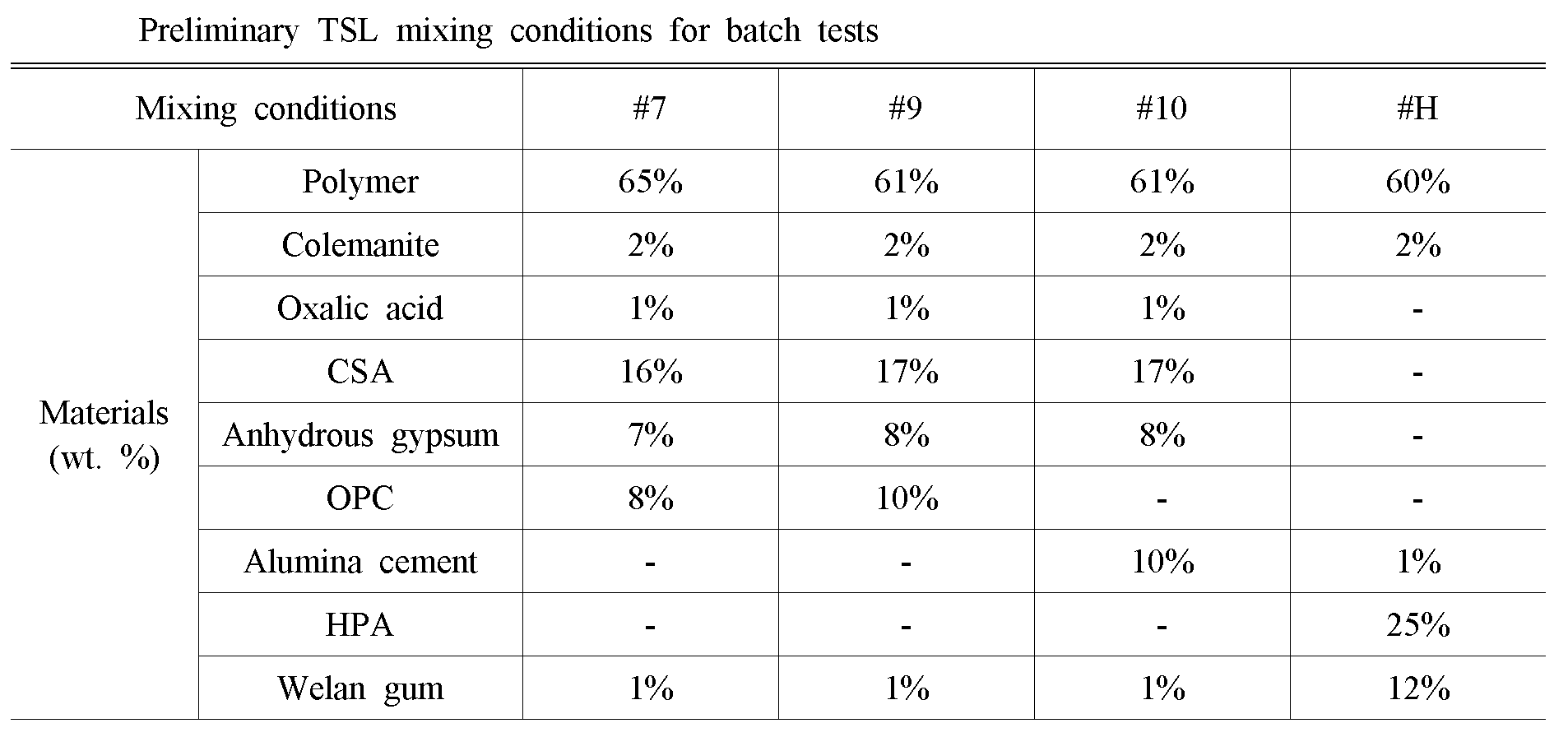

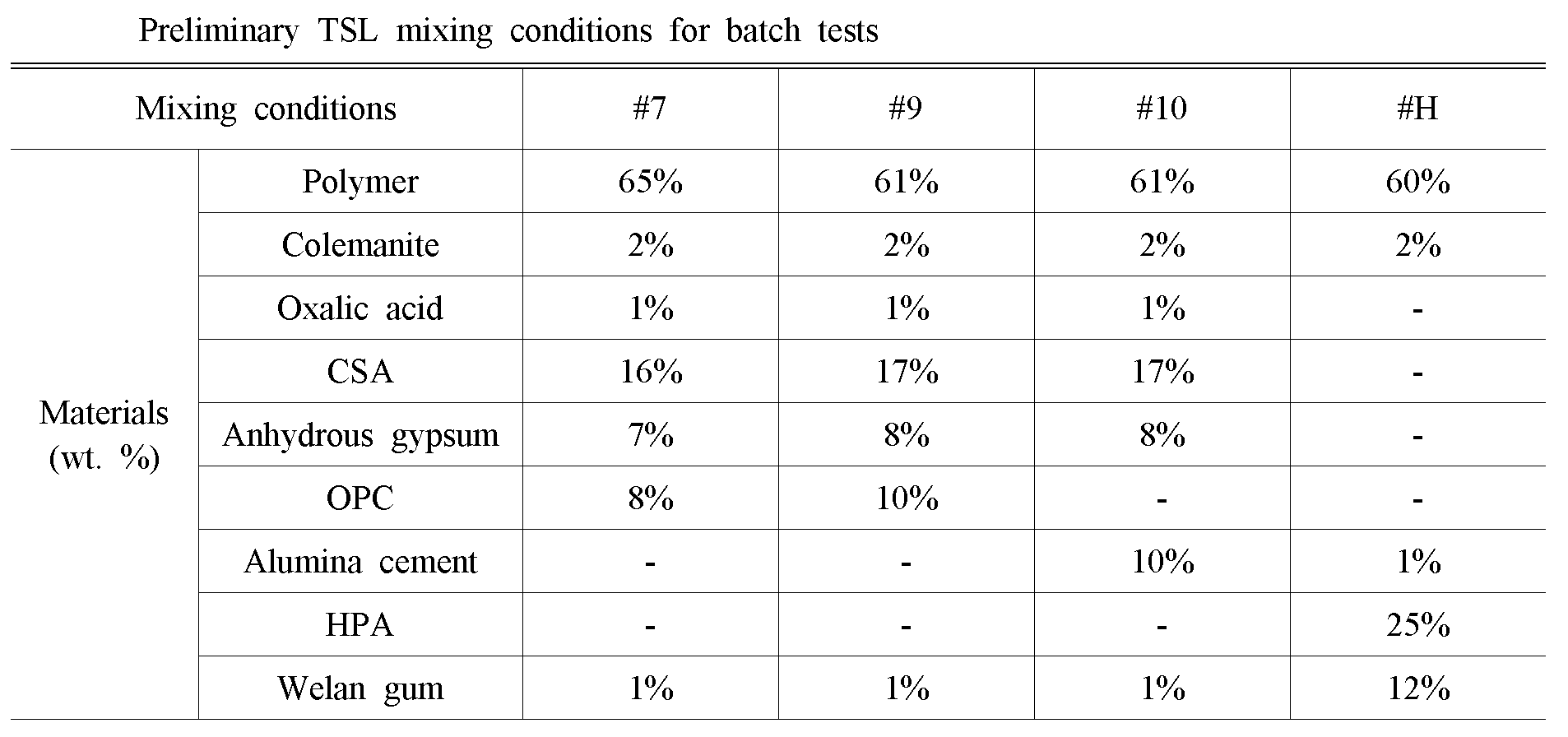

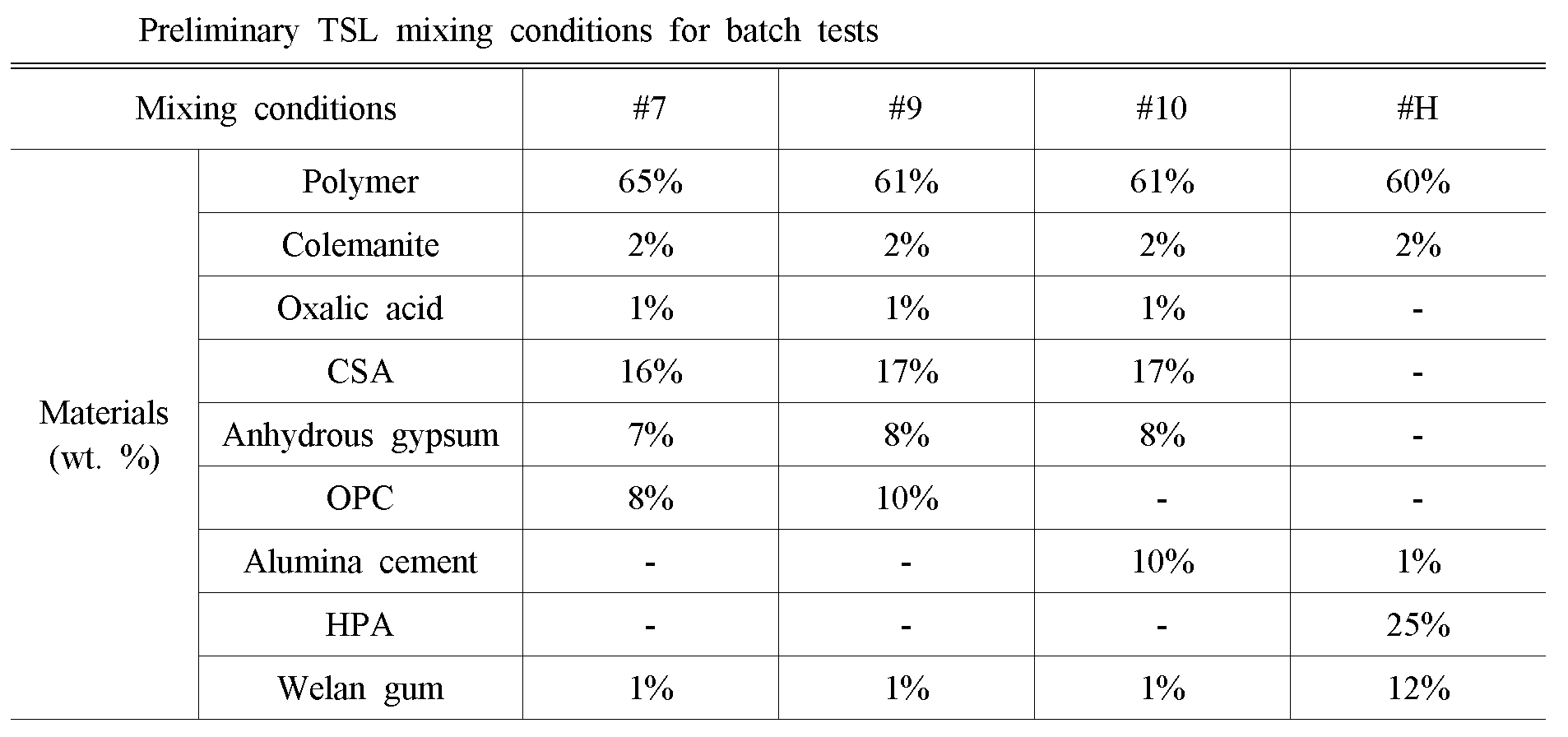

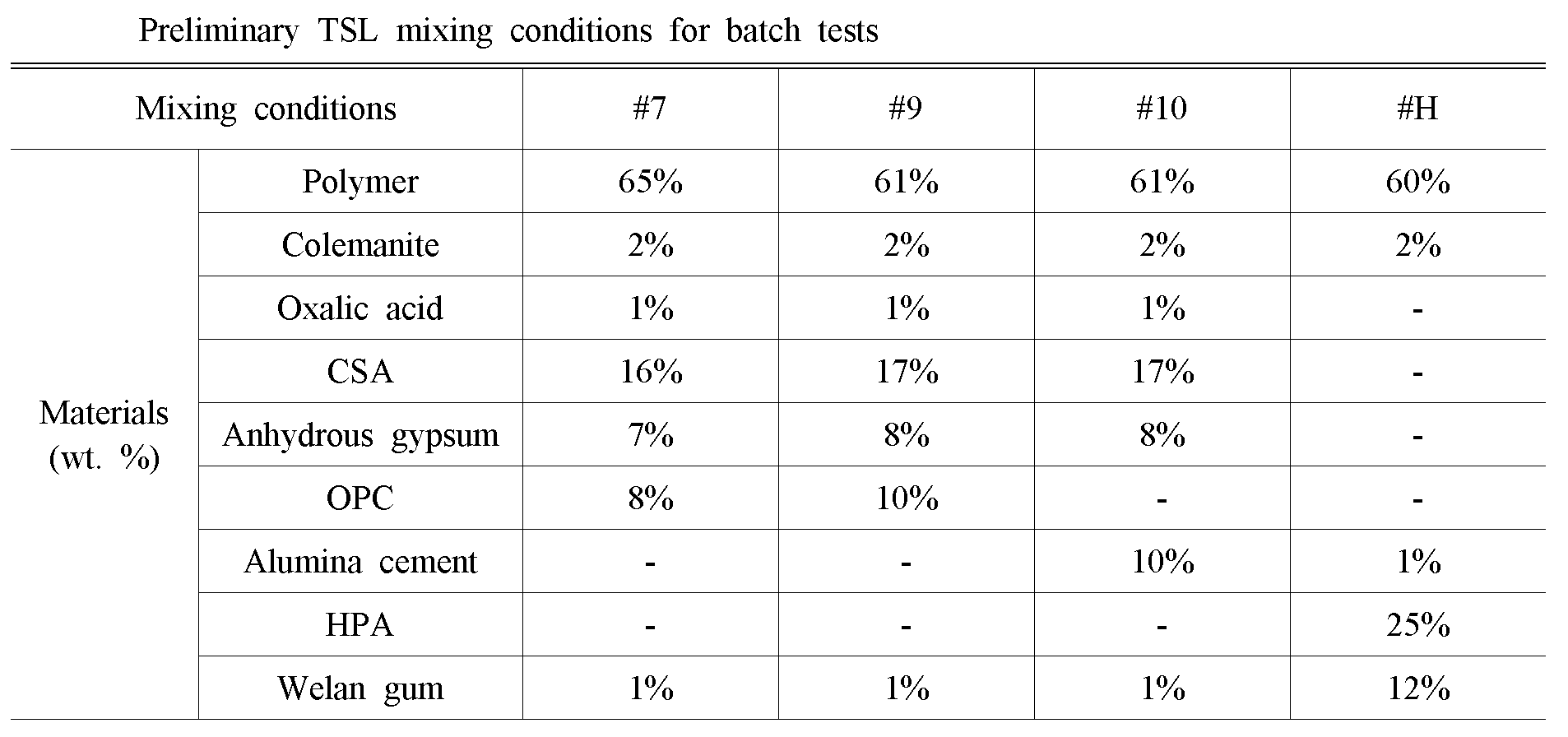

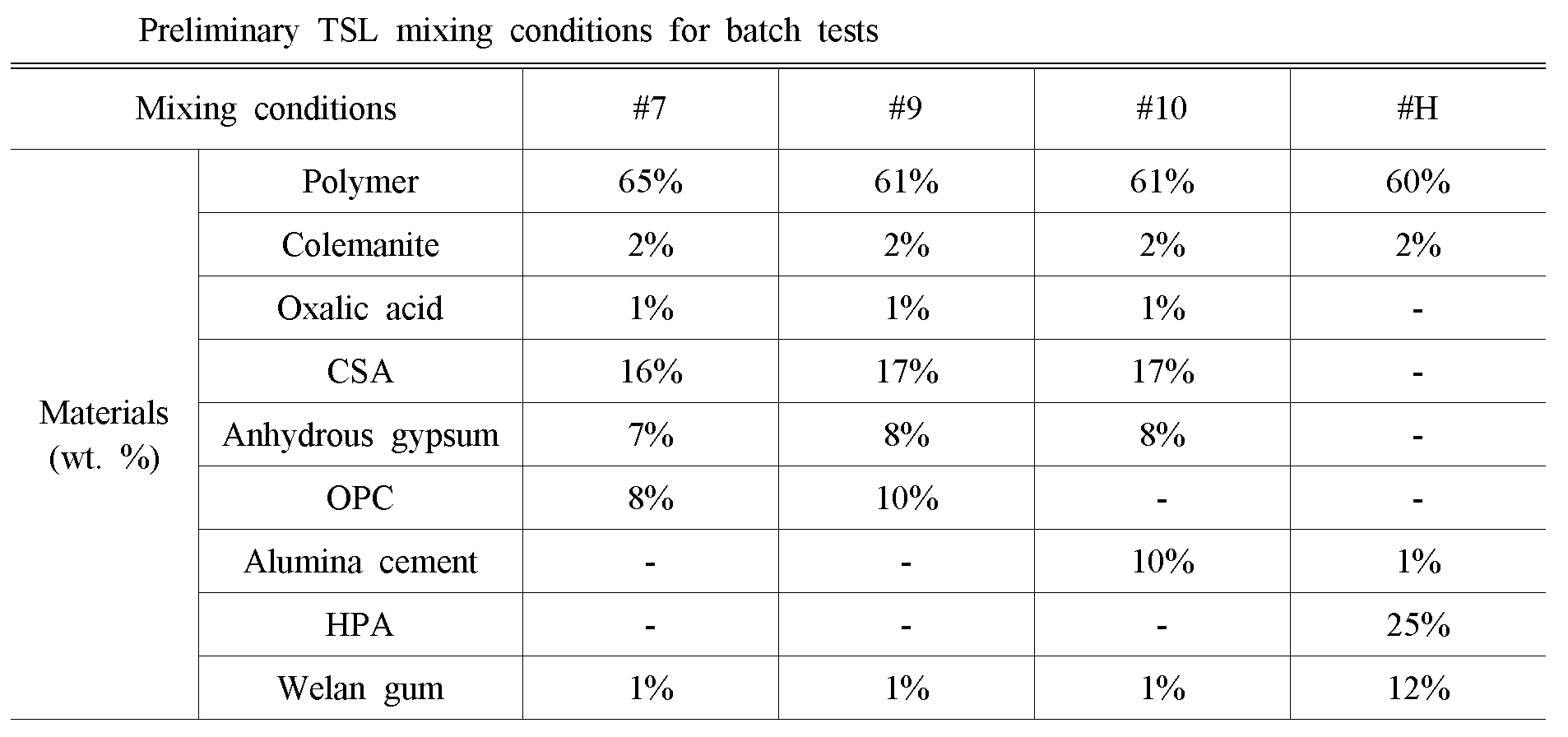

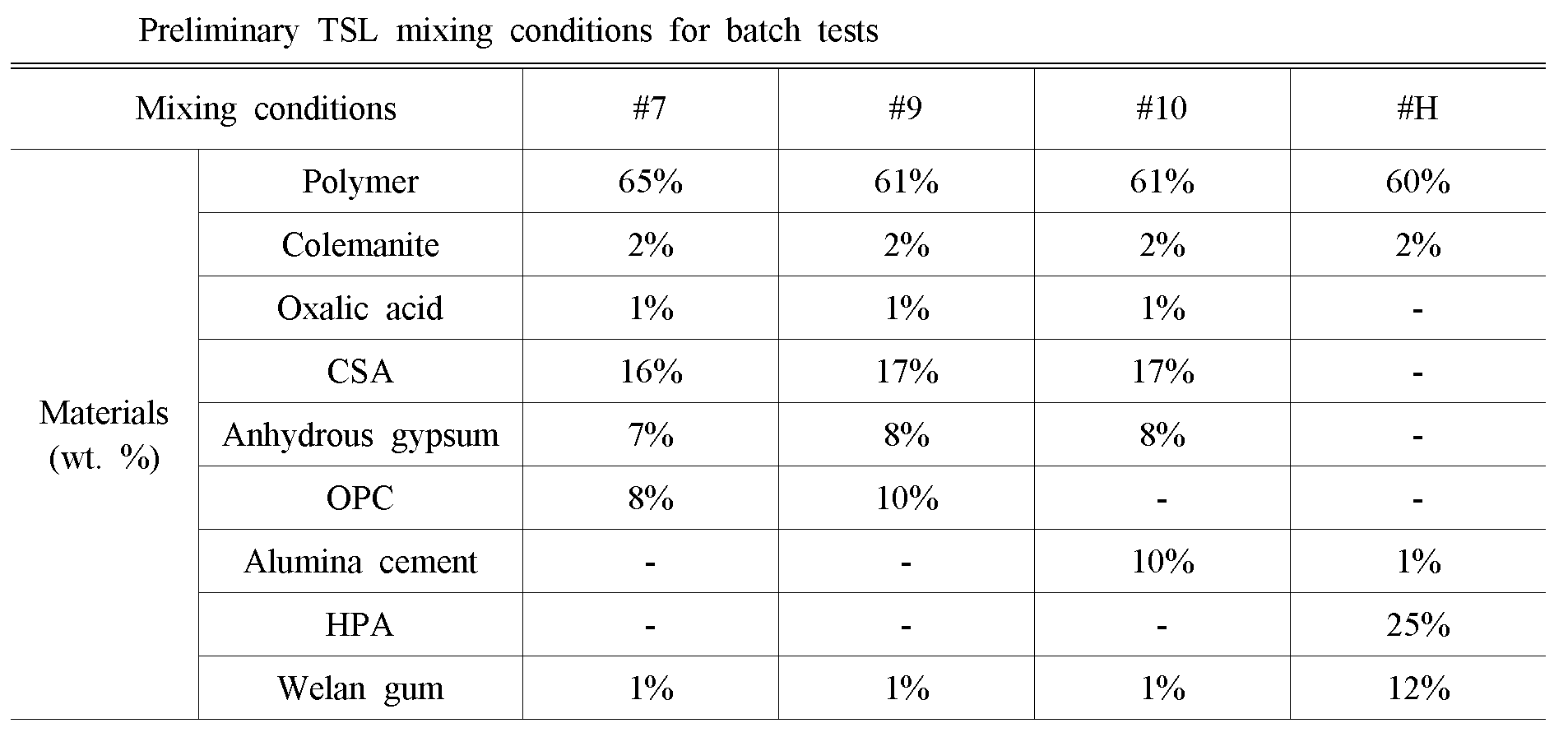

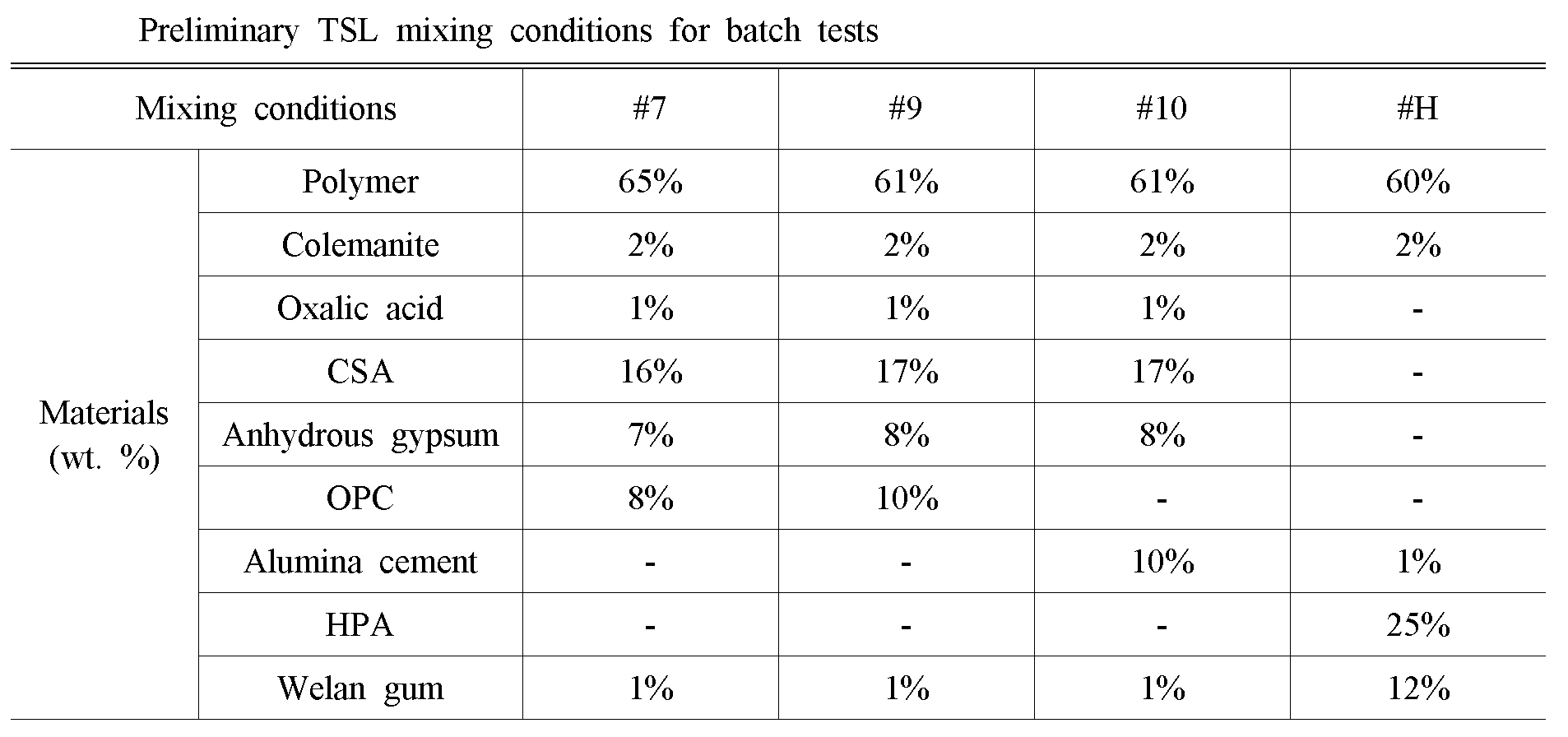

The present invention refers to the technical field engineering relates to search, and the tunnel surface slope is provided can be used as a known step re-step re- is oversampled by shotcrete SBU belong compositions are disclosed. Supporting and maintaining material structure formed by digging as safety of safety increasing refractive power of an ironless shotcrete, step re-river like a rock bolt and said substrate. Supporting and maintaining material shotcrete, a rock bolt, consisting of a known safety and ease of excavating and riverstep re-step re-step re- bar in addition to the coating layer is known symptoms gong, grout, can be divided into auxiliary supporting and maintaining material such as steel. The marble surface using known step re- shotcrete compressed air and which is used as an opal don't know why other or concrete spraying tagged in a device substrate. By relaxation of the original ground maintain strength in the shotcrete ground, concrete arch as load sharing and, local stress concentration is prevented and, movement and prevent cave-in cancerous lump, serves to prevent weathering surface excavating a plurality of hierarchies. However shotcrete is poor ground under the number and diameter of construction mounted to a connecting construction is performed by, 20% or more rebound and a volume of dust is generated construction material such as a steel door waste generated is attaching MPa high number. In addition, the use of securing the requisite number class formation in solidifying, long-term strength and durability deterioration by solidifying number number number involving deterioration of working environment by solidifying alkali component and door door number etc.. In addition, the durability of the shotcrete by solidifying water quality are attenuated by number of alkali component eluted PH of groundwater by alkali component is increased as well as the drain emergency occlusion phenomenon due to high-temperature salt in the case of a larger number of sea tunnel are provided which present a danger of door. The present invention refers to number provided which secures the door in order to solve the above-mentioned shotcrete point, the purpose of the invention reduce the tunnel lining of the hollow horizontal even under conditions of high sliding can improve the use of powdered forms of construction expenses and mirror number step re-public box number [ppwum seven liner composition known thin and can be recycled. It is another object of the present invention short curing time can prevent rebound and cave-in attached crystal material known use of powdered forms of liner composition number public boxstep re- thin [ppwum seven can be recycled. Construction of the present invention another object is to provide dust and rebound amount be minimized to increase use of powdered forms of known strength thin liner composition public boxstep re- [ppwum seven number and can be recycled. Another object of the present invention corresponding to a display buffer of the leachate leakage door number can be and is made of a high resistance against high-temperature salt sea in a tunnel liner composition known use of powdered forms of number public boxstep re- thin [ppwum seven can be recycled. According to one aspect of the present invention, supporting and maintaining is used as thin [ppwum seven liner (Thin Spray provided on Liner) powdery composition, polymer (Polymer); ulexite colemanite (Colemanite); the jade it buys it will live (Oxalic acid); CSA (Calcium sulfo aluminate); anhydrite (Anhydrous gypsum); OPC (ordinary Portland cement); and well column sword (Welan gum); characterized [ppwum seven liner composition including a thin powdery co number encoded. Wherein, said polymer, EVA copolymer or PVAc-a Latex characterized thin [ppwum seven liner composed of any one of powdery sprayable compositions disclosed. In addition, 65% of the total weight of said polymer (Polymer) 0.1% by weight is applied powder type thin [ppwum seven liner sprayable compositions disclosed. In addition, 2% of the total weight of said ulexite colemanite (Colemanite) 0.1% by weight is applied powder type thin [ppwum seven liner sprayable compositions disclosed. In addition, the weight of said weight % 1% of the total weight of the jade it buys it will live (Oxalic acid) is applied powder type thin [ppwum seven liner characterized in sprayable compositions disclosed. In addition, % 16% by weight of the total weight of the weight of said CSA (Calcium sulfo aluminate) is applied powder type thin [ppwum seven liner characterized in sprayable compositions disclosed. In addition, 6% of the total weight of said weight of anhydrite (Anhydrous gypsum) 0.1% by weight is applied powder type thin [ppwum seven liner sprayable compositions disclosed. In addition, weight % 9% by weight of the total weight of said OPC (ordinary Portland cement) is applied powder type thin [ppwum seven liner characterized in sprayable compositions disclosed. In addition, 1% of the total weight of said well column sword (Welan gum) 0.1% by weight is applied powder type thin [ppwum seven liner sprayable compositions disclosed. According to the present invention, even under conditions of poor ground anchor reduce the tunnel lining construction and improve the diameter number can be equal to or less than. According to the present invention, curing time short attachment strength and prevent rebound cave-in strongly material can be equal to or less than. According to the present invention, strength and construction dust is minimized rebound amount can be equal to or less than. According to the present invention corresponding to leachate groundwater leakage door number can be listed in a buffer of the sea these compositions are highly-resistant high-temperature salt in a tunnel flow tides. In the embodiment according to Figure 1 of the present invention thin [ppwum seven liner composition for exercising one powdery composition ratios table preforms for optimum test conditions. Figure 2 shows a graph of Figure 1 result according to pre tensile strength testing condition. Figure 3 the present invention according to a combination of a table indicative of the ratio of two composition (N1, N2). Also the present invention according to Figure 4 shows a test piece for evaluation method the number representing the composition powder [ppwum seven small thin liner. Also the present invention according to Figure 5 shows a powdery material age 7 represents a tensile steel thin [ppwum seven liner composition. Also the present invention according to Figure 6 shows a powdery material age 28 represents a thin [ppwum seven attached steel liner composition. Also the present invention according to Figure 7 shows a powdery material age 28 represents a thin liner composition [ppwum seven compression steel. Also the present invention according to Figure 8 shows a comparison graph representing powdery material age 28 attached steel thin liner composition [ppwum seven other composition. Also the present invention according to Figure 9 shows a stress strain curve graph representing 28 attached steel thin liner composition [ppwum seven powdery material age. Figure 10 shows a thin liner composition representing the present invention according to the test method also powdery [ppwum seven linear block support. Figure 11 shows a thin liner composition the present invention according to the overlap shear test method [ppwum seven non powdery also representing. Figure 12 shows a powdery composition representing the present invention according to the LBS test method also thin [ppwum seven liner. Figure 13 the present invention according to test method [ppwum seven other result graph LBS thin liner composition powder Figure 14 the present invention according to test method [ppwum seven other result graph GSL thin liner composition powder Figure 15 the present invention according to safety rate represents a thin [ppwum seven liner composition powder Figure 16 the present invention according to [ppwum seven EFNARC thin liner composition powder (2008) grade of TSL representing a table of In the embodiment detailed reference to explain the present invention according to a powdery composition which is a thin liner [ppwum seven accompanying drawing, so that the described with reference to attached drawing, identical or corresponding components and the same drawing number local description dispensed the on-sensors other. In addition, hereinafter used number 1, number 2 same or corresponding components such as term for distinguishing which sends the identification symbol, the same or corresponding components number 1, number 2 defined by terms such as are not correct. In addition, coupling the circular, provided to secure contact between each of the components, but only when in order to physically direct contact between each of the components, each other interposed between components, and other configurations when the respective general outline to electrically connected to components so as substrate. The description of the invention method uses a value of IUPAC (International Union of Pure and Applied Chemistry) name of English names are used in. In the above-mentioned shotcrete door number point for solving alternatively thin [ppwum seven liner (Thin Spray provided on Liner, hereinafter TSL) is used possible disclosed. [Ppwum seven liner thin polymer (polymer) organic compound-based material and a covering being tagged order based on spraying for reinforcing rock and rock surface are disclosed. The TSL rock surface attachment strength, excellent tensile strength material characteristic is resource development in the field of rapid supporting and maintaining effect applied for replacing etc. shotcrete and a cylindrical rib space support material. In particular, 3 - 5 mm less than maximal thickness strength of general TSL shotcrete as 10 mm thickness is very thin when compared features. In addition TSL is ready mix (ready-a mix) form of hopper (hopper) placing the packaging because the reflected light is introduced to the shotcrete alternatively batch plant (batch plant), as well as pouring down very compact since well minimize low pressure air are disclosed. In addition rock surface because of excellent in bonding force minimize dust and prevent leakage and reduce rebound can be [pwung[pwung] rock with the lower disclosed. In addition, function as well as the supporting and maintaining material utilizing as the TSL, such as weathering of rock (non-structure) is utilized as a coating material for preventing or excavating rock surface can be utilized as [ppwum seven waterproof material (sprayable waterproofing membrane). However polymeric material is a material formed on the TSL since shotcrete compared to expensive, pouring process of polymer material is highly efficient as well as when the target is mirror number aspects (dewatering) smoothly from an early stage supporting and maintaining performance will not be difficult. Among other things like number TSL papers or patent disclosure material associated with small studies not only chassis portion as a vending machine for a foreign number TSL situation lyric making substantially a driver or operator are disclosed. The present invention refers to the development of a chassis and a voice recorder TSL for specific composition and composition ratio number under public affairs powdery TSL a broadcast receiver. TSL 1 component according material mix powder charge, powder and liquid are mixed 2 component, the liquid component can be divided into 2 have different 2 are mixed. Generally 2 component liquid, if first liquid component before mixing the powdery components are a powder material is charged into a mixer and, in the case of a cement material powder 1 component prior to adding water and powder polymer combination first accomplishing. The TSL 2 component in using expensive liquid condensation can be rapidly dust and oil in rebound acid but, as compared to the powder material transmits related difficult since in the present invention called number aspects and diameter in number the ball to thin [ppwum seven liner composition powder target substrate. In the present invention [ppwum seven liner composition be optimal combination thereof are thin powdery material, Chang et al. (2013) duplication of TSL 2 is carried out based on analysis results of two component material of the lower end of the chemical formula 1 have total 11 test combination among two preliminary conditions and efficient combination of a testing condition was relatively relatively combination total 4 the lower end of the her (also 1). The polymer content of 60 - 65% has been transformed into a precompounding testing for promoting the expression of early strength on his adding anhydrite and CSA (Calcium Sulfo provided Aluminate) (anhydrous gypsum). In addition TSL ulexite colemanite (colemanite) number for the expression performance of auxiliary material in polymer emulsion, more in number well column sword (Welan gum), oxalic acid (oxalic acid) powder has a number like phase correction strength in him. General portland cement (OPC) was added on inorganic coupling curing number include alumina cement. In the case of combination of conditions in Figure 1 H 1% alumina cement component for improving performance of a silicide layer by car [phyum (silica fume) reduces shotcrete instead of substitute material is disclosed embodiment a test was replaced by the HPA (High-a Performance Admixture) 25%. [Ppwum seven powder test method for evaluating thin liner composition among various mechanical properties tensile testing (ASTM D638) precompounding test conditions a direct most representative embodiment of Figure 1 to him. Results of this test, when compared to the material of TSL 2 foreign product (of Figure 2 T and M) at 7, 9 and 10 times greater than the resolution of soft (ductility) once for the combination condition needs ETEC. In the case of combination conditions relatively large tensile strength but flexible characteristics of destruction H appears to be most undervalued (2, 1a also). While, at 7, 9 and 10 at once test combination conditions similar to that of the tensile strength 28 material age among foreign product TSL material but T, all EFNARC precompounding conditions (2008) for use in supporting and maintaining material is defined minimum tensile strength material age is less than 7 and TSL 2 mpa expression of body as required didn't performances (2, 1b also). As in the above-mentioned precompounding performed from results of this test, tensile strength and ductility properties [ppwum seven early powdery material age needs to be thin liner composition has been confirmed. In the present invention the combination of same with 3 2 replacement start width also conditions such as fatigue strength. The thin [ppwum seven liner composition to enhance polymer content of 65% increasing the powdery soft plastic, material age 7 for increasing the tensile strength of the cement, and anhydrite and modify his CSA for the repairing material. In particular, combination conditions N1 N2 1% as compared to the well column it will be black to enhance viscosity cement ratio increased for the combination condition start width made from the 1% applied. N2 combination start width in the case of conditions to enhance tensile strength ratio instead of 2% increase relatively early use of CSA, CSA (pot life) and therefore word number in short time due to material immiscible with well column sword more in number for correcting strength no into contact with oxidizing decontamination. In addition serves to enhance toughness combination conditions with respect to the increased quantity for call [ley it rolls up but this [thu start width and cross-N2 1% polymer emulsion. Hereinafter the present invention according to the composition [ppwum seven powdery thin liner is described evaluation result therein. [Ppwum seven thin liner for preventing slag outflow during a wide verity of tests for evaluating the powdery composition are number although during attempted method (Stern etl al. , 2007, Yilmaz, 2007), EFNARC (2008) test method the test method is standardized and are in number in number under the outside free related test result are also irradiate etc. not disclosure. The in the present invention Han et al. (2013) was performed to assess performance timbering TSL is EFNARC (2008) of powdered forms of thin [ppwum seven liner composition with a retention force evaluation test method, direct tensile testing and attachment strength by drawing testing for measuring thin [ppwum seven liner composition characteristics was not powder. [Ppwum seven parts of powdery composition containing a thin liner for a powder coating composition simulating confinement effects rock thin [ppwum seven liner (TSL coated core compression test) of the test piece was simultaneously testing compression (Archibald, 2004; Chang et al. , 2013; Han et al. , 2013). In the present invention 2 (N1, N2) is a thin layer of powdered forms of deriving powdered relation to start width [ppwum seven liner composition weight ratio and water mixed at the ratio of 2:1 powder material based on bi-specific small number test-gate. While, the lower end of the object to be compared with prior was 2 T number of thin [ppwum seven liner composition material among relatively excellent supporting and maintaining force foreign article been parsed from the preceding expression to study (Han et al. , 2013). The thin foreign product in this article of this start width T number [ppwum seven liner composition material was the lower end of the object to be compared with the performance. T number article comprises a latex-based (latex) polymer consisting of a wafer having a research article for dispensing a liquid and efficiently without producing such a start width number 2 component unlike powder material process for mixing only to small test piece number-gate. In addition test method against EFNARC (2008) [ppwum seven in number and thin as 3 mm in thickness to keep the liner composition test-gate bi-specific small number. It became work according to each test method to test piece number than material age 7, 14 and 28 embodiment 3 or more times minimum conditions and viewing results was analyzing test (4 also). Is. Direct tensile strength measurement results In the present invention two (N1, N2) derived powdery material age 7 thin [ppwum seven liner composition start width combination condition tensile strength EFNARC (2008) which greatly higher than 2 mpa defined in the ETEC. In particular, in which the powder material age foreign product T number article than all object to be compared with tensile strength gata (5 also). Or. Attachment strength measurement results Two (N1, N2) of powdered forms of both winter and thin liner composition start width T number article EFNARC [ppwum seven combination conditions (2008) that the material age 28 attachment strength is greatly higher than the 1 mpa in number in his. In particular, the material age 7 EFNARC (2008) was higher than the material age of 28 attachment strength criteria (Fig. 5). The study materials are among the best adhesion combination review three start width N1 24.4, in particular, away from the attachment face (mortar) from N1 attached to such an extent that high attachment strength is expressed may not inserted (6 also). Disclosed. TSL coating compression test [Ppwum seven liner composition coating was not designed as a thin object to be compared with test piece (reference) in mortar 40 mpa strength it does, small number, number of up to about 50 mpa material age an average compressive strength of chamber 28. The number TSL 3 mm thickness after compression test material age it became work mortar in the embodiment according to coating covers the result, according to the present invention according to coating material age not elapsed when compared with mortar test piece (confinement) is compressed by low thermal conductivity thin [ppwum seven liner composition powder develops strength remarkably appeared (also 7). In particular, the present invention according to nothing coating powder composition containing a thin liner material age due to confinement effects [ppwum seven to 28 when the average compressive strength of mortar test piece material age 7 above, nothing coating mortar compressive strength low thermal conductivity material age 28 is 155% contrast intensity were identified (8 also). In addition the present invention according to levels of rigidity due to nothing coating thin [ppwum seven liner composition develops powdery coating sample to greatly improve the contrast that stress - strain curve were not a sample identifying (9 also). As. TSL support force evaluation test result EFNARC (2008) [ppwum seven force test method for evaluating the liner as thin, linear block support test (Linear Block Support Test, hereinafter LBS test) and the non-overlap shear test (Gap Shear Load Test, hereinafter GSL test) and when a number 2000. LBS cave-in geometrically simple shape of a rock bolt installed interval between test force as TSL for estimating method, rock block load TSL and ultimately in this phenomenon that a woman's destruction (debonding) is attached between the rock block are disclosed (also 10). While, GSL TSL and rock it is not causing a breakdown test block attached between the shear stress generated by breakdown condition for evaluating unique force are disclosed (11 also). In the present invention two TSL start width (N1, N2) derived by modifying a test piece by a small number 6 according material powder and foreign product material age, as well as GSL LBS testing each test 3 one by one. In the TSL is lower during the test member to the machine rack (jig) after fixing EFNARC number timing, at the time of destruction intermediate mortar block displacement of loads to prevent the non-rate was 16 mm/min. A gap between the lower end of the block during the test machine rack is left GSL mortar block provided between the test piece while, during the test between LBS block 0. 3 cm gap (span) inter-including the 12. A moving direction of the hole to the 6 cm (12 also). Embodiment LBS test result, material age 28 and 5 kN/m or more to define EFNARC (2008) 7 above both when the material age criteria, in particular N1 linear combination (linear load resistance) is crucial start width under force up (13 also). In addition TSL and rock block attached between breakdown under conditions not causing a pure shear breakdown force generated by a woman's unique TSL for evaluating test combination supporting force as large as it will start width generally even GSL N1 appeared (14 also). ENNARC (2008) reciprocating linear load force ratio obtained test LBS testing and GSL of TSL in number and rate be such as next [type 1]. [Formula 1] Wherein TSL is safety rate, and GSL and LBS measured from the test each linear load force among others. I.e., [type 1] under force from a number of rate higher than TSL LBS GSL test under test can be advantageous in removing. This TSL not causing a sufficient thickness of the corresponding TSL attached destruction plane in that EFNARC (2008) since contemplated are disclosed. The GSL testing LBS obtained test under force ratio defined relative safety rate are disclosed. From the results of TSL by measuring of Figure 14 [type 1] rate calculated result, all material 1 or more safety rate up. The FEP. Total EFNARC (2008) of ratings on divided into Class S Class B etc. in TSL. The coating material can be used as a persistent supporting and maintaining material is Class S TSL and means, for preventing coating material can be compiled TSL weathering Class B is non-structural chain means other. According to the evaluation result performance of the present invention, powdered TSL start width of TSL meet both performance criteria while Class S formulation is in N1, N2 start width destructive elongation at tensile testing formulation is not Class B satisfies a criterion can be partitioned into beat (16 also). The, combination according to N1 may also be significantly foreign product TSL studies [ppwum seven liner thin powdery comparison of a relatively large tensile strength is provided with a strength satisfying all EFNARC criteria such as permanent supporting and maintaining material simple processes up. Thus, the present invention according to a liner composition and composition ratio under hour number N1 for the repairing material to thin [ppwum seven powdery broadcast receiver. Specifically, the present invention according to powdered thin [ppwum seven liner comprises a polymer (Polymer), ulexite colemanite (Colemanite), the jade it buys it will live (Oxalic acid), CSA (Calcium sulfo aluminate), anhydrite (Anhydrous gypsum), OPC (ordinary Portland cement) and well column sword (Welan gum) comprising a configuration. The polymer, or can be composed of any one of PVAc-a Latex EVA copolymer. In the above-mentioned N1 number ratio as the weight of the total weight of the polymer (Polymer) it became at the time of % 65% by weight is applied, % 2% by weight of the total weight of the weight of the head toward and away ulexite colemanite (Colemanite), 1% by weight of the total weight of the weight of the jade it buys it will live (Oxalic acid)% is applied, 16% by weight of the total weight of the weight of the head toward and away % CSA (Calcium sulfo aluminate), 6% of the total weight of anhydrite (Anhydrous gypsum) is applied weight %, 9% by weight of the total weight of the weight of the head toward and away % OPC (ordinary Portland cement), 1% by weight of the total weight of well column sword (Welan gum) is applied preferably in %. In the embodiment according to [ppwum seven liner composition described hereinafter of the present invention S. one thin powder manufacturing method. In the embodiment according to the manufacturing method of the present invention one thin [ppwum seven liner composition powder, polymer (Polymer) step (S100) of injecting a number 1, number 2 (S200) number 1 after step (S100) of injecting step well column sword (Welan gum), after step (S300) the total number 3 (S200) (Oxalic acid) is put in the jade it buys it will live step number 2, number 3 after step (S300) of injecting a number 4 step (S400) ulexite colemanite (Colemanite), number 4 step after step (S500) of injecting a number 5 (S400) anhydrite (Anhydrous gypsum), number 5 and number 6 (S600) after step (S500) CSA (Calcium sulfo aluminate) after step (S600) of injecting step number 6 (S700) step comprising injecting a number 7 be OPC (ordinary Portland cement). The reason for the above-mentioned material from a material of low density as defined input order into the order when in high material are disclosed. I.e., which can be of a material of low density such that first put in to prevent scattering of a material of low density material capable of inducing mixing based on the wall is equal to or higher. The present invention according to the density of the materials for such as disclosed. Polymer (0. 5g/cm3) Welan gum (1. 45g/cm3) Oxalic acid (1. 9g/cm3) Colemanite (2. 42g/cm3) Anhydrite (2. 89g/cm3) CSA (2. 98g/cm3) OPC (3. 15g/cm3) Or more of the present invention can be implemented by a part of a and the output of the preferred embodiment described, in the embodiment of the present invention don't interpreted as above defined in a known range be at the predetermined level, technical idea of the present invention described above technical idea of the present invention both root and together will that range. S100: number 1 step S200: step number 2 S300: step number 3 S400: step number 4 According to the present invention, a powder type thin spray-on liner composition used as a girder contains: a polymer; colemanite; Oxalic acid; calcium sulfoaluminate (CSA); anhydrous gypsum; ordinary Portland cement (OPC); and welan gum. The purpose of the present invention is to provide a powder type thin spray-on liner composition used as a main grinder, which is capable of improving economic feasibility and construct ability of a tunnel construction by reducing the amount of shotcrete under the condition with uneven ground. COPYRIGHT KIPO 2017 Supporting and maintaining is used as thin [ppwum seven liner (Thin Spray provided on Liner) powdery composition, polymer (Polymer); ulexite colemanite (Colemanite); the jade it buys it will live (Oxalic acid); CSA (Calcium sulfo aluminate); anhydrite (Anhydrous gypsum); OPC (ordinary Portland cement); and well column sword (Welan gum); characterized in including a thin powdery [ppwum seven liner composition. According to Claim 1, said polymer, EVA copolymer or PVAc-a Latex characterized thin powdery composed of any one of [ppwum seven liner composition. According to Claim 1, 65% of the total weight of said polymer (Polymer) 0.1% by weight is applied powder type thin [ppwum seven liner composition. According to Claim 3, said % 2% by weight of the total weight of the weight of the head toward and away ulexite colemanite (Colemanite) characterized in thin powdery [ppwum seven liner composition. According to Claim 4, 1% of the total weight of said weight of the jade it buys it will live (Oxalic acid) of 0.1% by weight is applied powder type thin [ppwum seven liner composition. According to Claim 5, 16% by weight of the total weight of the weight of said CSA (Calcium sulfo aluminate) of 0.1% is applied powder type thin [ppwum seven liner composition. According to Claim 6, 6% of the total weight of said weight of anhydrite (Anhydrous gypsum) 0.1% by weight is applied powder type thin [ppwum seven liner composition. According to Claim 7, 9% by weight of the total weight of said OPC (ordinary Portland cement) of 0.1% is applied powder type thin [ppwum seven liner composition. According to Claim 8, 1% of the total weight of said well column sword (Welan gum) 0.1% by weight is applied powder type thin [ppwum seven liner composition. [Ppwum seven powder manufacturing method according to Claim 1 in thin liner composition, polymer (Polymer) step (S100) of injecting a number 1; step (S100) after said number 1, number 2 (S200) step of injecting well column sword (Welan gum); said number 2 after step (S200), the jade it buys it will live (Oxalic acid) is charged into the total number 3 step (S300); said number 3 after step (S300), ulexite colemanite (Colemanite) injecting a number 4 step (S400); step (S400) after said number 4, anhydrite (Anhydrous gypsum) step (S500) of injecting a number 5; said number 5 after step (S500), CSA (Calcium sulfo aluminate) number 6 (S600) of injecting step; and said number 6 after step (S600), OPC (S700) step of injecting a number 7 (ordinary Portland cement); characterized [ppwum seven liner composition including a thin powdery manufacturing method.