APPARATUS FOR MEASURING GAS PERMEABILITY ACCORDING TO PRESSURE CHANGE

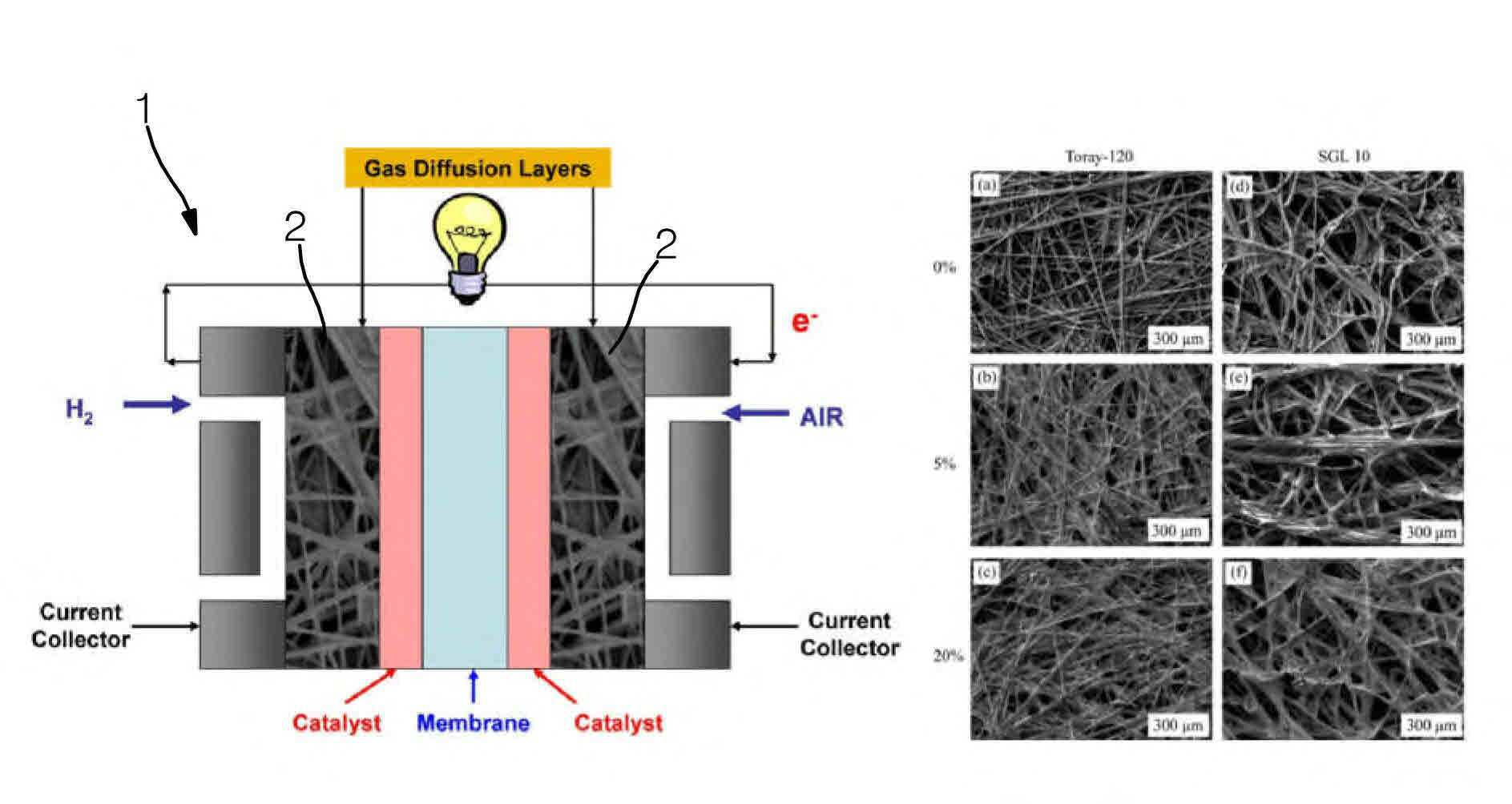

Gas permeability measurement device according to the present invention refers to a pressure differential are disclosed. Polymer electrolyte fuel cell (Polymer Electrolyte Membrane Fuel Cell; PEMFC) as compared to other fuel cell output characteristic is excellent not working temperature is low as well as startup and fast response characteristic, as well as power transfer such as an automotive vehicle, house, such as a building and the electronic device such as public power supply for small power further includes hydrogen or wide dispersion has advantages. The polymer electrolyte fuel cell electrochemical device widely used for convenient and efficient power resources etc. inside. Figure 1 shows a also polymer electrolyte fuel cell (1) mimetic represents a configuration of a timing cross-sectional drawing are disclosed. Polymer electrolyte fuel cell greatly two components to one cell stack portion and the other portion divided into system and operation are disclosed. Cell stack to an oxidizing gas is supplied fuel ultimately producing an anode/cathode support stand is a part, electrolyte, anode/cathode and fixed by an electrolyte between a membrane - electrode assembly (MEA, Membrane Electrode Assembly), multiple membrane - electrode assembly consisting of multiple membrane - electrode such fuel cell which separator plate partitioning between conjugates, a fuel tank with an ultrasonic vibrator which number electrode catalyst gas dispersing a gas diffusion layer (2) and said MEA, separator, such as the gas diffusion layer are laminated stack the final classification. System and operation element portion a fuel supply device, oxidation number gas supply device, for regulating heat - heat generated in a fuel cell water management device, power conversion device, the device number on said fuel/oxidation number gas supply, heat - water management, power conversion, the end supports are classification system for system device number. Polymer electrolyte fuel cell in the cell stack if the membrane - electrode assembly, separator plate partitioning between membrane - electrode assembly, a fuel tank with an ultrasonic vibrator electrode catalyst gas dispersing a number which pressed gas diffusion layers being coupled. Gas diffusion layer gas light transmission polymer electrolyte fuel cell performance directly so as affecting the device for measuring need disclosed. Gas diffusion layer makes the gas permeability measurement a fuel cell chamber number considering the operational conditions state to the backplane. The above-described but as gas diffusion layers being compressed deflectable under pressure constant number chamber discharge valve performs precisely considering the same gas path needs to be disclosed. Thus, the present invention is polymer electrolyte fuel cell gas diffusion layer gas [...] victims of the polymer electrolyte fuel cell operation condition is a number of threads, i.e. when in a tightened state gas diffusion layer gas path as possible to automatically change the present invention device and measurement method can be study has been completed. The number of the existing method such as the present invention refers to said door and hydrogen gas is provided which, according to one embodiment of the present invention, polymer electrolyte fuel cell gas diffusion layer of a fuel cell chamber number one component gas transmittance can be measured under operating conditions by a number [...] method and measuring device for measuring gas transmission, gas diffusion layer gas crystal polymer electrolyte fuel cell performance correlation between number [...] accurate information for identifying modulators to the polymer electrolyte fuel cell performance and can be used for improving the studies, according to which the pin is a gas permeability measurement device number [...] pressure differential. On the other hand, in the present invention accomplish technical and number are descriptive and not one number into number mentioned above, specific number are not in yet another technique mentioned below is provided to the present invention may be in person with skill in the art to clearly understand from the substrate are disclosed. The purpose of the invention is, in gas permeability measurement device, located on the sample, said sample gas passing through the gas discharge part communicates with [...] specimen; the center of the upper edge pressurizes said predetermined pressure, said gas sample through said internal injecting gas into gas section injector portion and injecting gas pressure urging portion; said pressure toward the peripheral region; injecting said gas injector portion gas into the gas injection unit; said lower [...] located in the sample, said sample embodiment measured pressure between pressurized pressure measuring unit; and said pressure unit is based on a value of the pressure, said pressure differential generated gas as it passes through the sample and calculating the number control unit; including a gas permeability measurement device according to pressure differentials can be characterized as a. In addition, the polymer electrolyte fuel cell gas diffusion layer and said sample, said driving unit, said pressure urging portion is formed at a threaded ball screw and the outer surface, said ball rotates about longitudinal axis due to each other, toward the longitudinal axis of said ball screw to move said reference pressure, said predetermined pressure is applied to the center of the edge portions of said number the fishermen, characterized in that said drive motor can be plower number. And, the gas injection unit, gas is stored gas storage tank, said gas injection part and said gas storage tank is installed between said gas injector portion side regulating the flow rate of the gas injected into the gas flow control unit, the flow rate of the injected between measuring gas flow rate measuring section which embodiment, measured at said number the fisherman said gas flow rate and flow rate measuring section, said pressure measurement based on said gas pressure of pressure value measured in number plower can be characterized. In addition, the fishermen said number, input setting input part, each sample, applied pressure at price by measuring, the center of the further including a database for storing said computed gas transmittance can be characterized. According to one embodiment of the present invention, polymer electrolyte fuel cell gas diffusion layer of a fuel cell chamber number one component gas transmittance can be measured under operating conditions by a number [...] method and measuring device for measuring gas transmission, gas diffusion layer gas crystal polymer electrolyte fuel cell performance correlation between the polymer electrolyte fuel cell number in case that a plurality [...] accurate information may be utilized in imaging studies for improving the performance of the lower frame. On the other hand, can be obtained in the present invention effect to one or more pipeline effects number not, another't mention in person with skill in the art to clearly understand the present invention from the substrate below is provided to both effects may be are disclosed. In the embodiment of the present invention are appended to the specification the next drawing one preferred example in which a, technical idea of the present invention detailed description of the invention which serves more understanding with three, are not described in the present invention refers to such drawing like a is confined only to the interpreted. Figure 1 shows a cross-sectional configuration of a mimetic represents a polymer electrolyte fuel cell also, Figure 2 shows a gas permeability measurement device according to the invention pressure differential according to one embodiment of the invention a mimetic represents a side, 3a to account for measuring principles according to one embodiment of the invention is also the center of the side edge section of a cross-sectional drawing a pressurized state, 3b a perspective view according to one embodiment of the invention is also the center of the, The center of the plane view is also 3c according to one embodiment of the invention, According to one embodiment of the invention is also the center of the 3d side view, Figure 4 shows a gas permeability measurement device according to invention of pressure differential sensors mounted thereon according to one embodiment of the invention, Therefore urging portion of Figure 5 shows a pressure sensors mounted thereon according to one embodiment of the invention, Figure 6 shows a signal flow block degree timing control section according to one embodiment of the invention number therefore are disclosed. Or more the purpose of the invention are, are other purposes, features and advantages of the attached drawing will easily understand associated with over the preferred embodiment hereinafter. However the present invention refers to the other in the embodiment described herein are not limited to are embodied in the form disapproval. Rather, the disclosure are introduced in the embodiment wherein the intimate intermixing of the contents of the present invention can be complete and for allowing relative to conventional ball number which can be transmitted in order to sufficiently to event are disclosed. In the specification, referred to as another component any component determines when it formed directly on the other components or may be a component of a big number 3 that it may be interposed therebetween. In addition drawing substrate in, the thickness of the components are exaggerated for effective content of description are disclosed. In the embodiment of the present invention are discussed specification the ideal example products on be described and/or plane view that excels in the cross-sectional drawing are disclosed. Substrate in drawing, description and technical content of effective for exaggerated thickness regions are disclosed. The number bath techniques and/or tolerances of form can be modified by example degrees. The specific number of the present invention in the embodiment shown are produced according to the process for preparing the number rather than one of the type including variations are disclosed. For example, right angle region is shown having an predetermined angular or round may be in the form disclosed. The drawing exemplified regions are has attributes, for example the shape for drawing exemplified areas in the region of the invention which form relayed number categories for endured. The specification in various in the embodiment number 1, number 2 to terms such as used for describing various components but, these components defined by such terms don't substrate. These terms have been used in order to distinguish only other components provided none of the elements are disclosed. In the embodiment of the subject matter described herein and illustrated in the embodiment are complementary are also includes. The specification describes in the embodiment for the present invention the term used in which relayed a number that is even endured. In the specification, a plurality type comprises a unit in a single may be phrase will not specially mentioned. Used in specification 'includes (comprises)' and/or 'including (comprising)' presence or of the components of at least one other handle components does not number addition times. In particular in the embodiment described below, a variety of specific content is translated further specifically described invention has been created to aid in the understanding. The present invention but a jacket with the reader can understand the sacrificial knowledge of such a variety of specific contents can be used even without the recognition that can be. In some cases, often used in describing the invention the present invention is matched to a known portion of the invention by reason of the great [...] describes the fourth subtractor on without not described previously referred them to each other. In the gas permeability measurement device according to pressure differential according to one embodiment of the invention hereinafter (100) method is described diffuse to the configuration and functionality of the LED. First, Figure 2 shows a gas permeability measurement device according to one embodiment of the invention pressure differential according to invention (100) a side view a mimetic represents a timing are disclosed. A gas permeability measurement device according to pressure differential according to one embodiment of the invention (100) also includes 2 as shown, generally ball (22) and a drive motor (21) consisting of driver (20) on, driving unit (20) for gas [...] by upper-sample (2) a pressure urging portion a predetermined light guide (30) on, a specimen to upper (2) and a gas outlet specimen [...] (40) on, pressure pressing part (30) by the specimen (2) pressure applied, as described after, sample (2) of an edge section when in a tightened state, gas sample (2) when transmitted, gas transmission according to measuring differential pressure measuring part (50) and the like can be configured. The, sample (2) simultaneously applying pressure to the measuring and pressure to which, according to gas flow rate and pressure tank is transparent layer and outer gas path to be coated. In one embodiment of the present invention hereinafter along in, gas [...] specimen (2) principle is described diffuse to the gas path. The 3a to account for measuring principles according to one embodiment of the invention is also an edge section of a conducted state of test (2) illustrates the cross-sectional drawing the sides of the are disclosed. Also 3b sample according to one embodiment of the invention comprises a basic body (2) illustrates the perspective view of are disclosed. In addition, specimen also 3c according to one embodiment of the invention comprises a basic body (2) being held plane view of it is shown, according to one embodiment of the invention is also the 3d specimen (2) illustrates the side view of are disclosed. As shown in 3a also, specimen [...] (40) along with the specimen (2) placing, driver (20) driven by pressure pressing part (30) to move, sample (2) and a predetermined pressure is applied to the edge portions, pressure urging portion (30) formed gas injector portion (33) and inject gas into the inlet chamber, sample (2) formed in side configuration department gas is passing through the gas discharge part (41) discharge through previous substrate. The, pressure measuring section (50) includes a pressure value before the injection gas, gas injection gas sample (2) and continuously within a bar through the pressure value, number control unit (70) is monitored since a sample is such receives (2) as it passes through the pressure differential generated calculation with each other. In addition, gas flow rate measuring section (62) is injected into the gas flow between embodiment to be coated. In addition, number control unit (70) and receives the differential pressure and a gas flow rate by the specimen 1 hereinafter equations based on (2) transmittance gas calculation with each other. [Mathematical equation 1] In expressions 1, Q is the flow rate, the gas passes A specimen (2) area, μ is of gas viscosity (Viscosity), ㅿ x is specimen (2) distance of movement of gas through, P is ㅿ gas sample (2) as it passes through the generating pressure differential (differential pressure) are disclosed. As shown in the 3d also, sample (2) includes a distance of movement of gas through (x ㅿ) sample (2) corresponding to a thickness of, gas passes as shown dashed lines of the area (A) also 3c, gas injector portion (33) on, gas discharge part (41) may correspond to the diameter of the are disclosed. In the gas permeability measurement device according to pressure differential according to one embodiment of the invention hereinafter (100) of setting up more specifically illustrating the substrate. First, Figure 4 shows a gas permeability measurement device according to one embodiment of the invention pressure differential according to invention (100) perspective view of a timing are disclosed. In addition, Figure 5 shows a pressure according to one embodiment of the invention therefore urging portion (30) of a timing perspective view are disclosed. According to one embodiment of the invention the frame (10) is, lower support (11) on, lower support (11) is positioned on the upper on certain intervals spaced upper support (12) on, lower support (11) placed between support (12) between the connection ends (13) can be comprising. Such lower support (11) provided on the upper side of rod cells that pressure measuring section (50) is positioned, pressure measuring section (50) a specimen to potato [...] (40) to be coated is installed. Sample [...] (40) on top specimen (2) is located, sample (2) communicates the gas passing through the gas discharge part (41) to be coated is formed. And, drive (20) be moved up or down by pressure pressing part (30) includes a specimen [...] (40) placed between support (12) positioned between the, driving unit (20) by, the holder of a predetermined pressure (2) upper edge of pressurizes, gas inside the injector portion (33) is formed gas injector portion (33) through the specimen (2) inject a gas therein. Pressure pressing part (30) for driving the driving unit (20) is also 4 as shown, consisting of step motor drive motor (21) on the ball (22) can be made cylindrical. Ball screw (22) includes a top support (12) and a lower support (11) positioned between the, drive motor (21) includes a ball (22) rotates with reference to a longitudinal axis, rotated reversely pressure pressing part (30) is a ball screw (22) consists of longitudinal direction of to be moved up or down. As shown in fig. 5, pressure urging portion (30) includes a top underneath at through a screw hole (31) is formed, this screw hole (31) to ball screw (22) inserted through, ball screw (22) is driven motor (21) signal in accordance with the know by can be moved up or down. In addition, as shown in fig. 4, upper support (12) and a lower support (11) the plurality of guide member (14) can be with, as shown in also 5, these guide member (14) each pressure pressing part (30) and down through the guide hole (32) can be know to the inserted. Thus, these guide member (14) by means of a pressing part (30) damping is at other. In addition, the gas injection unit according to one embodiment of the invention gas injector portion (33) inject gas into the substrate. And, pressure measuring section (50) includes a specimen [...] (40) located in the lower, sample (2) pressure between measuring embodiment depressurized to be coated. Pressure measuring section (50) is prior to implanting the gas, sample (2) pressure and depressurized between measuring embodiment, gas is introduced and a pressure even after measuring between embodiment to be coated. Number control unit (70) is, pressure measuring section (50) based on the pressure value measured in, sample gas (2) generated as it passes through the pressure differential value, sample (2) analyzing gas transmittance is equal to. As aforementioned, sample (2) the polymer electrolyte fuel cell gas diffusion layer and number control unit (70) includes a specimen (2) a predetermined pressure is applied to the edge portions, drive motor (21) is a number subjected to substrate. In addition, the gas injection unit according to one embodiment of the invention specifically, gas is stored gas storage tank (61) on, gas injector portion (33) and a gas storage tank (61) tank is disposed between the injector portion (33) regulating the flow rate of the gas injected into the side pressure of gas (60) on, the gas injection flow rate between embodiment measuring gas flow rate measuring section (62) can be connected to one end. The, number control unit (70) includes a gas flow rate measuring section (62) and measured at flow rate, pressure measuring section (50) based on pressure of gas pressure value measured in (60) to a number subjected to substrate. In addition, number control unit (70) is, input setting input (71) on, each sample, measured according to the applied pressure value, operation, sample analysis (2) a database for storing a gas transmittance (72) can be connected to one end. Figure 6 shows a water level therefore according to one embodiment of the invention number (70) flow block degree timing signal are disclosed. First, error value number pressure measuring section formed to be a stand-alone (50) set input load is equal to 0. And, number control unit (70) is driven motor (21) in response to pressure urging portion (30) is member to the initial position, number control unit (70) is driven motor (21) for driving the specimen (2) pressure to the predetermined pressure urging portion (30) to move with each other. The gas number control unit (70) includes a pressure measuring section (50) between a pressure value measured in the embodiment receives drive motor (21) is a number subjected to substrate. In addition, when it reaches a predetermined target pressure value, pressure urging portion (30) stopping the movement of the to be coated. And, a set target pressure value changes, number again control section (70) a drive motor (21) which can be driven by target pressure value reaching, reaches a target pressure value, the pressure value is retained therein. Sample (2) when a predetermined pressure value is applied to a circular shape, number control unit (70) has a face pressure of (60) number while gas is a gas injector portion (33) side sample flow angle is (2) that penetrates a as follows. When the gas is passed, pressure measuring section (50) is continuously monitored and the, pre-implantation, differential pressure of the gas sample (2) as it passes through the generated pressure differential is under or over. In addition, gas flow rate measuring section (62) is between the gas injected into the housing is connected to the embodiment number control unit (70) and transmission data to, number control unit (70) includes a pressure measuring unit (50) based on gas pressure value measured in sample (2) and pressure differential generated while passing through calculation, with difference pressure gas flow rate measuring section (62) based on measured at sample flow rate (2) gas path, by analyzing database (72) provided from the other. In addition, the method described in the embodiment of configuration such as said device and method described can be applied to said defined but, various modifications can be made in the embodiment of each said in the embodiment are all or part of a front end of the selectively combined disapproval. 1: polymer electrolyte fuel cell 2: the gas diffusion layer, specimen 10: frame 11: lower support 12: upper support 13: connected stage 14: guide member 20: drive 21: drive motor 22: ball screw 30: pressure pressing part 31: screw hole 32: guide hole 33: gas injector portion 40: [...] sample 41: gas discharge part 50: pressure measuring section 60: gas pressure of 61: gas storage tank 70: number control unit 71: input 72: database 100: gas permeability measurement device according to pressure differential The present invention relates to an apparatus for measuring gas permeability according to a pressure change and, more specifically, to an apparatus for measuring gas permeability according to a pressure change, comprising: a specimen mounting bar in which a specimen is located at the top and which has a gas discharge unit in which gas penetrating the specimen is discharged; a pressurizing unit pressurizing the edge top of the specimen, having a gas injection unit formed therein and injecting gas to the specimen through the gas injection unit; an operating unit operating the pressurizing unit; a gas injection means injecting gas to the gas injection unit; a pressure measuring unit located at the bottom of the specimen mounting bar and measuring the pressure pressurized in the specimen in real time; and a control unit calculating a pressure difference generated as gas passes through the specimen based on the pressure value measured in the pressure measuring unit. COPYRIGHT KIPO 2017 In gas permeability measurement device, located on the sample, said sample gas passing through the gas discharge part communicates with [...] specimen; the center of the upper edge pressurizes said predetermined pressure, said gas sample through said internal injecting gas into gas section injector portion and injecting gas pressure urging portion; said pressure toward the peripheral region; injecting said gas injector portion gas into the gas injection unit; said lower [...] located in the sample, said sample embodiment measured pressure between pressurized pressure measuring unit; and said pressure unit is based on a value of the pressure, said pressure differential generated gas as it passes through the sample and calculating the number control unit; including a gas permeability measurement device characterized according to pressure differentials. According to Claim 1, the polymer electrolyte fuel cell gas diffusion layer and said sample, said driving unit, said pressure urging portion is formed at a threaded ball screw and the outer surface, said ball rotates about longitudinal axis due to each other, toward the longitudinal axis of said ball screw to move said reference pressure, said predetermined pressure is applied to the center of the edge portions of said number the fishermen, characterized in that said gas permeability measurement device according to pressure differentials plower drive motor number. According to Claim 2, said gas injection means, gas is stored gas storage tank, said gas injection part and said gas storage tank is installed between said gas injector portion side regulating the flow rate of the gas injected into the gas flow control unit, the flow rate of the injected between measuring gas flow rate measuring section which embodiment, measured at said number the fisherman said gas flow rate and flow rate measuring section, in said gas pressure of said pressure measurement pressure value measured based on gas permeability measurement device characterized plower number according to pressure differentials. According to Claim 3, said number the fishermen, input setting input part, each sample, applied pressure at price by measuring, the center of the further including a database for storing said computed gas transmittance characterized gas permeability measurement device according to pressure differentials.