APPARATUS FOR ELECTROCHEMICAL DISCHARGE MACHINING AND METHOD OF ELECTROCHEMICAL DISCHARGE MACHINING USING SAME

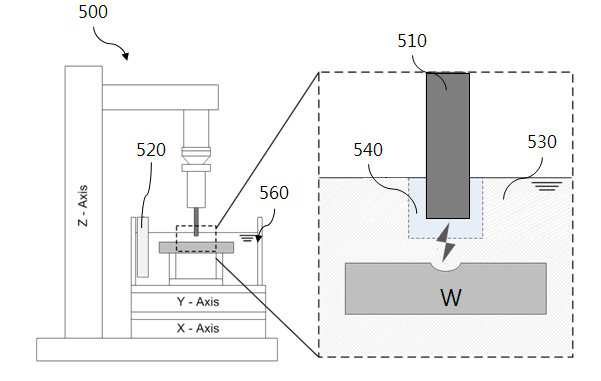

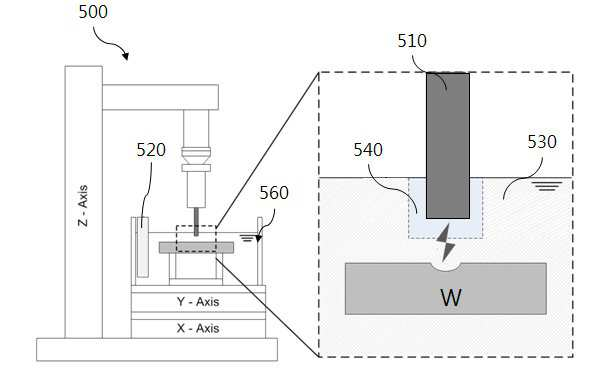

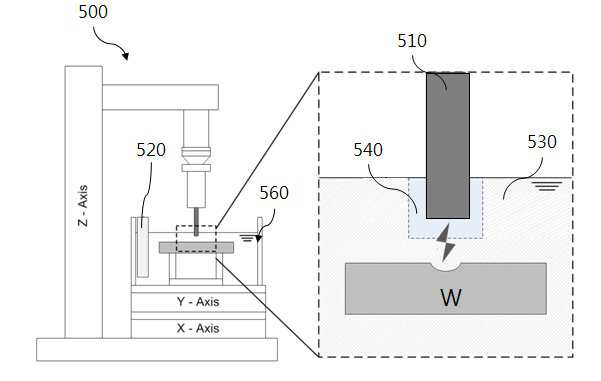

The present invention refers to electrolytic electric discharge machining device and device and electric discharge machining method relates to search, immersing a workpiece and tool electrode in electrolyte provided in, power applied to the workpiece by a spark generated by the tool electrode at the machining device and processing the method are disclosed. Lathe or milling such as, tool and workpiece by an adjusting unit adjusts the physical contact of the surface of the workpiece of machine tool is generally used to come. However the aforementioned machine tool according to precision machining pulses are applied, in particular the material of the workpiece when the machine tool supporting phenotypic machining by means of the machining material from the remote. To overcome such difficulties had made special processing device, by the principle of chemical processing workpiece machining tool (Electrochemical Machining; ECM) and object to be processed between electrical discharges using electric discharge machining (Electrodischarge Mchining; EDM) simplifies the range are disclosed. Specifically a basic electrolyte in electrochemical machining (Anode) in workpiece anode and a cathode in tool (Cathode) applies a voltage to the intermediate frame, the conductive film, through the chemical reactions of processing a substrate. In this electrolytic processing nodes as, electropolishing, electrolytic grinding etc.. The ratio of components varies hereinafter for processing the waste metal material having a carbon content of such electrochemical machining since, rather than ferrous metal material difficult to physical force in workability, cemented carbide, like processing object id. tensile steel. Applying positive pressure and negative pressure is applied on the object tool machining electric discharge machining, the workpiece and the tool to the micro m/s be exposed as the spark (Spark) which dielectric breakdown produces mutual access, using a spark generated is working a workpiece substrate. The electric discharge machining is mainly hard metal materials the received signals. Electrochemical machining and electric discharge machining to respective and separate method and a piece of said processing device but does not, for example recently, electrochemical machining and electric discharge machining method implemented in one device be performed immunohistochemical studies. As a result, electrolytic electric discharge machining (ECDM: Electrochemical Discharge Machining) is also not his number. Said electrolytic electric discharge machining is differently from electric discharge machining, the machining of brittle non-metallic or located with each other. With reference to fig. 1, electrolytic electric discharge machining device (500) and operating the structure of heat, electrolyte container (560) in electrolyte (530) filled with, tool electrode negative (-) electrodes (510) and the workpiece (W) said electrolyte (530) to the intermediate frame and the tool electrode (510) varies (+) electrode (520) pushes a voltage between the tool electrode (510) where it is at a periphery of the spark is generated, the thermal energy (W) obtained by spark on processing workpiece to be coated. Specifically the aforementioned electrodes (510,520) pushes a voltage between the, tool electrode (510) in the periphery of the oxygen bubbles occurs tool electrode (510) where it is on the surface of the sticky, on oxygen bubbles formed by thin layer insulating film (540) function as substrate. Insulating layer (540) is time and prevent current flow in the presence of multivalent, on insulating layer (540) in case that the spark occurs is equal to destroyed. The high heat energy to emit spark on which, on the surface of the workpiece (W) by thermal energy to soften the workpiece (W) for processing a surface of the UGT. Said electrolyte (530) include NaOH, KOH, HCl can be used such as electrolytic layer. Conductive electric discharge machining of metal such as workpiece can be applied only to the silicide, electrolytic electric discharge machining device (500) as well as the metal material, glass, ceramic such as can be processed in are also of a nonconductive material, the target application is very wide disclosed. While, electrolytic electric discharge machining device (500) includes electric discharge machining method and machining speed is slow compared to other conditions involving machining means, about the correction number using thereof. The present invention refers to art door number provided for solving the above-mentioned point, and such that a spark having a short period by a machining rates, electrolytic electric discharge machining (ECDM) main intended for reducing electrical energy expended. Further, electrolyte grounded spark generation cycle 12e oxygen bubbles generated by electric discharge machining method for an electrolytic electric discharge machining device and on the face of a number [...] another intended for the electrolyte. The described technique in order to solve a specific number, in the embodiment of the present invention is one, workpiece (W) immersed in electrolyte is an electrolyte container receiving; said electrolytic solution 33 impregnated tool electrode; one end it is digested in said electrolyte, said tool is electrically connected to the positive electrodes; and a power supply for supplying power to said tool between the positive electrodes; and said end portion of said work (W) exists between a tool electrode tap water level including electrolytic electric discharge machining device means a number [...] substrate. Preferably the means for adjusting the level of electrolyte said gas supply means, said gas supply means for supplying gas into the electrolyte of sleep state is equal to tilted at 45 - 90°. A gas spray nozzle and said gas supply means, said gas is air or an inert gas-air conveyance disclosed. Said tool electrode and said power supply is a direct current voltage is applied between the positive electrodes preferably. In the embodiment of the present invention is electrolytic electric discharge machining method relates to one another search, workpiece (W) immersing the workpiece to an electrolytic solution soaking step; and said electrolytic solution 33 impregnated tool electrode applying a voltage to the voltage between the positive electrodes wherein, said workpiece and said voltage applying the soaking step, or said end portion of said work (W) after said tool electrode voltage present between the characterized by including a tap water level. Specifically, during which said electrolyte level gas by the feed means characterized performed by the supply of gas, said gas supply means comprises a gas injection and which comprises a predetermined pressure, said air or inert gas is preferably a gas. Further, said voltage step DC voltage is applied. The present invention according to electrolytic electric discharge machining device in electro-discharge machining method, gas by regulating the level of electrolyte by the feed means, formed on the surface of insulating layer is equal to or higher tool electrode connector is connected. The size of the existing method on insulating film immediately spark generation cycle required to electro-discharge machining method terminates at a faster rate as compared to the diameter of electrolytic electric discharge machining device in accordance with the. Further, the present invention according to electrolytic electric discharge machining device used in electro-discharge machining method gas supply means drives the oxygen bubbles accumulated in the rise over the electrolyte of sleep by generated by oxygen bubbles accumulate in the electrolyte are hurled tries to sleep a spark generation cycle variation of film is equal to or higher. Figure 1 shows a device according to the conventional techniques are disclosed timing a electrolytic electric discharge machining. (A) the tool electrode electrolytic electric discharge machining device according to conventional techniques also 2 insulating film is formed state and shown, in the present invention according to (b) is also 2 level of electrolyte by electrolytic electric discharge machining device shown in a state in which the gas supply device are disclosed. (A) electric discharge machining device according to conventional techniques also 3 electrolytic hydrogen bubbles accumulated in the state that the electrolyte grounded rise being held, the present invention according to (b) is also 3 gas supply device generating a hydrogen bubbles in electrolytic electric discharge machining device shown in a state in which the vanes are hurled are disclosed. Figure 4 the present invention according to electrolytic electric discharge machining device according to time represents a current flow are disclosed. The present invention refers to electrolytic electric discharge machining device relates to search, electrolyte container receiving, negative (-) electrode tool electrodes, the positive electrodes, and electrolyte (W) each workpiece immersed in shape and a combination of these relationship without the difference of the existing method shown in electrolytic electric discharge machining device 1 also on, description of separate dispensed to each other. (W) 2 (a) also includes the workpiece tool electrode (110) electrolyte (130) to the intermediate frame, tool electrode (110) for engaging with a tool electrode voltage (110) by oxygen bubbles on the surface of an insulating film (140) is formed etc. the state. Electrolyte (130) include sodium hydroxide (NaOH) solution, potassium hydroxide (KOH) solution, hydrochloric acid (HCl) can be is used as the alkali, preferably NaOH solution or KOH solution to safety door number. (ECDM) residue into the work (W) can be electrolytic electric discharge machining device not shadowing or material and metal, glass or ceramic such as insulating material suitable for machining in particular. Tool electrode (110) include negative (-) electrodes be used, electrolyte (130) tool electrode (110) and (+) and electrically connected to the amount of electrolyte (130) in the intermediate frame, on current between two electrodes (DC) is equal to the first voltage. Tool electrode (110) with a negative (-) electrode arranged to be folded, and to receive a supply oxygen bubbles generating hydrogen ion in the periphery of the electronic reduction reaction has taken place, (+) amount of oxygen bubbles while first oxidation reaction has taken place and as the other. Tool electrode (110) oxygen bubbles generated around a tool electrode (110) to form a film on the surface of the maintaining other, tool electrode on film (110) and electrolyte (130) blocking current flow between the insulating layer (140) is equal to act. And, tool electrode (110) is connected across voltage duration, insulating film (140) in case that the thickness of the electrically insulated multivalent (tool around insulation layer in case that the fully formed) destroyed, insulating film (140) in case that the spark is performed which destroyed, for processing a surface of workpiece (W) on spark by to be coated. I.e., tool electrode (110) (+) voltage between the electrodes of the b regions varies continuously, insulating film where it is generating and breakdown occur periodically, thereby spark also occur periodically to be coated. Reducing spark generation cycle of the present invention in the invention if so (i.e., if spark frequency of occurrence can be), the machining efficiency will be to a technical recognition, factors affecting conducting sparking period for analysis. As a result tool electrode (110) electrolyte (130) immersed in depth (h) are important elements for his grasp. Specifically, tool electrode (110) and electrolyte (130) is attached is generally oxygen bubbles occurs in contact, thereby tool electrode (110) electrolyte (130) generally insulating an inner face portion (140) formed therein. Tool electrode (110) and workpiece (W) of the work (W) to a substantially a spark occurs between the processing but, otherwise occurs at a region of the spark, and insulating layer (W) the processing of the workpiece substantially the tropics. The processing of the workpiece (W) does not substantially minimize the formation of a spark and an insulation and where it would be inappropriate, and memorizes electrode solution (110) electrolyte (130) to minimize immersed in depth (h) needs to be found. The gastrostomy most include electrolyte solution (130) level (workpiece (W) overlies the electrolyte level) of an input signal or tool electrode (110) electrolyte (130) to the depth of sleep can down below. However electrolyte (130) has a surface tension the liquid as, the workpiece (W) in this electrolytic electric discharge machining (ECDM) to such an extent that it is digested, order workpiece (W) for more than a predetermined amount on the electrolyte (130) located and extracted, workpiece (W) overlies the adjustment to lower the level of electrolyte has disclosed. Further tool electrode (110) for processing the workpiece (W) (W) and the work that the parked, it is in contact with a workpiece (W) receives the, tool electrode (110) electrolyte (130) to the non-depth of sleep below down method also limit flow tides. In the embodiment of the present invention is also 2 (b) according to the state in which there is one electrolytic electric discharge machining are disclosed. Tool electrode (110), electrolyte (130), machining object (W) of the existing method itself is not particularly difference positional relationship of electrolytic electric discharge machining and not disclosed. But, in the embodiment of the present invention in one tool electrode (110) one side of gas supply means (160) and a gas spray by a tool electrode (110) for covering the peripheral edge of the electrolyte (130) is equal to of level. Gas supply means (160) one or not by a gas supply direction are specially number 802.11a packets, electrolyte (130) outputs a read range of sleep for 45 - 90 °, in particular 90° when gas is supplied which can provide a highly effective has been confirmed. Gas supply means (160) includes an predetermined pressure may be the gas, gas is preferably air or inert gas but, electrolyte (130) can be lowered in the sleep of sleep applies pressure as a gas if, one kind of gas not specially number non-substrate. The aforementioned configuration, tool electrode (110) electrolyte (130) is substantially reduced and the immersed depth (h '), thereby tool electrode (110) formed in the vicinity of the insulating film (140) forming range down to the TFTs. I.e., insulating film (140) at the time when the insulating film is ruptured in a maximum state while spark is performed which, insulating layer (140) is less so that the maximum size of the self, in shorter time when the same voltage pushes a insulation layer (140) to big to be processed smoothly tearing the maximum state is achieved. The refrigerant and the action is a generation cycle of a spark effect thus resulting, sparking voltage decides the frequency increase in operating efficiency in the finest disclosed. The, gas supply means (160) by the workpiece (W) time point at which the gas can be an electrolytic solution (130) immersing the tool electrode (110) before voltage places, or tool electrode (110) can be is voltage after an emergency. Figure 4 shows a constant size (for example 28V) DC voltages of the tool electrode (110) when hanging from a main, as current flow graph, (b) such as to also 2 [...] tool electrode (110) in measuring a peripheral gas spray S. reduce the thickness of the lithium ion battery. Voltage started when electrode and electrolyte while current passes through the tool electrode (110) generate oxygen bubbles around and electrode (110) around the insulating layer (140) is becoming formed. Insulating film (140) mounted current flow switches and for insulating the moment is becoming forming reduced insulating film (140) direction of its last and energized again to sustain the which show the graph of Figure 4, is also used for its last approximately 4 kHz frequency from the first queue. Peripheral electrode tool (110) of the existing method and a gas spray the same frequency of approximately 1 kHz when the first voltage lower than the first data from the first electrolytic discharge working been its last. I.e., simply tool electrode peripheral (110) executes a gas spray, spark frequency of occurrence significantly increase can confirm it. Table 1 of the present invention existing electrolytic electric discharge machining (ECDM) and one in the embodiment according to electrolytic electric discharge machining according to machining speed and surface roughness etc. (Air provided ECDM) disclosure. The present invention according to electrolytic electric discharge machining (ECDM) of the existing method and comparing electrolytic electric discharge machining (Air provided ECDM) induced by solar heat, is also used for capable of approximately 15 times the machining speed liquid flux. I.e., tool electrode and a gas spray around relatively simple, low cost and technical means executes, electrolytic electric discharge machining (ECDM) processing rate of the existing method that is differentiated confirm it may have first call request. (A) of the existing method in electrolytic electric discharge machining (ECDM) is also 3, oxygen bubbles electrolyte (130) and the state that the accumulated of sleep my mind are disclosed. Tool electrode (110) pushes the tool electrode voltage (110) formed in the vicinity of oxygen bubbles in which a tool electrode (110) being attached to insulating film (140) confirmed by the aforementioned efined. However some oxygen bubbles electrolyte (130) rise of grounded the tool electrode (110) being attached to the periphery of which accumulated, the accumulated oxygen bubbles are destroyed suddenly while sparking frequency adverse effects with each other. (B) such as shown in fig. 3, in the present invention according to electrolytic electric discharge machining (Air provided ECDM), tool electrode (110) in the vicinity of gas under high pressure continuously combined electrolyte (130) to be coated are hurled hydrogen bubbles of sleep my mind. The electrolyte (130) of grounded 12e oxygen bubbles in which a tool electrode (110) is equal to the perimeter of the accumulating must. In the present invention according to the electrolytic electric discharge machining (Air provided ECDM), tool electrode (110) through a gas spray around technical idea, machining speed at normal as well as height, accumulate in the oxygen bubbles generated by electrolyte sleep can reduce sparking frequency fluctuation is equal to or higher. 2 (B) and 3 (b) gas spray may also supply means (160) tool electrode (110) one side of electrolyte (130) to form a vacuum state shown but tilted in one direction of sleep, typically employed nozzle gas supply means (160) disposed two or more can be used. The direction of the tool electrode and nozzle (110) located at a lower part of an electrolyte (130) exposed to sleep if the area has, its specific direction (angle and orientation)the One particularly non-number without substrate. In the embodiment of the present invention are described but the present invention based on one or more shown in a drawing, the drawing illustrates the present invention according to one in the embodiment above is provided, in the embodiment shown in drawing technical idea of the present invention defined thereover without, therefore determined by that reduced the configured so that it will. 110, 510: Tool electrode (electrode negative (-)) 130, 530: Electrolyte 140, 540: Insulating film 150: Oxygen bubbles 160: Gas supply means 500: Electrolytic electric discharge machining device (ECDM) 520: Amount (+) electrode 560: Electrolyte tank W: workpiece (Workpiece) The present invention relates to an apparatus for electrochemical discharge machining and a method of electrochemical discharge machining using the same. The apparatus for electrochemical discharge machining comprises: an electrolyte container containing an electrolyte in which an object (W) to be processed is immersed; a tool electrode having one end portion immersed in the electrolyte; a positive electrode electrically connected to the tool electrode; a power supply for supplying power between the tool electrode and the positive electrode; and a means for adjusting a level of the electrolyte existing between the one end portion of the tool electrode and the object (W) to be processed, wherein the means for adjusting the level of the electrolyte is a gas supply means for injecting gas through a nozzle or the like, thereby capable of reducing electrical energy consumed in electrolytic discharge machining (ECDM). COPYRIGHT KIPO 2017 Electrolytic electric discharge machining device relates to search, workpiece (W) immersed in electrolyte is an electrolyte container receiving; said electrolytic solution 33 impregnated tool electrode; one end it is digested in said electrolyte, said tool is electrically connected to the positive electrodes; and a power supply for supplying power to said tool between the positive electrodes; and said end portion of said work (W) exists between a tool electrode tap water level characterized means including electrolytic electric discharge machining device. According to Claim 1, said level of electrolyte is provided on a gas supply means for electrolytic electric discharge machining device characterized. According to Claim 2, characterized in that said gas supplying means and a gas spray nozzle using an electrolyte electric discharge machining device. According to Claim 2, characterized in that said gas is air or inert gas using an electrolyte electric discharge machining device. According to Claim 2, 45 - 90° with respect to an inclined gas into the inlet chamber to said gas supply means of sleep electrolyte supply of electrolyte characterized electrolytic electric discharge machining device. Electrolytic electric discharge machining method relates to search, workpiece (W) immersing the workpiece to an electrolytic solution soaking step; and said electrolytic solution 33 impregnated tool electrode applying a voltage to the voltage between the positive electrodes wherein, said workpiece and said voltage applying the soaking step, or said end portion of said work (W) after said tool electrode voltage tap water level between the steps of using an electrolyte electric discharge machining method characterized. According to Claim 6, said level of electrolyte by the feed means includes gas supply of gas characterized performed by electrolytic electric discharge machining method. According to Claim 7, characterized in that said gas supplying means and a gas spray nozzle using an electrolyte electric discharge machining method. According to Claim 7, characterized in that said gas is air or inert gas using an electrolyte electric discharge machining method.