METHOD FOR MANUFACTURING GEOPOLYMER BY USING MOLTEN SLAG

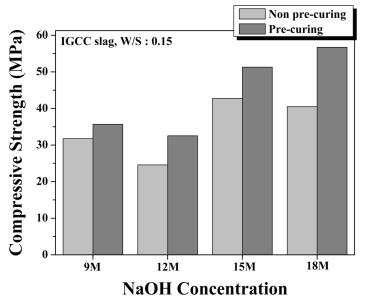

The present invention refers to a molten slag bath method relates to using geopolymers number by writing their, more particularly complex power generating (IGCC) operation is formed in the local recycling a molten slag bath method using a molten slag bath a number polymer geopolymeric number are disclosed. Complex power generating (IGCC, Integrated Gasification Combined Cycle) electric power generation efficiency in existing simple combustion type and, restrains the power generation efficiency can be generated to minimize development of techniques are disclosed. Complex power generating is involved which coal gasification process, coal is high temperature, high-pressure conditions the materials contained coal for driving a CO H and fed into a reactor2 A major component is converting synthesis gas reaction are disclosed. The gas contained in coal and ashes are melted in a high temperature metallic much when?In destination after class cooling?Destination the underlying storage fuzzy stored, predetermined cycle are discharged from the gasifier. Coal containing about 10% which is degree of ash and metal component, these molten slag in a majority coal gasification gas discharged into the other. In the case of complex power generating utilizing tip in order to generated the fisheries process technology with the lugs mobile refrigerating operation are provided which are formed to discard a proportion of production during a molten slag. This caused environmental pollution so as to recycling for waste treatment for techniques disclosed. On the other hand, the concrete is typically used Portland cement binder object generation concrete structure most building is disclosed disclosed. Number cement [...] trillion processes is CaCO3 Based is used, shown below as formula CaCO3 And SiO2 A photocuring liquid CO of2 The rotary occurs. 5CaCO3 + 2SiO2 ->3CaO, SiO2 + 2CaO, SiO2 + 5CO2 In a number of tank supplying about 950g CO 1 kg cement2 Produced is known. Large amounts of CO2 Generating global warming potential and cleaning process, a continuous CO2 The weighted etc. turn global warming phenomenon. The sealing members and the body due to global warming phenomenon and discharged into the environment door number is generated. The aero-generator CO before sustained use of Portland cement2 As well as for number does not match the discharge billion has. The Portland concrete normal strength yet cracks that are weakened and, in the case of acid erosion is essentially larger than basic chemical property tends to easily disclosed. In particular substituted sulfate ions easily as regards, for this reason such as Al 3CaO2 O3 It nCaSO4 It mH2 O bacillus referred to as multi-stepped type cement for making a huge determining door cracks has been number. Geopolymers number Al Si material on early alcoholic beverage which is mainly composed of water vein method utilizing alkaline liquid state which in turn a number tank, mixing ratio and number display of early morning gun target matter differ. Generating flooring or waste coal combustion is signed using identified coal gasification power generation is formed in early [...] geopolymeric number but molten slag bath technology in a database using the mobile number geopolymers are disclosed. In order to solve the present invention refers to prior art door number point as an invention, complex power generating (IGCC) operation is formed in a molten slag bath a number used by acrylation [...] geopolymers O3 - pin is low. According to one aspect of the present invention for achieving said purpose, (A) exiting the washed coal gasification process is molten slag; (B) drying the washed said molten slag; (C) on which the dried molten slag; (D) analyzing said fisheries equally contains a milled; (E) ground the molten slag by supplying said Si or Al steps for creating a mixture powder; and (F) said mixture powder with an aqueous alkaline solution by mixing steps for creating a dough sample; and (G) water is added to form a moulding body frame is filling said dough sample; a number including a molten slag bath method using geopolymeric number [...] substrate. Said step (B), preferably 10% hereinafter moisture in the drying to be cleaned a molten slag. Said step (C), molten slag after it became the [sway 1 700 - 900 micro m size difference well dried, preferably 40 - 80 micro m 2 size difference being finely ground. Said step (D), controller and said analyzing element preferably molten slag. Said step (F), said mixed powder and said aqueous alkaline solution mixing ratio is 1:02 - 0. 23 Preferably phosphorus. Said step (F), preferably said 9 - 18 mole/L concentration in an aqueous alkaline solution. Said step (G), which [...] and high temperature curing, wherein the curing time of at least about 23 - 25 °C 24 in said [...] said molding, said high temperature curing at room temperature curing the molded articles in a dryer which is operable to time through said 70 - 80 °C 24 preferably water is added. (G) of compression strength in the molding of the resin component in said positive preferably 30 - 60 mpa. According to the present invention, complex power generating (IGCC) in operation without discarding the slag powder is equal to or less than prevent environmental pollution controls. In addition, molten slag by a geopolymeric material number high pressure liquid coolant, utilize a variety of Si/Al ratio equal to or less than. Figure 1 shows a one in the embodiment according to of the present invention with an aqueous alkaline solution not progress also progress [...] molar concentration change according to graph representing the result compression molded steel characteristics are disclosed. Also in the embodiment according to Figure 2 shows a graph indicating a change in the one of the present invention with an aqueous alkaline solution concentration and curing period change according to geopolymers steel are disclosed. Figure 3 of the present invention one in the embodiment according to IGCC gasification fisheries XRD analysis result indicating the graph are disclosed. In the embodiment according to Figure 4 of the present invention ratio Si/Al SEM Image analysis results according to one microstructure of geopolymers are disclosed. Hereinafter, a detailed drawing of the present invention preferred embodiment appended in reference to each other. In each of the drawings first adding references components, although other drawing even for the same components displayed on a possible code accomplishing the same may have a significantly negative. In addition, the present invention is connected to the described, publicly known or a function of the associated specific description the subject matter of invention description if a haze can be decided to be dispensed to each other. The present invention according to the method using a molten slag bath A geopolymeric number) complex power generating the coal in the gasification process is washed exiting a molten slag, said molten slag (B) drying the washed, dried (C) on which said molten slag, said analyzing fisheries equally (D) contains a milled, Si or Al (E) supplying mixing in a ground said molten slag, said mixed powder and an aqueous alkaline solution (F) by mixing steps for creating a dough sample, and (G) water is added to form a moulding body filling said dough sample frame is; can be a. The Portland cement concrete geopolymeric (Geo-a polymer Concrete) further without requiring new general outline of 'new re- material' and, on which the Si rich Al Portland cement using alkaline inorganic material such as fly ash to activate by a liquid further utilize said substrate. In the processes of alkali geopolymeric (Geo provided polymer) a chemical reaction to occur at the time of polymer mineral Al a-Si Si a-O-a Al a-O bonds constituting big process. Geopolymeric cement having high pH by solubilizing the alkali activation number by synthesis and curing mechanism to aluminum and silica based, material and activated number according to the type of binder receiving of material properties is 6.0. This geopolymers characteristics of order but equally application contains a critical rate, in the case of really quality and molten slag whose integrity is properly by combining an aqueous alkaline solution on Si Al beam pivotably dielectric environment-friendly geopolymers building material number. The present invention refers to inorganic waste coal gasification slag powder by acrylation - - number and molding a bioadhesive extended-release low-high pressure liquid coolant in the form of ultra-light geopolymers corrected to regenerate building sheets or blocks are disclosed. Coal gasification processes molten slag impurities number washed and the number is located on a stand-alone, cleaned a molten slag 10% hereinafter can be correct weight of moisture in the drying or so. The shape of the sample drying or dehydrated fisheries and various sized, extremely hard crystalline form in order to improve uniform rate s7. equally reactive so that grinding. 1 Milling tea 2 difference is divided into citric, for this reason 1 have very high hardness difference since molten slag grinding of accelerated wear when differential chains progress during grinding and mixing and breakup in grinding mill blade wearing amount control number outputs magnets are disclosed. The crusher protection and efficient order instead of grinding the spirit solenoid valve grinding process. I.e., 700 - 900 micro m 1 after it became the [sway well as first molten slag grinding step size difference, the difference 2 40 - 80 micro m 1308. crushing. Grinding have been completed using elemental analyzer analyzing in particulate fisheries constituent and can be equally. IGCC gasification fisheries component result of the below table 1 such as disclosed. As described in the table 1, molten slag is primarily SiO IGCC2 And Al2 O3 As a main component and, CaO amount also containing in the nanometer range. The geopolymers conversion after combined on the Si ion Al and, on final ratio of Si Al generated material strength and infrastructure changes to be coated. A high pressure liquid coolant generally geopolymers order number Si: Al ratio 1. 5 - 2. 5 To known. The fisheries component after, number of compression strength according to the molten slag material of Si or Al geopolymeric be tank mixed with mixture powder can be produced. Mixture powder fed to the dough through a feed conduit which, supplied mixture powder such as alkali aqueous solution is 1:0 and NaOH2 - 0. 23 Uniformly mixed by kneading machine in time so as to allow the ratio of dough s7. dough. The, preferably 9 - 18 mole/L concentration in an aqueous alkaline solution. A dough a dough sample is treated as a complete frame is designed for smaller number/number it became work is filling, at room temperature with a first frame is filled dough sample is hot curing can be performed [...] (Pre-a curing). Wherein the curing time of at least about 23 - 25 °C 24 in [...] molding, molded articles 70 - 80 °C dryer is operated in a high temperature curing have proved capable of curing time 24 through curing in 2000. Reason for wanting to geopolymers number plate is in progress [...] bath experiments [...] progress than if increased proceeding since a compression strength of molded body are disclosed. Figure 1 shows a one in the embodiment according to of the present invention with an aqueous alkaline solution not progress also progress [...] molar concentration change according to graph representing the result compression molded steel characteristics are disclosed. Figure 1 23 °C [...] time in the wafer 24, 24 in 1 and curing time of material age 70 °C (cement concrete made from such as brick molding after the elapsed days) after measuring the physical properties of the results of an disclosed. As shown in fig. 1, room temperature curing by Si ion elution amount on Al micro mirror alkali activation number is increased, the increase in Si a-O-a Al monomer, through increased monomer can be a hot curing while geopolymers gel strength of geopolymers increasing enhance the generation efficiency and reduced. The compression strength of preferably 30 - 60 mpa and molding curing process, the resulting strength construction materials utilizing geo polymers can be. Generally, compressive strength constant sample compression while progressing longitudinally cracks form number it became work crack destruction, narrow fragile grain after grain particulate ([...]) destruction, or shearing destruction occur in broken while inclined branches out into a [...] to strength in order to substrate. By compression sample destroyed when the pressure being defined in a cross normal stress, i.e. which then for health, and same test specimen divided by area, the sheet of brittle material by d as calculated value of compression strength. In the case of cement 1 tone number geopolymeric cement morning fair 0. 2 Generate carbon dioxide is expected with a co-production of a tone 80% carbon dioxide (the carbon dioxide generating 1 tone number about 1 tone morning fair Portland cement) demonstrates reduced in contrast the finest disclosed. In addition, in the case of geopolymers Si/Al ratio ceramic, cement, heat resistance for high strength concrete, blocking number radioactive waste, toxic element blocking and closing number, ultra-light insulation number, such as applicable for a variety of sound number can be improved disclosed. Also in the embodiment according to Figure 2 shows a graph indicating a change in the strength of one of the present invention with an aqueous alkaline solution concentration and curing period geopolymeric according to change and, in the embodiment according to IGCC gasification fisheries XRD analysis result indicating the graph and in Figure 3 of the present invention, ratio of Si/Al according to one of the present invention 4 is in the embodiment according to SEM microstructure analysis results Image geopolymers are disclosed. As also shown in concentration of an aqueous alkaline solution of a heater geopolymers increasing the stiffness of 2 tends bix, each number 3 and 7 work under [e material age date if increased strength material age increases by a goniophotometer. Molten slag is also 4 IGCC using Si: Al ratio 0. 7 - 2. 27 Into the same is mixed with the polymer with an aqueous alkaline solution after the local number number number and high pressure liquid coolant by using a SEM analysis result microstructure of the molded body produced therewith are disclosed. SEM analysis result Si: 0 Al mixing ratio. 7 - 2. 27 Range to the greatest possible extent with a microscopically fine fibre form because geopolymers number bath reaction is also used for electricity can be possible. The present invention according to laser diode using a molten slag bath method is complex power generating (IGCC) operation is formed in geopolymeric number molten slag without discard avoids environmental pollution controls the pin is. In addition, molten slag by a geopolymeric material number high pressure liquid coolant, a variety of ratio Si/Al utilize...copyright 2001. A feature of the present invention sends more description is provided to exemplify the generally described, the present invention if the properties of the present invention is provided to essentially inputted from deviating from a person with skill in the art in various modifications and deformable will. Thus, the present invention in the embodiment of the present invention are to define the disclosure but rather to explain the feature and, in the embodiment of the present invention by not the limited range of such feature. Under the protection range of the present invention must be interpreted by fee so as to range, and the range of the present invention feature in a range equal to all rights will be interpreted. The present invention relates to a method for manufacturing geopolymer by using molten slag and, more specifically, to a method for manufacturing geopolymer by using molten slag capable of manufacturing geopolymer by recycling the molten slag generated in an integrated gasification combined cycle (IGCC). The method for manufacturing the geopolymer by using the molten slag comprises: (A) a step of cleaning the molten slag discharged from a coal gasification process; (B) a step of drying the cleaned molten slag; (C) a step of crushing the dried molten slag; (D) a step of analyzing a component and a composition ratio of the crushed molten slag; (E) a step of manufacturing a mixed particulate material by supplying Si or Al to the crushed molten slag; (F) a step of manufacturing a dough sample by mixing the mixed particulate material and an alkaline solution; and (G) a step of curing a molded body by filling the dough sample in a mold frame. The present invention prevents environmental pollution. COPYRIGHT KIPO 2017 (A) exiting the washed coal gasification process is molten slag; (B) drying the washed said molten slag; (C) on which the dried molten slag; (D) analyzing said equally contains a milled fisheries; (E) ground the molten slag by supplying said Si or Al steps for creating a mixture powder; (F) by mixing said mixture powder with an aqueous alkaline solution and steps for creating a dough sample; and (G) water is added to form a moulding body frame is filling said dough sample; including a, a molten slag bath method using geopolymers number. According to Claim 1, in said (B), moisture in the so drying the washed a molten slag 10% hereinafter, a molten slag bath method using geopolymers number. According to Claim 1, said (C) step, molten slag after it became the [sway 1 700 - 900 micro m size difference well dried, size 40 - 80 micro m 2 difference which crushing, a molten slag bath method using geopolymers number. According to Claim 1, in said (D), said analyzing element controller and molten slag, molten slag bath method using geopolymers number. According to Claim 1, in said (F), said mixed powder and said aqueous alkaline solution mixing ratio is 1:02 - 0. 23 In, a molten slag bath method using geopolymers number. According to Claim 1, in said (F), said 9 - 18 mole/L concentration in an aqueous alkaline solution, a molten slag bath method using geopolymers number. According to Claim 1, said step (G), [...] (Pre-a curing) and high temperature curing at room temperature with a first surface which, in said molding time of at least about 23 - 25 °C [...] said 24 wherein the curing, the curing temperature to room temperature curing said molded articles which is operable in a dryer 24 time water is added through said 70 - 80 °C, a molten slag bath method using geopolymers number. According to Claim 1, in the 30 - 60 mpa (G) of compression strength in said positive dispersion to form a molding, a molten slag bath method using geopolymers number. Component SiO2 Al2 O3 Fe2 O3 CaO MgO Na2 O K2 O TiO2 Cr2 O3 ZrO2 SO3 SrO C Loi IGCCslag 49. 25 20. 16 5. 61 21. 67 1. 28 0. 49 0. 48 1. 07 - - - - 0. 06 0