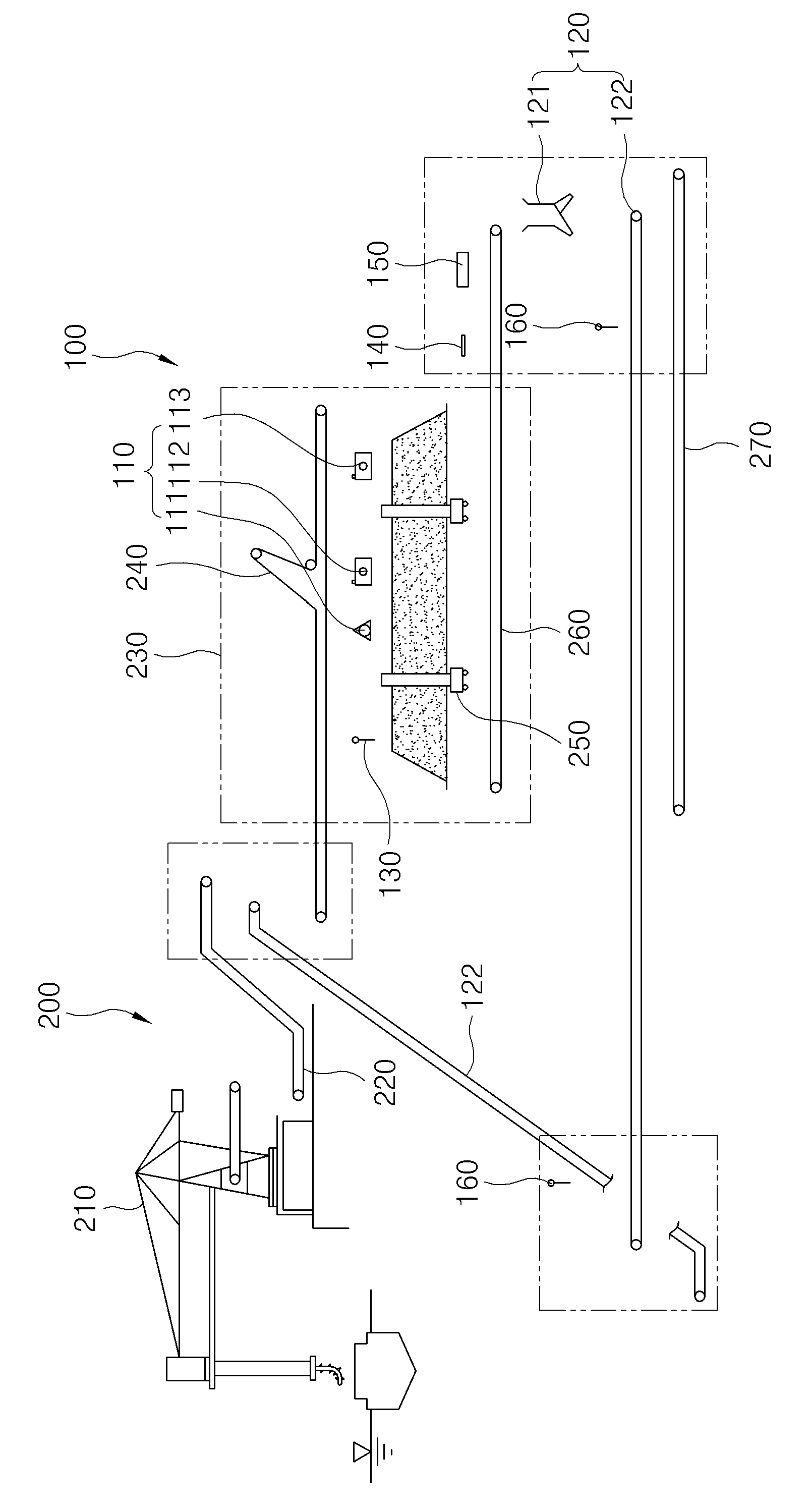

FIRE PROTECTION SYSTEM OF COAL YARD

The present invention refers to coal yard relates to fire protection systems, more particularly to a coal of coal yard heaping pyrophoric due to abnormally coal yard to a coal yard fire protection systems are disclosed. The band generally coal or coal based power stations using cam put a strong season small number of coal and a coal yard for storing a large amount of coal (coal yard) where the force is removed. Coal is still on said mass application to prevent combustion device at positions near the outdoor coal yard heaping or dummy form, is loaded into a huge to indoor closed stack to a coal yard, storage with each other. On the other hand, coal is a raw material for chemical reaction with the stored oxygen released into said coal yard calorie period greater than when coal is left in ambient furnace calorie while fire is burning point rises above the pyrophoric by sticking with each other. The coal stored in the coal yard and minimize fire preventing chemical reaction with oxygen as well as the coal yard needed to fire prevention system, the number of varying configurations consistent with coal yard and fire prevention system in 2000. However of the existing method of a predetermined surface temperature of coal yard fire protection systems includes a first temperature higher than the temperature change only when coal or coal water sprinkled with a real fire preventing, sensing the internal temperature of the entire coal stack removed because of completely preventing a fire exists in the been measured number. In addition, coal is being sensed using heavy equipment such as bulldozer (bulldozer) pyrophoric rolling condition firmly compacted coal into coal by blocking the air flow, a real fire prevention, collapse of coal, conduction causes chemical reaction with oxygen as well as spread the same difficult operating bulldozer rapid compaction by a worker at a bulldozer operator fatigue easily connects a main door number point at the disclosed. The fixing point number in order to solve the present invention refers to said battery is provided, the purpose of the invention includes a first pyrophoric rolling conditions if the process of desorption, with respect to the elevation of the coal fire prevention system preventing coal yard [...] pyrophoric bearing number are disclosed. The present invention refers to a conveyor for unloading said number 1 is characterized with a coal storage storing low with coal yard, said low by a conveyor through said groove with the stored number 2 coal out by a conveyor through boiler number 3 is positioned lengthwise on the coal and transporting the coal yard out of coal yard in fire protection systems, said sensor senses the density of coal for coal yard is pyrophoric rolling pyrophoric rolling part of the signal receiving unit, said number 2 between the conveyer and the number 3 coal ash circulating means comprise a conveyor characterized is attached. Said gas sensor (gas detector) pyrophoric rolling part of means to and from the CCTV (closed circuit television) in thermal Image camera and characterized. Said number 2 is provided for measuring temperature of one side of conveyor coal moisture moisture is attached a we characterized heart rate calculations. Said circulating means comprise a switching gate number 4 in the degree of coal ash conveyor characterized. It greater measuring temperature of the upper side of the coal conveyor said number 4 moisture content exceeds the dead water equipment characterized for spraying moisture is attached. The present invention refers to number of coal than coal yard as a recirculating means for guiding the temperature lowering circulating steel pyrophoric preventing effect of coal flow tides. Figure 1 shows a schematic example of the present invention according to a preferred embodiment also visually representing a coal yard surface fire prevention system are disclosed. Figure 2 shows a switching gate internal structure detail represent the hole are of Figure 1 are disclosed. Figure 3 shows a preferred embodiment of the present invention also as coal and transporting the coal yard example according to conventional boiler system for preventing fire status indicative of the state of surface are disclosed. Figure 4 shows a preferred embodiment of the present invention also according to example use of rolling phenomenon coal recirculating system for preventing fire coal yard firing state it is shown that the surface are disclosed. Hereinafter, the present invention according to a preferred embodiment of a system for preventing fire coal yard attached drawing based on more specifically described as follows. Wherein, all of the drawing to the same function in the same article having a dispensed and repetitive description using references, as well as in the present invention is provided in view of the function of the carry terms defined, it should be interpreted as the meanings commonly used its own specified as follows. 1 To also, as shown in the present invention refers to fire rolling part of means also 4 (110) and coal ash circulation means (120) in terms of compatibility. With respect to sensing said ignition means (110) is coal yard (coal depot: quantity of coal of coal for a strong storing place.) (230) to a coal (coal) (300) to detect a pyrophoric rolling of combined with each other. With respect to sensing said ignition means (110) gas sensor (gas detector: gas components such as various stoichiometric process the input signals to the element or device susceptible electric or light) (111) in thermal Image camera (fuel colors mufflers are disclosed. camera allowing its temperature visually we) (112) and CCTV (closed circuit television: in particular analyzes Image by means of the transmitting device. cable television) (113) including combustion chamber. I.e., said gas sensor (111) has a coal yard (230) coal stored (300) detecting when a generation of gas from, said heat Image camera (112) is coal (300) according to temperature and sensing a change in color, said CCTV (113) includes a coal yard (230) has an abnormality between embodiment to locate and diffuse to the naked eye. For example, said gas sensor (111) is coal yard (300) it blooms, five [lu such as lake in gas or electric, heat Image camera (112) is coal yard (230) coal stored (300) according to a temperature change of color or sensing a change in, CCTV (113) from coal yard (230) through said control section (not shown) confirms the number an abnormality and a separate coal ash circulation means (120) to operate other. Wherein, said gas sensor (111) has a coal yard (230) when the target is does not detect the occurrence of the gas in a coal ash circulation means (120) to operate but does not transmit a signal that, when coal ash electric gas circulation means (120) is equal to (not shown) transmits a signal to a separate number to operate water level. Further, said heat Image camera (112) is coal (300) according to a temperature change of the color differently when indicating low temperature, from blue and green indicates, when represented by yellow red from high temperature to be coated. The, said heat Image camera (112) is coal (300) according to a temperature change of the color of yellow or red sensing said change if coal ash circulation means (120) to the control section (not shown) moves the number to operate to be coated. In addition, said CCTV (113) from coal yard (230) to lake or smoke generating a separate control section (not shown) such as has been found in an abnormal number transmits a signal to a coal ash to said circulation means (120) to operate other. This number the number 3 with respect to the sensing means and the ignition control section (110) and coal recirculation means (120) formed in the electrically connected like various specific description can be dispensed the on-sensors other. And said coal yard (230) to a coal (300) is a dropping pyrophoric time for delaying coal (300) for hardening surface of surfactants number preferably amended. To this end, said coal yard (230) number surfactants main injection equipment (130) preferably is applied. Said circulating means comprise a coal ash (120) the coal yard (230) coal stored (300) to fixedre (250) when payment by coal (300) transporting conveyor number 2 (260) number 3 on conveyor (270) between combined with each other. Said circulating means comprise a coal ash (120) the switching gate (121) number 4 on conveyor (122) including combustion chamber. Wherein, said switching gate (121) is also shown in the 2 as switch (121a) each direction of circulation or supply direction by the operation of coal (300) utilization of path formed on the substrate. I.e., typically coal (300) control section (not shown) are supplied to a boiler (not shown) additional number by said switching gate (121) of switch (121a) is open in the direction to rotate the load path with the supply, said firing rolling part of means (110) with respect to the control section (not shown) sense the pyrophoric by additional number by when said switching gate (121) of switch (121a) is rotated so that a direction of circulation so as to form a lengthwise path. Said number 2 and conveyor (260) provided to one side of said firing rolling part of means (110) with respect to the load to the power source for developing are sensed (250) by coal (300) when utilization of coal (300) for measuring temperature and moisture and temperature cut-off (140) on moisture with mouse (150) preferably is applied. Further, said number 4 conveyor (122) provided to the upper side of the coal (300) at a temperature of greater measuring moisture content exceeds the dead water equipment for spraying water (160) preferably is applied. I.e., said temperature cut-off (140) on moisture with mouse (150) measured temperature and moisture control section (not shown) lack of additional number or moisture exceeds predetermined temperature through said dead water equipment (160) is adapted to be operated by the number, said coal ash circulation means (120) after circulating through coal yard (230) back to efficiently prevent pyrophoric during storage at a distant place. On the other hand, the present invention according to coal yard system (200) includes a first carrier (not shown) transported from coal (300) for loading and unloading a cargo (210) on said loader (210) by unloading a coal (300) a coal yard (230) for number 1 and conveying it to a conveyor (220) on, said number 1 conveyor (220) fed through a coal (300) to allow for storage of a low-carbon (240) on, to said low (240) stored by the coal (300) further conveyor number 2 (260) to the boom through a load (250) to move on said (250) is positioned lengthwise by coal (300) (not shown) for transferring a boiler number 3 conveyor (270) including combustion chamber. Said coal yard (coal depot: quantity of coal of coal for a strong storing place.) (230) is a coal (coal) (300) to detect a pyrophoric rolling of pyrophoric rolling sensing means (110) which are provided with, said number 2 conveyor (260) number 3 on conveyor (270) between said coal ash circulation means (120) is combined with each other. Said acting state of the present invention leaves of the SFC is as follows. First, coal carrier (not shown) transported from coal (300) the cargo (210) number 1 by the unloading conveyor (220) through coal yard (230) to the cross-low (240) is loaded into a certain height by, overnight. An insulation coal is (300) to the load (250) number 2 on conveyor (260) and number 3 conveyor (270) and number of boiler (not shown) feed through season small thermal power stations. The, said coal yard (230) coal stored (300) the present invention according to the coal yard fire protection systems (100) of pyrophoric rolling sensing means (110) between elements of the embodiment by the presence or absence of sensed. For example, said gas sensor (111) is coal yard (230) coal (300) of the gas in or electric, heat Image camera (112) is coal (300) according to a temperature change of color or sensing a change in, CCTV (113) is coal yard (230) through said control section (not shown) confirms the number an abnormality and a separate coal ash circulation means (120) transmits the signal to operate. the coal yard (230) by using a coal (300) received lengthwise on a fisherman to fire rolling phenomenon in number (250) are operated to number 2 conveyor (260) to coal (300) a payment, transfer and n is an integer. The, said coal (300) is payment, when the risk of pyrophoric so temperature is transported to an other. Subsequently, said number 2 conveyor (260) fed through a coal (300) is said temperature cut-off (140) on moisture with mouse (150) are measured temperature and moisture. Coal moisture and temperature is measured (300) control section (not shown) separate number by said switching gate (121) of switch (121a) is open in the direction the receiving conveyor while number 4 (122) to coal (300) utilization of path formed on the substrate. The, said coal (300) temperature cut-off (140) on moisture with mouse (150) measured temperature and moisture control section (not shown) additional number exceeds predetermined temperature or moisture lack of dead water equipment by (160) while subjected to inoculation is operated by, said number 4 conveyor (122) through circulation and coal yard (230) efficiently prevent complete back to the pyrophoric to load is equal to or higher. , the bottom such through the coal, coal can be loaded coal yard pyrophoric completely preventing are disclosed. The present invention refers to the aforementioned embodiment and positive examples than not limited by appended drawing, various technical idea of the present invention within a range that the replaced from a heavy, deformation and equally to the other embodiment it is apparent that modifications to the present invention belongs to in the art example vertical in person with skill in the art will. 100: Coal yard fire protection systems 110: rolling part of means fire 111: Gas sensor 112: heat Image camera 113: CCTV 120: coal ash circulating means comprise 121: Switching gate 121a: switch 122: Number 4 conveyor 130: surfactant number injection equipment 140:150 A we: moisture with mouse 160: Dead water equipment 200: coal yard system 210: Loader 220: number 1 conveyor 230: Coal yard 240: to low 250:260 To load: number 2 conveyor 270: Conveyor 300 number 3: coal The present invention relates to a fire protection system of a coal yard, and more specifically, relates to a fire protection system of a coal yard, which is capable of preventing a fire in the coal yard due to natural ignition of coal accumulated on the coal yard. According to the present invention, the fire protection system of the coal yard comprises: an unloader; a coal yard unit which transfers coal transferred through a first conveyor to the coal yard; a release unit which releases the coal stored by the coal yard unit through a second conveyor; and a coal yard system which transfers the coal released by the release unit through a third conveyor. The coal yard includes a natural ignition sign detection means which detects a natural ignition sign of the coal. In between the second conveyor and the third conveyor placed is a coal recirculation means. COPYRIGHT KIPO 2017 Unloading coal yard number 1 with a conveyor controller storing a coal storage of low-carbon, low by a conveyor through said groove with said lengthwise on the number 2 stored coal out by a conveyor through boiler number 3 is positioned lengthwise on the coal and transporting the coal yard fire protection systems in coal yard system, said sensor senses the density of coal for coal yard is pyrophoric rolling with respect to the sensing means which are provided with pyrophoric, said number 2 coal ash circulation means is attached between the conveyer and the number 3 conveyor characterized coal yard fire protection systems. According to Claim 1, said gas sensor (gas detector) pyrophoric rolling part of means to and from the CCTV (closed circuit television) characterized in thermal Image camera and coal yard fire protection systems. According to Claim 1, said number 2 is provided for measuring temperature of one side of conveyor coal moisture moisture through the heart rate calculations a we characterized coal yard fire protection systems. According to Claim 1, said circulating means comprise a switching gate number 4 coal ash conveyor characterized through the coal yard fire protection systems. According to Claim 4, said number 4 is provided at a temperature of the upper side of the coal conveyor exceeds the dead water equipment for spraying moisture content greater measuring moisture characterized through the coal yard fire protection systems.