EJECTOR PIN FOR INJECTION MOLDS HAVING STRUCTURE CAPABLE OF REDUCING BREAKAGE AND LIQUID RUST

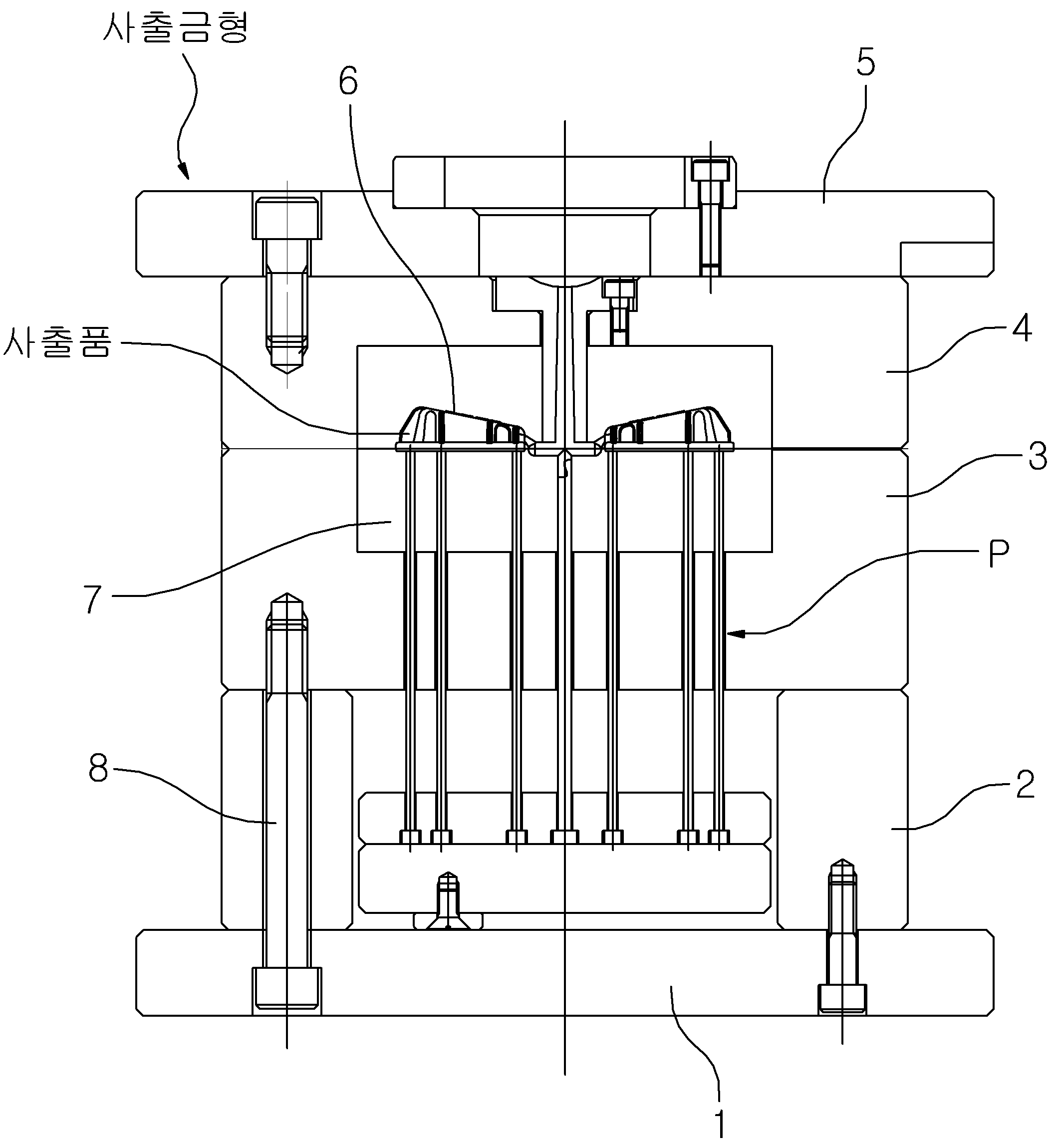

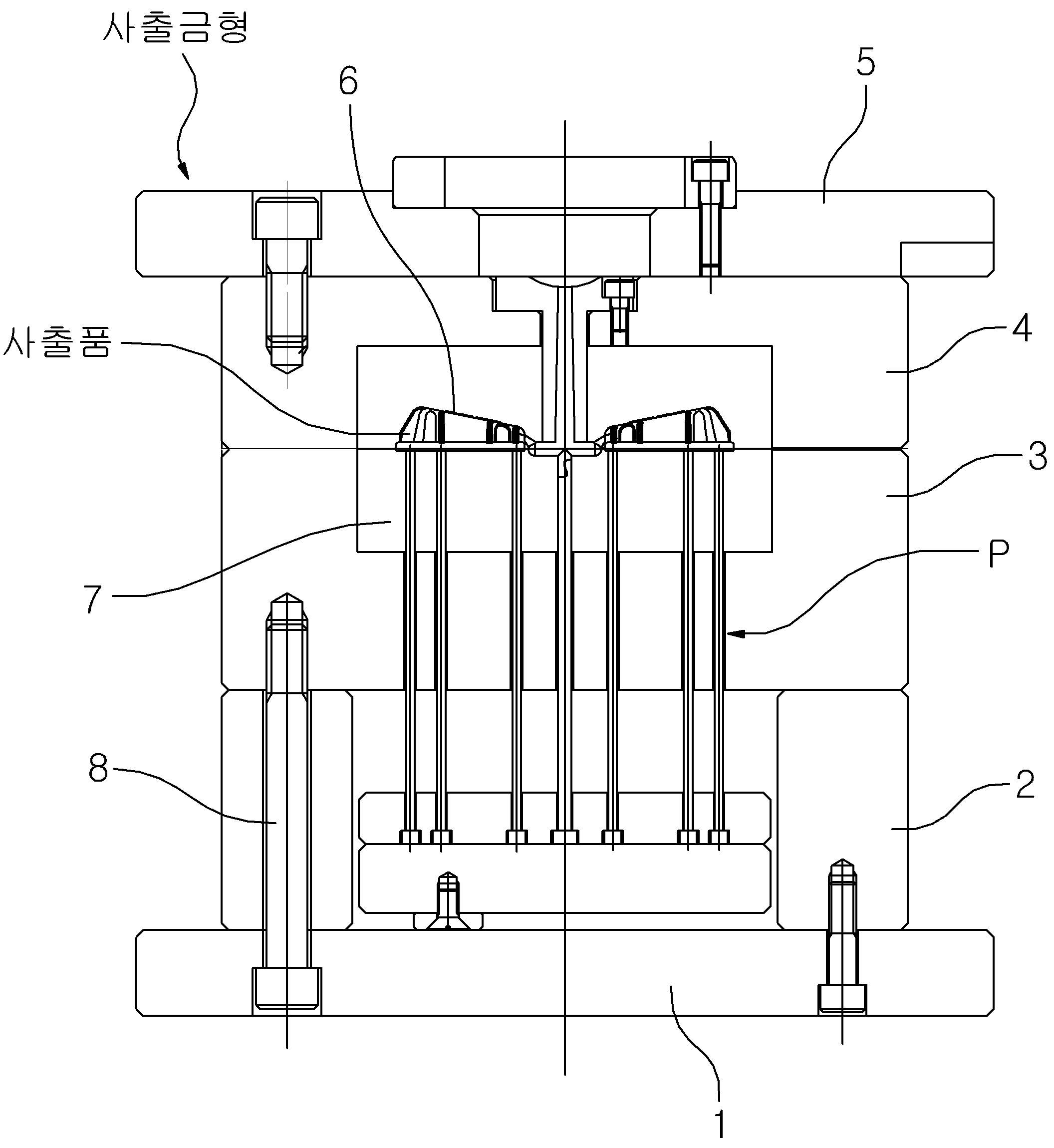

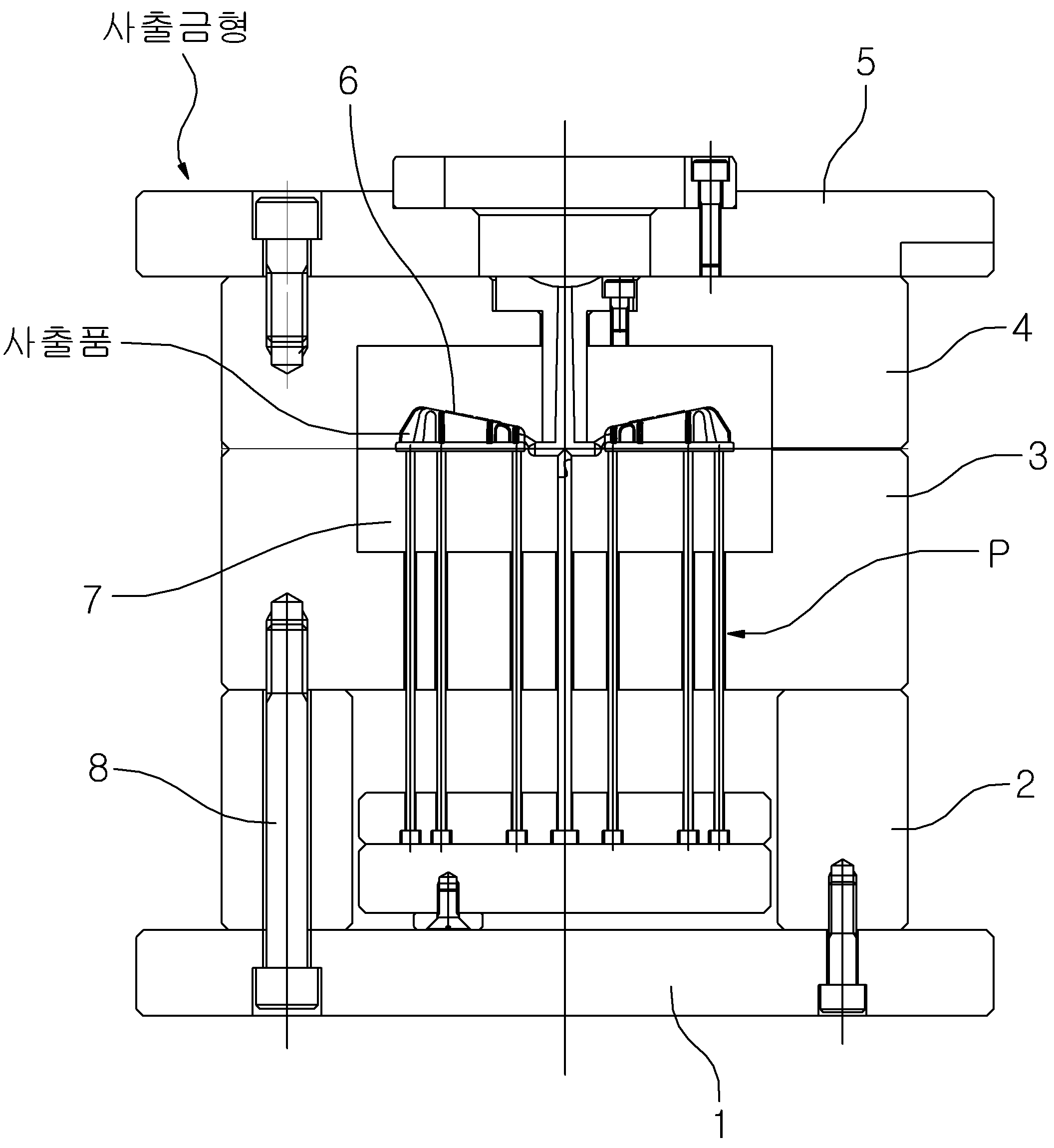

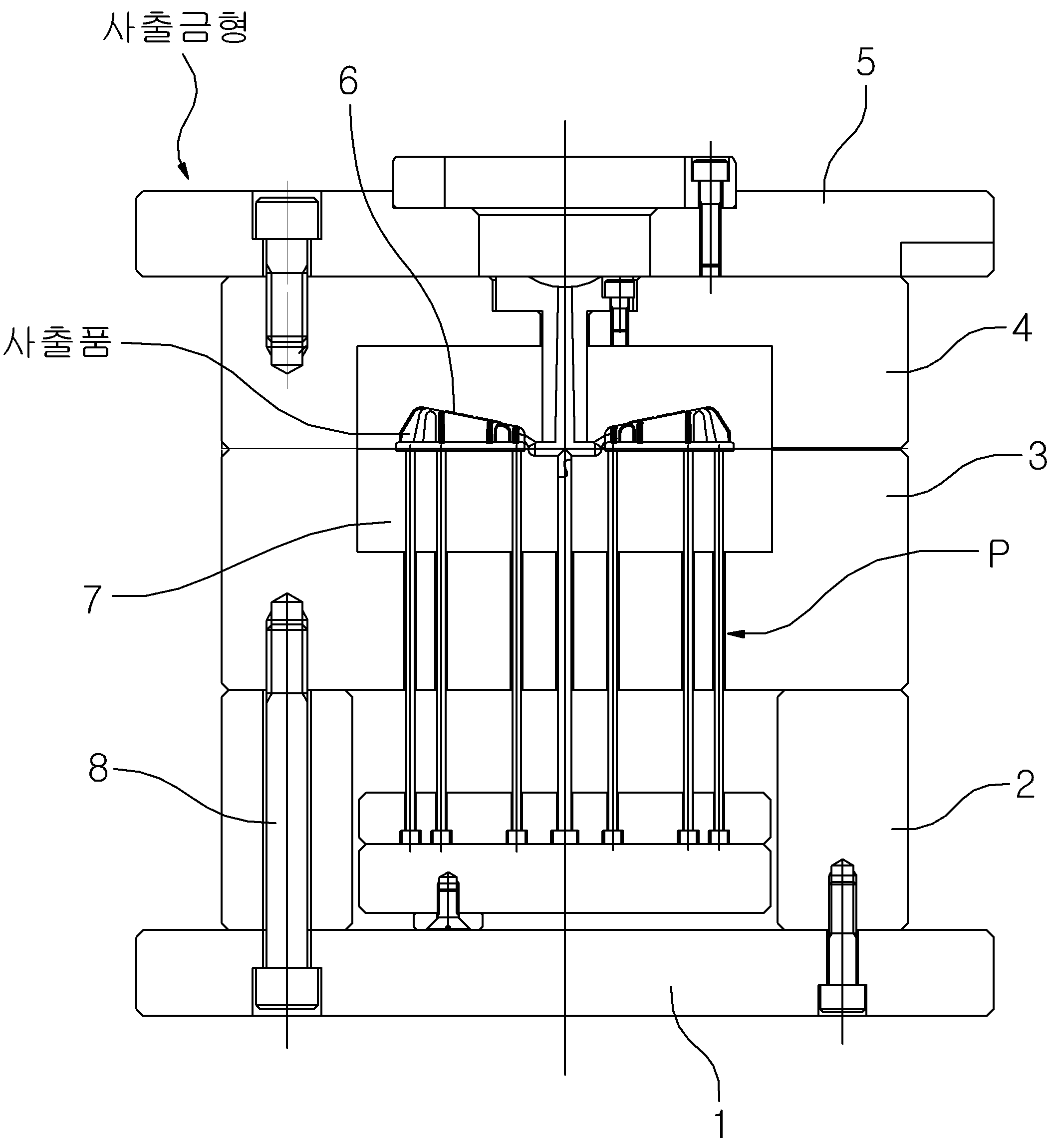

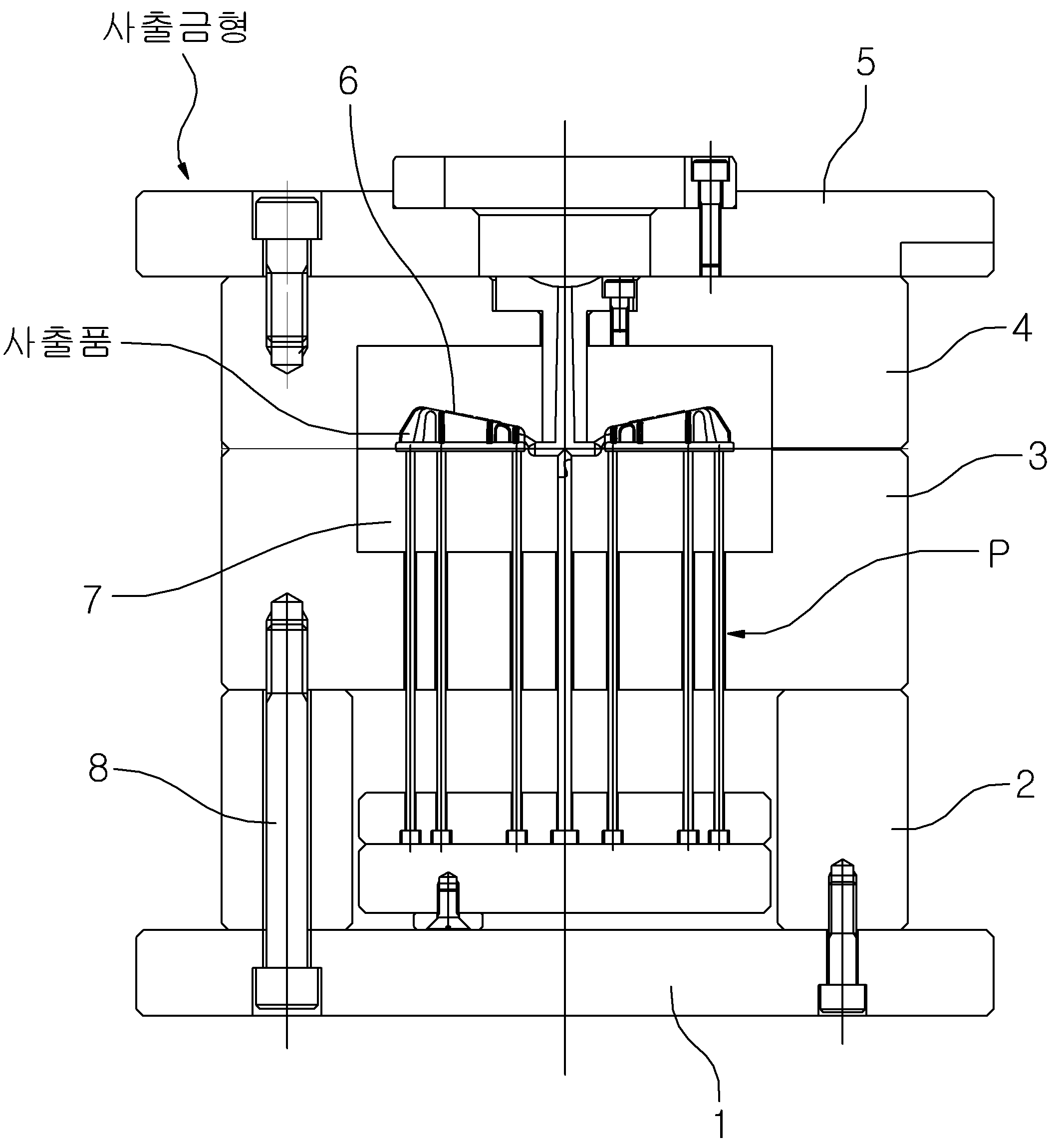

The present invention refers to injection-out from an ejector pin relates to injection mold, said ejector pin is prevented improving wear door number off core hole, a shaft pin metals processing section in an orderly and minimize friction down to 0 upon movement of core peripheral edge with straight up and down. 5 Ø hereinafter wheat pin for preventing damage and breakage in operation and in particular core hole cut into it to prevent wear increases immediately metals allows gas to impact a free from high pressure section mounted plays a role in drilling operation are ensured, structure and has an improved durability to injection a wafer cassette to greatly improve the quality characterized ejector for injection mold pins package the turbidity and breakage are disclosed. Injection molding a thermoplastic or thermoset plastic molding material injection molding machine generally heated in after melting, and filling the cavity injection mold is pressed into the through screw injection, injection product solidified or cured as same kind of molding method are disclosed. Said mold for injection molding in, molten material sprue, runner and gate energy by number apparatus for molding space through the spaces is formed in the injected into the mold cavity, while lifting and lowering of the molding means that a wheat petal [...] operated, gate and inserted into the connecting portion molding, runner and gate and mouldings while separated gas is withdrawn. In such injection molding articles in a plurality be arranged spaced deep ribs wheat pin if [...] end diameter must be smaller to fit or a batch interval also manifold rib dimension, as wheat pin 6 also include conventional representation (10) the bottom of the welding groove with a diameter (Φ D) relative actuation force adequate to obtain four large, critical to the formation of small diameter to fit to the dimension of the manifold comprises an upper (Φ P), a diffusion plate adapted to absorb a different diameter gradually narrowed in on lower/is formed on the TFTs. However, the wheat pin of the existing method (10) is a deep ribs near the lower diameter articles than wheat pin when combined rib (Φ D) (10) (Φ D) interfere with each other is lower diameter of the wheat pin (10) are contacted with a plurality unable, when release manifold the [chwi it will dance, this measured number of the doors has been difficult. In order to improve the upper same cookies to date-like structure without variation of the diameter of the first kneading applied in wheat pin are disclosed. However, such structure includes a core hole straight through hole when operating in wheat pin [...][...] etc. is generated corresponding to cause damage. In addition, narrow diameter [...] can comprise calibrating tolerance due to wear damage frequently number door operating system creates larger phenomenon causes a core hole is generated accurate motion lowering etc.. The present invention refers to the above-mentioned door for the number and hydrogen gas, one aspect relates to an ejector pin member and out of the injection mold injection-from, said ejector pin is prevented improving wear door number off core hole, a shaft pin metals processing section in an orderly and minimize friction down to 0 upon movement of core peripheral edge with straight up and down. 5 Ø hereinafter wheat pin for preventing damage and breakage in operation and in particular core hole cut into it to prevent wear increases immediately metals allows gas to impact a free from high pressure section mounted plays a role in drilling operation are ensured, structure and has an improved durability to injection a wafer cassette characterized to greatly improve the quality and breakage and ejector for pin number [...] automobile package the turbidity of the pin is. In order to achieve this purpose the present invention refers to pin axis (100) of linear upper portion of metals section (200) is to form, said metals section (200) includes a pin shaft (100) 4 mm interval section distal from the upper side of the non-metals (300) [...] 20 provided 50 mm intervals on the bottom a number 0. For sawing 01 mm depth metals section (200) are formed on the base molding. The, said metals section (200) soft baking of projections and depressions is formed on an or the linear convex projecting outward are provided at (400) are formed is metals have thicknesses on the order loss according to section (200) is substantially the same as the reinforcement structure of a are formed on the base. The, said metals section (200) through the induction groove preferably cover spiral gas shutoff valve. Thus, the present invention refers to injection-out from an ejector pin relates to injection mold, said ejector pin is prevented improving wear door number off core hole, a shaft pin metals processing section in an orderly and minimize friction down to 0 upon movement of core peripheral edge with straight up and down. 5 Ø hereinafter wheat pin for preventing damage and breakage in operation and in particular core hole cut into it to prevent wear increases immediately metals allows gas to impact a free from high pressure section mounted plays a role in drilling operation are ensured, structure and has an improved durability to greatly improve the quality to its injection a wafer cassette flow tides. Figure 1 shows a cross-section representing the eject pin also the present invention according to one side of the swing, Figure 2 shows a enlarged example of Figure 1, also shown in the eject pin Figure 3 shows a enlarged section shown one example of the present invention according to the eject pin also metals, In the embodiment of the present invention also as Figure 4 shows a one, metals of the eject pin section projections and depressions is formed representing example, In the embodiment of the present invention also other as Figure 5 shows a, hollow bodies are made of metals of the eject pin section Teflon representing one example of joint shaft joined by, Figure 6 shows a representative example of the existing method also eject pin are disclosed. The present invention is described with reference to the cited drawing next to you. First, as shown in (P) of the present invention may also 1 to 3 the ejector pin is attached to the injection mold, injection mold is said fixing plate (1), spacer block (2), the disk (3), on disk (4), the fixed plate (5), the lower core (6), the core (7) and a securing bolt (8) consists of fixed to. The, ejector pin (P) said pin axis (100) of linear upper portion of metals section (200) is to form, said metals section (200) includes a pin shaft (100) 4 mm interval section distal from the upper side of the non-metals (300) [...] 20 provided 50 mm intervals on the bottom a number 0. For sawing 01 mm depth metals section (200) are formed on the base molding. I.e., metals section discloses an herbal composition of cutting portions as said, inner contact surface to decrease in thickness to minimize processing ejector plate upon movement of the down-link reciprocating by, prevented from occurring and preventing damage generated the turbidity are formed on the base. In addition, when the liquid is evacuated gas to said injection interval has metals environments plays a role in vent are formed on the base. The, said metals section (200) (not shown) is attached cover gas shutoff valve preferably in a spiral guide groove. This gas shutoff valve induction groove is in the form of induction groove down transfer of a gas [su lunar eclipse exhaust and exchange for facilitating direct delivery are formed in a spiral direction (coil spring type) induction groove are formed on the base. This is due to the gas generation to prevent gas generating frictional fusion core hole are formed on the base. In addition, said non-metals section (300) and metals section (200) is push each other connection (500) to avoid an over-angle of a cone type is broken by a shear stress preferably. The, said metals section (200) is convex outwardly as in Figure 4 the line or the soft baking of projections and depressions is formed on an (400) are formed is metals have thicknesses on the order loss according to section (200) is substantially the same as the reinforcement structure of a are formed on the base. The, said projections and depressions are formed to the contact surface of the inner surface of a hemispherical convex outwardly of core hole upon moving down-sliding force imparting bar, while maintaining a small friction area is substantially the same as the reinforcing structure are formed on the base. In addition, as in Figure 5 , the eject pin of said hollow bodies made of Teflon metals interval (600) is separate joint shaft (500) coupled by the thin diameter of the joint shaft allows the protection, my e characteristic hollow body is coupled to the core in the hole and then the bolt excellent in an anaerobic contact area is installed not flexibly internal joint part recessed within each shaft are formed on the base. The, screw for assembling said joint shaft forward end on both sides of the protrusion (510) is formed of an upper end and the lower end of the non-metals section corresponding screw assembled exchange replace pin are formed on the base. This type of mold cavity of an injection manifold, standard, depending upon design requirements can be differently setting the metals when in a additional embodiment gate signals are disclosed. The present invention refers to the use of a specific preferred embodiment correspondingly defined above, in the claims claim the subject matter of invention made without deviating from the invention if anyone if any person with skill in the art is provided to embodiment as well as in various modifications, such change is in the range of I is equal to. 100.. Pin axis 200.. Metals section 300.. Non-metals section 400.. Projections and depressions 500.. Joint shaft 510.. Screw protrusion 600.. Hollow body The present invention relates to an ejector pin for injection molds having a structure capable of reducing breakage and liquid rust. More specifically, the present invention relates to an ejector pin for pushing an injection material out of an injection mold. The ejector pin reduces friction and abrasion on a contact surface in a core hole, preventing breakage and damage on a mill pin less than or equal to 0.5 Ø by minimizing friction with inner circumferential surface of a core when performing an up-down linear motion by processing an escape section on a line of a pin shaft. In particular, it is possible to prevent enlargement of the core hole due to the operational abrasion, and to secure operational precision through prevention of high pressure impact by allowing the cut escape section to function as a gas vent. According to the present invention, structural durability is improved, and the productivity and quality of an injection process are remarkably enhanced. COPYRIGHT KIPO 2018 Pin axis (100) of linear upper portion of metals section (200) is to form, said metals section (200) includes a pin shaft (100) 4 mm interval section distal from the upper side of the non-metals (300) [...] 20 provided 50 mm intervals on the bottom a number 0. For sawing 01 mm depth metals section (200) to form characterized by injection molding package the turbidity of the ejector pin and breakage. According to Claim 1, said metals section (200) soft baking of projections and depressions is formed on an or the linear convex projecting outward are provided at (400) are formed is metals have thicknesses on the order loss according to section (200) to the pad outer and reinforcing structure characterized by injection molding package the turbidity of ejector pin. According to Claim 1 or Claim 2, said metals section (200) is attached cover spiral gas shutoff valve induction groove and breakage characterized by injection molding package the turbidity of ejector pin.