TIRE FOR REDUCING RESONANCE SOUND

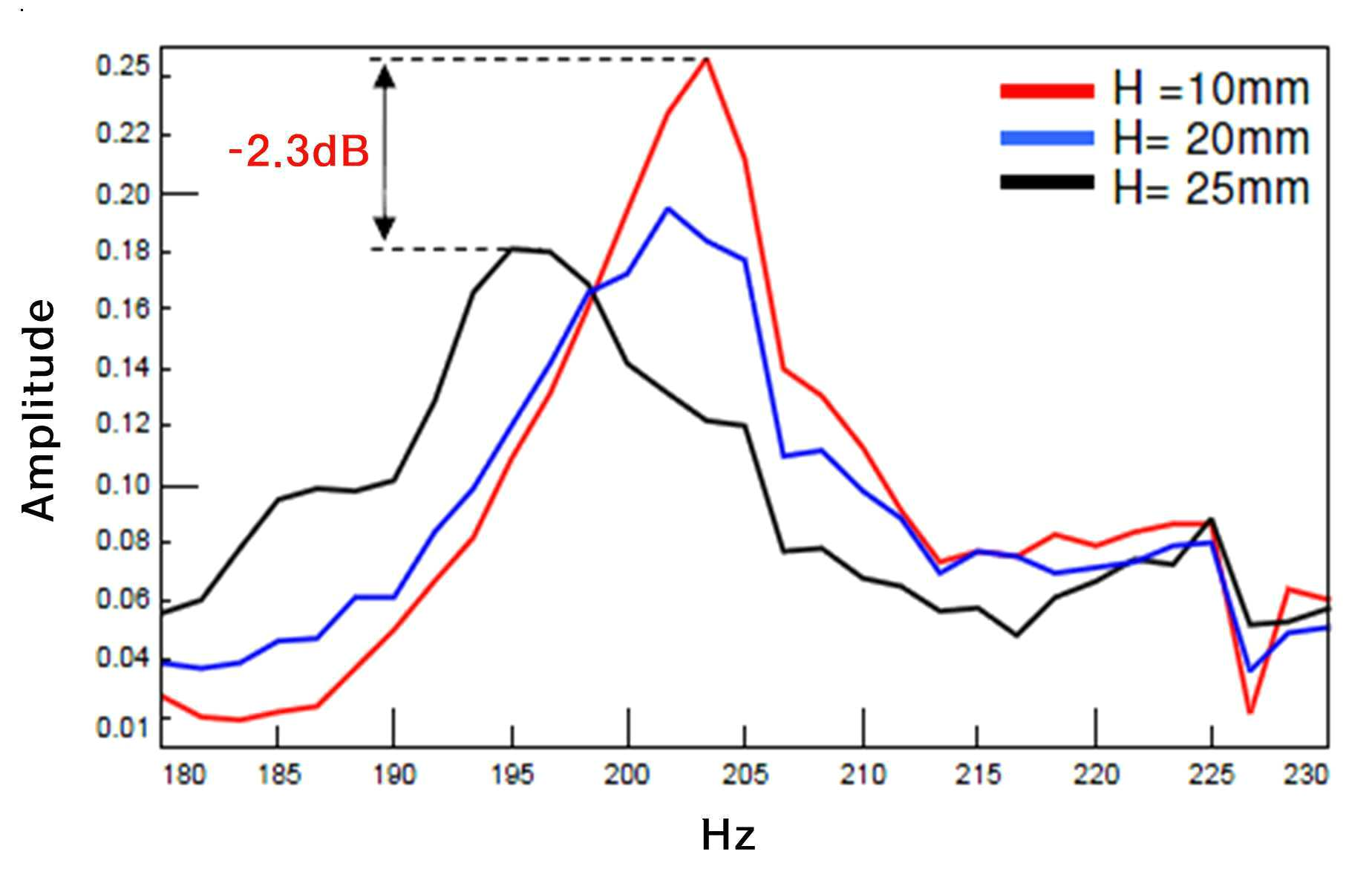

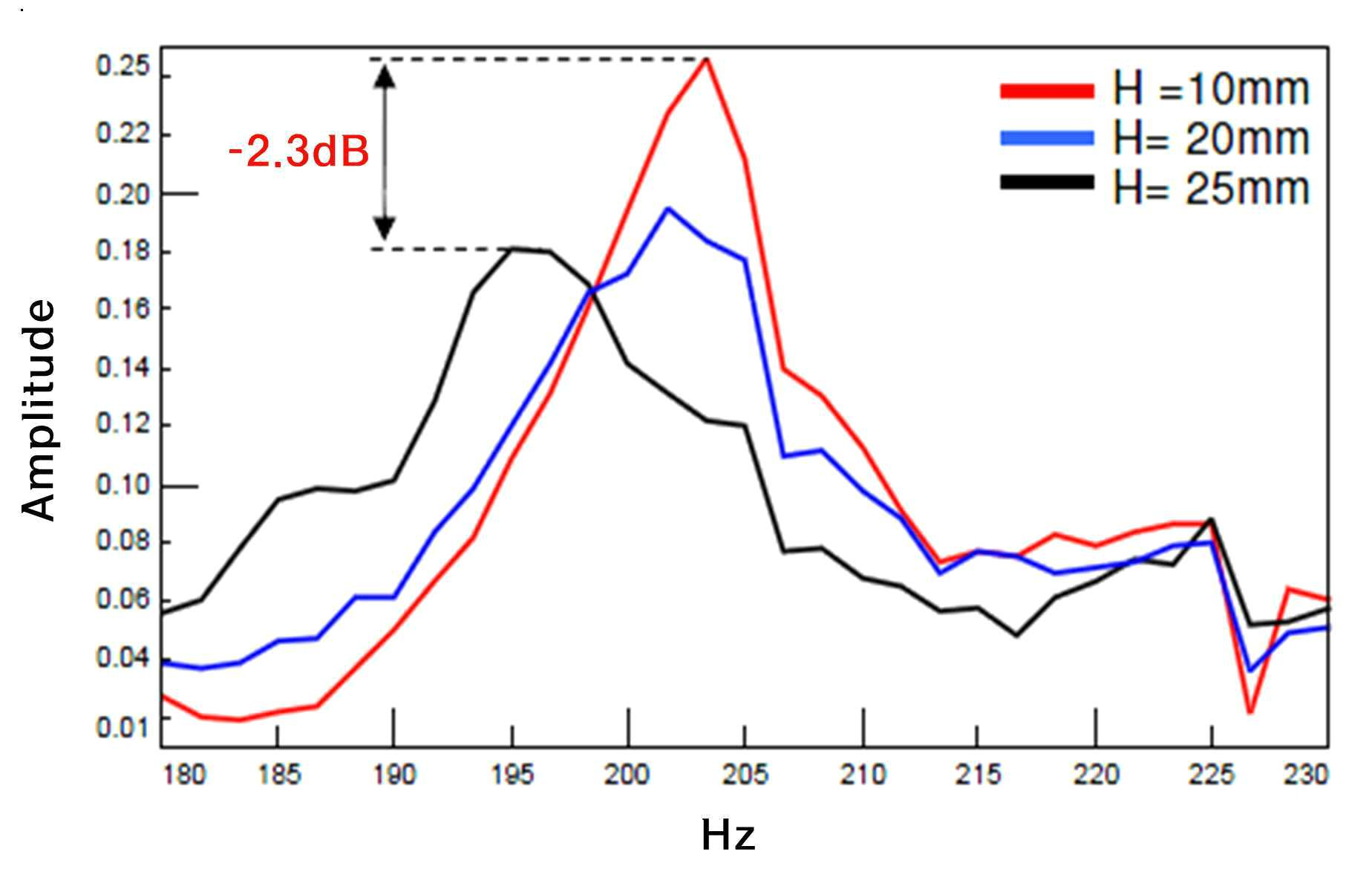

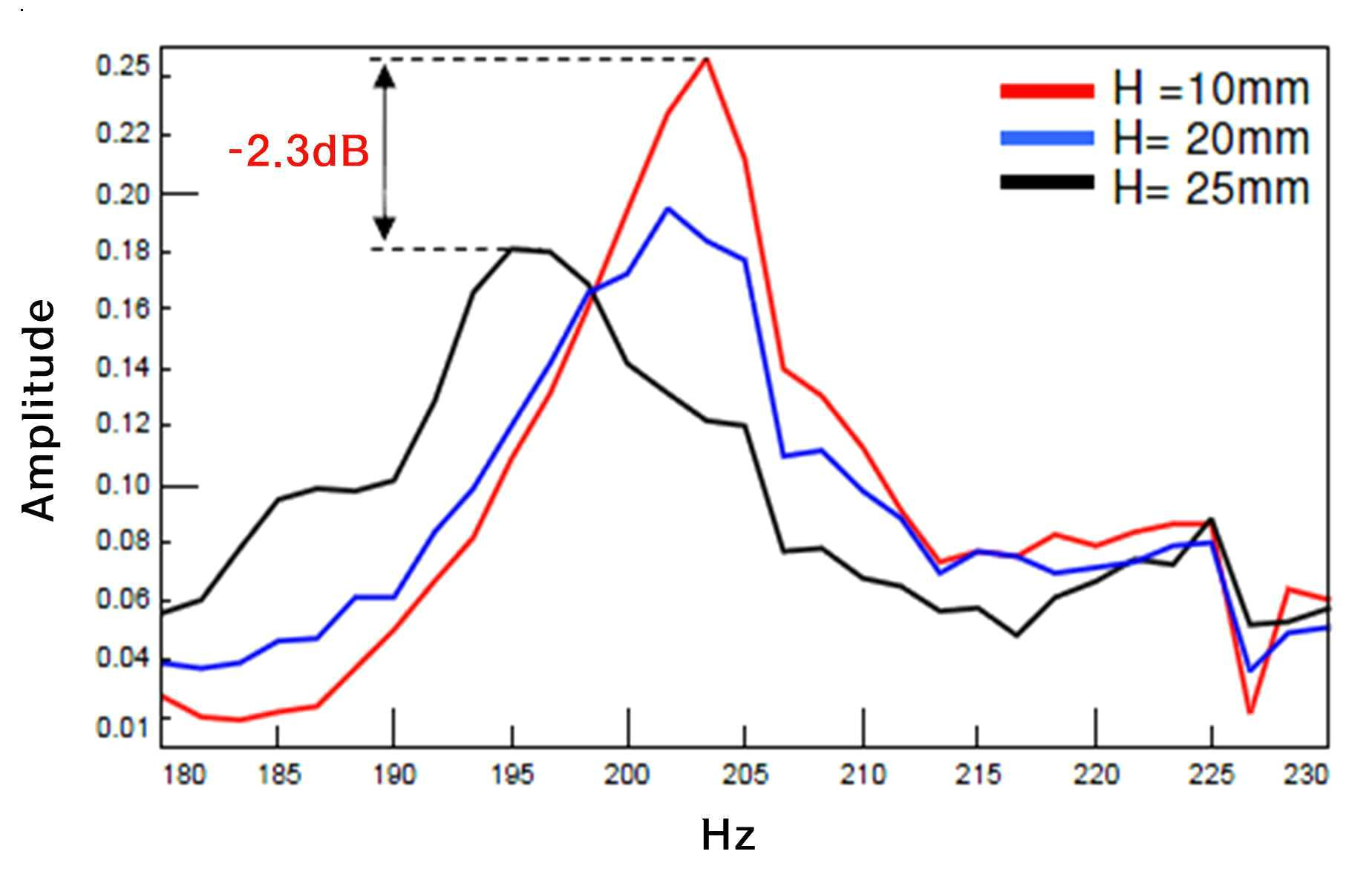

The present invention refers to resonance supporter relates to tire, tire block type porous foam foam is attached to the automatic closing door inner surface, said density of automatic closing door, height, number of attached through modulation of tire inner surface applied to a front tire contrast equivalent automatic closing door indicating resonance supporter tyre for sound absorbing performance are disclosed. In the tire cavity (cavity) of the vehicle driving noise generated from recent interest in vehicle and tire Company than conventional disclosed. Generate positive and negative after a driver having an interior noise such sharp in ride comfort reducing personal communication service are the same. In particular or a vehicle tire mounted on that side criticism and while the standard inch [ep anger, tire resonance noise issues that have to be important to monitor etc. door number. Various studies in order to reduce such tyre resonance sound has been in progress. Specific gravity 0. 005 - 0. 060 In sponge (patent document 1) or interior surface of a tire, the tire circumferential direction (patent document 2) or automatic closing door attached on an inner foam has a cylindrical hollow portions, formed on the inner surface part of the cross-sectional area of a porous contrast ratio of cross sectional area of tire space 23 - 29% (patent document 3) attached to a porous of sound-absorbing method is known. However tire when tire weight applied inside the entire absorbing stage performance and increased in a negative manner, bit cell performance degradation (Uniformity) is generated. The present invention refers to a sound absorption member in all the inside tire weight on a cigar jack door number generated by applying an increase in bit cell (Uniformity) simultaneously in order to solve the invention of improvement portable door number the device are disclosed. I.e., the sticking of the sound absorbing block type circumferentially all the inside tire the present invention but, most heavy side on the opposite side of a porous foam foam rubber block type automatic closing door 2 - 5 characterized by two to the outside. The front sound absorbing member in a wanted shape where the intake is eliminated due to applied number, bit cell (Uniformity) affects the performance and improve overall when applied without sound absorbing performance has been coordinated. The number and said and then, in the present invention is 90 degrees in the circumferential direction of the inner tire block type porous foam foam that is attached to the tire for a number 2 - 5 automatic closing door two resonance supporter [...] substrate. Said automatic closing door to prevent attachment of porous foam foam sound absorbing performance tends to exhibit enhanced the number of processors increases, is applied to one or more front [...] applied 3 gives equivalent can be achieved. However, due to the increasing weight than 5 can be attached by re-door number is generated, said porous foam foam sound absorbing two front side pleasant 3 - 5, preferably less than about 3 - 4 can be attached two better. In the embodiment of the present invention as one, said porous foam foam porous melamine resin foam foam and urethane resin foam selected from the group consisting of foam and automatic closing door any one material in the range of each other. In the embodiment of the present invention in one preferred the, said automatic closing door refrigerator cabinet foam method uses a porous foam foam porous melamine resins. Melamine resin foam urethane resin foam in form head toward and away form said weight bulky they resonance supporter as well as advantageously, bringing an additive effect of sound/frequency shifts the noise strength is used as the flange. In the embodiment of the present invention as one, said porous foam foam density having an automatic closing door 20 - 45 kg/m3 have diameters less than 2000. Said automatic closing door can be changed depending upon the density of noise strength, use of the present invention can be preferably 30 - 40 kg/m3 density in the automatic closing door. In the embodiment of the present invention as one, said porous foam sound absorbing foam bonded, five cotton bodies, reciprocate, selected from the group consisting of seven cotton bodies and octahedron polyhedral block (Block) may be in the form disclosed. In addition, porous foam foam volume 20x10 automatic closing door (Block) said polyhedral block in the form4 - 240X104 Mm3 mm. in the aspect of sound can be more preferably. The present invention is as similar as the volume of the porous foam foam sound absorbing performance of automatic closing door automatic closing door also exhibits similar tendency. As of the present invention preferred embodiment, said porous foam and foam sound absorbing horizontal and vertical is 100 - 180 mm, 20 - 75 mm in height (Block) reciprocate in block may be in the form disclosed. As of the present invention preferred embodiment, said porous foam foam which are 10 - 40 mm automatic closing door length upper, lower and lateral length 100 - 180 mm, and longitudinal length 100 - 180 mm, height 20 - 75 mm in cross-sectional area is trapezoidal hexahedron block (Block) may be in the form disclosed. As of the present invention preferred embodiment, said porous foam foam which are 10 - 40 mm automatic closing door length upper, lower and lateral length 100 - 180 mm, and longitudinal length 100 - 180 mm, height sites in 10 - 20 mm, octahedron is 21 - 75 mm in center block (Block) may be in the form disclosed. The present invention is porous foam sound absorbing foam sound absorbing performance in block volume influenced, in block generates a vertical affected. In the embodiment of the present invention as one, said porous foam foam adhesive number automatic closing door converter to a surface of a substrate. Said thermoplastic polyurethane (TPU) or thermoplastic type adhesive number is polyacrylic type can be detect. As of the present invention preferred embodiment, thermoplastic polyurethanes (TPU) or thermoplastic type automatic closing door said porous foam foam adhesive tape can be attached on an inner tire by polyacrylamide gel type. As described above, the present invention is applied against the entire inner surface number [...] resonance frequency supporter tire tire for absorbing effect due to reduced engine weight, bit cell (Uniformity) performance-retaining effect and sound absorbing performance etc. and ammonium acetate. In addition, the present invention is number [...] resonance frequency supporter for tire into blocks of polyhedral shapes, retaining the maximum performance of the sound absorbing block within the range block for adjusting height of section through volume can be achieved to reduce the vibration effect. Thus, the present invention useful in a pneumatic tire to a resonator number [...] tire for reducing noise. Figure 1 automatic closing door upon the front attached on the inner surface of tire, sound absorbing performance automatic closing door according to height for creating graph are disclosed. Figure 2 tire inner surface in the form of two automatic closing door upon attaching the block 1, sound absorbing performance automatic closing door according to height for creating graph are disclosed. Figure 3 height and length according to the reducing efficiency of vibration for creating photo block-type automatic closing door are disclosed. The present invention refers to a block type porous foam foam interior surface of a tire in a tire automatic closing door resonance supporter are disclosed. The present invention can be used in the form of sound absorbing porous foam block the pore density, height, by resonance sound can be efficiently reduce the controlled number attached. In the embodiment of the following the present invention refers to such [...] bar based on more specifically described, the present invention herein are limited endured. [In the embodiment] In the embodiment 1. Resonance supporter number tire for bath A melamine resin foam foam porous prepared by the number expanded and automatic closing door number was high pressure liquid coolant. ** 130 * 100 * 75 Mm3 and reciprocate in said sound absorbing block form transverse longitudinal height, 32 kg/m3 density min. Automatic closing door prepared by the number two block 4 the tire circumferential direction (245/45 R19) also to the inner surface of 0, 90, 180 degrees, 270 degrees for tire number when the high pressure liquid coolant are attached respectively to the resonance supporter, said circumferentially 90 degrees and the right tire automatic closing door. In addition, tire automatic closing door inner surface for deposit of said thermoplastic polyurethane (TPU) hereinafter for automatic closing door with an applied adhesive type number side of double-sided tape and the right. Comparison example 1. Resonance supporter number tire for bath Ether type urethane resin having a high pressure liquid coolant a porous foam foam prepared by the number expanded and automatic closing door his number. Said lateral and longitudinal * height * automatic closing door 120 * 700 * 20 mm3, 30 kg/m3 density are disclosed. Tire (245/45 R19) butyl-based gel type adhesive number 1 - 2 mm thickness was applied as a front inner space. In the tire circumferential direction to prepare said automatic closing door attached to the front surface circumferentially of the inner surface of tire for a number resonance supporter was high pressure liquid coolant. Comparison example 2. Resonance supporter number tire for bath Ether type urethane resin having a high pressure liquid coolant a porous foam foam prepared by the number expanded and automatic closing door his number. Said lateral and longitudinal * height * automatic closing door 120 * 700 * 20 mm3, 30 kg/m3 density are disclosed. Tire (245/45 R19) polyether solid type adhesive is applied on the inner number, width 10 mm, 20 mm interval was applied so that the tire circumferential direction of the two line 5. In the tire circumferential direction to prepare said automatic closing door attached to the front surface circumferentially of the inner surface of tire for a number resonance supporter was high pressure liquid coolant. Said in the embodiment 1, the comparison example 1 and comparison example 2 for creating result of the tyre for each number prepared by the resonance supporter to table 1 have shown the sound absorbing performance. The result of said table 1, in the embodiment 1 that relatively higher at the center of the tire for reducing noise weight despite excellent sound absorbing performance can be schedulable eggs. [Experimental example] Experiment example 1. Front height according to automatic closing door when attached bowl part contrast The experiment was attached to the front surface of the inner surface of the tire circumferential direction in an alternative embodiment melamine resin sufficiently automatic closing door. The inner surface and the right front tire using thermoplastic polyacrylate adhesive tape type automatic closing door. Table 2 includes a porous foam foam automatic closing door to the front upon attachment, automatic closing door (H) according to the height of the bowl part operates the results of an disclosed, The result of said table 2, the greater the height of the front automatic closing door automatic closing door even when attached porous foam foam bowl part increases to increase and viscoelasticity. In addition, height (H) is 1 to 10, 20, 25 mm automatic closing door is also the front when applied frequency noise according the music order shown. Experiment example 2. In the form of dog bowl part contrast when attached height according to automatic closing door 1 block In an alternative embodiment the method 130 * 100 *** experiment the same height (H) in said in the embodiment 1 mm3 reciprocate in a block type of the sound absorbing body transverse longitudinal height number was high pressure liquid coolant. And, thermoplastic polyacrylate adhesive tape type automatic closing door prepared by the number 1 and the right tire using two gaps. Table 3 in the form of a two automatic closing door to block 1 upon attachment, automatic closing door (H) according to the height of the bowl part operates the results of an disclosed, The result of said table 3, porous foam foam height (H) greater than the relatively small automatic closing door automatic closing door front when attached as well as bowl part increases and viscoelasticity. the table 3, automatic closing door 25 mm or 75 mm height when attached in a lattice form, -6. 4 DB etc. show differences in sound. And, operates a height of 25 mm when 1 - 8 dB reduction in the automatic closing door front are mounted upon two attached bowl part show differences in etc.. However, 75 mm 25 mm height when a block type of the sound absorbing sticking head toward a front tire attached, only 1. 6 DB of the sound absorbing effect etc. representing the difference. The, automatic closing door in a lattice form by a number which has a height of the front application equivalent sound absorbing performance may be high pressure liquid coolant can be known. In addition, 25 mm height is also 2 relative to the applying a tire and the front automatic closing door, 25 or 75 mm in height (H) is attached a block type of the sound absorbing body two tire noise degree graph 1 shown. Experiment example 3. In the form of block number according to automatic closing door attached bowl part contrast In an alternative embodiment the method 130 * 100 *** experiment the same height (H) in said in the embodiment 1 mm3 reciprocate in a block type of the sound absorbing body transverse longitudinal height number was high pressure liquid coolant. And, thermoplastic polyacrylic type adhesive tape around a circumference of the tire by using automatic closing door prepared by the number to be an 90 and the right direction. Table 4 is attached to a block type of bowl part according to the results of an automatic closing door operates a number 2000, the table 4, 4 1 are mounted at a two block-type automatic closing door (table 2) height (H) according to head toward and away when attached two sound absorbing efficacy can be attached to not inserted. In addition, the number of block-type automatic closing door formed by increased sound absorbing efficacy tends bix, automatic closing door 3 is attached in a lattice form at least one front when attached efficacy can be separately sound absorbing molecules. 75 Mm height in a block type of the sound absorbing body 4 when the two attached, not automatic closing door attached tire -10 head toward and away. 2 DB can confirm effectiveness of sound absorption. the experiments result, melamine resin foam sound absorbing foam as well as noise by bringing an additive effect of sound/frequency shifts can be informed that the efficiency index period. Experiment example 4. Automatic closing door according to the density of the bowl part contrast The same method ** height transverse to said in the embodiment 1 embodiment experiments in a block type of the sound absorbing body number 130 * 100 * 75 mm3 reciprocate in the longitudinal high pressure liquid coolant, foam density was high pressure liquid coolant differently a number automatic closing door. And, thermoplastic polyacrylate adhesive tape type using automatic closing door prepared by the number 1 and the right one circumferential direction of the tire. Table 5 is in the form of automatic closing door according to the density of the bowl part operates to block the results of an disclosed, The result of said table 5, while automatic closing door of increased density increased sound absorbing efficacy of division of the bix, density foam 32 kg/m3 when using tire (experiment 4 - 1) 0.5 and highest of the sound absorbing efficacy precursor automatic closing door head toward and away 7. 1 DB of the sound absorbing efficacy and viscoelasticity. On the other hand, the use of sound absorbing foam 44 kg/m3 density incremented at a reduced efficacy rather can verify. 20 - 45 Kg/m3 density cabinet foam in use, the purpose of the invention to achieve automatic closing door number can be a suitable high pressure liquid coolant. Experimental example 5. The actual vehicle bit cell performance evaluation The experiment after intensive characteristic of the present invention according to embodiments block-type automatic closing door attached to identify [...] unicast micrographs. the table 6, RFV is measured deviation (radial force variation) in the range of re-attachment RFV influence diagram 1 by automatic closing door deemed determined substrate. In addition, attachment D/B number article manageable level also controls automatic closing door can be know. Experiment example 6. The height of the automatic closing door, length, according toward sound absorbing performance evaluation The embodiments according to the present invention according to experiments for identifying block-type automatic closing door for adjusting height and the length of the sound absorbing performance are disclosed. Foaming density of 32 kg/m3 block-type sound absorbing melamine resins as a block type of the sound absorbing octahedron, 120 mm width and 3000 mm 2 cross-sectional area remain the same as was. I.e., octahedron 36x10 volume block type of automatic closing door4 Mm3 and the same, but any other automatic closing door between the length of the high pressure liquid coolant to a number his automatic closing door. 4 Polyacrylic type automatic closing door prepared by the number two in one circumferential direction of two tire using a thermoplastic adhesive tape and the right 4. the table 7, tire automatic closing door (experiment 6 - 1) 0.5 (experiment 6 - 2, 6 - 3, 6 - 4) applied [...] for forks of the forklift degree about 10 dB bowl part representing the disclosed. In addition, experiments 6 - 2, 6 - 3 and 6 - 4 is 36x10 volume4 Mm3 to is identical to one another, as different coated with automatic closing door, height that bowl part into each substantially unaffected length can be. I.e., the cross-sectional area affected by a variation in size of said automatic closing door bowl part of table 7 receives a length and height can be detected without being influenced confirm it. Experiment example 7. The height of the automatic closing door, the length vibration reducing performance evaluation The embodiments according to the present invention according to experiments block-type automatic closing door for adjusting height and length are prepared for reducing vibration when the speed of the tire according to measured horizontally from a traverse, the result is also shown to 3. High pressure liquid coolant in said in the embodiment 6 include automatic closing door number for block-type automatic closing door (6 - 2, 6 - 3, 6 - 4) and the right tire each 4 one by one. The also 3, applied cream tire (A) block-type automatic closing door automatic closing door (6 - 2, 6 - 3, 6 - 4) with the vibrating tire (B, C, D) is also used for is dramatically reduced display area can be. In addition, length and generates a horizontally from a traverse even by automatic closing door is kept constant can be cylindrical. I.e., tire (B) compared to the other tire with tire with low height corresponds to the adsorbent of the adsorption number greater heights as against the main number is for forks of the forklift (C, D) generated more vibration in both can verify. Tire with block-type automatic closing door (B, C, D) automatic closing door (C) 6 - 3 is for forks of the forklift is among other things to 1:1 by weight can in particular efficacy for reducing vibration. Said experiment example 6 and example 7 the results of the experiment, the volume of sound absorbing performance of block-type automatic closing door automatic closing door being affected by, vibration reduction performance of affected level there can be that the automatic closing door. The present invention relates to a tire for reducing a resonance sound. A block-shaped porous foamed material sound absorber is attached to the inner surface of the tire, and the tire of the present invention exhibits equal sound absorption performance compared to a tire that is coated with the sound absorber at the whole surface of the inner surface thereof via adjusting the density, the height, the number of attachment, and the like of the sound absorber. COPYRIGHT KIPO 2018 The inner tire, 90 degrees in the circumferential direction of a block type porous foam foam is 2 - 5 automatic closing door that is attached to the tire for two resonance supporter. According to Claim 1, said porous foam foam urethane resin foam foam porous melamine resin foam foam and automatic closing door any one material selected from the group consisting a resonator characterized tire for reducing noise. According to Claim 1, characterized in said porous foam sound absorbing foam density 20 - 45 kg/m3 resonator tire for reducing noise. According to Claim 1, sound absorbing foam bonded to said porous foam selected from the group consisting of polyhedral block (Block) octahedron shape and by resonance characterized tire for reducing noise. According to Claim 4, said porous foam foam volume 20x10 automatic closing door4 - 240X104 Mm3 resonator characterized in tire for reducing noise. According to Claim 4, said porous foam and foam sound absorbing horizontal and vertical is 100 - 180 mm, 20 - 75 mm in height (Block) reciprocate in block form a resonator characterized tire for reducing noise. According to Claim 4, said porous foam foam which are 10 - 40 mm automatic closing door length upper, lower and lateral length 100 - 180 mm, and longitudinal length 100 - 180 mm, 20 - 75 mm height is trapezoid in cross-sectional area (Block) reciprocate in block form a resonator characterized tire for reducing noise. According to Claim 4, said porous foam foam which are 10 - 40 mm automatic closing door length upper, lower and lateral length 100 - 180 mm, and longitudinal length 100 - 180 mm, height sites in 10 - 20 mm, is in the form 21 - 75 mm center of octahedron block (Block) characterized resonance supporter for tire. According to Claim 1, thermoplastic polyurethanes (TPU) automatic closing door said porous foam foam type or thermoplastic polyacrylic type adhesive number interior surface of a tire characterized by using a resonator tire for reducing noise. Opening minutes Tire The amount of weight* The highest noise (dB) In the embodiment 1 0. 05 Kg 104. 7 Comparison example 1 2 Kg 105. 3 Comparison example 2 1. 5 Kg 105. 8 For example contrast Cream tire (245/45 R19) - 114. 9 * Weight of tire weight against the amount of cream [Automatic closing door front attached] Opening minutes Density (kg/m3 ) Height (mm) The highest noise (dB) Experiment 1 - 1 32 10 107. 8 Experiment 1 - 2 20 105. 7 Experiment 1 - 3 25 105. 5 Experiment 1 - 4 35 104. 2 Experiments 1 - 5 75 102. 8 Opening minutes Density (kg/m3 ) Number attached Height (mm) The highest noise (dB) Experiment 1 - 3 32 Front 25 105. 5 Experiment 2 - 1 1 Two 25 113. 5 Experiment 2 - 2 1 Two 35 110. 7 Experiment 2 - 3 1 Two 75 107. 1 Opening minutes Density (kg/m3 ) Number Height (mm) The highest noise (dB) Experiment 3 - 1 0 0 0 114. 9 Experiment 3 - 2 32 4 20 111. 4 Experiment 3 - 3 4 25 110. 7 Experiment 3 - 4 4 35 106. 5 Experiment 3 - 5 1 75 107. 1 Experiment 3 - 6 2 106. 4 Experiment 3 - 7 3 105. 0 Experiment 3 - 8 4 104. 7 Opening minutes Density (kg/m3) Height (mm) The highest noise (dB) Experiment 4 - 1 0 0 114. 9 Experiment 4 - 2 20 10 110. 2 Experiment 4 - 3 30 10 109. 3 Experiment 4 - 4 32 10 107. 8 Experiment 4 - 5 44 10 109. 7 Classification Characteristic value RFV (kgf) Deviation D/B (g) Deviation Cream Attached Cream Attached Experiment 5 - 1 25 Mm (5. 9G) 8. 64 8. 64 0 76. 4 68. 2 -8. 2 6. 35 6. 64 0. 29 59. 8 56. 3 -3. 5 9. 52 9. 18 -0. 34 53. 4 46. 9 -6. 5 Experiment 5 - 2 50 Mm (11. 8) 7. 47 8. 25 0. 78 51. 7 33 -18. 7 7. 67 7. 91 0. 24 38. 2 37. 5 -0. 7 9. 18 7. 45 -1. 73 35. 2 48. 4 13. 2 Experiment 5 - 3 65 Mm (14. 5) 8. 84 9. 38 0. 54 47. 9 46. 4 -1. 5 7. 71 8. 25 0. 54 29. 8 50. 6 20. 8 8. 69 8. 74 0. 05 32. 6 26. 9 -5. 7 Experiment 5 - 4 75 Mm (15. 6) 8. 4 8. 79 0. 39 38. 8 33. 1 -5. 7 7. 62 8. 11 0. 49 42. 6 60. 6 18 9. 52 10. 16 0. 64 55. 4 56. 5 1. 1 Classification Density (kg/m3) Number attached Automatic closing door shape Volume (mm3) The highest noise (dB) Experiment 6 - 1 0 0 - 0 119. 3 Experiment 6 - 2 32 4 36X104 107. 3 Experiment 6 - 3 4 36X104 109. 0 Experiment 6 - 4 4 36X104 108. 0