Process and installation to ensure the homogenisation of a single divided product of irregular quality or the homogenisation of a mixture of two or several products divided introduced into definite proportions.

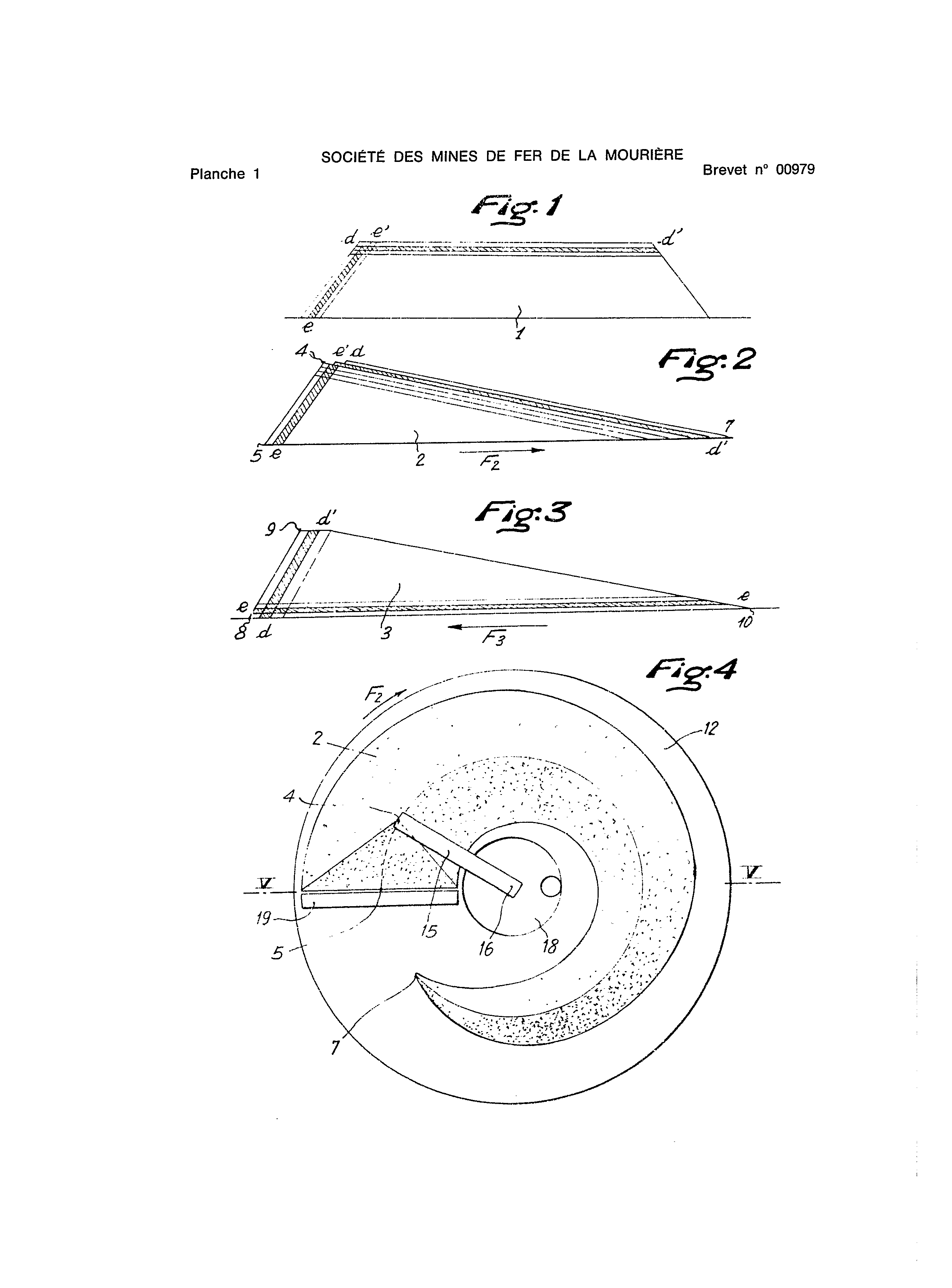

AS AFRICAN AND MALAGASY 9TH INDUSTRIAL PROPERTY P. 887 Yaounde (Cameroon) Patent International Patent Classification: 02 no. 00979 b. oo.iwp.i. Requested to 10 hr 32 28 December 1964 IO.A.M.P. Mn to the I. (G.P. no. 51,083) by the Company of the Mourière iron mine, residing in France. Issued 7 August 1968, published at Method and installation for homogenizing a product divided single quality irregular or homogenization of a mixture of two or more divided products introduced in defined proportions. The present invention is essentially concerned a method for homogenizing a pro - bro divided single quality irregular or the homogé - neisation of a mixture of two or more products divided introduced in defined proportions. This method is of the type in which the homogeneity of the mixture desired is obtained or promoted by deposition of heap various components as claimed layers substantially parallel to and resuming next product wafers, also parallel, forming a certain angle with the direction of deposition layers. When it is desired homogenization of tonnage lisher - aRF, a known process is used in metallurgy in the name "bedding", comprising depositing heap, as the horizontal layers, the product to homogé - néiser and resuming the heap thus formed in inclined layers which intersect the planes of deposition. Where it is desirable to perform mixtures by applying the method of "bedding", be arranged - required telling of two storage areas; comes in claimed on finds the heap as a separate operation, on the other the heap in formation. The importance of the room needed, and the fact that the discontinuous operation causes changes in quality at each change of heap, are - ORIGIN vénients inherent in this method. The present invention is to overcome these disadvantages. The method according to the invention is characterized particularly in that the operations of recquired and resumption are effected so conti - bare, and, optionally simultaneously, on a use Motor - single centeredly, the recquired constituents being made under substantially closed curve, in to achieve a heap having the shape of a horn abundance curved in a closed curve. In one embodiment, the constituents the mixture making being deposited according to planes parallel slightly inclined relative to the horizontal, the failover is performed in neighboring slices of the vertical, corresponding to the inclination of the slope of ébou - ard the heap, for example. In another embodiment, the exa - killing of the mixture to perform being deposited according to vertically adjacent planes, corresponding to the slope slope of the heap for example, the recovery carried out with substantially horizontal slices. The invention also relates to an installation for homogenizing a product divided single quality irregular or homogenization of a mixture of two or more divided products introduced in defined proportions. The equipment is particularly, in that it comprises, in combination, a substantially circular location for heap or storage of the mixture components is desired, suitable means for ensuring formation of a heap having, in plan view, an approximately circular or that of a cornucopia, means specific to ensure recovery materials stored, and means for conjugating said recquired and resuming, so they are continually, and, optionally, simultaneously, on said location and this, according to planes, beds or slices which make a certain angle between them. In one embodiment, the location of the intended recquired is a circular surface having a planar, substantially centrally, a cavity forming the central funnel or conical hopper, means recquired mentioned consisting of a belt conveyor, a chute or the like whose end overhanging the heap, describes the reciprocating rotary motion thereto for scanning a sector defined by the two ends of the heap formed on said circular area, while the resume means mentioned consist of any error recovery apparatus such as the apparatus to movable arms, auger, conveyor or harrow and like, precipitant to said funnel center materials resumed at foot slope of the heap at the end thereof, which has the highest cross section. According to another embodiment, the location of the intended recquired or storage is constituted by an annular trough of revolution, in cross-section, for example, substantially triangular, comprising at its lower part a circular slot through which can be resumed, the forming means comprising said heap in a belt conveyor, a chute or the like, whose end overhanging the heap is driven in a slow continuous circular movement, corresponding to the progression slope of the heap. Other features of the invention will appear in the course of the description which will follow. In the accompanying drawings, given solely by way of example: Figure 1 schematically shows how the recquired and resumption of the product according to the method known as " bedding>e; Figure 2 schematically shows the development of a heap obtained according to the invention, the constituents of the mixture are deposited to perform parallel plane slightly inclined relative to the horizontal and resumption carried out with neighboring slices of the vertical, corresponding to the slope slope of the heap; Figure 3 schematically shows the development of another heap obtained according to the invention, the constituents of the mixture are deposited according to realize of the adjacent planes vertically, corresponding to the slope slope of the heap e.g., and resuming carried out with substantially horizontal slices; Figure 4 shows a plan view of a mixing device according to the invention, comprising a flat circular area for heap; Figure 5 is a cross-section suivaut the line V-V of Figure 4; Figure 6 shows a plan view of a mixing device according to the invention, comprising an annular trough for heap; Figure 7 is a cross section along line v1i-to-VII of Figure 6; Figure 8 is a cross-sectional view of an installation slightly different from that depicted in Figures 6 and 7. The invention essentially consists in replacing the method of mixing using a purely "static" heap known as "bedding" by a method which, in terms of the principle, derives from the previous, but for advancing the heap on the storage location. The progress of the heap being effected along a closed curve, this provides the possibility for recquired (deposits) and resumption (cuts) with continuity of operation that it is impossible to obtain otherwise. Figure 1 represents a heap 1, which was determined according to the method of "bedding" mentioned above. Has seen on the heap 1 successive beds of deposits that have been carried out substantially horizontally. Upon designation by means of marks Figure 2 represents a heap 2 corresponding to the method according to the invention, on the heap 2, the successive beds of deposition, in parallel layers as Contrary to what occurred in the case of the heap 1 of Figure 1, the heap 2 may not disappear on site; it is proposed to continue contributions according to beds of deposits The heap 3 shown in Figure 3, also in accordance with the method according to the invention, is established by placing the blend components to perform next beds successive deposition, forming slots The heap 3, as the heap 2, can be maintained in continuous operation if the compensated by recquired in 8 - 9 resuming carried out in 8 - 10. The heap 3 will be moved and progress along the arrow F.3 . One can, of course, as it will be in examples of facilities described below, organize the heap along a closed curve, the point 8 and point 10 now neighbors, thereby circularly moving heap on a place of relatively small dimensions. We Figures 4 and 5 an installation for implementing the method according to the invention. The heap 2 is formed on a substantially circular area 12. The constituents of the mixture to scrape up are conveyed up to the mixing plant by a conveyor 13 which discharges them from the vicinity of the end 14 of a conveyor 15 pivotable about a vertical axis 16, 17 so that its end can describe a circular motion above the storage area 12. At the center of the storage area 12 there is a conical hopper or funnel 18, whose top flange is substantially circular in the plane of plane area 12. Error recovery apparatus 19 is arranged radially on the circular area 12. This apparatus is driven by a rotary motion about the axis 16, its type varies according to the product to be handled: apparatus to movable arms, worm, harrow and conveyor, andc. The operation of the installation just-described is extremely simple. The products to be mixed can be fed by the conveyor 13 are distributed on the heap by the conveyor 15, which is capable of swinging about the axis 16, fast enough layers of product deposited on the heap are not too thick. The amplitude of the vibrations is proximate a full circle; in the plan view of Figure 4, it will appreciate that the movement of the conveyor 15 takes place the point 4 at point 7, and vice versa By designing that the heaped advancing in the direction of 1. A method for homogenizing a product divided single quality irregular or homogenization of a mixture of two or more divided products introduced in defined proportions, of the type in which the homogeneity of the desired mixture is obtained, or promoted by the various components in a stack along substantially parallel layers and resume next wafers also parallel, forming a certain angle with the direction of deposition layers, this method being noteworthy, in particular by the following characteristics, taken separately or in combination: c.. The blend components perform being deposited along vertically adjacent planes, corresponding to the slope slope of the heap for example, the resumption is performed in substantially horizontal slices. /. The take up of materials following substantially parallel slices of repose at the heap based on the aforementioned flat circular area, is performed by a reclaimer any, precipitating the materials resumed and homogenized in a funnel disposed at the center of said circular area. i. the settling of the mixture at the top of the heap formed in the aforesaid annular hopper is effected by means of a conveyor, a chute or the like, the end of which describes a slow continuous circular movement according to progress of repose. LL. A device for homogenizing a product divided single quality irregular or homogenization of a mixture of two or more divided products introduced in a specified ratio by the above method, and remarkable, in particular by the following characteristics, taken separately or in combination: c.. A synchronizing device is provided between the means for achieving a heap on the circular area above and in which the means for ensuring the recovery and transportation into the funnel said central, so that the scanned sector above remains constant and moves about the axis of the circular heap at a speed substantially equal to the forward speed of the resumption means described above. e. scrapers there are mobile in the circular slot mentioned, for the purpose of promoting the extraction or the extraction thereof from the feed hopper mentioned annular. SOCIAL GAMES IRON MINES THE MOURIERE Proxy: John Màtip