PROJECTION DEVICE AND LIGHT SOURCE TEMPERATURE REGULATING METHOD THEREFOR

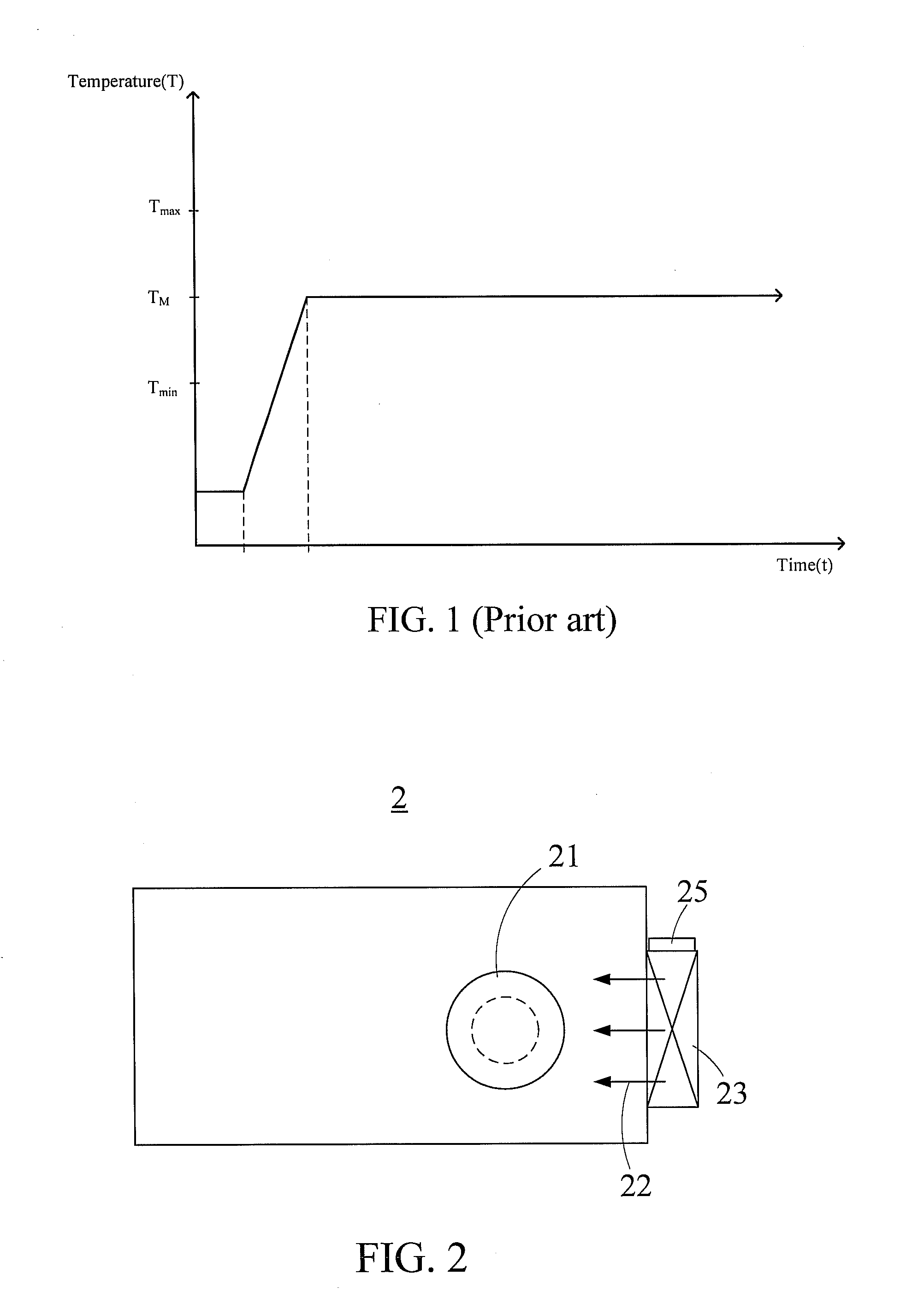

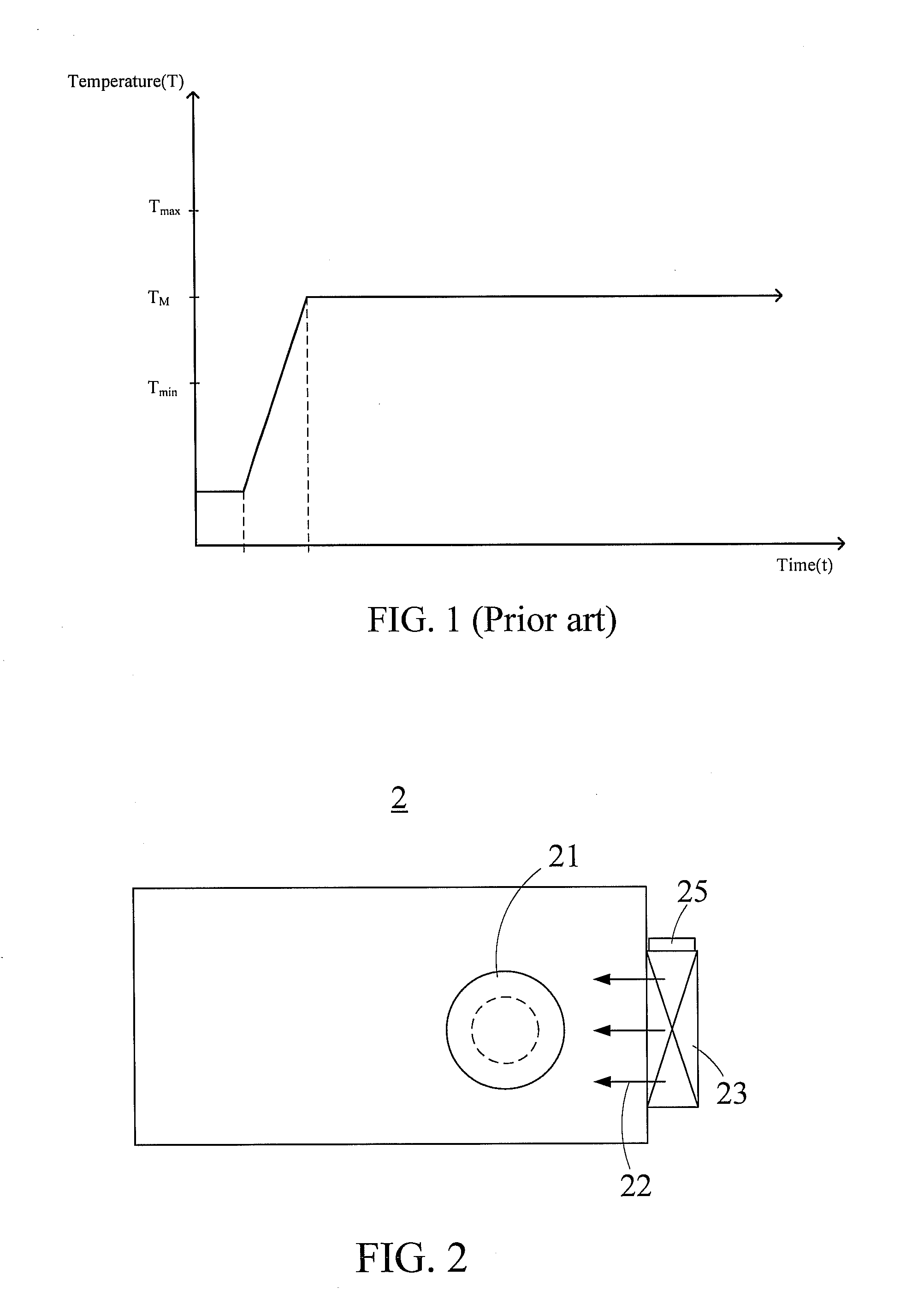

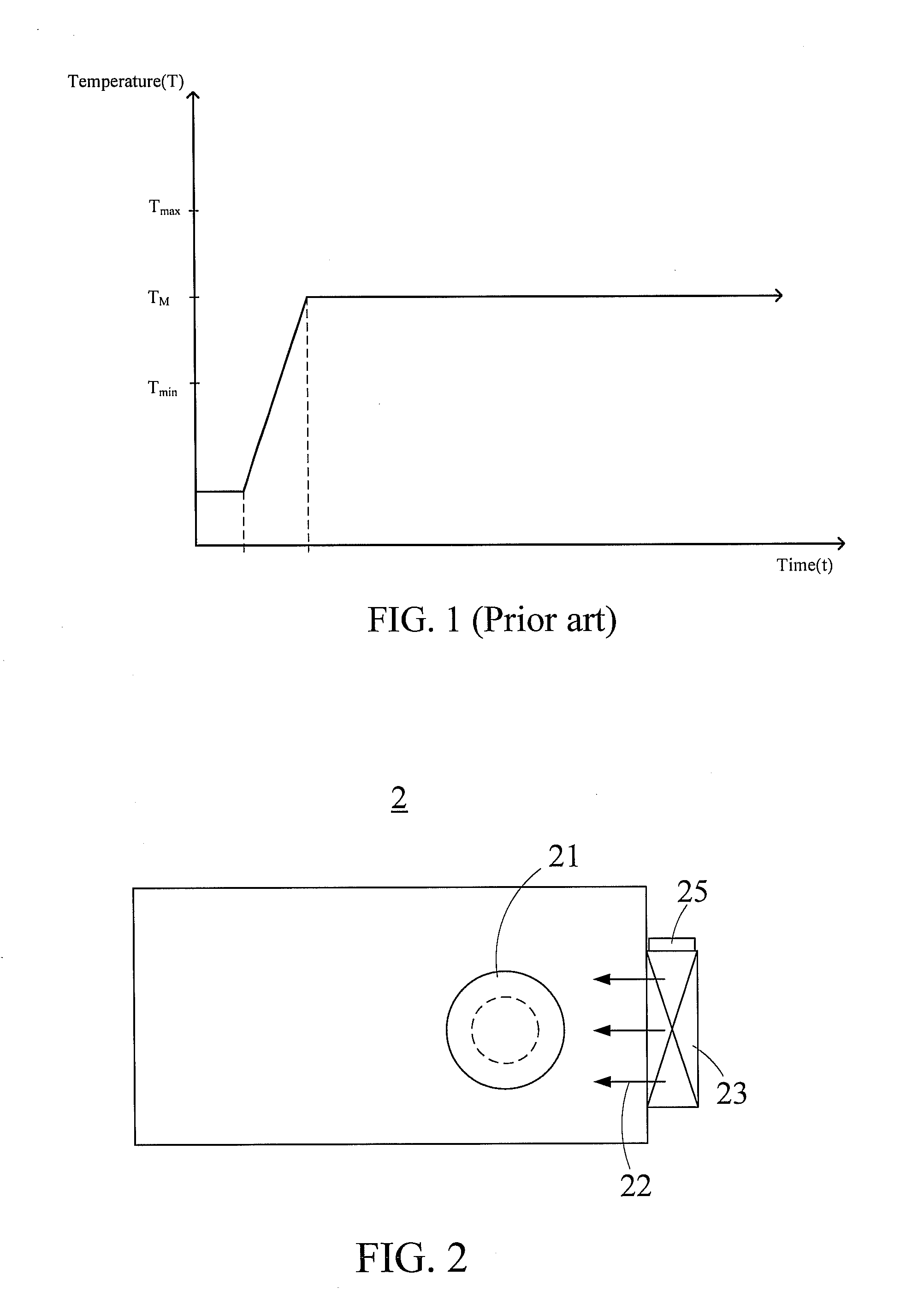

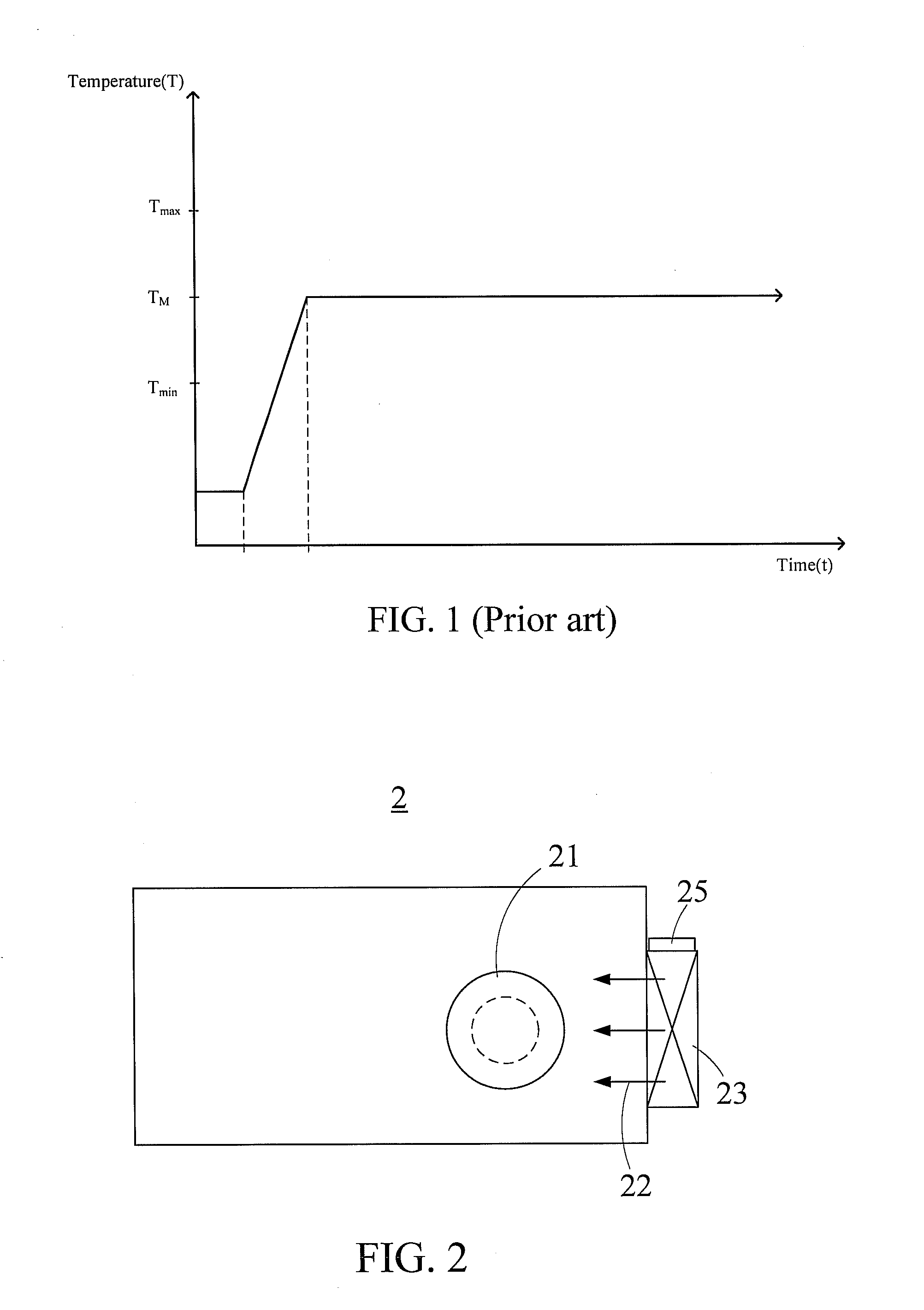

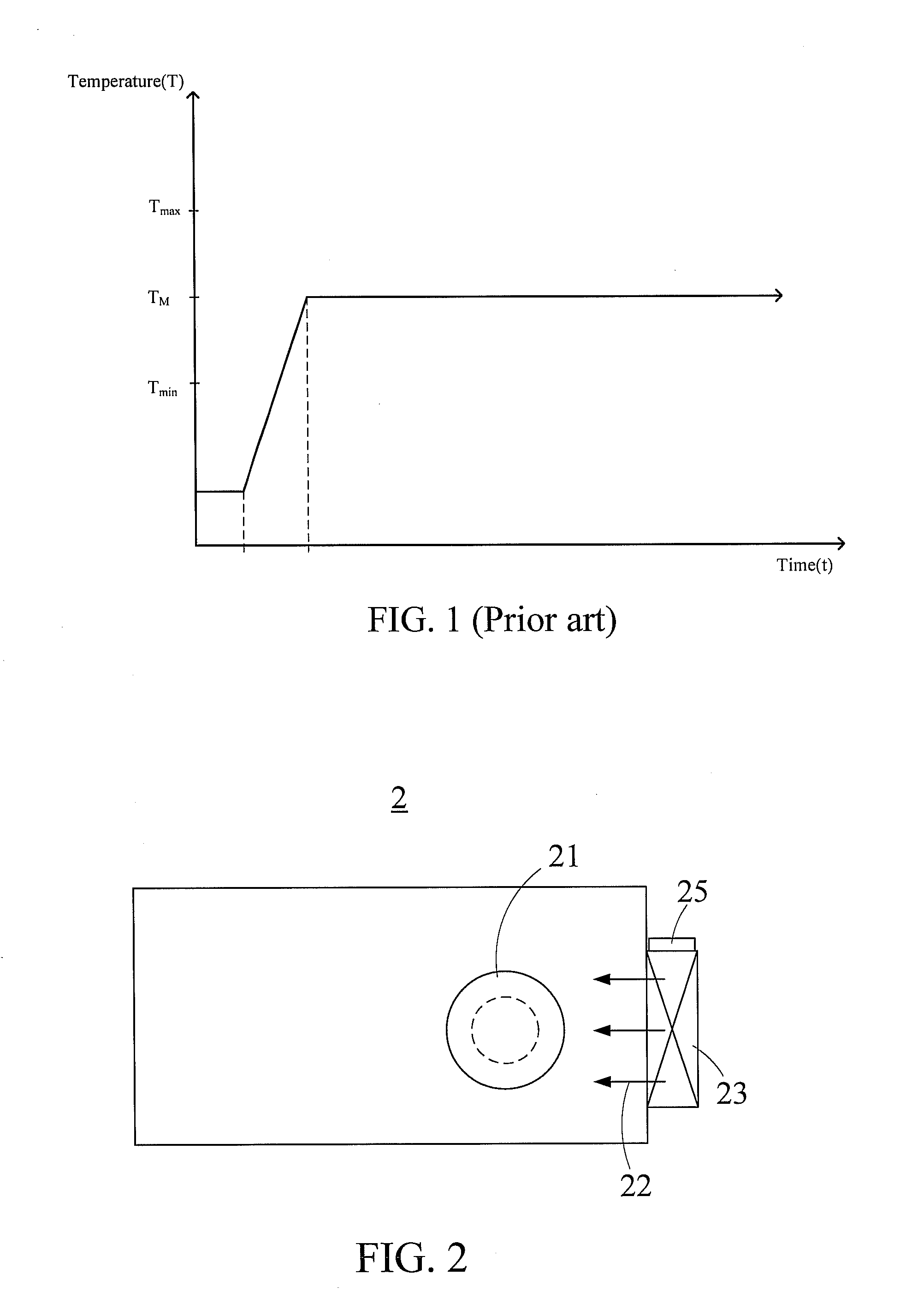

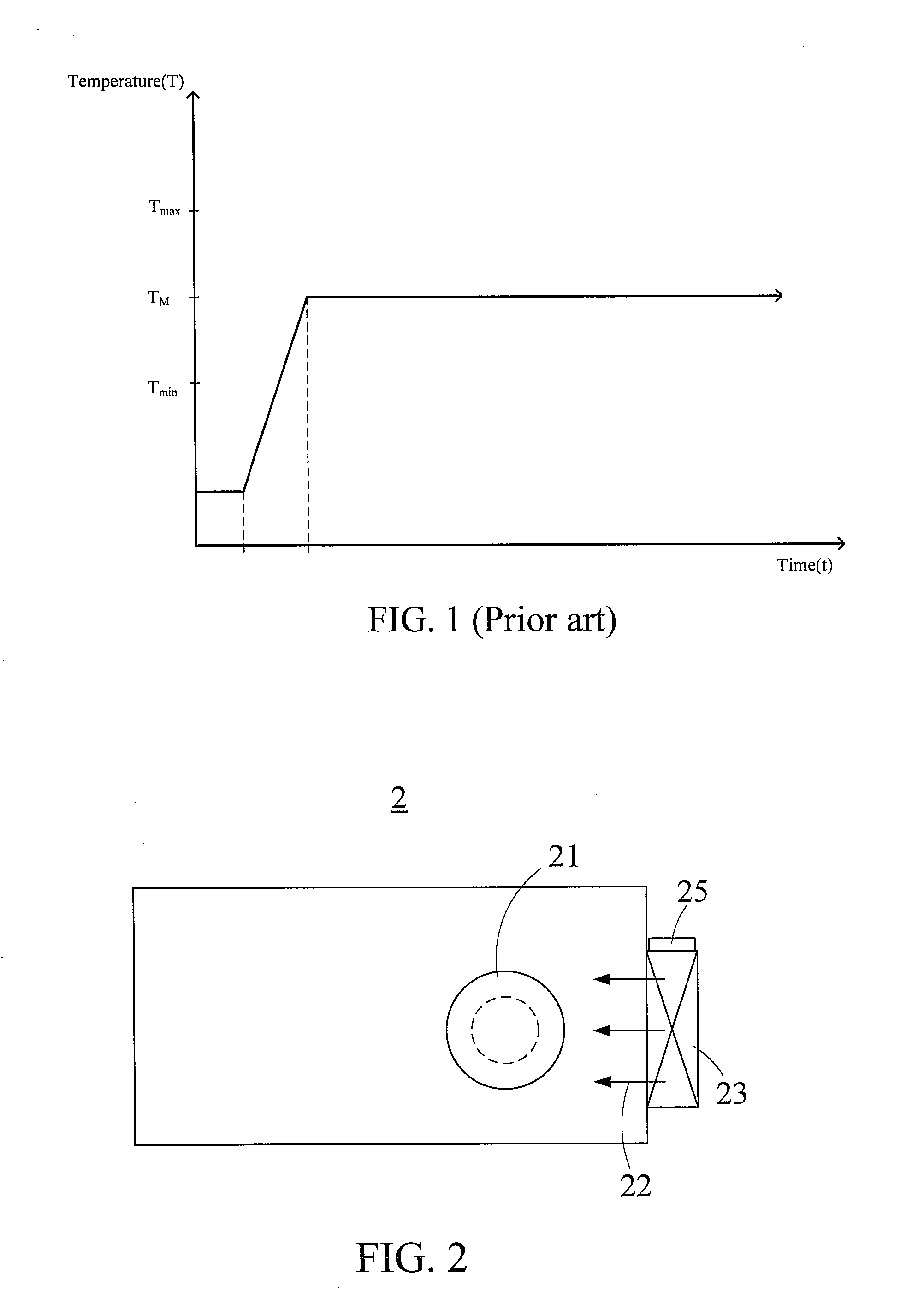

This application claims the benefits of the priority based on Taiwan Patent Application No. 099121814 filed on Jul. 2, 2010, the disclosures of which are incorporated herein by reference in their entirety. Not applicable. 1. Field of the Invention The present invention provides a projection device and a light source temperature regulating method thereof. In particular, the present invention provides a projection device and a light source temperature regulating method thereof to enable a working temperature of a light source to vary within a range by actively adjusting a cooling capacity of a cooling unit. 2. Descriptions of the Related Art Projection devices have been widely applied in meetings and home theaters due to its advantage of projecting an image onto a large-size display for many users to watch. With the progress of science and manufacturing technology, the projection devices are becoming more lightweight and low profiled for good portability, high luminance and high lumen. A conventional projection device usually adopts a single bulb or a plurality of bulbs as its light source, and light beams generated by the light source pass through various optical components to form an image which is projected onto a display screen for users to watch. Components inside the projection device may generate heat during operation. In particular, the light source usually has a maximum temperature. Therefore, a cooling unit is usually disposed to assist in heat dissipation of the light source when lit to prevent the bulb(s) per se or other components inside the projection device from being damaged due to an excessively high working temperature. However, a wick of each bulb has its respective physical properties. If the same volume of cooling airflow is provided, a state of insufficient or excessive cooling may exist for a long time period even though the working temperature of the light source may still narrowly fall within the range defined by the maximum tolerance temperature Tmaxand the minimum recommendation temperature Tmin. In particular, if the state of insufficient cooling exists for a long time period, the wick would stay at a relatively high temperature for a long time period, thereby resulting in recrystallization of quartz and causing the so-called whitening phenomenon; otherwise, if the state of excessive cooling exists for a long time period, the wick would stay at a relatively low temperature for a long period, thereby resulting in poor circulation of halogen and causing the so-called blackening phenomenon. Either the whitening or the blackening phenomena of the wick has an adverse affect on usability and service life of the bulb. In view of this, an urgent need exists in the art to provide, on the basis of the existing optical system, a projection device and a light source temperature regulating method thereof that can prolong the service life of the light source. An objective of the present invention is to provide a projection device and a light source temperature regulating method thereof. The projection device has a cooling unit that can actively adjust a cooling capacity so that a working temperature of a light source can vary within a particular anticipated range but not stay at a fixed working temperature for a long time period. Thus, the whitening or blacking of a wick can be prevented. Another objective of the present invention is to provide a projection device and a light source temperature regulating method thereof. In the projection device, a cooling unit for actively varying the cooling capacity can be designed to have the working temperature of a light source vary periodically or in a multi-stage way within a particular anticipated range. To achieve the aforesaid objectives, the present invention discloses a projective device, which comprises a light source, a cooling unit and a control unit. A working temperature of the light source is defined and measured, the cooling unit is capable of cooling the light source, and the control unit can actively adjust an operation of the cooling unit. Thereby, the working temperature of the light source can vary within an anticipated range in response to the operation of the cooling unit. The present invention further discloses a light source temperature regulating method for the aforesaid projection device, which comprises the following steps: determining a first working temperature and a second working temperature of the light source; determining a first cooling capacity and a second cooling capacity of the cooling unit in response to the first working temperature and the second working temperature; and adjusting the cooling unit actively for providing the first cooling capacity or the second cooling capacity to the light source. The detailed technology and preferred embodiments implemented for the subject invention are described in the following paragraphs accompanying the appended drawings for people skilled in this field to well appreciate the features of the claimed invention. Actually, the light source 21 is preferably an ultra high pressure (UHP) mercury lamp with a wick, and the wick is usually a point with a maximum temperature. The cooling unit 23 preferably comprises a fan, and the cooling airflow 22 generated by the fan blows toward the wick for cooling purposes. The control unit 25 varies a volume or a flow rate of the cooling airflow 22 by controlling the cooling unit 23 to adjust the cooling capacity. The control unit 25 can control the cooling unit 23 by actively adjusting a rotating speed or a voltage of the fan to vary the volume or the flow rate of the cooling airflow 22. In reference to In detail, the cooling unit 23 has a first cooling capacity and a second cooling capacity. The first cooling capacity is weaker than the second cooling capacity. The working temperature TOof the light source 21 can be a first working temperature THand a second working temperature TLin response to the first cooling capacity and the second cooling capacity. The first working temperature THis higher than the second working temperature TL. Since the first working temperature THand the second working temperature TLboth fall within the anticipated range TR, the first working temperature THis lower than or equal to the maximum tolerance temperature Tmax, and the second working temperature TLis higher than or equal to the minimum recommendation temperature Tmin. Through the control unit 25, the first cooling capacity (e.g., the fan operated at a low rotating speed) of the cooling unit 23 can be applied to the wick to maintain the light source at the first working temperature THfor a time period, and then the second cooling capacity (e.g., the fan operated at a high rotating speed) is applied to the wick so that the working temperature TOof the light source falls to the second working temperature TLfor other time period. Because the working temperature TOis changed from high to low, the wick of the bulb in the projection device 2 can be prevented from being whiten or blacken. As shown in In addition to the adjusting manner as shown in In further reference to An embodiment of the present invention will be described hereinafter. In reference to It shall be noted that the numerical values and the time parameters of the temperatures described above are only used to illustrate the examples of the present invention but not to limit the technical features of the present invention. In addition to the first cooling capacity and the second cooling capacity described above, the present invention can further include a third cooling capacity corresponding to a third working temperature and a fourth cooling capacity corresponding to a fourth working temperature, although the present invention is not merely limited thereto. In other examples, the control unit 25 can actively adjust the cooling unit 23 to vary in different working anticipated ranges to prevent the wick of the bulb from being insufficiently cooled or excessively cooled for a long time period. Thereby, the occurrence of whitening and blackening of the wick is reduced as much as possible. Another embodiment of the present invention is a light source temperature regulating method for use in the projection device 2, a flowchart of which is shown in According to above disclosures of the present invention, the cooling capacity of the cooling unit can be adjusted actively so that the working temperature of the light source can vary within a particular anticipated range but not stay fixed for a long time period. This can effectively prevent the wick from being whitened or blackened to prolong the service life of the light source. The above disclosure is related to the detailed technical contents and inventive features thereof. People skilled in this field may proceed with a variety of modifications and replacements based on the disclosures and suggestions of the invention as described without departing from the characteristics thereof. Nevertheless, although such modifications and replacements are not fully disclosed in the above descriptions, they have substantially been covered in the following claims as appended. A projection device and a light source temperature regulating method thereof are provided. The projection device comprises a light source, a cooling unit and a control unit. The light source is operated at a working temperature. The cooling unit provides a cooling capacity to the light source. The control unit actively adjusts the cooling capacity of the cooling unit, and thus allows the working temperature of the light source to vary within the anticipated range. 1. A projection device, comprising:

a light source with a measurable working temperature; a cooling unit for cooling the light source; and a control unit adjusting an operation of the cooling unit; whereby the working temperature of the light source varies within a range in response to the operation of the cooling unit. 2. The projection device as claimed in 3. The projection device as claimed in 4. The projection device as claimed in 5. The projection device as claimed in 6. The projection device as claimed in 7. The projection device as claimed in 8. The projection device as claimed in 9. The projection device as claimed in 10. The projection device as claimed in 11. A light source temperature regulating method for a projection device, the projection device comprising a light source and a cooling device, the method comprising:

determining a first working temperature and a second working temperature of the light source; determining a first cooling capacity and a second cooling capacity of the cooling unit in response to the first working temperature and the second working temperature; and adjusting the cooling unit for providing the first cooling capacity or the second cooling capacity to the light source. 12. The method as claimed in defining a range according to a maximum tolerance temperature and a minimum recommendation temperature of the light source, in which the first working temperature and the second working temperature are within the range. 13. The method as claimed in 14. The method as claimed in lighting up the light source to raise the temperature of the light source reaching a start temperature which is higher than the first working temperature. 15. The method as claimed in CROSS-REFERENCES TO RELATED APPLICATIONS

BACKGROUND OF THE INVENTION

SUMMARY OF THE INVENTION

BRIEF DESCRIPTION OF THE DRAWINGS

DESCRIPTION OF THE PREFERRED EMBODIMENT