Wrapping Method and Unit for Folding a Sheet of Wrapping Material about a Group of Cigarettes

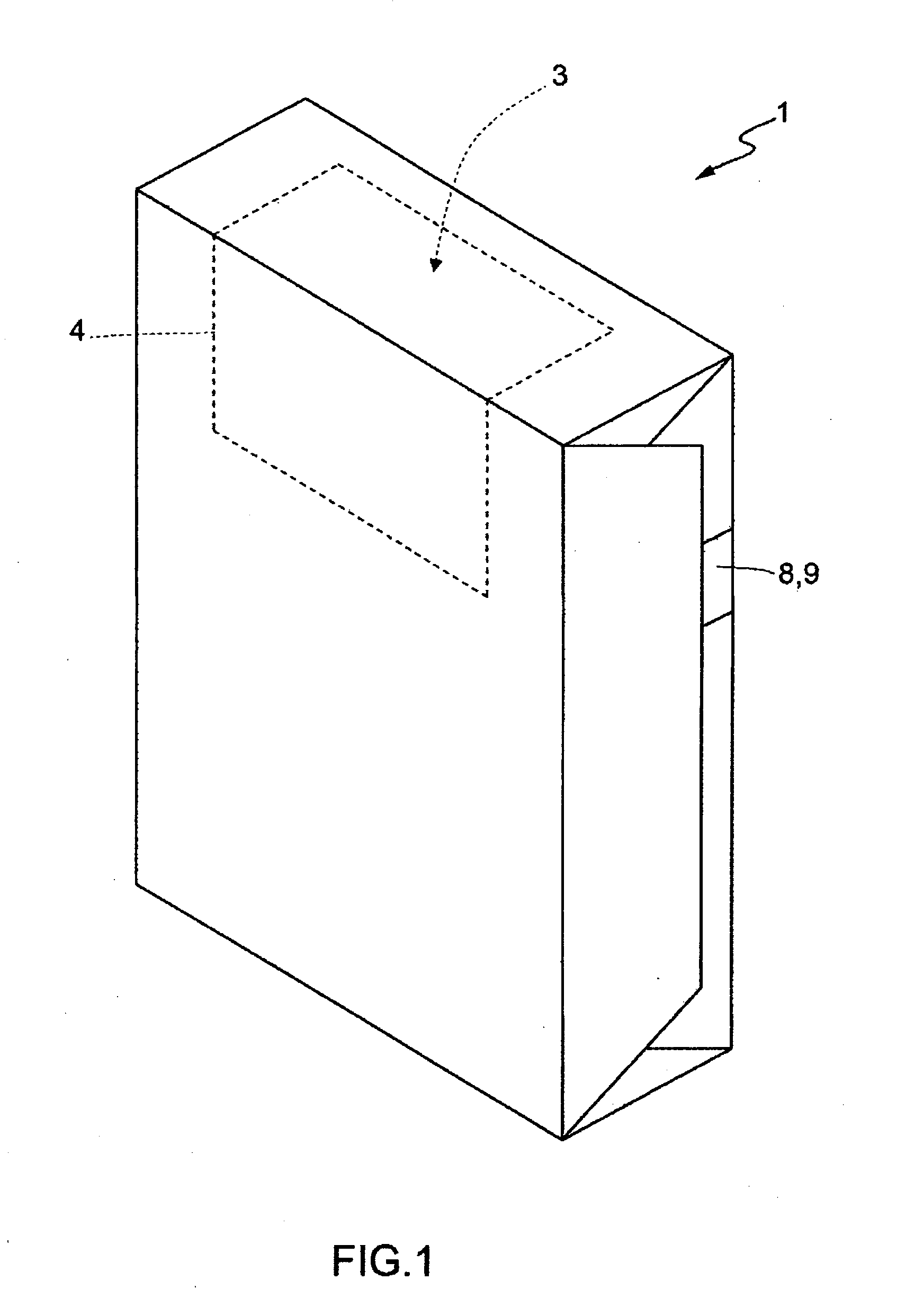

The present invention relates to a wrapping method and unit for folding a sheet of wrapping material about a group of cigarettes. A packet of cigarettes normally comprises an inner package defined by a group of cigarettes wrapped in a sheet of inner packing material; and an outer package enclosing the inner package, and which may be cup-shaped and made from a sheet of outer packing material folded about the inner package (soft packet of cigarettes), or may be defined by a rigid hinged-lid box formed by folding a rigid blank about the inner package (rigid packet of cigarettes). In a conventional packet of cigarettes, the group of cigarettes is wrapped internally in a rectangular sheet of foil inner wrapping material with no glue, and is packed externally in a rectangular sheet of outer packing material that is stabilized using glue. Tobacco is highly sensitive to environment. That is, in contact with the atmosphere, its organic characteristics tend to vary alongside variations in humidity (by losing or absorbing too much moisture) or due to evaporation of the volatile substances with which the tobacco is impregnated (especially in the case of aromatic cigarettes treated with spices such as cloves). To preserve the tobacco, packets of cigarettes are therefore cellophane-wrapped, i.e. wrapped in a heat-sealed overwrapping of airtight plastic material. This, however, may not always be sufficient to fully preserve the tobacco in the packet, especially if the packet is consumed some time after manufacture. Moreover, when the packet is unsealed, the overwrapping is removed, thus exposing the tobacco to the atmosphere, and, if the cigarettes are not consumed soon after the packet is unsealed, the organic characteristics of the remaining cigarettes may deteriorate. In an attempt to eliminate this drawback, patent U.S. Pat. No. 4,300,676A1 proposes a rigid packet of cigarettes, in which the inner package is airtight, and comprises a sheet of airtight heat-seal wrapping material having a cigarette extraction opening closed by a reusable cover flap. It has been observed that folding the sheet of inner wrapping material about the group of cigarettes may damage the ends of the cigarettes and result in localized deformation (of both the filter-tipped and plain ends, i.e. where the tobacco is exposed), and/or tobacco spill (i.e. tobacco fallout, obviously only from the plain ends). This applies in particular to the corner cigarettes in the group, though damage is also evident in all the outermost cigarettes, i.e. located along the fold lines of the sheet of inner wrapping material. Folding a sheet of airtight inner wrapping material is particularly harmful, by being thicker (and therefore stiffer) than conventional sheets of foil wrapping material. Heat sealing the superimposed portions of the sheet of inner wrapping material may also damage the cigarettes underneath, in that, to achieve a good-quality (i.e. airtight) seal quickly (modern packing machines operate at a rate of 500 packets a minute, which means heat sealing must be completed in a fraction of a second), the superimposed portions must be subjected to considerable pressure—which is inevitably transmitted to and may cause permanent deformation of the cigarettes underneath—and must be heated to a high temperature, with the obvious danger of possibly overheating the tobacco in the cigarettes underneath (thus resulting in local drying and alteration of the organic characteristics of the tobacco). It is an object of the present invention to provide a wrapping method and unit for folding a sheet of wrapping material about a group of cigarettes, which method and unit are cheap and easy to implement and designed to eliminate the above drawbacks. According to the present invention, there are provided a wrapping method and unit for folding a sheet of wrapping material about a group of cigarettes, as claimed in the accompanying Claims. A number of non-limiting embodiments of the present invention will be described by way of example with reference to the accompanying drawings, in which: Number 1 in As described in atent U.S. Pat. No. 4,300,676A1, package 1 of cigarettes as described above may be inserted inside a known rigid, hinged-lid cigarette packet, and extraction opening 3 may be closed by a reusable open-close cover flap fixed to package 1 using non-dry, re-stick adhesive. Package 1 is formed by folding a sheet 5 of wrapping material (shown schematically in Before being folded about group 2 of cigarettes, sheet 5 of wrapping material is cut to define extraction opening 3, and is then fitted, if necessary, with the cover flap gummed on the underside, i.e. the underside surface of the cover flap is coated with re-stick adhesive, which glues the portion of sheet 5′of wrapping material inside extraction opening 3 permanently to the cover flap, and, outside extraction opening 3, glues sheet 5 of wrapping material detachably to the cover flap. In another embodiment, not shown, package 1 comprises a U-shaped cardboard stiffener inserted inside package 1, contacting group 2 of cigarettes, and which comprises a rectangular central panel positioned contacting a bottom wall of group 2 defined by the ends of the cigarettes (or positioned contacting a front wall of group 2 defined by the cylindrical lateral walls of the cigarettes); and two lateral wings connected to the central panel along two fold lines and positioned contacting the minor lateral walls of group 2 defined by the cylindrical lateral walls of the cigarettes. To begin with, end wall 7 Number 10 in Packing machine 10 comprises a group-forming unit (not shown in Wrapping unit 11 in Each pocket 14 on wrapping wheel 12 receives a group 2 of cigarettes together with a corresponding sheet 5 of wrapping material at an input station 15. More specifically, sheet 5 of wrapping material is fed to input station 15 by a feed device 16, so as to be positioned in front of the inlet of pocket 14 and perpendicular to the travelling direction of group 2 of cigarettes; and, as group 2 is pushed inside pocket 14, sheet 5 of wrapping material is intercepted by group 2 and folds gradually into a U about group 2 as this is inserted inside pocket 14. As stated, each sheet 5 of wrapping material is fed to input station 15 so as to be positioned asymmetrically in front of the inlet of pocket 14 of wrapping unit 12. In other words, the centreline of sheet 5 of wrapping material is offset with respect to the centreline of pocket 14 of wrapping unit 12 at input station 15, so that, when folded into a U about group 2, sheet 5 of wrapping material has an outer portion 8 projecting from pocket 14, and an inner portion 9 opposite outer portion 8 and resting on lateral wall 6 Each pocket 14 has a U-shaped longitudinal section, and comprises an end wall, and two opposite parallel lateral walls. One lateral wall of each pocket 14, contacting lateral wall 6 A circular folding rail 19 immediately downstream from input station 15 provides for folding outer portion 8 ninety degrees onto end wall 7 At a folding and heat seal station 20 downstream from input station 15, the tubular shape of sheet 5 of wrapping material is completed and stabilized by heat sealing. Folding and heat seal station 20 comprises a movable folding device 21, which is movable radially (i.e. perpendicular to axis of rotation 13) between a rest position ( As shown in Folding and heat seal station 20 also comprises a movable sealing device 24 which rotates between a rest position ( The At an output station 25 downstream from folding and heat seal station 20, group 2 of cigarettes, together with the tubular sheet 5 of wrapping material, is expelled from pocket 14 of wrapping wheel 12 and fed to further known folding devices (not shown), which finish folding sheet 5 of wrapping material about group 2 of cigarettes to form package 1, the finished form of which is stabilized by heat sealing. The further known folding devices (not shown) may, for example, be of the type described in Patent Application EP2008935A1. In wrapping unit 11 as described above, folding sheet 5 of wrapping material (particularly outer portion against inner portion 9) produces very little mechanical stress on, and therefore no damage to, the cigarettes in group 2. Moreover, when heat sealing the superimposed portions of portions 8 and 9, sheet 5 of wrapping material, as opposed to being pressed against group 2 of cigarettes, is gripped between two metal parts (transverse support 17 and sealing device 24). Which means the superimposed portions of portions 8 and 9 can be heat sealed by applying considerable pressure and at high temperature, with no damage to the cigarettes in group 2, thus ensuring a high-quality, fast seal (compatible with the demands of modern, fast-operating packing machines). A method and unit (11) for folding a sheet (5) of wrapping material about a group (2) of cigarettes, the method including the steps of: feeding the group (2) of cigarettes and the sheet (5) of wrapping material into a pocket (14) of a wrapping conveyor (12), so the sheet (5) of wrapping material folds into a U inside the pocket (14) and has an outer portion (8) projecting from the pocket (14), and an inner portion (9) resting on a lateral wall (a) of the group (2) of cigarettes; folding the inner portion (9) 90° with respect to the lateral wall (6a) of the group (2) of cigarettes, so the inner portion (9) is perpendicular to the lateral wall (6a); folding the outer portion (8) into an L inside the pocket (14), onto the lateral wall (6a) of the group (2) of cigarettes and onto the inner portion (9) perpendicular to the lateral wall (6a), so as to superimpose the outer portion (8) and the inner portion (9) and impart a tubular shape to the sheet (5) of wrapping material; and heat sealing the outer portion (8) and inner portion (9) to each other. 1) A method of folding a sheet of wrapping material about a group of cigarettes, the method comprising the steps of:

feeding the group (2) of cigarettes and the sheet (5) of wrapping material into a pocket (14) of a wrapping conveyor (12), so the sheet (5) of wrapping material folds into a U inside the pocket (14) and has an outer portion (8) projecting from the pocket (14), and an inner portion (9) resting on a lateral wall (6 folding the inner portion (9) 90° with respect to the lateral wall (6 folding the outer portion (8) into an L onto the lateral wall (6 heat sealing the outer portion (8) and inner portion (9) to each other. 2) A method as claimed in feeding the sheet (5) of wrapping material asymmetrically in front of the inlet of the pocket (14); and inserting the group (2) of cigarettes into the pocket (14) together with the sheet (5) of wrapping material, which folds into a U about the group (2) of cigarettes. 3) A method as claimed in 4) A method as claimed in 5) A method as claimed in 6) A method as claimed in 7) A method as claimed in 8) A method as claimed in 9) A method as claimed in 10) A method as claimed in 11) A method as claimed in 12) A method as claimed in 13) A wrapping unit for folding a sheet of wrapping material about a group of cigarettes, the unit (11) comprising:

a wrapping conveyor (12) having at least one pocket (14); an input station (15) for feeding the group (2) of cigarettes and the sheet (5) of wrapping material into the pocket (14), so the sheet (5) of wrapping material folds into a U inside the pocket (14) and has an outer portion (8) projecting from the pocket (14), and an inner portion (9) resting on a lateral wall (6 a first folding device for folding the inner portion (9) 90° with respect to the lateral wall (6 a second folding device (21) for folding the outer portion (8) onto the lateral wall (6 a sealing device (24) for heat sealing the outer portion (8) and inner portion (9) to each other.TECHNICAL FIELD

BACKGROUND ART

DISCLOSURE OF THE INVENTION

BRIEF DESCRIPTION OF THE DRAWINGS

PREFERRED EMBODIMENTS OF THE INVENTION