PLATE TYPE HEAT EXCHANGER

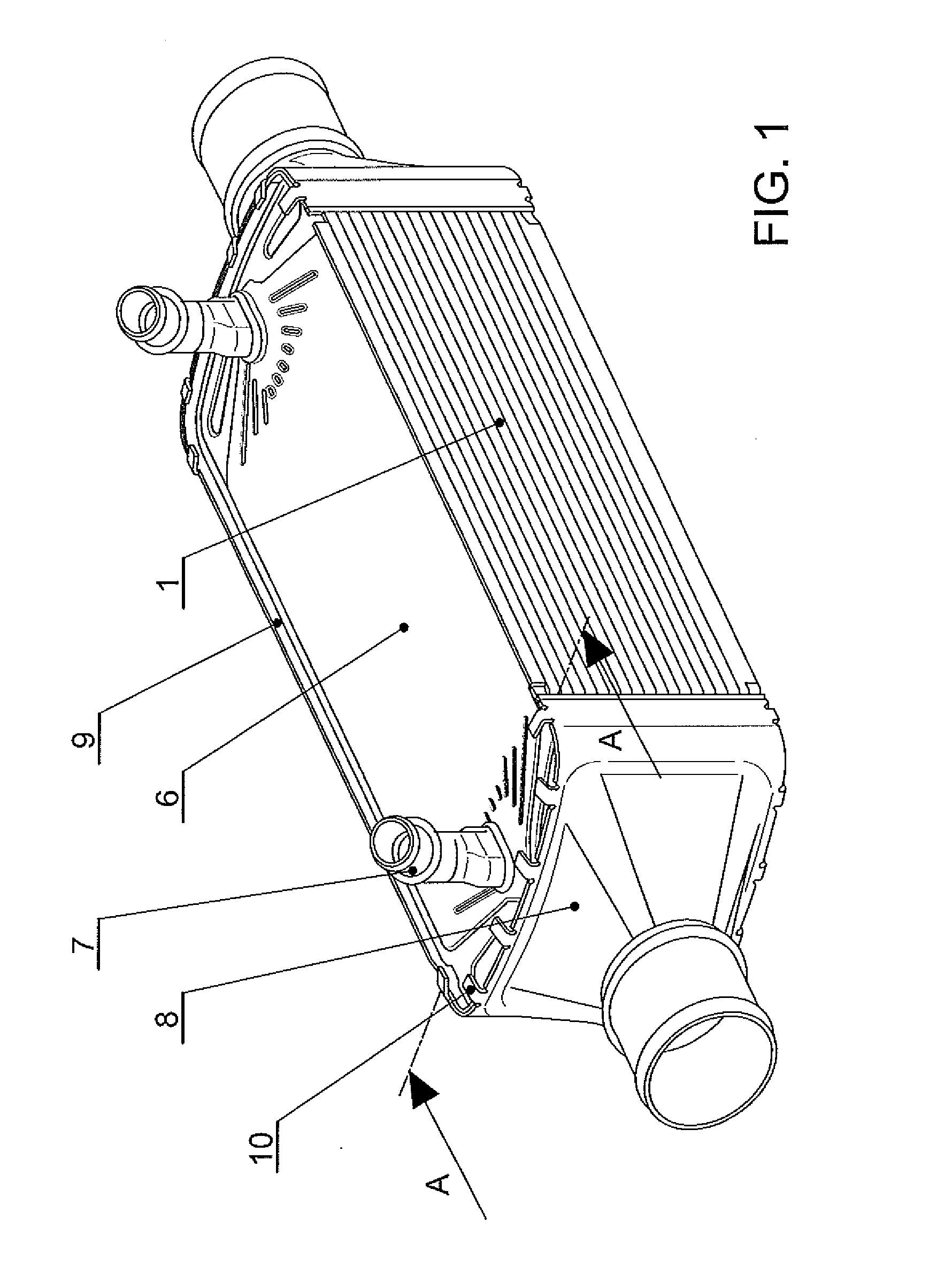

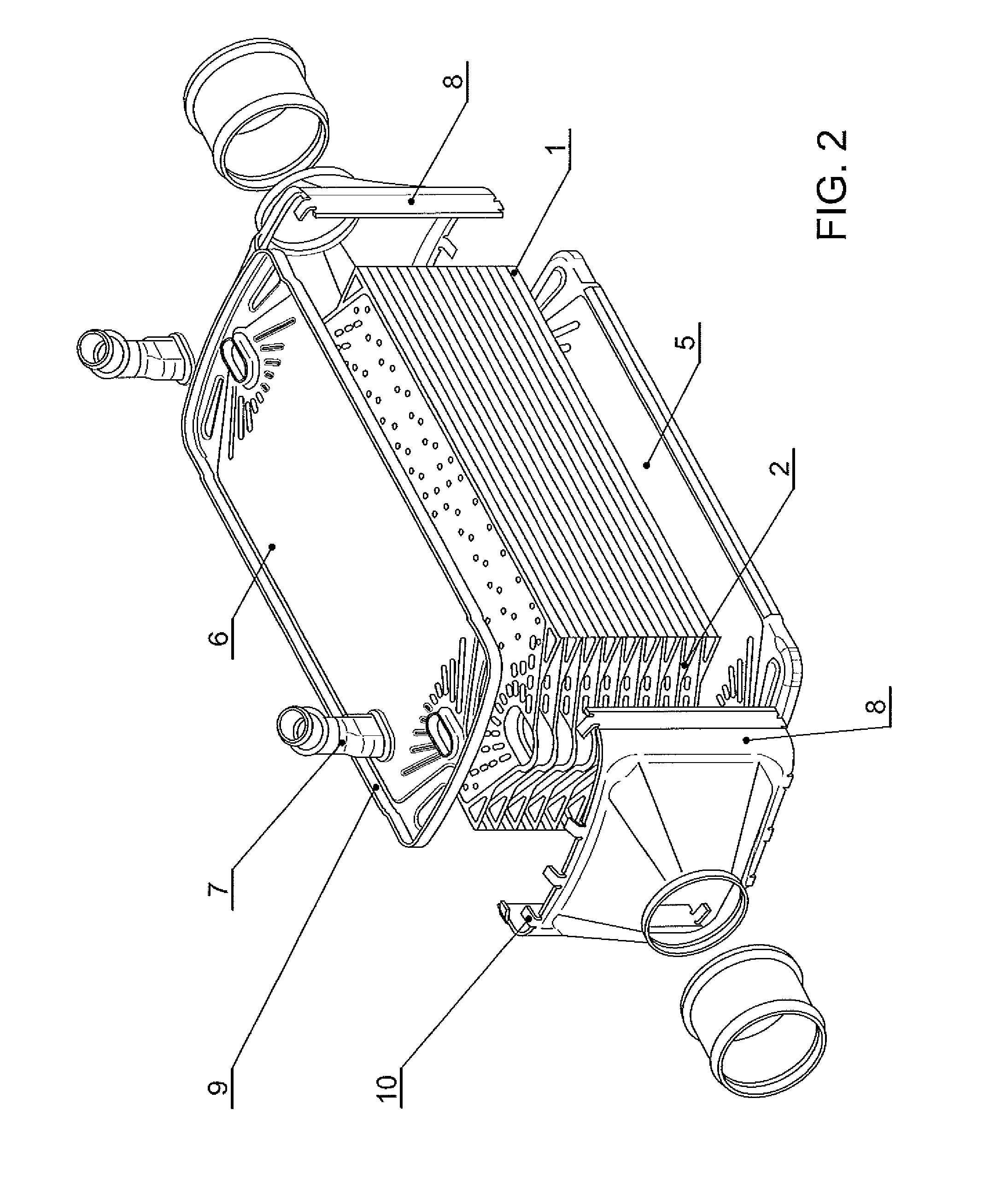

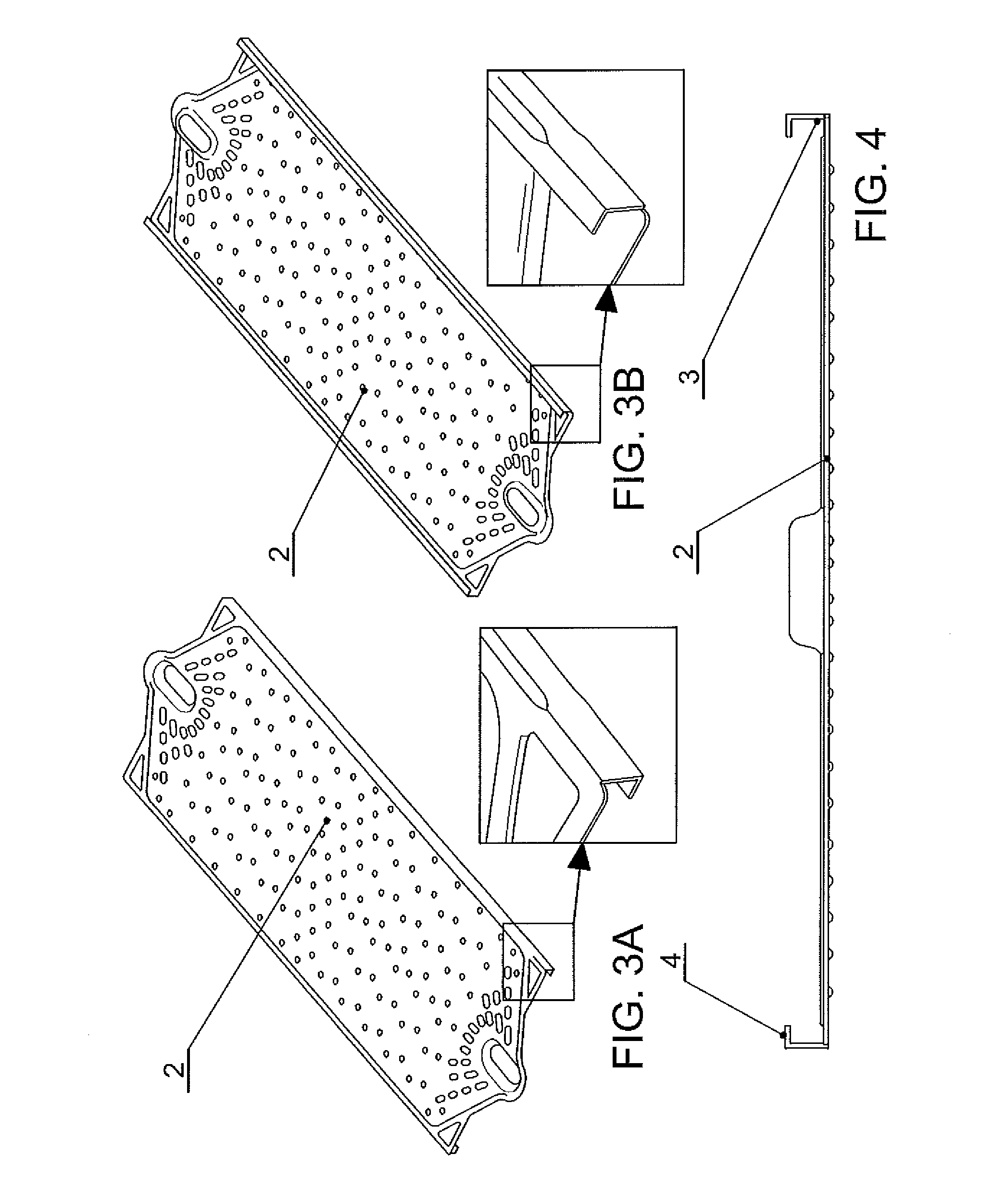

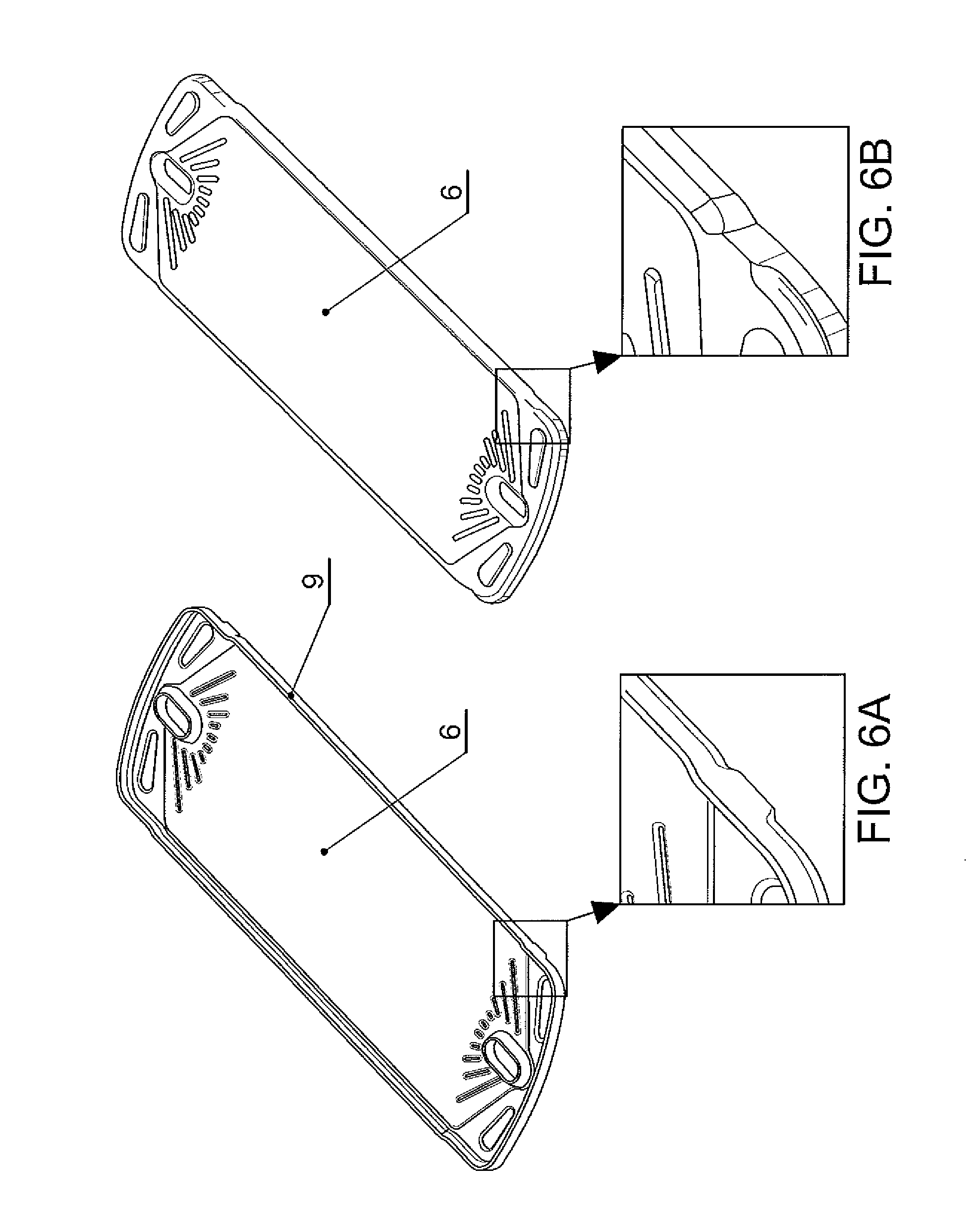

This application claims priority to Czech Republic Patent Application No. PV 2012-128 filed on Feb. 21, 2012, hereby incorporated herein by reference in its entirety. The invention concerns a plate heat exchanger, and more particularly to a plate type heat exchanger for cooling of compressed air in motor vehicles. Plate type heat exchangers are commonly known in the art. One such plate type heat exchanger is disclosed in U.S. Pat. App. Pub. No. 2006/0011333A1. The plate type heat exchanger includes a heat exchange assembly formed by a system of two different types of interconnected heat exchange plates. The first heat exchange plate is a plate with low longitudinal side webs terminating in seating rims oriented toward the longitudinal center axis of the heat exchange plate. The second heat exchange plate is a horizontal plate, having a width corresponding to a width of the first heat exchange plate. The second heat exchange plate is placed on the seating rims of the first heat exchange plate and connected thereto. The system of the two heat exchange plates are connected and stacked to form the heat exchange assembly. The heat exchange assembly is then placed between a bottom cover and a top cover of the exchanger. The top cover is provided with couplings at opposite ends for an inlet and an outlet of refrigerant. Each end of the heat exchange assembly, with longitudinal openings of passageways formed between the heat exchange plates, is provided with a manifold with an aperture for a passage of cooling air. A drawback of the plate type heat exchanger is that two different types of heat exchange plates are required to produce the heat exchange assembly. In concordance and agreement with the present invention, a plate type heat exchanger including a plurality of interconnected heat exchange plates in stack relationship which minimizes a cost and complexity of manufacture, as well as an overall weight of the exchanger, has surprisingly been discovered. The problems associated with the prior art plate type heat exchanger are solved by the plate type heat exchanger of the present invention. The plate type heat exchanger according to an embodiment the present invention includes a heat exchange assembly formed from stacked and interconnected heat exchange plates. The heat exchange plates include low longitudinal side webs terminating in seating rims oriented toward the longitudinal center axis of the heat exchange plate. The heat exchange plates are placed between a bottom cover and a top cover of the exchanger. The top cover is provided with couplings at opposite ends for an inlet and an outlet of refrigerant. Each end of the heat exchange assembly, with longitudinal openings of passageways formed between the heat exchange plates, is provided with a manifold with an aperture for a passage of cooled air. According to the invention, the heat exchange assembly is formed from an even number of identical heat exchange plates which are assembled into closely adjoining pairs of heat exchange plates. The heat exchange plates are joined by the seating rims on the longitudinal lateral webs. Each of the covers formed by a plate with an outwardly oriented peripheral rim has a width greater than a width of the heat exchange assembly. Only in regions at the ends of the heat exchange assembly is the width of the covers equal to the width of the heat exchange assembly for connecting a manifold to end parts of the covers and tight seating on the sides of the heat exchange assembly. The essence of the plate type heat exchanger is that each of the manifolds has a height corresponding to a spacing between a free edge of the peripheral rim of the bottom cover and a free edge of the peripheral rim of the top cover. For connection to the opposite ends of the heat exchange assembly, each of the manifolds is provided with one or more attachment mechanisms such as a set of snaps, for example, configured to interact with the peripheral rims on the respective end parts of the covers. It must also be considered as being essential to this solution that the manifold has a multilateral truncated pyramid shape, for example, between the parts for connection to the heat exchange assembly with the covers and the aperture for intake or delivery of the cooled air. An advantage of the plate type heat exchanger according to the invention is the need to manufacture only one type of heat exchange plate, one type of cover, and one type of manifold. Another advantage is the simplified method of sealing and connecting the manifolds to the opposite ends between the covers of the heat exchange assembly. Furthermore, it is not necessary to use side covers (not shown) in this design, as is required in prior art exchanger systems. The above, as well as other advantages of the present invention, will become readily apparent to those skilled in the art from the following detailed description, when considered in the light of the accompanying drawings: The following detailed description describes various exemplary embodiments of the invention. The description enables one skilled in the art to make and use the invention, and is not intended to limit the scope of the invention in any manner. The heat exchange assembly 1 is placed between a bottom cover 5 and a top cover 6 of the exchanger (see Each end of the heat exchange assembly 1, with longitudinal openings of passageways formed between the heat exchange plates 2, is provided with a manifold 8 (see As a non-limiting example, the heat exchange assembly 1 includes an even number of identical heat exchange plates 2 assembled (connected) into closely adjoining pairs of heat exchange plates 2. The heat exchange plates 2 are joined together by the seating rims 4 on the longitudinal lateral webs 3 (see Each of the covers 5, 6 formed by a plate with the outwardly oriented peripheral rim 9 (see Each of the manifolds 8 advantageously has a multilateral truncated pyramid shape between the parts for connection to the heat exchange assembly 1 with the covers 5, 6 and an aperture for passage of the cooled air. From the foregoing description, one ordinarily skilled in the art can easily ascertain the essential characteristics of this invention and, without departing from the spirit and scope thereof, can make various changes and modifications to the invention to adapt it to various usages and conditions. A plate type heat exchanger of the present invention includes a heat exchange assembly formed by a plurality of interconnected heat exchange plates in stacked relationship. Each of the heat exchange plates includes longitudinal side webs terminating in seating rims extending toward a longitudinal center axis of the heat exchange plate. The heat exchange plates are disposed between a bottom cover and a top cover of the exchanger. The top cover is provided with couplings at opposite ends for an inlet and an outlet of refrigerant. Each end of the heat exchange assembly, with longitudinal openings of passageways formed between the heat exchange plates, is provided with a manifold having an aperture for a passage of cooled air therethrough. 1. A plate type heat exchanger, comprising:

a heat exchange assembly formed by a plurality of heat exchange plates in stacked relationship, wherein each of the heat exchange plates includes a web extending along at least a portion of a periphery of the heat exchange plate, the web terminating in a seating rim extending toward a longitudinal center axis of the heat exchange plate. 2. The heat exchanger of 3. The heat exchanger of 4. The heat exchanger of 5. The heat exchanger of 6. The heat exchanger of 7. The heat exchanger of 8. The heat exchanger of 9. A plate type heat exchanger, comprising:

a first cover having an outwardly extending peripheral rim; a second cover having an outwardly extending peripheral rim; and a heat exchange assembly disposed between the first cover and the second cover, the heat exchange assembly formed by a plurality of heat exchange plates in stacked relationship and configured to receive a first fluid therein, wherein each of the heat exchange plates includes a web extending along at least a portion of a periphery of the heat exchange plate, the web terminating in a seating rim extending toward a longitudinal center axis of the heat exchange plate, and wherein one of the heat exchange plates is joined to an adjacent one of the heat exchange plates along the seating rims thereof. 10. The heat exchanger of 11. The heat exchanger of 12. The heat exchanger of 13. The heat exchanger of 14. The heat exchanger of 15. The heat exchanger of 16. The heat exchanger of 17. The heat exchanger of 18. A plate type heat exchanger, comprising:

a first cover having an outwardly extending peripheral rim; a second cover having an outwardly extending peripheral rim, wherein at least one of the first cover and the second cover is provided with at least one coupling to permit a first fluid to be received into the heat exchanger; a heat exchange assembly disposed between the first cover and the second cover, the heat exchange assembly formed by a plurality of heat exchange plates in stacked relationship, wherein each of the heat exchange plates includes a web extending along at least a portion of a periphery of the heat exchange plate, the web terminating in a seating rim extending toward a longitudinal center axis of the heat exchange plate, and wherein one of the heat exchange plates is joined to an adjacent one of the heat exchange plates along the seating rims thereof; and a manifold coupled to at least one of a first end and a second end of the heat exchange assembly, the manifold including an aperture formed therein to permit a second fluid to be received into the heat exchange assembly. 19. The heat exchanger of 20. The heat exchanger of CROSS-REFERENCE TO RELATED APPLICATION

FIELD OF INVENTION

BACKGROUND OF THE INVENTION

SUMMARY OF THE INVENTION

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION OF EXEMPLARY EMBODIMENTS OF THE INVENTION

LIST OF REFERENCE NUMBERS