APPARATUS AND METHODS FOR IRRADIATING SUBSTRATES WITH ULTRAVIOLET LIGHT

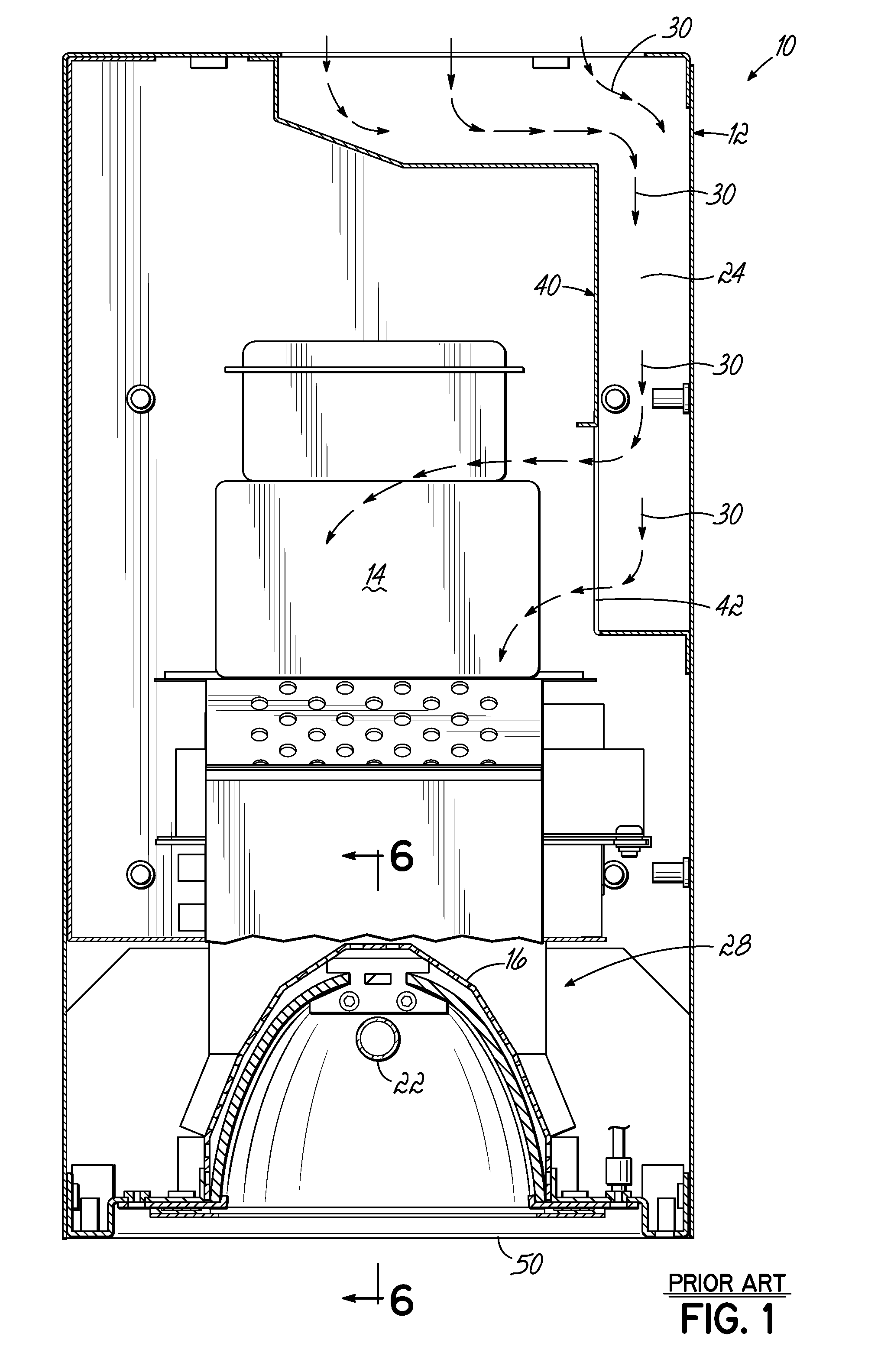

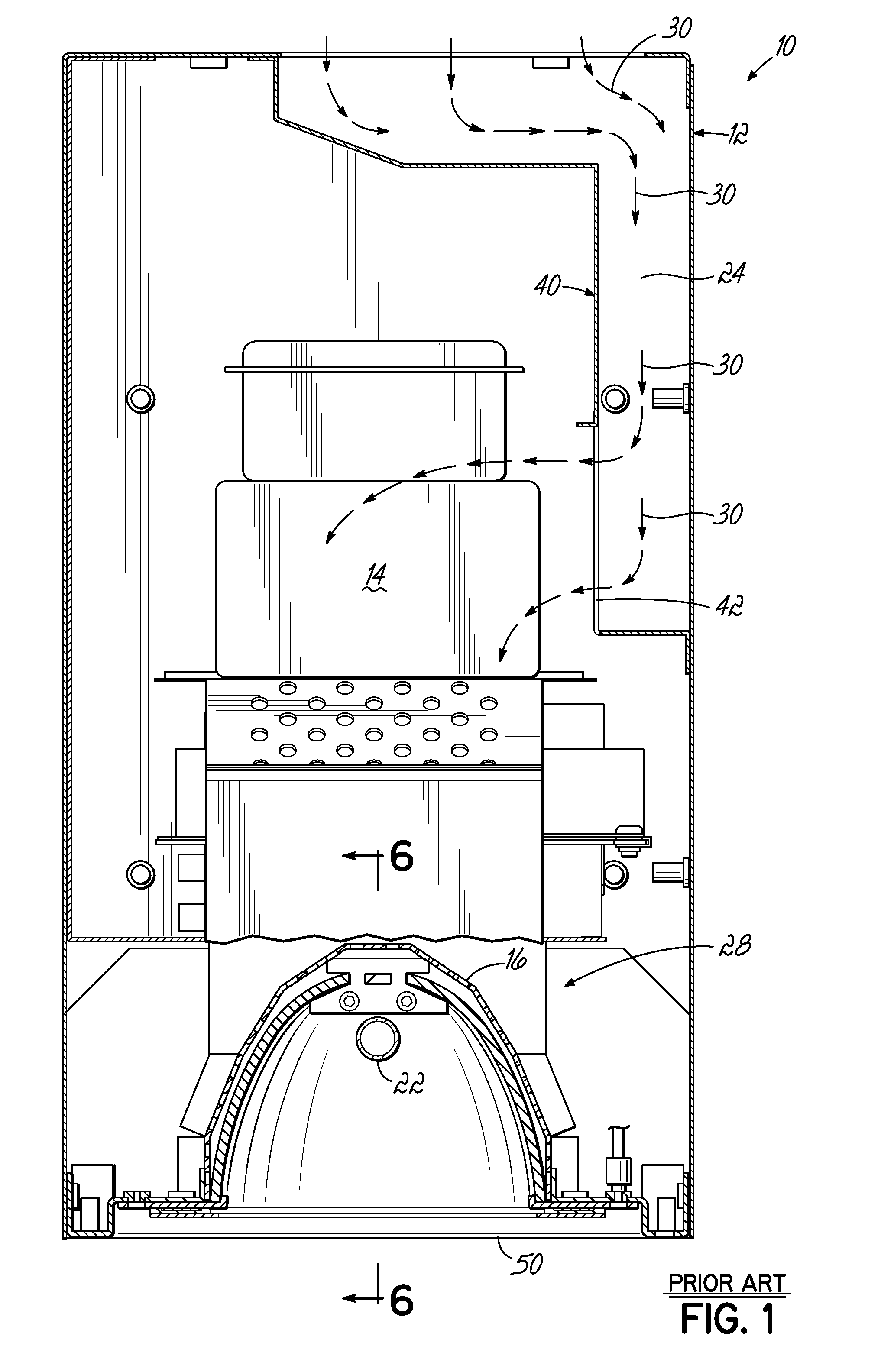

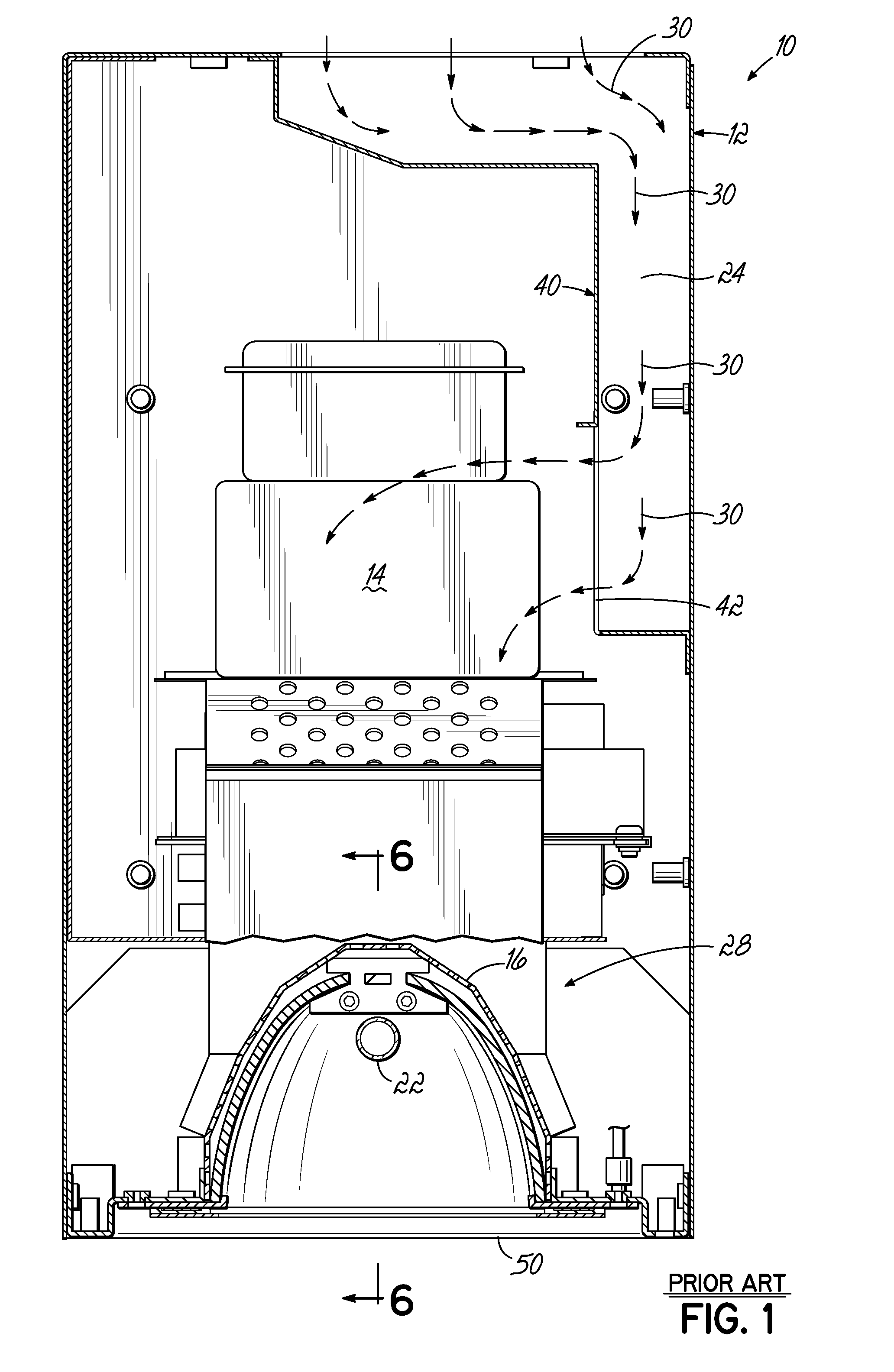

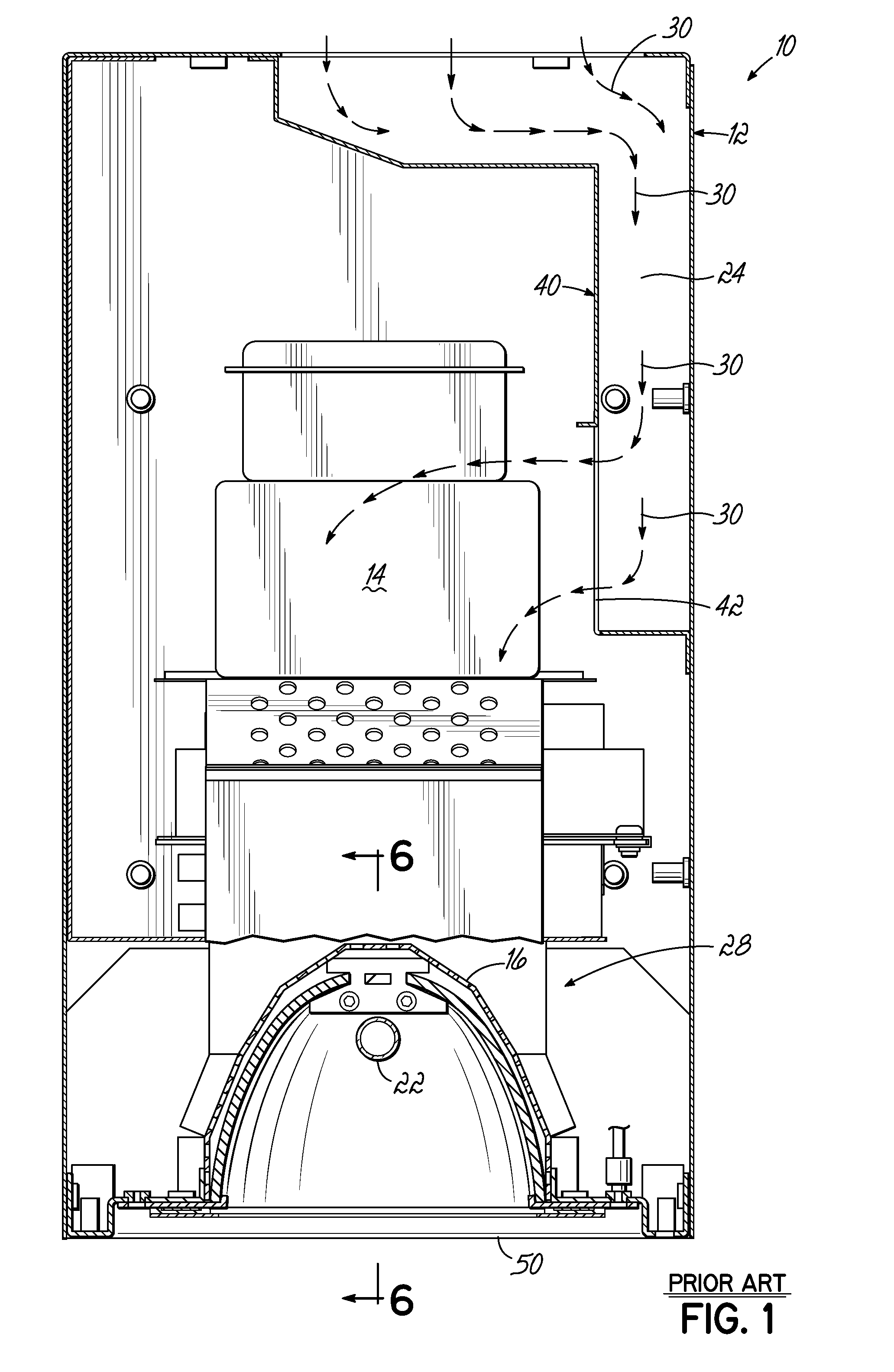

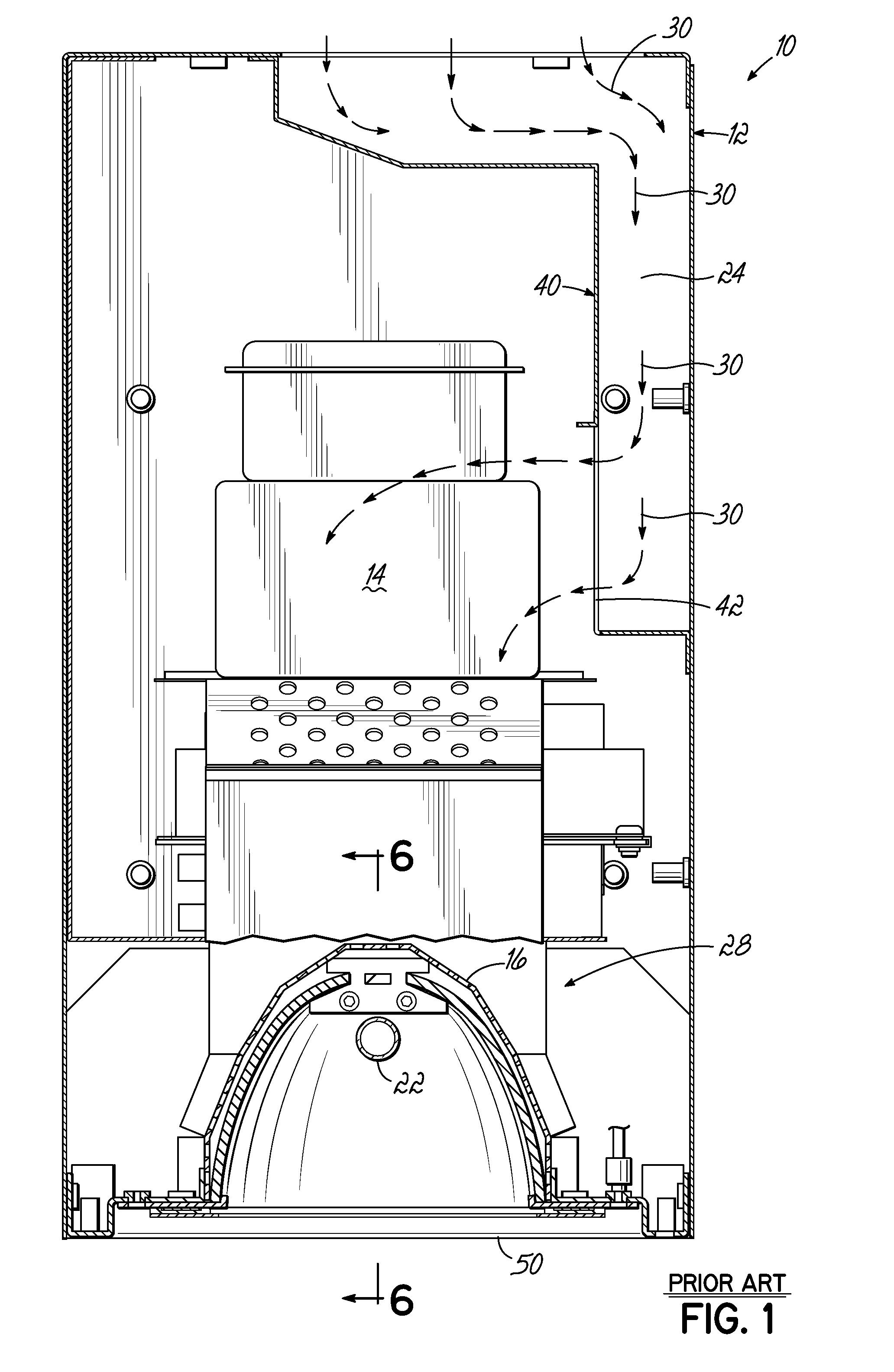

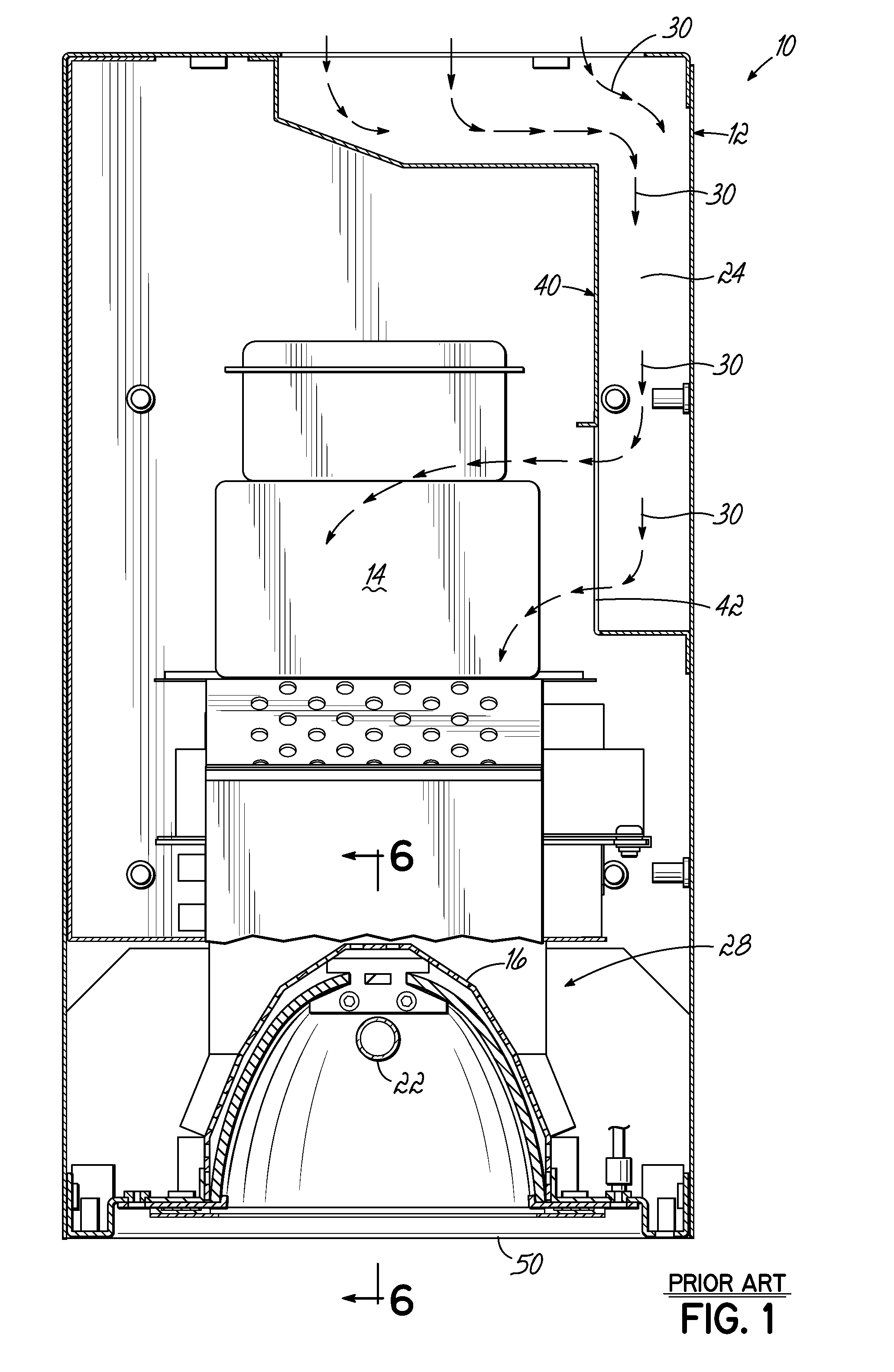

This application claims the benefit of Application Ser. No. 61/899,409, filed Nov. 4, 2013 (pending), the disclosure of which is hereby incorporated by reference herein. The present invention relates generally to microwave-excited ultraviolet lamp systems and methods. Ultraviolet lamp systems or lamp heads are used in many applications. For example, systems may be used for heating or curing of adhesives, sealants, inks or other coatings or for other purposes such as surface treatments. These systems typically couple microwave energy to an electrodeless lamp, such as an ultraviolet (UV) plasma lamp bulb mounted within a microwave chamber of the lamp system. In many ultraviolet lamp systems, one or more magnetrons are provided in the lamp head housing to direct microwave radiation to the plasma lamp bulb within the microwave chamber. The magnetrons are coupled to the microwave chamber through waveguides that include output ports connected to an upper end of the chamber. When the plasma lamp bulb is sufficiently excited by the microwave energy, it emits ultraviolet radiation through an open lamp face of the lamp system to irradiate a substrate which is positioned at an optimal distance from the open lamp face. A source of forced air is fluidly connected to a housing of the lamp system which contains the magnetrons, the microwave chamber and the plasma lamp bulb. The source of forced air is operable to direct cooling air, such as 350 CFM of cooling air for example, through the housing and into the microwave chamber to cool the magnetrons and the plasma lamp bulb during irradiation of the substrate by the lamp system. In some UV heating and curing applications, the lamp system includes a mesh screen mounted at the open lamp face. The screen is transmissive to ultraviolet radiation but is opaque to microwaves. The configuration of the mesh screen also permits the significant airflow of cooling air to pass therethrough and toward the substrate. In other applications, the substrates irradiated by the UV lamp may be rather wide and require multiple lamp heads to be mounted adjacent one another across the width of the substrate. The substrate is then moved relative to the lamp heads in order to irradiate the entire surface of the substrate that is facing the lamp heads. For example, these substrates may comprise large, flat panels used for flat screen televisions, or films such as those used for tinting windows. In such cases, it is important to provide uniform exposure of ultraviolet radiation across the full width of the substrate. A problem that has developed involves the occurrence of “striping” in which thin bands or stripes of underexposed substrate areas occur generally between the adjacent lamp heads. Therefore, it would be desirable to provide continued improvements in this area to provide more effective cooling within a lamp head housing, and to provide more uniform ultraviolet irradiation to wide substrates when using multiple, adjacently mounted lamp heads. These and other features of the various embodiments of this invention will become more readily apparent to those of ordinary skill upon review of the following detailed description of the illustrated embodiments taken in conjunction with the accompanying drawings. In an illustrative embodiment the invention provides an apparatus for generating ultraviolet light for irradiating a substrate. The apparatus includes a housing enclosing an interior space. The housing includes an inlet for receiving a cooling air flow, and a window configured to emit ultraviolet light and discharge the cooling air flow. A lamp bulb is mounted within the interior space between the inlet and the window. First and second microwave generators are respectively mounted between the inlet and the lamp bulb. A plate structure is positioned between the inlet and the first and second microwave generators. The plate structure at least partially defines a plenum within the housing and includes first and second openings generally aligned with the respective first and second microwave generators to direct first and second portions of the cooling air flow at the first and second microwave generators. The plate structure may comprise more than one plate, or may be constructed from multiple, distinct plates. The housing further comprises a top side and a rear side. The inlet is located in the top side, and the plate structure extends from the top side to the rear side. The plate structure includes a section oriented at an acute angle relative to vertical between the top side and the rear side. The invention further provides a method of irradiating a substrate with ultraviolet light from at least first and second apparatus. Each apparatus includes a housing holding an ultraviolet lamp bulb and including a window. The method comprises mounting the first and second apparatus adjacent to one another with the ultraviolet lamp bulbs extending generally parallel to each other along their respective lengths. The substrate is positioned at an optimal distance from the windows of the first and second apparatus. The first and second apparatus and the substrate are moved relative to one another in a direction perpendicular to the respective lengths of the ultraviolet lamp bulbs. While moving the first and second apparatus and the substrate relative to one another, ultraviolet light is emitted from each apparatus through the respective windows such that adjacent patterns of ultraviolet light are directed onto the substrate. The patterns emitted from the adjacent apparatus meet on the substrate to prevent underexposed areas along the substrate at the locations generally between the adjacent first and second apparatus. Mounting the first and second apparatus further comprises mounting the first and second apparatus in abutting, contacting relationship to one another. Mounting the first and second apparatus also further comprises orienting the ultraviolet lamp bulbs to extend coaxial relative to each other along their respective lengths. Various additional features and advantages of the invention will become more apparent to those of ordinary skill in the art upon review of the following detailed description of the illustrative embodiments taken in conjunction with the accompanying drawings. Now referring to As will be appreciated from the discussion to follow, these features help to provide a wider pattern of ultraviolet light emission from the window 50′ and, when multiple apparatus 10′ are mounted adjacent each other, helps to eliminate the striping issue discussed above. More specifically, because the assembly of the magnetrons 14 and the lamp bulb 22 has been moved closer to the window 50′, this effectively ensures that more of the scattered ultraviolet light at the ends of the window 50′ spreads farther outwardly onto the substrate 60. The outward spreading of the light energy provides sufficient overlap between adjacent apparatus 10′ that the areas on the substrate 60 generally between the adjacent apparatus 10′ are sufficiently irradiated thereby providing uniform irradiation across the entire width of the substrate. This is accomplished while maintaining the proximity of the window 50′ at an optimal height or distance from the substrate, as opposed to moving farther from the substrate where the intensity of the ultraviolet radiation would be less. Referring to As shown in While the present invention has been illustrated by the description of one or more embodiments thereof, and while the embodiments have been described in considerable detail, they are not intended to restrict or in any way limit the scope of the appended claims to such detail. The various features shown and described herein may be used alone or in any combination. Additional advantages and modifications will readily appear to those skilled in the art. The invention in its broader aspects is therefore not limited to the specific details, representative apparatus and method and illustrative examples shown and described. Accordingly, departures may be from such details without departing from the scope of the general inventive concept. An apparatus for generating ultraviolet light for irradiating a substrate. The apparatus includes a housing enclosing an interior space. The housing includes an inlet for receiving a cooling air flow, and a window configured to emit ultraviolet light and discharge the cooling air flow. A lamp bulb is mounted within the interior space between the inlet and the window. First and second microwave generators are mounted between the inlet and the lamp bulb. A plate is positioned between the inlet and the first and second microwave generators, the plate at least partially defining a plenum within the housing and including first and second openings generally aligned with the respective first and second microwave generators to direct first and second portions of the cooling air flow at the first and second microwave generators. 1. An apparatus for generating ultraviolet light for irradiating a substrate, the apparatus comprising:

a housing enclosing an interior space, said housing including an inlet for receiving a cooling air flow, and a window configured to emit ultraviolet light and discharge the cooling air flow; a lamp bulb mounted within said interior space between said inlet and said window; first and second microwave generators, each mounted between said inlet and said lamp bulb; and a plate structure positioned between said inlet and said first and second microwave generators, said plate structure at least partially defining a plenum within said housing and including first and second openings generally aligned with the respective first and second microwave generators to direct first and second portions of the cooling air flow at the first and second microwave generators. 2. The apparatus of 3. A method of irradiating a substrate with ultraviolet light from at least first and second apparatus, each apparatus including a housing holding an ultraviolet lamp bulb and including a window, comprising:

mounting the first and second apparatus adjacent to one another with the ultraviolet lamp bulbs extending generally parallel to each other along their respective lengths; positioning the substrate at an optimal distance from the windows of the first and second apparatus; moving the first and second apparatus and the substrate relative to one another in a direction perpendicular to the respective lengths of the ultraviolet lamp bulbs; and while moving the first and second apparatus and the substrate relative to one another, emitting the ultraviolet light from each apparatus through the respective windows such that adjacent patterns of ultraviolet light are directed onto the substrate, and the patterns emitted from the adjacent apparatus meet on the substrate to prevent underexposed areas along the substrate at the locations generally between the adjacent first and second apparatus. 4. The method of mounting the first and second apparatus in abutting, contacting relationship to one another. 5. The method of mounting the first and second apparatus with the ultraviolet lamp bulbs extending coaxially to each other along their respective lengths.CROSS-REFERENCE TO RELATED APPLICATION

TECHNICAL FIELD

BACKGROUND

SUMMARY

BRIEF DESCRIPTION OF THE DRAWINGS

DETAILED DESCRIPTION